Introduction: Navigating the Global Market for reconstituted leather

The global market for reconstituted leather presents a unique opportunity for international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe. As businesses increasingly seek sustainable and cost-effective materials, understanding how to source high-quality reconstituted leather can be a game-changer. This guide aims to address the complexities associated with sourcing reconstituted leather, including the various types available, their applications across industries, and the crucial steps for vetting suppliers.

B2B buyers often face challenges in distinguishing between genuine leather and its reconstituted counterparts, which can lead to costly purchasing errors. With insights into the production processes, durability, and market trends of reconstituted leather, this comprehensive resource empowers businesses to make informed decisions that align with their quality standards and budget constraints. Additionally, we will explore pricing structures, sustainability considerations, and best practices for integrating reconstituted leather into product lines—from upholstery to fashion accessories.

By leveraging the knowledge in this guide, buyers can confidently navigate the complexities of the reconstituted leather market, ensuring they invest in materials that meet their business needs while also appealing to environmentally conscious consumers. This strategic approach not only enhances product offerings but also fosters long-term relationships with reliable suppliers.

Table Of Contents

- Top 5 Reconstituted Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for reconstituted leather

- Understanding reconstituted leather Types and Variations

- Key Industrial Applications of reconstituted leather

- 3 Common User Pain Points for ‘reconstituted leather’ & Their Solutions

- Strategic Material Selection Guide for reconstituted leather

- In-depth Look: Manufacturing Processes and Quality Assurance for reconstituted leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘reconstituted leather’

- Comprehensive Cost and Pricing Analysis for reconstituted leather Sourcing

- Alternatives Analysis: Comparing reconstituted leather With Other Solutions

- Essential Technical Properties and Trade Terminology for reconstituted leather

- Navigating Market Dynamics and Sourcing Trends in the reconstituted leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of reconstituted leather

- Strategic Sourcing Conclusion and Outlook for reconstituted leather

- Important Disclaimer & Terms of Use

Understanding reconstituted leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Bonded Leather | Made from shredded leather scraps mixed with binders; embossed to mimic genuine leather | Upholstery, low-cost fashion items | Pros: Cost-effective, visually appealing. Cons: Limited durability, may peel over time. |

| Skóra PU | Synthetic leather made from polyurethane; offers a soft feel and is often more water-resistant | Fashion accessories, budget-friendly furniture | Pros: Easy to clean, resistant to moisture. Cons: Not as breathable, can wear out faster than natural leather. |

| Recycled Leather | Composed of recycled leather fibers and synthetic materials; eco-friendly option | Eco-conscious brands, sustainable fashion | Pros: Environmentally friendly, unique textures. Cons: Variable quality, may not be as durable as full-grain leather. |

| Sztuczna skóra | Completely synthetic; made from materials like PVC or polyurethane; no animal products | Budget fashion, temporary use items | Pros: Animal-friendly, low-cost. Cons: Lacks durability, less authentic look and feel. |

| Blended Leather | Combination of genuine leather and synthetic materials; often has a more natural appearance than bonded leather | High-end fashion, luxury goods | Pros: Better durability than bonded leather, retains some authentic qualities. Cons: Higher cost, still not as long-lasting as full-grain options. |

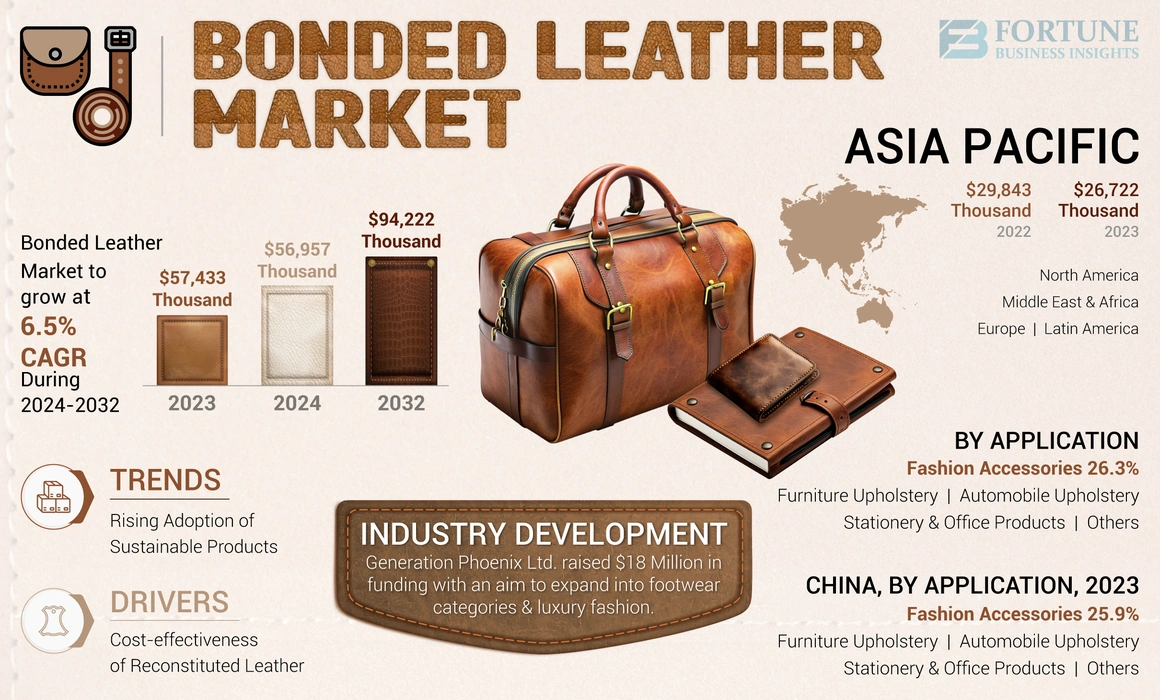

What Are the Key Characteristics of Bonded Leather?

Bonded leather is produced by shredding leftover leather scraps and mixing them with a polyurethane binder. This combination is then pressed onto a fiber backing and embossed to create a leather-like appearance. It is primarily used in upholstery and budget fashion items due to its cost-effectiveness. However, buyers should be aware that while it looks appealing, it typically lasts only 2-5 years before showing signs of wear, such as peeling or cracking, making it a less viable long-term investment.

How Does PU Leather Differ From Other Types?

PU leather, or polyurethane leather, is a synthetic alternative that mimics the soft texture of real leather. It is often more water-resistant and easier to clean, making it suitable for fashion accessories and budget-friendly furniture. While it provides a visually attractive option, it lacks the breathability of genuine leather and may wear out faster, which can be a concern for B2B buyers focusing on longevity and quality in their products.

Why Consider Recycled Leather for Eco-Friendly Brands?

Recycled leather is crafted from repurposed leather fibers combined with synthetic materials, offering an environmentally friendly alternative. This type is gaining popularity among eco-conscious brands and sustainable fashion initiatives. The unique textures and aesthetic appeal can attract consumers looking for green products. However, the quality can vary, and businesses should ensure that the recycled leather meets their durability and performance standards.

What Are the Advantages and Disadvantages of Faux Leather?

Faux leather is entirely synthetic, made from materials like PVC or polyurethane, and contains no animal products. Its affordability makes it a popular choice for budget fashion and temporary use items. While it is animal-friendly, it often lacks the durability and authentic look of genuine leather, which may deter buyers seeking quality for long-term use. Businesses should weigh the cost savings against potential customer satisfaction and product lifespan.

How Does Blended Leather Offer a Compromise?

Blended leather combines genuine leather with synthetic materials, providing a balance between authenticity and cost. This type retains some natural qualities while enhancing durability compared to bonded leather. It is often used in high-end fashion and luxury goods, appealing to buyers who want an elegant look without the full investment in premium leather. However, it is still more expensive than other synthetic options, and businesses should evaluate whether the added cost aligns with their brand positioning and customer expectations.

Key Industrial Applications of reconstituted leather

| Industry/Sector | Specific Application of reconstituted leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for sofas and chairs | Cost-effective alternative to genuine leather, offering aesthetic appeal and durability at a lower price. | Ensure compliance with fire safety standards and durability tests. Assess the environmental impact of the materials used. |

| Automotive | Interior trims and seating | Provides a stylish, durable finish that is easier to maintain than traditional leather. | Verify compatibility with automotive regulations and ensure color and texture consistency across batches. |

| Fashion Accessories | Bags, wallets, and small goods | Versatile material that allows for creative designs while reducing production costs. | Focus on sourcing from reputable manufacturers to ensure quality and ethical production practices. |

| Home Decor | Wall coverings and decorative items | Enhances interior aesthetics while being a sustainable choice using recycled materials. | Confirm supplier certifications for sustainability and quality assurance to meet international standards. |

| Stationery Products | Journals, planners, and portfolios | Provides a premium look and feel at a fraction of the cost of genuine leather, appealing to budget-conscious consumers. | Assess the longevity of the material and its resistance to wear, ensuring it meets customer expectations for quality. |

How is Reconstituted Leather Used in Furniture Manufacturing?

In the furniture manufacturing industry, reconstituted leather is increasingly utilized for upholstery in sofas and chairs. This material offers a visually appealing alternative to genuine leather at a more accessible price point, making it attractive for both manufacturers and consumers. The durability and easy maintenance of reconstituted leather address common issues associated with traditional leather, such as high costs and susceptibility to damage. For international buyers, particularly from regions like Africa and South America, sourcing high-quality reconstituted leather that meets local fire safety standards and durability tests is crucial.

What Role Does Reconstituted Leather Play in the Automotive Sector?

In the automotive sector, reconstituted leather is prominently used for interior trims and seating. Its stylish appearance and durability make it a favored option for car manufacturers looking to enhance vehicle aesthetics without the high costs associated with genuine leather. Additionally, reconstituted leather is easier to clean and maintain, addressing the practical needs of consumers. B2B buyers should consider the compatibility of the material with automotive regulations, ensuring that it meets safety and quality standards while maintaining a consistent look and feel across vehicle models.

Why Choose Reconstituted Leather for Fashion Accessories?

The fashion accessories industry benefits significantly from the use of reconstituted leather in products like bags, wallets, and small goods. This versatile material allows designers to create innovative and stylish products while keeping production costs low. For B2B buyers in the fashion sector, sourcing from reputable manufacturers is essential to ensure the quality and ethical production of these materials. Additionally, understanding the environmental impact of reconstituted leather can enhance brand reputation, particularly in markets that prioritize sustainability.

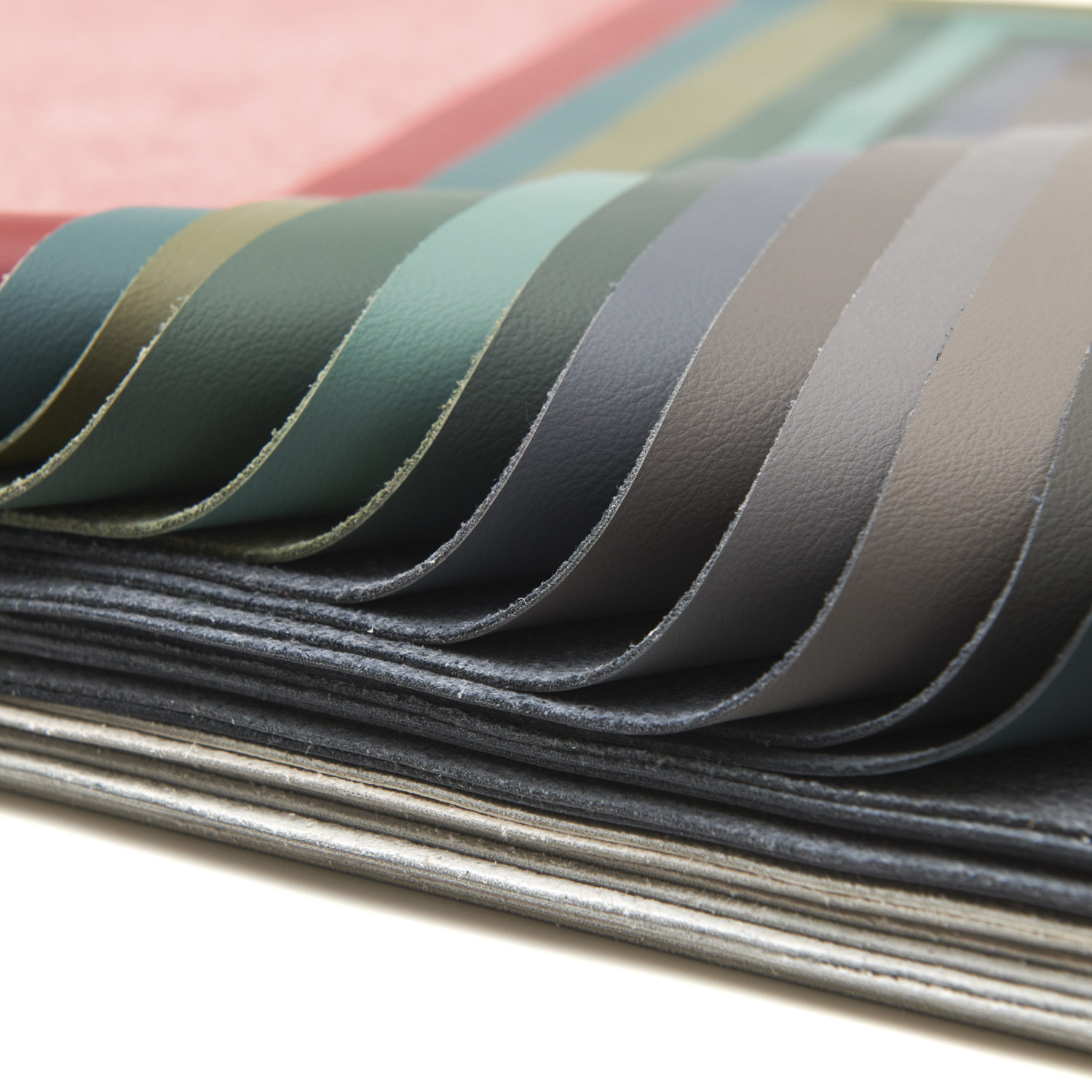

Illustrative image related to reconstituted leather

How is Reconstituted Leather Applied in Home Decor?

In home decor, reconstituted leather is used for wall coverings and decorative items, providing an elegant aesthetic while promoting sustainability through the use of recycled materials. This application not only enhances the visual appeal of interiors but also addresses the growing consumer demand for eco-friendly products. Buyers from Europe and the Middle East should focus on confirming supplier certifications for sustainability and quality assurance, ensuring that the products meet international standards and consumer expectations.

What are the Benefits of Reconstituted Leather in Stationery Products?

Reconstituted leather is increasingly popular in the stationery products sector, used in items such as journals, planners, and portfolios. It offers a premium look and feel at a fraction of the cost of genuine leather, making it appealing to budget-conscious consumers. For B2B buyers, assessing the longevity of the material and its resistance to wear is vital to ensure that the products meet customer expectations for quality. Additionally, sourcing from manufacturers with a commitment to quality can enhance the overall perception of the brand in the market.

3 Common User Pain Points for ‘reconstituted leather’ & Their Solutions

Scenario 1: Navigating Quality Confusion in Reconstituted Leather Products

The Problem: B2B buyers often face a significant challenge in distinguishing high-quality reconstituted leather from subpar options. With varying definitions and standards across manufacturers, buyers may encounter products labeled as “bonded leather” or “blended leather,” which can lead to confusion. This lack of clarity can result in purchasing items that do not meet quality expectations, leading to dissatisfaction among end customers and potential financial loss for businesses.

The Solution: To mitigate this issue, buyers should implement a stringent sourcing strategy. Begin by requesting detailed specifications from suppliers, including the percentage of genuine leather content and the specific materials used in the binding process. It’s essential to verify if the product has been tested for durability and performance. Building relationships with reputable manufacturers who prioritize transparency will enable buyers to procure reliable products. Additionally, consider conducting sample tests before placing bulk orders to ensure the quality meets your standards. Understanding the differences between terms like “genuine leather” and “bonded leather” will empower buyers to make informed decisions, minimizing the risk of poor-quality purchases.

Scenario 2: Understanding the Longevity of Reconstituted Leather

The Problem: Many B2B buyers are enticed by the affordability of reconstituted leather, only to discover that it often has a significantly shorter lifespan compared to genuine leather. This can lead to unexpected replacement costs and dissatisfaction from clients who expect durability in their leather goods. The challenge is further compounded when buyers are not aware of the typical lifespan of various leather types, leading them to make decisions based solely on price.

Illustrative image related to reconstituted leather

The Solution: Educating buyers about the expected lifespan of reconstituted leather compared to genuine leather is crucial. Suppliers should provide clear information on the durability and maintenance requirements of their products. B2B buyers can mitigate risks by considering the intended use of the reconstituted leather items. For instance, if the products are meant for high-traffic areas, investing in higher-quality, thicker reconstituted leather will yield better results. Additionally, recommend implementing a maintenance plan that includes regular cleaning and conditioning to extend the life of the material. By understanding the trade-offs between cost and longevity, buyers can make more strategic purchasing decisions that align with their long-term goals.

Scenario 3: Environmental Concerns and Sustainability Issues with Reconstituted Leather

The Problem: As sustainability becomes increasingly important to consumers and businesses alike, B2B buyers may struggle with the environmental implications of sourcing reconstituted leather. Many buyers are concerned about the environmental footprint of synthetic binders used in the production process, which can deter them from making purchases that align with their corporate social responsibility goals.

The Solution: To address these concerns, buyers should prioritize sourcing from manufacturers who utilize eco-friendly production processes. Seek suppliers that use biodegradable binders or those that have certifications related to sustainability. Engaging with suppliers who provide transparency about their sourcing and manufacturing practices can help buyers ensure that their purchases align with their sustainability objectives. Additionally, consider evaluating the lifecycle impact of reconstituted leather compared to other materials, promoting the recycled nature of some products. By making informed choices and advocating for sustainable practices within the supply chain, B2B buyers can confidently align their purchasing decisions with their environmental values while still accessing the cost benefits of reconstituted leather.

Strategic Material Selection Guide for reconstituted leather

When selecting materials for reconstituted leather, B2B buyers must consider various factors that impact product performance, cost, and suitability for specific applications. Below is an analysis of common materials used in the production of reconstituted leather, focusing on their properties, advantages, disadvantages, and implications for international buyers.

Illustrative image related to reconstituted leather

What Are the Key Properties of Polyurethane (PU) in Reconstituted Leather?

Polyurethane (PU) is a prevalent material in reconstituted leather production. It offers a soft, leather-like texture while being lightweight and flexible. PU can withstand moderate temperature variations but may not perform well under extreme heat or cold. Its resistance to moisture makes it suitable for various applications, including upholstery and fashion accessories.

Pros: PU reconstituted leather is generally more durable than other synthetic options, providing a lifespan of 2 to 5 years with proper care. It is also relatively easy to clean and maintain, making it a practical choice for high-traffic items.

Cons: While PU offers a leather-like appearance, it lacks the breathability of genuine leather, which can lead to discomfort in warmer climates. Additionally, its environmental impact is a concern, as the production process involves synthetic chemicals.

How Does Recycled Leather Fiber Perform in Reconstituted Leather?

Recycled leather fiber, often mixed with a binding agent, forms another common material in reconstituted leather. This material is created from leftover leather scraps, making it an eco-friendly option that appeals to sustainability-conscious buyers.

Pros: The use of recycled leather fibers can enhance the aesthetic appeal of the final product, providing a unique texture and appearance. It is often more affordable than full-grain leather, making it an attractive option for budget-conscious buyers.

Illustrative image related to reconstituted leather

Cons: The durability of recycled leather fiber can vary significantly based on the quality of the source material. It may not withstand wear and tear as effectively as higher-grade options, leading to a shorter lifespan of 1 to 3 years.

What Are the Implications of Latex in Reconstituted Leather?

Latex is sometimes used as a binding agent in the production of reconstituted leather. It provides flexibility and can enhance the overall texture of the material. However, latex can be sensitive to temperature and humidity, which may affect its performance in various environments.

Pros: Latex-bound reconstituted leather can offer a soft feel and is often less expensive than other materials. It can be suitable for applications where cost is a primary concern, such as in low-end furniture or fashion accessories.

Cons: The main drawback of latex is its susceptibility to degradation over time, particularly when exposed to UV light or extreme temperatures. This can lead to cracking and peeling, significantly reducing the product’s lifespan to 1 to 2 years.

What Should International Buyers Consider When Choosing Reconstituted Leather Materials?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, must consider compliance with local regulations and standards. Common standards such as ASTM, DIN, and JIS may dictate material quality and safety. Additionally, preferences for sustainable materials are increasing, particularly in markets like Europe, where eco-friendly products are favored. Buyers should also be aware of the climatic conditions in their regions, as temperature and humidity can significantly affect the performance of reconstituted leather products.

Illustrative image related to reconstituted leather

| Materiał | Typical Use Case for Reconstituted Leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane (PU) | Upholstery, fashion accessories | Durable and easy to maintain | Lacks breathability | Medium |

| Recycled Leather Fiber | Eco-friendly products, budget items | Unique texture and sustainable choice | Variable durability | Low |

| Latex | Low-end furniture, fashion accessories | Cost-effective and flexible | Prone to degradation | Low |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, enabling informed decisions when sourcing reconstituted leather products.

In-depth Look: Manufacturing Processes and Quality Assurance for reconstituted leather

What Are the Key Stages in the Manufacturing Process of Reconstituted Leather?

Reconstituted leather, also known as bonded leather, is created through a series of well-defined manufacturing processes that transform recycled leather scraps into a versatile material suitable for various applications. Understanding these stages is crucial for B2B buyers looking for reliable suppliers and quality products.

Material Preparation: What Goes Into Reconstituted Leather?

The first step in manufacturing reconstituted leather involves sourcing and preparing the raw materials. This typically includes leftover leather scraps and fibers, which are collected from the production of higher-quality leather goods. These scraps are then shredded into fine particles to create a uniform consistency.

Once shredded, the leather fibers are combined with a binding agent, usually polyurethane or latex, which serves to hold the particles together. This mixture is then subjected to a process called emulsification, where it is blended until it reaches a homogenous state. This stage is critical as the quality of the binding agent and the ratio of leather to synthetic materials can significantly impact the final product’s durability and appearance.

Forming: How Is Reconstituted Leather Shaped?

In the forming stage, the prepared mixture is spread onto a backing material, often made of fiber or paper. The application technique can vary; some manufacturers use a spray method to ensure an even coating, while others may opt for a casting method where the mixture is poured onto the backing.

Once applied, the surface is embossed with a texture that mimics natural leather grains. This step not only enhances the aesthetic appeal but also provides a functional surface that can withstand wear and tear. The embossing process is often performed using heated plates that imprint the desired pattern onto the material.

Assembly: What Are the Steps to Final Product Creation?

After forming, the reconstituted leather undergoes an assembly phase where it is cut and sewn into various products. This could include items like handbags, furniture upholstery, or accessories. The precision in cutting and stitching is crucial, as it affects both the product’s durability and its marketability.

Illustrative image related to reconstituted leather

Quality craftsmanship during the assembly stage is vital. Manufacturers may employ skilled labor or automated machinery to ensure consistency and minimize defects. Attention to detail at this stage can significantly enhance the perceived value of the final product.

Finishing: What Techniques Enhance the Appearance and Longevity?

The finishing stage involves applying treatments to enhance the look and feel of the reconstituted leather. This can include applying dyes, protective coatings, and other treatments that improve durability and resistance to stains and moisture. Common finishes may include matte, glossy, or textured surfaces.

Finishing techniques can also vary widely, with some manufacturers opting for environmentally friendly options that appeal to sustainability-conscious buyers. The choice of finish can significantly influence the product’s market positioning, making it essential for B2B buyers to understand the options available.

What Quality Assurance Measures Are Essential for Reconstituted Leather?

Quality assurance is a critical component of the manufacturing process for reconstituted leather, ensuring that the final product meets international standards and buyer expectations. Understanding these measures can help B2B buyers make informed decisions when selecting suppliers.

What International Standards Should B2B Buyers Consider?

Reconstituted leather manufacturers often adhere to international quality standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards indicates that the manufacturer has implemented effective processes to ensure consistent product quality.

Illustrative image related to reconstituted leather

In addition to ISO 9001, specific industry standards may apply, depending on the product’s intended use. For example, CE marking may be relevant for products sold in Europe, indicating conformity with health, safety, and environmental protection standards. B2B buyers should inquire about these certifications during the supplier selection process.

How Are Quality Control Checkpoints Structured?

Quality control (QC) is typically organized into three main checkpoints:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials, including the leather scraps and binding agents, to ensure they meet predefined specifications. This step is vital for identifying any potential issues before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing stages, IPQC monitors the processes to ensure that they adhere to quality standards. This may include sampling and testing the mixture during the forming stage or inspecting the embossing quality.

-

Final Quality Control (FQC): Once the products are assembled and finished, FQC involves a thorough inspection of the final goods. This can include visual inspections for defects, testing for durability, and assessing the overall appearance and functionality of the products.

What Testing Methods Are Commonly Used?

Various testing methods are employed to assess the quality of reconstituted leather. Common tests include:

- Tensile Strength Testing: Measures the material’s ability to withstand tension without breaking.

- Abrasion Resistance Testing: Evaluates how well the surface withstands wear from friction.

- Colorfastness Testing: Assesses the material’s resistance to fading or discoloration when exposed to light or washing.

These tests help ensure that the final product meets or exceeds industry standards, providing reassurance to B2B buyers regarding its performance and longevity.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying the quality control measures of a supplier is critical for B2B buyers, particularly those operating in diverse international markets. Here are actionable strategies for ensuring that suppliers meet quality standards:

What Are the Best Practices for Supplier Audits?

Conducting regular audits is one of the most effective ways to verify a supplier’s quality control processes. These audits can be performed by the buyer or a third-party inspection service. Key areas to focus on during an audit include:

Illustrative image related to reconstituted leather

- Production Processes: Assess whether the supplier follows established protocols for material preparation, forming, assembly, and finishing.

- Quality Control Procedures: Review the QC checkpoints and testing methods to ensure they align with industry standards.

- Certification Documentation: Request copies of relevant certifications, such as ISO 9001 or CE marking, to verify compliance with international standards.

How Can B2B Buyers Leverage Reports and Third-Party Inspections?

Suppliers should provide detailed reports on their quality control processes, including results from testing and inspections. B2B buyers can request these reports to gain insights into the supplier’s commitment to quality.

Additionally, utilizing third-party inspection services can provide an unbiased assessment of the supplier’s processes and products. These services can conduct random inspections and testing, offering an added layer of assurance for B2B buyers.

Conclusion: Why Quality Assurance in Reconstituted Leather Matters for International Buyers

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance measures for reconstituted leather is essential. By focusing on the key stages of production and implementing rigorous quality control protocols, buyers can ensure they source products that meet their standards and expectations. This knowledge not only aids in making informed purchasing decisions but also strengthens supplier relationships by emphasizing the importance of quality in the competitive marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘reconstituted leather’

Wprowadzenie

This sourcing guide serves as a practical checklist for B2B buyers looking to procure reconstituted leather, also known as bonded leather or blended leather. Understanding the nuances of this material, along with the proper steps to source it effectively, is crucial for making informed purchasing decisions that align with both quality and budget considerations.

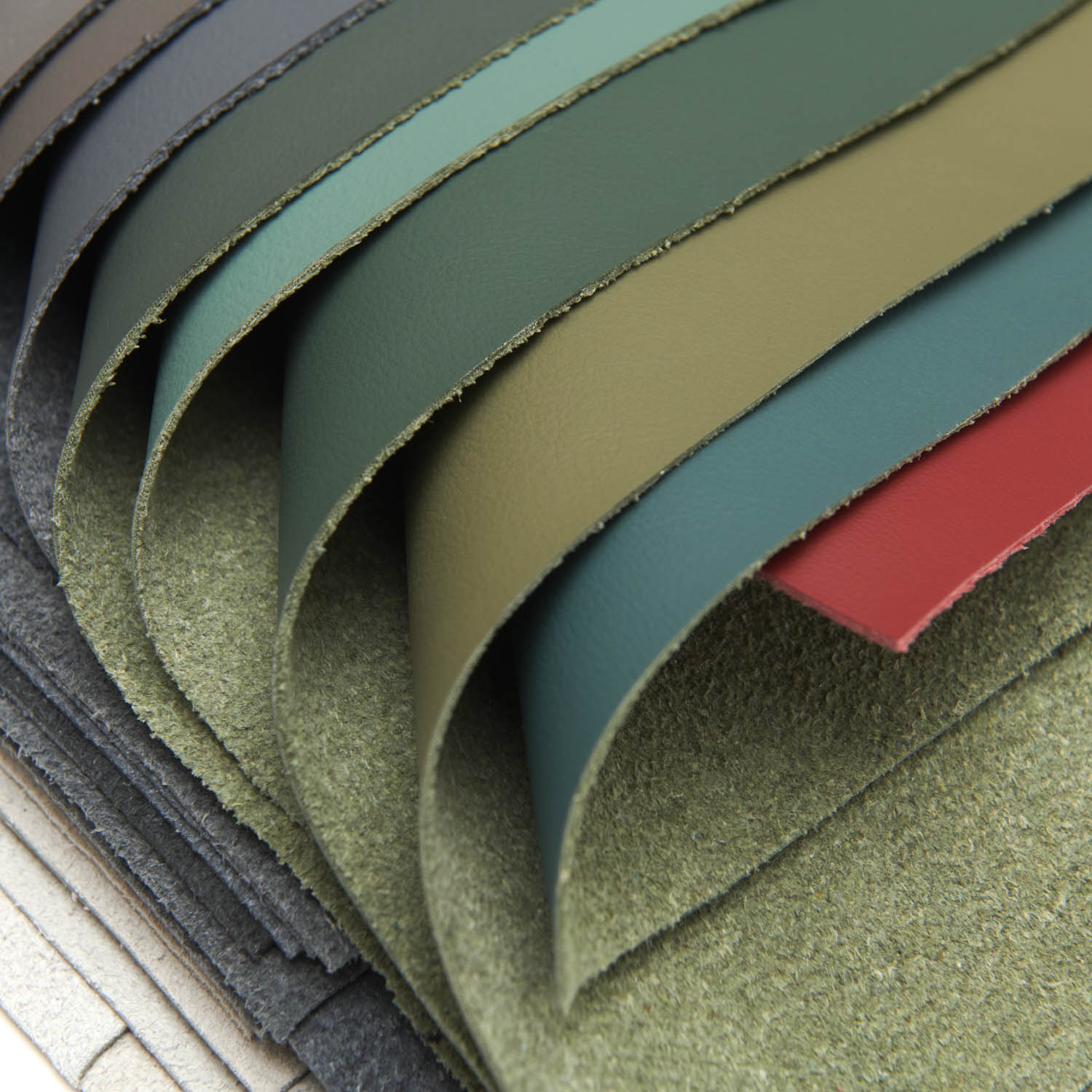

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical specifications for reconstituted leather. Consider factors such as thickness, texture, color, and intended use (e.g., upholstery, accessories, or automotive). A well-defined specification helps ensure that suppliers can meet your exact requirements, reducing the risk of receiving subpar materials.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of reconstituted leather. Look for companies with a proven track record and positive reviews from other B2B buyers. Utilize online platforms, trade shows, and industry associations to gather information and create a shortlist of potential suppliers.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers possess relevant certifications and adhere to industry standards. Certifications such as ISO, REACH, and environmental sustainability credentials indicate a commitment to quality and responsible sourcing practices. This step not only ensures material quality but also aligns your procurement with ethical and sustainable practices.

Step 4: Request Samples

Always request samples of reconstituted leather before finalizing any orders. Evaluating physical samples allows you to assess the material’s appearance, texture, and durability firsthand. This step is crucial to ensure that the product meets your specifications and expectations, preventing costly mistakes later on.

Step 5: Inquire About Production Methods

Understanding the production methods used to create the reconstituted leather is vital. Inquire about the percentage of genuine leather content and the types of binding agents used in the manufacturing process. This knowledge can help you gauge the quality and longevity of the material, allowing for better decision-making.

Step 6: Negotiate Terms and Pricing

Once you’ve identified a suitable supplier, engage in negotiations regarding pricing, delivery timelines, and payment terms. Ensure that all agreements are clearly documented to avoid misunderstandings. A thorough negotiation process can lead to cost savings and improved contractual terms that benefit your business.

Step 7: Establish Quality Control Procedures

Implement quality control measures to monitor the reconstituted leather upon arrival. This includes inspecting the material for defects, consistency, and adherence to your specifications. Establishing a quality control protocol ensures that you receive the expected standard of materials, safeguarding your product’s integrity and reputation.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing reconstituted leather more effectively, ensuring high-quality materials that meet their specific needs.

Comprehensive Cost and Pricing Analysis for reconstituted leather Sourcing

What Are the Key Cost Components for Sourcing Reconstituted Leather?

When sourcing reconstituted leather, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The base cost of reconstituted leather is influenced by the quality of the leather scraps used, the type of binding agents (such as polyurethane or latex), and any additional treatments for durability and aesthetics. Higher-quality materials will increase the overall cost but may offer better performance and longevity.

-

Labor: Labor costs involve the workforce required for processing, including shredding, mixing, and pressing the leather fibers. Regions with lower labor costs can provide competitive pricing, but this may also correlate with varying quality levels.

-

Manufacturing Overhead: This includes expenses related to factory operation, utilities, maintenance, and administrative costs. Efficient manufacturing processes can reduce overhead, impacting the final pricing positively.

-

Tooling: Initial tooling costs for machinery and equipment used in the production of reconstituted leather can be significant. Depending on the complexity of the manufacturing process, these costs may be spread over large production runs, reducing the per-unit cost.

-

Quality Control (QC): Implementing robust QC processes ensures that the final product meets buyer specifications. This adds to the overall cost but protects against quality issues that can lead to returns and dissatisfaction.

-

Logistics: Transportation and warehousing costs will vary based on the origin of the materials and the delivery locations. Efficient logistics can minimize costs, particularly when sourcing materials internationally.

-

Margin: Suppliers typically include a profit margin that reflects their operational costs, market demand, and competitive positioning. Understanding this margin can aid buyers in negotiations.

How Do Price Influencers Affect the Cost of Reconstituted Leather?

Several factors can influence the pricing of reconstituted leather, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk orders, making it advantageous for buyers to source larger quantities. Understanding the MOQ can help buyers plan their purchases more strategically.

-

Specifications and Customization: Custom designs or specifications can incur additional costs. Buyers should clarify their needs upfront to avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials or certifications (e.g., eco-friendly certifications) may command higher prices. However, these can also enhance the product’s marketability and longevity.

-

Supplier Factors: The reputation, reliability, and geographical location of the supplier can impact pricing. Suppliers with a track record of quality may charge more but reduce risks associated with poor-quality products.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define the responsibilities of buyers and sellers, affecting shipping costs and risk management.

What Are the Best Buyer Tips for Negotiating Costs and Ensuring Value?

For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, effective negotiation and cost management are vital:

-

Negotiation Strategies: Always enter negotiations well-informed about market prices and competitor offerings. Leverage volume commitments to negotiate better rates, and be prepared to walk away if terms are not favorable.

-

Total Cost of Ownership (TCO): Assess the TCO rather than just the upfront price. Consider factors like durability, maintenance, and potential replacement costs when evaluating suppliers.

-

Pricing Nuances for International Buyers: Currency fluctuations, import tariffs, and local market conditions can affect pricing. Stay updated on these factors to make informed purchasing decisions.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing, priority service, and insights into new products or trends.

-

Request Samples: Before committing to a large order, request samples to evaluate quality and ensure it meets your specifications. This can save significant costs in the long run.

Disclaimer on Indicative Prices

Prices for reconstituted leather can vary widely based on market conditions, supplier practices, and specific buyer requirements. Always conduct thorough research and seek multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing reconstituted leather With Other Solutions

Understanding Alternatives to Reconstituted Leather

In the quest for sustainable and cost-effective materials, reconstituted leather presents a viable option. However, it is crucial for B2B buyers to explore other alternatives that may offer distinct advantages depending on their specific needs. This analysis compares reconstituted leather with two primary alternatives: genuine leather and synthetic leather. By examining key performance indicators, cost implications, and use cases, businesses can make informed decisions.

| Comparison Aspect | Reconstituted Leather | Genuine Leather | Synthetic Leather |

|---|---|---|---|

| Performance | Moderate durability; susceptible to peeling | High durability; ages well | Varies; can be durable but depends on quality |

| Cost | Lower initial cost | Higher initial investment | Generally lower cost |

| Ease of Implementation | Easy to work with; versatile | Requires skilled craftsmanship | Easy to manufacture |

| Maintenance | Minimal care required; prone to wear | Requires regular conditioning | Low maintenance; easy to clean |

| Best Use Case | Budget-friendly applications; furniture | High-end products; luxury goods | Fashion items; accessories |

What Are the Advantages and Disadvantages of Genuine Leather?

Genuine leather is the traditional choice for quality and durability. Its unique natural grain and ability to develop a patina over time make it an appealing option for luxury items. The longevity of genuine leather can range from 10 to 30 years with proper care, making it a sound long-term investment. However, the higher initial cost may be a barrier for some businesses, particularly those with tight budgets. Additionally, the sourcing and tanning processes can raise ethical and environmental concerns.

How Does Synthetic Leather Compare to Reconstituted Leather?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), is designed to mimic the appearance of genuine leather while being more affordable. One of its primary advantages is the wide range of colors and textures available, allowing for creative flexibility in product design. Maintenance is straightforward, as synthetic leather is typically easy to clean and resistant to stains. However, the durability can vary significantly based on the manufacturing process. Lower-quality synthetic leathers may not last as long as reconstituted leather, leading to potential issues with wear and tear.

Conclusion: How Should B2B Buyers Choose the Right Material?

When selecting the appropriate material for their needs, B2B buyers should consider several factors including budget, intended use, and desired longevity. Reconstituted leather serves as a cost-effective alternative suitable for budget-conscious projects, while genuine leather appeals to those seeking high-quality and durable products. Synthetic leather may offer versatility and ease of maintenance, making it a good option for fashion accessories. Ultimately, understanding the specific requirements of a project will guide businesses in choosing the most suitable leather alternative.

Essential Technical Properties and Trade Terminology for reconstituted leather

What Are the Key Technical Properties of Reconstituted Leather?

Understanding the essential technical properties of reconstituted leather is critical for B2B buyers looking to make informed purchasing decisions. Here are several key specifications:

Illustrative image related to reconstituted leather

1. Material Composition

Reconstituted leather, often referred to as bonded leather, is primarily made from leftover leather scraps, which are shredded and combined with a binding agent such as polyurethane or latex. This composition gives it a unique texture that mimics genuine leather while being more economical. For B2B buyers, understanding material composition is crucial for assessing product quality and aligning it with customer expectations.

2. Thickness and Weight

The thickness of reconstituted leather typically ranges from 0.5 mm to 2 mm, while the weight can vary based on the production process and intended application. These specifications are important for manufacturers as they impact the durability and usability of the final product. Thicker materials may be more durable but can also affect the comfort and flexibility of items like furniture upholstery or fashion accessories.

3. Tolerance Levels

Tolerance refers to the allowable variation in the material’s dimensions and properties during production. For reconstituted leather, this can include variations in thickness, color, and texture. Establishing clear tolerance levels is essential for manufacturers to ensure consistency in large production runs, ultimately affecting product quality and customer satisfaction.

4. Durability Rating

Durability is a critical factor that encompasses the lifespan and resistance to wear and tear of reconstituted leather products. Typically, bonded leather has a durability rating of around 2 to 5 years, significantly lower than genuine leather. This rating is vital for B2B buyers to consider when evaluating the long-term cost-effectiveness of their purchases, particularly in high-traffic applications.

5. Environmental Impact

The production of reconstituted leather is often viewed as more sustainable compared to traditional leather, as it utilizes waste materials. Understanding the environmental impact and sustainability practices associated with reconstituted leather can be a selling point for companies looking to enhance their eco-friendly credentials in the market.

Illustrative image related to reconstituted leather

What Are Common Trade Terms in the Reconstituted Leather Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the reconstituted leather market. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are used in another company’s end product. In the context of reconstituted leather, an OEM might manufacture leather components for furniture or automotive industries. Understanding OEM relationships can aid buyers in establishing partnerships and ensuring quality standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For reconstituted leather, MOQs can vary significantly based on the manufacturer and specific product line. Buyers must consider MOQ when planning inventory and managing costs, as larger orders might lead to better pricing but also require more upfront investment.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting price quotes for specific products. In the reconstituted leather industry, issuing an RFQ helps buyers gather competitive pricing and terms from multiple suppliers, facilitating informed purchasing decisions.

Illustrative image related to reconstituted leather

4. Incoterms

Incoterms (International Commercial Terms) are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is vital for B2B buyers to understand shipping costs, risks, and responsibilities, which can significantly impact the overall cost of purchasing reconstituted leather.

5. Lead Time

Lead time is the duration between placing an order and receiving the product. In the reconstituted leather industry, understanding lead times is crucial for supply chain planning and inventory management. Buyers must factor in lead times when coordinating production schedules and ensuring timely delivery to clients.

By grasping these technical properties and trade terms, B2B buyers can navigate the reconstituted leather market more effectively, making decisions that align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the reconstituted leather Sector

What Are the Key Market Trends Impacting the Reconstituted Leather Sector?

The reconstituted leather sector is experiencing significant transformation driven by a combination of technological advancements, shifting consumer preferences, and economic factors. Globally, the demand for cost-effective and versatile materials is on the rise, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. In regions like Brazil and Nigeria, where economic growth is fostering a burgeoning middle class, reconstituted leather offers an affordable alternative to traditional leather without compromising on aesthetics.

Illustrative image related to reconstituted leather

Emerging B2B technologies such as blockchain are enhancing supply chain transparency, allowing international buyers to trace the origins of their materials. This is particularly crucial in regions where the authenticity and quality of leather products can vary widely. Additionally, advancements in manufacturing processes are leading to improved durability and texture in reconstituted leather, making it increasingly viable for high-end applications like furniture and fashion accessories.

Furthermore, the market is witnessing a growing emphasis on customization and personalization, with suppliers increasingly offering bespoke solutions to meet specific buyer requirements. This trend is particularly relevant for businesses targeting niche markets or seeking to differentiate themselves through unique product offerings.

How Is Sustainability Influencing Sourcing Decisions in the Reconstituted Leather Market?

Sustainability has become a cornerstone of sourcing decisions in the reconstituted leather sector. International buyers are increasingly aware of the environmental impact associated with leather production, including deforestation, water usage, and chemical pollution. As a result, there is a rising demand for ethically sourced materials that align with sustainability goals.

Illustrative image related to reconstituted leather

Reconstituted leather, often made from recycled leather scraps and sustainable binders, presents an eco-friendlier option compared to traditional leather. Buyers are encouraged to seek suppliers who hold certifications such as Global Recycled Standard (GRS) or OEKO-TEX, which assure environmentally responsible practices throughout the supply chain. These certifications not only enhance product credibility but also appeal to a growing consumer base that prioritizes eco-conscious purchasing.

Moreover, companies are increasingly investing in sustainable production methods, such as waterless tanning and non-toxic dyes, to further reduce their environmental footprint. This commitment to sustainability not only satisfies regulatory requirements but also positions businesses favorably in a competitive marketplace increasingly driven by consumer demand for responsible products.

What Is the Historical Context of Reconstituted Leather in B2B Markets?

Reconstituted leather, also known as bonded leather, has evolved significantly since its inception. Initially developed as a cost-effective alternative to genuine leather in the mid-20th century, it gained traction due to its affordability and versatility. Early applications were primarily in lower-end products, such as furniture and book covers.

Over the years, advancements in technology and manufacturing processes have improved the quality and aesthetic appeal of reconstituted leather, allowing it to penetrate higher-end markets. Today, it is used in a variety of applications, from automotive interiors to luxury handbags, reflecting a broader acceptance and recognition of its potential.

Illustrative image related to reconstituted leather

As global markets continue to evolve, understanding the historical context of reconstituted leather provides valuable insights into current trends and future opportunities. Buyers can leverage this knowledge to make informed sourcing decisions that align with both their business objectives and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of reconstituted leather

-

1. How do I assess the quality of reconstituted leather before purchase?

To assess the quality of reconstituted leather, inquire about its composition and manufacturing process. Reconstituted leather typically contains a mix of leather fibers and synthetic materials. Request samples to evaluate texture, durability, and appearance. Look for certifications or standards that ensure quality, such as ISO certifications. Additionally, consider the supplier’s reputation and experience in the industry to gauge reliability. -

2. What is the best use case for reconstituted leather in B2B applications?

Reconstituted leather is ideal for applications where budget constraints are significant, such as furniture upholstery, fashion accessories, or promotional items. Its cost-effectiveness makes it suitable for high-volume production without compromising on aesthetics. However, for luxury products or items requiring high durability, consider higher-grade materials like full-grain or top-grain leather. -

3. What are the typical minimum order quantities (MOQs) for reconstituted leather suppliers?

MOQs for reconstituted leather can vary significantly based on the supplier and the specific material requested. Generally, you might encounter MOQs ranging from 50 to 500 yards, depending on the production capabilities and inventory of the supplier. It’s advisable to discuss your needs directly with potential suppliers to negotiate favorable terms that align with your business model. -

4. What payment terms should I expect when sourcing reconstituted leather internationally?

Payment terms for international transactions typically include options like advance payment, letters of credit, or payment upon delivery. Many suppliers require a deposit (often 30-50%) upfront, with the balance payable before shipment. Always clarify payment methods and timelines in advance to ensure smooth transactions and avoid potential delays in production or shipping. -

5. How can I ensure compliance with international trade regulations when importing reconstituted leather?

To ensure compliance with international trade regulations, familiarize yourself with the import laws of your country and the exporting country. Verify that the supplier provides necessary documentation, such as customs declarations and quality certifications. It may also be helpful to consult with a customs broker or trade expert to navigate tariffs, import duties, and any specific regulations related to leather products. -

6. What quality assurance measures should I implement when sourcing reconstituted leather?

Implementing quality assurance measures involves establishing clear criteria for materials and production standards. Request detailed product specifications from suppliers, and consider conducting factory audits or third-party inspections. Additionally, require samples for testing before bulk orders and establish a return policy for defective goods to mitigate risks associated with quality issues. -

7. How do I find reliable suppliers of reconstituted leather in different regions?

To find reliable suppliers, utilize online trade platforms, industry trade shows, and professional networks. Conduct thorough research on potential suppliers by checking reviews, ratings, and their history of fulfilling orders. Engaging with industry associations can also provide recommendations. Once you identify candidates, initiate communication to assess responsiveness and willingness to meet your specific needs. -

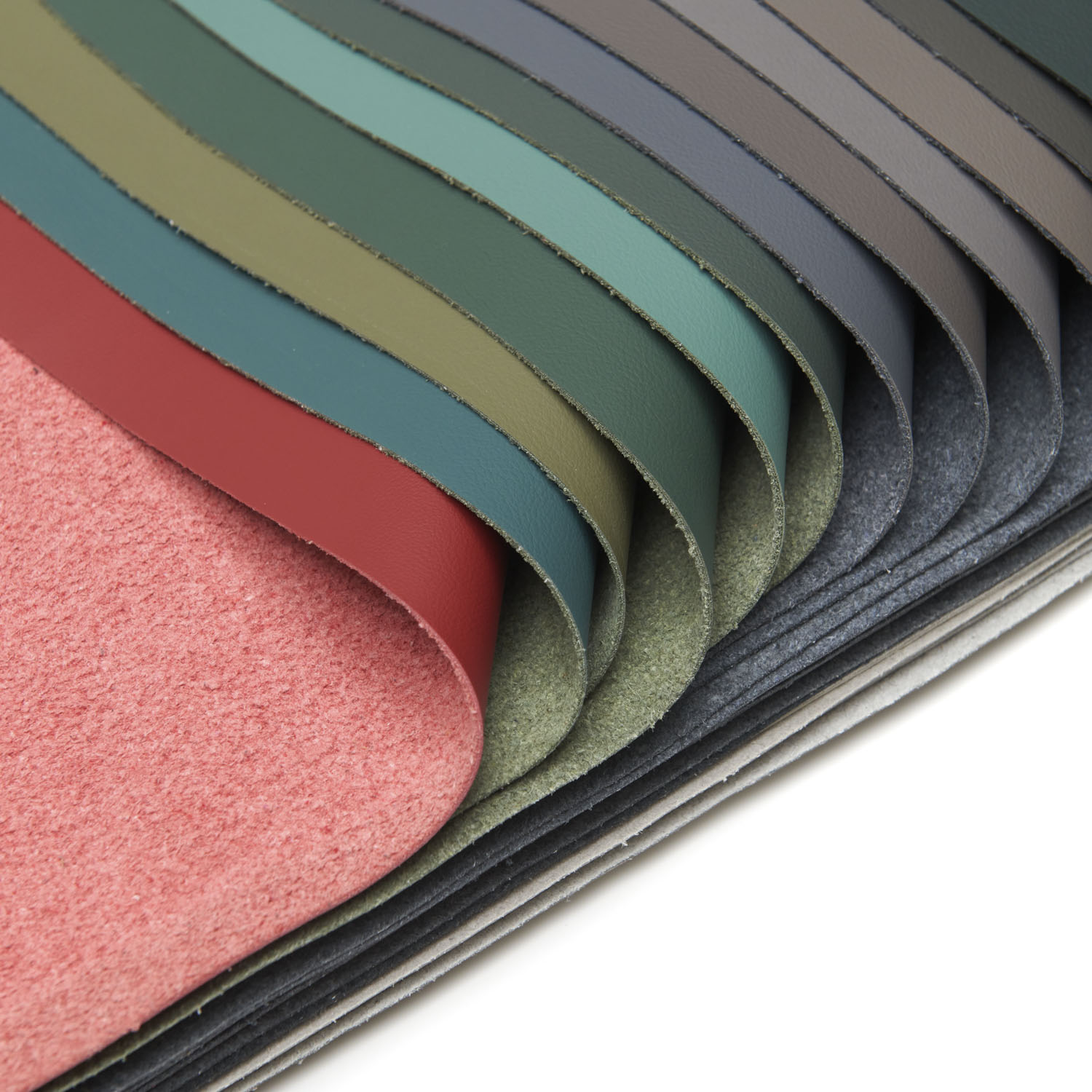

8. What customization options are available for reconstituted leather products?

Customization options for reconstituted leather products can include color, texture, thickness, and embossing patterns. Many suppliers offer a range of finishes to cater to specific aesthetic requirements. Discuss your design needs with potential suppliers to explore available options, and request prototypes to evaluate the final product before committing to larger orders. This can help ensure that the final product meets your brand’s standards and vision.

Top 5 Reconstituted Leather Manufacturers & Suppliers List

1. Mission Mercantile – Genuine Leather Products

Domain: missionmercantile.com

Registered: 2015 (10 years)

Introduction: Genuine leather vs. bonded leather comparison, product categories include leather bags (backpacks, briefcases, duffle bags, luggage, tote bags), leather accessories (toiletry kits, beverage carriers, travel accessories, wallets), leather hunting and outdoor gear (cases, accessories), and women’s bags (tote bags, handbags, backpacks). Collections include Theodore, Campaign, White Wing, Heritage, El…

2. Radermecker – Reconstituted Leather Solutions

Domain: radermecker.com

Registered: 2015 (10 years)

Introduction: Reconstituted leather, also known as synthetic or artificial leather, is made from leather scraps and synthetic binders (PU, PVC, latex, acrylic). It contains 10-17% real leather and is manufactured to mimic the look and feel of genuine leather. It is less durable than full grain leather, which retains its natural texture and is more breathable. Reconstituted leather is often used in clothing, foo…

3. Talas Online – In Stock Rating 4.0/5

Domain: talasonline.com

Registered: 2000 (25 years)

Introduction: This company, Talas Online – In Stock Rating 4.0/5, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Manuel Dreesmann – Bonded Leather Solutions

Domain: manuel-dreesmann.com

Registered: 2017 (8 years)

Introduction: This company, Manuel Dreesmann – Bonded Leather Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Buffalo Jackson – Leather Goods

Domain: buffalojackson.com

Registered: 2011 (14 years)

Introduction: Buffalo Jackson offers a variety of leather goods including men’s and women’s collections, leather bags, jackets, wallets, and accessories. Their products feature full grain leather and include categories such as leather briefcases, messenger bags, duffle bags, travel bags, backpacks, totes, and camera bags. The leather jackets come in various styles including bomber, motorcycle, outdoor, puffer, …

Strategic Sourcing Conclusion and Outlook for reconstituted leather

In conclusion, strategic sourcing of reconstituted leather presents a unique opportunity for international B2B buyers seeking cost-effective and versatile materials. This synthetic alternative, often referred to as bonded or blended leather, offers a visually appealing finish at a fraction of the price of genuine leather. However, it’s crucial to discern quality differences, as the longevity and durability of reconstituted leather can vary significantly.

As you navigate the sourcing landscape, prioritize suppliers who provide transparency regarding the composition and quality of their products. This diligence will help you avoid inferior options and ensure you invest in materials that meet your project requirements. Building relationships with reputable manufacturers in Africa, South America, the Middle East, and Europe will not only enhance your supply chain resilience but also foster innovation in your product offerings.

Looking ahead, the demand for sustainable and economically viable leather alternatives is poised to grow. Embrace this trend by integrating high-quality reconstituted leather into your product lines. Take action now by exploring partnerships with trusted suppliers who can meet your needs for quality, sustainability, and cost-efficiency in the evolving leather market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.