Introduction: Navigating the Global Market for how do you make fruit leather

Navigating the intricate landscape of sourcing high-quality fruit leather can present unique challenges for international B2B buyers. Understanding how to make fruit leather that meets diverse consumer demands is essential for suppliers aiming to stand out in competitive markets across Africa, South America, the Middle East, and Europe, including countries like Nigeria and Saudi Arabia. This guide delves into the various types of fruit leather, their applications in health-conscious markets, and critical considerations for supplier vetting.

In addition, it outlines cost factors associated with production, including ingredient sourcing, manufacturing processes, and packaging options, ensuring that buyers can make informed purchasing decisions. By equipping B2B buyers with comprehensive insights, this guide empowers them to navigate the complexities of the global market, enabling them to select suppliers who align with their quality standards and consumer preferences. From exploring the nutritional benefits of fruit leather to understanding market trends and consumer tastes, every aspect is designed to enhance your sourcing strategy. Whether you are a distributor, retailer, or manufacturer, this guide serves as a valuable resource to capitalize on the growing demand for healthy, natural snacks, facilitating successful partnerships and business growth in the fruit leather sector.

Table Of Contents

- Top 7 How Do You Make Fruit Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how do you make fruit leather

- Understanding how do you make fruit leather Types and Variations

- Key Industrial Applications of how do you make fruit leather

- 3 Common User Pain Points for ‘how do you make fruit leather’ & Their Solutions

- Strategic Material Selection Guide for how do you make fruit leather

- In-depth Look: Manufacturing Processes and Quality Assurance for how do you make fruit leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how do you make fruit leather’

- Comprehensive Cost and Pricing Analysis for how do you make fruit leather Sourcing

- Alternatives Analysis: Comparing how do you make fruit leather With Other Solutions

- Essential Technical Properties and Trade Terminology for how do you make fruit leather

- Navigating Market Dynamics and Sourcing Trends in the how do you make fruit leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how do you make fruit leather

- Strategic Sourcing Conclusion and Outlook for how do you make fruit leather

- Important Disclaimer & Terms of Use

Understanding how do you make fruit leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Traditional Fruit Leather | Made from pureed fresh fruit, often baked or dehydrated. | Snack food manufacturing, retail. | Pros: Natural ingredients, customizable flavors. Cons: Longer production time. |

| Mixed Fruit Leather | Combines multiple fruits for unique flavors. | Specialty food products, gourmet markets. | Pros: Diverse flavor profiles, appealing to niche markets. Cons: Requires careful balancing of flavors. |

| Fruit Leather with Additives | Includes added spices, sweeteners, or colorings. | Health food sectors, functional snacks. | Pros: Enhanced taste, potential for health claims. Cons: May deter consumers seeking natural products. |

| Low-Sugar Fruit Leather | Uses low-carb fruits or sugar substitutes. | Health-conscious markets, fitness sectors. | Pros: Appeals to health-focused consumers, lower calorie content. Cons: Limited fruit options can affect flavor. |

| Vegan Fruit Leather | Made without animal products, often gluten-free. | Vegan and organic food markets. | Pros: Expanding consumer base, aligns with dietary trends. Cons: May have a shorter shelf life. |

What are the Characteristics of Traditional Fruit Leather?

Traditional fruit leather is crafted from pureed fresh fruits, such as strawberries, mangoes, or apples, which are then dehydrated or baked at low temperatures. This method preserves the natural flavors and nutrients of the fruit, making it an attractive option for snack food manufacturers looking to offer healthy alternatives to processed snacks. Buyers should consider the production time and equipment needed, as well as sourcing high-quality fruits to ensure a superior product.

How Does Mixed Fruit Leather Differ from Traditional Options?

Mixed fruit leather combines various fruits to create unique flavor combinations, catering to gourmet markets and specialty food product lines. This variation allows manufacturers to target niche consumer segments looking for innovative snack options. However, balancing flavors can be challenging, and buyers must ensure consistent sourcing of fruits to maintain product quality. This type can enhance brand differentiation in competitive markets.

What are the Advantages of Adding Ingredients to Fruit Leather?

Fruit leather with additives includes spices, sweeteners, or natural colorings, appealing to the health food sector and functional snack markets. These enhancements can elevate taste and provide potential health benefits, which can be marketed to consumers. However, buyers should be cautious, as such additives may deter consumers who prefer natural products. Understanding market trends and consumer preferences is crucial for successful product development in this category.

Why is Low-Sugar Fruit Leather Important for Health-Conscious Consumers?

Low-sugar fruit leather uses low-carb fruits or sugar substitutes, making it a popular choice among health-conscious consumers and fitness markets. This type of fruit leather can cater to dietary restrictions and preferences, positioning businesses favorably in a growing market. However, the limited selection of fruits can affect flavor, requiring buyers to consider the balance between health benefits and taste satisfaction.

How Does Vegan Fruit Leather Fit into Current Market Trends?

Vegan fruit leather is crafted without any animal products and is often gluten-free, aligning with the increasing demand for plant-based and organic food options. This type of fruit leather appeals to a broad consumer base, including those following vegan diets or seeking healthier snack alternatives. However, buyers should be aware of the potentially shorter shelf life due to the absence of preservatives, necessitating effective distribution and inventory management strategies.

Key Industrial Applications of how do you make fruit leather

| Industry/Sector | Specific Application of how do you make fruit leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Manufacturing of healthy snacks and dried fruit products | Provides a natural alternative to sugary snacks, appealing to health-conscious consumers | Sourcing high-quality, fresh fruits; ensuring compliance with food safety standards |

| Retail & Distribution | Selling fruit leather as a consumer snack | Diversifies product offerings and meets growing demand for healthy snacks | Identifying reliable suppliers and ensuring consistent product quality |

| Hospitality | Utilizing fruit leather in gourmet dishes and desserts | Enhances menu offerings with unique, healthy ingredients | Sourcing innovative recipes and seasonal fruits for freshness |

| Nutraceuticals | Incorporating fruit leather in health supplements | Adds value to products by providing natural vitamins and nutrients | Ensuring traceability of ingredients and adherence to health regulations |

| Export & Import | Trading fruit leather in international markets | Capitalizes on global health trends and diversifies revenue streams | Understanding import/export regulations and market preferences in target regions |

How is Fruit Leather Used in Food Processing and What Problems Does It Solve?

In the food processing industry, fruit leather is manufactured as a healthy snack alternative, leveraging natural ingredients to cater to health-conscious consumers. This application solves the issue of high sugar content in traditional snacks, offering a product that is both nutritious and appealing. Buyers in this sector must prioritize sourcing high-quality, fresh fruits and ensure compliance with food safety standards to maintain product integrity and consumer trust.

What Role Does Fruit Leather Play in Retail and Distribution?

Fruit leather serves as a popular consumer snack in retail and distribution, allowing businesses to diversify their product offerings. As demand for healthier snack options grows, retailers can capitalize on this trend by providing fruit leather products that appeal to health-conscious buyers. Key considerations for B2B buyers include identifying reliable suppliers to ensure consistent product quality and availability, as well as effective marketing strategies to highlight the health benefits of fruit leather.

How Can Hospitality Businesses Benefit from Using Fruit Leather?

In the hospitality sector, fruit leather can be creatively incorporated into gourmet dishes and desserts, enhancing menu offerings with unique and healthy ingredients. This application not only attracts health-conscious diners but also provides chefs with innovative ways to utilize seasonal fruits. Buyers in this industry should focus on sourcing innovative recipes and fresh fruits to maintain a dynamic menu that reflects current culinary trends.

Why is Fruit Leather Valuable in Nutraceuticals?

The nutraceuticals industry can incorporate fruit leather into health supplements, adding value by providing natural vitamins and nutrients. This application addresses the growing consumer demand for health-focused products that are both functional and delicious. B2B buyers must ensure traceability of ingredients and adherence to health regulations to meet consumer expectations and maintain product credibility.

How Does the Export and Import of Fruit Leather Impact Global Markets?

The trade of fruit leather in international markets allows businesses to capitalize on global health trends while diversifying revenue streams. This application is particularly relevant for B2B buyers from regions such as Africa, South America, the Middle East, and Europe, where health-conscious products are gaining traction. Buyers must navigate import/export regulations and understand market preferences to successfully position fruit leather within these diverse markets.

3 Common User Pain Points for ‘how do you make fruit leather’ & Their Solutions

Scenario 1: Navigating Ingredient Sourcing Challenges for Fruit Leather Production

The Problem: A common challenge for B2B buyers in the fruit leather industry is sourcing high-quality, consistent ingredients. Many producers face difficulties in obtaining ripe, flavorful fruits that meet their quality standards, particularly in regions with varying agricultural conditions. Factors such as seasonal availability, price fluctuations, and the potential for spoilage during transport can significantly impact production schedules and product quality. This not only affects the taste and texture of the final product but can also lead to increased costs and customer dissatisfaction.

The Solution: To overcome these sourcing challenges, B2B buyers should establish relationships with reliable local farmers or fruit suppliers who can provide fresh, seasonal produce. Implementing a collaborative approach, such as a farm-to-factory model, can help ensure a consistent supply of high-quality fruits. Buyers should also consider diversifying their fruit sources to include frozen options during off-seasons, as frozen fruits maintain their nutritional value and flavor profile. Additionally, utilizing technology for inventory management can optimize purchasing decisions and minimize waste, ensuring that only the best ingredients are used for fruit leather production.

Scenario 2: Ensuring Consistency in Production Processes for Fruit Leather

The Problem: In the production of fruit leather, maintaining consistency in texture and flavor can be a significant hurdle for manufacturers. Variations in fruit ripeness, differences in preparation methods, and inconsistencies in drying times can lead to batches that do not meet the desired quality. This inconsistency can result in product recalls, wasted materials, and lost customer trust, ultimately affecting the bottom line.

The Solution: To ensure consistency, B2B buyers should standardize their production processes by developing detailed recipes and production guidelines that are strictly adhered to by all staff. Implementing quality control measures at each stage of production is crucial; this includes establishing clear specifications for fruit selection, preparation, and drying methods. Investing in training for staff on these standardized procedures can enhance product quality. Additionally, using data analytics to monitor production metrics can help identify patterns or anomalies, allowing for timely adjustments to maintain the desired quality across all batches.

Scenario 3: Navigating Regulatory Compliance in the Fruit Leather Market

The Problem: Regulatory compliance can be a complex issue for B2B buyers in the fruit leather industry, particularly when exporting products to different regions. Each country may have specific regulations concerning food safety, labeling, and ingredient transparency. Failing to comply with these regulations can lead to fines, product recalls, and damage to brand reputation, posing a significant risk for businesses.

The Solution: To effectively navigate regulatory compliance, B2B buyers should engage with legal experts or consultants who specialize in food regulations in the target export markets. It is essential to stay informed about the latest regulatory changes and ensure that all products meet local standards, including labeling requirements and ingredient disclosures. Creating a compliance checklist for each market can streamline this process. Additionally, buyers should consider obtaining certifications (such as organic or non-GMO) that may enhance product credibility and appeal in competitive markets. Regular audits of production practices against regulatory standards can also help maintain compliance and build consumer trust.

Strategic Material Selection Guide for how do you make fruit leather

When selecting materials for producing fruit leather, it is essential to consider various factors that influence the quality, safety, and efficiency of the production process. The following analysis examines four common materials used in the preparation of fruit leather, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What are the Key Properties of Silicone Mats in Fruit Leather Production?

Silicone mats are increasingly popular for baking and dehydrating fruit leather due to their non-stick properties and heat resistance. They can withstand temperatures up to 450°F (232°C) without degrading, making them suitable for extended drying processes. Silicone mats are also flexible, allowing easy removal of the finished product without sticking.

Pros and Cons:

– Pros: Durable, reusable, easy to clean, and non-toxic. They provide a consistent surface for drying, ensuring even moisture removal.

– Cons: Higher initial cost compared to parchment paper and may require specific cleaning protocols to maintain longevity.

Impact on Application:

Silicone mats are compatible with various fruits and do not react chemically with acidic ingredients, preserving the flavor and quality of the fruit leather.

Considerations for International Buyers:

Buyers should ensure that silicone mats comply with food safety standards such as FDA regulations and European food contact materials guidelines. They should also consider local preferences for reusable products, which are gaining traction in many markets.

How Do Parchment Papers Affect the Quality of Fruit Leather?

Parchment paper is a widely used material for lining baking sheets in fruit leather production. It is typically treated with silicone to provide a non-stick surface that can withstand moderate heat.

Pros and Cons:

– Pros: Cost-effective, disposable, and readily available in various sizes. It allows for easy cleanup and prevents sticking.

– Cons: Not reusable and can burn at high temperatures, potentially affecting the flavor and quality of the fruit leather.

Impact on Application:

Parchment paper is suitable for most fruit types, but its heat tolerance limits its use in high-temperature drying processes.

Considerations for International Buyers:

Buyers should confirm that parchment paper meets local food safety standards, such as those set by ASTM or DIN, particularly in regions where food safety regulations are stringent.

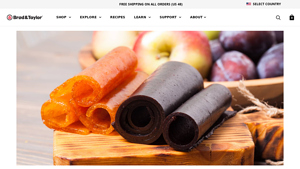

Illustrative image related to how do you make fruit leather

Why is Glass a Preferred Material for Storage of Fruit Leather?

Glass containers are often used for storing finished fruit leather due to their inert properties and ability to maintain product freshness.

Pros and Cons:

– Pros: Non-reactive, recyclable, and provides an airtight seal, preventing moisture and contamination.

– Cons: Heavier and more fragile than plastic alternatives, which can increase shipping costs and risk of breakage.

Impact on Application:

Glass is ideal for long-term storage, ensuring that the fruit leather retains its flavor and texture without leaching chemicals.

Illustrative image related to how do you make fruit leather

Considerations for International Buyers:

Buyers should consider local recycling capabilities and consumer preferences for sustainable packaging. Compliance with food safety standards is also crucial, especially in regions with strict regulations.

What Role Does Dehydrator Material Play in Fruit Leather Production?

Dehydrators, often made from plastic or stainless steel, are essential for producing fruit leather efficiently. The material used can impact the durability and effectiveness of the dehydrator.

Pros and Cons:

– Pros: Stainless steel models are durable and resistant to corrosion, while high-quality plastics can be lightweight and cost-effective.

– Cons: Cheaper plastic dehydrators may warp under high heat, affecting performance and safety.

Impact on Application:

The choice of dehydrator material can influence the drying time and quality of the fruit leather. Stainless steel options tend to provide better heat distribution, while plastic may be more accessible for small-scale operations.

Considerations for International Buyers:

Buyers should evaluate the availability of replacement parts and the manufacturer’s compliance with international safety standards. In regions with high humidity, durable materials that resist corrosion are particularly important.

Illustrative image related to how do you make fruit leather

Summary Table of Material Selection for Fruit Leather Production

| Material | Typical Use Case for how do you make fruit leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicone Mats | Baking and dehydrating fruit leather | Durable and reusable | Higher initial cost | Medium |

| Parchment Paper | Lining baking sheets for fruit leather | Cost-effective and disposable | Not reusable, can burn at high temps | Low |

| Glass | Storing finished fruit leather | Non-reactive and airtight | Heavy and fragile | Medium |

| Dehydrator Material | Drying fruit leather efficiently | Durable and effective heat distribution | Cheaper plastics may warp | Medium to High |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in fruit leather production, helping them make informed decisions that align with their operational needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for how do you make fruit leather

What Are the Key Stages in the Manufacturing Process of Fruit Leather?

The manufacturing process of fruit leather involves several critical stages that ensure the product’s quality and consistency. Understanding these stages is essential for B2B buyers looking to source high-quality fruit leather.

Material Preparation: How Is Raw Fruit Processed?

The first step in manufacturing fruit leather is the careful selection and preparation of raw fruits. High-quality fruits are chosen based on ripeness and flavor to ensure the final product meets customer expectations. After selection, fruits undergo washing to remove pesticides and contaminants.

Next, the fruits are peeled (if necessary), cored, and chopped into smaller pieces to facilitate blending. This preparation stage may also include sorting to eliminate any damaged or overly ripe fruits. The use of organic and locally sourced fruits can appeal to buyers who prioritize sustainability and natural ingredients.

How Is the Fruit Puree Formed?

Once the fruits are prepared, they are blended into a smooth puree. This process may involve the addition of natural acids, such as lemon juice, which not only enhances flavor but also helps retain the fruit’s color. The blending should be thorough to ensure an even consistency, as any lumps can affect the texture of the final product.

What Techniques Are Used in the Drying Process?

The drying stage is crucial in transforming the fruit puree into leather. This can be achieved using various methods, including:

Illustrative image related to how do you make fruit leather

-

Oven Drying: The puree is spread evenly onto baking sheets lined with parchment paper and dried in an oven at low temperatures (usually around 170°F or 77°C). This method allows for controlled moisture removal, ensuring that the fruit leather maintains a chewy texture.

-

Dehydration: Some manufacturers utilize dehydrators, which provide a more energy-efficient way to remove moisture. Dehydrators maintain a consistent temperature, which helps achieve a uniform product.

-

Freeze-Drying: While less common, freeze-drying is another technique that preserves the fruit’s nutritional value and flavor. This method involves freezing the puree and then removing moisture in a vacuum environment.

After drying, the fruit leather is cooled before being cut into strips or rolled, ready for packaging.

What Quality Assurance Measures Are Implemented in Fruit Leather Production?

Quality assurance (QA) is vital in the fruit leather manufacturing process to ensure that the final product meets safety and quality standards. For B2B buyers, understanding these QA measures can provide confidence in their sourcing decisions.

Which International Standards Are Relevant for Quality Assurance?

Adhering to international standards is crucial for maintaining product quality and safety. ISO 9001 is a widely recognized standard for quality management systems (QMS) that helps organizations ensure they meet customer and regulatory requirements. Compliance with ISO 9001 can enhance a supplier’s credibility, especially in international markets.

In addition to ISO standards, regional certifications such as CE (European Conformity) for products sold in Europe and API (American Petroleum Institute) for specific food-grade materials may also apply. Suppliers should provide documentation that verifies compliance with these standards.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are integral to maintaining product integrity throughout the manufacturing process. Typical QC checkpoints include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival at the facility. Fruits are examined for quality, ripeness, and the absence of contaminants.

-

In-Process Quality Control (IPQC): During the manufacturing process, operators conduct regular checks to ensure that the blending and drying processes meet specified parameters. This may include monitoring temperature, humidity, and texture.

-

Final Quality Control (FQC): After production, the finished fruit leather undergoes final inspections to confirm it meets the specified quality standards. This includes checking for taste, texture, and packaging integrity.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should conduct due diligence to ensure that their suppliers adhere to stringent quality control practices. Here are actionable steps:

-

Audits: Request to conduct regular audits of the supplier’s manufacturing facilities. This can help verify compliance with international standards and internal quality protocols.

-

Quality Reports: Suppliers should provide quality assurance reports that detail testing results, including moisture content, microbiological testing, and sensory evaluations.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures. This is particularly important for international buyers who may not have direct oversight.

What Testing Methods Are Commonly Used in Fruit Leather Production?

Various testing methods are utilized to ensure the quality and safety of fruit leather. These may include:

-

Microbiological Testing: To ensure that the product is free from harmful bacteria and pathogens, microbiological testing is performed.

-

Moisture Content Analysis: Excess moisture can lead to spoilage, so manufacturers typically perform moisture content tests to ensure that the product falls within acceptable ranges.

-

Sensory Evaluation: Taste tests and texture assessments are conducted to ensure that the final product meets consumer expectations.

What Are the Unique Quality Assurance Considerations for International B2B Buyers?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, several nuances in quality assurance should be considered:

-

Regulatory Compliance: Different regions have distinct regulatory frameworks governing food safety and quality. Buyers should ensure that suppliers comply with local regulations, which can vary significantly.

-

Cultural Preferences: Understanding regional preferences for flavors, sweetness levels, and packaging can influence the success of fruit leather in international markets.

-

Sustainability Practices: Many buyers now prioritize suppliers that implement sustainable practices, such as using organic ingredients and environmentally friendly packaging.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing fruit leather, ensuring they receive a high-quality product that meets their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how do you make fruit leather’

Introdução

In the competitive landscape of food production, creating high-quality fruit leather is an appealing opportunity for businesses looking to diversify their product offerings. This step-by-step checklist provides B2B buyers with actionable insights for sourcing ingredients and equipment essential for producing fruit leather. Following these guidelines will help ensure that your fruit leather meets both quality standards and market demands.

1. Identify Your Target Market

Understanding your target market is fundamental to developing a successful fruit leather product. Different regions may have varying preferences for flavors, sweetness levels, and packaging. Conduct market research to determine which fruits and flavors are in demand in your specific markets, such as Africa, South America, the Middle East, and Europe.

2. Source Quality Ingredients

The quality of your fruit leather is directly linked to the ingredients you use. Seek suppliers that provide fresh, organic, and sustainably sourced fruits.

– Considerations:

– Verify the freshness and ripeness of fruits to ensure optimal flavor and texture.

– Look for suppliers who can offer a variety of fruit options, including seasonal and exotic varieties, to cater to diverse consumer tastes.

3. Evaluate Equipment Needs

Assess the equipment required for producing fruit leather efficiently. Depending on your production scale, you may need dehydrators, ovens, or blending machines.

– Key Points:

– Identify energy-efficient and durable equipment that aligns with your production volume.

– Consider suppliers that offer maintenance services or warranties to minimize downtime.

4. Verify Supplier Certifications

Before finalizing any supplier, confirm that they hold relevant certifications such as organic, non-GMO, or fair trade. This is particularly important for buyers in regions with strict food safety regulations.

– What to Look For:

– Request documentation that proves compliance with local and international food safety standards.

– Check for third-party audits or certifications that validate the supplier’s practices.

Illustrative image related to how do you make fruit leather

5. Request Samples for Quality Testing

Obtaining samples from potential suppliers is crucial for evaluating the quality of their products. Conduct taste tests and analyze texture to ensure they meet your specifications.

– Testing Considerations:

– Assess the flavor profile and texture to determine if they align with your target market’s preferences.

– Test for consistency in product quality to ensure batch-to-batch reliability.

6. Establish Supply Chain Logistics

Once you have selected your suppliers, it’s vital to establish a reliable logistics plan to ensure timely delivery of ingredients and equipment.

– Logistics Tips:

– Discuss shipping options and timelines to prevent production delays.

– Consider suppliers with a local presence to reduce transportation costs and improve delivery times.

7. Plan for Storage and Shelf Life

Fruit leather has specific storage requirements to maintain its quality over time. Work with suppliers who can provide guidance on best practices for storage and shelf life.

– Important Factors:

– Determine optimal packaging solutions to extend shelf life without compromising quality.

– Discuss storage conditions with suppliers to ensure your product remains fresh and appealing to consumers.

By following this checklist, B2B buyers can effectively navigate the sourcing process for producing high-quality fruit leather, ensuring they meet market demands while maintaining product integrity.

Comprehensive Cost and Pricing Analysis for how do you make fruit leather Sourcing

What Are the Key Cost Components for Sourcing Ingredients for Fruit Leather Production?

When considering the production of fruit leather, several cost components need to be factored into the overall pricing strategy. The primary materials include fresh fruit, lemon juice, and any optional sweeteners or spices. The cost of these materials can vary significantly based on regional availability and seasonal fluctuations. For instance, sourcing berries may be more expensive in regions where they are not locally grown.

Illustrative image related to how do you make fruit leather

Labor costs involve the workforce required for both production and quality control. This includes skilled labor for processing the fruit and unskilled labor for packing and logistics. Manufacturing overhead includes utilities, maintenance of equipment, and facility costs, which can differ based on geographic location and local economic conditions. Tooling costs may be minimal if using standard kitchen equipment, but any specialized machinery will increase initial investment.

Quality control (QC) is crucial in ensuring the final product meets food safety standards, particularly for international markets. This may involve additional costs for testing and certification, which can be a significant factor for buyers seeking to enter markets with stringent regulations.

How Do Price Influencers Affect the Cost of Fruit Leather Production?

Several key factors influence the pricing of fruit leather. Volume and minimum order quantities (MOQ) can significantly impact pricing; larger orders typically reduce the per-unit cost. Customization in terms of flavor or packaging can also lead to variations in price. Buyers should consider the specifications they require, as unique formulations may necessitate additional R&D costs.

The quality of raw materials plays a critical role. Organic or non-GMO fruits often come at a premium, and suppliers may charge more for certified ingredients. Supplier reliability, including their history, certifications, and geographical proximity, can also influence costs. For international buyers, understanding Incoterms is essential, as they dictate shipping responsibilities and costs, which can substantially affect the overall price.

What Buyer Tips Can Help Achieve Cost-Efficiency in Fruit Leather Sourcing?

Negotiation is key in B2B transactions, especially when dealing with suppliers across different regions. Buyers should leverage their purchasing volume and establish long-term relationships to secure better pricing. Understanding the total cost of ownership (TCO) is vital; this includes not only the purchase price but also shipping, storage, and any potential tariffs or duties.

International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, should be aware of pricing nuances. Fluctuations in currency exchange rates can impact costs, making it essential to factor in these variables when negotiating contracts. Additionally, buyers should consider local market conditions that may affect pricing, such as economic stability, import restrictions, and competition.

What Should Buyers Keep in Mind Regarding Indicative Prices?

It’s important for buyers to recognize that prices can vary widely based on the factors outlined above. While indicative prices can provide a useful benchmark, they should not be taken as fixed costs. Engaging in thorough market research and supplier evaluations will yield a more accurate understanding of potential expenses. By staying informed and adaptable, buyers can navigate the complexities of sourcing fruit leather and achieve favorable pricing outcomes.

Illustrative image related to how do you make fruit leather

Alternatives Analysis: Comparing how do you make fruit leather With Other Solutions

Introduction to Alternative Solutions for Making Fruit Leather

When it comes to producing fruit leather, businesses have several methods and technologies available. Each alternative presents unique benefits and drawbacks, which can significantly impact production efficiency, cost, and product quality. Understanding these alternatives can help B2B buyers make informed decisions that align with their operational goals and market demands.

Comparison Table

| Comparison Aspect | How Do You Make Fruit Leather | Dehydrator Method | Commercial Fruit Leather Machine |

|---|---|---|---|

| Performance | High-quality, natural product; customizable flavors | Consistent quality; retains nutrients | High-volume production; uniform results |

| Cost | Low initial investment; minimal ingredients | Moderate investment; energy costs | High initial investment; operational costs |

| Ease of Implementation | Simple, requires basic kitchen equipment | Moderate; requires some setup | Complex; requires training and maintenance |

| Maintenance | Low; occasional cleaning of utensils | Moderate; cleaning dehydrator components | High; regular maintenance and calibration |

| Best Use Case | Small-scale production for niche markets | Mid-sized production; health-conscious consumers | Large-scale production for commercial markets |

Detailed Breakdown of Alternatives

Dehydrator Method

The dehydrator method utilizes a specialized appliance designed to remove moisture from food. This method is known for its ability to produce consistent quality fruit leather while preserving nutrients. The performance of a dehydrator can be superior to traditional oven methods, particularly in retaining flavor and color. However, the initial investment in a good dehydrator can be moderate, and there are ongoing energy costs associated with its operation. Maintenance is manageable, but users must regularly clean the dehydrator’s trays to prevent contamination. This method is ideal for mid-sized producers looking to cater to health-conscious consumers seeking high-quality snacks.

Commercial Fruit Leather Machine

For businesses focused on large-scale production, investing in a commercial fruit leather machine can be a game-changer. These machines are designed to automate the process, ensuring uniformity in texture and flavor across batches. They are particularly suited for companies aiming to meet high demand in commercial markets. However, the initial investment is significant, and operational costs can be high due to energy and maintenance requirements. Training staff to operate and maintain such machines adds to the complexity. This method is best for enterprises looking to scale up operations and maintain consistent quality in their fruit leather products.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the right method for producing fruit leather depends on several factors, including production scale, budget, and desired product quality. Small businesses or niche producers may find the traditional method of making fruit leather appealing due to its low cost and ease of use. In contrast, mid-sized producers might benefit from the efficiency of a dehydrator, while large-scale operations could see significant advantages from investing in a commercial machine. By carefully assessing their specific needs and market demands, B2B buyers can make informed choices that enhance their production capabilities and product offerings.

Essential Technical Properties and Trade Terminology for how do you make fruit leather

What Are the Key Technical Properties for Making Fruit Leather?

When producing fruit leather, several critical technical properties must be considered to ensure quality, consistency, and marketability. Understanding these specifications is vital for B2B buyers, especially when sourcing ingredients or equipment.

-

Fruit Quality Grade

The quality of fruit used in the production of fruit leather is paramount. Fruits should be graded based on ripeness, color, and absence of blemishes or rot. Higher quality fruit not only yields better taste and texture but also affects the nutritional profile of the final product. For B2B buyers, ensuring consistent quality can lead to higher consumer satisfaction and lower return rates. -

Moisture Content Tolerance

The moisture content of the fruit puree is critical in achieving the right texture in fruit leather. Ideally, the moisture content should be between 15-20% to ensure a chewy and pliable product. Too much moisture can lead to spoilage, while too little can result in a brittle texture. Buyers should be aware of moisture specifications when sourcing fruit or equipment to maintain product standards. -

pH Level

The pH level of the fruit puree can significantly influence the flavor and preservation of the fruit leather. A pH of around 3.5 to 4.5 is generally ideal for fruit leather, as it helps preserve color and flavor while also inhibiting microbial growth. B2B buyers should consider pH testing as part of their quality control processes to ensure a safe and appealing product. -

Thickness Specification

The thickness of the fruit puree layer spread on the baking sheet or dehydrator tray is crucial for even drying. A uniform thickness of approximately 1/8 inch is recommended to ensure consistent drying times and texture. For buyers, understanding thickness specifications can help in selecting the right production equipment and optimizing processing times. -

Shelf Life

The expected shelf life of fruit leather is influenced by several factors, including moisture content, pH, and packaging. Typically, fruit leather can last up to one year if stored properly. B2B buyers should assess packaging options that extend shelf life, such as vacuum sealing or moisture-proof materials, to enhance product viability in the market.

What Are Common Trade Terms Related to Fruit Leather Production?

Navigating the B2B landscape requires familiarity with industry jargon. Here are several essential terms relevant to fruit leather production and procurement.

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce equipment used in the manufacturing of fruit leather, such as dehydrators or packaging machines. Understanding OEM relationships can help buyers negotiate better pricing and support services for equipment. -

MOQ (Minimum Order Quantity)

MOQ is the minimum quantity of a product that a supplier is willing to sell. For fruit leather production, this could apply to raw materials like fruit purees or packaging materials. Knowing MOQs is crucial for buyers to manage inventory levels and cash flow effectively. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request pricing and terms from suppliers for specific products or services. In the context of fruit leather, an RFQ can help buyers compare costs and negotiate terms before placing orders. -

Incoterms (International Commercial Terms)

These are a set of international rules that define the responsibilities of buyers and sellers in global trade. For fruit leather producers, understanding Incoterms is essential for determining shipping responsibilities, risk management, and cost allocation. -

Brix Level

Brix is a measurement of sugar content in an aqueous solution, often used in the fruit industry. For fruit leather, Brix levels can indicate sweetness and flavor intensity. Buyers should be aware of Brix specifications to ensure the desired taste profile in their products. -

Dehydration Rate

This term refers to the speed at which moisture is removed from the fruit puree during production. A controlled dehydration rate is essential to prevent over-drying or under-drying, which can affect texture and shelf life. Understanding this parameter can help buyers optimize their production processes.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance product quality and operational efficiency in the fruit leather market.

Navigating Market Dynamics and Sourcing Trends in the how do you make fruit leather Sector

What Are the Current Market Dynamics and Key Trends in the Fruit Leather Sector?

The fruit leather market is witnessing significant growth driven by a surge in health-conscious consumers seeking natural snack alternatives. This trend is particularly pronounced in regions such as Africa, South America, the Middle East, and Europe, where demand for nutritious and convenient snacks is on the rise. B2B buyers in these areas are increasingly looking to source high-quality fruit leather made from real fruit, free from artificial additives and sugars.

Emerging technologies in food processing and preservation are reshaping how fruit leather is produced. Innovations such as advanced dehydration methods and improved puree techniques enhance flavor retention and texture, making fruit leather more appealing to end consumers. Additionally, the adoption of e-commerce platforms is facilitating easier access to suppliers and manufacturers, enabling B2B buyers to compare products and prices efficiently.

Another key trend is the integration of local sourcing strategies. Many businesses are prioritizing partnerships with local farmers to ensure the freshness of ingredients while also supporting local economies. This approach not only reduces transportation costs but also aligns with growing consumer preferences for locally sourced products. In summary, B2B buyers should stay informed about these market dynamics and consider leveraging local partnerships and technology-driven solutions to enhance their sourcing strategies.

Illustrative image related to how do you make fruit leather

How Does Sustainability and Ethical Sourcing Impact the Fruit Leather Industry?

Sustainability is becoming a cornerstone of the fruit leather sector, driven by increasing consumer awareness regarding environmental impact. B2B buyers are now more than ever prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes sourcing fruits from farms that employ eco-friendly agricultural methods, minimizing chemical use, and practicing responsible water management.

Ethical sourcing is equally crucial, as buyers seek transparency in their supply chains. Certifications such as Fair Trade and organic labels not only assure customers of product quality but also reflect a commitment to social responsibility. By choosing suppliers with these certifications, B2B buyers can align their purchasing decisions with their corporate values and consumer expectations.

Furthermore, the use of sustainable packaging is gaining traction. Buyers are encouraged to seek out suppliers who utilize biodegradable or recyclable materials, reducing the overall environmental footprint of their products. Investing in sustainability and ethical sourcing not only enhances brand reputation but can also lead to cost savings in the long run by fostering loyalty among increasingly eco-conscious consumers.

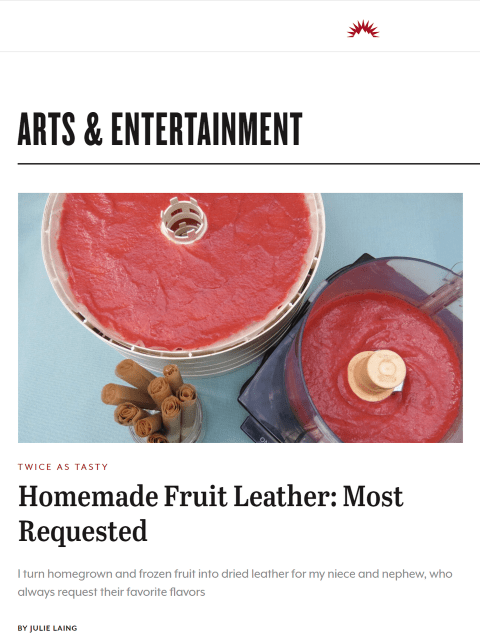

What Is the Brief Evolution and History of Fruit Leather Production?

The concept of fruit leather dates back centuries, with origins in ancient cultures that preserved fruits by drying them in the sun. This method was practical for ensuring food availability during off-seasons and was particularly common in regions with abundant fruit harvests. Over time, the process evolved, incorporating various fruit purees and flavoring techniques, leading to the modern fruit leather products we see today.

In the late 20th century, the introduction of commercial fruit leather in Western markets popularized this snack, especially among children. However, it was often laden with artificial ingredients, leading to a resurgence of interest in healthier, homemade alternatives. Today, the focus has shifted toward natural, organic fruit leather, as consumers demand healthier snack options with minimal processing. This evolution reflects broader trends in the food industry, emphasizing health, sustainability, and ethical sourcing, which are now critical considerations for B2B buyers in the sector.

Frequently Asked Questions (FAQs) for B2B Buyers of how do you make fruit leather

-

How do I ensure the quality of fruit leather from suppliers?

To ensure the quality of fruit leather, conduct a thorough vetting process for potential suppliers. Request samples to evaluate the texture, flavor, and overall quality of the product. Additionally, inquire about their sourcing practices, production methods, and quality assurance protocols. Certifications such as HACCP or ISO can also indicate a commitment to quality. Establishing a solid communication channel with suppliers can help clarify any quality concerns and ensure that your specifications are met consistently. -

What are the best fruits to use for making fruit leather?

The best fruits for making fruit leather are those that have high sugar content and lower moisture levels, such as strawberries, apples, mangoes, and bananas. These fruits provide a natural sweetness and desirable texture. However, you can also experiment with other fruits, including blueberries, peaches, and apricots, based on regional availability. Understanding local fruit varieties can help you customize your fruit leather products to meet market preferences in your target regions. -

What is the minimum order quantity (MOQ) for sourcing fruit leather?

Minimum order quantities (MOQ) for fruit leather can vary significantly depending on the supplier and their production capabilities. Typically, MOQs can range from 100 kg to several tons. When negotiating with suppliers, consider your market demand and storage capacity to determine a feasible order size. If you’re entering a new market, discuss flexible options with suppliers to test the demand without overcommitting to large quantities initially. -

How can I customize fruit leather products for my market?

Customization of fruit leather can involve varying the fruit combinations, adjusting sweetness levels, or incorporating unique flavorings such as spices or extracts. Collaborate with suppliers who can accommodate these changes and provide options for packaging that align with your brand. Conduct market research to identify consumer preferences in your target regions, which can guide your customization efforts and help differentiate your product in competitive markets. -

What payment terms should I negotiate with fruit leather suppliers?

When negotiating payment terms, consider factors like order size, supplier trustworthiness, and shipping arrangements. Common terms include 30% upfront payment with the balance due upon delivery, or net 30/60 days after receipt. It’s essential to establish clear terms that protect both parties, and considering the use of letters of credit can provide additional security for larger transactions. Always ensure that payment terms align with your cash flow management strategy. -

What logistics considerations should I keep in mind when sourcing fruit leather?

Logistics for sourcing fruit leather include evaluating shipping methods, lead times, and potential tariffs or import duties based on your location. Collaborate with suppliers to determine the best shipping options that balance cost and delivery speed. Consider using third-party logistics providers who specialize in food products to ensure compliance with local regulations and maintain product integrity during transit. Keeping a close eye on the supply chain can help you mitigate risks related to spoilage or delays. -

How do I ensure compliance with international food safety standards for fruit leather?

To ensure compliance with international food safety standards, work with suppliers who adhere to recognized certifications such as HACCP, ISO 22000, or local food safety regulations. Request documentation that verifies their adherence to these standards. Additionally, consider conducting periodic audits or quality checks on suppliers to maintain compliance. Educating your team about relevant regulations in your target markets can also help you navigate the complexities of international food safety requirements. -

What are the best practices for storing fruit leather to maintain freshness?

To maintain the freshness of fruit leather, store it in a cool, dry place, ideally in airtight packaging. Refrigeration can extend shelf life, particularly in humid climates, but ensure it’s sealed properly to prevent moisture absorption. For long-term storage, freezing is an effective option, but be aware that color and texture may change over time. Educating your clients on proper storage practices can enhance product satisfaction and reduce returns or complaints related to quality degradation.

Top 7 How Do You Make Fruit Leather Manufacturers & Suppliers List

1. Wholesome Yum – Healthy Fruit Leather

Domain: wholesomeyum.com

Registered: 2015 (10 years)

Introduction: This healthy fruit leather recipe is a homemade version of fruit rollups made with real, fresh fruit and no added sugar. It has a fruity, chewy texture and is less sweet than store-bought versions. The recipe allows for customization with various fruits such as strawberries, mangoes, and other berries, requiring about one pound (2 to 3 cups) of fruit. Lemon juice is added to enhance flavor and col…

2. Simply Recipes – Fruit Leather

Domain: simplyrecipes.com

Registered: 2002 (23 years)

Introduction: Fruit Leather Recipe: No artificial ingredients, made with fresh fruits like apricots, peaches, plums, berries, apples, pears, or grapes. Optional ingredients include water, lemon juice, sugar, and spices (cinnamon, nutmeg). Prep time: 20 mins, Cook time: 9 hrs, Total time: 9 hrs 20 mins, Servings: 10 servings, Yield: 1 sheet. Storage: Room temperature for up to 1 month, refrigerate for up to 6 mo…

3. Allrecipes – Blueberry Fruit Leather

Domain: allrecipes.com

Registered: 1998 (27 years)

Introduction: Ingredients: 16 ounces fresh blueberries, 1 tablespoon lemon juice. Directions: Preheat oven to 150-170 degrees F. Blend fruit and lemon juice until smooth. Spread puree on parchment-lined baking sheet. Dehydrate in oven for 4-6 hours until moisture is dried out. Cool, slice, and enjoy.

4. Reddit – Fruit Leather Preparation Tips

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: First time making fruit leather; using strawberries and mangos; seeking tips for preparation; interested in sweetness levels and ratios for sugar/honey; mentions using pure, fresh fruits; suggests using a food processor for puréeing; recommends spreading purée evenly; suggests adding lemon juice for sweetness; mentions using silicone sheets for easier removal; suggests mixing apple sauce with othe…

5. Instructables – Homemade Fruit Leather Recipe

Domain: instructables.com

Registered: 2005 (20 years)

Introduction: Homemade Fruit Leather Recipe by Paige Russell

– Type: Dried Snack

– Main Ingredient: Ripe fruit (e.g., pears, apricots, peaches, plums, berries, apples, grapes)

– Additional Ingredients: Lemon juice (fresh or bottled) or ascorbic acid

– Tools Required: Dehydrator or oven, fruit leather dehydrator sheets or parchment paper, cutting board, paring knife, chef’s knife, medium bowl, small bowl, citrus…

6. Brod and Taylor – Sahara Folding Dehydrator

Domain: brodandtaylor.com

Registered: 2010 (15 years)

Introduction: Fruit leather is a wholesome snack made by pureeing fruits, spreading the mixture thinly, and dehydrating it. The Sahara Folding Dehydrator is recommended for optimal air circulation and dual time/temperature control. Non-Stick Silicone Mats are used for easy peeling and cleanup. Ingredients include various fruits (e.g., berries, bananas, apples), optional sweeteners (granulated sugar, honey, mapl…

7. Food52 – Plum Fruit Leather Recipe

Domain: food52.com

Registered: 2009 (16 years)

Introduction: Plum Fruit Leather

– Recipe Creator: Erin Jeanne McDowell

– Test Kitchen-Approved

– Serves: About 16 pieces

– Prep Time: 15 Minutes

– Cook Time: 6 Hours 30 Minutes

– Ingredients: 1 1/4 pound (565 grams) plums (pitted and roughly chopped), 1 tablespoon (15 grams) freshly squeezed lemon juice, 1 tablespoon to 1/3 cup (12 to 66 grams) granulated sugar (adjust for sweetness), 1 pinch fine sea salt.

– …

Strategic Sourcing Conclusion and Outlook for how do you make fruit leather

As the demand for natural and healthy snacks continues to rise globally, understanding the strategic sourcing of ingredients for fruit leather production is crucial for B2B buyers. Key takeaways include the importance of selecting high-quality, ripe fruits that not only enhance flavor but also optimize nutritional value. Establishing reliable supplier relationships ensures consistent quality and availability, particularly when sourcing from diverse regions across Africa, South America, the Middle East, and Europe.

In addition, leveraging local fruit varieties can reduce transportation costs and support regional economies. Buyers should also consider the implications of processing methods, such as dehydration techniques that preserve flavor and texture while meeting health-conscious consumer preferences.

Looking ahead, the fruit leather market presents significant growth opportunities. By investing in strategic sourcing practices and fostering partnerships with local farmers and suppliers, international buyers can capitalize on emerging trends in healthy snacking. This proactive approach not only strengthens supply chains but also positions businesses to respond effectively to evolving consumer demands. Engage with your suppliers today to explore innovative fruit leather solutions that cater to diverse markets and enhance your product offerings.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.