Introduction: Navigating the Global Market for leather working supplies near me

In the competitive landscape of leatherworking, sourcing high-quality leather working supplies near me poses a significant challenge for B2B buyers, particularly those operating across diverse regions such as Africa, South America, the Middle East, and Europe. With varying local markets, fluctuating costs, and differing supplier reputations, the task of finding reliable sources can be daunting. This guide aims to streamline your procurement process by providing an in-depth analysis of the types of leather working supplies available, their applications, and essential factors to consider when selecting suppliers.

We delve into various categories, including tools, hardware, and materials, addressing how each component plays a crucial role in the leather crafting process. Additionally, this guide offers insights into supplier vetting strategies to ensure quality and reliability, as well as cost analysis to help you make informed purchasing decisions. Understanding these elements is vital for businesses looking to enhance their leathercrafting capabilities while maintaining budgetary constraints.

By empowering international B2B buyers, particularly from markets like Nigeria and Brazil, this comprehensive resource enables you to navigate the complexities of the global leather supply chain effectively. Equip yourself with the knowledge to source the right supplies, optimize production, and ultimately elevate your business in the thriving leather industry.

Table Of Contents

- Top 3 Leather Working Supplies Near Me Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather working supplies near me

- Understanding leather working supplies near me Types and Variations

- Key Industrial Applications of leather working supplies near me

- 3 Common User Pain Points for ‘leather working supplies near me’ & Their Solutions

- Strategic Material Selection Guide for leather working supplies near me

- In-depth Look: Manufacturing Processes and Quality Assurance for leather working supplies near me

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather working supplies near me’

- Comprehensive Cost and Pricing Analysis for leather working supplies near me Sourcing

- Alternatives Analysis: Comparing leather working supplies near me With Other Solutions

- Essential Technical Properties and Trade Terminology for leather working supplies near me

- Navigating Market Dynamics and Sourcing Trends in the leather working supplies near me Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather working supplies near me

- Strategic Sourcing Conclusion and Outlook for leather working supplies near me

- Important Disclaimer & Terms of Use

Understanding leather working supplies near me Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Veg-Tan Leather | Natural tanning process, eco-friendly, versatile | High-end leather goods, custom projects | Pros: Sustainable, easy to dye. Cons: Can be more expensive. |

| Chrome-Tan Leather | Soft, supple feel, wide color range | Fashion accessories, upholstery | Pros: Cost-effective, durable. Cons: Less environmentally friendly. |

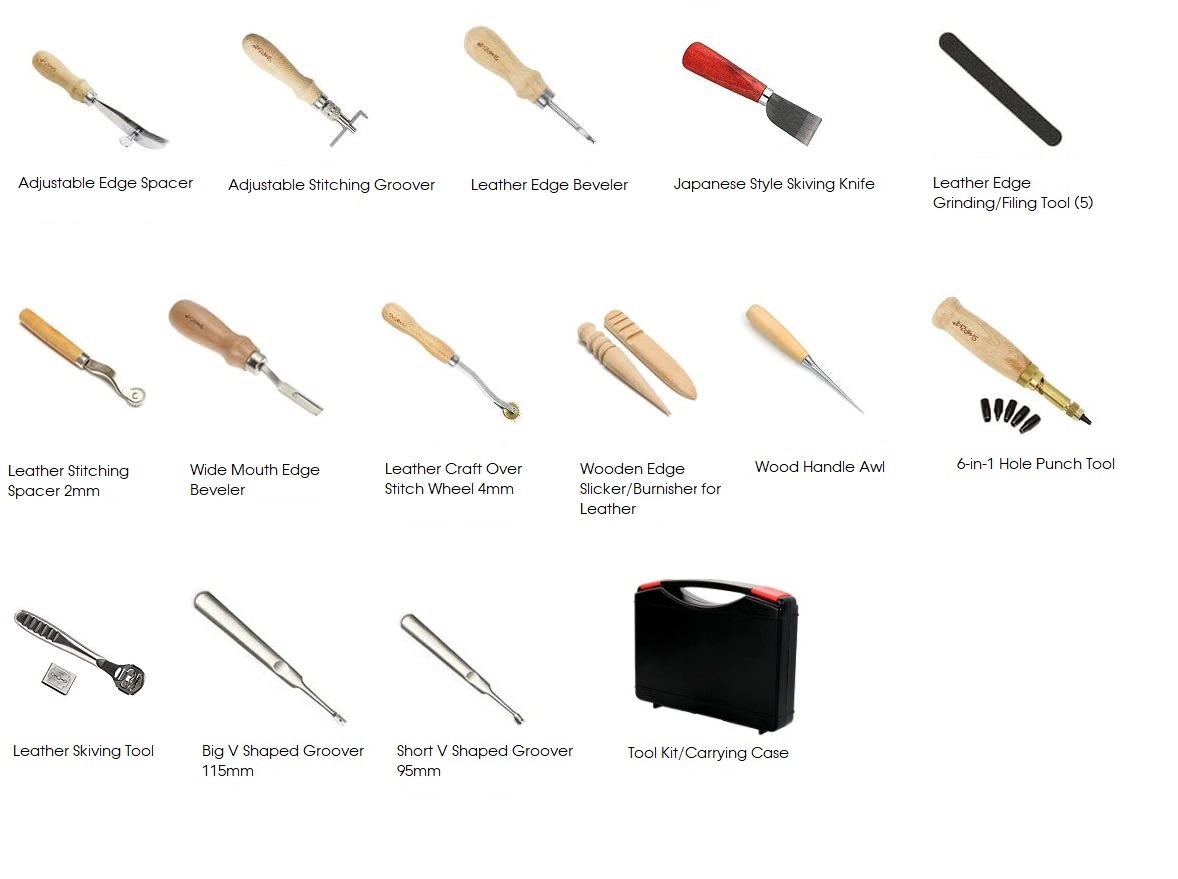

| Leather Tools & Hardware | Includes cutting tools, stitching supplies, and fasteners | Manufacturing, repairs, and crafting | Pros: Essential for quality craftsmanship. Cons: Requires skill to use effectively. |

| Leather Finishing Products | Dyes, conditioners, and protective finishes | Enhancing product durability and aesthetics | Pros: Improves longevity, variety of finishes. Cons: May require additional application techniques. |

| Leather Craft Kits | Pre-packaged supplies for specific projects | Education, hobbyist markets | Pros: Convenient for beginners, comprehensive. Cons: Limited to specific projects. |

What Are the Key Characteristics of Veg-Tan Leather for B2B Buyers?

Veg-tan leather is derived from natural plant materials, making it an eco-friendly option prized for its durability and versatility. It is particularly suitable for high-end leather goods, such as wallets, belts, and custom projects, where a premium finish is essential. B2B buyers should consider the leather’s ability to accept dyes and finishes well, allowing for customization. However, its price point may be higher than synthetic alternatives, which could impact budget-sensitive projects.

How Does Chrome-Tan Leather Serve Various Industries?

Chrome-tan leather is known for its soft, supple texture and wide range of color options, making it ideal for fashion accessories and upholstery. Its cost-effectiveness and durability make it a popular choice among manufacturers. B2B buyers should weigh the benefits of its aesthetic appeal against the environmental concerns associated with the chrome tanning process. Understanding the specific needs of their projects can help buyers make informed decisions regarding this leather type.

Why Are Leather Tools & Hardware Essential for Craftsmanship?

Leather tools and hardware, including cutting instruments, stitching supplies, and fasteners, are crucial for both manufacturing and repair processes. These items are essential for achieving high-quality craftsmanship and ensuring the longevity of leather products. B2B buyers should focus on the quality and durability of these tools, as well as the skill level required for effective use. Investing in reliable tools can lead to better production outcomes and customer satisfaction.

Illustrative image related to leather working supplies near me

What Role Do Leather Finishing Products Play in Product Development?

Leather finishing products, such as dyes, conditioners, and protective coatings, play a significant role in enhancing the durability and visual appeal of leather goods. They allow manufacturers to create a diverse range of finishes, catering to different market demands. B2B buyers need to consider the application techniques and compatibility with various leather types when selecting these products. While they improve product longevity, additional skills may be required for optimal results.

How Do Leather Craft Kits Facilitate Entry into the Market?

Leather craft kits provide a convenient solution for beginners and educational purposes, containing all necessary materials for specific projects. They cater to hobbyist markets and can serve as an entry point for businesses looking to diversify their product offerings. B2B buyers should evaluate the comprehensiveness of these kits and their alignment with market trends. While they simplify the crafting process, the limitations on project variety may restrict creative exploration.

Key Industrial Applications of leather working supplies near me

| Industry/Sector | Specific Application of leather working supplies near me | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Custom leather garments and accessories | High-quality materials enhance brand reputation | Look for local suppliers with diverse leather types and colors. |

| Automotive | Upholstery and interior leather components | Durable and aesthetic materials improve vehicle value | Ensure compliance with local regulations on materials used. |

| Furniture Manufacturing | Leather upholstery for sofas and chairs | Increases product appeal and longevity | Prioritize suppliers offering bulk options and sustainable practices. |

| Footwear | Leather for shoes and boots manufacturing | High-quality leather ensures comfort and durability | Verify the sourcing of leather to meet ethical standards. |

| Craft and Hobby | DIY leather crafting kits and tools | Supports local artisans and small businesses | Seek suppliers with comprehensive kits for beginners and pros alike. |

How Are Leather Working Supplies Used in the Fashion and Apparel Industry?

In the fashion and apparel sector, leather working supplies are essential for creating custom garments and accessories. Designers utilize high-quality leather to develop unique products that can differentiate their brand in a competitive market. This sector often requires diverse leather types, such as vegetable-tanned or chrome-tanned options, to meet aesthetic and functional needs. International buyers from regions like Africa and Europe should focus on suppliers that offer a variety of textures and colors to cater to different fashion trends.

Illustrative image related to leather working supplies near me

What Role Do Leather Working Supplies Play in the Automotive Industry?

The automotive industry employs leather working supplies primarily for upholstery and interior components. Using premium leather enhances the aesthetic appeal and comfort of vehicles, thereby increasing their market value. Buyers in this sector must consider the durability and maintenance of leather materials, ensuring they can withstand wear and tear. Additionally, compliance with local regulations regarding materials is crucial, especially for international buyers sourcing from regions with varying standards.

How Is Leather Utilized in Furniture Manufacturing?

In furniture manufacturing, leather working supplies are vital for creating upholstered items like sofas and chairs. The use of high-quality leather not only enhances the visual appeal but also extends the lifespan of the furniture. Manufacturers should seek suppliers who can provide bulk orders and options for sustainable leather sourcing. This is particularly important for businesses in South America and the Middle East, where environmental considerations are increasingly influencing consumer preferences.

Why Is Leather Important for Footwear Production?

Leather is a fundamental material in footwear manufacturing, used for crafting shoes and boots that prioritize comfort and durability. High-quality leather ensures that footwear can withstand daily use while providing a comfortable fit. Buyers should verify the ethical sourcing of leather to align with consumer expectations, particularly in European markets where sustainability is a key concern. Additionally, accessing local suppliers can streamline the procurement process and reduce lead times.

How Do Leather Working Supplies Support Craft and Hobby Markets?

In the craft and hobby sector, leather working supplies, including DIY kits and tools, empower local artisans and small businesses to create custom leather goods. These supplies range from basic tools to comprehensive kits that cater to various skill levels. For international buyers, especially those from Africa and South America, sourcing from local suppliers can foster community engagement and support local economies. Ensuring that suppliers provide quality materials and instructional resources can further enhance the crafting experience.

3 Common User Pain Points for ‘leather working supplies near me’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Leather Supplies Locally

The Problem: B2B buyers, especially those in emerging markets like Nigeria or Brazil, often struggle to find quality leather supplies locally. Many suppliers may not carry a diverse range of products, or the quality may not meet the specific needs of the buyer’s projects. Additionally, limited availability can lead to delays in production, which can be detrimental for businesses operating under tight deadlines.

The Solution: To overcome sourcing challenges, buyers should consider establishing relationships with reputable online suppliers who specialize in leather working supplies and can ship internationally. Platforms like Tandy Leather and Weaver Leather Supply offer a wide variety of products and can provide detailed information about the quality and specifications of their materials. Buyers should leverage these platforms by subscribing to newsletters for updates on new products and discounts. Furthermore, they can reach out to customer service representatives for tailored recommendations based on their specific project needs, ensuring they select the right type of leather—be it veg-tanned or chrome-tanned—for their applications. Implementing a just-in-time inventory strategy can also help manage costs while ensuring that quality materials are available when needed.

Scenario 2: Lack of Knowledge on Leatherworking Techniques and Tools

The Problem: Many B2B buyers may possess leather crafting skills but lack advanced knowledge of specific techniques or the tools necessary to execute complex projects. This knowledge gap can result in wasted materials, increased labor costs, and subpar product quality, ultimately impacting customer satisfaction and business reputation.

The Solution: To address this knowledge gap, buyers should invest in training and education resources provided by industry leaders. Websites like Tandy Leather offer extensive educational material, including tutorials on dyeing, finishing, and tooling leather. Buyers can participate in online workshops or local classes to enhance their skills and learn about the latest techniques and tools. Additionally, engaging with online forums or social media groups dedicated to leather crafting can provide a community support system where buyers can ask questions and share experiences. By building a solid foundation of skills and knowledge, businesses can improve their craftsmanship, reduce waste, and ultimately enhance the quality of their products.

Scenario 3: Uncertainty About Pricing and Quality of Leather Supplies

The Problem: B2B buyers often face uncertainty regarding the pricing and quality of leather supplies. Fluctuating prices, especially for high-quality materials, can make budgeting challenging. Additionally, distinguishing between different grades of leather can be daunting, leading to potential overpayments for inferior products or purchasing the wrong type altogether.

The Solution: To mitigate these concerns, buyers should conduct thorough market research to understand the typical price ranges for various types of leather and supplies. Utilizing comparison tools available on supplier websites can help assess quality against price. Establishing relationships with multiple suppliers can also provide insights into fair pricing and availability of materials. Furthermore, buyers should request samples before making bulk purchases to evaluate the quality firsthand. Engaging in discussions with suppliers about their sourcing processes and material specifications can also provide assurance regarding the integrity of the products being purchased. By being informed and proactive in their purchasing decisions, buyers can make confident investments that align with their budget and quality expectations.

Illustrative image related to leather working supplies near me

Strategic Material Selection Guide for leather working supplies near me

What Are the Key Properties of Common Leatherworking Materials?

When selecting leatherworking supplies, understanding the properties of various materials is crucial for ensuring optimal performance and suitability for specific applications. Here, we analyze four common materials used in leatherworking: vegetable-tanned leather, chrome-tanned leather, synthetic leather, and suede.

What Are the Key Properties of Vegetable-Tanned Leather?

Vegetable-tanned leather is known for its eco-friendly tanning process, using natural tannins from plant sources. This type of leather is breathable and can be dyed or finished easily, making it versatile for various applications, including bags, belts, and wallets.

Pros: It is durable and develops a beautiful patina over time, enhancing its aesthetic appeal. Additionally, it is biodegradable, aligning with sustainable practices.

Cons: The tanning process can be time-consuming and costly, which may impact the final product’s price. It is also less resistant to water and stains compared to other types of leather.

Impact on Application: Ideal for high-quality leather goods that require a natural look and feel, vegetable-tanned leather is perfect for products that will be used for years.

Considerations for International Buyers: Compliance with environmental regulations is essential, especially in regions like Europe where sustainability is prioritized. Buyers should also ensure that suppliers adhere to standards such as ASTM for material quality.

How Does Chrome-Tanned Leather Compare?

Chrome-tanned leather is processed using chromium salts, resulting in a softer and more pliable material. This type of leather is commonly used in fashion items, upholstery, and automotive interiors.

Pros: It is highly resistant to water, stains, and fading, making it suitable for a wide range of applications. The tanning process is faster, which can lower costs.

Cons: The environmental impact of chrome tanning is significant, raising concerns about chemical waste. This may affect its acceptance in markets that prioritize eco-friendliness.

Impact on Application: Chrome-tanned leather is ideal for products requiring flexibility and durability, such as shoes and bags that undergo frequent use.

Considerations for International Buyers: Buyers must be aware of local regulations regarding chemical use and waste disposal, particularly in regions like Africa and South America, where environmental standards may vary.

What Are the Benefits of Synthetic Leather?

Synthetic leather, or faux leather, is made from polyurethane or polyvinyl chloride (PVC). It mimics the look and feel of real leather while offering various advantages.

Illustrative image related to leather working supplies near me

Pros: It is often more affordable than genuine leather and can be produced in various colors and textures. Additionally, it is easier to clean and maintain.

Cons: Synthetic leather may not be as durable as natural leather and can wear out more quickly, especially in high-friction applications. It also lacks the unique aging characteristics of real leather.

Impact on Application: Suitable for fashion items, furniture, and accessories, synthetic leather is an excellent choice for budget-conscious projects.

Considerations for International Buyers: Buyers should ensure that synthetic materials meet safety and quality standards, such as REACH in Europe, to avoid issues related to harmful chemicals.

Why Choose Suede Leather for Specific Applications?

Suede leather, made from the underside of animal hides, is soft and has a unique texture. It is commonly used for fashion items, upholstery, and accessories.

Illustrative image related to leather working supplies near me

Pros: Suede offers a luxurious feel and is available in various colors. It is also lightweight, making it suitable for garments and soft goods.

Cons: It is less durable than full-grain leather and more susceptible to stains and water damage. Proper care and maintenance are essential to prolong its lifespan.

Impact on Application: Suede is ideal for products that prioritize aesthetics over durability, such as fashion accessories and decorative items.

Illustrative image related to leather working supplies near me

Considerations for International Buyers: Buyers should consider the sourcing of suede, ensuring compliance with ethical standards, particularly in regions where animal welfare is a concern.

Summary Table of Leatherworking Materials

| Materiał | Typical Use Case for leather working supplies near me | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | High-quality bags, belts, wallets | Eco-friendly, develops a beautiful patina | Time-consuming tanning process, less water-resistant | Medium |

| Chrome-Tanned Leather | Fashion items, upholstery, automotive interiors | Highly durable and water-resistant | Environmental concerns due to chemical use | Medium |

| Synthetic Leather | Fashion items, furniture, accessories | Affordable, easy to maintain | Less durable, lacks unique aging characteristics | Low |

| Suede Leather | Fashion accessories, decorative items | Luxurious feel, available in various colors | Less durable, susceptible to stains and water | Medium |

This guide provides B2B buyers with a comprehensive understanding of the materials available for leatherworking supplies. By considering the properties, pros and cons, and specific regional considerations, buyers can make informed decisions that align with their business needs and sustainability goals.

In-depth Look: Manufacturing Processes and Quality Assurance for leather working supplies near me

What Are the Main Stages of Manufacturing Leather Working Supplies?

The manufacturing of leather working supplies involves several critical stages: material preparation, forming, assembly, and finishing. Each stage plays a pivotal role in ensuring the quality and durability of the final products.

Illustrative image related to leather working supplies near me

How Is Material Prepared for Leather Working Supplies?

Material preparation is the first step, where high-quality leather is sourced, often from tanneries that comply with international standards. This phase includes the selection of leather types, such as vegetable-tanned or chrome-tanned, based on the intended application. Additionally, leather is often conditioned and dyed to achieve desired colors and textures, enhancing both aesthetics and functionality.

During this phase, suppliers may utilize techniques such as splitting and skiving to ensure uniform thickness and weight. This is particularly important for B2B buyers who require consistency across bulk orders. The choice of leather quality directly impacts the final product, making it essential for buyers to understand the material specifications.

What Techniques Are Used in the Forming Stage?

The forming stage encompasses cutting, stamping, and tooling processes that shape the leather into usable forms. Advanced machinery, like laser cutters and die-cutting presses, is often employed for precision cutting, especially when producing intricate designs or large quantities.

Stamping and tooling techniques add unique patterns and textures, which can differentiate products in the marketplace. B2B buyers should inquire about the specific techniques used by suppliers, as these can affect both the quality and cost of the final products.

How Are Leather Working Supplies Assembled?

Assembly involves stitching, bonding, or riveting various leather components together. The choice of assembly method can significantly influence the durability and functionality of the leather item. For example, high-quality hand stitching is often preferred for premium products, while machine stitching may be used for mass-produced items.

Illustrative image related to leather working supplies near me

In this phase, it is crucial for suppliers to maintain meticulous attention to detail. B2B buyers should request information on the assembly processes, including the types of threads and adhesives used, as these directly impact the product’s longevity.

What Are the Final Finishing Techniques Applied?

Finishing is the last stage of the manufacturing process and includes applying protective coatings, dyes, and conditioners to enhance the leather’s appearance and resistance to wear. Techniques such as buffing and polishing can give the leather a refined look while ensuring it is ready for shipment.

B2B buyers should understand the finishing techniques employed, as these can affect not only aesthetics but also the product’s performance in different environments. For instance, finishes that enhance water resistance are critical for items intended for outdoor use.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is vital in ensuring that leather working supplies meet both international standards and industry-specific requirements. Suppliers often adhere to ISO 9001, which provides a framework for quality management systems, ensuring consistent product quality and customer satisfaction.

Which International Standards Are Relevant to Leather Working Supplies?

In addition to ISO 9001, B2B buyers should consider other relevant certifications such as CE marking for products sold within the European Union and the American API standards for specific applications. These certifications indicate that the products have been tested and meet safety and performance criteria.

Understanding the standards applicable to leather working supplies is crucial for international buyers, particularly when importing products into countries with strict regulations.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are essential throughout the manufacturing process to maintain high standards. Common checkpoints include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival at the manufacturing facility to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Continuous monitoring during production helps identify defects early, minimizing waste and rework.

-

Final Quality Control (FQC): The final inspection before shipping verifies that the finished products meet all specifications and quality standards.

B2B buyers should inquire about these QC checkpoints and how suppliers document their quality control processes.

Illustrative image related to leather working supplies near me

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers adhere to robust quality control practices, B2B buyers can take several steps:

-

Conduct Audits: Regular audits of manufacturing facilities can provide insight into the operational quality control measures in place. This can be done through on-site visits or third-party audit services.

-

Request Quality Reports: Suppliers should provide documentation detailing their quality control processes, including test results and compliance with standards. These reports can help buyers assess the reliability of their suppliers.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of product quality before shipment. This is particularly beneficial for international transactions, where buyers may not be able to inspect products in person.

What Are the Common Testing Methods for Leather Products?

Testing methods vary depending on the intended use of the leather products. Common tests include:

-

Tensile Strength Testing: Determines the maximum load the leather can bear before breaking, essential for products like belts and straps.

-

Flexural Testing: Assesses the leather’s ability to withstand bending, important for items that will experience frequent movement.

-

Water Resistance Testing: Evaluates how well the leather repels moisture, which is crucial for outdoor applications.

Understanding these testing methods enables B2B buyers to better assess the quality and suitability of leather working supplies for their specific needs.

What QC Considerations Are Unique for International B2B Buyers?

International buyers must navigate additional nuances in quality control, such as differing regulations and standards across countries. For instance, products exported to the European market must comply with REACH regulations concerning chemical safety.

Furthermore, cultural differences may influence quality expectations. Buyers from regions like Africa and South America may prioritize durability and functionality, while European buyers might focus more on aesthetics and craftsmanship.

In conclusion, a thorough understanding of manufacturing processes and quality assurance practices is essential for B2B buyers in the leather industry. By focusing on these elements, buyers can ensure they partner with suppliers who meet their quality standards and business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather working supplies near me’

In the world of leather crafting, sourcing quality supplies is crucial for ensuring the success of your projects. This guide serves as a practical checklist for B2B buyers looking to procure leather working supplies locally. By following these steps, you can streamline your sourcing process and establish reliable partnerships with suppliers.

Step 1: Identify Your Specific Needs

Understanding your project requirements is the first step in sourcing leather working supplies. Define the types of leather, tools, and accessories you need based on the products you intend to create.

– Considerations include:

– Types of leather (e.g., vegetable-tanned, chrome-tanned)

– Essential tools (e.g., cutting tools, stitching supplies)

– Accessories (e.g., hardware like buckles and rivets)

Step 2: Research Local Suppliers

Finding suppliers nearby can reduce shipping costs and lead times. Conduct thorough research using online directories, trade associations, and local business listings.

– Look for:

– Established suppliers with good reputations

– Reviews and ratings from other businesses

– Availability of a range of products that meet your needs

Illustrative image related to leather working supplies near me

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions.

– Questions to ask:

– What is their experience in the leather industry?

– Can they provide samples of their products?

– What are their minimum order quantities and pricing structures?

Step 4: Verify Product Quality

Quality is paramount in leather working. Ensure that the materials offered meet your standards by requesting samples or visiting their facilities if possible.

– Important factors include:

– Leather grades and finishes

– Durability and thickness specifications

– Compliance with industry standards for safety and quality

Step 5: Assess Pricing and Terms

Understanding pricing is essential for maintaining your budget. Compare prices among different suppliers but also consider their terms of service.

– Key points to review:

– Bulk discounts and payment terms

– Shipping costs and delivery timelines

– Return policies and warranties

Step 6: Establish Communication Channels

Effective communication is vital for a successful partnership. Establish clear lines of communication with your suppliers to facilitate smooth transactions.

– Best practices include:

– Regular check-ins to discuss orders and issues

– Utilizing email, phone, or messaging apps for quick responses

– Setting expectations for response times and order updates

Illustrative image related to leather working supplies near me

Step 7: Build Long-Term Relationships

Once you find a reliable supplier, focus on building a long-term relationship. This can lead to better prices, priority service, and access to new products.

– Strategies for relationship building:

– Provide feedback on products and services

– Engage in regular discussions about upcoming projects

– Participate in supplier events or trade shows to strengthen ties

By following this checklist, B2B buyers can efficiently navigate the sourcing landscape for leather working supplies, ensuring they partner with suppliers who meet their needs and support their business goals.

Comprehensive Cost and Pricing Analysis for leather working supplies near me Sourcing

What Are the Key Cost Components for Sourcing Leather Working Supplies?

When analyzing the cost structure for sourcing leather working supplies, it’s essential to break down the various cost components involved. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Illustrative image related to leather working supplies near me

-

Materials: The type and quality of leather significantly affect the price. For instance, vegetable-tanned leather typically costs more than chrome-tanned due to its processing and durability. Additionally, specialty leathers, such as exotic skins, will come at a premium.

-

Labor: Skilled labor is often required for leather crafting. The cost of labor varies significantly depending on the region. Countries with a higher skill level in leather craftsmanship may charge more, impacting overall pricing.

-

Manufacturing Overhead: This includes costs associated with running production facilities, such as utilities and maintenance. Efficient operations can lower overhead costs, which can be passed on to buyers.

-

Tooling: Custom tooling for specific projects can add to initial costs. However, investing in quality tools can improve production efficiency and product quality over time.

-

Quality Control (QC): Ensuring that leather products meet quality standards is critical, especially for B2B transactions. QC processes can incur additional costs but are necessary to minimize returns and enhance customer satisfaction.

-

Logistics: Shipping costs can vary widely based on distance, weight, and mode of transport. This is particularly important for international buyers who need to consider tariffs, duties, and shipping insurance.

-

Margin: Suppliers typically add a profit margin on top of their costs, which can vary based on competition, demand, and product uniqueness.

How Do Price Influencers Impact Leather Working Supplies Sourcing?

Several factors influence the pricing of leather working supplies, which international buyers should consider:

-

Volume/MOQ: Purchasing in bulk can significantly reduce per-unit costs. Suppliers often provide discounts for larger orders, allowing buyers to optimize their budgets.

-

Specifications/Customization: Custom orders typically command higher prices due to the additional labor and materials involved. Buyers should weigh the need for customization against potential cost savings from standard products.

-

Materials: The choice of materials directly impacts pricing. Sustainable or ethically sourced materials may attract higher costs but appeal to a growing market segment concerned about environmental impact.

-

Quality/Certifications: Products that come with certifications (e.g., eco-friendly, cruelty-free) can be priced higher. Buyers should consider whether these certifications align with their brand values and customer expectations.

-

Supplier Factors: Supplier reputation and reliability can influence pricing. Established suppliers may charge a premium, but the assurance of quality and service can justify the cost.

-

Incoterms: Understanding international shipping terms is crucial. Incoterms can dictate who is responsible for shipping costs, insurance, and risk, affecting overall pricing strategies.

What Are Essential Buyer Tips for Cost-Efficiency in Leather Working Supplies Sourcing?

B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should adopt strategic approaches to maximize cost-efficiency:

-

Negotiation: Always engage in negotiations with suppliers. Understanding the cost structure allows buyers to negotiate better terms and pricing, particularly for bulk orders.

-

Total Cost of Ownership (TCO): Evaluate the long-term costs associated with products, including maintenance, durability, and potential resale value. Lower initial prices may lead to higher TCO if quality is compromised.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and shipping delays when sourcing internationally. These factors can significantly affect the final landed cost of products.

-

Local vs. International Sourcing: Consider local suppliers for specific materials to reduce shipping costs and lead times. However, balance this with the quality and pricing offered by international suppliers.

Disclaimer on Indicative Prices

Prices for leather working supplies can vary widely based on the factors discussed. The figures provided in supplier listings are indicative and subject to change based on market conditions, supplier pricing strategies, and other economic factors. Always request updated quotes and consider all cost components before making purchasing decisions.

Alternatives Analysis: Comparing leather working supplies near me With Other Solutions

Exploring Alternatives to Leather Working Supplies Near Me

In the leatherworking industry, sourcing high-quality supplies is crucial for successful projects. While purchasing leather working supplies locally offers convenience, several alternative solutions can also meet the needs of businesses, especially for international B2B buyers. This section compares traditional local sourcing with online suppliers and DIY leatherworking techniques.

Illustrative image related to leather working supplies near me

| Comparison Aspect | Leather Working Supplies Near Me | Online Leather Supply Stores | DIY Leatherworking Techniques |

|---|---|---|---|

| Performance | Immediate access to products | Extensive product variety | Customization capabilities |

| Cost | Potentially higher local prices | Competitive pricing | Variable, depends on materials |

| Ease of Implementation | Simple, straightforward shopping | Requires internet access | Requires skill and time |

| Maintenance | Minimal, depends on storage | Inventory management needed | Ongoing skills development |

| Best Use Case | Quick projects, urgent needs | Large scale production | Custom, unique creations |

What Are the Advantages and Disadvantages of Online Leather Supply Stores?

Online leather supply stores, such as Tandy Leather and Weaver Leather Supply, provide a vast array of products, from tools to specialty leathers. Their performance is often superior in terms of variety, allowing buyers to access specialized materials that may not be available locally. Costs can be competitive, especially when factoring in bulk purchases or discounts. However, buyers need reliable internet access and may face shipping delays. This method is particularly beneficial for businesses with ongoing projects that require specific materials regularly.

How Do DIY Leatherworking Techniques Compare?

DIY leatherworking techniques offer a unique alternative, empowering artisans to create customized products from scratch. This method excels in performance as it allows for full creative control and personalization. Costs can vary significantly, depending on the materials chosen and the complexity of the project. While the initial setup may require investment in tools and materials, ongoing maintenance is primarily focused on skill enhancement. However, the steep learning curve can deter some buyers, making this approach best suited for niche markets or artisans looking to differentiate their products.

Conclusion: Which Solution is Right for Your Leatherworking Needs?

When choosing between local leather working supplies, online stores, and DIY methods, B2B buyers should consider their specific needs and operational capabilities. For businesses requiring quick access to materials, local suppliers may be advantageous. In contrast, those looking for variety and competitive pricing may prefer online sources. Meanwhile, DIY techniques are ideal for companies focused on customization and unique offerings. By assessing the performance, cost, and implementation ease of each option, businesses can make informed decisions that align with their operational strategies and market demands.

Essential Technical Properties and Trade Terminology for leather working supplies near me

What Are the Essential Technical Properties of Leather Working Supplies?

Understanding the technical specifications of leather working supplies is crucial for B2B buyers, particularly when sourcing materials for production. Here are key properties to consider:

Illustrative image related to leather working supplies near me

-

Material Grade

Material grade refers to the quality classification of leather, typically ranging from full-grain to corrected grain. Full-grain leather is the highest quality, retaining the natural grain and durability. Buyers should prioritize higher grades for products requiring longevity and aesthetic appeal. Understanding these grades helps in selecting the right leather for specific applications, such as luxury goods versus budget items. -

Thickness and Weight

The thickness of leather is measured in ounces (oz) or millimeters (mm), influencing its strength and suitability for various projects. For example, heavier leather (8-10 oz) is ideal for belts and holsters, while lighter leather (2-4 oz) suits wallets and bags. Weight specifications are vital for calculating shipping costs and ensuring the selected leather meets project requirements. -

Tanning Method

Tanning methods, such as chrome tanning and vegetable tanning, significantly impact the leather’s properties. Chrome-tanned leather is more water-resistant and flexible, while vegetable-tanned leather is eco-friendly and ideal for tooling. Buyers must consider the tanning method based on the intended end-use and market preferences, especially in regions with specific environmental regulations. -

Finish Type

The finish applied to leather determines its appearance and performance characteristics. Common finishes include aniline, semi-aniline, and pigmented, each providing different levels of color saturation and protection. Understanding the finish type is essential for ensuring the leather meets aesthetic expectations and functional requirements, such as scratch resistance. -

Durability Ratings

Leather durability can be assessed through various tests, including abrasion resistance and tensile strength. These ratings help buyers evaluate how well the leather will perform under stress or wear. Choosing materials with appropriate durability ratings is crucial for products that will face heavy use, such as work gear or accessories. -

Colorfastness

This property indicates how well the dye adheres to the leather and resists fading over time. High colorfastness is critical for products exposed to sunlight or moisture. Buyers must ensure that the leather’s colorfastness meets their quality standards to avoid issues like discoloration in finished products.

What Common Trade Terms Should B2B Buyers Know in the Leather Industry?

Familiarity with industry jargon is essential for smooth transactions and effective negotiations. Here are some commonly used terms in the leather supply chain:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are sold under another company’s brand. In leather supply, an OEM may manufacture leather goods for various brands, allowing buyers to leverage established supply chains while maintaining brand integrity. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it influences purchasing decisions and inventory management. Understanding MOQ helps businesses balance demand with supply capabilities. -

RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit price quotes from suppliers for specific products or services. In leather sourcing, an RFQ should detail specifications such as material grade, thickness, and finish type, ensuring suppliers provide accurate pricing. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping and delivery. Familiarity with Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is essential for managing logistics and avoiding disputes in international transactions. -

Lead Time

Lead time refers to the period from placing an order to its delivery. Understanding lead times is critical for production planning and inventory management, allowing businesses to maintain optimal stock levels and fulfill customer demand efficiently. -

Certification Standards

Certification standards, such as ISO or Leather Working Group (LWG) certification, indicate compliance with quality and environmental standards. Buyers should prioritize suppliers with relevant certifications to ensure product quality and sustainability, especially in markets sensitive to ethical sourcing.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, optimize their supply chain processes, and foster stronger relationships with suppliers in the leather industry.

Navigating Market Dynamics and Sourcing Trends in the leather working supplies near me Sector

What Are the Current Market Dynamics and Key Trends in Leather Working Supplies?

The global leather working supplies market is experiencing a significant transformation driven by various factors, including technological advancements, changing consumer preferences, and economic shifts. One of the primary drivers is the increasing demand for custom and artisanal leather products, particularly in emerging markets like Africa and South America, where craftsmanship is gaining traction. B2B buyers in these regions are seeking high-quality, specialized tools and materials that cater to local artisans and small-scale manufacturers.

Emerging technologies such as e-commerce platforms and digital supply chain solutions are reshaping the sourcing landscape. B2B buyers can now access a wider range of suppliers and products with ease, allowing for more competitive pricing and better inventory management. Additionally, the rise of social media and online marketplaces has facilitated the sharing of ideas and techniques among leatherworkers, encouraging innovation and collaboration.

Sourcing trends are also leaning towards local suppliers as businesses aim to reduce lead times and shipping costs. This shift is particularly relevant for international buyers who are increasingly looking for suppliers that can meet their specific needs while maintaining quality. As a result, the market is witnessing a rise in partnerships and collaborations between local artisans and international brands, which can enhance product offerings and market reach.

Illustrative image related to leather working supplies near me

How Important Is Sustainability and Ethical Sourcing in the Leather Working Supplies Market?

Sustainability and ethical sourcing are becoming critical considerations for B2B buyers in the leather working supplies sector. The environmental impact of leather production, including deforestation and pollution from tanning processes, has prompted many companies to seek eco-friendly alternatives and practices. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainability through responsible sourcing, waste reduction, and the use of environmentally friendly materials.

The demand for “green” certifications, such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) certification, is on the rise. These certifications help buyers identify suppliers who adhere to stringent environmental and ethical standards, ensuring that the leather products they source are produced responsibly. Furthermore, many businesses are exploring alternative materials, such as plant-based leathers and recycled materials, which align with sustainable practices while catering to the growing consumer demand for eco-friendly products.

Incorporating sustainability into the supply chain is not just an ethical choice; it also enhances brand reputation and can lead to increased customer loyalty. As consumers become more conscious of the environmental impact of their purchases, B2B buyers who prioritize sustainability will likely gain a competitive edge in the market.

What Is the Brief Evolution and History of Leather Working Supplies?

The history of leather working supplies dates back thousands of years, with leather being one of the first materials used by humans for clothing, tools, and shelter. Traditionally, leather crafting was a localized skill, passed down through generations, and often involved natural tanning processes that were more sustainable than modern methods.

Illustrative image related to leather working supplies near me

As global trade expanded, so did the leather industry, leading to the establishment of specialized suppliers and manufacturers. The 20th century saw significant advancements in technology, including the introduction of synthetic materials, which began to compete with traditional leather. However, the artisanal movement of the late 20th and early 21st centuries revived interest in handcrafted leather goods, leading to a resurgence of demand for high-quality leather working supplies.

Today, the leather working supplies market is characterized by a blend of traditional craftsmanship and modern innovation. B2B buyers are not only looking for tools and materials that enhance their production capabilities but are also increasingly interested in sustainable practices and ethical sourcing. This evolution reflects a broader shift in consumer behavior towards more responsible and authentic products, positioning the leather working supplies sector at the intersection of tradition and modernity.

Frequently Asked Questions (FAQs) for B2B Buyers of leather working supplies near me

-

How do I solve supply chain issues when sourcing leather working supplies?

To address supply chain challenges, start by building relationships with multiple suppliers to diversify your sources. Investigate logistics options that align with your geographical needs, especially if you’re importing to regions like Africa or South America. Utilize technology for real-time tracking and inventory management. Always have a contingency plan for delays, and consider local regulations that may impact shipping times and costs. Establishing clear communication with suppliers can also mitigate misunderstandings and streamline operations. -

What is the best leather type for crafting durable products?

For durability in leather crafting, full-grain leather is often considered the best choice. It retains the natural grain and is less processed, making it stronger and more resistant to wear and tear. Vegetable-tanned leather is also an excellent option for projects requiring dyeing and tooling, as it allows for better absorption of dyes. When sourcing, consider the specific use case of your products to select the most suitable leather type, such as chrome-tanned for flexibility or suede for a softer finish. -

What factors should I consider when vetting leather suppliers?

When vetting suppliers, assess their reputation through reviews and referrals, especially from businesses in your region. Verify certifications and compliance with international quality standards to ensure consistency in product quality. Request samples to evaluate the leather’s texture, finish, and durability firsthand. Additionally, inquire about their sourcing practices to ensure ethical and sustainable procurement. It’s also essential to discuss their capacity to meet your order volumes and timelines to avoid future disruptions. -

What are the typical minimum order quantities (MOQs) for leather supplies?

Minimum order quantities for leather supplies can vary widely depending on the supplier and the type of leather. Generally, MOQs may range from 5 to 100 square feet for hides, while tools and accessories might have lower MOQs. If you are a smaller business, seek suppliers who are flexible with MOQs or those who offer bulk purchasing options that can lower costs. Always confirm these details upfront to avoid unexpected expenses or excess inventory. -

What payment terms are common in international leather supply transactions?

Common payment terms for international transactions include Letter of Credit (LC), advance payment, or net terms (such as net 30 or net 60 days). Establishing clear payment terms is crucial to mitigate risks associated with international trade. Depending on your relationship with the supplier, you might negotiate better terms based on your order volume. Always ensure that payment methods are secure, and consider using escrow services for high-value transactions to protect both parties. -

How can I customize leather products to meet my business needs?

Customization options for leather products often include selecting the type of leather, finishes, and sizes. Many suppliers offer services such as embossing, dyeing, and cutting to specific patterns. When discussing customization, be clear about your design specifications and order quantities, as this can influence pricing and lead times. It’s advisable to request prototypes or samples before placing a large order to ensure that the final product aligns with your expectations. -

What quality assurance (QA) measures should I implement when sourcing leather?

Implementing quality assurance measures involves setting clear specifications for leather quality, such as thickness, grain, and finish. Establish a process for inspecting materials upon arrival, including checking for defects or inconsistencies. Consider conducting regular audits of your suppliers to ensure they adhere to agreed-upon standards. Building a strong relationship with your suppliers can also facilitate better communication regarding quality issues, leading to timely resolutions. -

What logistics considerations should I keep in mind when importing leather supplies?

Logistics play a critical role in the timely delivery of leather supplies. Consider the shipping methods available, such as air freight for speed or sea freight for cost-effectiveness. Understand the customs regulations in your country to avoid delays, including any tariffs or import duties. Working with a logistics partner who specializes in international trade can streamline the process. Additionally, ensure that your suppliers have robust packaging to protect the leather during transit, minimizing the risk of damage.

Top 3 Leather Working Supplies Near Me Manufacturers & Suppliers List

1. Tandy Leather – Quality Leather Supplies

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Quality Leather Supplies, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Weaver Leather Supply – Leathercrafting Supplies

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Weaver Leather Supply offers a variety of leathercrafting and leatherworking supplies including different types of leather (ChahinLeather®, Hermann Oak® Veg Tan, Chrome Tanned, Water Buffalo Leather), leather cuts (double shoulders, backs, bends, panels, half sides, whole hides), textures (top grain, pebbled, smooth, pull-up, waxy, matte), and tools (cutting tools, hand stitching tools, leather to…

3. Hobby Lobby – Craft Supplies

Domain: hobbylobby.com

Registered: 1995 (30 years)

Introduction: Standard Style Alphabet Stamps – Price: $17.99

Black Poundo Board – Price: $8.99

Stitching Needles – Price: $1.49

Beeswax – Price: $2.49

Diamond Stitching Chisel – Price: $3.99

Edge Beveler – Size 3 – Price: $10.99

Beige Wood Slicker – Price: $0.99

Steel Square – Price: $1.99

Black Latigo Leather Lace – Price: $1.99

Reusable Glue Spreaders – Price: $1.99

Leather Skiving Tool – Price: $3.99

Bright …

Strategic Sourcing Conclusion and Outlook for leather working supplies near me

In the dynamic landscape of leather working supplies, strategic sourcing emerges as a pivotal strategy for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. Understanding local supplier capabilities, product quality, and logistics can significantly enhance operational efficiency and product offerings. By leveraging regional suppliers, businesses can not only mitigate costs but also ensure a steady supply chain that responds swiftly to market demands.

Illustrative image related to leather working supplies near me

Moreover, embracing innovation in sourcing—such as the integration of digital tools for procurement—can streamline processes and enhance collaboration with suppliers. This adaptability is essential in catering to the unique preferences and standards of various markets, from Nigeria’s artisanal leather goods to Brazil’s vibrant fashion accessories.

As you consider your sourcing strategy, prioritize building relationships with suppliers who align with your quality and ethical standards. The future of leather working supplies holds immense potential, and now is the time to capitalize on these opportunities. Engage with local and international suppliers to cultivate a network that supports your growth and success in the leather industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to leather working supplies near me

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.