Introduction: Navigating the Global Market for custom leather jacket mens

In the competitive landscape of international fashion, sourcing custom leather jackets for men presents a unique challenge for B2B buyers. The demand for personalized, high-quality apparel is rising, yet navigating the myriad of options and suppliers can be overwhelming. This comprehensive guide aims to demystify the global market for custom leather jackets, providing valuable insights into the various types available, their applications, and the crucial elements of supplier vetting.

From understanding the nuances of leather types and craftsmanship to exploring cost structures and shipping logistics, this guide equips international buyers—particularly those from Africa, South America, the Middle East, and Europe, including markets like Nigeria and Germany—with the knowledge needed to make informed purchasing decisions. By addressing key considerations such as quality assurance, ethical sourcing, and customization options, this resource empowers businesses to confidently select suppliers who align with their brand values and consumer expectations.

Navigating the complexities of sourcing custom leather jackets has never been easier; with the right information, B2B buyers can enhance their product offerings and meet the evolving demands of their clientele. Explore the sections ahead to unlock the potential of bespoke leather fashion and elevate your business strategy in this dynamic marketplace.

Table Of Contents

- Top 6 Custom Leather Jacket Mens Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather jacket mens

- Understanding custom leather jacket mens Types and Variations

- Key Industrial Applications of custom leather jacket mens

- 3 Common User Pain Points for ‘custom leather jacket mens’ & Their Solutions

- Strategic Material Selection Guide for custom leather jacket mens

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather jacket mens

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather jacket mens’

- Comprehensive Cost and Pricing Analysis for custom leather jacket mens Sourcing

- Alternatives Analysis: Comparing custom leather jacket mens With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather jacket mens

- Navigating Market Dynamics and Sourcing Trends in the custom leather jacket mens Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather jacket mens

- Strategic Sourcing Conclusion and Outlook for custom leather jacket mens

- Important Disclaimer & Terms of Use

Understanding custom leather jacket mens Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Biker Jacket | Asymmetrical zipper, rugged design, and pockets | Motorcycle apparel retailers, fashion boutiques | Pros: Durable, stylish, appeals to niche markets. Cons: May not suit all body types or occasions. |

| Bomber Jacket | Fitted waist, ribbed cuffs, and a classic silhouette | Uniform suppliers, casual wear retailers | Pros: Versatile, timeless appeal. Cons: Limited customization options compared to other styles. |

| Aviator Jacket | Distinctive collar, often with fur lining | Aviation-themed stores, military surplus | Pros: Unique aesthetic, functional warmth. Cons: Higher price point due to premium materials. |

| Long Coat | Extended length, tailored fit, often with a belt | High-end fashion retailers, formal wear suppliers | Pros: Elegant, suitable for formal occasions. Cons: May be too warm for mild climates. |

| Custom Tailored Jacket | Fully customizable fit and design | Fashion designers, bespoke tailoring shops | Pros: Perfect fit, unique designs tailored to client preferences. Cons: Longer production time, potentially higher costs. |

What are the Key Characteristics of Biker Jackets?

Biker jackets are characterized by their rugged design, asymmetrical zippers, and multiple pockets. Typically made from high-quality leather, these jackets are built for durability and protection, making them ideal for motorcycle apparel retailers. B2B buyers should consider the appeal of this style to younger demographics and those interested in motorcycle culture. The robust nature of biker jackets caters well to niche markets, but potential buyers should be aware that the fit may not be universally flattering for all body types.

How Does the Bomber Jacket Stand Out in Custom Leather?

Bomber jackets feature a fitted waist and ribbed cuffs, contributing to their classic silhouette. This style is particularly popular among casual wear retailers and can be easily integrated into various collections. B2B buyers should note the bomber jacket’s versatility, making it suitable for both men and women across different age groups. However, customization options may be limited compared to other styles, which could be a drawback for businesses looking to offer unique designs.

What Makes Aviator Jackets a Unique Choice for B2B Buyers?

Aviator jackets are distinguished by their unique collar and often include a fur lining for added warmth. Commonly associated with aviation and military themes, these jackets are a great fit for specialty stores and military surplus suppliers. B2B buyers should consider the aesthetic appeal and functionality of aviator jackets, especially in colder climates. However, the use of premium materials can lead to a higher price point, which may affect purchasing decisions.

Why Consider Long Coats for Formal Wear?

Long coats are tailored for elegance, featuring an extended length and often a belt to accentuate the waist. They are well-suited for high-end fashion retailers and formal wear suppliers. B2B buyers should recognize the demand for sophisticated outerwear in formal settings, as these jackets can elevate any outfit. However, the warmth of long coats may be a disadvantage in milder climates, limiting their appeal in certain regions.

What are the Benefits of Offering Custom Tailored Jackets?

Custom tailored jackets provide a fully customizable fit and design, appealing to fashion designers and bespoke tailoring shops. This type of jacket allows businesses to cater to individual customer preferences, ensuring a perfect fit and unique style. B2B buyers should weigh the advantages of offering personalized products against the longer production times and potentially higher costs involved. The ability to provide a truly bespoke experience can set a business apart in a competitive market.

Key Industrial Applications of custom leather jacket mens

| Industry/Sector | Specific Application of custom leather jacket mens | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | Custom Fashion Lines | Differentiation in a competitive market through unique offerings | Quality assurance, ethical sourcing, and production timelines |

| Motorcycle Gear | Protective Biker Jackets | Enhanced safety and style for motorcycle enthusiasts | Durability of materials, compliance with safety standards |

| Corporate Branding | Branded Workwear | Strengthening brand identity and employee morale | Customization options, minimum order quantities, and lead times |

| Film and Entertainment | Costume Design for Productions | Authenticity in character portrayal and brand partnerships | Collaboration with designers, flexibility in design alterations |

| Military and Tactical | Custom Tactical Jackets | Functional apparel for operational effectiveness | Material strength, weather resistance, and customization capabilities |

How Are Custom Leather Jackets Used in the Fashion Retail Sector?

In the fashion retail industry, custom leather jackets serve as a key differentiator for brands looking to establish unique product lines. By offering bespoke options, retailers can attract customers seeking individuality and exclusivity. This application addresses the growing demand for personalized fashion, allowing brands to cater to diverse body types and styles. International buyers, particularly from regions like Africa and Europe, must consider quality assurance and ethical sourcing practices to ensure they align with consumer expectations.

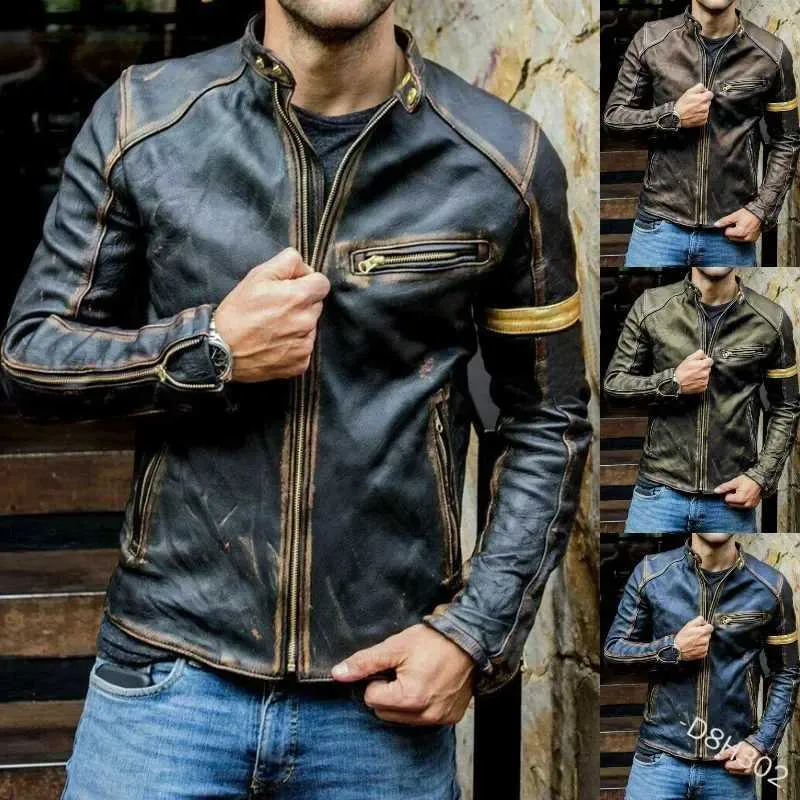

Illustrative image related to custom leather jacket mens

What Role Do Custom Leather Jackets Play in Motorcycle Gear?

Motorcycle enthusiasts often seek custom leather jackets that provide both protection and style. These jackets are designed to withstand the rigors of riding while offering a fashionable look. For businesses in this sector, the primary challenge is ensuring that the materials used meet safety standards without compromising on comfort. Buyers should focus on sourcing durable leather and features such as reinforced stitching and weather resistance to appeal to a dedicated market segment.

How Can Custom Leather Jackets Enhance Corporate Branding?

In the corporate world, custom leather jackets can be utilized as branded workwear, enhancing employee morale and reinforcing brand identity. Companies can create a cohesive look that aligns with their branding efforts, making employees feel valued and part of a team. B2B buyers from South America and the Middle East should prioritize customization options and minimum order quantities to ensure they can meet their branding needs effectively. Additionally, lead times for production are critical to align with marketing campaigns.

What Is the Importance of Custom Leather Jackets in Film and Entertainment?

In the film and entertainment industry, custom leather jackets are essential for costume design, helping to create authentic character portrayals. These jackets can be tailored to meet specific design requirements, enhancing the visual storytelling of productions. B2B buyers in this sector must focus on collaboration with designers and flexibility in design alterations to ensure that the final product aligns with the artistic vision of the project. This adaptability is crucial for meeting tight production schedules.

How Are Custom Leather Jackets Utilized in Military and Tactical Applications?

Custom leather jackets are increasingly used in military and tactical applications, where functionality and durability are paramount. These jackets provide essential protection against various environmental conditions while allowing for customization to meet specific operational needs. Buyers in this sector must consider the strength of materials, weather resistance, and customization capabilities to ensure that the jackets fulfill the rigorous demands of military use. Sourcing from reputable manufacturers with experience in tactical gear is vital for maintaining quality standards.

Illustrative image related to custom leather jacket mens

3 Common User Pain Points for ‘custom leather jacket mens’ & Their Solutions

Scenario 1: Sizing and Fit Challenges for Custom Leather Jackets

The Problem: One of the most significant challenges B2B buyers face when sourcing custom leather jackets is ensuring accurate sizing and fit for their clients. In many cases, different manufacturers have varying size standards, leading to confusion and dissatisfaction among end-users. This can result in increased returns, wasted resources, and a tarnished reputation for the buyer. For instance, a retailer may receive a shipment of jackets that are either too large or too small, prompting the need for exchanges and additional costs.

The Solution: To mitigate sizing issues, B2B buyers should prioritize suppliers that offer comprehensive size guides and customization options. Request manufacturers to provide virtual sizing tools or consultation services that assist in accurately measuring customers. Moreover, consider implementing a sample program where buyers can order a few jackets in different sizes to evaluate fit and quality before making bulk purchases. This proactive approach not only ensures customer satisfaction but also reduces the likelihood of returns, ultimately preserving profit margins.

Scenario 2: Quality Assurance in Custom Leather Materials

The Problem: Another pain point for B2B buyers is the inconsistency in leather quality across different suppliers. When sourcing custom leather jackets, buyers often encounter variations in leather texture, durability, and appearance, which can lead to dissatisfaction among end customers. This inconsistency can be particularly problematic when fulfilling large orders, as it may jeopardize the brand’s reputation and lead to costly re-manufacturing.

The Solution: To ensure quality assurance, buyers should conduct thorough research on potential suppliers, focusing on their sourcing practices and material certifications. Request samples of leather before placing a large order to evaluate its quality firsthand. Additionally, establish quality control standards and conduct inspections upon delivery to verify that the materials meet specified requirements. Collaborating with suppliers who are transparent about their sourcing processes and can provide detailed information about the leather’s origins and treatment will greatly enhance the reliability of the final product.

Illustrative image related to custom leather jacket mens

Scenario 3: Customization Limitations and Process Complexity

The Problem: B2B buyers often find themselves frustrated by the limitations of customization options when ordering custom leather jackets. Many manufacturers may offer a limited range of styles, colors, or embellishments, which can hinder a buyer’s ability to meet specific client needs. Furthermore, the customization process can be cumbersome, with inadequate support leading to confusion about design specifications and timelines.

The Solution: To tackle these challenges, B2B buyers should seek out suppliers that offer extensive customization capabilities, including a wide array of materials, colors, and design elements. Engage with manufacturers who provide personalized consultations to help buyers articulate their vision effectively. A streamlined design process, facilitated by user-friendly online platforms, can simplify the ordering experience. Establishing clear communication channels and timelines with the supplier will also ensure that expectations are met, leading to a smoother production process and greater customer satisfaction. By fostering a collaborative relationship with manufacturers, buyers can enhance their product offerings and address client preferences more effectively.

Strategic Material Selection Guide for custom leather jacket mens

When selecting materials for custom leather jackets, understanding the properties, advantages, and limitations of various leather types is crucial for B2B buyers. This guide analyzes four common materials used in the production of custom leather jackets, providing insights into their performance, suitability, and considerations for international markets.

What Are the Key Properties of Full Grain Leather for Custom Leather Jackets?

Full grain leather is renowned for its durability and natural appearance, retaining the hide’s original texture. This leather type is resistant to wear and tear, making it an excellent choice for high-quality jackets. It can withstand varying temperatures, though it is essential to note that it may require regular conditioning to maintain its suppleness.

Pros: Full grain leather is incredibly durable, ages beautifully, and develops a unique patina over time. It is also breathable, making it suitable for different climates.

Illustrative image related to custom leather jacket mens

Cons: The main drawback is its higher cost compared to other leather types. Additionally, full grain leather can be more challenging to work with due to its thickness, which may complicate manufacturing processes.

Impact on Application: Full grain leather is compatible with various finishes and can be dyed in multiple colors, allowing for significant customization.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East may prefer full grain leather for its luxury appeal. Compliance with environmental standards related to leather tanning should be considered, especially in countries with strict regulations.

How Does Top Grain Leather Compare for Custom Leather Jackets?

Top grain leather is similar to full grain but has been sanded and treated to remove imperfections. This results in a smoother finish, making it a popular choice for fashion-forward designs.

Pros: It is generally more affordable than full grain leather while still offering a good balance of durability and aesthetics. The smoother surface allows for easier dyeing and finishing options.

Cons: While still durable, it is less resistant to wear than full grain leather. It may not develop the same character over time, which can be a disadvantage for buyers seeking a unique look.

Impact on Application: Top grain leather can be used effectively in fashion applications where appearance is prioritized over ruggedness.

Considerations for International Buyers: Buyers in South America may find top grain leather appealing due to its cost-effectiveness. However, they should ensure that the leather meets local quality standards.

What Are the Benefits of Suede Leather for Custom Leather Jackets?

Suede leather, made from the underside of the hide, offers a soft texture and a unique aesthetic. It is less durable than full grain or top grain leather but can be suitable for specific designs.

Pros: Suede is lightweight and provides a luxurious feel. It can be dyed in various colors, making it versatile for fashion applications.

Cons: The primary limitation is its susceptibility to stains and damage from moisture, which can be a concern in humid climates.

Impact on Application: Suede is best used in jackets designed for fashion rather than rugged use, making it suitable for urban environments.

Considerations for International Buyers: Buyers from Africa, where humidity can be high, should consider the environmental conditions when opting for suede. Compliance with local textile regulations is also essential.

Why Choose Bonded Leather for Custom Leather Jackets?

Bonded leather is made from leftover leather scraps that are bonded together with a polyurethane layer. This material is often marketed as a more sustainable option.

Pros: It is cost-effective and can provide a leather-like appearance at a lower price point. Bonded leather is also easier to clean than natural leather.

Cons: Its durability is significantly lower than traditional leather types, and it may not offer the same luxury feel.

Impact on Application: Bonded leather is suitable for entry-level products but may not meet the expectations of high-end fashion markets.

Considerations for International Buyers: Buyers in Europe may appreciate the sustainability aspect of bonded leather, but they should be cautious about its lower quality and ensure it meets local standards for leather products.

Summary Table of Material Selection for Custom Leather Jackets

| Material | Typical Use Case for custom leather jacket mens | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full Grain Leather | High-end fashion jackets | Exceptional durability and character | Higher cost, manufacturing complexity | Elevado |

| Top Grain Leather | Fashion-forward designs | Cost-effective, smooth finish | Less durable than full grain | Medium |

| Camurça | Fashion jackets for urban use | Luxurious feel, versatile colors | Susceptible to stains and moisture | Medium |

| Bonded Leather | Entry-level jackets | Cost-effective, easier to clean | Lower durability, less luxury feel | Low |

By understanding these materials and their implications, international B2B buyers can make informed decisions that align with their market needs and customer preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather jacket mens

What Are the Key Stages in the Manufacturing Process of Custom Leather Jackets for Men?

The manufacturing process of custom leather jackets is intricate and requires attention to detail at every stage. The primary stages include material preparation, forming, assembly, and finishing. Each stage is critical in ensuring that the final product not only meets aesthetic standards but also performs well in terms of durability and comfort.

Illustrative image related to custom leather jacket mens

How Is Material Prepared for Custom Leather Jackets?

Material preparation begins with sourcing high-quality leather, often full-grain, which is considered the best grade for durability and aesthetics. Suppliers typically establish relationships with tanneries worldwide, ensuring that they receive ethically sourced leather as a byproduct of the meat industry. Once the leather is procured, it undergoes inspection to verify its quality. This includes checking for flaws such as scars, color inconsistencies, and thickness variations.

Afterward, leather is conditioned and dyed if necessary, using eco-friendly dyes to meet international standards. Additional materials such as linings, zippers, and threads are also sourced, with emphasis placed on quality and functionality—YKK zippers, for example, are a popular choice due to their reliability.

What Techniques Are Used in Forming Custom Leather Jackets?

The forming stage involves cutting the leather according to the specific measurements and designs provided by the customer. Advanced cutting techniques, including laser cutting for precision, are often employed to ensure that each piece aligns perfectly with the design specifications.

Illustrative image related to custom leather jacket mens

Once cut, the leather pieces are shaped into the desired forms. Techniques such as molding or pleating may be used to create unique designs or to enhance the jacket’s fit. This stage is crucial as it sets the foundation for the jacket’s overall silhouette and wearability.

How Are Custom Leather Jackets Assembled?

Assembly involves stitching the various cut pieces together. High-quality stitching techniques are essential to ensure durability; for instance, double-stitched seams are often used in areas of high stress. Craftsmen may also employ hand-stitching methods for specific details, adding a bespoke touch to the jacket.

During assembly, features such as pockets, collars, and embellishments are integrated. Customizations such as embroidery, logos, or personalized quotes can be added at this stage, allowing buyers to express their individuality. Quality control checkpoints are established throughout the assembly process to catch any potential issues early on.

What Finishing Processes Are Involved in Custom Leather Jackets?

The finishing stage is where the jacket is refined and prepared for delivery. This includes trimming excess threads, applying protective coatings, and conditioning the leather to enhance its appearance and longevity. Finishing techniques can also involve distressing the leather for a vintage look or adding treatments for water resistance.

Illustrative image related to custom leather jacket mens

Finally, the jackets undergo a thorough inspection to ensure they meet quality standards before packaging and shipping. This is a critical step, as it is often the last opportunity to catch any imperfections.

What Quality Assurance Standards Are Important for Custom Leather Jacket Manufacturing?

Quality assurance in the custom leather jacket manufacturing process is paramount, particularly for B2B buyers who may be investing significant resources. Adherence to international quality standards, such as ISO 9001, ensures that manufacturers maintain a consistent quality management system. This standard emphasizes continuous improvement and customer satisfaction, which are crucial for long-term business relationships.

How Do Industry-Specific Standards Apply to Custom Leather Jacket Production?

In addition to general quality standards, industry-specific certifications may apply, such as CE marking for safety and environmental compliance in Europe. B2B buyers should inquire about these certifications to ensure that the products meet the necessary legal and safety requirements in their respective markets.

What Are the Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints should be strategically placed throughout the manufacturing process to maintain high standards.

-

Incoming Quality Control (IQC): At this stage, incoming materials are inspected for defects and compliance with specifications before they are used in production.

-

In-Process Quality Control (IPQC): This involves monitoring the manufacturing process itself. Regular checks are performed during cutting, stitching, and assembly to catch errors early.

-

Final Quality Control (FQC): The final inspection occurs after the jackets are completed. This step ensures that the product meets all design specifications and quality standards before shipping.

Common testing methods include visual inspections, measurement checks, and stress tests on zippers and seams to ensure durability.

Illustrative image related to custom leather jacket mens

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to ensure that their suppliers adhere to stringent quality control practices. This can be achieved through:

-

Supplier Audits: Conducting regular audits of suppliers can help verify compliance with quality standards. This includes reviewing their QC processes and inspecting their facilities.

-

Requesting Quality Reports: Buyers should ask for documentation that outlines the QC measures taken during production, including inspection reports and testing results.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control practices. This is especially important for international transactions where buyers cannot physically inspect the products.

What Are the QC and Certification Nuances for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control and certification is crucial. Different regions may have varying standards and expectations, which can impact the importation process. For instance, buyers from Europe may need to ensure that products comply with EU regulations, while those from Africa may have different local standards.

Additionally, buyers should be aware of potential customs duties and taxes that may apply to imported goods. Engaging with suppliers who have experience in international trade can help navigate these complexities.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures in the production of custom leather jackets is essential for B2B buyers. By focusing on quality at every stage, from material selection to final inspection, businesses can ensure they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather jacket mens’

To assist B2B buyers in successfully procuring custom leather jackets for men, this guide outlines essential steps to ensure quality, fit, and satisfaction. By following this checklist, buyers can navigate the complexities of sourcing custom leather jackets while maintaining a focus on quality and individual specifications.

Illustrative image related to custom leather jacket mens

Step 1: Identify Your Target Market and Needs

Understanding your target market is foundational. Determine the specific demographics of your customers, including their preferences for style, fit, and functionality. This insight will guide your design choices and help you communicate effectively with suppliers about what your market demands.

- Consider regional styles: Different regions may have unique preferences for leather jacket styles.

- Assess seasonal needs: Determine if your market requires jackets suitable for warmer or colder climates.

Step 2: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the specifications for your custom leather jackets. This includes materials, sizes, design features, and any additional customizations.

- Material selection: Decide on the type of leather (e.g., full grain, top grain) based on durability and aesthetics.

- Customization options: Consider features like embroidery, pockets, and lining materials to enhance the product’s appeal.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your specifications and quality standards. Request detailed company profiles, production capabilities, and references.

- Check for certifications: Look for quality management certifications (e.g., ISO 9001) to gauge their commitment to quality.

- Assess production capacity: Ensure the supplier can handle your required order volume within your timeline.

Step 4: Request Samples for Quality Assurance

Before placing a bulk order, request samples of the jackets. This step is crucial for evaluating the quality of craftsmanship, materials, and fit.

- Inspect the samples: Check stitching quality, leather texture, and overall finish.

- Fit testing: If possible, have a few individuals try on the samples to assess fit and comfort.

Step 5: Discuss Customization Options and Pricing

Engage with your selected supplier to discuss customization options and pricing structures. Ensure transparency in pricing, including any potential additional costs for custom features.

Illustrative image related to custom leather jacket mens

- Negotiate terms: Don’t hesitate to negotiate pricing based on order volume and customization complexity.

- Clarify payment terms: Understand the payment structure, including deposits and payment schedules.

Step 6: Review Shipping and Return Policies

Understand the shipping logistics and return policies provided by the supplier. This can save you from unexpected costs and complications.

- Shipping options: Evaluate international shipping methods and costs, particularly if you’re sourcing from overseas.

- Return and alteration policies: Ensure there are clear guidelines for returns or alterations, especially for custom items.

Step 7: Establish Ongoing Communication

Once you select a supplier, maintain open lines of communication throughout the production process. This ensures any potential issues are addressed promptly.

- Regular updates: Request progress reports on the order status to stay informed.

- Feedback loop: Provide feedback on samples and prototypes to guide the final production.

By adhering to this step-by-step checklist, B2B buyers can effectively navigate the complexities of sourcing custom leather jackets for men, ensuring they deliver high-quality products that meet their market’s demands.

Comprehensive Cost and Pricing Analysis for custom leather jacket mens Sourcing

What Are the Key Cost Components in Custom Leather Jacket Manufacturing?

When sourcing custom leather jackets, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of leather significantly affects pricing. Full-grain leather, known for its durability and quality, commands a higher price than other grades. Additionally, the cost of lining fabrics, zippers, and hardware can vary widely based on quality and brand (e.g., YKK zippers).

-

Labor: Skilled labor is essential in producing custom jackets. The craftsmanship involved in tailoring, cutting, and assembling jackets adds to labor costs. Regions with a strong tradition in leather craftsmanship may offer higher quality but at a premium price.

-

Manufacturing Overhead: This includes costs related to the production facility, utilities, and administrative expenses. Companies that focus on ethical manufacturing practices may incur additional costs, which can be reflected in the final price.

-

Tooling: For custom designs, tooling costs can be significant. This may include the creation of patterns or molds for unique jacket designs, which are factored into the overall cost.

-

Quality Control (QC): Ensuring that each jacket meets quality standards incurs additional costs. A robust QC process can prevent defects but will add to the overall price.

-

Logistics: Shipping costs can vary greatly depending on the destination and shipping methods used. For international buyers, understanding Incoterms is essential to determine who bears these costs and responsibilities.

-

Margin: Lastly, the supplier’s margin is a key consideration. The markup on custom leather jackets can vary based on brand positioning and market demand.

How Do Price Influencers Impact Custom Leather Jacket Costs?

Several factors influence the pricing of custom leather jackets, particularly in international markets:

Illustrative image related to custom leather jacket mens

-

Volume and Minimum Order Quantity (MOQ): Bulk orders can significantly reduce the per-unit cost. Suppliers often offer discounts for larger orders, making it advantageous for B2B buyers to plan purchases accordingly.

-

Specifications and Customization: The level of customization desired will impact the final price. More intricate designs or unique materials will generally lead to higher costs. Buyers should balance their desire for uniqueness with budget constraints.

-

Material Quality and Certifications: Jackets made from ethically sourced, high-quality materials may come at a premium. Certifications related to sustainability and ethical practices can also influence price, appealing to buyers focused on corporate responsibility.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with a track record of quality may charge more, but they often provide assurance of product quality and service.

-

Incoterms: Understanding shipping terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial. These terms dictate who is responsible for shipping costs and customs duties, impacting the overall cost.

What Are Some Negotiation Tips for B2B Buyers of Custom Leather Jackets?

For international buyers from regions like Africa, South America, the Middle East, and Europe, effective negotiation can lead to cost savings:

-

Research and Benchmarking: Understand market prices and competitor offerings to negotiate from an informed position. Having data on average costs can strengthen your negotiation stance.

-

Clarify Specifications: Be clear about your requirements to avoid unexpected costs. Providing detailed specifications can help suppliers give accurate quotes.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also factors like shipping, customs duties, and potential alterations. A lower purchase price may not always translate to lower overall costs.

-

Build Relationships: Long-term partnerships can lead to better pricing and terms. Suppliers are often more willing to negotiate with clients they see as long-term partners.

-

Explore Alternative Suppliers: Don’t hesitate to seek quotes from multiple suppliers. This competition can lead to better pricing and terms.

Conclusion: Navigating Pricing Nuances in International Markets

When sourcing custom leather jackets, understanding the complex cost structure and price influencers is vital for B2B buyers. Factors such as material choices, customization levels, and supplier reliability can significantly impact pricing. By employing effective negotiation strategies and considering the total cost of ownership, international buyers can secure favorable terms and ensure quality products that meet their specific needs. Always remember that prices can fluctuate based on market conditions and specific supplier practices, so it’s wise to remain adaptable and informed.

Alternatives Analysis: Comparing custom leather jacket mens With Other Solutions

Understanding Alternatives to Custom Leather Jackets for Men’s Fashion

In the competitive landscape of men’s fashion, particularly in the realm of leather jackets, it’s crucial for B2B buyers to explore various alternatives to custom leather jackets. These alternatives may offer different benefits regarding cost, performance, and suitability for specific market needs. Below, we examine custom leather jackets in comparison to other viable solutions: mass-produced leather jackets and synthetic leather options.

Comparison Table

| Comparison Aspect | Custom Leather Jacket Mens | Mass-Produced Leather Jacket | Synthetic Leather Jacket |

|---|---|---|---|

| Performance | Tailored fit, high durability | Standard fit, variable quality | Generally lower durability, but water-resistant |

| Cost | Higher initial investment ($398-$502) | More affordable ($150-$300) | Budget-friendly ($50-$150) |

| Ease of Implementation | Requires detailed measurements and design input | Quick purchase with immediate availability | Easy to source with immediate availability |

| Maintenance | Requires specialized care | Moderate care needed | Easy to clean and maintain |

| Best Use Case | Unique, bespoke fashion statements | Everyday wear, casual outings | Cost-effective, eco-friendly options for general use |

Detailed Breakdown of Alternatives

Mass-Produced Leather Jackets

Mass-produced leather jackets are often available at lower price points, making them attractive for budget-conscious consumers. They offer the advantage of immediate availability, allowing businesses to stock up quickly for retail. However, the trade-off often lies in the fit and quality; these jackets may not cater to individual sizes or preferences and can suffer from inconsistent quality. For businesses targeting the mainstream market, mass-produced options could suffice, but they may lack the unique appeal that custom designs offer.

Illustrative image related to custom leather jacket mens

Synthetic Leather Jackets

Synthetic leather, or faux leather, has gained popularity due to its affordability and ethical appeal. These jackets are generally easier to maintain and can be produced in various styles and colors, making them versatile options for retailers. However, synthetic leather typically does not match the durability and luxury feel of genuine leather, which may be a drawback for buyers seeking high-quality fashion items. For businesses focused on eco-friendliness or budget constraints, synthetic options present an attractive alternative.

Conclusion: Choosing the Right Leather Jacket Solution for Your Business Needs

When evaluating alternatives to custom leather jackets, B2B buyers must consider their target market, budget, and the specific attributes they seek in a product. Custom leather jackets provide a unique, tailored experience that resonates with consumers looking for individuality and quality. In contrast, mass-produced and synthetic leather jackets cater to different segments of the market, emphasizing affordability and convenience. Ultimately, the right choice will depend on the strategic goals of the business and the preferences of its clientele. By carefully analyzing these options, buyers can position themselves effectively in the competitive fashion landscape.

Essential Technical Properties and Trade Terminology for custom leather jacket mens

What Are the Key Technical Properties of Custom Leather Jackets for Men?

When sourcing custom leather jackets, understanding the technical properties is crucial for ensuring quality and meeting specific buyer needs. Here are some essential specifications:

1. Material Grade: What Makes Leather Quality Stand Out?

Leather jackets can be made from various types of leather, with full-grain leather being the highest quality. This leather type retains the natural texture and imperfections, providing durability and a luxurious look. For B2B buyers, selecting the right material grade is vital as it affects the jacket’s longevity, aesthetics, and overall value. Lower grades, like bonded leather, might be more affordable but can compromise on durability and appeal.

Illustrative image related to custom leather jacket mens

2. Tolerance: Why Precision Matters in Custom Fit

Tolerance refers to the allowable deviation from specified dimensions in the manufacturing process. For custom leather jackets, maintaining tight tolerances ensures a perfect fit tailored to individual measurements. This precision is particularly important in B2B transactions where end consumers expect high-quality, well-fitted products. Accurate tolerances prevent returns and enhance customer satisfaction.

3. Stitching Density: How Does It Affect Durability?

Stitching density, measured in stitches per inch (SPI), indicates the number of stitches used in a seam. A higher SPI typically translates to greater durability, which is essential for leather jackets that undergo significant wear and tear. For B2B buyers, understanding this property helps assess the jacket’s strength and longevity, thus influencing purchasing decisions.

4. Lining Fabric: What Role Does It Play?

The lining fabric of a leather jacket impacts comfort, warmth, and breathability. Common materials include polyester, satin, or cotton blends. Selecting the appropriate lining is critical for enhancing the wearer’s experience, especially in varying climates. B2B buyers should consider the target market’s climate when specifying lining options to ensure customer satisfaction.

5. Hardware Quality: Why It Matters for Aesthetic and Functionality

The quality of zippers and other hardware components can significantly influence both the aesthetic appeal and functionality of a leather jacket. For example, YKK zippers are known for their reliability and smooth operation. B2B buyers should prioritize quality hardware to enhance the overall perception of their products and reduce the likelihood of returns due to faulty components.

What Are Common Trade Terms Related to Custom Leather Jackets?

In the world of custom leather jackets, specific terminology is commonly used. Understanding these terms can facilitate smoother transactions and clearer communications.

Illustrative image related to custom leather jacket mens

1. OEM (Original Equipment Manufacturer): What Does It Mean?

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the leather industry, OEM partnerships can allow brands to offer custom designs without investing in their own manufacturing facilities. This is particularly beneficial for B2B buyers looking to expand their product offerings efficiently.

2. MOQ (Minimum Order Quantity): Why Is It Important?

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for B2B buyers, as it affects inventory management and cash flow. Suppliers may set MOQs to ensure production efficiency, but buyers should negotiate terms that align with their sales forecasts and market demand.

3. RFQ (Request for Quotation): How to Use It Effectively

An RFQ is a document sent to suppliers asking for a quote on specific products or services. For B2B buyers, issuing an RFQ can streamline the sourcing process, allowing them to compare prices and terms from multiple suppliers. A well-crafted RFQ ensures clarity in requirements, which can lead to more accurate quotes.

4. Incoterms: How Do They Affect Shipping and Costs?

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms is vital for B2B buyers to understand their obligations and potential costs associated with the importation of custom leather jackets.

By grasping these essential properties and trade terms, B2B buyers can make informed decisions, ensuring they procure high-quality custom leather jackets that meet their market needs and customer expectations.

Navigating Market Dynamics and Sourcing Trends in the custom leather jacket mens Sector

What are the Current Market Dynamics and Key Trends in the Custom Leather Jacket Sector?

The global market for custom leather jackets is experiencing robust growth, driven by an increasing demand for personalized fashion and sustainable materials. This trend is particularly evident in regions such as Africa, South America, the Middle East, and Europe, where consumers are leaning towards unique pieces that reflect their individuality. B2B buyers are increasingly seeking suppliers that offer bespoke services, allowing them to meet diverse client needs—from unique designs to specific sizing requirements. The rise of digital tools for customization, including virtual fitting apps and online design consultations, is reshaping how businesses interact with manufacturers, making the sourcing process more efficient and user-friendly.

Emerging technologies, such as 3D printing and AI-driven design tools, are also enhancing the production process, allowing for quicker turnarounds and reduced waste. This aligns with the growing consumer expectation for transparency in the supply chain, prompting buyers to prioritize manufacturers that provide insights into their production practices. Moreover, the rise of e-commerce platforms has enabled international buyers to access a wider variety of options, thereby increasing competition among suppliers.

How Does Sustainability and Ethical Sourcing Impact the Custom Leather Jacket Market?

As the focus on sustainability intensifies, B2B buyers are increasingly prioritizing ethical sourcing and environmentally friendly practices. The leather industry, traditionally associated with significant environmental impacts, is undergoing transformation as suppliers adopt more sustainable methods. This includes sourcing leather as a byproduct of the meat industry and utilizing eco-friendly tanning processes to minimize waste and pollution.

Illustrative image related to custom leather jacket mens

Buyers are becoming more discerning, seeking suppliers that can demonstrate a commitment to sustainability through certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS). These certifications not only assure buyers of ethical practices but also enhance brand reputation in a market that increasingly values corporate responsibility. Additionally, the integration of recycled materials into the production of leather jackets is gaining traction, offering a dual benefit of reducing environmental impact while appealing to eco-conscious consumers.

What is the Historical Context of Custom Leather Jackets and Its Relevance Today?

The evolution of custom leather jackets can be traced back to their origins as functional garments for aviators and motorcyclists in the early 20th century. Over the decades, these jackets have transcended their practical roots to become symbols of rebellion and fashion statements, heavily influenced by cultural icons and trends.

In recent years, the custom leather jacket market has adapted to changing consumer preferences, emphasizing personalization and craftsmanship. This shift reflects a broader trend towards individuality in fashion, where consumers increasingly seek unique pieces that resonate with their personal style. For B2B buyers, understanding this historical context is crucial, as it informs current consumer expectations and the significance of bespoke offerings in the marketplace.

By leveraging these insights, international B2B buyers can navigate the complexities of sourcing custom leather jackets effectively, ensuring they align with market demands while also promoting sustainability and ethical practices in their supply chains.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather jacket mens

-

How do I ensure the quality of custom leather jackets from international suppliers?

To ensure quality when sourcing custom leather jackets, request samples before committing to a larger order. Evaluate the leather’s texture, durability, and craftsmanship. Additionally, inquire about the supplier’s production process and materials used. Look for certifications or standards they meet, and check for reviews or testimonials from other B2B buyers. Establishing a clear communication channel for quality expectations and setting up quality assurance (QA) protocols can further ensure that the products meet your standards. -

What are the typical minimum order quantities (MOQs) for custom leather jackets?

MOQs for custom leather jackets can vary significantly among suppliers, often ranging from 50 to 200 units per order. It’s essential to discuss MOQs upfront during negotiations, as they can impact pricing and lead times. Some suppliers may offer lower MOQs for first-time orders or allow for a trial run, while others may require higher quantities for custom designs. Consider your inventory needs and budget when evaluating different suppliers. -

What customization options are available for men’s leather jackets?

Customization options for men’s leather jackets typically include choices in leather type, color, lining fabric, and hardware. You can also select features like pockets, zippers, embroidery, and additional design elements. Many suppliers offer bespoke services that allow you to create a unique design tailored to your brand’s identity. Discuss your vision with the supplier to explore the full range of customization possibilities, ensuring it aligns with your target market’s preferences. -

What payment terms should I expect when sourcing custom leather jackets?

Payment terms can vary widely among suppliers, but it is common to encounter options such as a 30% deposit upfront with the balance due upon shipment or delivery. Some suppliers may offer more flexible terms based on your relationship or order size. Always clarify payment methods accepted (e.g., bank transfer, credit card, PayPal) and ensure that all terms are documented in the contract. This will help avoid misunderstandings and protect your investment. -

How can I vet potential suppliers for custom leather jackets?

To effectively vet suppliers, conduct thorough research including background checks, financial stability assessments, and reviews from previous clients. Request references and contact them to gauge their experience with the supplier. Visit the supplier’s facility if possible, or use virtual tours to assess their production capabilities and quality control processes. Finally, ensure they comply with ethical manufacturing practices, as this can impact your brand’s reputation. -

What logistics considerations should I be aware of when importing leather jackets?

When importing leather jackets, consider shipping costs, delivery times, and customs regulations in your country. Familiarize yourself with import duties and taxes that may apply, especially for international shipments. Collaborate with a logistics partner who specializes in international trade to streamline the shipping process. Additionally, ensure that the supplier provides necessary documentation for customs clearance, including invoices and certificates of origin. -

How do I handle returns and alterations for custom leather jackets?

Handling returns and alterations for custom leather jackets can be challenging due to their personalized nature. Establish a clear return policy with the supplier before placing an order. Understand that many suppliers do not accept returns on customized items but may offer alterations or remakes if the product does not meet agreed specifications. Maintain open communication with your supplier to facilitate any necessary adjustments to ensure customer satisfaction. -

What are the trends in men’s custom leather jackets that I should consider?

Staying informed about fashion trends in men’s custom leather jackets is crucial for appealing to your target market. Current trends include sustainable materials, oversized fits, and unique color palettes. Additionally, incorporating technology, such as weather-resistant coatings or removable linings, can enhance the functionality of jackets. Regularly review fashion forecasts and attend trade shows to keep your offerings fresh and aligned with consumer preferences.

Top 6 Custom Leather Jacket Mens Manufacturers & Suppliers List

1. Lusso Leather – Custom Leather Jackets

Domain: lussoleather.com

Registered: 2016 (9 years)

Introduction: Custom Leather Jackets – Design Your Own Leather Jacket

Regular price: $502.00

Sale price: $398.00

Free Shipping and 30 days for Returns/Alterations

Available Sizes: XSmall, Small, Medium, Large, Xlarge, XXL, Custom Size, Custom Plus Size

Custom Plus Size Price: $481.00

Customization options include:

– Selection of fabrics and leathers

– Custom embroidery, sublimation printing, logos, graphics, le…

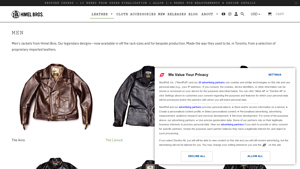

2. Himel Bros – Men’s Bespoke Leather Jackets

Domain: himelbros.com

Registered: 2010 (15 years)

Introduction: Men’s Bespoke Leather Jackets from Himel Bros. • Bespoke Orders take 12 weeks from order finalization • Allow 1-2 weeks for measurements & design details • Made in Toronto from proprietary imported leathers • Available in off the rack sizes and for bespoke production • Price: $2,950.00 • Product names include: The Avro, The Canuck, The Chevalier, The Frobisher, The Heron A-1, The Imperial, The Ken…

3. Mahileather – Branded Leather Jacket

Domain: mahileather.com

Registered: 2014 (11 years)

Introduction: {“product_name”: “Branded Leather Jacket”, “price”: “$215.46”, “original_price”: “$239.40”, “discount”: “10% OFF”, “material”: “premium leather”, “shipping”: “Free Worldwide Shipping”, “warranty”: “1 Year Warranty”, “returns”: “30 day returns”, “availability”: “Delivered to most destinations in 5 business days”, “sizes”: [“Small”, “Medium”, “Large”], “colors”: [“White”, “Grey”, “Black”, “Navy Sued…

4. LeatherCult – Handmade Leather Apparel

Domain: leathercult.com

Registered: 2010 (15 years)

Introduction: LeatherCult offers a wide range of leather apparel for men, women, and boys, including tops, jackets, blazers, long coats, vests, suits, pants, shorts, and chaps. The products are handmade using premium leather, ensuring a custom fit and high-quality craftsmanship. They provide options for custom sizes ranging from XS to 4XL, and feature various styles including celebrity jackets. The site emphasi…

5. Custom Cowboy Shop – Men’s Leather Jackets

Domain: customcowboyshop.com

Registered: 2000 (25 years)

Introduction: [{‘name’: “Collins Men’s Leather Jacket”, ‘price’: ‘$325.00’}, {‘name’: “Men’s Leather Shirt Jacket”, ‘price’: ‘$350.00’, ‘availability’: ‘Sold Out’}, {‘name’: ‘Vintage Leather Bomber Jacket’, ‘price’: ‘$345.00’}, {‘name’: “Men’s Clyde Leather Jacket”, ‘price’: ‘from $330.00’}]

6. Vanson Leathers – Custom Leather Motorcycle Jackets

Domain: vansonleathers.com

Registered: 1997 (28 years)

Introduction: Leather Motorcycle Jackets, Hand Made in USA, Custom men’s and women’s leather jackets, Off-the-rack leather motorcycle jackets and suits, Custom racing suits, Cafe Racer Jackets, Concealed Carry Jackets, Performance motorcycle products, Limited Warranty valid for one year against defects in workmanship and materials, Selection includes leather jackets for motorcycling, road racing, drag racing, c…

Strategic Sourcing Conclusion and Outlook for custom leather jacket mens

In conclusion, strategic sourcing for custom leather jackets presents a unique opportunity for international B2B buyers to capitalize on the growing demand for personalized fashion. By partnering with manufacturers that emphasize quality craftsmanship, ethical practices, and a wide range of customization options, businesses can cater to a diverse clientele. The advantages of sourcing from reputable suppliers include access to premium materials, bespoke tailoring, and the ability to meet specific market needs, such as unique sizes and styles that resonate with local cultures.

Illustrative image related to custom leather jacket mens

As the global market continues to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, the importance of building strong supplier relationships cannot be overstated. Buyers should prioritize transparency in sourcing processes and consider the long-term benefits of investing in quality over quantity.

Looking ahead, now is the time to engage with trusted manufacturers who can bring your vision for custom leather jackets to life. Embrace the potential for growth in this dynamic sector and differentiate your offerings by delivering high-quality, stylish, and personalized products that appeal to modern consumers. Start your journey towards successful sourcing today and position your business for future success in the competitive fashion landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to custom leather jacket mens