Introduction: Navigating the Global Market for custom leather patches no minimum

In today’s competitive landscape, sourcing custom leather patches with no minimum order requirements poses a unique challenge for international B2B buyers. Whether you represent a fashion brand in Europe, an outdoor gear company in South America, or a promotional merchandise provider in Africa, the need for flexibility in order sizes can significantly impact your branding and marketing strategies. This guide aims to simplify your journey through the global market for custom leather patches, addressing various types, applications, and the nuances of supplier vetting.

From high-quality laser-engraved patches to versatile adhesive options, understanding the breadth of products available is crucial for making informed purchasing decisions. We will explore the materials used, customization options, and pricing structures, ensuring you have a comprehensive understanding of what to expect from suppliers. Additionally, this guide offers insights into the importance of sustainability in material sourcing, particularly for buyers in regions like the Middle East and Africa, where eco-conscious practices are increasingly valued.

By the end of this guide, you will be equipped with the knowledge to navigate the complexities of sourcing custom leather patches, empowering you to make decisions that align with your brand’s identity and operational needs. Whether you’re looking to enhance your product line or create unique promotional items, our insights will help you find the right partners to achieve your goals.

Table Of Contents

- Top 9 Custom Leather Patches No Minimum Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather patches no minimum

- Understanding custom leather patches no minimum Types and Variations

- Key Industrial Applications of custom leather patches no minimum

- 3 Common User Pain Points for ‘custom leather patches no minimum’ & Their Solutions

- Strategic Material Selection Guide for custom leather patches no minimum

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather patches no minimum

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather patches no minimum’

- Comprehensive Cost and Pricing Analysis for custom leather patches no minimum Sourcing

- Alternatives Analysis: Comparing custom leather patches no minimum With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather patches no minimum

- Navigating Market Dynamics and Sourcing Trends in the custom leather patches no minimum Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather patches no minimum

- Strategic Sourcing Conclusion and Outlook for custom leather patches no minimum

- Important Disclaimer & Terms of Use

Understanding custom leather patches no minimum Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Laser Engraved Leather Patches | High-detail engraving, customizable shapes, durable finish | Apparel branding, promotional items, gifts | Pros: Elegant look, long-lasting; Cons: Higher setup cost. |

| Iron-On Leather Patches | Heat-activated backing for easy application | Custom merchandise, events, personal gifts | Pros: Quick application, no sewing required; Cons: Heat-sensitive leather may warp. |

| Sew-On Leather Patches | Traditional attachment method, available in various sizes and shapes | Uniforms, jackets, bags, and outdoor gear | Pros: Strong attachment, versatile; Cons: Requires sewing skills. |

| Faux Leather Patches | Eco-friendly alternative, available in various colors and textures | Fashion brands, promotional giveaways | Pros: Cost-effective, vegan option; Cons: Less durable than genuine leather. |

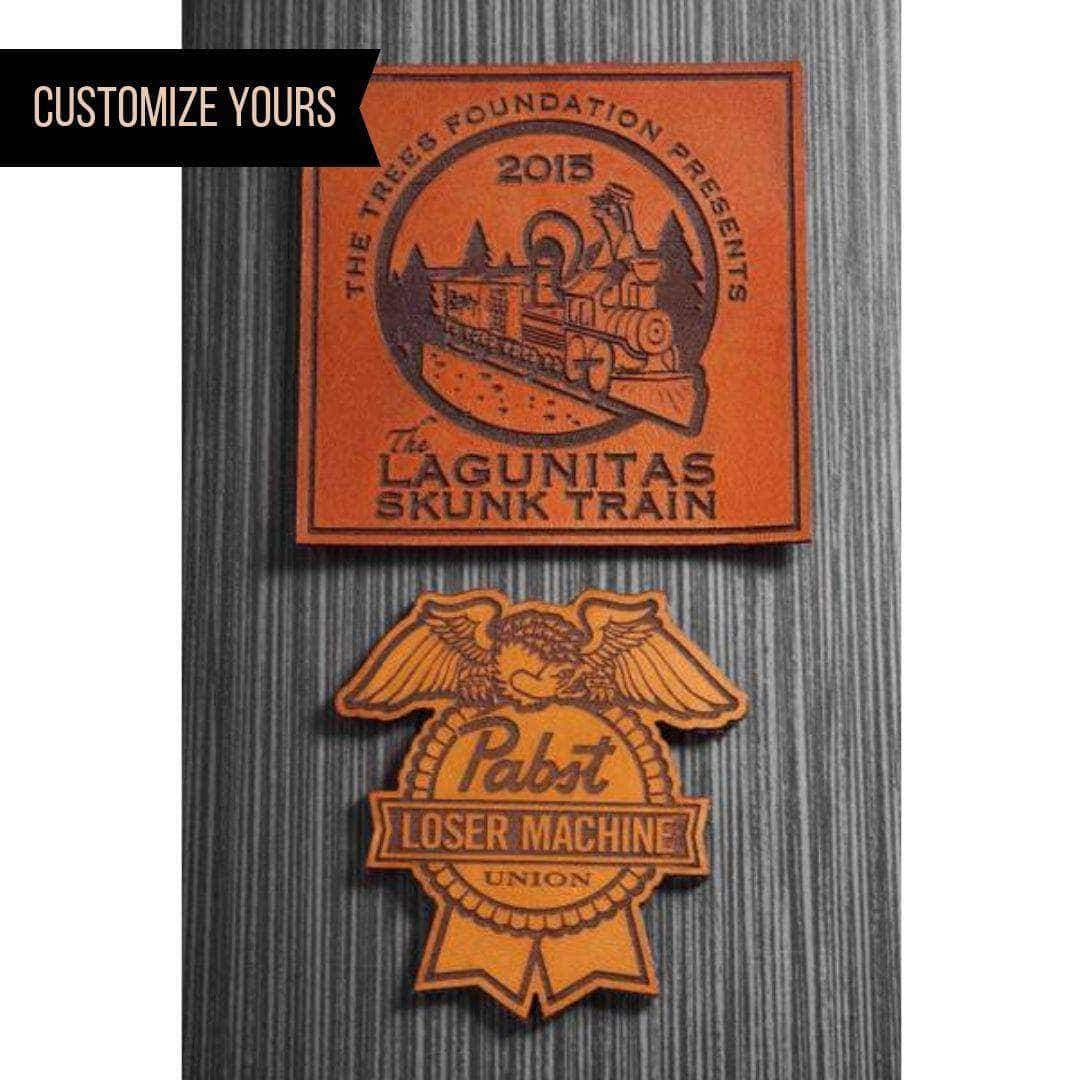

| Custom Shape Leather Patches | Unique designs tailored to specific brand needs | Branding, events, team identity | Pros: Fully customizable; Cons: May require longer lead times. |

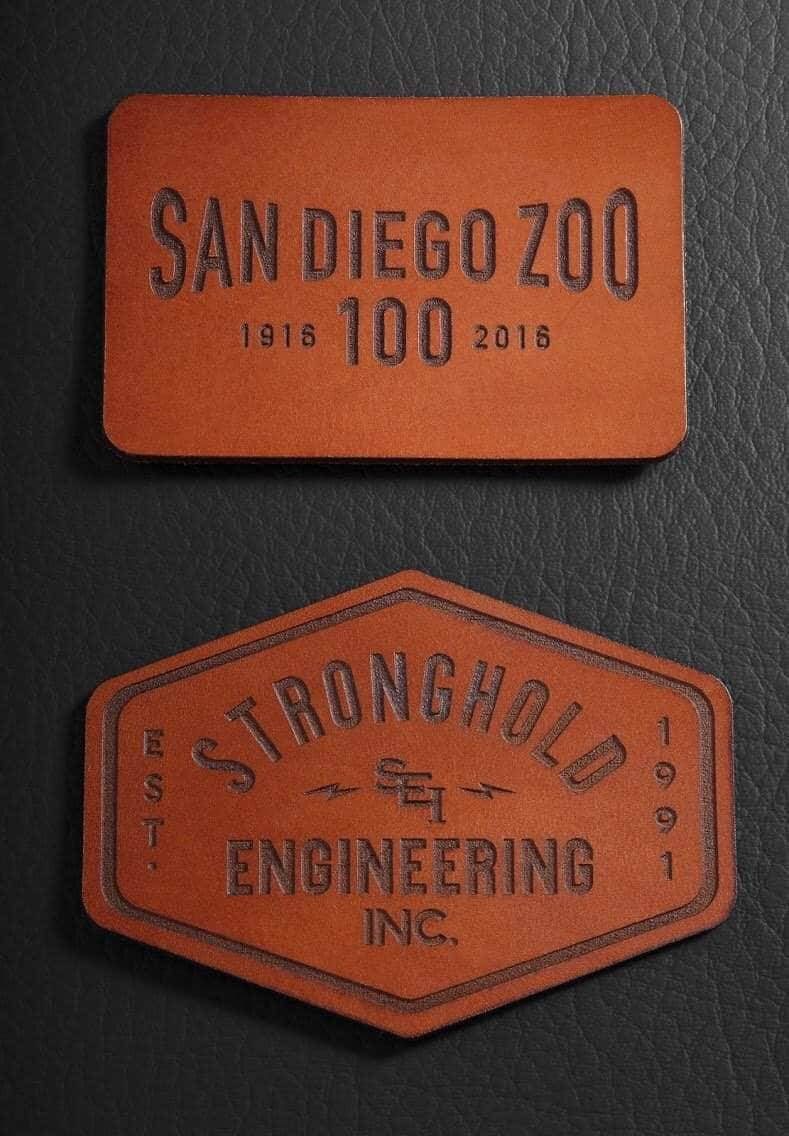

What are Laser Engraved Leather Patches and Their Benefits for B2B Buyers?

Laser engraved leather patches are distinguished by their intricate detailing and the ability to customize shapes to fit brand identity. These patches are durable, thanks to a protective coating that seals the engraved areas, making them suitable for a variety of applications, including apparel branding and promotional items. B2B buyers should consider the initial setup costs, as they may be higher than simpler options, but the elegant and professional appearance can justify the investment.

How Do Iron-On Leather Patches Work and Who Should Use Them?

Iron-on leather patches feature a heat-activated backing that allows for quick and easy application, making them ideal for custom merchandise and event giveaways. They offer a convenient solution for businesses looking to add branding to items without the need for sewing. However, buyers should be cautious about the heat sensitivity of certain leather types, as excessive heat can warp the material, potentially affecting the final product’s appearance.

What Are the Advantages of Sew-On Leather Patches for Businesses?

Sew-on leather patches are a traditional method of attachment that provides a strong, durable bond, making them suitable for uniforms, jackets, and outdoor gear. Available in various sizes and shapes, these patches can be tailored to meet specific branding needs. While they offer great versatility and longevity, businesses should be aware that applying these patches requires sewing skills, which could add labor costs.

Why Consider Faux Leather Patches for Eco-Friendly Branding?

Faux leather patches present an eco-friendly alternative to genuine leather, available in a variety of colors and textures. They are particularly appealing to fashion brands and businesses focused on sustainability. While they are cost-effective and suitable for promotional giveaways, buyers should note that faux leather may not offer the same level of durability as genuine leather options, which could impact long-term branding efforts.

How Do Custom Shape Leather Patches Enhance Brand Identity?

Custom shape leather patches allow businesses to create unique designs tailored to their specific branding needs. This flexibility makes them ideal for team identity and promotional events. However, the customization process may require longer lead times, which buyers should factor into their planning. The investment in unique designs can significantly enhance brand visibility and recognition in competitive markets.

Key Industrial Applications of custom leather patches no minimum

| Industry/Sector | Specific Application of custom leather patches no minimum | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Custom branding on jackets, hats, and bags | Enhances brand identity and customer loyalty | Quality of leather, customization options, and lead times |

| Outdoor and Adventure | Patches for backpacks and outdoor gear | Adds durability and uniqueness to products | Weather resistance, attachment methods, and bulk pricing |

| Automotive and Biker Clubs | Motorcycle jackets and club insignias | Fosters community identity and brand recognition | Design intricacy, material durability, and order flexibility |

| Corporate Branding | Employee uniforms and promotional items | Professional appearance and team cohesion | Customization capabilities, production speed, and minimum order size |

| Crafts and DIY | Personalization for handmade goods | Increases perceived value and uniqueness | Sourcing of eco-friendly materials and production techniques |

How Can Custom Leather Patches Enhance Fashion and Apparel Branding?

In the fashion and apparel industry, custom leather patches are a powerful tool for branding. They can be seamlessly integrated into jackets, hats, and bags, providing a premium look that captures consumer attention. For international buyers, especially from regions like Europe and South America, the ability to order patches with no minimums allows for small batch production tailored to local market demands. This flexibility helps brands test new designs without significant upfront investment, while high-quality materials ensure that the patches withstand wear and maintain their aesthetic appeal.

What Role Do Custom Leather Patches Play in Outdoor and Adventure Gear?

Outdoor and adventure brands utilize custom leather patches to enhance the durability and uniqueness of their products, such as backpacks and camping gear. These patches not only add a rugged aesthetic but also serve practical purposes, like reinforcing seams or covering wear-and-tear. For B2B buyers in regions such as Africa and the Middle East, sourcing patches that are weather-resistant and made from premium materials is crucial. Additionally, the no minimum order policy allows these businesses to create limited edition items that resonate with their target audience, driving sales and brand loyalty.

How Are Custom Leather Patches Used in Automotive and Biker Clubs?

Custom leather patches are integral to the identity of motorcycle clubs and automotive brands, often featuring club insignias or logos on jackets and vests. These patches foster a sense of belonging and community among members, enhancing brand recognition. For international buyers, particularly in regions like Saudi Arabia and Nigeria, sourcing high-quality, durable patches with intricate designs is essential. The ability to order without minimums enables clubs to adapt designs for various events or member needs, ensuring that every patch reflects their unique identity.

In What Ways Do Custom Leather Patches Support Corporate Branding?

In the corporate sector, custom leather patches are increasingly used on employee uniforms and promotional items. They enhance the professional appearance of staff, promoting a cohesive brand image. For businesses looking to source these patches, considerations include the customization options available and the speed of production. The no minimum order policy is particularly beneficial for companies looking to create patches for specific events or campaigns without committing to large quantities, allowing for greater flexibility in branding efforts.

How Do Custom Leather Patches Add Value to Crafts and DIY Projects?

Crafts and DIY enthusiasts often use custom leather patches to personalize handmade goods, from bags to home decor. These patches increase the perceived value of products, making them more appealing to consumers. For international buyers, sourcing eco-friendly materials can be a priority, as sustainability becomes a significant factor in purchasing decisions. The flexibility of ordering custom patches with no minimum requirements allows crafters to experiment with designs, making it easier to cater to niche markets and individual customer preferences.

3 Common User Pain Points for ‘custom leather patches no minimum’ & Their Solutions

Scenario 1: Navigating Quality Control in Custom Leather Patches

The Problem:

B2B buyers often face challenges related to quality control when ordering custom leather patches without minimums. With varying suppliers, there can be inconsistencies in leather quality, engraving precision, and overall durability of the patches. This can lead to wasted resources, as businesses may receive inferior products that do not meet their branding needs, ultimately affecting customer satisfaction and brand reputation.

The Solution:

To ensure quality, buyers should prioritize suppliers with a strong track record of producing high-quality leather patches. Request samples before placing bulk orders, as this allows for an assessment of the material, craftsmanship, and engraving quality. Additionally, inquire about the supplier’s production process, including the sourcing of leather and the technology used for engraving. Look for suppliers who offer guarantees or warranties on their products, as this indicates confidence in their quality standards. Establishing clear communication about your expectations and specifications can further mitigate risks.

Scenario 2: Overcoming Design Limitations in Custom Orders

The Problem:

Another common issue is the limitation in design options when sourcing custom leather patches with no minimum order requirements. Buyers may find that many suppliers only provide a limited range of shapes, sizes, and customization options, which can hinder the ability to create unique branding elements that resonate with their target audience. This is particularly problematic for businesses looking to differentiate themselves in competitive markets.

The Solution:

To address this, buyers should seek suppliers that offer extensive customization options, including various shapes, sizes, and backing types. Look for companies that allow for fully personalized designs, accommodating unique logos or artwork. When placing an order, clearly articulate your design vision and ask if the supplier can accommodate special requests. If available, take advantage of design consultation services, as these can provide insights into how to best utilize the patch for your branding needs. Using digital mock-ups can also help visualize the final product before production begins, ensuring it aligns with your expectations.

Scenario 3: Managing Costs Effectively with No Minimum Orders

The Problem:

While the option for no minimum orders is attractive, B2B buyers often struggle with cost management. Purchasing smaller quantities can lead to higher per-unit costs, which may not align with budget constraints, especially for startups or smaller businesses looking to maintain financial viability while branding their products.

Illustrative image related to custom leather patches no minimum

The Solution:

Buyers should conduct a thorough cost analysis when considering custom leather patches. Start by comparing prices across multiple suppliers to find the best value without sacrificing quality. Some suppliers may offer bulk discounts, so even if you don’t need a large quantity initially, it might be worth considering a larger order to reduce costs per unit. Additionally, consider the total lifecycle cost of the patches, including shipping and potential reorders. Engaging with suppliers about your budget constraints may lead to flexible solutions, such as phased ordering or discounts for future orders. Leveraging relationships with suppliers can also open doors for negotiation and better pricing structures, which are crucial for sustaining long-term business partnerships.

Strategic Material Selection Guide for custom leather patches no minimum

When selecting materials for custom leather patches with no minimum order requirements, B2B buyers must consider various factors that influence the performance, durability, and overall suitability of the patches for their intended applications. Below are analyses of four common materials used in the production of custom leather patches, each with distinct properties, advantages, and limitations.

What are the Key Properties of Genuine Leather for Custom Patches?

Genuine leather, particularly full-grain leather, is a popular choice for custom patches due to its natural durability and aesthetic appeal. This material is renowned for its high tensile strength, which allows it to withstand wear and tear over time. Genuine leather is also breathable, making it suitable for various environmental conditions.

Pros: The primary advantages of genuine leather include its long-lasting nature, ability to develop a unique patina over time, and its premium look that enhances brand perception. It is also compatible with various attachment methods, such as sewing and adhesive backing.

Illustrative image related to custom leather patches no minimum

Cons: However, genuine leather can be more expensive than synthetic alternatives, which may be a consideration for budget-conscious buyers. Additionally, it requires specific care to maintain its appearance, which could be a drawback for some applications.

How Does Faux Leather Compare to Genuine Leather for Patches?

Faux leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), provides a more cost-effective alternative to genuine leather. This material mimics the look and feel of real leather while offering additional benefits, such as being easier to clean and maintain.

Pros: Faux leather is typically lighter and more flexible than genuine leather, making it suitable for intricate designs and shapes. It is also available in a variety of colors and textures, allowing for greater customization.

Cons: On the downside, faux leather may not offer the same level of durability as genuine leather, especially in harsh conditions. It can also be less breathable, potentially leading to issues with adhesion in high-temperature environments.

What are the Advantages of Suede Leather for Custom Patches?

Suede, a type of leather with a napped finish, is another option for custom patches. It is softer and has a unique texture that can add a distinctive touch to products.

Illustrative image related to custom leather patches no minimum

Pros: Suede is often perceived as luxurious and can be used to create high-end products. Its softness allows for comfortable wear, making it ideal for clothing applications.

Cons: However, suede is less resistant to moisture and stains compared to other leather types, which can limit its use in certain applications. It may also require more maintenance to keep it looking its best.

How Do Synthetic Materials Impact the Custom Leather Patch Market?

Synthetic materials, such as polyester blends, are increasingly being used in the production of custom patches. These materials can be engineered to mimic the properties of leather while offering enhanced durability and weather resistance.

Pros: Synthetic materials are often more affordable and can be produced in various colors and finishes, appealing to a broader range of buyers. They are also generally more resistant to environmental factors, making them suitable for outdoor applications.

Illustrative image related to custom leather patches no minimum

Cons: The primary limitation of synthetic materials is that they may not provide the same aesthetic appeal as genuine leather. Additionally, they can be less breathable, which may affect their application in clothing.

Summary Table of Material Options for Custom Leather Patches

| Materiał | Typical Use Case for custom leather patches no minimum | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Genuine Leather | Premium apparel, bags, and accessories | Long-lasting and develops unique patina | Higher cost and requires maintenance | High |

| Sztuczna skóra | Budget-friendly apparel and promotional items | Cost-effective and easy to maintain | Less durable and less breathable | Medium |

| Suede Leather | High-end clothing and luxury accessories | Luxurious feel and comfortable wear | Less moisture resistant and requires upkeep | Medium |

| Synthetic Materials | Outdoor gear, casual apparel, and promotional patches | Weather-resistant and affordable | May lack aesthetic appeal of real leather | Low |

This strategic material selection guide provides B2B buyers with essential insights into the various materials available for custom leather patches with no minimum order requirements. By understanding the properties, advantages, and limitations of each material, buyers can make informed decisions that align with their branding and application needs.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather patches no minimum

What Are the Key Stages in the Manufacturing Process for Custom Leather Patches?

The manufacturing of custom leather patches involves several crucial stages: material preparation, forming, assembly, and finishing. Each of these stages is designed to ensure that the final product meets the highest standards of quality and durability.

How Is Material Prepared for Custom Leather Patches?

The first step in the manufacturing process is material preparation. Quality leather, either genuine or faux, is sourced from reputable suppliers. For instance, vegetable-tanned leather is popular due to its environmentally friendly properties. Once the leather is sourced, it undergoes a quality check to ensure it meets the required specifications. This includes evaluating the leather for uniformity in texture, color, and thickness.

Illustrative image related to custom leather patches no minimum

After passing the initial inspection, the leather is cut into the desired shapes and sizes according to the specifications provided by the buyer. This is typically done using precision cutting techniques such as laser cutting, which allows for intricate designs and high levels of detail.

What Techniques Are Used in Forming Custom Leather Patches?

Once the leather is prepared, the forming stage begins. This involves applying the design elements to the leather patches, which can include logos, text, or other graphics. Techniques such as laser engraving or embossing are commonly used. Laser engraving is particularly favored for its precision and ability to produce high-resolution designs without compromising the integrity of the leather.

For patches that require additional features, such as adhesive backing, this is integrated during the forming stage. The choice of backing—whether for sewing or heat application—depends on the intended use of the patch and customer preferences.

Illustrative image related to custom leather patches no minimum

How Are Custom Leather Patches Assembled?

The assembly stage involves putting together the various components of the patch. For example, if the patch includes multiple layers or additional materials (like fabric or velcro), these are securely attached during this stage. Quality adhesives and stitching methods are employed to ensure durability.

Attention to detail is paramount here, as any flaws in assembly can affect the overall quality and aesthetic appeal of the final product. Each patch is checked for consistency with the design specifications before moving on to the next stage.

What Finishing Techniques Are Used for Custom Leather Patches?

The finishing stage is critical in enhancing the patch’s appearance and longevity. This may include applying protective coatings that make the leather water-resistant and help maintain its quality over time. Additional treatments can also be applied to enhance the color and texture of the leather.

Quality assurance checks are conducted at this stage to ensure that each patch meets the set standards. This includes visual inspections for any defects and functionality tests for features like adhesive backing.

Illustrative image related to custom leather patches no minimum

What Quality Assurance Measures Are Essential for Custom Leather Patches?

Quality assurance is vital in the manufacturing of custom leather patches to ensure they meet international standards and customer expectations. Various quality control checkpoints are established throughout the manufacturing process.

What International Standards Should B2B Buyers Look For?

B2B buyers should be aware of relevant international quality standards, such as ISO 9001, which provides a framework for quality management systems. Compliance with these standards indicates that the manufacturer has established processes to ensure consistent quality and customer satisfaction.

Other industry-specific certifications, such as CE marking for safety and environmental compliance, may also be important depending on the target market and application of the patches. For instance, buyers in the European market often look for CE compliance to ensure products meet health and safety standards.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are crucial at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting the raw materials upon arrival to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, random samples may be taken to assess compliance with design specifications and manufacturing processes.

-

Final Quality Control (FQC): This stage involves a thorough inspection of finished products before they are packaged and shipped. This includes checking for defects, ensuring that all specifications have been met, and confirming that the products are ready for delivery.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can verify a supplier’s quality control practices through several methods:

-

Supplier Audits: Conducting on-site audits can provide insights into a manufacturer’s processes, quality control measures, and overall production capabilities. Buyers can request access to quality management documentation and records of past audits.

-

Quality Reports: Suppliers should provide detailed quality reports that outline their testing methods, results, and compliance with international standards. This transparency helps buyers assess the reliability of the supplier.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing process and product quality. This is particularly important for international buyers who may not have the resources for on-site inspections.

What Nuances Should International Buyers Consider Regarding Quality Control?

When sourcing custom leather patches from international suppliers, particularly from regions like Africa, South America, the Middle East, and Europe, buyers should consider several nuances:

Illustrative image related to custom leather patches no minimum

-

Cultural Differences in Quality Standards: Different regions may have varying standards for quality and craftsmanship. Understanding these differences is crucial to setting realistic expectations and ensuring satisfaction with the final product.

-

Logistics and Shipping Considerations: Quality can be affected by shipping conditions. Buyers should discuss how suppliers package their products to minimize damage during transit, and consider using shipping methods that provide tracking and insurance.

-

Regulatory Compliance: Different countries have specific regulations regarding materials used in products, especially those that come into contact with skin. Buyers should ensure that the materials used in the patches comply with local regulations in their target markets.

In conclusion, understanding the manufacturing processes and quality assurance measures for custom leather patches is essential for B2B buyers. By focusing on key production stages, quality control practices, and international standards, buyers can make informed decisions that lead to successful partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather patches no minimum’

In the ever-evolving landscape of custom merchandise, sourcing custom leather patches with no minimum order quantities can offer businesses a unique branding opportunity. This guide provides actionable steps for B2B buyers, ensuring a streamlined procurement process that meets their specific needs.

Step 1: Identify Your Brand’s Requirements

Understanding your brand’s specific needs is the first step in sourcing custom leather patches. Determine the purpose of the patches—whether for promotional use, employee uniforms, or product embellishments. Consider factors such as size, shape, color, and design complexity. A clear understanding of your requirements will help you communicate effectively with potential suppliers.

Step 2: Research and Shortlist Suppliers

Take the time to explore various suppliers that specialize in custom leather patches. Look for companies that emphasize quality, craftsmanship, and flexibility in their offerings. Create a shortlist of suppliers that not only provide the product you need but also have a reputation for reliability and customer service.

- Check online reviews and testimonials.

- Investigate their portfolio for past projects.

Step 3: Evaluate Material Options

Different projects may require different types of leather. Evaluate the material options offered by suppliers, such as genuine leather, faux leather, or specialty finishes. Consider the durability, aesthetic appeal, and environmental impact of each material.

- Genuine Leather: Offers authenticity and longevity.

- Faux Leather: Typically more cost-effective and environmentally friendly.

Step 4: Clarify Customization Capabilities

Before proceeding, confirm the level of customization available. Suppliers should be able to accommodate various designs, colors, and attachment methods. Discuss the intricacies of your design, including engraving and printing options, to ensure they can meet your expectations.

- Ask about artwork submission guidelines.

- Inquire about the possibility of custom shapes or sizes.

Step 5: Request Sample Products

It’s prudent to request samples before placing a bulk order. This allows you to assess the quality of the materials, craftsmanship, and how well your design translates to the actual product. A sample will give you a tangible sense of the supplier’s capabilities.

Step 6: Discuss Pricing and Payment Terms

Engage in a conversation about pricing structures, especially since you’re looking for no minimum orders. Understand the cost breakdown for different quantities and customization levels. Additionally, clarify payment terms to avoid any surprises later in the process.

- Ask about discounts for bulk purchases.

- Ensure transparency regarding shipping and handling fees.

Step 7: Confirm Lead Times and Shipping Options

Finally, confirm the expected production lead times and shipping options. Establishing clear timelines is essential for planning your marketing or branding initiatives. Ensure that the supplier can meet your deadlines and is flexible in accommodating any urgent requests.

Illustrative image related to custom leather patches no minimum

By following these steps, B2B buyers can effectively navigate the process of sourcing custom leather patches with no minimum order requirements. This strategic approach not only enhances the likelihood of a successful procurement experience but also ensures that the final product aligns perfectly with your brand’s identity and goals.

Comprehensive Cost and Pricing Analysis for custom leather patches no minimum Sourcing

What Are the Key Cost Components in Sourcing Custom Leather Patches with No Minimum Order Quantity?

When analyzing the cost structure for custom leather patches with no minimum order quantity, several key components come into play. These include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margins.

-

Materials: The choice of leather—whether genuine or faux—significantly affects costs. Premium options like top-grain leather will demand a higher price, while synthetic materials may be more affordable. Additionally, the complexity of the design and engraving can influence the cost of raw materials.

-

Labor: Labor costs are incurred during both the design and production phases. Skilled artisans or technicians are required for tasks like laser engraving, which can increase overall costs. However, automation in the manufacturing process can help reduce labor costs.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, rent, and equipment maintenance. Factories in regions with lower operational costs may offer more competitive pricing.

-

Tooling: Initial setup and tooling costs can be significant, especially for custom designs. However, with no minimum orders, suppliers may spread these costs over several orders, making them more manageable for buyers.

-

Quality Control (QC): Ensuring that each patch meets quality standards is crucial, especially for international buyers. QC processes may involve additional costs, but they are vital for maintaining brand reputation.

-

Logistics: Shipping costs vary based on distance and shipping method. International buyers must consider customs duties and tariffs, which can affect the total landed cost of products.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on market demand, competition, and the perceived value of the product.

How Do Price Influencers Impact the Cost of Custom Leather Patches?

Several factors can influence the pricing of custom leather patches. Understanding these can help B2B buyers negotiate better deals.

-

Volume and Minimum Order Quantity (MOQ): Although the focus is on no minimum order quantity, suppliers often provide discounts for larger orders. Buyers should consider their future needs to leverage better pricing.

-

Specifications and Customization: Unique designs or specific shapes can increase costs. Buyers should balance their customization desires with budget constraints.

-

Material Quality and Certifications: Higher-quality materials come at a premium. Certifications for sustainability or ethical sourcing may also affect pricing. Buyers should inquire about these factors to ensure their patches align with brand values.

-

Supplier Factors: The supplier’s location, reputation, and experience can all influence pricing. Established suppliers may charge more but offer better quality and reliability.

-

Incoterms: Understanding shipping terms is crucial for international buyers. Costs can vary significantly based on whether the seller or buyer is responsible for shipping and customs.

What Tips Can Help International B2B Buyers Optimize Costs for Custom Leather Patches?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, optimizing costs requires a strategic approach:

Illustrative image related to custom leather patches no minimum

-

Negotiation: Engage suppliers in discussions about pricing, especially for bulk orders. Building a good relationship can lead to more favorable terms.

-

Cost-Efficiency: Evaluate the total cost of ownership, including not just the purchase price but also logistics, duty fees, and potential reorders. This perspective helps in making informed purchasing decisions.

-

Pricing Nuances: Be aware of currency fluctuations and their impact on pricing. International payments may incur additional fees, so consider using local currency or bulk purchasing to mitigate these costs.

-

Local Regulations and Market Understanding: Familiarize yourself with local regulations regarding imported goods, as well as market trends in your region. This knowledge can inform your purchasing strategy and help you avoid unexpected costs.

Disclaimer on Indicative Prices

While this analysis provides a comprehensive overview of the cost structure and pricing dynamics for custom leather patches with no minimum order requirements, prices can vary significantly based on specific orders, supplier capabilities, and market conditions. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing custom leather patches no minimum With Other Solutions

Exploring Alternatives to Custom Leather Patches with No Minimum Order

When considering branding and customization options for apparel and accessories, businesses often seek alternatives to custom leather patches with no minimum order requirements. Understanding these alternatives can help B2B buyers make informed decisions that align with their branding strategies, budget constraints, and operational needs. Below is a comparative analysis of custom leather patches against two viable alternatives: embroidered patches and PVC (polyvinyl chloride) patches.

| Comparison Aspect | Custom Leather Patches No Minimum | Embroidered Patches | PVC Patches |

|---|---|---|---|

| Performance | Durable, high-quality, premium look | Good durability, vibrant colors | Weather-resistant, flexible |

| Cost | Higher initial cost, but no minimums | Generally lower cost per unit | Low cost, especially in bulk |

| Ease of Implementation | Simple setup with no minimums | Requires setup for each design | Quick to produce, easy to order |

| Maintenance | Requires care to maintain appearance | Low maintenance, machine washable | Easy to clean, durable against elements |

| Best Use Case | Premium branding, fashion items | Casual wear, promotional items | Outdoor gear, children’s products |

What Are the Pros and Cons of Embroidered Patches?

Embroidered patches are a popular alternative to custom leather patches, particularly for businesses looking for a cost-effective solution. These patches feature designs stitched into fabric, offering vibrant colors and a textured appearance. They are generally less expensive than leather patches, especially in bulk orders. However, embroidered patches may not convey the same premium feel as leather, which can be a disadvantage for brands aiming for a high-end image. Additionally, while they are durable, they can be less resistant to wear and weather compared to leather, potentially requiring more frequent replacements.

How Do PVC Patches Compare to Custom Leather Patches?

PVC patches present another viable alternative, especially for businesses focused on budget and functionality. Made from flexible plastic, these patches are often used in outdoor gear or children’s clothing due to their weather resistance and durability. PVC patches can be produced quickly and are typically less expensive than leather options. However, they lack the premium aesthetic of leather patches and may not be suitable for high-fashion applications. Furthermore, while they are easy to clean and maintain, they may not offer the same level of customization in terms of intricate designs compared to leather patches.

Making the Right Choice for Your Branding Needs

When selecting the appropriate solution for custom branding, B2B buyers should consider several factors, including budget, intended use, and the desired brand image. Custom leather patches without minimum orders provide a unique opportunity for businesses to achieve a premium look without committing to large quantities. Conversely, embroidered patches may be more suitable for cost-sensitive projects, while PVC patches excel in durability and quick production timelines. By evaluating these alternatives against their specific branding goals, businesses can choose the most effective method to enhance their visibility and market presence.

Essential Technical Properties and Trade Terminology for custom leather patches no minimum

What Are the Key Technical Properties of Custom Leather Patches with No Minimum Order?

When sourcing custom leather patches, understanding the technical specifications is crucial for ensuring quality and suitability for your brand. Here are some essential properties:

1. Material Grade

The quality of leather is often classified into different grades. Top-grain leather, for instance, is known for its durability and premium feel, making it ideal for high-end products. B2B buyers should prioritize material grade as it directly affects the patch’s longevity and appearance. Faux leather alternatives can also be considered for budget-conscious projects, but they may not offer the same durability.

2. Tolerance

Tolerance refers to the allowable variation in dimensions during production. For custom patches, maintaining tight tolerances ensures that the final product meets design specifications accurately. This is especially important for intricate designs or logos, where precision can impact brand representation. A standard tolerance for leather patches is typically ±1mm, but this can vary based on the manufacturing process.

3. Backing Options

Understanding the different backing options available for leather patches is vital. Common choices include sew-on, iron-on, or adhesive backing. Each type offers distinct benefits: sew-on provides a permanent solution, while adhesive backing allows for quicker applications without sewing. For B2B buyers, selecting the appropriate backing type ensures that the patches are suited for their intended use, whether on apparel or hard goods.

4. Engraving and Printing Techniques

The method used to create designs on leather patches can significantly influence the final product. Laser engraving is a popular choice due to its precision and durability; designs are etched into the leather, ensuring they do not wear off over time. Understanding these techniques helps buyers select the best option for their branding needs, as some methods may be more suitable for detailed logos than others.

5. Water Resistance

For patches intended for outdoor use, water resistance is an important property. Some manufacturers offer patches treated with a water-resistant coating, which enhances durability and longevity. This feature is particularly valuable for brands in sectors like outdoor apparel or sports gear, where exposure to the elements is common.

Illustrative image related to custom leather patches no minimum

What Are the Common Terms Used in the Custom Leather Patch Industry?

Familiarity with industry terminology is crucial for effective communication and negotiation with suppliers. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of custom leather patches, an OEM can create patches designed specifically for another brand, ensuring that the patches meet unique specifications and branding requirements.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In the custom leather patch market, the term “no minimum” is advantageous for small businesses or startups, allowing them to order as few patches as they need without incurring excess costs.

3. RFQ (Request for Quote)

An RFQ is a document that a buyer sends to suppliers to obtain pricing and terms for specific products. For custom leather patches, issuing an RFQ allows businesses to compare prices, quality, and lead times from different manufacturers, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in the shipping process. Understanding these terms helps B2B buyers clarify who is responsible for shipping costs, insurance, and risk during transit, which is essential for international transactions.

Illustrative image related to custom leather patches no minimum

5. Customization

Customization in the leather patch industry refers to the ability to modify design elements, sizes, shapes, and materials according to client specifications. This flexibility is crucial for brands looking to create unique products that align with their identity and messaging.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing custom leather patches, ensuring they select products that meet their quality standards and business needs.

Navigating Market Dynamics and Sourcing Trends in the custom leather patches no minimum Sector

What are the Current Market Dynamics and Key Trends for Custom Leather Patches with No Minimum Order?

The global market for custom leather patches, particularly those offered with no minimum order requirements, is experiencing robust growth driven by various factors. Increasing demand for personalized branding solutions among businesses, especially in apparel and accessory sectors, is a primary driver. This trend is particularly evident in regions like Africa, South America, the Middle East, and Europe, where small to medium-sized enterprises (SMEs) are eager to differentiate their offerings without the financial burden of bulk orders.

Emerging B2B technologies, such as online design tools and digital marketplaces, are transforming the sourcing landscape. These platforms allow buyers to easily customize and order patches tailored to their specific branding needs, streamlining the procurement process. Additionally, advancements in laser engraving and printing technologies enhance the quality and precision of the final product, allowing for intricate designs that can attract discerning customers.

Market dynamics are also influenced by the growing trend of sustainable fashion. As consumers become increasingly aware of environmental issues, brands are seeking ethically sourced materials for their products, including leather patches. This shift is prompting manufacturers to adopt sustainable practices, catering to the eco-conscious buyer segment across international markets.

How are Sustainability and Ethical Sourcing Shaping the Custom Leather Patch Industry?

Sustainability is becoming a cornerstone of the custom leather patch industry. With the rising awareness of environmental impacts associated with leather production, buyers are prioritizing suppliers who demonstrate commitment to ethical sourcing practices. This includes using vegetable-tanned leather and ensuring that the entire supply chain adheres to environmentally friendly standards.

Illustrative image related to custom leather patches no minimum

Certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) are gaining importance among B2B buyers looking to verify the sustainability credentials of their suppliers. These certifications not only guarantee that materials are sourced responsibly but also indicate that the production processes are designed to minimize waste and reduce carbon footprints.

For buyers in regions like Africa and South America, where local craftsmanship is rich, sourcing from local artisans who practice sustainable methods can create a unique value proposition. By aligning with ethical sourcing principles, brands can enhance their image and appeal to a growing segment of consumers who value sustainability, ultimately leading to increased loyalty and market share.

What is the Historical Context of Custom Leather Patches?

The tradition of using leather patches dates back centuries, originally serving practical purposes in the repair of clothing and gear. Over time, these patches evolved into a form of personal and group identity, especially among communities like motorcycle clubs and sports teams. The 20th century saw a shift towards decorative patches, often featuring intricate designs and logos, reflecting the wearer’s affiliation or personal style.

With the rise of the digital age, customization became more accessible. Today, buyers can order custom leather patches without the constraints of minimum quantities, allowing for greater flexibility and creativity. This evolution not only caters to individual consumers but also meets the needs of businesses seeking distinctive branding solutions. As the market continues to evolve, the fusion of tradition with modern technology promises exciting opportunities for innovation in the custom leather patch sector.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather patches no minimum

-

How do I ensure quality when sourcing custom leather patches with no minimum order?

To ensure quality when sourcing custom leather patches, start by vetting suppliers thoroughly. Request samples to assess the material, craftsmanship, and engraving details. Look for suppliers with positive reviews and a proven track record in the industry. Additionally, inquire about their production processes, material sourcing, and quality assurance practices. Establish clear specifications for your patches, including size, design, and durability requirements, to minimize discrepancies in the final product. -

What customization options are available for custom leather patches?

Customization options for leather patches are extensive. Buyers can select from various shapes, sizes, colors, and types of leather, including genuine and faux options. Most suppliers offer laser engraving to include logos, text, or unique designs. Some also provide different backing options, such as sew-on or adhesive, allowing for versatile applications on clothing and accessories. Discuss your specific design needs with the supplier to explore all available customization choices. -

What payment terms should I expect when ordering custom leather patches?

Payment terms for custom leather patches can vary by supplier. Common practices include upfront payment for small orders or a deposit for larger quantities, with the balance due before shipment. Some suppliers may offer credit terms for established customers. Always clarify payment methods accepted (e.g., credit card, bank transfer) and any additional fees for international transactions. Ensure you receive a clear invoice outlining the total cost, including shipping and potential customs duties. -

How can I effectively communicate my design requirements to the supplier?

To effectively communicate your design requirements, provide high-resolution artwork in accepted formats (e.g., vector files). Include detailed notes about colors, dimensions, and any specific design elements. If applicable, reference similar designs you admire to give the supplier a clearer vision of your expectations. Regular communication throughout the design process is crucial, so be open to feedback and adjustments from the supplier to achieve the best results. -

What are the logistics considerations for ordering custom leather patches internationally?

When ordering custom leather patches internationally, consider shipping times, customs regulations, and potential tariffs. Research the supplier’s shipping options, including express and standard delivery, to choose what fits your timeline. Ensure the supplier provides tracking information for your order. Familiarize yourself with import regulations in your country to avoid unexpected delays or additional costs. Partnering with a supplier experienced in international shipping can simplify this process. -

What is the typical turnaround time for custom leather patch orders?

Turnaround times for custom leather patch orders can vary based on order size, complexity, and the supplier’s production capacity. Generally, expect a timeframe of 2-4 weeks for standard orders. For urgent needs, some suppliers may offer expedited services at an additional cost. Always discuss your timeline with the supplier before placing an order to ensure they can meet your deadlines and factor in shipping time for international deliveries. -

How do I handle quality assurance for custom leather patches?

Handling quality assurance involves implementing a systematic approach. Request a pre-production sample to evaluate the quality of materials and craftsmanship before full-scale production. Establish clear quality standards with the supplier, detailing acceptable tolerances for size, design accuracy, and durability. Consider periodic inspections during production if your order is large. After receiving your order, inspect a sample of the patches to confirm they meet your specifications before distributing them. -

What are the advantages of ordering custom leather patches with no minimum order requirements?

Ordering custom leather patches with no minimum order requirements offers significant flexibility for businesses. It allows for testing new designs or branding initiatives without committing to large quantities, reducing financial risk. This option is ideal for startups or companies looking to create limited edition products. Additionally, it enables businesses to customize patches for specific events or campaigns, ensuring they can meet diverse customer demands without excess inventory.

Top 9 Custom Leather Patches No Minimum Manufacturers & Suppliers List

1. Printing Studio – Premium Laser Engraved Leather Patches

Domain: printingstudio.com

Registered: 1998 (27 years)

Introduction: Premium Laser Engraved Leather Patches for Custom Designs – No Minimum. Price: $10.00. Ideal for hats, jeans, jackets, backpacks, and bags. Adhesive backing option available for hard goods. Made in the USA from high-quality natural leather or faux material. Custom shapes available: circles, ovals, rectangles, squares, hexagons, triangles, or custom contours. Crafted in Florida from Hermann Oak Exp…

2. Lazer Designs – Custom Patches

Domain: lazerdesigns.com

Registered: 2002 (23 years)

Introduction: This company, Lazer Designs – Custom Patches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Apex Transfers – Custom Faux Leather Patches

Domain: apextransfers.com

Registered: 2015 (10 years)

Introduction: Faux leather patches are customizable, durable, and versatile. They can be used for various applications such as clothing, bags, and accessories. The patches are available in different sizes and shapes, allowing for personalized designs. They are easy to apply and can be sewn or ironed on. Ideal for branding, promotions, or personal projects.

4. The Patch IO – Custom Leather Patches

Domain: thepatchio.com

Registered: 2021 (4 years)

Introduction: Custom Leather Patches with No Minimum Order Quantity (MOQ) for hats, jackets, and clothes. Features include: Free Quote, 10% OFF Custom Patch Sale, USA-based top design studio, bulk order discounts, free iron-on/velcro backing, express delivery options. Available shapes: Circle, Square, Rectangle, Oval, Custom Shape. Styles include: Embossed, Debossed, Screen Printed, Laser Engraving. Recommended…

5. Ninja Patches – Custom Embroidered Patches

Domain: ninjapatches.com

Registered: 2022 (3 years)

Introduction: Custom Patches for Hats & Apparel, Shipped Fast! Patches ship as fast as 5 business days with free shipping. Custom quality patches delivered in 6-9 days after proof approval. High-quality transfers available with no setup, art fees, or minimums. Various patch types include: 1. Embroidered Patches – As low as $1.42 each. 2. 3D Embroidered Patches – As low as $2.31 each. 3. Full Color Printed Patch…

6. GS-JJ – Custom Patches

Domain: gs-jj.com

Registered: 2015 (10 years)

Introduction: Custom Patches with no minimum order quantity. Prices start from $0.24 each. 20% off promotion available. Free design and 24-hour free proof. On-time delivery and 24/7 customer support. Various types of patches offered include: Embroidered Patches (from $0.24), PVC Patches (from $0.26), Woven Patches (from $0.54), Printed Patches (from $0.61), Chenille Patches (from $0.68), 3D Embroidered Patches …

7. Leather Patch Company – Authentic Leather Patch Hats

Domain: leatherpatchcompany.com

Registered: 2017 (8 years)

Introduction: Authentic Leather Patch Hats made from 100% authentic leather, hand-stitched with thick saddle thread. Available in various styles and custom patch shapes. Four hide colors to choose from: Natural Leather & Natural Stitching, Dark Brown Leather & Dark Brown Stitching, Chestnut Leather & Dark Brown Stitching, Black Leather & Black Stitching. No minimum order quantity; can order as few as one hat. P…

8. 4inCustomPatch – Custom Patches

Domain: 4incustompatch.com

Registered: 2021 (4 years)

Introduction: Custom Patches No Minimum | 20% OFF Today! Coupon Code: SAVE20. Types of Custom Patches: Embroidery Patch, Woven Patch, Printed Patch, Chenille Patch, PVC Patch, Leather Patch, Bullion Patch. Styles of Custom Patches: Anime Patch, Backpack Patch, Biker Patch, Dog Patch, Iron-on Patch, Military Patch, Morale Patch, Name Patch, Velcro Patch, Police Patch, Scout Patch, Sew-on Patch, Sticker Patch, T-…

9. Quality Embroidered Patches – Custom Embroidered Solutions

Domain: qualityembroideredpatches.com

Registered: 2007 (18 years)

Introduction: Custom Embroidered Patches with free setup and no minimum order requirement. Over 20 years of experience in designing and manufacturing patches. Options include 3D embroidery, button loop patches, custom chenille patches, leather patches, metallic thread colors, patch border options, color blending, PVC patches, and woven patches. Satisfaction guarantee within 30 days of receiving patches. Custome…

Strategic Sourcing Conclusion and Outlook for custom leather patches no minimum

How Can Strategic Sourcing Enhance Your Procurement of Custom Leather Patches?

In today’s competitive landscape, strategic sourcing of custom leather patches with no minimum order requirements offers significant advantages for international B2B buyers. By leveraging the flexibility of no minimums, businesses can tailor their orders to meet specific needs, whether for promotional events, team branding, or unique product offerings. This adaptability not only enhances brand identity but also reduces excess inventory costs, allowing for more efficient cash flow management.

Illustrative image related to custom leather patches no minimum

High-quality custom leather patches are versatile, serving various applications from fashion to outdoor gear. The ability to customize shapes, sizes, and materials ensures that businesses can align their patches with their brand aesthetics. Additionally, utilizing suppliers who prioritize sustainable practices and premium materials can enhance your brand’s reputation in an increasingly eco-conscious market.

As you look to the future, consider the potential of custom leather patches as a key component of your branding strategy. Explore diverse sourcing options that emphasize quality and craftsmanship, enabling your brand to stand out in crowded markets across Africa, South America, the Middle East, and Europe. Take the first step today by reaching out to reliable suppliers to elevate your brand with bespoke leather patches that resonate with your target audience.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to custom leather patches no minimum