Introduction: Navigating the Global Market for custom leather sectional

Navigating the global market for custom leather sectionals presents a unique challenge for international B2B buyers seeking to source quality, comfortable seating solutions that meet diverse consumer preferences. As the demand for personalized and stylish furniture continues to rise across regions such as Africa, South America, the Middle East, and Europe—including prominent markets like Brazil and Nigeria—buyers must consider various factors to ensure successful procurement.

This comprehensive guide delves into the intricate world of custom leather sectionals, covering essential topics such as types of sectionals, their applications in both residential and commercial settings, and best practices for supplier vetting. Additionally, it provides insights on pricing structures, customization options, and logistics, equipping buyers with the knowledge needed to make informed purchasing decisions.

By addressing key considerations and challenges, this guide empowers international B2B buyers to navigate the complexities of the furniture market confidently. With a focus on quality, design versatility, and supplier reliability, you will be well-prepared to select the perfect custom leather sectional that not only enhances your offerings but also resonates with your target audience’s aesthetic and functional needs.

Table Of Contents

- Top 9 Custom Leather Sectional Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather sectional

- Understanding custom leather sectional Types and Variations

- Key Industrial Applications of custom leather sectional

- 3 Common User Pain Points for ‘custom leather sectional’ & Their Solutions

- Strategic Material Selection Guide for custom leather sectional

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather sectional

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather sectional’

- Comprehensive Cost and Pricing Analysis for custom leather sectional Sourcing

- Alternatives Analysis: Comparing custom leather sectional With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather sectional

- Navigating Market Dynamics and Sourcing Trends in the custom leather sectional Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather sectional

- Strategic Sourcing Conclusion and Outlook for custom leather sectional

- Important Disclaimer & Terms of Use

Understanding custom leather sectional Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| U-Shaped Sectionals | Offers ample seating with a defined shape. | Large lounges, waiting areas. | Pros: Maximizes space; great for gatherings. Cons: Requires larger rooms. |

| L-Shaped Sectionals | Compact design suitable for corners. | Small offices, residential spaces. | Pros: Space-efficient; versatile. Cons: Limited seating capacity compared to U-shape. |

| Modular Sectionals | Interchangeable components for flexibility. | Custom layouts in showrooms, events. | Pros: Customizable; adaptable to various spaces. Cons: May require more planning for assembly. |

| Chaise Sectionals | Features an extended lounge area. | Luxury residential, upscale lounges. | Pros: Offers relaxation; stylish. Cons: Can be bulky; may not fit smaller spaces. |

| Reclining Sectionals | Includes reclining features for comfort. | Home theaters, relaxation areas. | Pros: Enhanced comfort; appealing to consumers. Cons: More expensive; maintenance of mechanisms needed. |

What Are the Key Characteristics of U-Shaped Sectionals?

U-shaped sectionals are designed to create a cozy gathering space, providing ample seating for multiple users. Their shape allows for easy conversation flow and is ideal for larger lounges or waiting areas. B2B buyers should consider the dimensions of the space to ensure the sectional fits comfortably. Additionally, the arrangement can enhance the aesthetic appeal of the environment, making it a popular choice for hospitality venues.

How Do L-Shaped Sectionals Benefit Small Spaces?

L-shaped sectionals are perfect for maximizing seating in smaller rooms by fitting snugly into corners. This design is particularly beneficial for small offices or residential spaces, as it utilizes space efficiently while still providing a comfortable seating option. B2B buyers should assess the layout of their space to determine the best placement for an L-shaped sectional to optimize functionality and style.

Why Choose Modular Sectionals for Custom Layouts?

Modular sectionals offer unparalleled flexibility, allowing businesses to create custom layouts that fit their specific needs. Each component can be rearranged or expanded, making them ideal for showrooms or event spaces where adaptability is crucial. B2B buyers should evaluate the ease of assembly and disassembly, as well as the potential for future reconfiguration, to ensure long-term usability.

What Are the Advantages of Chaise Sectionals?

Chaise sectionals provide a stylish and comfortable lounging area, making them a popular choice for luxury residential projects and upscale lounges. The extended seating area invites relaxation and can serve as a focal point in any room. Buyers should consider the overall dimensions and style compatibility with existing furniture to ensure a cohesive design.

How Do Reclining Sectionals Enhance Comfort in Commercial Spaces?

Reclining sectionals are designed for ultimate comfort, often featuring mechanisms that allow users to adjust their seating position. This makes them ideal for home theaters or relaxation areas in commercial settings. B2B buyers must weigh the benefits of comfort against potential maintenance needs and higher costs associated with reclining mechanisms, ensuring they align with their target market’s expectations.

Illustrative image related to custom leather sectional

Key Industrial Applications of custom leather sectional

| Industry/Sector | Specific Application of custom leather sectional | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Luxury hotel lounges and suites | Enhances guest experience and brand image | Durability, customization options, and delivery timelines |

| Corporate Offices | Executive lounges and meeting spaces | Promotes comfort and productivity for employees | Ergonomics, design aesthetics, and material quality |

| Retail | High-end showrooms and customer waiting areas | Creates a welcoming environment that drives sales | Style adaptability, upholstery options, and maintenance |

| Residential Development | Model homes and upscale apartment complexes | Attracts buyers with stylish and functional designs | Space optimization, customization, and delivery logistics |

| Event Planning | High-profile event venues and exhibitions | Provides a sophisticated seating solution for attendees | Flexibility in design, comfort, and transportability |

How is custom leather sectional utilized in the hospitality industry?

In the hospitality sector, custom leather sectionals are frequently employed in luxury hotel lounges and suites. These pieces not only enhance the aesthetic appeal of the space but also significantly improve guest comfort. Buyers in this industry often seek durable materials that can withstand heavy use while maintaining a high-end appearance. Customization options for color, design, and size allow hotels to create a unique ambiance that aligns with their brand image. Moreover, timely delivery is crucial to meet opening deadlines or seasonal demands.

What role does custom leather sectional play in corporate offices?

In corporate settings, custom leather sectionals are ideal for executive lounges and meeting spaces. They foster a relaxed atmosphere that encourages collaboration and creativity among employees. Businesses benefit from the ergonomic design of these sectionals, which promotes comfort during long meetings. Buyers need to consider the aesthetic appeal that reflects their corporate identity, as well as the quality of materials to ensure longevity. Additionally, the ability to customize seating arrangements to fit various office layouts is a significant advantage.

How do retail environments leverage custom leather sectional?

Retail businesses often utilize custom leather sectionals in high-end showrooms and customer waiting areas. These sectionals create a welcoming environment that enhances the shopping experience, encouraging customers to linger longer and engage with the brand. The adaptability of style and color options allows retailers to align the furniture with their brand identity. For international buyers, factors such as ease of maintenance and the ability to source unique designs that stand out in competitive markets are essential considerations.

What is the significance of custom leather sectional in residential development?

In residential development, particularly for model homes and upscale apartment complexes, custom leather sectionals serve as a focal point that attracts potential buyers. These sectionals offer both style and functionality, showcasing how space can be optimized for modern living. Developers often seek customization options to meet the diverse tastes of their clientele, ensuring that the furniture complements the overall design scheme. Timely delivery and installation are also critical to align with marketing strategies and open house events.

How can event planners utilize custom leather sectional for events?

Event planners often turn to custom leather sectionals for high-profile venues and exhibitions, as they provide sophisticated seating solutions that enhance the overall guest experience. The flexibility in design allows planners to create various seating arrangements tailored to specific events, whether formal or casual. Comfort is a priority for attendees, making the choice of high-quality materials essential. Additionally, the transportability of these sectionals is a key consideration, enabling easy setup and takedown at different locations.

3 Common User Pain Points for ‘custom leather sectional’ & Their Solutions

Scenario 1: Navigating Customization Options for Unique Spaces

The Problem: B2B buyers often face the challenge of selecting a custom leather sectional that fits specific spatial requirements and aesthetic preferences. For instance, a buyer from a boutique hotel might need a sectional that not only complements the interior design but also maximizes seating without overwhelming the space. The myriad of choices available—different sizes, configurations, and leather types—can lead to confusion and hesitation in making a decision that aligns with both functional and stylistic goals.

The Solution: To effectively navigate the customization options, buyers should start by conducting a comprehensive needs assessment that includes measuring the space and understanding the design theme. Engage with manufacturers that offer a wide range of customizable options, such as modular designs that can be adapted to fit various layouts. It is beneficial to request samples of different leather types and colors to visualize how they will work in the intended environment. Additionally, collaborating with interior designers who have experience in sourcing custom furniture can provide invaluable insights and help in making informed choices that enhance the overall design.

Scenario 2: Ensuring Quality and Durability in Leather Sectionals

The Problem: Quality concerns are paramount when purchasing custom leather sectionals, especially in regions with varying climate conditions, such as Africa and South America. B2B buyers often worry about the durability of leather materials and whether they can withstand heavy usage in commercial settings, such as lounges or offices. The risk of investing in a product that may not perform well under specific conditions can lead to significant financial losses and damage to brand reputation.

Illustrative image related to custom leather sectional

The Solution: To mitigate quality concerns, buyers should prioritize sourcing from reputable manufacturers known for their craftsmanship and quality control processes. Request detailed specifications regarding the leather used, including its grade, treatment processes, and any warranties offered. Additionally, conducting product testing or seeking certifications related to wear resistance and environmental adaptability can assure buyers of the sectional’s durability. Establishing a long-term relationship with suppliers who provide ongoing support and maintenance options can also enhance the longevity of the investment.

Scenario 3: Managing Lead Times and Delivery Expectations

The Problem: For many B2B buyers, especially those operating in fast-paced industries, lead times for custom leather sectionals can pose a significant issue. Buyers might encounter delays in delivery that disrupt project timelines, particularly when outfitting new venues or renovating existing spaces. The uncertainty of when the sectional will arrive can complicate scheduling and impact overall operational efficiency.

The Solution: To manage lead times effectively, it is crucial to communicate clearly with suppliers about project timelines from the outset. Establishing a detailed schedule that includes milestones for design approval, production, and shipping can help set realistic expectations. Buyers should consider manufacturers that offer in-stock options or quicker turnaround times for popular styles, which can serve as a fallback if delays occur. Additionally, maintaining open lines of communication throughout the production process can help buyers stay informed and allow for adjustments as needed, ensuring that any potential delays are addressed proactively.

Strategic Material Selection Guide for custom leather sectional

What are the Key Properties of Different Leather Materials for Custom Sectionals?

When selecting materials for custom leather sectionals, various types of leather offer distinct properties that can significantly affect the performance and suitability of the final product. Understanding these materials is crucial for B2B buyers aiming to meet specific market demands.

Full Grain Leather

Full grain leather is the highest quality leather available, retaining the natural grain and imperfections of the hide. This material boasts exceptional durability, with a high resistance to wear and tear, making it ideal for high-traffic areas. Its breathability also allows for temperature regulation, enhancing comfort.

Pros: Full grain leather is highly durable, develops a beautiful patina over time, and offers superior breathability. It is also resistant to moisture and stains when treated properly.

Cons: The cost of full grain leather is on the higher end, which may impact overall product pricing. Additionally, it requires specialized care to maintain its appearance.

Illustrative image related to custom leather sectional

Impact on Application: Full grain leather is suitable for luxury markets and high-end furniture retailers, appealing to consumers who value quality and longevity.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East may prefer full grain leather due to its luxury appeal, while ensuring compliance with local regulations regarding leather sourcing and treatment.

Top Grain Leather

Top grain leather is slightly less durable than full grain but is more affordable and easier to maintain. It is sanded and refinished to remove imperfections, resulting in a smooth surface.

Pros: This type of leather is more resistant to stains and easier to clean, making it suitable for families or commercial settings. It also offers a good balance between quality and cost.

Cons: While top grain leather is durable, it does not develop the same character over time as full grain leather. It may also be less breathable.

Illustrative image related to custom leather sectional

Impact on Application: Ideal for mid-range furniture markets, top grain leather provides a good compromise between luxury and practicality.

Considerations for International Buyers: Buyers in South America and Africa may find top grain leather appealing due to its cost-effectiveness and ease of maintenance, but should consider local preferences for leather quality.

Bonded Leather

Bonded leather is made from leftover leather scraps that are bonded together with a polyurethane coating. It is the most affordable option available.

Pros: Bonded leather is cost-effective and can mimic the appearance of genuine leather, making it accessible for budget-conscious buyers.

Cons: It is significantly less durable than full or top grain leather, with a tendency to wear out more quickly. It is also less breathable and can develop cracks over time.

Impact on Application: Suitable for entry-level furniture or temporary solutions, bonded leather is often used in budget-friendly markets.

Considerations for International Buyers: In regions like Nigeria and Brazil, where cost is a significant factor, bonded leather may be appealing. However, buyers should be cautious about quality perception and local market standards.

Faux Leather (PU Leather)

Faux leather, often made from polyurethane (PU), is a synthetic alternative that offers a leather-like appearance without using animal hides.

Illustrative image related to custom leather sectional

Pros: It is typically more affordable and easier to clean than genuine leather. Faux leather is also available in a variety of colors and textures.

Cons: While it offers good aesthetics, faux leather lacks the durability and breathability of genuine leather. It may also degrade more quickly under high temperatures.

Impact on Application: Faux leather is popular in the budget and eco-friendly markets, appealing to consumers looking for cruelty-free options.

Considerations for International Buyers: Buyers in Europe may appreciate the ethical aspect of faux leather, while those in the Middle East might be more focused on durability and climate resistance.

Summary Table of Material Selection for Custom Leather Sectionals

| Materiał | Typical Use Case for custom leather sectional | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full Grain Leather | Luxury furniture, high-end markets | Exceptional durability and breathability | High cost and requires specialized care | High |

| Top Grain Leather | Mid-range furniture, family settings | Good balance of quality and cost | Less character than full grain | Medium |

| Bonded Leather | Budget-friendly furniture, temporary solutions | Cost-effective and visually appealing | Less durable, prone to wear | Low |

| Sztuczna skóra | Eco-friendly markets, budget furniture | Affordable and easy to clean | Lacks durability and breathability | Low |

This strategic material selection guide aims to equip international B2B buyers with the insights necessary to make informed purchasing decisions tailored to their specific market needs.

Illustrative image related to custom leather sectional

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather sectional

What Are the Main Stages in the Manufacturing Process of Custom Leather Sectionals?

The manufacturing of custom leather sectionals involves several critical stages that ensure both the quality and aesthetics of the final product. Understanding these stages helps B2B buyers assess the capabilities of potential suppliers.

Material Preparation: What Steps Are Involved?

The first step in manufacturing is material preparation. This includes sourcing high-quality leather, which is often treated and dyed to meet specific design requirements. Suppliers typically use full-grain or top-grain leather for premium products, as these types provide durability and a luxurious feel.

In addition to leather, other materials such as wood for the frame and various fillings for cushions must be sourced. The wood is usually treated to prevent warping and ensure longevity, while fillings can range from foam to down, depending on the desired comfort level.

How Is the Forming Process Carried Out?

Once materials are prepared, the next step is forming. This involves cutting the leather and other materials into specific shapes and sizes according to design specifications. Advanced cutting techniques, such as laser cutting, may be employed for precision.

After cutting, the leather pieces undergo a stitching process, where skilled artisans or automated machines sew the pieces together. This stage is crucial for ensuring that seams are strong and aesthetically pleasing, as any imperfections can impact the overall quality of the sectional.

Illustrative image related to custom leather sectional

What Happens During Assembly?

Assembly is the next critical stage where the sectional comes together. Frames are constructed using interlocking designs, often made from laminated hardwood, which enhances strength and stability. This phase may also include the installation of springs or support systems, such as drop-in coils or sinuous wire foundations, that provide comfort and durability.

During assembly, manufacturers pay close attention to ensure that all components fit seamlessly. Quality checks are often integrated into this stage to catch any defects early in the process.

How Is Finishing Completed?

The finishing stage is where the sectional is prepared for sale. This includes applying protective coatings to the leather, ensuring resistance to stains and wear. Final touches may involve adding decorative elements, such as nailhead trim or custom upholstery details.

Before leaving the factory, each sectional undergoes a thorough inspection to ensure it meets the company’s quality standards and customer specifications.

What Quality Assurance Measures Are in Place for Custom Leather Sectionals?

Quality assurance (QA) is paramount in the manufacturing of custom leather sectionals. Implementing robust QA processes not only ensures product quality but also builds trust with international buyers.

Which International Standards Should Be Considered?

B2B buyers should look for suppliers who adhere to international quality standards such as ISO 9001. This certification indicates that the manufacturer follows a quality management system that consistently produces products that meet customer and regulatory requirements.

In addition to ISO standards, industry-specific certifications like CE (Conformité Européenne) or API (American Petroleum Institute) may be relevant, especially for companies exporting to Europe or involved in specialized markets.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are critical at various stages of production:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet required specifications. This step prevents defective materials from entering the production process.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC involves ongoing inspections at different stages to identify defects early. This might include checking stitching quality, frame alignment, and assembly integrity.

-

Final Quality Control (FQC): Before products are shipped, FQC ensures that the final product meets all quality standards. This includes visual inspections and physical tests, such as checking for structural integrity and comfort.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control measures of potential suppliers:

-

Supplier Audits: Conducting regular audits of suppliers allows buyers to assess their manufacturing processes and quality assurance practices firsthand.

-

Requesting Quality Reports: Suppliers should be able to provide documentation demonstrating compliance with international standards and results from their internal quality checks.

-

Third-Party Inspections: Engaging third-party inspection services provides an unbiased assessment of product quality and adherence to specifications before shipment.

What Nuances Should International Buyers Be Aware of?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances related to quality assurance.

Are There Regional Compliance Standards to Consider?

Different regions may have specific compliance standards that manufacturers must meet. For example, European countries often require products to comply with CE marking, while some African nations may have their own sets of regulations governing imports.

Illustrative image related to custom leather sectional

How Do Cultural Expectations Impact Quality?

Cultural expectations can also influence perceptions of quality. For example, buyers in some regions may prioritize aesthetics and luxury over durability, while others may focus more on functional aspects. Understanding these nuances can help buyers communicate their needs effectively to suppliers.

Conclusion

Manufacturing custom leather sectionals involves a detailed process that requires careful attention to quality assurance at every stage. By understanding the manufacturing processes and the importance of quality control, B2B buyers can make informed decisions when selecting suppliers. This knowledge is especially vital for international buyers navigating diverse markets and regulations. Ultimately, investing time in evaluating manufacturing practices will lead to stronger partnerships and higher-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather sectional’

This guide aims to provide a structured approach for B2B buyers interested in procuring custom leather sectionals. By following this step-by-step checklist, you will ensure that your sourcing process is efficient, informed, and aligned with your business needs.

Illustrative image related to custom leather sectional

Step 1: Define Your Technical Specifications

Establish clear technical specifications for your custom leather sectional, including dimensions, style, and material preferences. This step is essential as it will guide suppliers in understanding your exact requirements and help prevent misunderstandings later in the process. Consider factors like:

– Size: What dimensions fit your intended space?

– Style: Do you prefer modern, traditional, or a specific design aesthetic?

– Material Quality: What grade of leather do you require (e.g., top-grain, bonded)?

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in custom leather sectionals. Utilize online resources, trade shows, and industry recommendations to compile a list of reputable manufacturers. It’s vital to prioritize suppliers that have:

– Experience in Custom Orders: Ensure they have a proven track record with custom projects.

– Positive Reviews and References: Look for testimonials from other B2B buyers in your region or industry.

Step 3: Evaluate Supplier Certifications

Before moving forward, verify that your selected suppliers hold relevant certifications and adhere to industry standards. This is crucial for ensuring the quality and safety of your products. Key certifications to check include:

– ISO Certifications: Indicative of quality management systems.

– Sustainability Certifications: If environmental impact is a concern, look for suppliers with eco-friendly practices.

Step 4: Request Samples

Request samples of both the leather and the sectional design to assess the quality and craftsmanship. This allows you to gauge the tactile and visual qualities of the materials and the overall construction. Pay attention to:

– Leather Finish: Check for consistency and durability.

– Construction Quality: Look for sturdy frames and quality stitching.

Step 5: Clarify Lead Times and Delivery Options

Discuss lead times and delivery options with potential suppliers to ensure they align with your project timeline. Understanding their manufacturing capacity and delivery logistics is crucial, as delays can disrupt your operations. Consider asking about:

– Production Timeframes: How long will it take to produce your order?

– Shipping Options: What shipping methods do they offer for international deliveries?

Illustrative image related to custom leather sectional

Step 6: Negotiate Terms and Pricing

Once you have narrowed down your suppliers, negotiate the terms and pricing to secure the best deal. Ensure you understand all costs involved, including shipping, taxes, and potential tariffs, especially for international transactions. Key negotiation points may include:

– Minimum Order Quantities: Are there flexible options for smaller orders?

– Payment Terms: Discuss upfront payments, deposits, and final payment schedules.

Step 7: Finalize the Purchase Agreement

Before placing your order, finalize a purchase agreement that outlines all terms, including specifications, pricing, delivery timelines, and warranty information. This document is vital for protecting both parties and ensuring accountability. Key elements to include are:

– Detailed Product Descriptions: Ensure all specifications are documented.

– Warranties and Returns Policy: Understand the supplier’s policy on defects or dissatisfaction.

By following this checklist, B2B buyers can streamline their sourcing process for custom leather sectionals, ensuring a successful procurement experience.

Comprehensive Cost and Pricing Analysis for custom leather sectional Sourcing

What Are the Key Cost Components in Custom Leather Sectional Sourcing?

When sourcing custom leather sectionals, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

Illustrative image related to custom leather sectional

-

Materials: Leather quality significantly impacts pricing. Genuine leather is more expensive than synthetic alternatives. Additionally, factors like leather grade (top grain vs. split leather) and finish (aniline vs. pigmented) influence costs.

-

Labor: Skilled labor is required for crafting high-quality leather furniture. Labor costs vary by region, with countries that have lower labor costs potentially offering more competitive pricing. However, quality craftsmanship often comes at a premium.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can mitigate these overhead costs.

-

Tooling: Custom designs may require specialized tools and molds, which can add to the upfront costs. However, these costs are typically amortized over larger production runs.

-

Quality Control (QC): Rigorous quality control processes ensure that the final product meets standards. Implementing effective QC measures can prevent costly returns and reworks.

-

Logistics: Shipping costs can fluctuate based on distance, mode of transportation, and fuel prices. International shipping often incurs additional fees, such as customs duties.

-

Margin: Suppliers will add a profit margin to their costs, which can vary based on market competition and perceived value of the product.

How Do Price Influencers Affect the Cost of Custom Leather Sectionals?

Several factors influence the pricing of custom leather sectionals, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically yield lower per-unit costs due to economies of scale. Understanding a supplier’s MOQ can help buyers negotiate better pricing.

-

Specifications and Customization: Custom features, such as unique designs or added functionalities (e.g., reclining mechanisms), can increase costs. Buyers should assess the necessity of customizations versus standard options.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., eco-friendly or sustainable practices) often come with higher price tags. Buyers should weigh the benefits of these certifications against their budget.

-

Supplier Factors: Supplier reputation, location, and reliability can significantly impact pricing. Established suppliers may charge more for their expertise and proven quality.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international buyers. These terms dictate the responsibilities of buyers and sellers in shipping costs and risks, which can affect overall pricing.

What Tips Can Help Buyers Negotiate Better Prices for Custom Leather Sectionals?

B2B buyers can leverage several strategies to enhance their purchasing outcomes:

-

Negotiation Skills: Engaging in effective negotiation can lead to favorable pricing. Prepare by researching market prices and understanding the supplier’s cost structure to create a compelling case.

-

Cost-Efficiency Approaches: Evaluate the Total Cost of Ownership (TCO), which includes not only the purchase price but also maintenance, durability, and resale value. Investing slightly more in higher-quality products can yield long-term savings.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, and the Middle East should consider currency fluctuations, import duties, and shipping times. Building relationships with local suppliers may offer advantages in terms of pricing and logistics.

-

Customization Evaluation: Clearly define your needs upfront to avoid unnecessary customizations that inflate costs. Standard models may offer better pricing while still fulfilling functional requirements.

Disclaimer on Indicative Prices

Prices for custom leather sectionals can vary significantly based on the factors discussed. The information provided serves as a general guideline and should be used for comparative purposes only. Always consult with suppliers for the most accurate and current pricing tailored to specific needs and circumstances.

Alternatives Analysis: Comparing custom leather sectional With Other Solutions

Exploring Alternatives to Custom Leather Sectionals

When considering furniture solutions for commercial spaces, particularly in sectors like hospitality and corporate environments, the choice of seating can significantly influence customer experience and comfort. Custom leather sectionals are a popular choice due to their aesthetic appeal and durability. However, it is essential to evaluate alternatives that may serve similar purposes while offering distinct advantages or cost savings.

Comparison Table

| Comparison Aspect | Custom Leather Sectional | Modular Fabric Sectional | Traditional Sofas |

|---|---|---|---|

| Performance | High durability; resistant to wear and tear | Good flexibility; various configurations | Moderate durability; style-dependent |

| Cost | Higher investment; premium materials | Mid-range; affordable options available | Varies widely; can be low to high |

| Ease of Implementation | Requires customization; longer lead times | Quick setup; ready-to-assemble options available | Easy to find; readily available |

| Maintenance | Requires specific cleaning; leather care products needed | Generally easy to clean; machine washable covers | Varies; fabric types affect maintenance |

| Best Use Case | Luxury settings; long-term investment | Versatile spaces; frequent layout changes | Casual or traditional environments |

In-Depth Analysis of Alternatives

Modular Fabric Sectionals

Modular fabric sectionals offer significant flexibility, allowing businesses to adapt their seating arrangements based on varying needs. These sectionals are often designed for quick assembly and can be reconfigured easily, making them ideal for dynamic environments such as conference rooms or lounges. The cost of modular sectionals is typically lower than that of custom leather options, and they come in a variety of colors and fabrics, enhancing design versatility. However, the durability may not match that of leather, and they may require more frequent replacements in high-traffic areas.

Traditional Sofas

Traditional sofas, while often seen as a classic choice, come with their own set of benefits and drawbacks. They can range widely in price, from budget-friendly options to high-end designer pieces, making them accessible for various budgets. Traditional sofas can also add a timeless aesthetic to a space. However, their fixed designs can limit flexibility in seating arrangements and may not be as durable as leather sectionals in demanding environments. Maintenance needs will vary depending on the fabric used, with some requiring more care than others.

Illustrative image related to custom leather sectional

Making the Right Choice for Your Business

In selecting the right seating solution, B2B buyers should assess their specific needs based on functionality, aesthetic requirements, and budget constraints. Custom leather sectionals provide a long-lasting, stylish option that can enhance upscale environments, while modular fabric sectionals offer adaptability and affordability for changing spaces. Traditional sofas can serve as a versatile choice, balancing style and cost. Ultimately, the decision should reflect both the practical use of the space and the overall branding strategy of the business. By weighing these factors, buyers can ensure they invest in seating solutions that align with their operational goals and enhance customer satisfaction.

Essential Technical Properties and Trade Terminology for custom leather sectional

What Are the Key Technical Properties of Custom Leather Sectionals?

When considering custom leather sectionals for B2B procurement, understanding the critical specifications is essential for making informed purchasing decisions. Here are some vital properties:

1. Material Grade

The grade of leather used in sectionals is a crucial factor influencing quality and price. Leather is typically classified into several grades, ranging from full-grain (the highest quality) to bonded leather (the lowest). Full-grain leather, made from the top layer of the hide, retains the natural grain and is known for its durability and ability to develop a rich patina over time. This property is important for B2B buyers as it affects product longevity and customer satisfaction.

2. Frame Construction

A sectional’s frame construction is vital for its overall stability and durability. Look for sectionals made with solid hardwood frames, as they provide strength and resistance to warping. Additionally, interlocking or corner-blocked joints enhance structural integrity. For B2B buyers, understanding frame construction helps assess the potential lifespan of the furniture and its suitability for high-traffic environments.

3. Cushion Density

The density of the foam used in cushions determines comfort and support. Higher-density foam (measured in pounds per cubic foot) generally offers better durability and retains its shape longer. This is particularly relevant for businesses that expect frequent use of their seating. B2B buyers should consider cushion density to ensure that the sectional meets comfort standards while maintaining its aesthetic appeal over time.

4. Tolerance Levels

Tolerance refers to the acceptable range of variation in dimensions during the manufacturing process. For custom sectionals, maintaining tight tolerances is essential to ensure that all pieces fit together seamlessly. Tolerance levels can affect both aesthetics and functionality, making it crucial for B2B buyers to discuss these specifications with manufacturers to ensure high-quality production.

5. Finish and Treatment

The finish applied to leather can significantly influence its durability and maintenance requirements. Common treatments include protective coatings that enhance stain resistance and ease of cleaning. Understanding the type of finish is important for B2B buyers, as it affects the long-term upkeep of the sectional, which can impact overall ownership costs.

What Are Common Trade Terms Related to Custom Leather Sectionals?

Familiarity with industry terminology can facilitate smoother negotiations and procurement processes. Here are some essential trade terms:

Illustrative image related to custom leather sectional

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or products that are used in another company’s end product. In the context of custom leather sectionals, an OEM might manufacture the leather or components used in the sectional. B2B buyers often work with OEMs to ensure quality and consistency in their products.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell. This term is crucial for B2B buyers, as it can affect inventory management and cash flow. Understanding the MOQ helps businesses plan their purchases effectively, ensuring they meet supplier requirements without overstocking.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing information from suppliers for specific products. In the context of custom leather sectionals, issuing an RFQ allows businesses to compare offers and negotiate terms with multiple suppliers, ensuring competitive pricing and favorable conditions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global trade. They clarify who is responsible for shipping, insurance, and tariffs. Understanding Incoterms is essential for B2B buyers engaged in international procurement, as they help mitigate risks and ensure smooth transactions.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of the product. For custom leather sectionals, lead times can vary based on design complexity and manufacturing capabilities. B2B buyers must consider lead times when planning inventory and fulfilling customer orders, making it a critical factor in procurement decisions.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring that their investments in custom leather sectionals yield quality products that meet their business needs.

Navigating Market Dynamics and Sourcing Trends in the custom leather sectional Sector

What are the Current Market Dynamics and Key Trends in the Custom Leather Sectional Sector?

The custom leather sectional market is experiencing robust growth driven by several global factors, including increasing consumer demand for personalized home furnishings and a rise in disposable incomes, particularly in emerging markets such as Brazil, Nigeria, and various countries in the Middle East. As urbanization accelerates, the need for versatile, space-efficient furniture solutions is becoming paramount. The trend toward modular designs—where buyers can select various configurations, colors, and materials—aligns well with contemporary consumer preferences for customization.

Technological advancements are also reshaping the sourcing landscape. B2B buyers can leverage digital platforms that facilitate real-time communication with manufacturers and suppliers. This not only streamlines the procurement process but also enhances transparency in tracking orders and managing inventory. Additionally, the integration of AI and machine learning in supply chain management is helping businesses predict market trends and optimize their inventory based on consumer preferences.

Furthermore, international buyers are increasingly prioritizing quality and durability in their sourcing decisions. Custom leather sectionals, known for their longevity, are gaining traction. This is particularly relevant for markets in Africa and South America, where furniture durability can significantly impact buyer satisfaction and brand loyalty.

How is Sustainability and Ethical Sourcing Influencing the Custom Leather Sectional Market?

Sustainability has become a critical consideration for B2B buyers in the custom leather sectional sector. The environmental impact of leather production is significant, leading many companies to adopt more sustainable practices. Ethical sourcing of materials is no longer just a trend but a necessity, as consumers and businesses alike demand transparency in the supply chain. Buyers are increasingly interested in suppliers that provide certifications for sustainable practices, such as the Forest Stewardship Council (FSC) for wood and the Leather Working Group (LWG) for leather.

Investing in sustainable materials not only reduces the carbon footprint but also enhances brand reputation. Many manufacturers are now offering eco-friendly leather alternatives, such as vegetable-tanned leather and recycled materials, which appeal to environmentally conscious consumers. For international buyers, especially in regions like Europe, where environmental regulations are stringent, sourcing from companies that prioritize sustainability can also ensure compliance with local laws.

Additionally, ethical labor practices are becoming a focal point in supplier evaluations. Buyers are more inclined to partner with manufacturers that demonstrate a commitment to fair labor practices, transparency, and community engagement. This ethical approach not only fosters positive relationships but also aligns with the values of today’s socially aware consumers.

How Has the Custom Leather Sectional Market Evolved Over Time?

The custom leather sectional market has undergone significant transformation over the decades. Initially, leather furniture was considered a luxury item, primarily available to affluent consumers. However, with advancements in manufacturing processes and an increase in global competition, high-quality leather sectionals have become more accessible to a broader audience.

In the late 20th century, the introduction of synthetic leather alternatives began to reshape consumer preferences, offering a more affordable and diverse range of options. Today, the market is characterized by a blend of traditional craftsmanship and modern design, allowing consumers to choose from a variety of styles, colors, and configurations. This evolution reflects a shift in consumer behavior toward personalization and functionality, which is now a key driver in the B2B landscape for custom leather sectionals.

As manufacturers continue to innovate, the focus on sustainability and ethical sourcing will likely shape the future of the custom leather sectional market, making it essential for international B2B buyers to stay informed and adaptable to these changes.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather sectional

1. How do I determine the best customization options for a leather sectional?

To find the ideal customization options for a leather sectional, consider your target market’s preferences, including size, color, and design. Engage with potential customers to understand their needs, and evaluate materials that align with their aesthetic and durability requirements. Look for suppliers that offer a wide range of leather types, including full-grain and top-grain options, as well as various colors and textures. Request samples to assess quality and ensure the customization options are feasible within your budget and timeline.

2. What is the typical minimum order quantity (MOQ) for custom leather sectionals?

The MOQ for custom leather sectionals can vary significantly among suppliers, typically ranging from 10 to 50 units per order. Factors influencing MOQ include the supplier’s production capabilities, the complexity of customization, and the materials used. Before placing an order, discuss your needs with potential suppliers to negotiate terms that suit your business model. Understanding the MOQ is crucial for managing inventory and ensuring a steady flow of product to meet customer demand.

Illustrative image related to custom leather sectional

3. How can I effectively vet suppliers for custom leather sectionals?

Vetting suppliers involves several steps: start by researching their industry reputation and reading reviews from other B2B clients. Request references and case studies that demonstrate their experience with custom leather furniture. Conduct site visits if possible, or utilize video calls to inspect their production facilities. Additionally, assess their compliance with international quality standards and certifications, such as ISO or BIFMA, to ensure that they can deliver high-quality products consistently.

4. What payment terms should I expect when sourcing custom leather sectionals?

Payment terms can vary widely among suppliers but typically include options like deposits, net 30, or net 60. A common practice is to pay 30% upfront as a deposit to initiate production, with the balance due upon completion or delivery. Always clarify these terms in the contract to avoid misunderstandings. Additionally, consider using secure payment methods like letters of credit or escrow services, especially when dealing with international transactions, to protect your investment.

5. What are the key quality assurance practices for custom leather sectionals?

Quality assurance for custom leather sectionals should encompass several practices, including material inspection, production monitoring, and final product evaluation. Ensure that suppliers conduct thorough inspections of the leather before production begins, checking for defects or inconsistencies. During production, regular audits can help maintain quality standards. Finally, a comprehensive final inspection should confirm that the finished products meet the agreed-upon specifications before shipment.

6. How do logistics impact the sourcing of custom leather sectionals?

Logistics play a critical role in sourcing custom leather sectionals, affecting lead times, shipping costs, and overall supply chain efficiency. When selecting suppliers, evaluate their shipping capabilities and partnerships with freight companies. Consider potential customs regulations and tariffs in your target markets, which can influence delivery timelines and costs. Collaborating with logistics experts can help streamline the import process and ensure that your products arrive on time and in good condition.

Illustrative image related to custom leather sectional

7. What should I consider when choosing leather types for sectionals?

When selecting leather types for custom sectionals, prioritize factors such as durability, texture, and maintenance requirements. Full-grain leather, while more expensive, offers superior durability and a rich appearance, making it ideal for high-end markets. Conversely, top-grain leather is more affordable and easier to clean, appealing to budget-conscious buyers. Additionally, assess the environmental impact of the tanning process and consider sourcing from suppliers that use sustainable practices, as this can enhance your brand’s reputation.

8. How can I ensure that my custom leather sectionals meet international standards?

To ensure your custom leather sectionals comply with international standards, familiarize yourself with relevant regulations in your target markets, such as fire safety or material certifications. Collaborate with suppliers who adhere to these standards and can provide documentation to prove compliance. Additionally, consider third-party testing for quality assurance, which can validate that your products meet or exceed market expectations. This proactive approach not only protects your business but also builds trust with your customers.

Top 9 Custom Leather Sectional Manufacturers & Suppliers List

1. Bassett Furniture – Sectionals

Domain: bassettfurniture.com

Registered: 1996 (29 years)

Introduction: {“sectional_types”: [“U-Shaped Sectionals”, “L-Shaped Sectionals”, “Modular Sectionals”, “Chaise Sectionals”, “Reclining Sectionals”], “customization_options”: true, “in_stock_options”: [{“delivery_time”: “2-3 Weeks”, “quantity”: 11}, {“delivery_time”: “4-6 Weeks”, “quantity”: 7}], “custom_made_options”: [{“delivery_time”: “4-6 Weeks”, “quantity”: 54}, {“delivery_time”: “6-8 Weeks”, “quantity”: 33…

2. Leather Groups – Custom Leather Sectional Sofas

Domain: leathergroups.com

Registered: 2002 (23 years)

Introduction: Leather Sectional Sofas – Custom, Full-Grain & Made in USA. Features include: solid hardwood frame, feather and down cushioning, optional eight-way hand-tied suspension, and full-grain leathers. Customization options available for layout, depth, and leather selection. Made in California. Financing options available. Free white glove delivery. Types of leather include Full Grain, Aniline Full Grain…

3. Ethan Allen – Build-Your-Own Sectional

Domain: ethanallen.com

Registered: 1995 (30 years)

Introduction: Build-Your-Own Sectional from Ethan Allen offers customizable sectional sofas. Customers can select from various styles, fabrics, and configurations to create a personalized seating solution for their living space. The product is part of a promotional offer where spending $3,000 or more saves 20%, and spending up to $2,999 saves 15%. The sectionals are designed for comfort and style, reflecting cr…

4. Flexsteel – Living Room Furniture

Domain: flexsteel.com

Registered: 1996 (29 years)

Introduction: Product Type: Living Room Furniture

Motion Type: Power Reclining, Non-Power

Customizable Material: Fabric, Leather

Style: Modern & Contemporary, Traditional, Transitional

Features: Accent Pillows Included, Big & Tall, Charging Ports Included, CloudLux Cushion(s), Console, Cup Holders, Custom Wood Finish, FlexSync App Control, Heat & Air Massage, Heavy-Thread Stitching, Nailhead Trim, Power Headres…

5. Leathersofa – Alexandria Sectional

Domain: leathersofaco.com

Registered: 2004 (21 years)

Introduction: [{‘name’: ‘Alexandria Sectional (Left Arm Loveseat + Left Arm Right Chaise Sofa)’, ‘base_leather’: ‘Sooner Golden Tan’, ‘price’: ‘$9,200.00’, ‘description’: ‘Few designs offer a more perfect balance of style and comfort than the Alexandria. This contemporary off the floor silhouette features a beautifully sculpted frame and soft…’, ‘features’: ‘Left Arm Loveseat + Left Arm Right Chaise Sofa’}, {…

6. American Leather – Custom Sofas and Sectionals

Domain: americanleather.com

Registered: 1997 (28 years)

Introduction: Custom Sofas and Sectionals from American Leather feature modern styles, hundreds of configurations, and over 400 upholstery options. The collection includes various types of sofas and sectionals such as the Comfort Sleeper, Comfort Relax, and multiple contract-approved options. Notable products include the Alessandro Sectional, Athlea Cuddler, Barcelona Sectional, and many more. The offerings are…

7. BenchMade Modern – Skinny Fat Sectional

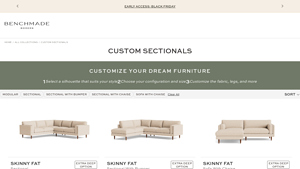

Domain: benchmademodern.com

Registered: 2014 (11 years)

Introduction: Custom Sectionals available at BenchMade Modern. Options include Modular Sectional, Sectional with Bumper, Sectional with Chaise, and Sofa with Chaise. Products are customizable in silhouette, configuration, size, fabric, and legs. Key products include: Skinny Fat Sectional (from $6,137), Eva Small Sectional (from $6,510), Tyler Sectional (from $5,585), Catalina Sectional (from $5,095), Laguna Sec…

8. Palliser Furniture – Acacia 41080 Power Headrest Power Reclining Sectional

Domain: sofasandsectionals.com

Registered: 2008 (17 years)

Introduction: Custom Sectionals available in various styles and upholstery fabrics. Key products include:

1. Acacia 41080 Power Headrest Power Reclining Sectional – Starting At $6,528.00 (By Palliser Furniture, 130 Colors, +100 leathers)

2. Alula 77247 Sectional – Starting At $3,114.00 (By Palliser Furniture, 136 Colors, +100 Leathers)

3. Amisk 77343 Sectional – Starting At $3,950.00 (By Palliser Furniture, …

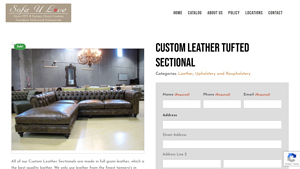

9. Sofa Su Love – Custom Leather Tufted Sectional

Domain: sofasulove.com

Registered: 2021 (4 years)

Introduction: Custom Leather Tufted Sectional, made from full grain leather, sourced from the finest tanneries in Italy. Available in any size and color.

Strategic Sourcing Conclusion and Outlook for custom leather sectional

How Can Strategic Sourcing Enhance Your Procurement of Custom Leather Sectionals?

In today’s competitive marketplace, strategic sourcing plays a pivotal role in securing high-quality custom leather sectionals that meet diverse consumer demands. By leveraging relationships with manufacturers, international B2B buyers can ensure access to a wide range of customizable options, from various leather finishes to different sectional configurations. This not only enhances product offerings but also provides the flexibility needed to respond to changing market trends and consumer preferences.

Understanding the nuances of sourcing—such as lead times, material quality, and supplier reliability—can significantly impact profitability and customer satisfaction. Buyers should prioritize partnerships with reputable manufacturers who emphasize durability and craftsmanship, ensuring that the products delivered align with the brand’s values and customer expectations.

As the market continues to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, there is a growing demand for personalized and stylish furniture solutions. Now is the time to act. Engage with suppliers who can offer tailored designs and sustainable materials, positioning your business for success in a thriving global marketplace. Embrace the future of furniture sourcing and elevate your product line with premium custom leather sectionals that resonate with your clientele.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.