Introduction: Navigating the Global Market for leather crafting supplies

In the dynamic landscape of leather crafting supplies, international B2B buyers face the pressing challenge of sourcing high-quality materials and tools that meet their specific needs. Whether you’re operating in Africa, South America, the Middle East, or Europe, the quest for reliable suppliers and diverse product offerings can be daunting. This guide delves into the intricacies of the global leather crafting supply market, providing essential insights into various types of leather, tools, and machinery available. It also highlights applications across different sectors, from fashion to upholstery, ensuring you find the right supplies for your projects.

Moreover, we will explore effective supplier vetting strategies, including quality assessments and certifications, to help you establish trustworthy partnerships. Understanding pricing structures and cost considerations will empower you to negotiate effectively, ensuring value for your investment. By the end of this guide, you will be equipped with the knowledge to make informed purchasing decisions, mitigating risks and enhancing your supply chain efficiency. Our focus on the unique needs of buyers from regions such as Saudi Arabia and Brazil ensures that you can navigate this global market with confidence, securing the best leather crafting supplies tailored to your business requirements.

Table Of Contents

- Top 8 Leather Crafting Supplies Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather crafting supplies

- Understanding leather crafting supplies Types and Variations

- Key Industrial Applications of leather crafting supplies

- 3 Common User Pain Points for ‘leather crafting supplies’ & Their Solutions

- Strategic Material Selection Guide for leather crafting supplies

- In-depth Look: Manufacturing Processes and Quality Assurance for leather crafting supplies

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather crafting supplies’

- Comprehensive Cost and Pricing Analysis for leather crafting supplies Sourcing

- Alternatives Analysis: Comparing leather crafting supplies With Other Solutions

- Essential Technical Properties and Trade Terminology for leather crafting supplies

- Navigating Market Dynamics and Sourcing Trends in the leather crafting supplies Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather crafting supplies

- Strategic Sourcing Conclusion and Outlook for leather crafting supplies

- Important Disclaimer & Terms of Use

Understanding leather crafting supplies Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Leather Types | Variety includes full-grain, top-grain, and suede. | Fashion, accessories, upholstery, automotive. | Pros: Durability and aesthetic appeal. Cons: Cost varies widely. |

| Tools and Equipment | Includes cutting tools, stitching tools, and punches. | Handbag making, garment production, custom goods. | Pros: Essential for quality craftsmanship. Cons: Initial investment can be high. |

| Leather Finishing Products | Dyes, conditioners, and sealants for leather. | Customization and maintenance of leather goods. | Pros: Enhances product longevity and appearance. Cons: Requires knowledge of application methods. |

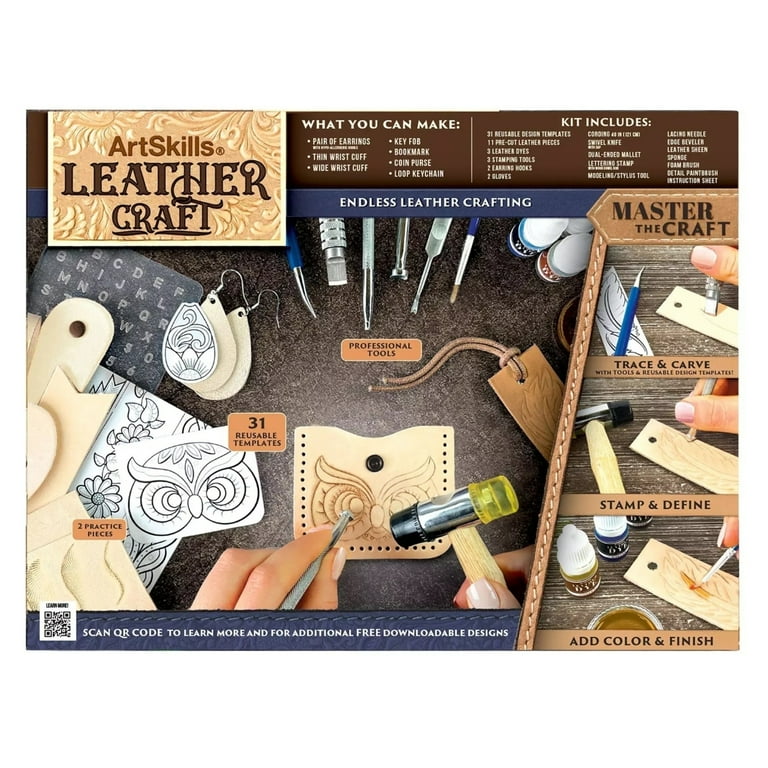

| Leather Crafting Kits | Pre-packaged sets with materials and instructions. | Education, DIY projects, and gifts. | Pros: Ideal for beginners and streamlined purchasing. Cons: Limited customization options. |

| Hardware Components | Includes buckles, rivets, and snaps. | Bag making, garment assembly, leather goods. | Pros: Variety enhances product functionality. Cons: Quality can vary by supplier. |

What Are the Distinguishing Features of Different Leather Types?

Leather types are crucial to the quality and application of leather goods. Full-grain leather is the highest quality, retaining the natural grain and durability, making it ideal for high-end fashion and accessories. Top-grain leather is slightly processed, offering a balance of quality and affordability, suitable for a wider range of products. Suede, on the other hand, provides a soft texture and is often used in fashion and upholstery. B2B buyers must consider the end-use and desired aesthetic when selecting leather types, as the cost and durability can vary significantly.

How Do Tools and Equipment Impact Leather Crafting?

The right tools and equipment are essential for successful leather crafting. Items such as cutting tools, stitching tools, and punches ensure precision and quality in the production process. These tools are commonly used in industries ranging from handbag making to custom leather goods. For B2B buyers, investing in high-quality tools can improve efficiency and the overall quality of the final product, although the initial investment might be substantial. Understanding the specific requirements of their projects can help buyers select the right tools.

Why Are Leather Finishing Products Important for B2B Buyers?

Leather finishing products, including dyes, conditioners, and sealants, play a vital role in enhancing the appearance and longevity of leather goods. These products allow businesses to customize their offerings, providing unique finishes that can differentiate them in a competitive market. B2B buyers should be aware of the application methods and compatibility of these products with different leather types to ensure optimal results. While these products can significantly enhance the final product, they require some expertise to apply correctly.

What Benefits Do Leather Crafting Kits Offer to Businesses?

Leather crafting kits are a convenient option for businesses looking to introduce new products or educate their employees. These kits typically contain all necessary materials and instructions, making them ideal for beginners or educational purposes. They are also popular as gifts or for DIY projects. However, B2B buyers should note that while kits simplify the process, they may limit customization options compared to sourcing individual materials. Evaluating the target audience’s skill level and interest can help in selecting the right kits.

How Do Hardware Components Enhance Leather Products?

Hardware components such as buckles, rivets, and snaps are essential for the functionality and aesthetic of leather goods. They provide durability and enhance the usability of products like bags and garments. For B2B buyers, sourcing high-quality hardware can ensure that the final products meet customer expectations for both appearance and performance. While the variety available can cater to diverse design needs, buyers should be cautious about quality discrepancies among suppliers, which can impact the overall product integrity.

Key Industrial Applications of leather crafting supplies

| Industry/Sector | Specific Application of Leather Crafting Supplies | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Handbag and Accessory Manufacturing | High-quality, customizable products enhance brand value. | Sourcing premium leather types and sustainable materials. |

| Automotive | Custom Leather Interiors | Enhances luxury appeal, increasing customer satisfaction. | Durability standards and compliance with automotive regulations. |

| Footwear | Shoe Production | Unique designs and comfort lead to competitive advantage. | Material sourcing for flexibility and wear resistance. |

| Furniture | Upholstery and Custom Furniture Design | Offers bespoke solutions that cater to high-end markets. | Availability of various leather grades and textures. |

| E-commerce & Retail | DIY Leather Craft Kits | Engages customers, creating additional revenue streams. | Packaging, shipping logistics, and kit customization. |

How Are Leather Crafting Supplies Used in the Fashion & Apparel Industry?

In the fashion and apparel sector, leather crafting supplies are essential for producing high-end handbags and accessories. Businesses can leverage customizable materials to create unique designs that resonate with their target audience. This not only enhances brand value but also meets the growing demand for personalized products. International buyers must consider the sourcing of premium leather types, ensuring they align with ethical standards and sustainability practices, which are increasingly important in global markets.

What Role Do Leather Crafting Supplies Play in the Automotive Sector?

Leather crafting supplies are crucial in the automotive industry, particularly for custom interiors that elevate the luxury appeal of vehicles. High-quality leather enhances the aesthetic and tactile experience for customers, leading to increased satisfaction and brand loyalty. When sourcing materials for automotive applications, businesses must focus on durability and compliance with industry regulations to ensure safety and longevity.

How Are Leather Crafting Supplies Essential for Footwear Production?

In the footwear industry, leather crafting supplies are used to create shoes that are not only stylish but also comfortable. The ability to design unique patterns and utilize various leather types offers a competitive edge in a crowded marketplace. Buyers from international markets should prioritize sourcing materials that provide the right balance of flexibility and wear resistance, ensuring that the end product meets consumer expectations for quality and durability.

In What Ways Do Leather Crafting Supplies Benefit Furniture Design?

For the furniture industry, leather crafting supplies are vital for upholstery and custom furniture design. Businesses can offer bespoke solutions that appeal to high-end markets, allowing them to differentiate their products. When sourcing leather for furniture applications, it’s important to consider the availability of different grades and textures, as these factors significantly influence the final product’s quality and aesthetic appeal.

How Can E-commerce and Retail Benefit from Leather Crafting Supplies?

E-commerce and retail businesses can utilize leather crafting supplies to create DIY leather craft kits, which engage customers and provide an additional revenue stream. These kits enable consumers to explore their creativity while crafting personalized items. Key considerations for international buyers include effective packaging and shipping logistics, as well as the ability to customize kits to meet regional preferences and trends.

3 Common User Pain Points for ‘leather crafting supplies’ & Their Solutions

Scenario 1: Sourcing Quality Leather Materials for Diverse Markets

The Problem: B2B buyers often struggle with sourcing high-quality leather materials that meet both their quality standards and the unique preferences of their local markets. For example, buyers in regions like South America may prefer specific leather textures or colors that are not readily available from suppliers in Europe. Additionally, inconsistencies in leather quality and sourcing practices can lead to production delays and increased costs, impacting the overall profitability of businesses.

The Solution: To effectively source quality leather, buyers should establish strong relationships with multiple suppliers across different regions. This strategy not only diversifies the supply chain but also allows buyers to gain insights into local market trends. Utilize online platforms and trade shows to discover suppliers that specialize in the desired leather types. Conduct thorough quality assessments through sample orders before committing to large purchases. Implementing a standardized quality-check process will ensure consistency and meet the varying demands of different markets. By maintaining an open line of communication with suppliers, buyers can negotiate customized offerings that align with their market needs, ensuring they always have access to the right materials.

Scenario 2: Navigating Complex Regulations on Leather Imports

The Problem: International buyers face significant challenges navigating the complex regulations surrounding the importation of leather goods. Different countries have varying requirements regarding environmental standards, animal welfare, and product safety certifications, which can complicate purchasing decisions. For instance, buyers in the Middle East may encounter stricter regulations due to cultural sensitivities towards animal products, leading to potential compliance issues and delays.

The Solution: To mitigate these challenges, B2B buyers should invest in understanding the regulatory landscape of their target markets. This can be achieved by collaborating with legal advisors who specialize in international trade and compliance. Buyers can also leverage trade associations that provide resources and updates on regulatory changes. Creating a checklist of necessary documentation—such as Certificates of Origin, health certificates, and compliance with local environmental standards—will streamline the import process. Additionally, working with suppliers who are knowledgeable about these regulations can facilitate smoother transactions and ensure compliance from the outset.

Scenario 3: Managing Inventory and Supply Chain Disruptions

The Problem: Fluctuations in demand and unexpected supply chain disruptions often leave B2B buyers with either excess inventory or shortages of leather crafting supplies. For example, during peak seasons, a sudden increase in demand for specific leather products can lead to stockouts, while off-peak periods may result in surplus inventory that ties up capital and storage space.

The Solution: Implementing an agile inventory management system is crucial for addressing these challenges. Buyers should adopt just-in-time (JIT) inventory practices, which allow for more responsive ordering based on real-time demand data. Utilizing inventory management software can provide analytics to forecast demand trends, ensuring that buyers can adjust their orders accordingly. Establishing safety stock levels for critical items will also help cushion against unexpected demand spikes. Furthermore, maintaining strong communication with suppliers can facilitate quicker reordering and delivery times, helping to mitigate the risks associated with supply chain disruptions. By adopting these proactive strategies, B2B buyers can maintain optimal inventory levels while minimizing costs.

Strategic Material Selection Guide for leather crafting supplies

What Are the Key Materials for Leather Crafting Supplies?

When selecting materials for leather crafting supplies, it’s essential to consider the properties, advantages, and limitations of various options. This analysis will focus on four common materials: vegetable-tanned leather, chrome-tanned leather, synthetic leather, and suede. Each material has unique characteristics that impact product performance and suitability for different applications, particularly for international B2B buyers.

How Does Vegetable-Tanned Leather Perform in Leather Crafting?

Vegetable-tanned leather is known for its natural tanning process using plant extracts, making it eco-friendly and biodegradable. This type of leather exhibits excellent durability and a unique ability to develop a rich patina over time, enhancing its aesthetic appeal. However, it can be more susceptible to water damage and may require additional treatments for moisture resistance.

Pros: High durability, excellent for tooling and dyeing, environmentally friendly.

Cons: Higher cost, longer manufacturing time, may require special care.

Impact on Application: Ideal for high-quality goods like belts and wallets, where aesthetics and longevity are paramount.

International Considerations: Buyers should ensure compliance with local environmental regulations regarding tanning processes and consider the demand for sustainable products in their markets.

Illustrative image related to leather crafting supplies

What Benefits Does Chrome-Tanned Leather Offer?

Chrome-tanned leather is treated with chromium salts, resulting in a softer and more pliable material. It is resistant to water and staining, making it suitable for a variety of applications, including bags and upholstery. However, the tanning process raises environmental concerns, particularly regarding the disposal of chromium waste.

Pros: Soft texture, excellent water resistance, quicker production time.

Cons: Environmental concerns, potential for chemical sensitivity, less suitable for tooling.

Impact on Application: Widely used in mass production of leather goods due to its cost-effectiveness and versatility.

International Considerations: Buyers must be aware of regulations related to chromium use and disposal in their respective countries, especially in Europe where stringent standards exist.

How Does Synthetic Leather Compare to Natural Options?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), mimics the look and feel of real leather while being more affordable. It is lightweight, easy to clean, and resistant to moisture, making it a popular choice for various applications. However, synthetic materials may lack the durability and aesthetic appeal of natural leather.

Pros: Cost-effective, easy maintenance, available in various colors and textures.

Cons: Less durable, may not age well, environmental concerns regarding production.

Impact on Application: Suitable for fashion items, upholstery, and accessories where cost and ease of care are prioritized.

International Considerations: Buyers should consider local preferences for eco-friendly materials and compliance with regulations regarding synthetic materials.

Illustrative image related to leather crafting supplies

What Role Does Suede Play in Leather Crafting?

Suede, derived from the inner layer of animal hides, is characterized by its soft texture and luxurious feel. It is commonly used in fashion accessories, shoes, and upholstery. While suede offers a unique aesthetic, it can be less durable than other leathers and may require special cleaning and care.

Pros: Soft texture, luxurious appearance, versatile for various applications.

Cons: Less durable, susceptible to staining, requires special care.

Impact on Application: Ideal for high-end fashion items and decorative applications where appearance is key.

International Considerations: Buyers should assess market demand for suede products and consider care instructions to ensure customer satisfaction.

Summary Table of Leather Crafting Materials

| Material | Typical Use Case for leather crafting supplies | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | High-quality belts, wallets | Eco-friendly, develops a rich patina | Higher cost, requires special care | Elevado |

| Chrome-Tanned Leather | Mass-produced bags, upholstery | Soft, excellent water resistance | Environmental concerns | Medium |

| Couro sintético | Fashion items, upholstery | Cost-effective, easy to clean | Less durable, environmental concerns | Low |

| Camurça | Fashion accessories, shoes | Luxurious appearance, soft texture | Less durable, requires special care | Medium |

This strategic material selection guide provides valuable insights for B2B buyers in Africa, South America, the Middle East, and Europe, assisting them in making informed decisions based on material properties, applications, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for leather crafting supplies

What Are the Key Stages in the Manufacturing Process of Leather Crafting Supplies?

The manufacturing process for leather crafting supplies involves several essential stages, each critical for ensuring the quality and durability of the final product. Understanding these stages can help B2B buyers make informed decisions when sourcing materials from suppliers.

Material Preparation: How Are Raw Materials Processed?

The first stage in manufacturing leather crafting supplies is material preparation. This involves selecting high-quality raw leather, which may be sourced from various animals such as cows, goats, or exotic species. The leather is then subjected to tanning, a chemical or natural process that transforms raw hides into durable, flexible materials. This stage often includes:

- Sorting and Grading: Raw hides are sorted based on quality, thickness, and intended use. Higher grades may be reserved for premium products.

- Cleaning and Conditioning: Hides are cleaned to remove hair and impurities and then conditioned with oils or waxes to enhance flexibility and prevent cracking.

- Dyeing: The leather may undergo dyeing processes to achieve specific colors or finishes, often using environmentally friendly dyes to meet international standards.

Forming: What Techniques Are Used to Shape Leather?

Once the leather is prepared, the next step is forming, where the material is shaped into various components of leather goods. Techniques used during this stage include:

- Cutting: Precision cutting tools or dies are employed to ensure accurate shapes, which is vital for the assembly of items like bags, belts, or wallets.

- Punching and Stamping: Specialized tools create holes for stitching or decorative patterns, enhancing both functionality and aesthetic appeal.

- Molding: For items requiring specific shapes, leather can be molded using heat and pressure, allowing for intricate designs.

Assembly: How Are Leather Products Constructed?

After forming, the assembly process begins. This stage involves stitching together the cut leather pieces using various techniques, such as:

- Hand Stitching: For high-end products, hand stitching is preferred for its craftsmanship and durability. Techniques like saddle stitching provide strength and longevity.

- Machine Stitching: This is often used for mass production, utilizing industrial sewing machines for speed and consistency.

- Joining Components: Other materials, such as zippers or hardware, are integrated into the product, requiring careful handling to maintain quality.

Finishing: What Steps Ensure a Polished Final Product?

Finishing is the final stage in the manufacturing process, where the leather products receive their last treatments. This may involve:

Illustrative image related to leather crafting supplies

- Edge Finishing: Edges are trimmed, dyed, and sealed to prevent fraying and improve aesthetics.

- Applying Protective Coatings: Leather goods may be treated with water-resistant or anti-stain finishes, enhancing durability and consumer appeal.

- Quality Control Checks: Before packaging, each item undergoes inspections to ensure it meets quality standards.

How Is Quality Assurance Implemented in Leather Crafting?

Quality assurance is paramount in the leather supply chain, especially for B2B buyers looking to ensure product integrity. Various international and industry-specific standards guide these practices.

What International Standards Govern Leather Crafting Quality?

B2B buyers should be aware of key international standards that apply to leather crafting supplies:

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers have processes in place to consistently meet customer and regulatory requirements.

- CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: These may apply when leather is used in specific applications, such as automotive or industrial sectors.

What Are the Critical Quality Control Checkpoints?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to monitor and verify product quality:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival for defects or inconsistencies.

- In-Process Quality Control (IPQC): Ongoing checks during production ensure adherence to specifications and prevent defects from progressing to later stages.

- Final Quality Control (FQC): Finished products undergo thorough inspections for functionality, appearance, and compliance with standards before shipping.

What Common Testing Methods Are Used in Leather Quality Assurance?

To ensure product quality, several testing methods are commonly employed:

- Physical Tests: These include tensile strength tests, abrasion resistance tests, and flexibility tests to assess durability and performance.

- Chemical Tests: Testing for harmful substances, such as heavy metals and azo dyes, is crucial to comply with safety regulations.

- Environmental Tests: Assessing how leather products perform under various environmental conditions (humidity, temperature) can help predict longevity.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international buyers, verifying the quality control processes of suppliers is essential to ensure they meet specific standards and deliver reliable products. Here are actionable steps to consider:

What Are Effective Verification Methods for Supplier Quality?

- Supplier Audits: Conducting on-site audits allows buyers to assess manufacturing practices, equipment, and adherence to quality standards firsthand.

- Requesting Quality Reports: Suppliers should provide documentation detailing their quality control processes, including testing results and compliance with international standards.

- Engaging Third-Party Inspectors: Utilizing independent inspectors to evaluate production facilities and conduct product checks can offer an unbiased assessment of quality.

What Nuances Should International Buyers Consider?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances that may affect their purchasing decisions:

Illustrative image related to leather crafting supplies

- Cultural Differences: Understanding local manufacturing practices and quality expectations can influence supplier relationships and negotiations.

- Regulatory Compliance: Different regions may have varying compliance requirements, making it essential for buyers to familiarize themselves with local laws and standards.

- Logistics and Supply Chain Management: International shipping can introduce risks; thus, verifying a supplier’s logistics capabilities is crucial for ensuring timely delivery and product integrity.

By comprehensively understanding the manufacturing processes and quality assurance practices involved in leather crafting supplies, B2B buyers can make informed choices that align with their business objectives and customer expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather crafting supplies’

Introdução

Sourcing leather crafting supplies for your business requires a strategic approach to ensure quality, reliability, and cost-effectiveness. This practical guide outlines essential steps to help international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, navigate the procurement process effectively.

Step 1: Identify Your Specific Needs

Before diving into the market, clearly define what leather crafting supplies your business requires. This includes types of leather (e.g., vegetable-tanned, chrome-tanned), tools (e.g., cutting dies, stitching supplies), and any specialized equipment. Understanding your specific needs helps streamline the sourcing process and ensures you focus on suppliers who can meet these requirements.

- Consider the end products: Are you crafting bags, wallets, or upholstery? Each product may require different materials and tools.

- Assess quality standards: Determine if you need premium materials for high-end products or more economical options for mass production.

Step 2: Research Potential Suppliers

Conduct comprehensive research to identify potential suppliers who specialize in leather crafting supplies. Utilize online directories, trade shows, and industry forums to compile a list of vendors.

- Check supplier ratings: Look for reviews and testimonials from other B2B buyers to gauge reliability.

- Evaluate their product range: Ensure they offer a diverse selection that aligns with your needs.

Step 3: Verify Supplier Certifications

Before finalizing a supplier, it’s essential to verify their certifications and compliance with industry standards. This step is crucial to ensure the materials are ethically sourced and meet quality benchmarks.

Illustrative image related to leather crafting supplies

- Request documentation: Ask for certifications related to environmental practices, quality control, and labor standards.

- Inquire about sourcing practices: Understanding where and how they source their materials can impact both quality and your brand reputation.

Step 4: Request Samples

Always request samples of the materials and tools before placing a bulk order. This step allows you to assess the quality firsthand and ensure they meet your specifications.

- Check for consistency: Evaluate the texture, color, and durability of the leather.

- Test tools for functionality: Ensure that tools perform as expected and are comfortable to use.

Step 5: Discuss Pricing and Terms

Engage in discussions about pricing, payment terms, and minimum order quantities. Understanding these financial aspects early can prevent future misunderstandings and help you budget effectively.

- Negotiate discounts: Many suppliers offer volume pricing or discounts for long-term contracts.

- Clarify payment methods: Ensure the payment terms are favorable and secure for both parties.

Step 6: Establish Communication Channels

Effective communication is key to a successful supplier relationship. Establish clear lines of communication to address any questions or issues that may arise during the procurement process.

Illustrative image related to leather crafting supplies

- Set expectations: Discuss preferred methods of communication and response times.

- Use technology: Consider utilizing platforms that allow for real-time updates on orders and inventory levels.

Step 7: Monitor Supplier Performance

Once you begin working with a supplier, continuously monitor their performance regarding quality, delivery times, and customer service. This step is vital for maintaining a reliable supply chain.

- Gather feedback: Regularly solicit feedback from your production team regarding the materials and tools.

- Assess reliability: Track delivery times and product quality to ensure they meet your business standards.

By following these steps, B2B buyers can effectively source leather crafting supplies that meet their business needs and maintain a competitive edge in the market.

Comprehensive Cost and Pricing Analysis for leather crafting supplies Sourcing

What Are the Key Cost Components in Leather Crafting Supplies Sourcing?

When sourcing leather crafting supplies, understanding the cost structure is crucial for effective budgeting and pricing strategies. The primary cost components include:

Illustrative image related to leather crafting supplies

-

Materials: The quality and type of leather (e.g., full-grain, top-grain, or bonded leather) significantly affect cost. Specialty leathers, such as exotic or embossed options, typically command higher prices. Additionally, the sourcing location impacts material costs due to varying tariffs and shipping expenses.

-

Labor: Skilled labor is essential in leather crafting, particularly for intricate designs or custom pieces. Labor costs can vary widely based on geographic location, with regions known for craftsmanship (like Italy or Brazil) potentially charging a premium.

-

Manufacturing Overhead: This includes the costs of utilities, rent, and equipment maintenance. Efficient production processes can minimize overhead costs, but initial investments in machinery and technology are often significant.

-

Tooling: The investment in tools—ranging from hand tools to industrial sewing machines—can be substantial. Buyers should consider the durability and efficiency of tools when assessing long-term costs.

-

Quality Control (QC): Implementing quality control measures to ensure product consistency adds to overall costs. However, this investment is critical for maintaining brand reputation and customer satisfaction.

-

Logistics: Shipping and handling costs, especially for international transactions, can significantly impact the final price. Factors such as shipping method, insurance, and customs duties must be considered.

-

Margin: Suppliers typically build a profit margin into their pricing. Understanding the market and competitive landscape helps buyers gauge reasonable margins.

How Do Price Influencers Affect Leather Crafting Supply Costs?

Several factors influence the pricing of leather crafting supplies:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchasing can lead to discounts, making it cost-effective for businesses with high demand. However, smaller buyers may face higher per-unit costs.

-

Specifications and Customization: Customized orders often incur additional costs due to the unique tooling and labor required. Buyers should weigh the benefits of customization against these costs.

-

Material Quality and Certifications: Premium materials and certified products (e.g., eco-friendly or ethically sourced leather) can lead to higher prices. Buyers should consider the long-term value these qualities add.

-

Supplier Factors: The supplier’s reputation, reliability, and geographic location can affect pricing. Established suppliers may charge more but offer better quality assurance and service.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is vital for budgeting. Incoterms dictate who pays for shipping and insurance, which can impact overall costs.

What Buyer Tips Can Enhance Cost-Efficiency in Leather Crafting Supplies?

To optimize sourcing costs, international B2B buyers should consider the following strategies:

-

Negotiation: Engage suppliers in discussions regarding pricing, especially for larger orders. Demonstrating a willingness to build a long-term relationship can lead to better terms.

-

Total Cost of Ownership (TCO): Evaluate the complete cost of sourcing, including shipping, duty fees, and potential returns. A lower purchase price may not always equate to savings when considering TCO.

-

Pricing Nuances for International Buyers: Be aware of exchange rates and economic conditions in the supplier’s country. Fluctuations can impact pricing and should be factored into purchasing decisions.

-

Research and Comparison: Leverage multiple suppliers to compare pricing and terms. This competitive approach can uncover better deals and alternatives.

Disclaimer on Indicative Prices

Prices for leather crafting supplies can vary significantly based on the above factors. The information provided here is for guidance purposes only, and actual costs may differ based on specific supplier conditions and market fluctuations. Always conduct due diligence before finalizing purchases.

Alternatives Analysis: Comparing leather crafting supplies With Other Solutions

Introduction to Alternative Solutions in Leather Crafting

In the leather crafting industry, sourcing the right supplies is crucial for ensuring quality and efficiency in production. While traditional leather crafting supplies are widely utilized, exploring alternative solutions can provide businesses with unique advantages. This analysis will compare leather crafting supplies with two viable alternatives: synthetic leather materials and 3D printing technology for leather goods.

Comparison Table

| Comparison Aspect | Leather Crafting Supplies | Synthetic Leather Materials | 3D Printing Technology for Leather Goods |

|---|---|---|---|

| Performance | High durability, aesthetic appeal | Varies; can mimic leather look | Customizable designs, consistent quality |

| Cost | Generally higher upfront costs | Typically lower initial costs | Varies based on technology and materials |

| Ease of Implementation | Requires skilled labor, traditional methods | Easier to work with, less skill needed | Requires technical expertise, software knowledge |

| Maintenance | Regular care needed for longevity | Generally low maintenance | Minimal maintenance, but technology dependent |

| Best Use Case | High-end products, bespoke items | Mass production, budget-friendly items | Prototyping, complex designs, innovative applications |

Detailed Breakdown of Alternatives

Synthetic Leather Materials

Synthetic leather, or faux leather, is a man-made alternative that has gained popularity due to its cost-effectiveness and ease of use. It is often less expensive than genuine leather, making it an attractive option for businesses looking to reduce production costs. Additionally, synthetic materials can be produced in various colors and textures, allowing for a broad range of design possibilities. However, the durability and aesthetic appeal may not match that of high-quality leather, and synthetic options can sometimes lead to perceptions of lower quality among consumers.

3D Printing Technology for Leather Goods

3D printing represents a revolutionary approach to leather crafting, allowing for the creation of customized products with precise specifications. This technology enables manufacturers to produce intricate designs that would be challenging to achieve with traditional methods. The initial investment in 3D printing technology can be high, requiring specialized equipment and skilled personnel. However, once established, this method can significantly reduce material waste and enable rapid prototyping. The downside includes potential limitations in material choices and the learning curve associated with adopting new technologies.

Conclusion: Choosing the Right Solution for Your Business

When selecting the right solution for leather crafting, B2B buyers must consider their specific needs, budget constraints, and production goals. Leather crafting supplies offer unmatched quality and traditional craftsmanship, making them ideal for bespoke and high-end products. Conversely, synthetic leather materials provide a cost-effective alternative for mass production, while 3D printing technology opens doors to innovation and customization. By assessing these alternatives against their operational requirements, businesses can make informed decisions that align with their strategic objectives and market demands.

Essential Technical Properties and Trade Terminology for leather crafting supplies

What Are the Key Technical Properties of Leather Crafting Supplies?

Understanding the technical specifications of leather crafting supplies is crucial for B2B buyers to ensure quality and suitability for their projects. Here are some essential properties to consider:

1. Material Grade

Material grade indicates the quality and type of leather used in products. Common grades include full-grain, top-grain, and corrected grain. Full-grain leather, sourced from the top layer of the hide, retains its natural texture and is known for durability and aging beautifully. Top-grain leather is sanded and treated for a smoother finish, making it more uniform but slightly less durable. Understanding material grades helps buyers select the right leather for specific applications, from luxury goods to rugged outdoor gear.

2. Thickness (Oz)

Thickness is measured in ounces (oz), with one ounce equating to approximately 1/64 of an inch. Leather thickness impacts its strength and usability; heavier leather (e.g., 8-10 oz) is ideal for belts and bags, while lighter leather (e.g., 2-3 oz) is suitable for linings and delicate items. B2B buyers must match the thickness to the intended use to ensure product performance and longevity.

3. Tolerance

Tolerance refers to the permissible limits of variation in the dimensions of leather pieces. For instance, a tolerance of ±1mm ensures that leather cut for straps remains consistent in size. Tighter tolerances are essential for products that require precision fitting, such as wallets and bags with multiple compartments. Understanding tolerance helps prevent costly production errors and ensures the final product meets design specifications.

4. Finish Type

Leather finishes can vary significantly and affect the product’s aesthetics and functionality. Common finishes include aniline, semi-aniline, and pigment finishes. Aniline leather is dyed without a topcoat, showcasing the hide’s natural beauty but is less resistant to stains. Pigment finishes provide a protective layer, making them more durable and easier to clean. Buyers should consider the intended use and maintenance requirements when selecting the finish type.

Illustrative image related to leather crafting supplies

5. Durability Rating

This rating assesses how well the leather withstands wear and tear, typically measured through tests like abrasion resistance. For products expected to endure heavy use, such as work gear or travel bags, a higher durability rating is essential. This property helps B2B buyers gauge the lifespan of leather products, ensuring they meet customer expectations and reduce return rates.

What Are Common Trade Terms in the Leather Crafting Industry?

Familiarity with industry terminology is vital for effective communication and negotiation in B2B transactions. Here are several key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that may be marketed by another manufacturer. In leather crafting, OEMs often provide custom leather goods based on a buyer’s specifications. Understanding OEM relationships can help buyers secure high-quality products tailored to their brand.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers, as it affects inventory management and cash flow. Knowing the MOQ allows businesses to plan purchases according to their production schedules and financial constraints.

3. RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit price quotes from suppliers. It typically includes specifications, quantities, and delivery requirements. Utilizing RFQs can streamline the procurement process, ensuring that buyers receive competitive pricing and terms.

Illustrative image related to leather crafting supplies

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, defining the responsibilities of buyers and sellers in international transactions. Key terms include FOB (Free On Board) and CIF (Cost, Insurance, and Freight). Understanding Incoterms is vital for managing shipping costs and responsibilities, particularly for international buyers.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving it. This term is critical for supply chain management, as it impacts production schedules and inventory levels. Buyers should clarify lead times with suppliers to ensure timely delivery and avoid production delays.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing leather crafting supplies, ultimately enhancing their product offerings and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the leather crafting supplies Sector

What Are the Current Market Dynamics and Key Trends in the Leather Crafting Supplies Sector?

The leather crafting supplies market is currently experiencing significant growth, driven by a surge in consumer interest for handmade and artisanal products. This trend is particularly pronounced in regions such as Africa, South America, the Middle East, and Europe, where local artisans are increasingly seeking high-quality leather materials and tools to create unique products. The rise of e-commerce platforms has also facilitated easier access to a wider range of supplies, enabling international buyers to source materials from global suppliers.

Emerging B2B tech trends, such as digital marketplaces and supply chain management software, are transforming the way businesses operate within this sector. Buyers can leverage these technologies to streamline sourcing processes, manage inventory, and enhance communication with suppliers. For instance, platforms like Weaver Leather Supply and Tandy Leather are not only selling products but also providing educational resources and community engagement, which are vital for fostering customer loyalty and repeat business.

Moreover, there is a growing demand for customization in leather goods. As consumers increasingly seek personalized items, businesses are adapting their offerings to include customizable leather products, requiring suppliers to be agile and responsive to changing buyer preferences. This dynamic environment necessitates that B2B buyers stay informed about market trends and technological advancements to remain competitive.

How Does Sustainability and Ethical Sourcing Impact the Leather Crafting Supplies Industry?

Sustainability and ethical sourcing have become paramount in the leather crafting supplies sector, influenced by increasing consumer awareness of environmental issues. The leather industry is traditionally associated with significant environmental impacts, including water pollution and resource depletion. As a result, suppliers are increasingly adopting sustainable practices, such as utilizing vegetable-tanned leather and sourcing hides from ethical suppliers.

For B2B buyers, the importance of ethical supply chains cannot be overstated. Consumers are increasingly demanding transparency in the sourcing of materials, pushing businesses to provide verifiable certifications for their products. Certifications such as the Leather Working Group (LWG) certification and the Global Organic Textile Standard (GOTS) are becoming critical in building trust with end consumers.

Furthermore, suppliers that prioritize sustainability often experience a competitive advantage in the marketplace. By offering eco-friendly materials and transparent sourcing practices, businesses can appeal to a broader audience, particularly in markets that value environmental responsibility. Buyers should actively seek suppliers who demonstrate a commitment to sustainability, as this not only aligns with ethical consumerism but also enhances brand reputation.

Illustrative image related to leather crafting supplies

What Is the Historical Context of the Leather Crafting Supplies Industry?

The leather crafting supplies industry has a rich history that dates back thousands of years, evolving from primitive techniques used by early humans to create tools and clothing. Over the centuries, leather has transitioned from a necessity for survival to a sought-after material for luxury goods. The Industrial Revolution marked a significant turning point, as mechanization enabled mass production of leather goods, making them more accessible to the general public.

In recent decades, there has been a resurgence in artisanal leather crafting, fueled by a growing appreciation for handmade products and a desire for sustainable practices. This evolution has led to the establishment of niche markets within the leather crafting supplies sector, where buyers are increasingly focused on quality, craftsmanship, and ethical sourcing. As this trend continues, it is vital for B2B buyers to understand the historical context and market evolution to better navigate current dynamics and consumer preferences.

Frequently Asked Questions (FAQs) for B2B Buyers of leather crafting supplies

-

How do I ensure the quality of leather crafting supplies from international suppliers?

To ensure quality, start by requesting samples from potential suppliers. Inspect the samples for texture, durability, and finish. It’s also beneficial to review certifications, such as ISO or other quality management standards, to gauge a supplier’s credibility. Additionally, consider visiting the supplier’s facility if possible or use third-party inspection services to evaluate production practices and material sourcing. Establishing a clear quality assurance (QA) protocol with your supplier can further mitigate risks. -

What is the best type of leather for crafting high-end products?

Full-grain leather is considered the best for high-end products due to its durability and natural appearance. It retains the hide’s original texture and markings, offering a unique aesthetic for each piece. Other good options include top-grain leather, which is slightly more processed but still maintains quality, and vegetable-tanned leather, known for its eco-friendliness and aging characteristics. Ultimately, the choice will depend on the specific product and desired finish. -

How can I customize leather products to meet my clients’ needs?

Customization options for leather products include choosing the type of leather, color, size, and finishes. Many suppliers offer bespoke services where you can specify dimensions, tooling patterns, and even hardware. It’s essential to communicate your design requirements clearly and confirm the supplier’s ability to meet these specifications. Establishing a collaborative relationship can lead to innovative solutions tailored to your clients’ preferences. -

What is the minimum order quantity (MOQ) for leather crafting supplies?

MOQs for leather crafting supplies can vary significantly by supplier and product type. Typically, MOQs range from 50 to 500 units, especially for customized items. When sourcing, inquire about MOQs upfront and discuss options for smaller orders if necessary. Some suppliers may offer flexibility or tiered pricing based on order size, allowing you to test products before committing to larger quantities. -

What payment terms should I expect when sourcing leather supplies internationally?

Payment terms can differ widely based on the supplier’s policies and your relationship with them. Common terms include upfront payments, partial payments upon order confirmation, and balance payments before shipment. It’s advisable to negotiate terms that provide a balance of security for both parties. Using secure payment methods, such as letters of credit or escrow services, can also protect your investment during international transactions. -

How do I vet suppliers for leather crafting supplies?

To vet suppliers, start by researching their reputation through online reviews and industry references. Request their business licenses, certifications, and details about their production capabilities. Engaging in direct communication can provide insight into their customer service and responsiveness. Additionally, consider visiting their facilities or using third-party audit services to assess their operations and quality control processes. -

What logistics considerations should I keep in mind when importing leather supplies?

Logistics considerations include understanding shipping methods, customs regulations, and potential tariffs in your country. Opt for reliable freight forwarders who specialize in international shipping to handle documentation and customs clearance efficiently. Be aware of lead times for production and shipping, and factor in potential delays, especially during peak seasons. Additionally, consider the storage requirements for leather products upon arrival to ensure quality is maintained. -

How can I stay updated on trends in the leather crafting industry?

To stay informed about industry trends, subscribe to relevant trade publications, join leathercraft forums, and participate in industry trade shows. Networking with other professionals in the field can provide insights into emerging techniques, materials, and consumer preferences. Online resources, including webinars and industry reports, can also help you keep pace with innovations and shifts in market demand, allowing you to adapt your sourcing strategies accordingly.

Top 8 Leather Crafting Supplies Manufacturers & Suppliers List

1. Weaver Leather Supply – Leathercrafting Supplies

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Weaver Leather Supply offers a wide range of leathercrafting and leatherworking supplies including various types of leather (ChahinLeather®, Hermann Oak® Veg Tan, Chrome Tanned, Water Buffalo Leather), leather cuts (double shoulders, single shoulders, panels, whole hides), textures (top grain, pebbled, smooth), tools (cutting tools, hand stitching tools, leather tooling tools), hardware (buckles, …

2. Buckleguy – Leather Working Tools

Domain: buckleguy.com

Registered: 2002 (23 years)

Introduction: Buckleguy offers a variety of leather working tools and supplies, including:

1. **Awl Needles** – Multiple shapes, priced between $10.62 – $14.13.

2. **Leather Bone Folder/Edge Slicker** – Multi-function tool priced at $28.94.

3. **Bone Folder** – Made of Cocobolo, priced at $17.67.

4. **Stitching Punch Replacement** – 1 piece, priced at $3.53.

5. **Straight Leather Slot Punch** – Available in si…

3. Tandy Leather – Quality Leather Goods

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Quality Leather Goods, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

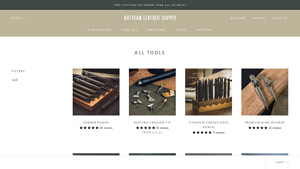

4. Artisan Leather Supply – Corner Punch

Domain: artisanleathersupply.com

Registered: 2020 (5 years)

Introduction: {“products”:[{“name”:”Corner Punch”,”reviews”:28,”price”:”From $14″},{“name”:”Electric Creaser Tip”,”reviews”:10,”price”:”From $17″},{“name”:”Titanium-Coated Hole Punch”,”reviews”:11,”price”:”From $5.50″},{“name”:”Premium Wing Divider”,”reviews”:32,”price”:”From $32″},{“name”:”Locking Pins (pack of 5)”,”reviews”:13,”price”:”From $5″},{“name”:”ARTISAN Pen Knife”,”reviews”:22,”price”:”From $11″},{“n…

5. Makers Leather Supply – Hermann Oak Tooling Side

Domain: makersleathersupply.com

Registered: 2012 (13 years)

Introduction: {“products”:[{“name”:”Hermann Oak – Branded Natural Tooling & Carving Side”,”price”:”$225.00″,”reviews”:”11 reviews”},{“name”:”Maker’s Breezy Clutch Purse/Wallet Acrylic Template Set”,”price”:”$34.95″,”reviews”:”4 reviews”},{“name”:”Maker’s Contact Cement”,”price”:”$32.95″,”reviews”:”25 reviews”},{“name”:”Maker’s Indelible Leather Marker – Precision Dye & Edge Finishing Pen”,”price”:”$6.95″,”revie…

6. Leathercraft Tools – Premium Dyed Leather

Domain: leathercrafttools.com

Registered: 2000 (25 years)

Introduction: Key products include: 1. LC Premium Dyed Leather – Exclusive dyed leather. 2. Okayama Denim – From the sacred place of denim. 3. Edge Top Wax – For a smooth and glossy finish. 4. LC Super PRO Edge Tool – Fine sharpness and sustainability. 5. YKK Zipper EXCELLA – Fully polished elements. 6. TOKO PRO Burnishing Gum – Keeps leather smooth. 7. LC SP Edge Kote – For a professional look edge. 8. Round F…

7. Identity Leathercraft – Premium Leather & Craft Tools

Domain: identityleathercraft.com

Registered: 2016 (9 years)

Introduction: Leather, Craft Tools, Products and Materials including: Vegetable Tanned Leather, Pre-cut Strips & Belt Blanks, Heritage UK Leathers, Modern & Speciality Leathers, Falconry Leather, Hair-on & Wool-on Sheepskin (Nappa), Soft Suede, Metallic Leathers, Pearlised Leathers, Small & Craft Cuts, Remnant Pieces & Bags, Leather Starter Offering, Embossing & Carving tools, Individual Stamps, 3D Stamps, Mini…

8. OA Leather Supply – Leather and Tools

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. OA Leather Supply (Canada) – Offers a variety of leathers and tools, ships worldwide, includes videos for leather types.

2. Buckleguy.com – Good resource for hardware and tools, shipping details outside the USA unknown.

3. CS Osborn – High-quality tools at a premium price.

4. Tandy.com – Mid-grade tools and leather available.

5. Bruce Johnson Leather – Refurbished draw knives, skiving knives, a…

Strategic Sourcing Conclusion and Outlook for leather crafting supplies

In the evolving landscape of leather crafting supplies, strategic sourcing remains critical for B2B buyers aiming to enhance their product offerings and operational efficiency. By leveraging a diversified supplier network, businesses can access high-quality materials and innovative tools that meet the growing demand for custom leather goods across various markets, including Africa, South America, the Middle East, and Europe.

Key takeaways emphasize the importance of understanding regional trends, such as the rising interest in sustainable materials and artisanal craftsmanship. Buyers should also prioritize suppliers who offer comprehensive support, including educational resources and timely delivery, to ensure seamless project execution.

Looking ahead, the global leather crafting market is poised for growth, driven by consumer preferences for unique, handcrafted products. Now is the time for international B2B buyers to capitalize on this momentum by forging strong partnerships with reliable suppliers. Investing in strategic sourcing today will not only enhance your competitive edge but also position your business to thrive in an increasingly dynamic market. Embrace the future of leather crafting—connect with suppliers who share your vision for quality and innovation.

Illustrative image related to leather crafting supplies

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.