Introduction: Navigating the Global Market for leather machine company

Navigating the intricate landscape of sourcing leather machines can be a daunting challenge for B2B buyers across the globe. The demand for high-quality, efficient machinery tailored to the unique needs of leather production is on the rise, particularly in emerging markets in Africa, South America, the Middle East, and Europe, including countries like Vietnam and Saudi Arabia. This guide aims to demystify the process of selecting the right leather machine company by providing actionable insights into the types of machinery available, their various applications, and essential criteria for vetting suppliers.

Buyers will find a comprehensive overview of the essential equipment required for leather crafting—from sewing machines to cutting tools—alongside detailed guidance on evaluating supplier reliability and quality. Additionally, we will address pricing structures and potential cost-saving strategies that can significantly impact your bottom line. By leveraging the information contained within this guide, international B2B buyers will be equipped to make informed purchasing decisions that align with their operational needs and budget constraints.

Whether you are a seasoned industry professional or new to the leather sector, understanding the nuances of the global leather machine market is crucial for fostering growth and innovation in your business. This guide empowers you to navigate the complexities of sourcing and investing in leather machinery, ensuring you select the best options for your specific requirements.

Table Of Contents

- Top 4 Leather Machine Company Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather machine company

- Understanding leather machine company Types and Variations

- Key Industrial Applications of leather machine company

- 3 Common User Pain Points for ‘leather machine company’ & Their Solutions

- Strategic Material Selection Guide for leather machine company

- In-depth Look: Manufacturing Processes and Quality Assurance for leather machine company

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather machine company’

- Comprehensive Cost and Pricing Analysis for leather machine company Sourcing

- Alternatives Analysis: Comparing leather machine company With Other Solutions

- Essential Technical Properties and Trade Terminology for leather machine company

- Navigating Market Dynamics and Sourcing Trends in the leather machine company Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather machine company

- Strategic Sourcing Conclusion and Outlook for leather machine company

- Important Disclaimer & Terms of Use

Understanding leather machine company Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Leather Sewing Machines | Designed for stitching leather with heavy-duty capabilities | Manufacturing leather goods, apparel, and accessories | Pros: Versatile, durable, high-quality stitching. Cons: Higher initial investment, requires maintenance. |

| Leather Cutting Machines | Precision cutting tools for various leather thicknesses | Production of leather patterns, straps, and components | Pros: Increases efficiency, reduces waste. Cons: Can be costly, requires skilled operation. |

| Leather Skiving Machines | Machines that thin leather edges for smooth finishes | Preparing leather for seams, belts, and wallets | Pros: Enhances product quality, consistent results. Cons: Limited to specific tasks, may require training. |

| Leather Embossing and Stamping Machines | Equipment for adding designs and textures to leather | Customization of leather products, branding | Pros: Unique product differentiation, high value-add. Cons: Initial setup can be complex, requires design knowledge. |

| Leather Finishing Machines | Machines that apply finishes and coatings to leather | Finalizing leather products for aesthetics and durability | Pros: Improves appearance and longevity. Cons: Additional operational costs, may require specialized materials. |

What Are Leather Sewing Machines and Their B2B Relevance?

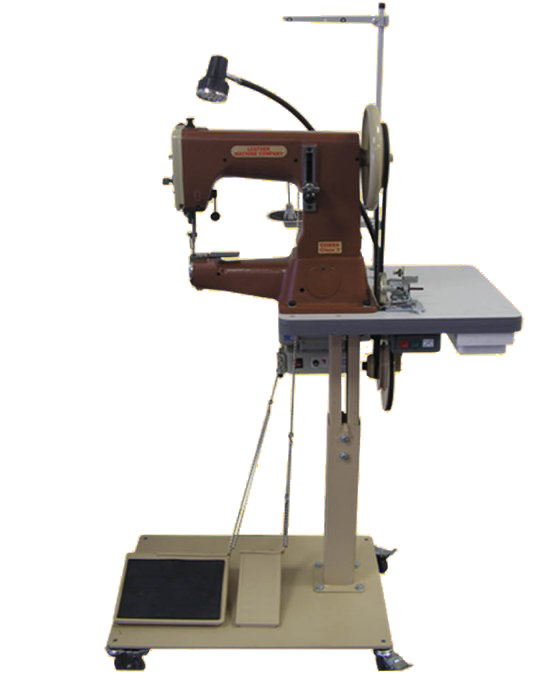

Leather sewing machines are engineered to handle the robust nature of leather, making them indispensable in the manufacturing of leather goods, such as bags, shoes, and garments. These machines come in various types, including walking foot and post bed models, each catering to specific stitching needs. B2B buyers should consider factors like machine durability, ease of use, and the availability of parts and service, as these influence long-term operational efficiency.

How Do Leather Cutting Machines Enhance Production Efficiency?

Leather cutting machines are vital for businesses engaged in high-volume production, offering precision cuts that minimize waste and ensure consistency in product dimensions. These machines can handle various leather types and thicknesses, making them suitable for crafting straps, patterns, and more. When purchasing, businesses should evaluate the machine’s cutting speed, ease of adjustment for different materials, and the manufacturer’s support for maintenance and parts.

What Advantages Do Leather Skiving Machines Offer?

Leather skiving machines are specialized tools that thin leather edges, allowing for seamless seams and a professional finish. They are particularly useful in industries focused on high-quality leather goods, such as wallets and belts. B2B buyers should assess the machine’s capacity to handle different leather weights, ease of adjustment, and the learning curve associated with operation, as these factors can impact production efficiency.

How Can Leather Embossing and Stamping Machines Differentiate Products?

Embossing and stamping machines allow businesses to add unique designs or branding to their leather products, enhancing their marketability. This customization capability is crucial for companies looking to stand out in competitive markets. Buyers should consider the machine’s versatility, ease of use, and the range of designs it can accommodate, as well as the associated costs for materials and setup.

Why Are Leather Finishing Machines Important for Product Quality?

Leather finishing machines apply protective coatings and aesthetic enhancements to finished leather products, significantly improving their market appeal and durability. For B2B buyers, understanding the types of finishes available and how they affect leather properties is crucial. Considerations should include the machine’s compatibility with various finish types, ease of operation, and the potential impact on overall production costs.

Key Industrial Applications of leather machine company

| Industry/Sector | Specific Application of leather machine company | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Footwear Manufacturing | Heavy-duty sewing machines for shoe assembly | Increases production speed and consistency in shoe manufacturing | Machine durability, compatibility with various leather types |

| Automotive Industry | Leather cutting and stitching machines for car interiors | Enhances quality and aesthetics of vehicle interiors | Precision cutting capabilities, ease of integration with existing systems |

| Fashion and Apparel | Embossing and stamping machines for leather accessories | Adds customization options, increasing product appeal | Versatility in designs, ease of use, and maintenance support |

| Upholstery and Furniture | Leather splitting machines for furniture upholstery | Reduces material waste and improves quality of finished products | Material compatibility, machine reliability, and service options |

| Leather Goods Production | Clicker presses for precise leather shapes | Minimizes labor costs and maximizes output efficiency | Scalability for production volume, safety features, and support services |

How Does Leather Machinery Benefit Footwear Manufacturing?

In the footwear manufacturing sector, heavy-duty sewing machines play a crucial role in the assembly of shoes. These machines are designed to handle various leather thicknesses, ensuring that the stitching is durable and consistent. For international buyers, particularly those in regions like Africa and the Middle East, sourcing machines that can withstand high production demands while offering reliability is essential. The ability to produce high-quality footwear efficiently translates to enhanced market competitiveness.

What Role Does Leather Machinery Play in the Automotive Industry?

The automotive industry relies heavily on leather for car interiors, where cutting and stitching machines are indispensable. These machines facilitate the precise cutting of leather components and their subsequent assembly into vehicle interiors. For businesses in South America and Europe, the challenge often lies in sourcing equipment that can integrate seamlessly with existing production lines while maintaining high standards of quality. Investing in advanced machinery can significantly elevate the overall aesthetic and functionality of automotive interiors.

Illustrative image related to leather machine company

How Can Fashion and Apparel Brands Leverage Leather Machinery?

In the fashion and apparel sector, embossing and stamping machines enable brands to personalize leather goods, making them more appealing to consumers. This capability is particularly beneficial for international brands looking to differentiate their products in competitive markets. Buyers should consider machines that offer a variety of design options and ease of use to streamline their production processes. The right machinery can enhance brand identity and drive consumer interest through unique product offerings.

What Benefits Do Upholstery and Furniture Manufacturers Gain from Leather Machinery?

Upholstery and furniture manufacturers utilize leather splitting machines to ensure that leather pieces are of uniform thickness, which is critical for quality control. These machines help reduce material waste and improve the overall quality of the finished products. For international buyers, particularly in Europe and the Middle East, sourcing reliable machinery that can handle different leather types while providing consistent results is vital. This investment can lead to significant cost savings and improved product quality.

How Do Clicker Presses Enhance Leather Goods Production?

Clicker presses are essential in the leather goods production industry, allowing for the precise cutting of leather shapes needed for various products. By minimizing labor costs and maximizing output efficiency, these machines are a game changer for manufacturers. Buyers from regions like Africa and South America should focus on sourcing clicker presses that offer scalability, ensuring they can meet increasing production demands without compromising on safety and quality. This efficiency can significantly impact profitability and market responsiveness.

Illustrative image related to leather machine company

3 Common User Pain Points for ‘leather machine company’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable Leather Machinery

The Problem: For B2B buyers in the leather manufacturing sector, sourcing high-quality machinery can be a daunting task. With numerous manufacturers and models available, buyers often struggle to identify reliable suppliers who can provide machines that meet their specific production needs. Compounding this issue is the challenge of navigating international shipping logistics, which can lead to delays, increased costs, and even damaged goods upon arrival.

The Solution: To effectively source reliable leather machinery, buyers should start by conducting thorough market research to identify reputable suppliers. This involves checking online reviews, industry forums, and testimonials from other businesses in similar sectors. Once potential suppliers are shortlisted, it’s essential to engage in direct communication, asking detailed questions about machine specifications, warranty policies, and after-sales support. Buyers should also consider visiting trade shows or industry exhibitions where they can see the machines in action and establish personal connections with manufacturers. Additionally, leveraging local distributors or agents who understand the regional market can streamline the purchasing process and reduce the complexities of international shipping.

Scenario 2: Challenges in Machine Maintenance and Repair

The Problem: Leather machinery, while robust, requires regular maintenance to ensure optimal performance. B2B buyers often face the challenge of inadequate support for maintenance and repairs, leading to downtime and loss of productivity. This is particularly problematic in regions where access to skilled technicians is limited, resulting in extended periods of inefficiency and potential loss of revenue.

Illustrative image related to leather machine company

The Solution: To mitigate maintenance challenges, buyers should prioritize investing in machines that come with comprehensive service packages or local support. When purchasing, they should inquire about the availability of spare parts and the training programs offered by the manufacturer for their staff. Establishing a maintenance schedule based on the machine’s usage will also help in identifying potential issues before they escalate. Furthermore, buyers can form partnerships with local service providers or technicians who specialize in leather machinery. Training in-house staff on basic troubleshooting can also empower businesses to handle minor repairs promptly, reducing reliance on external support.

Scenario 3: Inadequate Knowledge About Machine Capabilities

The Problem: Many B2B buyers lack a deep understanding of the various capabilities and features of leather machines, which can lead to purchasing equipment that does not fully meet their production requirements. This misalignment can result in inefficiencies, wasted materials, and ultimately, financial losses. Buyers often face difficulty in determining which machine is best suited for their specific applications, such as cutting, stitching, or embossing.

The Solution: To overcome knowledge gaps about machine capabilities, buyers should invest time in educating themselves through webinars, workshops, and training sessions offered by manufacturers or industry associations. It’s beneficial to create a detailed list of production needs and desired outcomes before engaging with suppliers. When consulting with manufacturers, buyers should discuss their specific applications and production goals, allowing suppliers to recommend machines that align with their needs. Additionally, utilizing demo machines before purchasing can provide practical insights into how a machine performs in real-world scenarios. This hands-on experience can significantly enhance decision-making and ensure that the machinery selected is the right fit for the business’s operational goals.

Strategic Material Selection Guide for leather machine company

What are the Key Materials for Leather Machinery and Their Properties?

When selecting materials for leather machinery, understanding the properties, advantages, and limitations of various materials is crucial for B2B buyers. Here, we analyze four common materials used in leather machinery: steel, aluminum, plastic, and rubber. Each material has unique characteristics that can influence the performance and suitability of machinery for specific applications.

Illustrative image related to leather machine company

How Does Steel Contribute to Leather Machinery Performance?

Steel is a primary material in the manufacturing of leather machinery due to its exceptional strength and durability. Key properties include high tensile strength, resistance to deformation under pressure, and excellent wear resistance. Steel components can withstand high temperatures and pressures, making them ideal for heavy-duty applications.

Pros: Steel’s durability ensures a long lifespan for machinery, which is crucial for businesses looking to minimize downtime. Its strength allows for the construction of robust machines capable of handling tough leather materials.

Cons: However, steel can be heavier than other materials, which may complicate machine mobility. Additionally, it is prone to corrosion if not properly treated, which can lead to increased maintenance costs.

Impact on Application: Steel is particularly suitable for high-load applications, such as sewing machines and cutting equipment. Its compatibility with various types of leather makes it a versatile choice.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that steel components comply with international standards such as ASTM or DIN to guarantee quality and safety.

What Role Does Aluminum Play in Leather Machinery?

Aluminum is another popular material due to its lightweight nature and resistance to corrosion. It is often used in components that require precision and ease of movement, such as frames and housings.

Pros: The lightweight nature of aluminum makes it easier to handle and transport machinery, reducing shipping costs. Additionally, aluminum’s resistance to rust enhances the longevity of machines, particularly in humid environments.

Cons: However, aluminum is generally less durable than steel and may not withstand heavy loads as effectively. This can limit its use in high-stress applications.

Impact on Application: Aluminum is ideal for parts that require high precision and low weight, such as guides and frames in sewing machines.

Considerations for International Buyers: Buyers should consider the local climate when selecting aluminum components, as extreme temperatures can affect performance. Compliance with JIS standards is also essential for ensuring quality.

How Does Plastic Material Enhance Leather Machinery Functionality?

Plastic materials, particularly high-density polyethylene (HDPE) and polycarbonate, are increasingly used in leather machinery for non-structural components due to their versatility and cost-effectiveness.

Pros: Plastics are lightweight, resistant to chemicals, and can be molded into complex shapes, making them ideal for components like guards and covers. Their lower cost can also reduce overall machinery expenses.

Cons: The primary drawback of plastic is its lower strength compared to metals, which may limit its application in high-stress environments. Additionally, certain plastics can degrade over time when exposed to UV light.

Impact on Application: Plastic is suitable for non-load-bearing applications, such as protective covers and guides, where weight savings are crucial.

Considerations for International Buyers: Buyers should ensure that the plastics used comply with environmental regulations in their respective regions, especially in Europe, where regulations are stringent.

What Advantages Does Rubber Provide in Leather Machinery?

Rubber is commonly used in leather machinery for components that require flexibility and shock absorption, such as gaskets and seals.

Pros: Rubber’s elasticity and ability to absorb vibrations make it ideal for reducing wear and tear on machinery. It also provides excellent grip and can enhance the safety of operations.

Illustrative image related to leather machine company

Cons: However, rubber can degrade over time, especially when exposed to oils and certain chemicals. This may necessitate more frequent replacements.

Impact on Application: Rubber components are essential for ensuring the longevity of machinery by minimizing friction and wear, particularly in moving parts.

Considerations for International Buyers: Buyers should consider the local availability of high-quality rubber materials and ensure compliance with relevant international standards to avoid performance issues.

Summary Table of Material Selection for Leather Machinery

| Materiał | Typical Use Case for leather machine company | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty sewing machines, cutting equipment | Exceptional strength and durability | Prone to corrosion, heavier weight | High |

| Aluminum | Frames and housings for precision machines | Lightweight and corrosion-resistant | Less durable under heavy loads | Medium |

| Plastic | Guards and covers for machinery | Cost-effective and versatile | Lower strength, UV degradation risk | Low |

| Rubber | Gaskets and seals for shock absorption | Excellent vibration absorption | Degrades over time with exposure | Medium |

This guide provides a comprehensive overview of material selection for leather machinery, enabling international B2B buyers to make informed decisions that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for leather machine company

The manufacturing processes and quality assurance practices in the leather machine industry are critical components that directly influence the performance, durability, and reliability of the machines. For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, understanding these processes can inform better purchasing decisions and foster long-term supplier relationships.

What Are the Main Stages of the Manufacturing Process for Leather Machines?

The manufacturing of leather machines typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage incorporates specific techniques and quality checks to ensure the final product meets industry standards.

How Is Material Prepared in Leather Machine Manufacturing?

The first step in the manufacturing process is material preparation. High-quality steel and aluminum are often used due to their strength and durability. Materials are sourced from reputable suppliers, and their quality is verified through inspection processes. Common practices include:

Illustrative image related to leather machine company

- Cutting and Shaping: Raw materials are cut into required shapes using laser cutting or CNC machines for precision.

- Surface Treatment: To enhance corrosion resistance and durability, materials undergo surface treatments such as anodizing or powder coating.

Ensuring the right material selection is crucial, as it directly affects the machine’s overall performance and longevity.

What Techniques Are Used in the Forming Stage?

The forming stage involves shaping the prepared materials into components that will make up the leather machines. Techniques commonly used include:

- Casting: For complex shapes, metal casting techniques may be employed to create machine parts.

- Machining: Precision machining ensures that components fit together seamlessly. This can involve turning, milling, and drilling processes.

- Welding: Various components are welded together to form structural parts of the machines, requiring skilled labor to ensure strong, reliable joints.

This stage is fundamental in determining the mechanical integrity of the machines.

How Is Assembly Conducted in Leather Machine Manufacturing?

Once the components are formed, they move to the assembly stage. This process is often systematic and includes:

Illustrative image related to leather machine company

- Component Assembly: Parts are assembled according to detailed schematics. Automated assembly lines may be used to enhance efficiency and reduce human error.

- Integration of Electronics: For machines that require electronic controls, the integration of motors, sensors, and wiring is performed. This step is critical for machines that feature advanced functionalities.

- Initial Testing: Before moving to finishing, assembled machines undergo preliminary tests to check for operational integrity.

Proper assembly is essential to ensure that the machines operate as intended and meet performance specifications.

What Finishing Processes Are Applied to Leather Machines?

The finishing stage adds the final touches to the machines, ensuring they are ready for market. This stage typically includes:

- Quality Coating: Final coatings are applied to protect against wear and environmental factors.

- Cosmetic Finishing: Machines are cleaned and polished, with branding and labeling applied for identification.

- Final Quality Checks: A thorough inspection is conducted to verify that each machine meets the defined specifications and quality standards.

Finishing not only enhances the aesthetic appeal of the machines but also contributes to their longevity and operational effectiveness.

How Is Quality Assurance Implemented in Leather Machine Manufacturing?

Quality assurance is a vital aspect of the manufacturing process that ensures products meet both international and industry-specific standards.

What International Standards Are Relevant to Leather Machine Quality Assurance?

For B2B buyers, understanding the applicable international standards is crucial for ensuring the quality and safety of leather machines. Some of the most relevant standards include:

- ISO 9001: This standard outlines criteria for a quality management system, emphasizing continuous improvement and customer satisfaction.

- CE Marking: Essential for products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For specific machinery, especially those used in industrial applications, adherence to American Petroleum Institute (API) standards may be necessary.

These standards help B2B buyers assess whether a supplier’s products are reliable and safe for use.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) is integral to ensuring that leather machines meet the necessary standards throughout the manufacturing process. Key QC checkpoints include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are performed to catch defects early and ensure adherence to specifications.

- Final Quality Control (FQC): Once manufacturing is complete, machines undergo rigorous testing to ensure they perform correctly and meet all quality standards.

Implementing these checkpoints helps minimize defects and ensure consistent product quality.

What Common Testing Methods Are Used in Leather Machine Quality Assurance?

A variety of testing methods are employed to ensure that leather machines meet quality standards. These may include:

- Functional Testing: Machines are operated to verify performance against specifications.

- Durability Testing: Machines are subjected to stress tests to evaluate their performance under extreme conditions.

- Safety Testing: Electrical safety tests ensure compliance with safety standards and regulations.

These testing methods provide B2B buyers with confidence in the reliability and safety of the machines they purchase.

Illustrative image related to leather machine company

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying a supplier’s quality control processes is essential. Here are several strategies:

- Supplier Audits: Conducting on-site audits can provide insights into the manufacturing processes and quality assurance practices in place.

- Requesting Quality Reports: Buyers can request documentation of quality control measures, testing results, and compliance with international standards.

- Third-Party Inspections: Engaging independent inspectors to evaluate the supplier’s quality control practices can provide an unbiased assessment.

These verification methods are crucial for building trust and ensuring that the supplier meets the buyer’s quality expectations.

What Are the Nuances of Quality Control for International B2B Buyers?

When dealing with suppliers from different regions, B2B buyers should be aware of specific nuances in quality control, including:

- Cultural Differences: Different regions may have varying approaches to quality management, which can affect communication and expectations.

- Regulatory Compliance: Understanding local regulations and standards is crucial for ensuring that products are compliant and safe for use in the buyer’s region.

- Supply Chain Challenges: Variability in supply chains can affect the consistency of quality. Buyers should evaluate the supplier’s supply chain management practices.

By being aware of these nuances, B2B buyers can navigate the complexities of international sourcing more effectively, ensuring that they procure high-quality leather machines that meet their operational needs.

In conclusion, the manufacturing processes and quality assurance practices in the leather machine industry are multi-faceted and require thorough understanding from B2B buyers. By focusing on material preparation, forming, assembly, finishing, and robust quality assurance measures, buyers can make informed purchasing decisions that enhance their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather machine company’

Wprowadzenie

This sourcing guide is designed for international B2B buyers seeking to procure machinery from leather machine companies. By following these steps, you can streamline the procurement process, ensuring you select the right equipment and supplier that meets your business needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements. This includes the types of leather you will be working with, the volume of production, and specific machine functions such as cutting, sewing, or embossing. Having defined specifications will help you communicate effectively with suppliers and ensure you receive suitable recommendations.

Step 2: Research Potential Suppliers

Conduct thorough research on various leather machine companies. Look for suppliers that have a strong reputation in your target markets, especially in regions like Africa, South America, the Middle East, and Europe. Utilize online platforms, trade shows, and industry publications to gather information on potential suppliers’ product offerings and customer feedback.

Step 3: Evaluate Supplier Certifications and Compliance

It is essential to verify that potential suppliers meet international quality standards and regulations. Check for certifications such as ISO 9001, which indicates a commitment to quality management. Compliance with local and international regulations ensures that the machinery will perform reliably and safely in your operations.

Step 4: Request Detailed Quotes

Once you have shortlisted suppliers, request detailed quotations that include pricing, lead times, and payment terms. Ensure that the quotes provide a comprehensive breakdown of costs, including shipping and installation fees. This transparency will help you compare options more effectively and avoid hidden costs later in the procurement process.

Step 5: Assess After-Sales Support and Warranty Terms

Inquire about the level of after-sales support offered by each supplier. Strong after-sales service can significantly impact your operations, especially when dealing with complex machinery. Look for warranties that cover parts and labor, and ask about training programs for your staff to ensure they can operate the equipment efficiently.

Step 6: Check References and Reviews

Before finalizing your decision, ask for references from existing clients who have similar needs. Reading reviews and testimonials can provide insights into the supplier’s reliability and customer service. Contacting previous customers will give you a clearer picture of what to expect from the supplier.

Step 7: Negotiate Terms and Finalize the Contract

Once you are satisfied with a supplier, enter negotiations to finalize terms. Discuss payment schedules, delivery timelines, and any additional services required. A well-structured contract should protect both parties and outline expectations clearly, minimizing the risk of misunderstandings.

By following these steps, you can effectively navigate the procurement process for leather machinery, ensuring that you make informed decisions that will benefit your business in the long run.

Comprehensive Cost and Pricing Analysis for leather machine company Sourcing

What Are the Key Cost Components in Leather Machine Manufacturing?

When sourcing leather machines, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: This includes the raw materials required for production, such as metal, plastic, and electronic components. The quality of materials directly impacts the durability and performance of the machines. Sourcing high-quality materials may increase upfront costs but often leads to lower maintenance and replacement expenses over time.

-

Labor: Labor costs encompass wages for skilled workers involved in the manufacturing process. In regions where skilled labor is scarce, companies may face higher labor costs. It’s crucial to consider the skill level required for operating and maintaining these machines, which can influence both initial and ongoing labor costs.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses associated with production. Efficient manufacturing processes can help minimize overhead costs, which is vital for maintaining competitive pricing.

-

Tooling: The initial investment in specialized tools and equipment for machine production can be significant. Tooling costs can vary based on the complexity of the machines and the level of customization required.

-

Quality Control (QC): Implementing rigorous QC processes ensures that the machines meet industry standards and customer expectations. While this adds to costs, it can prevent costly returns and repairs in the long run.

-

Logistics: Transportation costs for shipping machines to buyers, especially in international markets, can vary widely. Factors such as distance, shipping method, and tariffs can significantly influence total logistics expenses.

-

Margin: Manufacturers typically add a markup to cover their costs and ensure profitability. Understanding the margins in relation to the overall market can help buyers gauge fair pricing.

How Do Price Influencers Affect Leather Machine Sourcing?

Several factors influence the pricing of leather machines, particularly for international buyers:

-

Volume/MOQ: Minimum order quantities (MOQ) can impact pricing significantly. Larger orders often qualify for bulk discounts, making it more cost-effective for businesses with high demand.

-

Specifications and Customization: Customized machines that meet specific operational needs generally come at a premium. Buyers should assess whether customization adds value to their operations or if standard machines suffice.

-

Materials and Quality Certifications: The use of certified materials (e.g., ISO standards) can increase costs but often results in higher reliability and performance. Buyers should consider the long-term benefits of investing in certified machines.

-

Supplier Factors: The reputation and reliability of the supplier play a critical role in pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is vital for international transactions. These terms dictate the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs, directly affecting the total cost.

What Are Some Effective Buyer Tips for Leather Machine Sourcing?

For B2B buyers, particularly from Africa, South America, the Middle East, and Europe, the following tips can enhance cost-efficiency:

-

Negotiate Pricing: Leverage volume and long-term relationships to negotiate better terms. Many suppliers are open to discussions on price reductions, especially for repeat buyers.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, operational costs, and potential downtime. A lower-priced machine may incur higher long-term costs if it requires frequent repairs or lacks efficiency.

-

Understand Pricing Nuances: Be aware that pricing can vary significantly across regions due to factors like import duties, shipping costs, and local market conditions. Researching the market landscape can provide insights into fair pricing.

-

Ask for Samples and Demonstrations: Before making a large investment, request samples or demonstrations. This helps in assessing the machine’s performance and suitability for your specific needs.

-

Monitor Currency Fluctuations: For international purchases, currency exchange rates can significantly impact costs. Timing your purchase when rates are favorable can lead to substantial savings.

By comprehensively analyzing these cost components, price influencers, and practical buyer strategies, businesses can make informed decisions that align with their operational goals and budget constraints.

Alternatives Analysis: Comparing leather machine company With Other Solutions

Understanding Alternatives in Leather Machinery Solutions

When it comes to investing in leather machinery, B2B buyers have various options to consider. Each solution comes with unique features, costs, and operational requirements. This section will compare ‘Leather Machine Company’ with alternative machinery solutions, providing insights to help international buyers make informed decisions.

Comparison Table

| Comparison Aspect | Leather Machine Company | COBRA Leather Machines | Weaver Leather Supply Machines |

|---|---|---|---|

| Performance | High durability, precision stitching for various leather types | Versatile, suitable for heavy-duty and intricate work | Comprehensive range for both industrial and craft projects |

| Cost | Competitive pricing, typically ranging from $1,500 to $6,000 | Prices vary widely, with machines from $1,750 to $6,772.50 | Mid-range options, usually between $1,600 and $5,850 |

| Ease of Implementation | User-friendly setup with detailed manuals | Moderate; may require additional training for advanced features | Generally easy, but some machines may need professional setup |

| Maintenance | Low to moderate; regular oiling and occasional part replacement | Moderate; parts availability can affect downtime | Low; well-supported with replacement parts and user guides |

| Best Use Case | Ideal for small to medium-sized workshops focusing on custom leather goods | Best for large-scale production requiring robust machinery | Suitable for both hobbyists and professionals, offering flexibility in projects |

In-Depth Analysis of Alternatives

COBRA Leather Machines

COBRA machines are known for their robust performance and versatility, capable of handling a wide range of leather thicknesses. They excel in heavy-duty applications, making them a preferred choice for larger workshops or companies focused on mass production. However, the initial investment can be higher than ‘Leather Machine Company,’ and users may require training to fully utilize advanced features. The durable build and reliability can justify the cost for businesses that prioritize longevity and performance.

Weaver Leather Supply Machines

Weaver offers a comprehensive selection of leather machinery, ranging from manual to motorized options, which caters to both industrial and artisan needs. Their machines are typically user-friendly and backed by strong customer support, making them accessible for both beginners and seasoned professionals. However, while prices are generally reasonable, the variety can be overwhelming for new buyers. Choosing the right machine from their lineup requires careful consideration of specific project requirements and intended use.

Making the Right Choice for Your Leather Machinery Needs

Selecting the right leather machinery solution hinges on a thorough understanding of your operational needs and budget constraints. Consider factors such as the scale of production, types of leather projects, and the technical skill level of your team. Each alternative presents distinct advantages and potential drawbacks, so aligning your choice with your business goals is essential. Whether opting for ‘Leather Machine Company,’ COBRA, or Weaver, ensure that the selected machinery enhances productivity and quality in your leather operations.

Illustrative image related to leather machine company

Essential Technical Properties and Trade Terminology for leather machine company

What Are the Key Technical Properties of Leather Machines?

When sourcing leather machinery, understanding the technical specifications is crucial for making informed purchasing decisions. Here are some critical properties to consider:

-

Material Grade: The durability and performance of leather machines largely depend on the material from which they are constructed. High-grade steel or aluminum alloys are often used to ensure strength and longevity. In a B2B context, investing in machines with superior material grades can lead to lower maintenance costs and reduced downtime, which is vital for maintaining production efficiency.

-

Tolerance Levels: This refers to the permissible limits of variation in a machine’s dimensions. Precision is essential in leather crafting, as even minor deviations can affect the quality of the final product. High tolerance levels ensure that components fit together seamlessly, which is particularly important for industries requiring detailed craftsmanship, such as luxury leather goods. Buyers should prioritize machines that offer tight tolerance specifications to uphold product quality.

-

Power and Speed Ratings: The power rating (often expressed in watts or horsepower) and operational speed (stitches per minute) of a leather machine are significant factors that determine its efficiency and productivity. Machines with higher power ratings can handle thicker materials, while higher speed ratings allow for increased output. For B2B buyers, understanding these ratings can help align machinery capabilities with production demands.

-

Operating Mechanism: Leather machines can be manual, semi-automatic, or fully automatic. Each type has its advantages and disadvantages concerning labor costs, operational complexity, and production speed. For businesses aiming to scale operations, investing in automatic machines may provide a competitive edge by reducing labor costs and increasing throughput.

-

Maintenance Requirements: The ease of maintenance and availability of spare parts are critical considerations. Machines that require frequent servicing can lead to increased operational costs. Therefore, B2B buyers should seek equipment with straightforward maintenance protocols and readily available parts to minimize production disruptions.

-

Safety Features: In the industrial setting, safety is paramount. Machines equipped with advanced safety features—such as emergency stop buttons, protective guards, and automatic shut-offs—help to mitigate risks associated with leather processing. Understanding the safety specifications can help buyers ensure compliance with local regulations and protect their workforce.

What Are Common Trade Terms in the Leather Machinery Industry?

Familiarity with industry jargon is essential for effective communication and negotiation in the leather machinery market. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the leather machinery sector, OEM parts can be critical for ensuring compatibility and reliability. B2B buyers should consider sourcing from reputable OEMs to guarantee quality and performance.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for budget planning and inventory management. Buyers must evaluate their production needs against MOQs to avoid overcommitting resources.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to request pricing and terms for specific products. This term is commonly used in the procurement process, enabling buyers to gather competitive bids from multiple vendors and make informed purchasing decisions.

-

Incoterms (International Commercial Terms): These are predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping responsibilities, costs, and risk management, which is crucial for international B2B dealings.

-

Lead Time: Lead time is the period between the initiation of an order and the completion of the delivery. Understanding lead times is essential for supply chain management, particularly for businesses that rely on timely deliveries to meet production schedules.

-

Warranty: A warranty is a guarantee provided by the manufacturer regarding the condition of the machine and its performance over a specified period. For B2B buyers, a robust warranty can provide peace of mind and protect against unforeseen failures or defects, making it an important factor in purchasing decisions.

By grasping these technical properties and trade terms, B2B buyers can enhance their purchasing strategies, ultimately leading to better investment decisions in leather machinery.

Navigating Market Dynamics and Sourcing Trends in the leather machine company Sector

What Are the Key Trends Shaping the Leather Machine Industry for B2B Buyers?

The leather machine industry is experiencing notable shifts driven by globalization and technological advancements. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are witnessing an increased demand for efficient, high-performance machinery. Key trends include the adoption of automation and digitalization, which streamline production processes and enhance precision in leather crafting. As manufacturers aim to reduce operational costs and increase output, automated solutions such as CNC cutting machines and advanced sewing technologies are becoming essential.

Illustrative image related to leather machine company

Emerging sourcing trends also reflect a shift towards e-commerce platforms, enabling buyers to access a wider range of suppliers globally. This transition is particularly beneficial for buyers in developing markets, where traditional procurement methods may be less effective. Additionally, the rise of Industry 4.0 technologies is influencing the procurement of leather machinery, with an emphasis on smart machines that offer data analytics and predictive maintenance capabilities. These innovations not only optimize production but also provide valuable insights into operational efficiency, making them attractive investments for businesses looking to scale.

How Is Sustainability Impacting the Leather Machine Sector?

Sustainability is a critical consideration for B2B buyers in the leather machine industry. The environmental impact of leather production has prompted an increased focus on ethical sourcing and sustainable practices within the supply chain. International buyers are becoming more discerning, seeking suppliers who prioritize sustainable production methods and materials. This shift is reflected in the rising demand for eco-friendly leather alternatives, such as vegetable-tanned leather and synthetic materials that minimize ecological footprints.

Moreover, obtaining ‘green’ certifications has become crucial for suppliers aiming to appeal to environmentally conscious buyers. Certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) certification signal a commitment to sustainable practices, thereby enhancing brand reputation and marketability. For B2B buyers, partnering with certified suppliers not only aligns with corporate social responsibility goals but also mitigates risks associated with sourcing from less reputable vendors. As sustainability continues to influence purchasing decisions, the ability to provide transparent sourcing practices will be a significant competitive advantage.

Illustrative image related to leather machine company

What Is the Evolution of Leather Machinery in the B2B Landscape?

The evolution of leather machinery has played a pivotal role in shaping the current landscape of the leather industry. Initially dominated by manual tools and labor-intensive processes, the sector has transformed significantly over the past century. The introduction of electric-powered sewing machines and automated cutting equipment revolutionized production capabilities, allowing businesses to meet growing demand more efficiently.

As the market expanded, technological advancements led to the development of specialized machinery that catered to diverse applications, from crafting high-end leather goods to industrial manufacturing. Today, the focus is on integrating smart technologies, such as IoT and AI, into machinery to enhance productivity and reduce waste. This historical progression underscores the importance of continuous innovation in meeting the evolving needs of B2B buyers, who now expect machinery that not only performs well but also aligns with modern sustainability and efficiency standards.

In conclusion, understanding these market dynamics and trends is essential for international B2B buyers in the leather machine sector. By aligning procurement strategies with technological advancements and sustainability goals, buyers can position themselves favorably in a competitive global marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of leather machine company

-

How do I choose the right leather sewing machine for my business needs?

Selecting the appropriate leather sewing machine depends on your specific projects and production volume. Evaluate the types of leather you will be working with, as some machines handle heavier materials better than others. Consider features such as stitch types, speed, and ease of use. Additionally, review the machine’s capabilities in terms of thickness and materials to ensure it meets your production requirements. Finally, consult user reviews and reach out to suppliers for recommendations based on your unique needs. -

What are the advantages of using automated leather machinery over manual options?

Automated leather machinery offers several benefits, including increased efficiency, consistency in stitching, and the ability to handle larger volumes of work. Automation reduces the labor intensity associated with manual methods, allowing your workforce to focus on more complex tasks. Furthermore, automated machines often come equipped with advanced features such as programmable settings, which enhance precision and reduce errors. This can lead to higher quality products and lower production costs over time, making it a worthwhile investment for growing businesses. -

What should I consider when vetting international leather machine suppliers?

When vetting international suppliers, prioritize their reputation, experience, and customer feedback. Request references and check online reviews to gauge previous client satisfaction. Ensure they comply with international quality standards and regulations. Also, assess their production capabilities, lead times, and after-sales service. It’s beneficial to visit their facilities if possible or conduct a virtual tour to better understand their operations. A supplier’s responsiveness and communication style can also indicate their reliability and willingness to support your business needs. -

What are the typical minimum order quantities (MOQs) for leather machines?

Minimum order quantities can vary widely among suppliers, typically ranging from a single unit for smaller businesses to larger quantities for bulk orders. For custom machinery, expect higher MOQs due to the specific nature of the products. When negotiating, consider your budget and production capacity; some suppliers may be flexible with MOQs based on your long-term commitment or potential for repeat business. Always clarify MOQs before finalizing agreements to avoid unexpected costs. -

What payment terms should I expect when purchasing leather machinery internationally?

Payment terms can differ significantly based on the supplier and the nature of the transaction. Common options include full payment upfront, a deposit followed by the balance upon shipment, or payment on delivery. Some suppliers may offer financing options or credit terms for established buyers. It’s essential to discuss and negotiate payment terms upfront to ensure they align with your cash flow management. Additionally, inquire about accepted payment methods, such as wire transfers, letters of credit, or online payment platforms. -

How can I ensure the quality of leather machines before purchasing?

To ensure the quality of leather machines, request product samples or demonstrations from suppliers. Examine the machine’s construction, materials, and features to verify they meet your standards. Additionally, ask for certifications that indicate compliance with industry quality standards. Consider conducting third-party inspections or audits before finalizing your purchase, especially for large orders. Establishing a clear warranty and return policy can also provide peace of mind regarding the machine’s quality. -

What logistics considerations should I keep in mind when importing leather machinery?

Logistics play a critical role in importing leather machinery, including shipping methods, customs duties, and delivery timelines. Choose between air freight for speed or sea freight for cost-effectiveness, depending on your urgency and budget. Understand the customs regulations in your country to avoid delays and additional costs. Collaborate with a reliable freight forwarder who can help navigate the complexities of international shipping and ensure proper documentation is in place for a smooth import process. -

Can I customize leather machinery to suit my production needs?

Many manufacturers offer customization options for their leather machinery to better align with specific production requirements. This can include adjustments to machine specifications, features, or even custom-built machinery. When discussing customization with suppliers, provide detailed information about your production processes and desired outcomes. Keep in mind that custom orders may require longer lead times and potentially higher costs, so factor this into your planning and budgeting.

Top 4 Leather Machine Company Manufacturers & Suppliers List

1. Leather Machine Co – Heavy-Duty Leather Sewing Machines

Domain: leathermachineco.com

Registered: 2009 (16 years)

Introduction: This company, Leather Machine Co – Heavy-Duty Leather Sewing Machines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. American Leatherworks – COBRA Class 26

Domain: americanleatherworks.com

Registered: 2009 (16 years)

Introduction: {“products”:[{“name”:”COBRA Class 26″,”price”:”$3,444.00″,”description”:”FREE SHIPPING BUNDLE”},{“name”:”COBRA Class 4 \”Dream Machine\””,”price”:”$3,397.00″,”description”:”The COBRA Class 4 will sew from 6 oz. to 7/8″ leather for sewing skirting, all types of tack, bullet loops, chap leather and everything in between with ease.”},{“name”:”COBRA Class 26″,”price”:”$2,760.00″},{“name”:”COBRA MP Bur…

3. Weaver – Master Tool Cub Manual Leather Sewing Machine

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: {“products”:[{“name”:”Master Tool Cub Manual Leather Sewing Machine”,”price”:”$2,150.00″,”availability”:”Unavailable”},{“name”:”Weaver 303 Leather Sewing Machine, Complete with Stand & Servo Motor”,”price”:”$1,600.00″,”availability”:”Unavailable”},{“name”:”Master Tool EZ Edge Strap Beveler”,”price”:”$380.00″,”availability”:”Unavailable”},{“name”:”Master Tool Little Wonder®”,”price”:”$460.00″,”avai…

4. Leather Machine Co. – Sewing & Cutting Machinery

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Leather Machine Co. – Sewing & Cutting Machinery, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for leather machine company

As the leather industry continues to evolve, strategic sourcing remains a pivotal factor for companies seeking to enhance operational efficiency and product quality. International B2B buyers from Africa, South America, the Middle East, and Europe must prioritize sourcing high-quality leather machinery that meets their specific production needs. By leveraging advanced machines, such as those designed for sewing, cutting, and embossing, businesses can significantly reduce labor costs and increase production speed, ultimately boosting profitability.

Additionally, understanding the diverse range of available machinery—from manual to fully automated options—allows buyers to make informed decisions that align with their business objectives. The competitive landscape necessitates not only a focus on cost but also on quality and service, as evidenced by customer feedback highlighting the importance of reliable support and efficient logistics.

Looking ahead, the global market for leather machinery presents ample opportunities for growth. Buyers are encouraged to explore partnerships with reputable suppliers that offer innovative solutions tailored to their unique operational challenges. Investing in the right machinery today will position businesses for success in the increasingly competitive leather market of tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to leather machine company