Introduction: Navigating the Global Market for fabric material shoes

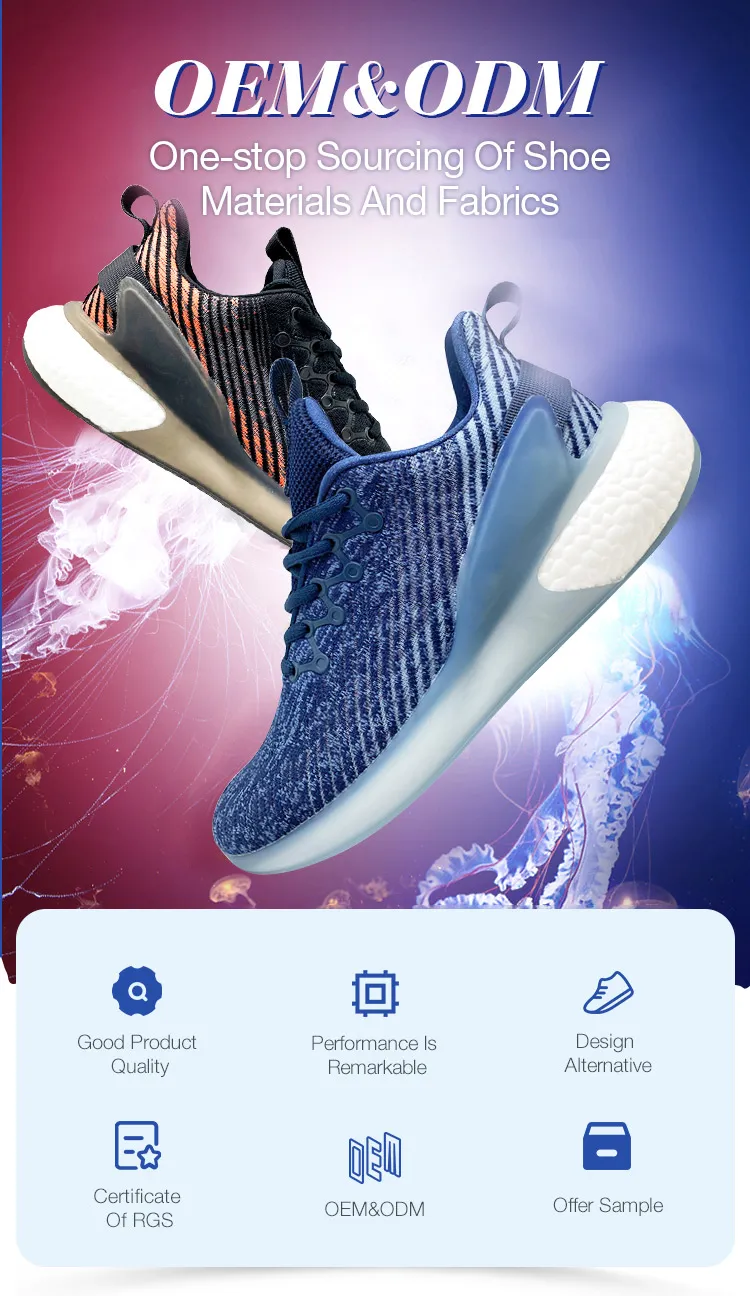

In the competitive landscape of global footwear, sourcing high-quality fabric material shoes presents a unique challenge for B2B buyers. As the demand for lightweight, durable, and stylish options continues to rise, understanding the nuances of fabric types, their applications, and supplier capabilities is crucial for making informed purchasing decisions. This guide offers an in-depth exploration of various fabric options, including polyester, nylon, cotton, and innovative blends, alongside their specific applications in footwear design.

We will also delve into critical aspects such as supplier vetting, import duties, and cost considerations that are particularly relevant to international buyers from regions like Africa, South America, the Middle East, and Europe—including key markets such as Germany and Nigeria. By equipping you with actionable insights and practical strategies, this guide empowers you to navigate the complexities of sourcing fabric material shoes effectively.

From understanding the intricacies of fabric weaves and treatments to evaluating supplier reliability and compliance with import regulations, our comprehensive resource serves as your roadmap in making confident, strategic decisions that align with your business objectives. Embrace the opportunity to enhance your footwear offerings with high-quality fabric materials that resonate with your target market’s demands.

Table Of Contents

- Top 5 Fabric Material Shoes Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for fabric material shoes

- Understanding fabric material shoes Types and Variations

- Key Industrial Applications of fabric material shoes

- 3 Common User Pain Points for ‘fabric material shoes’ & Their Solutions

- Strategic Material Selection Guide for fabric material shoes

- In-depth Look: Manufacturing Processes and Quality Assurance for fabric material shoes

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric material shoes’

- Comprehensive Cost and Pricing Analysis for fabric material shoes Sourcing

- Alternatives Analysis: Comparing fabric material shoes With Other Solutions

- Essential Technical Properties and Trade Terminology for fabric material shoes

- Navigating Market Dynamics and Sourcing Trends in the fabric material shoes Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of fabric material shoes

- Strategic Sourcing Conclusion and Outlook for fabric material shoes

- Important Disclaimer & Terms of Use

Understanding fabric material shoes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cotton Canvas Shoes | Durable, breathable, and often used in casual styles | Fashion retail, sports, casual wear | Pros: Eco-friendly, customizable. Cons: Less water-resistant. |

| Nylon Athletic Shoes | Lightweight, high durability, and often moisture-wicking | Sportswear, outdoor, fitness | Pros: Strong, quick-drying. Cons: Can be less breathable. |

| Polyester Fashion Shoes | Versatile, available in various colors and prints | Fashion retail, promotional items | Pros: Cost-effective, easy to print. Cons: May not be as durable as other materials. |

| Lycra-Blend Shoes | Stretchable, comfortable fit, often used in activewear | Sports, dance, leisure | Pros: Excellent flexibility, form-fitting. Cons: Limited durability over time. |

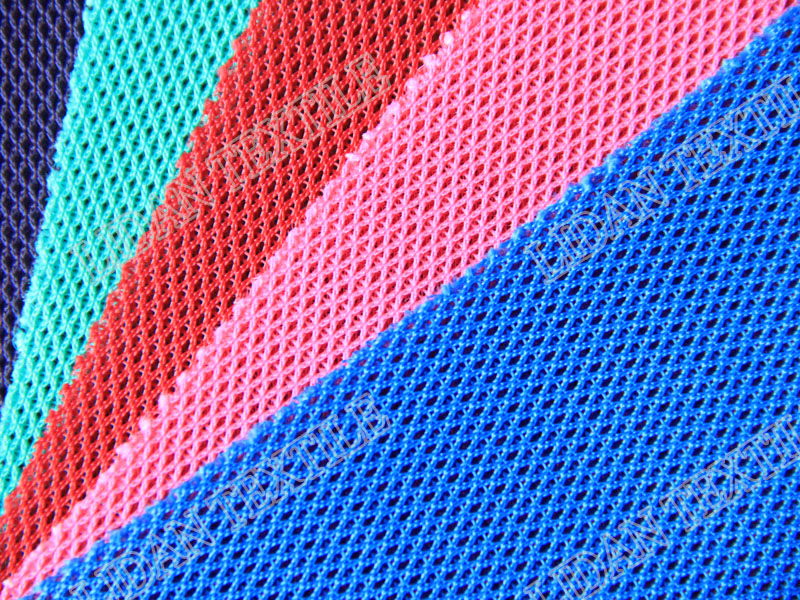

| Mesh Sneakers | Breathable, lightweight, often used for ventilation | Sports, casual wear, running | Pros: High ventilation, lightweight. Cons: May lack support for heavy use. |

What are the Characteristics of Cotton Canvas Shoes for B2B Buyers?

Cotton canvas shoes are a staple in casual footwear, recognized for their durability and breathability. They are particularly suitable for fashion retail and casual wear applications. When sourcing these shoes, B2B buyers should consider customization options, as cotton canvas readily accepts various printing techniques. However, it’s important to note that while they are eco-friendly, they tend to be less water-resistant than synthetic alternatives, which may affect their appeal in humid or wet climates.

Why Choose Nylon Athletic Shoes for Your Business Needs?

Nylon athletic shoes are highly regarded in the sports and outdoor sectors due to their lightweight construction and exceptional durability. They often feature moisture-wicking properties, making them ideal for intense physical activities. For B2B buyers, sourcing nylon athletic shoes requires attention to quality, as variations in nylon denier can significantly impact performance. While these shoes offer strength and quick-drying capabilities, buyers should also consider potential breathability issues, which can affect comfort during prolonged wear.

How Does Polyester Fit into Fashion Shoes?

Polyester fashion shoes provide versatility with a wide range of colors and patterns, making them popular in fashion retail and promotional items. They are typically more cost-effective than natural fibers, appealing to budget-conscious buyers. However, B2B purchasers should be aware that while polyester is easy to print on and customize, it may not offer the same durability as other materials, potentially leading to higher return rates if quality is not closely monitored.

What Makes Lycra-Blend Shoes Suitable for Activewear?

Lycra-blend shoes are designed for comfort and flexibility, making them ideal for sports, dance, and leisure markets. Their stretchable nature allows for a snug fit, enhancing user experience. B2B buyers should focus on the blend ratios when sourcing, as the right combination can significantly influence durability and performance. While Lycra offers excellent flexibility, it may not withstand heavy use over time, which could impact long-term customer satisfaction.

Why are Mesh Sneakers Popular Among B2B Buyers?

Mesh sneakers are favored for their breathability and lightweight design, often utilized in sports and casual wear. They provide excellent ventilation, making them suitable for warmer climates or high-intensity activities. B2B buyers should consider the balance between breathability and support when selecting mesh sneakers, as they may lack the necessary structure for extensive use. While they are ideal for casual applications, buyers should evaluate the trade-offs between comfort and durability to meet their customers’ needs effectively.

Key Industrial Applications of fabric material shoes

| Industry/Sector | Specific Application of fabric material shoes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports and Athletics | Performance footwear for athletes and teams | Enhanced performance, comfort, and durability | Supplier reliability, material quality, and compliance with sports regulations |

| Hospitality and Service | Uniform shoes for staff in hotels and restaurants | Improved employee comfort and brand image | Style variety, ease of cleaning, and bulk purchasing options |

| Healthcare | Non-slip, breathable shoes for medical staff | Safety, comfort, and hygiene | Compliance with safety standards, antimicrobial properties, and ease of maintenance |

| Manufacturing | Protective footwear for factory workers | Safety and compliance with occupational health standards | Durability, slip-resistance, and compliance with local regulations |

| Education | Casual and athletic shoes for students | Affordability, comfort, and style | Cost-effectiveness, durability for everyday use, and variety in sizes and styles |

How Are Fabric Material Shoes Used in Sports and Athletics?

In the sports and athletics sector, fabric material shoes are designed to enhance performance through lightweight construction and breathability. These shoes often incorporate advanced textile technologies, such as moisture-wicking and stretchable materials, which improve comfort during intense physical activity. For international buyers, particularly in regions like Africa and South America, sourcing options should focus on suppliers who can provide high-quality, durable fabrics that meet specific athletic standards while ensuring timely delivery for team uniforms and events.

What Role Do Fabric Material Shoes Play in the Hospitality and Service Industry?

Fabric material shoes serve as essential uniform footwear for staff in hotels and restaurants, offering a blend of style and functionality. These shoes are designed to provide comfort during long shifts while maintaining a professional appearance. Buyers in the Middle East and Europe must consider sourcing options that offer easy maintenance and a range of styles to match different corporate identities, ensuring that the footwear enhances the overall guest experience.

Illustrative image related to fabric material shoes

Why Are Fabric Material Shoes Important in Healthcare Settings?

In the healthcare industry, fabric material shoes are critical for medical staff who require non-slip, breathable footwear that supports long hours of standing and walking. These shoes often feature antimicrobial properties and are easy to clean, addressing hygiene concerns. International buyers, especially in regions like Africa and Europe, should prioritize sourcing from manufacturers that comply with health and safety regulations, ensuring that the footwear protects both staff and patients effectively.

How Do Fabric Material Shoes Enhance Safety in Manufacturing?

In manufacturing environments, fabric material shoes are vital for providing protective features such as slip resistance and durability. These shoes help ensure compliance with occupational health standards, reducing the risk of workplace accidents. Buyers from South America and Africa must focus on sourcing products that meet local safety regulations, emphasizing materials that withstand harsh conditions while still being comfortable for all-day wear.

What Advantages Do Fabric Material Shoes Offer in Educational Settings?

In educational environments, fabric material shoes are often favored for their affordability and comfort, making them suitable for students of all ages. These shoes are typically designed for daily wear, providing durability to withstand the rigors of school life. B2B buyers in Europe, particularly in Germany, should look for suppliers who offer a variety of sizes and styles, ensuring that the footwear meets the diverse needs of students while remaining cost-effective for bulk purchases.

3 Common User Pain Points for ‘fabric material shoes’ & Their Solutions

Scenario 1: Sourcing High-Quality Fabric for Shoes

The Problem: Many B2B buyers face the challenge of sourcing high-quality fabric material for shoes that meet both durability and comfort standards. This is particularly critical in markets where consumers are increasingly discerning about quality. Buyers may struggle with suppliers who offer low-quality fabrics that wear out quickly, leading to high return rates and dissatisfied customers. Additionally, with varying international standards for textile safety and performance, buyers must navigate a complex landscape to ensure compliance and consumer satisfaction.

Illustrative image related to fabric material shoes

The Solution: To overcome this sourcing challenge, buyers should prioritize working with suppliers who provide comprehensive product specifications, including thread count, fiber composition, and weave patterns. Establish relationships with manufacturers who have a reputation for quality and offer certifications that validate their materials against international standards. Conducting small-scale pilot runs can also help assess the fabric’s performance in real-world conditions before committing to larger orders. Furthermore, buyers should consider employing a fabric testing service to evaluate the durability, water resistance, and overall performance of the materials prior to finalizing their supply agreements.

Scenario 2: Managing Import Duties and Regulations

The Problem: Import duties and regulations can significantly impact the cost-effectiveness of sourcing fabric material shoes, especially for international buyers. For instance, shoes made predominantly of textile materials can incur high import duties, affecting profit margins. Buyers in regions such as Africa and South America may face additional challenges due to fluctuating tariffs and complex customs regulations, making it difficult to maintain competitive pricing.

The Solution: To effectively manage import duties, buyers should thoroughly research the tariff classifications relevant to their products in both the exporting and importing countries. Engaging a customs broker who specializes in footwear can provide invaluable insights into navigating these regulations. Additionally, buyers can explore the possibility of modifying their shoe designs to meet specific criteria that may reduce import duties, such as ensuring that the textile surface area remains below the threshold for higher tariffs. This proactive approach will help buyers reduce costs and enhance their competitive edge in the market.

Illustrative image related to fabric material shoes

Scenario 3: Addressing Consumer Concerns About Fabric Performance

The Problem: As consumers become more educated about footwear, they often express concerns regarding the performance of fabric material shoes, particularly regarding breathability, moisture-wicking, and durability. Buyers may find it challenging to reassure customers about the longevity and functionality of fabric shoes, leading to hesitation in purchasing decisions.

The Solution: To address these concerns, buyers should focus on sourcing fabrics that are engineered for high performance, such as those treated with moisture-wicking technologies or designed with breathable weaves. Collaborating with manufacturers who can provide detailed information about the fabric’s attributes, including testing results and user testimonials, can enhance buyer confidence. Providing consumers with clear information on the care and maintenance of fabric shoes will also help alleviate concerns about durability. Furthermore, implementing a return policy that allows consumers to test the products can build trust and encourage purchases, ultimately leading to higher customer satisfaction and loyalty.

Strategic Material Selection Guide for fabric material shoes

What Are the Key Properties of Common Materials Used in Fabric Material Shoes?

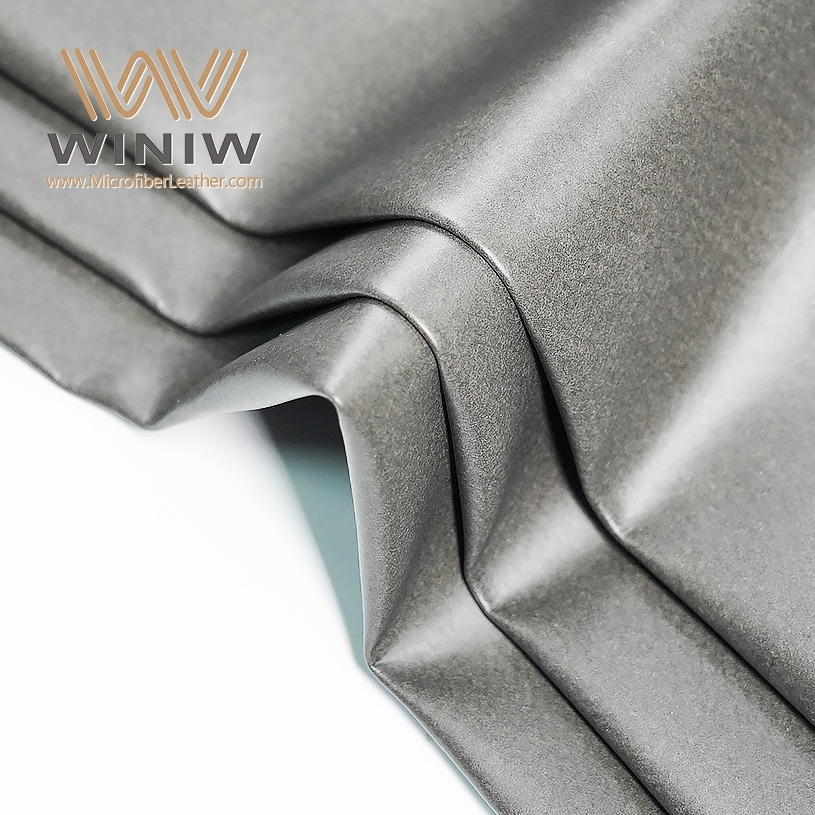

When selecting materials for fabric material shoes, it is essential to consider various factors that affect performance, durability, and overall suitability for specific applications. Below, we analyze four common materials used in the production of fabric shoes: polyester, nylon, cotton canvas, and lycra.

How Does Polyester Perform in Fabric Material Shoes?

Polyester is a synthetic fiber known for its durability and resistance to shrinking and stretching. It has a temperature tolerance that allows it to maintain shape under various conditions, making it suitable for both casual and athletic footwear. Polyester also exhibits good resistance to UV rays and is quick-drying, which is advantageous in humid climates.

Pros: Polyester is lightweight, cost-effective, and easy to dye, providing a wide range of color options. Its durability makes it suitable for high-wear applications.

Cons: While resistant to water, polyester can retain odors and may not be as breathable as natural fibers. It can also be less comfortable in extreme temperatures.

Impact on Application: Polyester shoes are often used in athletic and outdoor footwear, where moisture management and durability are critical.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is vital, especially regarding performance specifications. Buyers should also consider the environmental impact of polyester production, as sustainability is becoming increasingly important.

Illustrative image related to fabric material shoes

What Are the Advantages of Nylon in Fabric Material Shoes?

Nylon is another synthetic fiber that offers exceptional strength and elasticity. It has a high abrasion resistance and can withstand significant wear and tear, making it ideal for performance footwear. Nylon also has a good moisture-wicking property, which helps keep feet dry.

Pros: Its lightweight nature and high tensile strength make nylon a preferred choice for performance-oriented shoes. It also dries quickly and is resistant to mildew.

Cons: Nylon can be less UV resistant than polyester, leading to potential fading over time. Additionally, it may not provide the same level of comfort as natural fibers.

Impact on Application: Nylon is commonly used in sports shoes and outdoor footwear, where durability and moisture management are essential.

Considerations for International Buyers: Buyers should be aware of the varying import duties for nylon products in different regions, particularly in Africa and South America, where tariffs can significantly impact pricing.

Illustrative image related to fabric material shoes

Why Is Cotton Canvas a Preferred Material for Certain Fabric Shoes?

Cotton canvas is a natural fiber known for its breathability and comfort. It is often used in casual footwear and is especially favored for vulcanized shoe constructions, where its ability to withstand high temperatures is crucial.

Pros: Cotton canvas is biodegradable, offers excellent breathability, and can be treated for water resistance. It also provides a classic aesthetic that appeals to many consumers.

Cons: While durable, cotton canvas may not be as resistant to moisture and stains as synthetic options. It can also be heavier than other materials.

Impact on Application: Cotton canvas shoes are ideal for casual wear and are often used in environmentally conscious markets.

Considerations for International Buyers: Compliance with environmental regulations is essential, especially in Europe, where sustainable practices are increasingly scrutinized. Buyers should also consider the availability of treated cotton options for enhanced performance.

How Does Lycra Enhance the Performance of Fabric Material Shoes?

Lycra, or spandex, is a highly elastic synthetic fiber often blended with other materials to enhance stretchability and comfort. It is particularly useful in shoe linings and bindings where flexibility is crucial.

Pros: Lycra provides excellent stretch and recovery, ensuring a snug fit. It also enhances the overall comfort of shoes, making them suitable for long wear.

Cons: Lycra can degrade when exposed to high heat and may not be as durable as other materials when used in high-wear applications.

Impact on Application: Shoes that incorporate Lycra are often designed for athletic or performance use, where flexibility and comfort are paramount.

Considerations for International Buyers: Buyers should ensure that Lycra products meet international quality standards, particularly in markets with strict consumer protection laws.

Summary Table of Material Properties for Fabric Material Shoes

| Materiał | Typical Use Case for fabric material shoes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Athletic and outdoor footwear | Lightweight and durable | Retains odors, less breathable | Low |

| Nylon | Sports and performance footwear | High strength and abrasion resistance | Less UV resistant | Medium |

| Cotton Canvas | Casual and vulcanized shoes | Breathable and biodegradable | Less moisture resistant | Medium |

| Lycra | Athletic shoes and performance wear | Excellent stretch and comfort | Degrades under high heat | Medium |

This analysis provides a comprehensive overview of the materials used in fabric material shoes, highlighting their properties, advantages, and considerations for international B2B buyers.

In-depth Look: Manufacturing Processes and Quality Assurance for fabric material shoes

What Are the Main Stages in the Manufacturing Process of Fabric Material Shoes?

The manufacturing of fabric material shoes involves several key stages, each critical to ensuring that the final product meets quality and performance expectations. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Shoe Manufacturing?

Material preparation begins with the selection of appropriate textiles, which may include cotton, polyester, nylon, or specialized blends. Quality control starts here, as the materials must meet specific standards regarding weight, durability, and colorfastness. After selecting the fabrics, they are cut into patterns that correspond to the shoe design. This cutting process often uses automated machinery to ensure precision and reduce waste.

Once cut, the fabric may undergo various treatments, such as waterproofing or UV protection, depending on the intended use of the shoes. For instance, cotton fabrics may be treated with oil or wax, while synthetic materials might receive a durable water-repellent (DWR) coating. These treatments enhance the performance of the shoes and ensure they are suitable for various environmental conditions.

What Techniques Are Used in the Forming Stage?

The forming stage involves shaping the prepared materials into components of the shoe. Common techniques include weaving, knitting, and laminating. Weaving creates a sturdy fabric, while knitting allows for elasticity, essential for comfort and fit. High-tech meshes may also be used, especially for athletic shoes, to provide breathability and support.

Once the fabric is formed, it is often laminated with a thin layer of foam to control wrinkles and facilitate easier handling during assembly. This foam layer also helps prevent any inner layers from becoming visible through the outer fabric, maintaining the aesthetic quality of the shoe.

How Are Fabric Material Shoes Assembled?

Assembly is a critical phase in the manufacturing process, where the various components are stitched or bonded together. This step often involves advanced machinery for stitching and automated systems for applying adhesives. Key considerations during assembly include ensuring the correct alignment of materials and the strength of seams, which directly impact the shoe’s durability.

Quality checks are crucial during assembly. In-process quality control (IPQC) measures can be implemented to monitor stitching consistency and material adhesion, thereby preventing defects from progressing to the final stages.

What Finishing Processes Are Essential for Quality Fabric Shoes?

Finishing processes enhance the shoe’s appearance and functionality. This stage may include applying protective coatings, adding decorative elements, or finalizing the shoe’s aesthetic features, such as laces or branding. Each finishing touch must be carefully inspected to ensure that it meets the design specifications and quality standards.

Additionally, the shoes undergo final quality assurance checks, where they are inspected for defects in stitching, material integrity, and overall appearance. Proper finishing not only enhances the shoe’s appeal but also contributes to its longevity and performance.

How Is Quality Assurance Implemented in Fabric Material Shoe Manufacturing?

Quality assurance (QA) is vital in the manufacturing of fabric material shoes, ensuring compliance with international standards and meeting customer expectations.

What International Standards Should Buyers Be Aware Of?

International quality standards, such as ISO 9001, guide manufacturers in establishing effective quality management systems. Compliance with these standards is essential for maintaining consistency in production processes and ensuring that products meet customer requirements. In addition to ISO standards, industry-specific certifications such as CE marking (for products sold in the European Economic Area) and API standards may apply, depending on the target market.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to identify and rectify defects early. Key checkpoints include:

-

Incoming Quality Control (IQC): This stage assesses the quality of raw materials upon arrival at the manufacturing facility. It ensures that only materials meeting predetermined specifications are used in production.

-

In-Process Quality Control (IPQC): Conducted during the assembly phase, IPQC involves continuous monitoring of the production process to catch any deviations from quality standards.

-

Final Quality Control (FQC): The final inspection occurs after assembly and finishing. FQC focuses on the overall quality of the finished product, checking for visual defects, performance issues, and adherence to specifications.

What Common Testing Methods Are Employed for Quality Assurance?

Various testing methods are employed to validate the quality and performance of fabric material shoes. Common tests include:

- Durability Testing: Evaluating the lifespan of materials under stress, including abrasion and tear resistance tests.

- Water Resistance Testing: Assessing the effectiveness of water-repellent treatments through immersion or spray tests.

- Comfort Testing: Ensuring the shoes provide adequate support and fit, often through wear trials.

These tests help manufacturers identify potential issues before products reach the market.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers can take several steps to verify the quality control measures of their suppliers. Conducting audits is one of the most effective ways to assess a supplier’s manufacturing processes and quality management systems. An on-site audit allows buyers to observe production practices firsthand and ensure compliance with international standards.

Additionally, requesting detailed quality control reports can provide insights into a supplier’s performance metrics and historical quality data. Buyers should also consider third-party inspections, which offer an unbiased evaluation of the supplier’s quality assurance processes.

What Are the Quality Control Nuances for International Buyers?

For international buyers, understanding the nuances of quality control is crucial. Different countries may have varying regulations regarding product safety and quality standards. Buyers from Africa, South America, the Middle East, and Europe (e.g., Germany, Nigeria) should familiarize themselves with the specific requirements of their target markets.

Additionally, import duties and tariffs can significantly affect the total cost of goods. For instance, shoes with over 51% textile surface area may incur higher import duties, which could impact pricing strategies. Buyers should engage in thorough research and possibly consult with local experts to navigate these complexities effectively.

Illustrative image related to fabric material shoes

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for fabric material shoes is essential for B2B buyers. By focusing on these areas, businesses can ensure they are sourcing high-quality products that meet both their standards and the expectations of their customers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric material shoes’

Wprowadzenie

This practical sourcing guide provides a structured checklist for B2B buyers interested in procuring fabric material shoes. By following these steps, you can ensure that your sourcing process is efficient, effective, and aligned with your business requirements. This guide will help you navigate the complexities of textile selection, supplier evaluation, and compliance considerations.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for successful procurement. Consider factors such as desired fabric types, weight (denier), and specific performance characteristics like water resistance or breathability. Having a detailed specification helps in communicating your needs to suppliers and ensures that you receive products that meet your quality standards.

Step 2: Research Material Options

Understanding the various fabric types available for shoes is essential. Common materials include cotton, nylon, and polyester, each offering unique properties such as durability, stretchability, and water absorption. Researching these materials will enable you to select the best options that align with your product design and target market preferences.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conducting thorough evaluations is vital. Request detailed company profiles, certifications, and references from previous clients. Look for suppliers with experience in fabric material shoes and a solid reputation within your industry, particularly those who understand the specific needs of your target markets, such as Africa, South America, or Europe.

Step 4: Assess Compliance and Import Regulations

It’s critical to understand the compliance requirements and import regulations of your target market. Check for any specific certifications or quality standards that the fabrics must meet. Additionally, be aware of import duties, as textiles can incur high rates; for instance, shoes made with over 51% textile surface area may attract a 20% duty. Familiarizing yourself with these regulations can save your business significant costs and avoid delays.

Step 5: Request Samples for Quality Assessment

Before finalizing an order, always request samples of the fabrics you are considering. This allows you to evaluate the quality, texture, and overall appearance of the materials. Pay attention to how the fabric feels and performs in real-world conditions, as this will impact customer satisfaction and product longevity.

Step 6: Negotiate Pricing and Terms

Once you have identified suitable suppliers and materials, begin negotiations on pricing and terms. Be clear about your budget constraints and ensure that you discuss payment terms, delivery schedules, and potential discounts for bulk orders. A well-negotiated agreement can lead to better margins and a more sustainable supplier relationship.

Illustrative image related to fabric material shoes

Step 7: Establish Quality Control Procedures

Implementing a quality control process is essential for maintaining product standards. Work with your suppliers to define quality benchmarks and inspection protocols. Regular audits and checks during production can help mitigate risks and ensure that the final products align with your specifications and expectations.

By following this checklist, you will be better equipped to source high-quality fabric material shoes that meet your business needs while navigating the complexities of international procurement.

Comprehensive Cost and Pricing Analysis for fabric material shoes Sourcing

Understanding the cost structure of fabric material shoes is crucial for international B2B buyers looking to make informed sourcing decisions. This analysis breaks down the key components involved in pricing, as well as factors influencing costs and strategic tips for negotiation.

What Are the Key Cost Components in Fabric Material Shoes?

-

Materials: The choice of textiles significantly impacts the overall cost. Common materials include polyester, nylon, cotton, and specialized weaves. Each material carries different price points, influenced by market availability and quality standards. For example, high-quality cotton or advanced synthetic materials like 3D mesh may demand a premium.

-

Labor: Labor costs vary widely by region. Countries with lower wage rates may offer more competitive pricing, but this can affect quality and lead times. Buyers should consider the balance between cost and quality, particularly when sourcing from emerging markets.

-

Manufacturing Overhead: Overhead includes expenses related to factory operations, utilities, and workforce management. Efficient manufacturing processes can minimize these costs, but they may vary based on the supplier’s infrastructure and location.

-

Tooling: Initial tooling costs are often significant, especially for customized designs. These costs cover the creation of molds and other equipment needed for production. High tooling costs can be amortized over larger order volumes, making it essential to evaluate minimum order quantities (MOQs).

-

Quality Control (QC): Ensuring product quality often requires additional investments in QC processes. This includes inspections at various stages of production, which can add to the overall cost but is vital for maintaining standards.

-

Logistics: Shipping costs are influenced by the distance between suppliers and buyers, as well as the chosen Incoterms. International shipping can incur tariffs, taxes, and varying freight charges, which should be factored into the total cost.

-

Margin: Supplier margins vary based on competition, market demand, and the supplier’s business strategy. Understanding the typical margins in your target markets can help in negotiations.

How Do Price Influencers Affect Fabric Material Shoe Costs?

Several factors can impact pricing, including:

-

Volume/MOQ: Larger orders typically lead to lower per-unit costs. Suppliers are often willing to negotiate better rates for bulk purchases, making it beneficial for buyers to consolidate orders when possible.

-

Specifications and Customization: Custom designs or specific material requirements can lead to increased costs. Buyers should be clear about their needs to avoid unexpected expenses.

-

Quality and Certifications: Higher quality materials and certifications (e.g., eco-friendly or safety standards) can increase costs. Buyers should assess whether these certifications align with their market demands.

-

Supplier Factors: A supplier’s reputation, reliability, and capacity can influence pricing. Researching potential suppliers thoroughly can ensure a better partnership.

-

Incoterms: Understanding the terms of shipping and responsibility can prevent unexpected costs. Different Incoterms can shift the financial burden of shipping and insurance, impacting the total cost.

What Are the Best Tips for Buyers When Sourcing Fabric Material Shoes?

-

Negotiate Effectively: Leverage knowledge about market rates and supplier competition to negotiate better pricing. Building a relationship with suppliers can also lead to more favorable terms.

-

Focus on Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), which includes not just purchase price but also logistics, quality assurance, and potential returns. This holistic view can lead to better decision-making.

-

Understand Pricing Nuances: International buyers should be aware of local market conditions, currency fluctuations, and import duties that can affect overall costs. For instance, importing from regions with high tariffs can significantly impact profitability.

-

Be Mindful of Trends: Stay updated on industry trends that can influence material costs, such as shifts towards sustainable materials or changes in trade policies.

Disclaimer

Prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific order details. Always seek multiple quotes and conduct thorough due diligence before finalizing sourcing decisions.

Alternatives Analysis: Comparing fabric material shoes With Other Solutions

Understanding the Alternatives to Fabric Material Shoes

In the competitive landscape of footwear design, fabric material shoes offer unique advantages, but it’s crucial to evaluate alternative solutions. This analysis highlights the key attributes of fabric material shoes compared to other viable options, helping B2B buyers make informed decisions tailored to their specific market needs.

Comparison Table

| Comparison Aspect | Fabric Material Shoes | Leather Shoes | Synthetic Shoes |

|---|---|---|---|

| Performance | Lightweight, breathable, customizable | Durable, excellent wear resistance | Good flexibility, water-resistant |

| Cost | Moderate to high | High | Low to moderate |

| Ease of Implementation | Requires specialized knowledge for design | High skill required for crafting | Easy to mass-produce |

| Maintenance | Moderate, often machine washable | High, requires conditioning | Low, easy to clean |

| Best Use Case | Casual, sports, fashion | Formal, luxury, outdoor | Budget-friendly, everyday wear |

Detailed Breakdown of Alternatives

Leather Shoes: Pros and Cons

Leather shoes are renowned for their durability and timeless aesthetic. They provide excellent wear resistance, making them ideal for formal and luxury markets. However, the high cost of quality leather can be prohibitive, especially for budget-conscious buyers. Furthermore, crafting leather shoes demands significant skill, which can extend production timelines. Maintenance is also a consideration, as leather requires regular conditioning to maintain its appearance and longevity.

Synthetic Shoes: Pros and Cons

Synthetic shoes, often made from materials like EVA or PU, present a budget-friendly alternative with good flexibility and water resistance. They are easy to mass-produce, making them suitable for high-volume markets and quick turnaround times. However, synthetic materials may lack the breathability and comfort that fabric shoes provide, which could impact user satisfaction. Additionally, while they are low-maintenance, synthetic shoes may not offer the same level of aesthetic appeal as their fabric or leather counterparts.

Conclusion: Choosing the Right Footwear Solution

When selecting the appropriate footwear solution, B2B buyers should consider their target market, product positioning, and production capabilities. Fabric material shoes excel in versatility and customization, making them suitable for casual and fashion-forward applications. In contrast, leather shoes appeal to luxury and formal sectors, while synthetic options cater to budget-conscious consumers seeking practicality. Assessing these factors will enable buyers to make strategic decisions that align with their business objectives and customer expectations.

Essential Technical Properties and Trade Terminology for fabric material shoes

Understanding the technical properties and trade terminology associated with fabric material shoes is crucial for international B2B buyers. This knowledge facilitates informed decision-making, ensuring that procurement aligns with product specifications and market demands.

What Are the Key Technical Properties of Fabric Material Shoes?

1. Material Grade

Material grade refers to the classification of fabric based on its quality and performance characteristics. In the footwear industry, common grades include premium (high durability and performance) and standard (adequate for everyday use). Understanding material grades helps buyers select appropriate fabrics that meet end-user expectations and price points.

2. Denier

Denier measures the weight of the fabric thread, with a lower number indicating lighter fabric. For instance, 420D to 600D is standard for shoe fabrics, while 1000D is often used for heavy-duty applications like boots. This specification is vital for buyers as it directly impacts the durability and overall weight of the shoe, influencing consumer comfort and performance.

3. Fiber Composition

This term refers to the types of fibers used in the fabric, such as polyester, nylon, or cotton. Each fiber type has distinct properties, like water resistance or breathability. Buyers should prioritize fiber composition based on the intended use of the shoes, whether for athletic performance, casual wear, or specialized environments.

Illustrative image related to fabric material shoes

4. Weave Pattern

The weave pattern describes how the fabric threads are interlaced. Common patterns include plain, twill, and satin. The choice of weave affects the fabric’s strength, elasticity, and aesthetic appeal. Buyers need to understand weave patterns to ensure the final product meets functional requirements and aligns with design intentions.

5. Backing Material

Backing materials, such as PU (polyurethane) or PVC (polyvinyl chloride), provide structural support and durability to the fabric. The type of backing chosen can influence waterproofing, weight, and flexibility. Buyers must consider these factors when selecting fabrics to ensure they align with consumer needs and production capabilities.

What Are the Common Trade Terms in the Fabric Material Shoes Industry?

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of fabric material shoes, OEMs can provide specialized textile solutions tailored to specific designs. Understanding OEM relationships can help buyers negotiate better terms and ensure product quality.

Illustrative image related to fabric material shoes

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. This term is critical for buyers to understand, as it affects their inventory management and cash flow. By knowing the MOQ, buyers can plan their purchases more strategically, ensuring they meet both production needs and budget constraints.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price offers from suppliers. It typically includes specifications, quantities, and delivery requirements. Understanding how to craft and respond to RFQs is essential for buyers to obtain competitive pricing and terms, enabling them to make cost-effective purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping costs, insurance, and liability. Familiarity with these terms helps buyers understand their obligations and rights during the shipping process, reducing the risk of unexpected costs or delays.

5. DWR (Durable Water Repellent)

DWR refers to a treatment applied to fabrics to enhance water resistance. This is particularly relevant in the footwear industry, where performance in wet conditions is often a selling point. Buyers should consider DWR-treated fabrics for shoes designed for outdoor or athletic use to meet consumer expectations for durability and performance.

By grasping these essential technical properties and trade terms, B2B buyers can navigate the complex landscape of fabric material shoes more effectively, ensuring they make informed and strategic purchasing decisions.

Navigating Market Dynamics and Sourcing Trends in the fabric material shoes Sector

What Are the Key Drivers and Trends Influencing the Fabric Material Shoes Market?

The fabric material shoes market is experiencing dynamic growth driven by several global factors. Increasing consumer demand for comfortable, lightweight, and versatile footwear is one of the key drivers. The rise of athleisure culture has significantly influenced design trends, leading to a surge in the popularity of fabric shoes that blend functionality with fashion. Additionally, advancements in textile technology, such as the development of high-performance synthetic fibers and eco-friendly materials, are enhancing product offerings and expanding market potential.

Emerging B2B tech trends, particularly in sourcing and supply chain management, are reshaping how international buyers engage with suppliers. The adoption of digital platforms for procurement is streamlining the sourcing process, allowing businesses in regions like Africa, South America, the Middle East, and Europe to connect with manufacturers more efficiently. Furthermore, data analytics and AI are being utilized to predict market trends and optimize inventory management, thus reducing operational costs and improving responsiveness to market changes.

As sustainability becomes a focal point for consumers and brands alike, buyers are increasingly seeking suppliers who can demonstrate transparency and responsibility in their sourcing practices. The shift towards local sourcing and shorter supply chains is gaining traction, particularly in Europe, as businesses aim to minimize environmental impact while supporting regional economies.

Illustrative image related to fabric material shoes

How Is Sustainability Shaping the Sourcing of Fabric Material Shoes?

Sustainability is a critical consideration for B2B buyers in the fabric material shoes sector. The environmental impact of footwear production is significant, with traditional manufacturing processes often contributing to pollution and waste. Buyers are now prioritizing suppliers who adopt sustainable practices, such as using eco-friendly materials, minimizing water usage, and reducing carbon emissions.

Ethical sourcing is equally important, as brands increasingly focus on creating transparent supply chains that uphold labor rights and fair wages. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® Standard 100 are becoming essential for buyers looking to ensure their products meet rigorous environmental and social criteria.

Moreover, there is a growing trend towards the use of recycled materials in fabric shoes. Innovations in textile recycling are allowing manufacturers to create high-quality fabrics from post-consumer waste, appealing to environmentally conscious consumers and B2B buyers alike. This shift not only helps in reducing the environmental footprint but also opens up new marketing avenues for brands committed to sustainability.

What Is the Historical Context Behind Fabric Material Shoes?

The evolution of fabric material shoes can be traced back to the need for versatile, lightweight footwear that could cater to various lifestyles. Historically, shoes were made predominantly from leather and other rigid materials, which limited comfort and flexibility. The introduction of synthetic fibers in the mid-20th century revolutionized shoe design, allowing for the development of styles that were not only lighter but also more durable and water-resistant.

Over the years, the footwear industry has embraced innovative textile technologies, including advanced weaves and blends that enhance performance characteristics such as breathability and stretch. This evolution has been particularly significant in athletic and casual footwear segments, where fabric shoes have become synonymous with comfort and style. As consumer preferences continue to evolve, the fabric material shoes sector remains at the forefront of design innovation, reflecting broader trends in fashion, technology, and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of fabric material shoes

-

1. How do I choose the right fabric for my shoe production?

Selecting the right fabric for shoe production involves considering several factors, including the intended use of the shoes, target market, and desired durability. Common fabrics include polyester and nylon for lightweight and durable options, while cotton is essential for vulcanized shoes. Evaluate the fabric’s properties such as water resistance, stretchability, and breathability, as well as its aesthetic appeal. Additionally, consider the thread size (denier) and weave pattern, as these can significantly impact the performance and appearance of the final product. -

2. What are the common minimum order quantities (MOQs) for fabric material shoes?

Minimum order quantities (MOQs) for fabric material shoes can vary significantly depending on the supplier and the complexity of the design. Typically, MOQs can range from 100 to 1,000 pairs. It’s advisable to discuss your specific needs with potential suppliers to find a mutually agreeable MOQ. Some manufacturers may offer flexibility for first-time buyers or smaller businesses, while others may require higher volumes to justify production costs. Always inquire about the implications of lower order volumes on pricing. -

3. What are the key factors to consider when vetting suppliers for fabric material shoes?

When vetting suppliers, prioritize their experience in producing fabric material shoes, quality certifications, and adherence to international standards. Request samples to evaluate the fabric quality and craftsmanship. Look for reviews or testimonials from other B2B buyers, and consider visiting the supplier’s manufacturing facility if possible. Additionally, assess their capacity to fulfill orders on time and their ability to provide customization options that align with your brand’s needs. -

4. How can I customize fabric material shoes for my brand?

Customization options for fabric material shoes often include selecting specific fabrics, colors, patterns, and design elements that reflect your brand identity. Work closely with your supplier to discuss your customization requirements, and inquire about the design process, including any associated costs and lead times. Some suppliers may offer design assistance to help you create unique products. Ensure that any customization aligns with your target market’s preferences to maximize appeal. -

5. What payment terms should I expect when sourcing fabric material shoes internationally?

Payment terms can vary by supplier but typically include options such as a deposit followed by the balance upon delivery or after inspection. Common practices involve a 30-50% upfront payment to initiate production, with the remaining balance due before shipment. Discuss payment methods, such as wire transfers or letters of credit, and ensure they align with your financial capabilities. Always review the terms thoroughly to avoid unexpected costs or delays. -

6. How do import duties affect the cost of fabric material shoes?

Import duties on fabric material shoes can significantly impact overall costs. For instance, shoes with over 51% textile surface area may incur a 20% duty in some regions. Additionally, the country of origin can influence duty rates, so it’s essential to research the specific regulations for your importing country. Consider strategies to minimize duties, such as optimizing material composition or manufacturing practices, and ensure compliance with all local trade regulations. -

7. What quality assurance measures should I implement when sourcing fabric material shoes?

Implementing quality assurance (QA) measures is crucial to ensure that the fabric material shoes meet your specifications. Establish clear quality standards and conduct inspections at various stages of production, including pre-production samples and final inspections before shipment. Utilize third-party inspection services for unbiased assessments, and ensure that the supplier adheres to agreed-upon standards. Regular communication with the supplier about quality expectations can also help mitigate issues before they arise. -

8. What logistics considerations should I keep in mind when importing fabric material shoes?

When importing fabric material shoes, consider logistics factors such as shipping methods, lead times, and customs clearance processes. Choose between air freight for faster delivery or sea freight for cost-effectiveness. Understand the documentation required for customs, including bills of lading, invoices, and certificates of origin. Collaborate with experienced freight forwarders who can navigate the complexities of international shipping and ensure compliance with all regulations to avoid delays.

Top 5 Fabric Material Shoes Manufacturers & Suppliers List

1. Shoemakers Academy – Essential Textiles for Shoe Design

Domain: shoemakersacademy.com

Registered: 2022 (3 years)

Introduction: Textiles for Shoe Design: Understanding fabrics is essential for shoe design. Key textiles include nylon, polyester, lycra, and cotton canvas. Considerations for textile selection include thread size (measured in denier), fiber composition (cotton, wool, nylon, polyester, polypropylene, rayon, lycra), weave patterns (plain, twill, satin, basket, doddy, ripstop), backing materials (PU and PVC), siz…

2. Adidas – Key Product Details

Domain: adidas.com

Registered: 1995 (30 years)

Introduction: Key product details for adidas Textile Upper Shoes include: 1273 items available, categorized into various types such as Sneakers (1050), Cleats (178), Boots (35), and more. Sizes range from 1K to 18, including various half sizes. Activities covered include Casual (448) and Athletic (751), with best uses for Comfort (603), Speed (347), and Everyday (189). Features include Cushioned (601), Lightwei…

3. Breathable – Trail Running Shoes

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Breathable shoes made with non-synthetic materials such as leather, hemp, cotton, and bamboo. The user experiences discomfort with synthetic materials, particularly in hot conditions, and is seeking trail running shoes that are not entirely synthetic. They have tried various brands, including Innov8 and Hoka Zinal, and have modified their shoes with leather insoles and cotton socks. They are looki…

4. Allbirds – Wool Cruiser

Domain: allbirds.com

Registered: 2002 (23 years)

Introduction: Allbirds offers a range of comfortable and sustainable shoes and apparel, including men’s and women’s collections. Key products include the Wool Cruiser, Tree Dasher 2, and various waterproof options. The Wool Cruiser is a sophisticated sneaker made from merino wool, while the Tree Dasher 2 provides breathable comfort for everyday performance. The brand’s first fully waterproof collection is desig…

5. Etsy – Unique Shoe Fabric

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: This company, Etsy – Unique Shoe Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for fabric material shoes

As the global footwear market continues to evolve, the strategic sourcing of fabric material shoes presents a wealth of opportunities for international buyers. Understanding the diverse range of textiles available—such as nylon, polyester, and cotton—along with their unique properties, can significantly enhance product offerings. Key factors to consider include thread size, fiber composition, and surface treatments, which directly impact durability, aesthetics, and functionality.

Navigating the complexities of import duties and regulations is essential for maximizing profitability. For example, leveraging specific textile designs can mitigate high duty rates, making sourcing decisions more cost-effective.

Looking ahead, the demand for innovative and sustainable fabric materials is set to rise, driven by consumer preferences for eco-friendly products. B2B buyers from regions like Africa, South America, the Middle East, and Europe should proactively engage with suppliers who prioritize sustainability and technological advancements in textile production.

In conclusion, investing in strategic sourcing not only positions your business to capitalize on current trends but also prepares you for future market shifts. Embrace the potential of fabric material shoes and forge partnerships that will drive growth and innovation in the coming years.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.