Introduction: Navigating the Global Market for how to customize leather

In today’s competitive landscape, understanding how to customize leather is essential for B2B buyers looking to differentiate their products in the global market. Whether you are in Africa, South America, the Middle East, or Europe, the challenge remains the same: sourcing quality materials and techniques that meet specific design requirements while ensuring cost-effectiveness. This comprehensive guide addresses these challenges by exploring various customization techniques, including embossing, laser engraving, and carving, alongside their applications in different sectors such as fashion, automotive, and furniture.

By delving into supplier vetting processes and cost considerations, this guide empowers international B2B buyers to make informed purchasing decisions. We provide insights into the types of leather available, their suitability for different customization methods, and how to evaluate potential suppliers based on quality, pricing, and delivery capabilities. Additionally, our guide highlights emerging trends and innovative practices that can enhance your product offerings, ensuring you stay ahead of the competition.

Navigating the global market for leather customization doesn’t have to be daunting. With the right knowledge and resources, you can confidently choose materials and techniques that resonate with your brand and customer expectations, ultimately leading to greater business success.

Table Of Contents

- Top 3 How To Customize Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for how to customize leather

- Understanding how to customize leather Types and Variations

- Key Industrial Applications of how to customize leather

- 3 Common User Pain Points for ‘how to customize leather’ & Their Solutions

- Strategic Material Selection Guide for how to customize leather

- In-depth Look: Manufacturing Processes and Quality Assurance for how to customize leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to customize leather’

- Comprehensive Cost and Pricing Analysis for how to customize leather Sourcing

- Alternatives Analysis: Comparing how to customize leather With Other Solutions

- Essential Technical Properties and Trade Terminology for how to customize leather

- Navigating Market Dynamics and Sourcing Trends in the how to customize leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of how to customize leather

- Strategic Sourcing Conclusion and Outlook for how to customize leather

- Important Disclaimer & Terms of Use

Understanding how to customize leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Embossing | Creates raised designs on leather using heat or pressure | Custom gifts, branding, promotional items | Pros: Cost-effective, accessible for beginners. Cons: Limited detail compared to other methods. |

| Laser Engraving | Utilizes high-powered laser technology for intricate designs | High-end fashion, luxury goods, signage | Pros: Precision and detail, suitable for complex designs. Cons: High initial investment for equipment. |

| Carving | Involves cutting designs into leather for texture and depth | Artisan crafts, custom leather goods | Pros: Unique, artistic appeal. Cons: Time-consuming and requires skilled labor. |

| Perforation | Involves creating holes for decorative or functional purposes | Bags, wallets, fashion accessories | Pros: Versatile design options, can enhance functionality. Cons: Requires specialized tools and techniques. |

| Weaving | Uses strips of leather to create interwoven designs | Belts, bracelets, and decorative items | Pros: Unique aesthetic, customizable patterns. Cons: Labor-intensive, may require additional materials. |

What Are the Characteristics of Embossing in Leather Customization?

Embossing is a popular technique that creates raised designs on leather surfaces. This method is particularly favored for its accessibility, as it can be performed with simple tools like metal stamps and mallets, making it ideal for small businesses and artisans. It is commonly used for custom gifts, branding, and promotional items. When considering embossing, buyers should evaluate the complexity of their desired design, as this method is limited in detail compared to laser engraving. However, its cost-effectiveness makes it a great entry point for those new to leather customization.

How Does Laser Engraving Stand Out in Leather Customization?

Laser engraving employs advanced technology to etch intricate designs directly onto leather surfaces. This method is particularly advantageous for high-end fashion, luxury goods, and signage, where precision and detail are paramount. While it allows for complex designs that are difficult to achieve with manual methods, the initial investment in laser equipment can be substantial. Buyers interested in this technique should consider the long-term benefits of investing in high-quality machinery, as it can significantly enhance the product offerings and marketability of their leather goods.

Why Is Leather Carving Considered an Art Form?

Leather carving is a time-honored technique that involves cutting designs into the leather, providing depth and texture. This method is often used in artisan crafts and custom leather goods, appealing to consumers looking for unique, handcrafted items. While carving allows for a high degree of creativity and artistry, it is also labor-intensive and requires skilled artisans. Buyers should assess the availability of skilled labor and the time commitment involved in producing carved leather products, as these factors can influence production timelines and costs.

What Are the Benefits of Perforation in Leather Customization?

Perforation involves creating holes in leather for both decorative and functional purposes, offering a versatile design option for items such as bags, wallets, and fashion accessories. This technique can enhance the aesthetic appeal of a product while also contributing to its functionality, such as breathability or flexibility. Buyers should consider the tools required for perforation and the potential for creative designs when evaluating this method. While it can be labor-intensive, the unique patterns achieved through perforation can differentiate products in a competitive market.

How Does Weaving Contribute to Leather Customization?

Weaving involves using strips of leather to create interlaced designs, commonly seen in items like belts and bracelets. This technique allows for unique aesthetics and customizable patterns, appealing to consumers seeking personalized products. However, weaving can be labor-intensive and may require additional materials, which buyers should factor into their production costs. When considering weaving, businesses should evaluate their target market’s preferences for handcrafted, artisanal items, as this method can significantly enhance the perceived value of leather goods.

Key Industrial Applications of how to customize leather

| Industry/Sector | Specific Application of how to customize leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Customized leather garments and accessories | Enhances brand identity and customer loyalty through unique offerings | Source high-quality leather that meets international standards; consider local suppliers for sustainable options. |

| Automotive | Leather upholstery for vehicles | Increases vehicle value and customer satisfaction through premium customization | Ensure compliance with automotive industry standards; prioritize durability and colorfastness in materials. |

| Furniture & Interior Design | Bespoke leather furniture and decor items | Differentiates product line and attracts high-end clientele | Look for suppliers who offer a range of textures and finishes; consider customization capabilities for unique designs. |

| Sporting Goods | Personalized leather sports equipment | Boosts brand visibility and customer engagement through unique designs | Assess the durability of leather for high-use items; prioritize suppliers with a reputation for quality craftsmanship. |

| Gifts & Promotional Items | Customized leather gifts and corporate giveaways | Strengthens brand recall and customer relationships through personalized items | Evaluate suppliers based on their engraving and embossing capabilities; ensure timely delivery for promotional events. |

How is Customized Leather Used in the Fashion & Apparel Industry?

Customized leather is integral to the fashion industry, allowing brands to create unique garments and accessories that resonate with consumers. By offering personalized options, such as monograms or bespoke designs, businesses can enhance brand identity and foster customer loyalty. For international buyers, especially in regions like Africa and Europe, sourcing high-quality, ethically produced leather is crucial to meet both aesthetic and sustainability standards.

What Role Does Customized Leather Play in the Automotive Sector?

In the automotive industry, customized leather upholstery can significantly elevate the perceived value of vehicles. By offering bespoke interior designs, manufacturers can cater to luxury markets, thus enhancing customer satisfaction. Buyers should focus on sourcing materials that comply with stringent automotive standards, ensuring durability and colorfastness, particularly in harsh climates found in regions like the Middle East and Africa.

Why is Customized Leather Important for Furniture & Interior Design?

The furniture and interior design sector leverages customized leather to create bespoke items that stand out in a competitive market. This personalization allows businesses to attract high-end clientele seeking unique decor solutions. International buyers should prioritize suppliers who provide a diverse range of textures and finishes, ensuring that they can meet specific design requirements while maintaining quality.

How Does Customized Leather Enhance Sporting Goods?

Personalized leather sports equipment, such as gloves and bags, provides a unique selling proposition in the sporting goods sector. This customization boosts brand visibility and fosters a connection with customers who appreciate unique designs. For B2B buyers, assessing the durability and functionality of leather for high-use items is essential, with a focus on suppliers known for their craftsmanship and reliability.

What Benefits Do Customized Leather Gifts Offer for Businesses?

Customized leather gifts and promotional items are effective tools for strengthening brand recall and customer relationships. By offering personalized products, companies can create memorable experiences for clients and employees alike. International buyers should evaluate suppliers based on their engraving and embossing capabilities, ensuring that products are delivered on time for promotional events, which is particularly important in fast-paced markets across South America and Europe.

3 Common User Pain Points for ‘how to customize leather’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Leather Type for Customization

The Problem: One of the most significant challenges B2B buyers face when customizing leather is selecting the appropriate leather type for their specific application. With various options like full-grain, top-grain, and bonded leather available, it can be overwhelming to determine which type will provide the desired aesthetic and durability. Buyers may worry about the longevity of their products and whether the leather will hold up under usage conditions. This dilemma can lead to frustration and potentially costly mistakes if the wrong type is chosen for a particular project.

The Solution: To effectively navigate this challenge, B2B buyers should conduct thorough research on the characteristics of different leather types before making a purchase. For example, full-grain leather is renowned for its durability and unique patina, making it ideal for high-end products like luxury bags or furniture. Top-grain leather, being slightly less expensive and more uniform in appearance, is suitable for everyday items like wallets and belts. Buyers should also consider the intended use—items subjected to heavy wear should utilize more robust leathers. Additionally, establishing a relationship with reliable suppliers who can provide samples and guidance based on the specific needs of the business can help in making informed decisions.

Scenario 2: Mastering Customization Techniques without Expertise

The Problem: Many B2B buyers enter the leather customization field without a background in leathercraft, leading to uncertainty about which techniques to use for personalization. Whether they are looking to emboss logos, engrave names, or apply intricate designs, the lack of hands-on experience can result in poor-quality outcomes that don’t meet customer expectations. This skill gap can hinder businesses from fully leveraging the potential of customized leather products, ultimately affecting profitability and customer satisfaction.

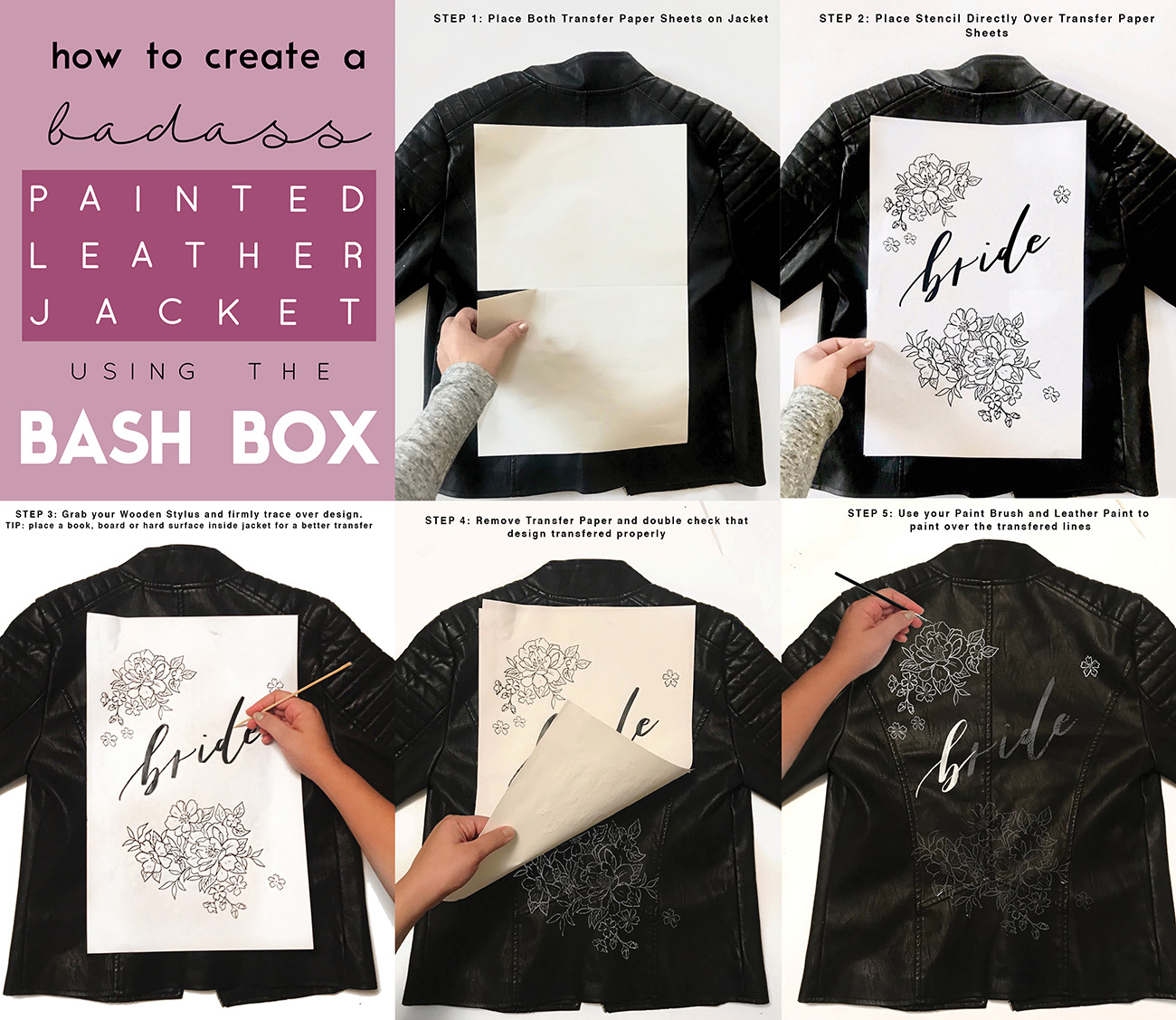

The Solution: To bridge the skill gap, companies should invest in training programs or workshops that focus on leather customization techniques. Collaborating with experienced leather artisans or enrolling in courses can provide invaluable insights and hands-on practice. Moreover, businesses can utilize online platforms that offer video tutorials and step-by-step guides tailored to various techniques such as embossing, carving, or laser engraving. For immediate results, companies may also consider partnering with specialized service providers who can handle the customization process until in-house expertise is developed. This approach not only ensures high-quality results but also allows businesses to focus on other critical aspects of their operations.

Scenario 3: Managing Production Costs for Customized Leather Items

The Problem: A frequent concern for B2B buyers is managing production costs while customizing leather goods. The process can often be perceived as expensive due to the costs associated with high-quality leather, specialized tools, and labor. Buyers may struggle to balance their budgets while ensuring the end product remains competitive in the market. This financial strain can lead to hesitancy in pursuing custom projects, which could otherwise differentiate their offerings.

The Solution: To effectively manage production costs, B2B buyers should adopt a strategic approach to sourcing materials and outsourcing processes. Establishing long-term relationships with leather suppliers can lead to bulk purchasing discounts, reducing material costs. Additionally, leveraging technology, such as laser engraving machines, can increase efficiency and reduce labor costs by automating parts of the customization process. Buyers should also analyze their pricing strategies, taking into account the value added by customization, and adjust their pricing models accordingly to ensure profitability. Finally, conducting a cost-benefit analysis for each customization project can help in making informed decisions about which customizations are worth the investment. By implementing these strategies, businesses can enhance their offerings while maintaining healthy profit margins.

Illustrative image related to how to customize leather

Strategic Material Selection Guide for how to customize leather

When considering the customization of leather, the selection of materials plays a crucial role in determining the quality and effectiveness of the final product. Below, we analyze four common materials used in leather customization, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Vegetable-Tanned Leather for Customization?

Vegetable-tanned leather is a popular choice for customization due to its natural tanning process, which uses tannins from plants. This method results in a material that is biodegradable and environmentally friendly. Key properties include excellent moisture absorption and breathability, making it suitable for various applications, including bags and wallets. However, it is sensitive to water and can darken over time.

Pros and Cons: The durability of vegetable-tanned leather is high, but it can be more expensive than chrome-tanned alternatives. The manufacturing complexity is moderate, as it requires skilled artisans for effective customization. This leather is ideal for high-end products but may not be suitable for mass production due to its cost.

Impact on Application: Vegetable-tanned leather is compatible with various customization techniques, including embossing and carving, making it versatile for personalized products.

Illustrative image related to how to customize leather

International Considerations: Buyers from regions like Africa and Europe may prefer this leather for its eco-friendliness. Compliance with standards such as REACH in Europe is essential, as many customers prioritize sustainable materials.

How Does Chrome-Tanned Leather Compare in Customization?

Chrome-tanned leather is another widely used material, known for its durability and resistance to water and stains. The tanning process involves chromium salts, which provide a soft texture and vibrant colors. Key properties include high resistance to wear and tear, making it ideal for items like shoes and jackets.

Pros and Cons: While chrome-tanned leather is more affordable and easier to work with, it lacks the same level of breathability as vegetable-tanned leather. The manufacturing complexity is lower, which can facilitate faster production times. However, it may not appeal to environmentally conscious consumers.

Impact on Application: This leather type is suitable for laser engraving and dyeing, allowing for intricate designs and colors. However, it may not hold up as well under heavy embossing.

International Considerations: Buyers from South America and the Middle East may find chrome-tanned leather appealing due to its cost-effectiveness. However, awareness of environmental regulations is crucial, as some markets are increasingly scrutinizing the use of chrome in leather production.

What Are the Benefits of Synthetic Leather in Customization?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), has gained popularity due to its affordability and versatility. Key properties include water resistance and ease of cleaning, making it suitable for various applications, including furniture and fashion accessories.

Illustrative image related to how to customize leather

Pros and Cons: Synthetic leather is lightweight and can mimic the appearance of genuine leather, but it lacks the durability and aging characteristics of natural leather. The manufacturing complexity is relatively low, allowing for mass production. However, it may not provide the same premium feel that consumers expect from leather products.

Impact on Application: Synthetic leather is compatible with various customization methods, including printing and embossing, but it may not hold intricate designs as well as natural leather.

International Considerations: Buyers in Germany and other European countries may prefer synthetic options for their cost-effectiveness. However, compliance with regulations regarding the use of harmful chemicals in synthetic materials is essential.

How Does Suede Leather Enhance Customization Options?

Suede leather, characterized by its soft, napped finish, is made from the underside of animal hides. Key properties include a luxurious feel and aesthetic appeal, making it popular for high-end fashion items. However, it is less durable and more prone to staining than other leather types.

Pros and Cons: Suede offers a unique texture that can elevate the look of customized products, but its maintenance requirements are high. The manufacturing complexity can be significant, as it requires careful handling to avoid damage during customization.

Impact on Application: Suede is best suited for embossing and laser engraving, but its delicate nature limits its use in high-wear items.

International Considerations: Buyers from Africa may appreciate the unique look of suede, but they should consider the climate and potential for staining. Compliance with animal welfare standards is also a factor in various regions.

Illustrative image related to how to customize leather

Summary Table

| Materiał | Typical Use Case for how to customize leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | High-end bags, wallets, and belts | Eco-friendly and customizable | Sensitive to water and higher cost | High |

| Chrome-Tanned Leather | Shoes, jackets, and accessories | Durable and cost-effective | Less breathable and eco-concerns | Medium |

| Synthetic Leather | Furniture and fashion accessories | Affordable and easy to clean | Lacks premium feel and durability | Low |

| Suede Leather | Fashion items and luxury goods | Luxurious texture and appearance | High maintenance and less durable | Medium |

This analysis provides valuable insights for B2B buyers looking to customize leather, enabling informed decisions based on material properties and market considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for how to customize leather

What Are the Main Stages of Manufacturing Leather Customization?

The customization of leather involves a series of well-defined manufacturing processes that ensure the material not only meets aesthetic demands but also adheres to quality standards. Understanding these stages is crucial for B2B buyers who wish to invest in customized leather products.

How Is Material Prepared for Leather Customization?

The first stage of leather customization begins with material preparation, where the type of leather is selected based on its intended use and customization techniques. Vegetable-tanned leather is often favored for its ability to hold designs better during embossing and carving.

-

Selection: Choose high-quality leather that aligns with your product specifications. Common types include full-grain, top-grain, and corrected leather, each offering different textures and durability.

-

Conditioning: The leather may undergo conditioning to enhance its pliability. This process often involves soaking in water to reach an optimal moisture content, which is crucial for techniques like embossing and carving.

-

Cutting: The leather is then cut into the desired shapes using die-cutting machines or hand tools. Precision in cutting is vital to minimize waste and ensure uniformity in the final product.

What Forming Techniques Are Used in Leather Customization?

Once the leather is prepared, the next step involves various forming techniques that bring designs to life.

Illustrative image related to how to customize leather

How Is Embossing Executed in Leather Customization?

Embossing is a widely used technique that involves creating raised designs on the leather surface. This can be achieved using metal stamps and a mallet or a hydraulic press for higher volume production.

-

Process: The leather is moistened to prevent cracking, and the stamp is aligned on the desired area. A firm strike with a mallet or press ensures a clear impression.

-

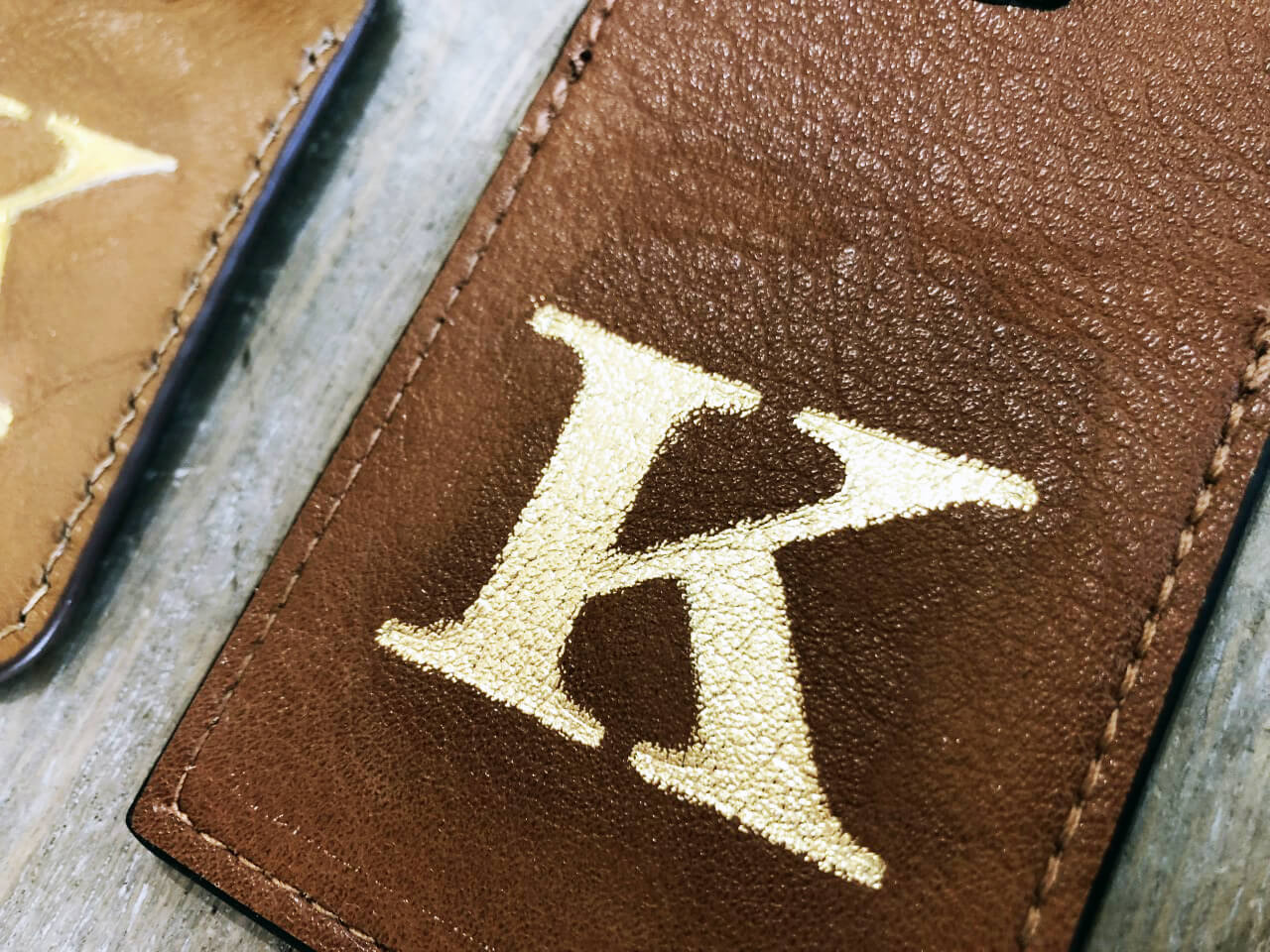

Finishing Touches: For added luxury, foil stamping can be integrated, where metallic foils are applied during the embossing process.

What Role Does Laser Engraving Play in Customization?

Laser engraving is an advanced method that uses high-powered lasers to etch intricate designs into the leather.

-

Precision: This technique allows for high precision and the ability to reproduce complex patterns consistently, making it ideal for custom logos or detailed images.

-

Material Compatibility: Various leather types can be laser-engraved, including full grain and bonded leather. The choice of leather impacts the final appearance of the engraving.

How Is Assembly Conducted in Leather Customization?

The assembly stage involves stitching and joining various leather pieces to create the final product.

-

Techniques: Hand-stitching and machine sewing are common methods, with the choice depending on the complexity of the item. Hand-stitching offers a unique, artisanal quality, while machine sewing ensures speed and uniformity.

-

Quality Control: During assembly, constant checks for alignment and stitching integrity are crucial to ensure that the final product meets quality expectations.

What Finishing Processes Are Important in Leather Customization?

Finishing processes enhance the durability and aesthetic appeal of the leather product.

-

Dyeing: Leather can be dyed post-assembly to achieve specific colors. Aniline and semi-aniline dyes are popular for their ability to maintain the natural look of the leather.

-

Sealing: A protective sealant may be applied to enhance water resistance and durability, ensuring the product withstands wear and tear.

What Quality Assurance Standards Should B2B Buyers Be Aware Of?

Quality assurance is an essential aspect of leather customization, ensuring that products meet international standards and buyer specifications.

Illustrative image related to how to customize leather

Which International Standards Are Relevant for Leather Customization?

Adhering to international standards such as ISO 9001 is critical for manufacturers aiming to assure quality and consistency. This standard focuses on quality management systems and is applicable to any organization, including leather manufacturers.

-

CE Marking: For products sold within the European market, CE marking indicates compliance with safety, health, and environmental protection standards.

-

API Standards: In specific industries, such as automotive or aerospace, adhering to API standards may be necessary for leather products used in those applications.

How Are Quality Control Checkpoints Structured in Leather Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process to ensure product integrity.

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials before they enter production. This step helps identify any defects in leather that could affect the final product.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular inspections are conducted to verify that processes adhere to specifications and standards.

-

Final Quality Control (FQC): The final product undergoes a thorough inspection to ensure it meets all quality standards before shipping.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential.

-

Supplier Audits: Conducting regular audits of suppliers can help ensure compliance with quality standards. This may include reviewing their manufacturing processes, quality assurance protocols, and certifications.

-

Quality Reports: Requesting detailed quality reports and documentation from suppliers can provide insights into their quality management practices.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing processes and the quality of the finished products.

What Are the Unique Quality Control Nuances for International B2B Buyers?

Different regions may have unique requirements for quality control. For example, buyers from Europe may prioritize CE compliance, while those from the Middle East may focus on specific local standards. Understanding these nuances can help buyers make informed decisions and select the right suppliers.

-

Cultural Considerations: Different countries may have varying expectations regarding quality and craftsmanship. Engaging local representatives or consultants can help bridge these gaps.

-

Regulatory Compliance: Ensure that your suppliers are compliant with local regulations regarding leather production, which can vary significantly across regions.

By understanding the manufacturing processes and quality assurance protocols involved in leather customization, B2B buyers can make informed decisions that lead to successful partnerships and high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to customize leather’

Wprowadzenie

This practical guide serves as a step-by-step checklist for B2B buyers interested in sourcing leather customization services. Whether you’re in Africa, South America, the Middle East, or Europe, understanding the nuances of customizing leather is essential for creating unique products that resonate with your target market. This checklist will help streamline your procurement process, ensuring that you select the right suppliers and customization techniques to meet your business needs.

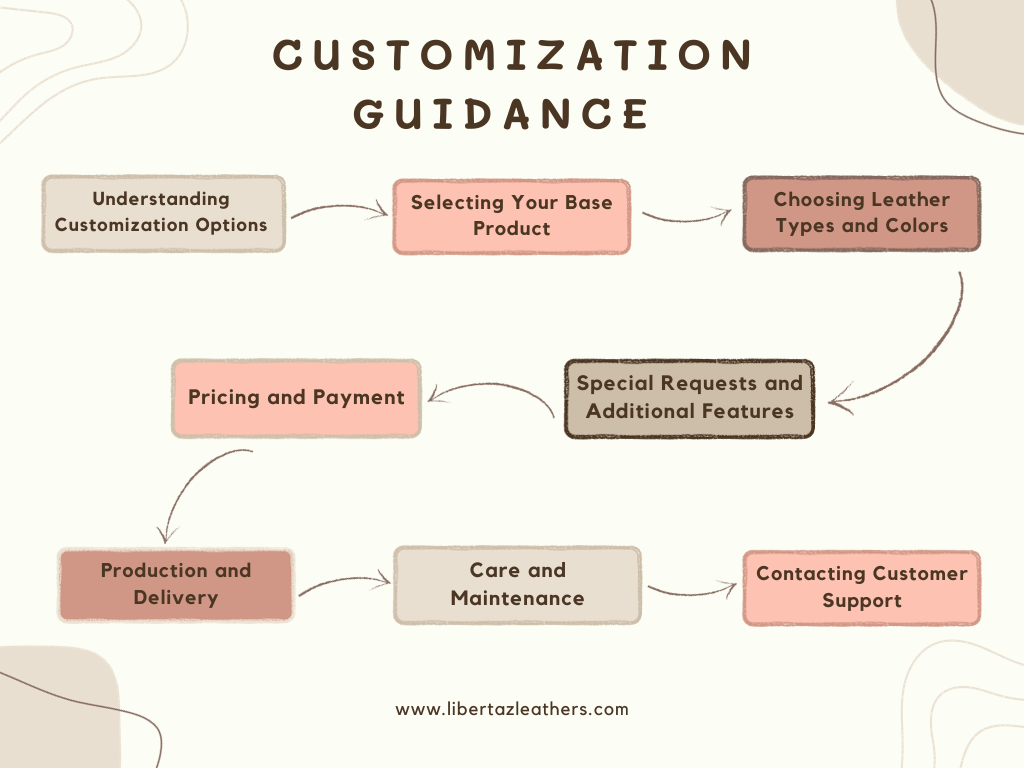

Step 1: Identify Your Customization Needs

Understanding your specific requirements is the first step in the sourcing process. Consider the types of leather products you wish to customize—be it bags, belts, or apparel—and the level of personalization required, such as engraving or embossing. This clarity will guide your discussions with suppliers and help you assess their capabilities.

Illustrative image related to how to customize leather

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in leather customization. Look for companies with a proven track record in your industry and region. Pay attention to their portfolios and client testimonials to gauge the quality of their work and reliability.

- Focus on Experience: Suppliers with years of experience are more likely to understand the intricacies of leather customization.

- Industry Specialization: Select suppliers that have expertise in your specific type of leather product to ensure they meet your quality standards.

Step 3: Evaluate Customization Techniques Offered

Different suppliers may offer various customization methods, such as embossing, laser engraving, or carving. Evaluate these techniques based on your design requirements and the aesthetic you wish to achieve.

- Technique Suitability: Ensure the techniques align with the type of leather you are using and the final look you want.

- Capability for Complexity: If your designs are intricate, confirm that the supplier can handle detailed work, particularly with laser engraving.

Step 4: Request Samples

Before making a commitment, request samples of customized leather products. This step is crucial for assessing the quality of craftsmanship and the accuracy of the designs.

- Quality Check: Examine the durability and finish of the samples.

- Design Accuracy: Ensure that the customization meets your specifications and expectations.

Step 5: Verify Compliance and Certifications

It’s essential to confirm that potential suppliers comply with industry standards and regulations, particularly regarding environmental practices and material sourcing.

- Certifications to Look For: ISO certifications, environmental compliance, and ethical sourcing certifications can indicate a supplier’s commitment to quality and sustainability.

- Transparency: Suppliers should be willing to provide documentation that proves their compliance.

Step 6: Negotiate Terms and Conditions

Once you have selected a potential supplier, negotiate terms that align with your business goals. Discuss pricing, lead times, and payment terms to ensure clarity.

Illustrative image related to how to customize leather

- Flexibility: Ensure that the supplier can accommodate your timelines and order sizes.

- Long-term Relationships: Consider establishing terms that foster a long-term partnership, which can lead to better rates and priority service in the future.

Step 7: Finalize Your Order

After all terms are agreed upon, place your order with clear specifications. Document everything to avoid misunderstandings in the production process.

- Confirm Specifications: Double-check that all customization details are accurately documented.

- Establish Communication: Maintain open lines of communication with the supplier throughout the production phase for updates and potential adjustments.

By following this checklist, B2B buyers can effectively navigate the leather customization landscape, ensuring high-quality results that meet their unique business needs.

Comprehensive Cost and Pricing Analysis for how to customize leather Sourcing

What Are the Key Cost Components for Customizing Leather Sourcing?

When sourcing customized leather, understanding the cost structure is crucial for B2B buyers aiming for profitability and quality. The primary cost components include:

-

Materials: The type of leather used significantly impacts costs. Vegetable-tanned leather, for instance, is often preferred for its workability and aesthetic appeal but may be more expensive than synthetic alternatives. Additionally, the thickness and quality of the leather can also influence pricing.

-

Labor: Labor costs vary based on the complexity of customization techniques, such as embossing, carving, or laser engraving. Skilled artisans command higher wages, especially for intricate designs. For mass production, consider the cost of skilled versus unskilled labor, as this can affect your overall pricing.

-

Manufacturing Overhead: This includes operational expenses such as utilities, rent, and general administrative costs. These costs are often distributed across all products, so efficient production processes can help lower the overhead allocated to each piece.

-

Tooling: Custom molds and stamps for embossing or engraving represent a significant upfront investment. The cost can vary based on the complexity of the design and the materials used for the tools.

-

Quality Control (QC): Ensuring that each piece meets quality standards incurs additional costs. This may involve inspections and testing, especially when dealing with international suppliers who may have different quality benchmarks.

-

Logistics: Shipping and handling costs, particularly for international transactions, can vary widely. Factors like distance, mode of transport, and Incoterms play critical roles in determining these costs.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the market rate for similar products can help in negotiating better deals.

How Do Price Influencers Impact Custom Leather Sourcing?

Several factors can influence the pricing of customized leather, particularly for international buyers:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can affect pricing. Larger orders often lead to lower unit costs due to economies of scale, while smaller orders may attract higher prices.

-

Specifications and Customization: The more intricate the design and higher the specifications (e.g., eco-friendly materials, specific certifications), the higher the price. Customization often requires additional labor and tooling, adding to the cost.

-

Quality and Certifications: Certifications for sustainability or quality can impact pricing. Buyers should weigh the benefits of sourcing certified leather against potential cost increases.

-

Supplier Factors: The reputation and reliability of suppliers can significantly affect pricing. Established suppliers may charge more due to their quality assurance processes and customer service.

-

Incoterms: Understanding shipping terms (such as FOB, CIF, etc.) is crucial for international buyers. These terms dictate who is responsible for costs at various stages of shipping, impacting the total cost of ownership.

What Buyer Tips Can Enhance Cost-Efficiency in Leather Customization?

International B2B buyers should consider the following strategies to maximize cost-efficiency:

-

Negotiation: Engage in negotiations with suppliers to achieve favorable terms, especially for larger orders. Build relationships with suppliers to facilitate better deals in the future.

-

Total Cost of Ownership (TCO): Evaluate the total cost, including shipping, customs duties, and any potential tariffs. This comprehensive view helps avoid surprises that could erode profit margins.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and how they can affect pricing. Consider hedging strategies if purchasing in foreign currencies.

-

Bulk Purchasing: If possible, consolidate orders to meet MOQs, thus reducing per-unit costs.

-

Quality vs. Cost: Balance the desire for cost savings with the need for quality. Sometimes, opting for a slightly more expensive supplier can result in better quality and lower TCO in the long run.

Conclusion

Understanding the cost structure and pricing influencers in the customized leather sourcing process is essential for B2B buyers. By evaluating all components and employing strategic negotiation techniques, businesses can optimize their sourcing decisions, ensuring both quality and profitability in their leather products.

Alternatives Analysis: Comparing how to customize leather With Other Solutions

The customization of leather products has become increasingly popular, offering businesses a unique way to differentiate their offerings in the market. However, various methods exist for personalizing leather, each with its own strengths and weaknesses. This analysis compares traditional leather customization techniques with alternative solutions that can also achieve similar personalization goals.

| Comparison Aspect | How To Customize Leather | Alternative 1: Digital Printing | Alternative 2: Vinyl Transfers |

|---|---|---|---|

| Performance | High-quality, durable designs | Good quality, but may fade over time | Excellent for vibrant colors and details |

| Cost | Moderate to high (depending on technique) | Lower initial investment | Low to moderate, depending on scale |

| Ease of Implementation | Requires skill and practice | Easy to implement, minimal training needed | Simple to apply with heat press |

| Maintenance | Requires care to maintain quality | Generally low maintenance | Low maintenance, but durability varies |

| Best Use Case | High-end, bespoke leather goods | Custom promotional items, apparel | Fast production of custom designs on various surfaces |

What Are the Pros and Cons of Digital Printing on Leather?

Digital printing has emerged as a versatile alternative for customizing leather. This method involves using specialized printers to apply designs directly onto the leather surface.

Pros: Digital printing allows for intricate designs and full-color images without the need for physical stencils or molds. It also enables quick production runs, making it ideal for businesses looking to offer customized products in smaller batches.

Cons: However, the durability of digital prints can be a concern. Over time, prints may fade or wear off, particularly in high-friction areas. Additionally, the initial investment in high-quality digital printing equipment can be significant, though it may be offset by lower labor costs.

How Do Vinyl Transfers Compare in Customization of Leather?

Vinyl transfers involve cutting designs from colored vinyl and then applying them to leather using heat. This method is often used for creating logos or simple designs.

Pros: Vinyl transfers are cost-effective and easy to implement, requiring minimal training for staff. They offer vibrant colors and can produce detailed designs quickly, making them suitable for promotional items or merchandise.

Cons: On the downside, vinyl can be less durable than traditional leather customization techniques. It may peel or crack over time, especially if subjected to frequent wear. This method is best suited for low-cost items or short-term promotional products rather than high-end leather goods.

Illustrative image related to how to customize leather

How Can B2B Buyers Choose the Right Customization Solution?

When selecting a customization method, B2B buyers should consider their specific needs, including budget, product type, and desired durability. For high-end leather goods that require longevity and a premium feel, traditional methods like embossing or laser engraving may be more appropriate. In contrast, for promotional items or quick production runs, digital printing or vinyl transfers might be the better choice. Ultimately, understanding the strengths and limitations of each method will empower buyers to make informed decisions that align with their business goals and customer expectations.

Essential Technical Properties and Trade Terminology for how to customize leather

What Are the Key Technical Properties of Leather Customization?

When customizing leather, understanding its critical technical properties is essential for ensuring quality and meeting production standards. Here are some vital specifications that B2B buyers should consider:

1. Material Grade

Material grade refers to the classification of leather based on its quality and finish. The main categories include full grain, top grain, genuine leather, and bonded leather. Each grade has distinct characteristics that affect durability, appearance, and suitability for various applications. For instance, full grain leather is the highest quality and most durable, making it ideal for luxury goods. Understanding these grades helps buyers select the right material for their specific needs, influencing both product quality and customer satisfaction.

2. Tolerance

Tolerance defines the acceptable variation in measurements during leather production and customization. It is crucial in ensuring that pieces fit together correctly and maintain consistent quality. For example, a tolerance of ±1 mm might be acceptable for some leather goods but not for high-precision items like watch straps. Buyers should be aware of tolerance specifications to avoid costly errors in production and ensure product integrity.

3. Thickness

Thickness is a key property that affects the leather’s durability, flexibility, and suitability for different applications. Measured in millimeters or ounces, leather thickness can range from very thin (for garments) to thick (for belts and bags). Understanding the required thickness for specific products helps businesses source the right materials and avoid issues such as stiffness or lack of support.

Illustrative image related to how to customize leather

4. Finish Type

The finish type refers to the surface treatment applied to leather, which can affect its appearance, texture, and resistance to wear and moisture. Common finishes include aniline, semi-aniline, and pigmented. Each finish has its benefits and drawbacks, impacting the leather’s aesthetics and functionality. Buyers must consider the end-use of the leather products to select the most appropriate finish.

5. Grain Pattern

Grain pattern is the natural texture of the leather surface, which can be enhanced through various treatments. Different grain patterns can affect how leather accepts dyes, engravings, and embossing. For custom designs, understanding the grain pattern helps in achieving desired aesthetic outcomes and ensuring that any personalization methods will be effective.

What Are Common Trade Terms in Leather Customization?

Navigating the leather customization market involves familiarizing oneself with industry jargon. Here are several key terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In leather customization, an OEM might create leather goods based on designs provided by another brand. This term is essential for buyers looking to partner with manufacturers who can produce high-quality products tailored to specific designs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for buyers as it impacts inventory management and production planning. For instance, if a leather manufacturer has an MOQ of 100 units, businesses must determine if they can sell that amount before committing to an order.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. In leather customization, buyers often use RFQs to compare prices and terms from different manufacturers. This process is crucial for budget planning and ensuring competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. They specify who is responsible for shipping, insurance, and tariffs, influencing the total cost of leather products. Familiarity with Incoterms helps buyers navigate international trade complexities and avoid misunderstandings.

5. Customization Options

Customization options refer to the various ways in which leather products can be altered to meet specific customer requirements. This may include embossing, engraving, dyeing, and cutting techniques. Understanding available customization options allows buyers to offer unique products that cater to market demands, enhancing competitiveness.

Illustrative image related to how to customize leather

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, optimize their supply chain, and ensure the successful customization of leather products.

Navigating Market Dynamics and Sourcing Trends in the how to customize leather Sector

What Are the Key Market Drivers and Trends in the Leather Customization Sector?

The global leather customization market is experiencing dynamic growth, driven by several factors. First, there is an increasing consumer demand for personalized products that reflect individuality. This trend is particularly strong in regions like Africa, South America, the Middle East, and Europe, where cultural diversity fuels the desire for unique leather goods. Additionally, the rise of e-commerce platforms has facilitated easier access for B2B buyers to source customizable leather products, enhancing market reach.

Emerging technologies are significantly influencing the customization landscape. Laser engraving, for instance, allows for intricate designs and rapid production, appealing to businesses looking to offer high-quality, customized leather products. Furthermore, automation and artificial intelligence are streamlining supply chains, reducing lead times and costs. For international buyers, understanding these technological advancements is crucial for staying competitive.

Another key trend is the shift towards sustainable practices. Buyers are increasingly prioritizing suppliers who demonstrate commitment to ethical sourcing and environmentally friendly production methods. This trend is particularly evident in Europe, where regulations surrounding sustainability are becoming more stringent. By aligning with these trends, B2B buyers can tap into new market opportunities while addressing the evolving preferences of consumers.

Illustrative image related to how to customize leather

How Important is Sustainability and Ethical Sourcing in the Leather Customization Market?

As the leather industry grapples with its environmental impact, sustainability and ethical sourcing have become paramount concerns for B2B buyers. Traditional leather tanning processes often involve harmful chemicals that pose risks to both the environment and human health. This reality has spurred demand for more sustainable alternatives, such as vegetable-tanned leather, which minimizes chemical use and environmental harm.

Ethical supply chains are also critical, particularly in regions where labor practices may be scrutinized. Buyers are increasingly seeking suppliers who can provide transparency in their sourcing practices, ensuring fair treatment of workers and adherence to labor laws. Certifications such as the Global Organic Textile Standard (GOTS) and Leather Working Group (LWG) certification are becoming essential for businesses looking to demonstrate their commitment to sustainability.

Moreover, incorporating ‘green’ materials into leather customization processes not only enhances brand reputation but also attracts environmentally conscious consumers. By prioritizing sustainability, B2B buyers can position themselves as leaders in ethical business practices, appealing to a growing segment of the market that values responsibility alongside quality.

What Is the Historical Context of Leather Customization in the B2B Sector?

The customization of leather has a rich history that dates back centuries, with roots in artisanal craftsmanship. Traditionally, leather was tailored for specific needs, whether for clothing, armor, or tools, often reflecting the cultural and social contexts of the time. As industrialization progressed in the 19th century, mass production began to dominate, diminishing the prominence of handcrafted leather goods.

Illustrative image related to how to customize leather

However, the late 20th century saw a resurgence of interest in personalized and bespoke leather products, driven by consumer desire for uniqueness and quality. This evolution has continued into the 21st century, where advancements in technology now enable rapid customization and mass personalization on a larger scale. Today, B2B buyers can leverage this historical context to understand market dynamics and consumer preferences, helping them make informed sourcing decisions in the leather customization sector.

Frequently Asked Questions (FAQs) for B2B Buyers of how to customize leather

-

How do I choose the right leather for customization?

Choosing the right leather for customization depends on the intended use and desired finish. Full-grain leather is ideal for high-end products due to its durability and natural aesthetics. Top-grain leather is slightly more affordable and offers a smooth surface for engraving. For projects requiring intricate designs, vegetable-tanned leather is recommended, as it absorbs dyes and allows for precise detailing. When sourcing, consider factors like texture, thickness, and color to ensure it aligns with your brand’s vision. -

What techniques are available for customizing leather?

There are several techniques for customizing leather, including embossing, laser engraving, carving, and weaving. Embossing involves pressing designs into the leather, while laser engraving uses a laser to etch intricate patterns. Carving is a more traditional method that allows for detailed artistry. Weaving can create unique textures and patterns. The choice of technique should align with your product’s aesthetic and functionality, as well as your production capabilities. -

What is the minimum order quantity (MOQ) for customized leather products?

The minimum order quantity (MOQ) for customized leather products varies by supplier. Generally, MOQs can range from 50 to 500 units, depending on the complexity of the customization and the supplier’s production capacity. It’s essential to discuss your specific needs with potential suppliers to negotiate favorable terms. Lower MOQs may be available for simpler designs or less intricate techniques, allowing for greater flexibility in initial orders. -

How can I ensure quality assurance for customized leather products?

To ensure quality assurance for customized leather products, establish clear specifications and standards with your supplier. Request samples before placing large orders to evaluate the material, craftsmanship, and customization techniques. Consider implementing quality control checks throughout the production process, including inspections at various stages. Additionally, working with suppliers who have relevant certifications or quality management systems can provide further assurance of product quality. -

What payment terms are typically offered for customized leather orders?

Payment terms for customized leather orders can vary significantly among suppliers. Common arrangements include a deposit upon order confirmation, with the balance due prior to shipping. Some suppliers may offer net payment terms, allowing for payment within a specified period after delivery. It’s important to negotiate terms that align with your cash flow and establish a clear agreement in writing to avoid any misunderstandings. -

How do I vet suppliers for customized leather products?

Vetting suppliers involves researching their reputation, production capabilities, and experience in the leather industry. Start by checking online reviews and testimonials from previous clients. Request references and inquire about their experience with similar projects. Additionally, assess their communication responsiveness and willingness to collaborate on your customization needs. If possible, visit their facilities to gain firsthand insight into their operations and quality control practices. -

What logistics considerations should I keep in mind when sourcing customized leather?

When sourcing customized leather, consider logistics factors such as shipping costs, delivery timelines, and customs regulations. Ensure that your supplier can accommodate your preferred shipping methods and timelines, especially if you’re operating in different regions, like Africa or Europe. Familiarize yourself with import duties and taxes for your destination country to avoid unexpected costs. Establishing a reliable logistics partner can streamline the import process and enhance overall efficiency. -

How can I handle disputes or issues with suppliers?

To handle disputes or issues with suppliers effectively, maintain open communication and document all interactions. Address concerns promptly and professionally, seeking to understand the supplier’s perspective. If necessary, refer to the terms of your contract to resolve conflicts. Consider mediation or arbitration as a means of resolving disputes amicably. Building a strong relationship with your supplier can also help in addressing issues collaboratively, minimizing potential conflicts in the future.

Top 3 How To Customize Leather Manufacturers & Suppliers List

1. Reddit – Leather Jacket Customization Tips

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: First-time customizing a leather jacket; planning to pick up two secondhand jackets from a charity store. One jacket to be painted as a gift with small designs and emblems; the second jacket to be recolored dark red. Seeking advice on paints/materials for detailing, possibility of painting a black jacket red, and general project tips. Recommended materials include saddle soap, Fiebings products, a…

2. Jennifer Maker – DIY Leather Journal

Domain: jennifermaker.com

Registered: 2017 (8 years)

Introduction: DIY leather journal made with genuine leather and jute twine, holds up to 50 sheets of 4″ x 6.5″ paper, customizable with initials, uses Cricut Maker 3 or original Maker, requires foil transfer tool, medium tip, fine debossing tip, deep cut housing and blade, includes tools like painter’s tape, TrueControl Knife, self-healing mat, ruler, scraper, and purple StrongGrip Machine Mat.

3. LaserPecker – Smart Laser Solutions

Domain: laserpecker.net

Registered: 2019 (6 years)

Introduction: LaserPecker LP5 Smart 20W Dual Laser, LaserPecker LP4 World’s First Dual Laser, LaserPecker LP3 Metal & Plastic, LaserPecker LP2 Portable and Handheld, LaserPecker LP1 Pro Pocket Diode Laser, LX2 The All-in-One Laser Cutter, LP2 Plus Desktop Laser Engraver & Cutter. Accessories include Safety Enclosure, Slide Extension, Rotary Extension, PowerPack Plus, Bluetooth Dongle. Software includes LDS Soft…

Strategic Sourcing Conclusion and Outlook for how to customize leather

In the evolving landscape of leather customization, strategic sourcing remains a crucial element for international B2B buyers. By leveraging diverse techniques such as embossing, laser engraving, and carving, businesses can create unique products that resonate with their clientele. Understanding the nuances of each method not only enhances the aesthetic appeal of leather goods but also allows for the personalization that modern consumers increasingly demand.

Investing in high-quality materials, such as vegetable-tanned leather, and selecting the right machinery or tools can streamline production and ensure durability. Buyers from regions like Africa, South America, the Middle East, and Europe should consider establishing partnerships with reputable suppliers to gain access to innovative technologies and skilled artisans.

As the market for customized leather continues to grow, now is the time to act. Explore opportunities to enhance your product offerings and differentiate your brand through personalized leather solutions. Engage with suppliers who understand your market needs and can provide tailored solutions that elevate your business. The future of leather customization is bright—embrace it and lead the charge in delivering exceptional, personalized leather products to your customers.

Illustrative image related to how to customize leather

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to how to customize leather