Introduction: Navigating the Global Market for black alcantara fabric

In the ever-evolving landscape of global textiles, sourcing high-quality black Alcantara fabric presents a unique challenge for B2B buyers seeking premium materials for automotive, fashion, and interior design applications. With its luxurious look and feel, Alcantara not only enhances product aesthetics but also offers exceptional durability and ease of maintenance. This guide aims to illuminate the multifaceted world of black Alcantara fabric, covering essential aspects such as types of Alcantara available, diverse applications across industries, effective supplier vetting strategies, and cost considerations tailored to international markets.

As buyers from regions like Africa, South America, the Middle East, and Europe (including countries like Vietnam and Brazil) navigate this complex market, understanding the intricacies of Alcantara sourcing becomes paramount. This comprehensive resource empowers decision-makers by providing actionable insights, ensuring that they make informed purchasing choices that align with their specific needs and industry standards. By delving into the specifications and applications of black Alcantara fabric, this guide equips businesses with the knowledge required to secure the best materials for their projects, enhancing both product quality and customer satisfaction.

Table Of Contents

- Top 7 Black Alcantara Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for black alcantara fabric

- Understanding black alcantara fabric Types and Variations

- Key Industrial Applications of black alcantara fabric

- 3 Common User Pain Points for ‘black alcantara fabric’ & Their Solutions

- Strategic Material Selection Guide for black alcantara fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for black alcantara fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘black alcantara fabric’

- Comprehensive Cost and Pricing Analysis for black alcantara fabric Sourcing

- Alternatives Analysis: Comparing black alcantara fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for black alcantara fabric

- Navigating Market Dynamics and Sourcing Trends in the black alcantara fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of black alcantara fabric

- Strategic Sourcing Conclusion and Outlook for black alcantara fabric

- Important Disclaimer & Terms of Use

Understanding black alcantara fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Alcantara Soft Foam Backed | 2mm thick foam backing, single layer | Automotive headliners, wrapping panels | Pros: Soft feel, easy to clean, durable. Cons: Slightly higher cost than unbacked options. |

| Alcantara Unbacked | Lightweight, single-layer fabric without backing | Automotive interiors, upholstery | Pros: Greater stretchability, lightweight. Cons: Less protection against wear and tear. |

| Alcantara Perforated | Features perforations for breathability and style | Automotive seating, fashion applications | Pros: Enhanced ventilation, unique aesthetic. Cons: May compromise durability in high-wear areas. |

| Alcantara Starlite | High-performance variant with UV and weather resistance | Outdoor furniture, automotive applications | Pros: Excellent durability, fade-resistant. Cons: Typically more expensive than standard options. |

| Alcantara Cover | Backed with a durable layer for added strength | Luxury automotive seating, high-end upholstery | Pros: Superior durability, easy maintenance. Cons: Heavier than unbacked variants. |

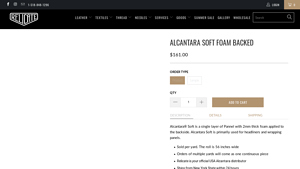

What Are the Key Characteristics of Alcantara Soft Foam Backed Fabric?

Alcantara Soft Foam Backed fabric is characterized by its 2mm thick foam backing, which provides additional comfort and insulation. This type is primarily used in automotive applications, particularly for headliners and wrapping panels, where a soft touch and durability are essential. Buyers should consider the cost-effectiveness of this option, as it balances quality with price, making it a popular choice for luxury vehicles.

How Does Alcantara Unbacked Fabric Differ from Other Types?

Alcantara Unbacked is a single-layer fabric that is lightweight and flexible, making it ideal for applications requiring stretchability, such as automotive interiors and upholstery. While it offers a soft and luxurious feel, B2B buyers should note that it may not provide the same level of protection against wear and tear as backed options. Its lightweight nature, however, can reduce shipping costs, making it an attractive choice for budget-conscious businesses.

What Are the Advantages of Using Alcantara Perforated Fabric?

Alcantara Perforated fabric features small holes that enhance breathability and add a unique design element. This type is particularly suited for automotive seating and fashion applications where comfort and aesthetics are prioritized. While it offers excellent ventilation, businesses must consider that the perforations might reduce durability in high-wear areas, necessitating careful application in specific environments.

Why Choose Alcantara Starlite for Outdoor Applications?

Alcantara Starlite is engineered for high performance, boasting UV and weather resistance, making it suitable for outdoor furniture and automotive applications. Its durability and fade resistance are significant advantages for businesses looking to invest in long-lasting materials. However, this premium option comes at a higher price point, which may require careful budget considerations for B2B buyers.

How Does Alcantara Cover Enhance Upholstery Projects?

Alcantara Cover is a backed fabric that provides superior durability and ease of maintenance, making it ideal for luxury automotive seating and high-end upholstery projects. Its backing adds strength and stability, which is crucial for applications where wear is a concern. While it is heavier than unbacked variants, its long-term performance justifies the investment for businesses focused on quality and longevity in their products.

Key Industrial Applications of black alcantara fabric

| Industry/Sector | Specific Application of black alcantara fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Interior upholstery for luxury vehicles | Enhances aesthetics, provides durability and easy maintenance | Sourcing certified Alcantara, ensuring color and texture consistency, minimum order quantities. |

| Furniture | Upholstery for high-end furniture | Offers premium look and feel, stain resistance, and durability | Consider weight, thickness, and backing options for different furniture applications. |

| Fashion and Apparel | Clothing and accessories | Lightweight, breathable, and easy to clean; ideal for high-fashion items | Verify fabric composition, ensure compliance with international quality standards. |

| Aerospace | Cabin interiors for private jets | Reduces glare, provides a luxurious feel, and is lightweight | Focus on weight specifications and fire-retardant certifications. |

| Home Décor | Wall coverings and decorative accents | Adds a touch of elegance, sound absorption, and easy maintenance | Assess color fastness and compatibility with adhesives for installation. |

How is Black Alcantara Fabric Used in the Automotive Industry?

In the automotive sector, black alcantara fabric is widely utilized for interior upholstery in luxury vehicles. Its soft texture and aesthetic appeal enhance the overall look of car interiors, making it a preferred choice for brands like Audi and Tesla. The fabric offers durability against wear and tear while being easy to clean, addressing common issues of maintenance in vehicle interiors. International buyers should prioritize sourcing certified Alcantara to ensure quality and consistency in color and texture, as well as consider minimum order quantities for bulk purchases.

What Role Does Black Alcantara Fabric Play in High-End Furniture?

Black alcantara fabric is increasingly popular in the high-end furniture market for upholstery. Its luxurious appearance and durability make it an attractive option for sofas, chairs, and other furniture items. The fabric is also stain-resistant, which appeals to businesses focused on longevity and ease of maintenance. Buyers should evaluate the weight and thickness of the fabric to ensure it meets the specific requirements of their furniture designs, and consider the backing options available to enhance performance.

How is Black Alcantara Fabric Transforming the Fashion and Apparel Sector?

In the fashion and apparel industry, black alcantara fabric is favored for clothing and accessories due to its lightweight and breathable properties. It is particularly suitable for high-fashion items where aesthetics and comfort are paramount. The fabric’s easy-to-clean nature solves the problem of maintenance in clothing, making it ideal for everyday wear. International buyers should verify the fabric composition and ensure compliance with international quality standards to maintain their brand reputation.

Why is Black Alcantara Fabric Essential for Aerospace Applications?

In the aerospace industry, black alcantara fabric is used for cabin interiors in private jets. Its lightweight nature contributes to overall weight reduction, which is crucial in aviation. Additionally, the fabric reduces glare, enhancing passenger comfort and experience. Buyers in this sector should focus on sourcing materials that meet specific weight specifications and fire-retardant certifications to ensure safety and compliance with industry regulations.

How Can Black Alcantara Fabric Enhance Home Décor?

Black alcantara fabric finds applications in home décor, particularly for wall coverings and decorative accents. Its elegant look adds sophistication to interiors while providing sound absorption qualities. The fabric is also easy to maintain, appealing to homeowners and interior designers alike. When sourcing for this application, it is essential to assess color fastness and compatibility with adhesives to ensure successful installation and longevity in various environments.

3 Common User Pain Points for ‘black alcantara fabric’ & Their Solutions

Scenario 1: Color Consistency Across Batches

The Problem: One major challenge B2B buyers face when sourcing black Alcantara fabric is ensuring color consistency across multiple batches. Variations in dye lots can lead to discrepancies in shades, which can be particularly problematic for businesses involved in high-end automotive or upholstery applications. Such inconsistencies can undermine product quality and customer satisfaction, ultimately affecting brand reputation.

Illustrative image related to black alcantara fabric

The Solution: To mitigate this issue, buyers should establish strong relationships with reputable suppliers who can guarantee consistent dye lots. Requesting color samples prior to bulk orders is crucial, as this allows for physical verification of the shade and texture. Additionally, consider specifying your needs in writing, including color codes and standards from recognized industry benchmarks. Regular communication with suppliers about upcoming projects can help them prepare and maintain consistent production standards, ensuring that all fabric purchased within a given timeframe matches perfectly.

Scenario 2: Durability and Maintenance Concerns

The Problem: Buyers in sectors such as automotive and furniture upholstery often express concerns about the durability and maintenance of black Alcantara fabric. While Alcantara is known for its resilience, it can still show signs of wear or staining if not properly cared for. This is particularly challenging for businesses that cater to high-traffic areas or environments where spills are likely.

The Solution: To address durability concerns, it is essential to provide clients with comprehensive care instructions that detail how to maintain Alcantara fabric effectively. Buyers should consider sourcing Alcantara that has been treated with protective coatings to enhance its resistance to stains and wear. Providing training for staff on proper cleaning techniques—such as using appropriate cleaning solutions and tools—can also help maintain the fabric’s appearance. Furthermore, including warranty information from suppliers that covers wear and tear can provide additional reassurance to clients regarding the longevity of their investment.

Scenario 3: Sourcing Quality Materials at Competitive Prices

The Problem: Sourcing black Alcantara fabric at competitive prices without sacrificing quality is a common pain point for B2B buyers. With numerous suppliers offering varied pricing structures, it can be difficult to determine which options provide the best value. Additionally, some suppliers may offer lower prices but compromise on quality, leading to dissatisfaction and potential returns.

Illustrative image related to black alcantara fabric

The Solution: To navigate this challenge, buyers should conduct thorough market research to identify reputable suppliers who offer competitive pricing without compromising quality. Establishing a clear understanding of the quality standards required for specific applications can help buyers ask the right questions and avoid low-quality alternatives. Leveraging bulk purchasing options or forming cooperatives with other businesses can lead to better pricing arrangements. Lastly, always requesting samples before making large orders can help ensure that the quality meets expectations, allowing buyers to make informed decisions that align with their budget and quality requirements.

Strategic Material Selection Guide for black alcantara fabric

What Are the Key Properties of Black Alcantara Fabric?

Black Alcantara fabric is a high-performance synthetic material that combines aesthetics with functionality. It is primarily composed of a blend of polyester and polyurethane, which provides a luxurious suede-like texture while ensuring durability and ease of maintenance. The fabric is often employed in automotive interiors, furniture, and fashion accessories due to its excellent wear resistance, withstanding over 30,000 Martindale cycles, which indicates its ability to endure heavy use without significant degradation.

What Are the Advantages and Disadvantages of Using Alcantara in B2B Applications?

Alcantara Soft Foam Backed

Key Properties: This variant features a 2mm foam backing, enhancing its insulation and comfort. It is suitable for applications like headliners and wrapped panels in vehicles.

Pros: The foam backing adds a layer of comfort and sound insulation, making it ideal for automotive interiors. Additionally, its easy-to-clean surface reduces maintenance costs.

Cons: The added foam can increase the overall thickness, potentially complicating manufacturing processes that require precise fitment. It also comes at a higher cost compared to unbacked versions.

Impact on Application: The foam backing makes it suitable for applications that require both aesthetic appeal and functional performance, such as luxury vehicles.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider local climate conditions, as the foam backing may retain heat. Compliance with local automotive standards is crucial, particularly in regions with stringent regulations.

Alcantara Unbacked

Key Properties: This version is a single-layer textile that is thinner and more flexible, making it easier to work with in various applications.

Pros: Its flexibility allows for seamless integration into complex shapes, making it ideal for door panels and intricate designs. It is also generally less expensive than foam-backed options.

Cons: While it is lightweight, it may not provide the same level of insulation or comfort as foam-backed variants, which could be a drawback in specific applications.

Illustrative image related to black alcantara fabric

Impact on Application: The unbacked Alcantara is often used in high-end automotive interiors where weight savings are critical, but it may not be suitable for applications requiring additional cushioning.

Considerations for International Buyers: Buyers should ensure that the unbacked version meets their specific requirements for durability and wear resistance, particularly in markets with high humidity or temperature fluctuations.

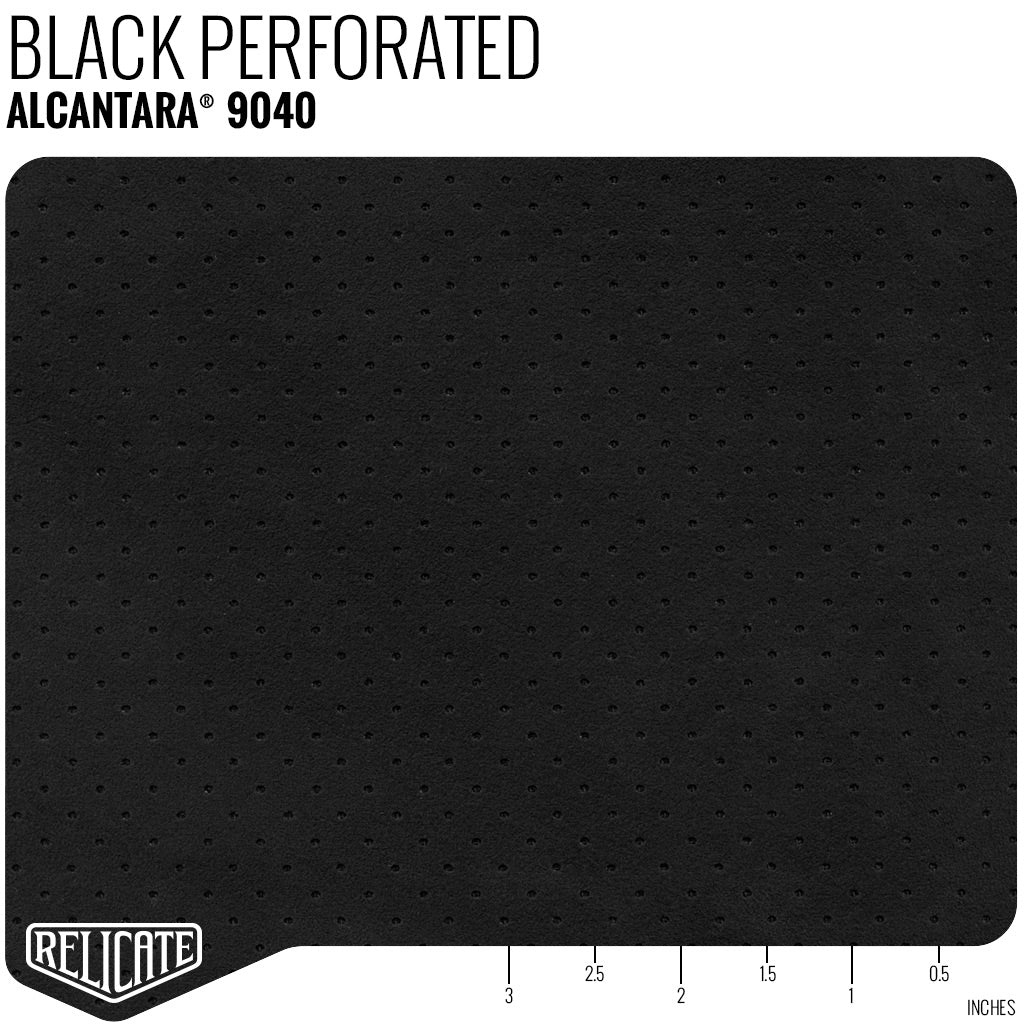

Alcantara Perforated

Key Properties: This variant features small perforations that enhance breathability and reduce glare, making it ideal for automotive applications.

Pros: The perforations allow for better air circulation, which can enhance comfort in hot climates. They also add a unique aesthetic appeal, making it popular in luxury vehicles.

Illustrative image related to black alcantara fabric

Cons: The perforated design may reduce overall durability compared to non-perforated options, especially in high-wear areas.

Impact on Application: Ideal for seating and headliners, the perforated Alcantara can improve comfort and style but may require careful handling during installation.

Considerations for International Buyers: Buyers should verify that the perforated design meets local standards for vehicle safety and comfort, especially in regions with varying climate conditions.

Summary Table of Material Selection for Black Alcantara Fabric

| Materiał | Typical Use Case for black alcantara fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alcantara Soft Foam Backed | Automotive headliners, wrapping panels | Enhanced comfort and sound insulation | Increased thickness complicates fitment | High |

| Alcantara Unbacked | Door panels, intricate designs | Flexibility for seamless integration | Lacks insulation, may not suit all needs | Medium |

| Alcantara Perforated | Seating, headliners | Improved breathability and unique aesthetics | Reduced durability in high-wear areas | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the different types of black Alcantara fabric available, helping them make informed decisions tailored to their specific applications and regional requirements.

Illustrative image related to black alcantara fabric

In-depth Look: Manufacturing Processes and Quality Assurance for black alcantara fabric

What Are the Main Stages of Manufacturing Black Alcantara Fabric?

The manufacturing process for black Alcantara fabric involves several key stages, each critical for ensuring the material meets both aesthetic and functional requirements.

-

Material Preparation: The first stage begins with the selection of high-quality raw materials. Black Alcantara is primarily made from a blend of polyester (68%) and polyurethane (32%), which offers durability and a suede-like feel. These materials undergo thorough cleaning and quality checks to eliminate impurities that could affect the final product.

-

Forming: In this stage, the prepared materials are processed into a non-woven fabric structure. This involves blending the polyester and polyurethane components, followed by methods such as needle punching or bonding to create a soft, flexible textile. The thickness of the fabric can vary, with typical specifications for Alcantara being around 1.0 mm to 3.0 mm, depending on the intended application, such as automotive interiors or fashion.

-

Assembly: Once the fabric is formed, it is cut and sewn according to specific patterns and designs. This stage may involve adding foam backing for enhanced comfort and structural integrity, particularly in applications like headliners and seating. Precise cutting and sewing techniques are crucial to ensure that each piece fits perfectly, especially in automotive applications where aesthetics and functionality are paramount.

-

Finishing: The final stage involves several finishing processes that enhance the fabric’s appearance and performance. This may include dyeing to achieve the desired black hue, applying protective coatings for stain resistance, and conducting treatments to improve durability. The finishing process also includes quality checks to ensure that the fabric meets industry standards for colorfastness, wear resistance, and overall quality.

What Quality Assurance Standards Are Relevant for Black Alcantara Fabric?

Quality assurance is vital in the production of black Alcantara fabric, ensuring that it meets international standards and customer expectations. The following are key quality assurance standards and checkpoints involved in the process:

-

International Standards: Compliance with ISO 9001 is crucial, as this standard outlines the requirements for a quality management system. It ensures that the manufacturing process is consistent, and products meet customer and regulatory requirements. Other relevant standards may include ISO 14001 for environmental management and ISO 50001 for energy management, which can be particularly relevant for sustainable sourcing.

-

Industry-Specific Certifications: Depending on the application, additional certifications may be necessary. For automotive applications, certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may apply, ensuring that the fabric meets safety and performance standards.

How Are Quality Control Checkpoints Integrated into the Manufacturing Process?

Quality control (QC) is integrated at various stages of the manufacturing process, ensuring that each batch of black Alcantara fabric meets strict quality standards.

Illustrative image related to black alcantara fabric

-

Incoming Quality Control (IQC): This initial checkpoint occurs when raw materials arrive at the facility. Here, materials are inspected for quality, consistency, and compliance with specifications. Any defective materials are rejected to prevent issues later in the production process.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular checks are performed to monitor processes and ensure that they adhere to defined parameters. This may include measuring fabric thickness, testing for consistency in color, and evaluating the strength of the bonding processes.

-

Final Quality Control (FQC): Once the fabric is completed, FQC checks are conducted to assess the final product before it is shipped. This includes testing for durability (e.g., Martindale abrasion tests), colorfastness (e.g., Xenotest), and overall appearance. These tests help ensure that the fabric not only looks good but will also perform well in its intended application.

What Testing Methods Are Commonly Used in Quality Assurance for Alcantara Fabric?

Several testing methods are employed to verify the quality of black Alcantara fabric, ensuring it meets the necessary performance criteria:

-

Martindale Abrasion Test: This test measures the fabric’s wear resistance by subjecting it to friction until it shows signs of wear. A standard of 30,000 cycles is often used for Alcantara, indicating excellent durability.

-

Xenotest for Lightfastness: This test assesses how well the fabric retains its color when exposed to light. A rating of 3 or higher on the grey scale is typically required for high-quality Alcantara.

-

Colorfastness to Rubbing: Tests for both dry and wet rubbing ensure that the color does not transfer onto other surfaces. Acceptable ratings are usually 4 for dry and 3-4 for wet rubbing.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is essential to ensure product reliability.

-

Supplier Audits: Conducting on-site audits of manufacturing facilities can provide insight into the supplier’s quality control practices. This includes reviewing their quality management system, production processes, and adherence to international standards.

-

Quality Reports: Requesting detailed quality reports that outline testing results and compliance with industry standards can help buyers assess the reliability of the fabric. These reports should include data from IQC, IPQC, and FQC stages.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control processes. These services can conduct random sample testing and verify compliance with international standards.

What Are the Nuances of Quality Certification for International B2B Buyers?

International B2B buyers must navigate specific nuances when it comes to quality certification for black Alcantara fabric.

Illustrative image related to black alcantara fabric

-

Regional Standards: Different regions may have varying standards and certifications. For example, European buyers might prioritize CE marking, while buyers in the Middle East may look for local compliance certificates.

-

Documentation Requirements: Buyers should be aware of the necessary documentation to facilitate customs clearance and compliance with local regulations. This may include certificates of origin, compliance certificates, and test reports.

-

Sustainability and Ethical Sourcing: Increasingly, buyers are placing importance on sustainability practices. Verifying that suppliers adhere to ethical sourcing standards and environmental regulations can be a significant factor in supplier selection.

By understanding the manufacturing processes and quality assurance standards associated with black Alcantara fabric, B2B buyers can make informed decisions, ensuring they source high-quality materials that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘black alcantara fabric’

This guide aims to assist B2B buyers in effectively sourcing black Alcantara fabric, ensuring that you make informed decisions throughout the procurement process. Alcantara, known for its luxurious feel and durability, is increasingly popular in various applications, particularly in automotive and upholstery industries. Follow this checklist to streamline your sourcing journey.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to outline your specific requirements for black Alcantara fabric. Consider factors such as thickness, width, and application type. For instance, if you’re using it for automotive interiors, you may require foam-backed variants for additional cushioning and durability.

- Grubość: Ensure it meets your project needs (typically ranging from 1.0 mm to 3.0 mm).

- Szerokość: Common widths are around 56 inches, but confirm to avoid wastage.

Step 2: Identify Reliable Suppliers

Finding a trustworthy supplier is crucial for ensuring quality and timely delivery. Conduct thorough research to identify suppliers with a solid reputation in the industry.

- Check Reviews and References: Look for customer testimonials and case studies that reflect the supplier’s reliability and product quality.

- Geographical Considerations: Prioritize suppliers who can efficiently ship to your region to minimize delays.

Step 3: Request Samples for Quality Assurance

Obtaining fabric samples is an essential step in the procurement process. Samples allow you to evaluate the texture, color accuracy, and overall quality of the fabric before making a bulk purchase.

- Limitations on Samples: Be mindful of any restrictions on the number of samples you can request from suppliers.

- Comparative Analysis: Use samples from multiple suppliers to assess quality differences and make an informed decision.

Step 4: Verify Supplier Certifications

Before finalizing your order, ensure that your chosen supplier holds the necessary certifications. Certifications can provide assurance regarding the quality and sustainability of the materials.

- Quality Standards: Look for certifications like ISO 9001 for quality management.

- Sustainability Practices: Consider suppliers that adhere to eco-friendly practices, which is increasingly important in today’s market.

Step 5: Negotiate Pricing and Terms

Once you’ve identified a suitable supplier, engage in negotiations to ensure you receive competitive pricing and favorable terms.

- Volume Discounts: Inquire about discounts for bulk orders as this can significantly reduce costs.

- Payment Terms: Clarify payment options and timelines to avoid any financial misunderstandings later.

Step 6: Confirm Shipping and Delivery Timelines

Understand the logistics involved in your order to prevent delays in receiving your fabric. Confirm shipping methods, costs, and estimated delivery times.

- Expedited Shipping: If time-sensitive, discuss expedited options with the supplier.

- Tracking Information: Ensure that you will receive tracking details once the shipment is dispatched.

Step 7: Establish a Follow-Up Process

After placing your order, set up a follow-up process to maintain communication with your supplier. This helps address any issues that may arise during production or shipping.

Illustrative image related to black alcantara fabric

- Regular Updates: Request regular updates on your order status.

- Feedback Loop: Provide feedback on the quality upon receipt to foster a strong supplier relationship for future orders.

By following this step-by-step checklist, B2B buyers can streamline their sourcing process for black Alcantara fabric, ensuring they secure high-quality materials that meet their specific needs.

Comprehensive Cost and Pricing Analysis for black alcantara fabric Sourcing

What Are the Key Cost Components for Sourcing Black Alcantara Fabric?

When sourcing black Alcantara fabric, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The base price of Alcantara fabric varies significantly based on its composition. Genuine Alcantara, typically comprising 68% polyester and 32% polyurethane, commands a higher price due to its premium quality and durability. Prices can range from $135 to $161 per yard, depending on the supplier and specific product features.

-

Labor: Labor costs involve the workforce engaged in the manufacturing process. This includes cutting, sewing, and finishing the fabric. Labor costs can fluctuate based on the country of origin, skill level required, and local wage standards.

-

Manufacturing Overhead: This includes expenses related to facility operations, utilities, and equipment maintenance. Suppliers often factor these costs into the final price of the fabric.

-

Tooling: For custom orders, tooling costs can be significant, especially if specialized machinery or molds are required for unique fabric designs or patterns.

-

Quality Control (QC): Ensuring the fabric meets specific standards is crucial. QC processes can add to the overall cost, particularly if third-party certifications or testing are involved.

-

Logistics: Shipping costs vary based on the distance from the supplier to the buyer, shipping method, and weight of the order. These costs can be particularly impactful for international buyers, who must also consider customs duties and taxes.

-

Margin: Suppliers typically add a margin to cover their costs and generate profit, which can vary based on market conditions and competition.

How Do Pricing Influencers Affect Black Alcantara Fabric Costs?

Several factors influence the pricing of black Alcantara fabric:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for bulk pricing, significantly reducing the cost per yard. Understanding a supplier’s MOQ can help buyers plan their purchases effectively.

-

Specifications and Customization: Custom specifications, such as thickness, backing options, or treatment for specific applications, can lead to higher costs. Buyers should evaluate whether these custom features are necessary for their projects.

-

Materials and Quality Certifications: The presence of certifications (e.g., ISO, OEKO-TEX) can affect pricing. Fabrics that meet stringent quality or environmental standards may carry a premium.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more for their proven quality and service but can also provide peace of mind regarding delivery and consistency.

-

Incoterms: The agreed Incoterms (e.g., FOB, CIF) determine who bears shipping costs and responsibilities, which can affect the total cost of ownership.

What Tips Can Buyers Leverage for Cost-Efficiency in Black Alcantara Fabric Procurement?

To optimize costs when sourcing black Alcantara fabric, buyers can consider the following strategies:

Illustrative image related to black alcantara fabric

-

Negotiation: Engaging in negotiations can yield better pricing, especially for larger orders. Demonstrating commitment to ongoing business can incentivize suppliers to offer discounts.

-

Understanding Total Cost of Ownership (TCO): Buyers should evaluate the TCO, which includes not only the purchase price but also logistics, handling, and any potential wastage or defects. This comprehensive view can help in making informed purchasing decisions.

-

Price Sensitivity: Keep an eye on market trends and competitor pricing. Being aware of seasonal fluctuations or changes in material costs can provide leverage during negotiations.

-

Sample Orders: Before committing to large purchases, requesting samples can help ensure the fabric meets quality expectations. This step can prevent costly mistakes in bulk orders.

-

International Considerations: For buyers from Africa, South America, the Middle East, and Europe, understanding local import regulations and tariffs can prevent unexpected costs. Additionally, developing relationships with local distributors can facilitate smoother transactions.

Disclaimer on Indicative Prices

Prices mentioned in this analysis are indicative and subject to change based on market conditions, supplier pricing strategies, and specific order details. Buyers are encouraged to obtain quotes from multiple suppliers to ensure competitive pricing and terms.

Alternatives Analysis: Comparing black alcantara fabric With Other Solutions

Exploring Alternatives to Black Alcantara Fabric

In the competitive world of upholstery and interior design, B2B buyers often seek alternatives to popular materials like black Alcantara fabric. Understanding the nuances of various options can aid in making informed purchasing decisions. This analysis compares black Alcantara fabric against other viable alternatives, including synthetic suede and genuine leather, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Black Alcantara Fabric | Synthetic Suede | Genuine Leather |

|---|---|---|---|

| Performance | Durable, high wear resistance, soft touch | Moderate durability, less wear resistance | Highly durable, natural aesthetic |

| Cost | Moderate ($135-$161 per yard) | Lower ($30-$50 per yard) | High ($200+ per hide) |

| Ease of Implementation | Easy to cut and sew; versatile applications | Simple to work with; lightweight | Requires specialized tools; heavy |

| Maintenance | Easy to clean, stain-resistant | Requires regular cleaning, less resistant to stains | Needs conditioning and regular care |

| Best Use Case | Automotive interiors, luxury applications | Fashion items, upholstery projects | High-end furniture, luxury goods |

What Are the Advantages and Disadvantages of Synthetic Suede?

Synthetic suede serves as a cost-effective alternative to black Alcantara fabric. It mimics the look and feel of suede while being lighter and more budget-friendly. However, it typically offers lower durability and wear resistance, making it less suitable for high-traffic areas or luxury applications. It is easy to clean but may require more frequent maintenance compared to Alcantara. This option is ideal for fashion items or upholstery projects where budget constraints are a priority.

Illustrative image related to black alcantara fabric

How Does Genuine Leather Compare to Black Alcantara Fabric?

Genuine leather is often viewed as the benchmark for quality in upholstery. It boasts unparalleled durability and a natural aesthetic that many consumers find appealing. However, it comes with a higher price tag and requires more specialized care, making it less accessible for some projects. While genuine leather can be used in high-end furniture and luxury goods, it may not be as easy to implement as Alcantara, especially for intricate designs that require precise cutting and sewing. Its maintenance demands—such as conditioning and protecting against stains—can also deter some buyers.

Conclusion: How to Choose the Right Material for Your Project?

When selecting the right fabric for your project, consider the specific requirements of your application, such as performance, budget, and maintenance needs. Black Alcantara fabric excels in high-end automotive and luxury upholstery due to its durability and ease of maintenance. In contrast, synthetic suede may appeal to those seeking affordability and lightweight options, while genuine leather remains a strong choice for those prioritizing aesthetics and durability. By weighing these factors, B2B buyers can make informed decisions that align with their project goals and customer expectations.

Essential Technical Properties and Trade Terminology for black alcantara fabric

What Are the Key Technical Properties of Black Alcantara Fabric?

Understanding the technical properties of black Alcantara fabric is crucial for B2B buyers looking to make informed purchasing decisions. Here are some of the critical specifications to consider:

-

Material Composition

Black Alcantara is primarily composed of 68% polyester and 32% polyurethane. This synthetic suede offers a soft, luxurious feel comparable to genuine leather but with enhanced durability. The unique blend provides resistance to wear and tear, making it suitable for high-traffic areas, particularly in automotive and interior applications. -

Thickness and Weight

The thickness of black Alcantara can vary, typically ranging from 1.0 mm to 3.0 mm, depending on the specific variant. The weight is generally around 270 gm² or more. These measurements are essential as they influence the fabric’s drape, durability, and suitability for various applications, such as upholstery, automotive interiors, and fashion. -

Breaking Load

The breaking load indicates the tensile strength of the fabric, measured in Newtons (N). For black Alcantara, the breaking load lengthwise is typically ≥ 225 N, while the transversal load is ≥ 175 N. A higher breaking load signifies that the fabric can withstand greater stress, making it ideal for demanding applications like automotive seating and interior panels. -

Wear Resistance

Alcantara exhibits excellent wear resistance, with a Martindale score of ≥ 30,000 cycles. This property is crucial for B2B buyers as it ensures that the fabric can endure frequent use without significant degradation in appearance or performance. This makes it a preferred choice for automotive interiors and high-end furniture. -

Color Fastness and Light Resistance

Black Alcantara is designed to maintain its color over time, with a light resistance rating of ≥ 3 on the Grey Scale. This property is particularly important for outdoor applications or areas with high sunlight exposure, ensuring that the fabric does not fade quickly. -

Care and Maintenance

The care instructions for black Alcantara are vital for maintaining its appearance and longevity. It is generally easy to clean, requiring only mild soap and water. This ease of maintenance is a significant advantage for B2B buyers in sectors where fabric cleanliness is paramount, such as automotive and hospitality.

What Common Trade Terms Should B2B Buyers Know When Purchasing Black Alcantara Fabric?

Familiarity with industry jargon can facilitate smoother transactions and clearer communication in B2B settings. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are sold under another company’s brand. For buyers, understanding OEM relationships can ensure they are sourcing genuine Alcantara products that meet industry standards, especially in automotive applications. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ for black Alcantara fabric is crucial for buyers to plan their purchases effectively, ensuring they can meet production needs without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. For B2B buyers, submitting an RFQ for black Alcantara fabric can lead to competitive pricing and better terms, allowing for informed decision-making. -

Incoterms

International Commercial Terms (Incoterms) define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for B2B buyers to clarify shipping, insurance, and import/export duties related to black Alcantara fabric. -

Backed vs. Unbacked Fabric

Backed fabric has an additional layer of material for added durability and stability, while unbacked fabric is lighter and more flexible. Knowing the difference helps buyers select the right type for their specific applications, whether it be for automotive interiors or fashion items. -

Sample Swatch

A sample swatch is a small piece of fabric provided to buyers for evaluation before making a larger purchase. Requesting a sample swatch of black Alcantara can help ensure color accuracy and suitability for the intended application, mitigating risks associated with purchasing unseen materials.

Understanding these properties and terms will empower B2B buyers to make well-informed decisions when sourcing black Alcantara fabric for their projects.

Navigating Market Dynamics and Sourcing Trends in the black alcantara fabric Sector

Market Overview & Key Trends

The global market for black Alcantara fabric is experiencing robust growth, driven by its increasing demand across various industries, particularly in automotive and luxury goods. With a unique blend of aesthetics and functionality, Alcantara fabric is favored for its soft texture, durability, and ease of maintenance. International B2B buyers, especially from emerging markets in Africa, South America, the Middle East, and Europe, are increasingly sourcing this material due to its versatility in applications ranging from automotive interiors to high-end fashion.

Key trends influencing sourcing decisions include the rise of online platforms that facilitate direct purchasing from manufacturers, enabling buyers to access competitive pricing and broader selections. Additionally, advancements in digital technologies, such as 3D modeling and virtual sampling, are reshaping how businesses interact with suppliers. These tools allow for more efficient design processes and reduced lead times, which are crucial for B2B operations in fast-paced markets.

The sustainability movement is another significant driver, with buyers increasingly prioritizing eco-friendly materials. As a result, Alcantara manufacturers are innovating to meet these demands, emphasizing the use of recycled materials and sustainable production processes. This shift not only aligns with global trends but also enhances brand reputation, making it a compelling reason for B2B buyers to engage with suppliers committed to sustainable practices.

Illustrative image related to black alcantara fabric

Sustainability & Ethical Sourcing in B2B

The environmental impact of textile production, including Alcantara fabrics, has become a focal point for B2B buyers concerned about sustainability. Alcantara, primarily composed of polyester and polyurethane, offers a more eco-conscious alternative to traditional leather. Manufacturers are increasingly adopting ethical sourcing practices, ensuring that their supply chains are transparent and environmentally responsible.

Buyers should look for suppliers who possess certifications such as OEKO-TEX® or GOTS (Global Organic Textile Standard), which signify adherence to strict environmental and social criteria. These certifications not only confirm the safety of the materials used but also reflect a commitment to reducing the ecological footprint of production processes.

Moreover, the demand for recycled Alcantara is rising, as it allows businesses to offer products that align with consumer preferences for sustainable goods. By sourcing black Alcantara fabric from suppliers who prioritize eco-friendly practices, B2B buyers can enhance their market positioning while contributing to a circular economy. This approach not only meets regulatory requirements but also appeals to a growing segment of environmentally conscious consumers.

Brief Evolution/History

Alcantara was first introduced in the late 1970s in Italy and quickly gained recognition for its innovative blend of polyester and polyurethane. Initially developed for the automotive industry, its luxurious feel and durability soon attracted attention from the fashion sector. Over the decades, Alcantara has evolved into a symbol of luxury and sustainability, with continuous advancements in technology allowing for increased versatility and applications.

Illustrative image related to black alcantara fabric

Today, Alcantara is not just a material but a brand synonymous with quality, being utilized in high-end automotive interiors and luxury fashion items. Its evolution reflects broader trends in the textile industry towards sustainability, innovation, and ethical sourcing, making it an attractive option for international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of black alcantara fabric

-

How do I choose the right black alcantara fabric for my project?

Selecting the appropriate black alcantara fabric depends on your specific application. Consider factors such as thickness, backing type, and intended use (e.g., automotive interiors, upholstery, or fashion). Alcantara comes in various forms, including foam-backed and unbacked options, each offering different levels of durability and flexibility. Request samples to assess texture and color accuracy, and consult with suppliers about their recommendations based on your project requirements. -

What are the main benefits of using black alcantara fabric in upholstery?

Black alcantara fabric is favored for its luxurious appearance and exceptional durability. It is easy to clean, resistant to wear, and has a high Martindale rating, making it suitable for high-traffic areas. Additionally, its suede-like texture provides a comfortable and sophisticated touch, enhancing the aesthetic appeal of any interior. Its ability to reduce glare and stay cool to the touch is particularly beneficial for automotive applications. -

What is the minimum order quantity (MOQ) for black alcantara fabric?

The MOQ for black alcantara fabric can vary significantly by supplier. Typically, it ranges from one yard to several hundred yards, depending on the supplier’s policies and the type of fabric ordered. It’s advisable to inquire directly with suppliers about their MOQ and whether discounts are available for larger orders, as this can impact your overall procurement strategy. -

How do I ensure the quality of black alcantara fabric before purchasing?

To ensure quality, always request samples before making a bulk purchase. This allows you to assess the fabric’s texture, color, and durability firsthand. Additionally, verify the supplier’s certifications and quality assurance processes. Look for suppliers who provide detailed specifications and have a solid reputation in the industry. Engaging in a conversation about their production methods can also give you insights into the fabric’s quality. -

What payment terms should I expect when sourcing black alcantara fabric internationally?

Payment terms can differ based on the supplier and your location. Common terms include advance payment, letter of credit, or net terms (e.g., net 30 or 60 days). Ensure to clarify these terms before placing an order and consider using secure payment methods to protect your investment. It’s also wise to discuss potential currency exchange rates and any additional fees related to international transactions. -

What logistics considerations should I keep in mind when importing black alcantara fabric?

When importing black alcantara fabric, consider shipping methods, lead times, and customs regulations. Choose a reliable logistics partner experienced in handling textiles to navigate potential delays. Be aware of import duties and taxes that may apply in your country, as these can affect overall costs. Additionally, ensure that the supplier provides proper documentation to facilitate smooth customs clearance. -

Can I customize black alcantara fabric for my specific needs?

Yes, many suppliers offer customization options for black alcantara fabric, such as specific dimensions, thickness, or even color variations. Discuss your requirements with the supplier to explore available customization services. This may include special finishes or treatments to enhance durability or aesthetic appeal. Keep in mind that customized orders may have longer lead times and different pricing structures. -

What are the best practices for maintaining black alcantara fabric?

Maintaining black alcantara fabric involves regular cleaning and care to preserve its appearance. Use a soft brush or cloth to remove dust and debris, and avoid harsh chemicals that could damage the fabric. For stains, gently blot with a damp cloth and mild soap; avoid soaking the material. Always refer to the care instructions provided by the supplier for specific cleaning methods to ensure longevity and maintain the fabric’s luxurious look.

Top 7 Black Alcantara Fabric Manufacturers & Suppliers List

1. Alcantara – Soft Foam Backed

Domain: relicate.com

Registered: 2013 (12 years)

Introduction: {“name”: “Alcantara Soft Foam Backed”, “price”: “$161.00”, “description”: “Alcantara Soft is a single layer of Pannel with 2mm thick foam applied to the backside. It is primarily used for headliners and wrapping panels. Sold per yard. The roll is 56 inches wide. Orders of multiple yards will come as one continuous piece.”, “specifications”: {“thickness”: “≥ 3.0 mm”, “unit_weight”: “UNI EN 29073-1 …

2. DLT Corporation – Alcantara Soft

Domain: dltcorporation.com

Registered: 2009 (16 years)

Introduction: Alcantara Soft is a foam-backed Italian synthetic suede composed of 68% Polyester and 32% Polyurethane. It is easy to clean, offers more grip and durability, reduces glare on the windshield, and remains cool to the touch. Available colors include Pearl White, Silver Grey, Orion Grey, Sand Grey, Mouse Grey, Basalt, Slate Grey, Dark Grey, Charcoal Black, Deep Black, Raw Amber, Dark Brown, Brombeer, …

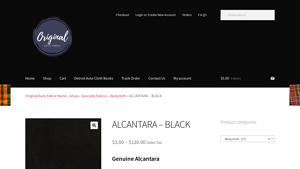

3. OEM Auto Fabric – ALCANTARA – BLACK

Domain: oemautofabric.com

Registered: 2018 (7 years)

Introduction: {“Product Name”: “ALCANTARA – BLACK”, “Material”: “Genuine Alcantara”, “Color”: “Black”, “Width”: “61 inches”, “Price Range”: “$3.00 – $120.00”, “SKU”: “ALCANTARA-BLACK”, “Categories”: [“Bodycloth”, “Specialty Fabrics”], “Tags”: [“Alcantara”, “Suede”]}

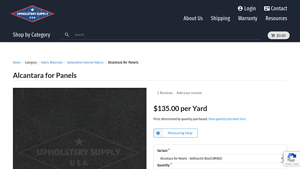

4. Upholstery Supply USA – Alcantara for Panels

Domain: upholsterysupplyusa.com

Registered: 2016 (9 years)

Introduction: {“product_name”: “Alcantara for Panels”, “color_options”: [“Anthracite Black (#9002)”, “Black (#9040)”, “Amber Glow (#1110)”, “Dark Brown (#9500)”, “Red (#4996)”, “Silver Grey (#4978)”, “Orion Grey (#2934)”, “Slate Grey (#2957)”], “price_per_yard”: {“1_to_9”: “$135.00”, “10_to_24”: “$130.00”, “25_plus”: “$125.00”}, “material_type”: “Genuine Alcantara Textile”, “made_in”: “Italy”, “applications”: […

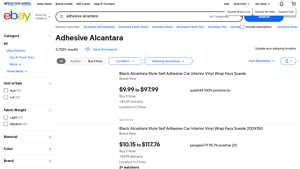

5. eBay – Adhesive Alcantara Products

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Adhesive Alcantara products available on eBay include various options such as faux suede, polyester, and suede materials. The items are categorized by features like self-adhesive and colorfast. Sizes range from squares to panels, with colors including black, beige, blue, brown, gray, green, orange, purple, and red. The majority of listings are new, with some used options available. Prices vary, wi…

6. Thibaut – ALCANTARA Geometric Fabrics

Domain: thibautdesign.com

Registered: 2002 (23 years)

Introduction: This company, Thibaut – ALCANTARA Geometric Fabrics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Alcantara – Sustainable Luxury Material

Domain: alcantara.com

Registered: 1996 (29 years)

Introduction: Alcantara is a 100% Italian brand known for its versatility and commitment to sustainability. It offers a unique material that combines aesthetics and performance, suitable for various applications in art, design, fashion, and luxury. The brand emphasizes its Italian heritage and innovation, providing endless possibilities for creative expression. Alcantara is involved in collaborations with fashi…

Strategic Sourcing Conclusion and Outlook for black alcantara fabric

As the demand for high-quality materials continues to rise, sourcing black Alcantara fabric presents a significant opportunity for international B2B buyers. Its unique combination of durability, aesthetic appeal, and ease of maintenance makes it a preferred choice across various industries, particularly in automotive and luxury goods. The fabric’s superior performance characteristics, including wear resistance and comfort, position it as a valuable alternative to traditional materials like leather.

Strategic sourcing of black Alcantara fabric not only enhances product offerings but also fosters long-term partnerships with reliable suppliers. By leveraging the advantages of Alcantara, businesses can cater to the evolving needs of consumers who prioritize sustainability and innovation. Buyers from Africa, South America, the Middle East, and Europe should consider engaging with established distributors to ensure access to genuine materials and favorable pricing structures.

Looking ahead, the market for black Alcantara fabric is poised for growth, driven by trends in eco-friendly materials and consumer preference for luxury experiences. Now is the time for businesses to act—evaluate your sourcing strategies, connect with reputable suppliers, and position your brand to meet the future demands of the marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.