Introduction: Navigating the Global Market for tandy leather factory locations

In the ever-evolving landscape of the global leather market, sourcing high-quality materials from reliable suppliers is a critical challenge for international B2B buyers. Understanding the intricacies of Tandy Leather factory locations can significantly enhance your procurement strategy, ensuring access to premium leather and crafting supplies. This guide serves as a comprehensive resource, detailing the various types of leather products available, their applications across different industries, and effective methods for vetting suppliers.

From the bustling markets of Brazil to the emerging economies of Africa and the established markets of Europe and the Middle East, buyers face unique obstacles in identifying trustworthy sources. This guide empowers you to make informed purchasing decisions by providing insights into cost structures, supplier reputations, and the latest industry trends. With detailed information on Tandy Leather’s distribution channels and local store offerings, you can optimize your sourcing processes and strengthen your supply chain.

Navigating the global market for Tandy Leather factory locations is not just about finding a supplier; it’s about establishing a partnership that drives your business forward. By leveraging the knowledge contained within this guide, you’ll be equipped to tackle the complexities of sourcing and enhance the overall quality of your leathercraft projects.

Table Of Contents

- Top 3 Tandy Leather Factory Locations Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for tandy leather factory locations

- Understanding tandy leather factory locations Types and Variations

- Key Industrial Applications of tandy leather factory locations

- 3 Common User Pain Points for ‘tandy leather factory locations’ & Their Solutions

- Strategic Material Selection Guide for tandy leather factory locations

- In-depth Look: Manufacturing Processes and Quality Assurance for tandy leather factory locations

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘tandy leather factory locations’

- Comprehensive Cost and Pricing Analysis for tandy leather factory locations Sourcing

- Alternatives Analysis: Comparing tandy leather factory locations With Other Solutions

- Essential Technical Properties and Trade Terminology for tandy leather factory locations

- Navigating Market Dynamics and Sourcing Trends in the tandy leather factory locations Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of tandy leather factory locations

- Strategic Sourcing Conclusion and Outlook for tandy leather factory locations

- Important Disclaimer & Terms of Use

Understanding tandy leather factory locations Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Flagship Retail Locations | Central hubs with full product range and expert staff | Retail partnerships, workshops, and demos | Pros: Comprehensive selection, expert advice. Cons: Higher pricing due to premium location. |

| Distribution Centers | Large warehouses focused on logistics and supply chain | Bulk purchasing, inventory management | Pros: Cost-effective for bulk orders. Cons: Limited direct customer interaction. |

| Regional Stores | Smaller retail outlets with localized product offerings | Localized partnerships, community engagement | Pros: Tailored inventory, community-focused. Cons: Limited range compared to flagship stores. |

| Online Stores | E-commerce platforms providing global access to products | International purchasing, ease of access | Pros: Convenience, wider reach. Cons: No tactile experience with products before purchase. |

| Maker Workshops | Dedicated spaces for hands-on learning and product testing | Skill development, product trials | Pros: Direct experience with tools and techniques. Cons: Limited availability and scheduling. |

What Are the Key Characteristics of Flagship Retail Locations?

Flagship retail locations serve as the cornerstone of Tandy Leather’s physical presence. These stores typically offer the most extensive range of products, including tools, kits, and leather types. They often feature knowledgeable staff who can provide personalized advice and product demonstrations. For B2B buyers, these locations are advantageous for forging retail partnerships and hosting workshops, although prices may be higher due to their premium positioning.

How Do Distribution Centers Enhance Supply Chain Efficiency?

Distribution centers are designed for efficient logistics and inventory management, providing bulk purchasing options for B2B buyers. These facilities focus on storing and distributing large quantities of leather and related supplies, making them ideal for businesses looking to manage inventory effectively. While they offer cost savings for bulk orders, the trade-off is often a lack of direct customer interaction, which can limit personalized service.

What Are the Benefits of Regional Stores for Local Businesses?

Regional stores cater to local markets with a selection tailored to community needs. These smaller outlets often engage in local partnerships and community events, making them suitable for businesses seeking to establish a local presence. While they provide a more personalized shopping experience, the range of products may be limited compared to flagship locations, which could be a consideration for buyers with specific needs.

How Can Online Stores Facilitate International Purchases?

Tandy Leather’s online stores offer a convenient platform for international B2B buyers to access a wide range of products. This e-commerce approach allows businesses in regions such as Africa, South America, and the Middle East to easily place orders without geographical limitations. However, the inability to physically inspect products before purchase can be a drawback, necessitating careful consideration of product descriptions and reviews.

What Opportunities Do Maker Workshops Present for Skill Development?

Maker workshops are an innovative approach by Tandy Leather to provide hands-on learning experiences. These dedicated spaces allow buyers to test tools and techniques before making a purchase, enhancing the overall value of their investment. While they offer unique opportunities for skill development and product familiarity, scheduling and availability can be limited, making it essential for businesses to plan ahead.

Key Industrial Applications of tandy leather factory locations

| Industry/Sector | Specific Application of tandy leather factory locations | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Sourcing high-quality leather for clothing and accessories | Access to premium materials that enhance product quality and brand image | Availability of diverse leather types, bulk purchasing options, and shipping logistics |

| Automotive | Custom leather interiors for vehicles | Enhances luxury and comfort, attracting high-end customers | Compliance with automotive standards, customization options, and lead times for production |

| Craft and Hobby | DIY leathercraft supplies for artisans | Provides a variety of tools and materials, fostering creativity and innovation | Local availability of supplies, pricing for small-scale purchases, and educational resources |

| Footwear | Leather for shoe manufacturing | Durability and aesthetic appeal, essential for competitive footwear products | Leather grades suitable for footwear, sourcing timelines, and quality assurance processes |

| Furniture | Upholstery leather for high-end furniture | Adds value and luxury appeal to furniture lines, increasing market demand | Consideration of hide sizes, color options, and compatibility with manufacturing processes |

How Can Tandy Leather Factory Locations Serve the Fashion and Apparel Industry?

Tandy Leather factory locations are pivotal for fashion and apparel brands looking to source high-quality leather. By providing access to diverse leather types, including veg-tanned and chrome-tanned options, businesses can enhance their product offerings. This is especially beneficial for international buyers from regions like Europe and South America, where premium materials can significantly elevate brand image. Key considerations include understanding bulk purchasing options and the logistics of international shipping to ensure timely delivery.

What Role Do Tandy Leather Locations Play in the Automotive Sector?

In the automotive industry, Tandy Leather locations serve as a critical resource for sourcing custom leather for vehicle interiors. High-quality leather enhances the luxury and comfort of vehicles, appealing to discerning consumers. International B2B buyers must ensure that the leather complies with automotive industry standards and can accommodate customization requests. Additionally, understanding lead times for production is essential to meet manufacturing schedules and consumer demand.

Why Are Tandy Leather Locations Important for Craft and Hobby Businesses?

For craft and hobby sectors, Tandy Leather factory locations provide a wealth of DIY leathercraft supplies. Artisans benefit from a variety of tools and materials that inspire creativity and innovation in their projects. Buyers from regions with burgeoning craft markets, such as Africa and South America, should consider local availability and competitive pricing for smaller-scale purchases. Furthermore, educational resources and workshops offered at these locations can enhance skills, leading to higher-quality outputs.

How Do Tandy Leather Locations Support the Footwear Industry?

Footwear manufacturers rely on Tandy Leather locations for sourcing durable and aesthetically appealing leather. The quality of leather is crucial for creating competitive footwear products that attract consumers. International buyers need to focus on the grades of leather suitable for footwear, ensuring they meet design specifications. Additionally, sourcing timelines should be aligned with production schedules to maintain market responsiveness.

What Advantages Do Tandy Leather Factory Locations Offer to the Furniture Sector?

In the furniture industry, Tandy Leather locations are invaluable for obtaining upholstery leather that adds luxury to furniture products. High-quality leather can significantly increase the market demand for furniture lines. Buyers must consider the sizes of hides available, color options, and how the leather integrates with existing manufacturing processes. Sourcing from Tandy can ensure a steady supply of premium materials that enhance the overall value of furniture offerings.

3 Common User Pain Points for ‘tandy leather factory locations’ & Their Solutions

Scenario 1: Difficulty in Finding the Right Tandy Leather Location

The Problem: International B2B buyers often struggle to locate the nearest Tandy Leather factory or retail outlet, especially in regions where Tandy’s presence may not be as pronounced. For businesses in Africa, South America, or the Middle East, the challenge intensifies with the added complications of language barriers, time zone differences, and varying local regulations. Buyers may waste valuable time searching for locations, leading to delays in sourcing essential leather products and supplies, which can impact project timelines and budgets.

The Solution: To mitigate this issue, buyers should utilize Tandy Leather’s online store locator tool, which allows users to search by zip code, city, or state. This resource not only provides the addresses of nearby stores but also includes crucial information such as store hours, available products, and contact details. Additionally, B2B buyers can enhance their search by connecting with local distributors or representatives who can facilitate orders and logistics. Establishing a direct line of communication with Tandy’s customer service can also provide personalized assistance in identifying the most suitable location for their needs, ensuring a smoother procurement process.

Scenario 2: Inadequate Product Knowledge Among Local Staff

The Problem: Another common pain point for B2B buyers is encountering staff at Tandy Leather locations who may lack in-depth knowledge about specific products, tools, or techniques relevant to advanced leather crafting. This issue can lead to misunderstandings regarding product applications and may result in purchasing the wrong items, causing project setbacks and increased costs. For businesses looking to implement specialized leatherwork, this knowledge gap can be particularly frustrating.

The Solution: To address this challenge, buyers should take advantage of Tandy Leather’s educational resources, including workshops and classes offered at various locations. By participating in these sessions, staff can gain hands-on experience and a deeper understanding of the products available, which can enhance their ability to serve B2B customers effectively. Additionally, buyers should request training sessions for their local teams from Tandy representatives, ensuring that the staff is well-equipped to answer technical questions and provide guidance on product use. This investment in knowledge will ultimately lead to more informed purchasing decisions and improved project outcomes.

Scenario 3: Limited Availability of Specialty Items

The Problem: B2B buyers may find that certain specialty leather items, tools, or materials are frequently out of stock at their nearest Tandy Leather location. This limitation can be particularly problematic for businesses that require specific materials for niche projects or custom orders. The inability to access these items can result in project delays and may force buyers to seek alternatives that do not meet their quality standards.

The Solution: To counteract stock availability issues, buyers should consider establishing a regular ordering schedule with Tandy Leather that includes forecasts for upcoming projects. By communicating their needs in advance, businesses can ensure that Tandy is aware of demand for specific items, allowing for better inventory management and allocation of resources. Additionally, buyers can explore the option of placing bulk orders or utilizing Tandy’s online store to directly purchase specialty items when local stock is insufficient. This proactive approach not only guarantees access to the necessary materials but also fosters a collaborative relationship with Tandy, which can lead to priority service and tailored solutions for future needs.

Illustrative image related to tandy leather factory locations

Strategic Material Selection Guide for tandy leather factory locations

What Are the Key Materials Used in Tandy Leather Factory Locations?

In the leather industry, the selection of materials is crucial for ensuring product quality and performance. Tandy Leather factory locations utilize various materials, each with distinct properties and applications. Below, we analyze four common materials relevant to Tandy Leather’s offerings, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Vegetable-Tanned Leather?

Vegetable-tanned leather is a staple in the leathercraft industry, known for its natural tanning process using plant extracts. This material exhibits excellent durability and flexibility, making it suitable for a wide range of applications, from belts to bags.

Pros:

– Durability: It has a long lifespan and develops a beautiful patina over time.

– Eco-Friendly: The natural tanning process is less harmful to the environment compared to chemical tanning.

– Versatility: Accepts dyes and finishes well, allowing for customization.

Cons:

– Cost: Generally more expensive than chrome-tanned leather.

– Water Sensitivity: Can be prone to water damage if not properly treated.

– Manufacturing Complexity: Requires skilled craftsmanship for optimal results.

Illustrative image related to tandy leather factory locations

How Does Chrome-Tanned Leather Compare?

Chrome-tanned leather is produced using chromium salts, providing a quicker tanning process. This material is known for its soft texture and resistance to water and heat.

Pros:

– Quick Drying: Faster production time compared to vegetable tanning.

– Water Resistance: Excellent for products exposed to moisture, such as outdoor gear.

– Softness: Offers a more supple feel, enhancing comfort in wearables.

Cons:

– Environmental Concerns: The tanning process can be harmful to the environment if not managed properly.

– Limited Customization: Less receptive to dyeing and finishing compared to vegetable-tanned leather.

– Durability Issues: May not develop the same character over time as vegetable-tanned leather.

What Are the Benefits of Suede and Nubuck?

Suede and nubuck are both types of leather that have been sanded or buffed to create a soft, velvety surface. These materials are often used in fashion and upholstery.

Pros:

– Aesthetic Appeal: Offers a unique texture and appearance, making it popular in high-end products.

– Comfort: Soft and flexible, providing a comfortable wear experience.

– Versatile Applications: Suitable for shoes, jackets, and accessories.

Illustrative image related to tandy leather factory locations

Cons:

– Staining: More susceptible to stains and water damage compared to other leather types.

– Maintenance: Requires regular care to maintain appearance and longevity.

– Cost: Generally more expensive due to the processing involved.

What Should International Buyers Consider When Selecting Materials?

When sourcing materials from Tandy Leather factory locations, international buyers must consider compliance with local regulations and standards. For instance, materials should meet ASTM standards in the U.S. or DIN standards in Europe. Buyers from regions such as Africa, South America, the Middle East, and Europe should also be aware of preferences for eco-friendly materials, especially in markets that emphasize sustainability. Additionally, understanding the import regulations and tariffs can significantly impact the overall cost and feasibility of sourcing specific materials.

Summary Table of Material Selection for Tandy Leather Factory Locations

| Materiał | Typical Use Case for Tandy Leather Factory Locations | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | Belts, bags, wallets | Eco-friendly and durable | More expensive than chrome-tanned | High |

| Chrome-Tanned Leather | Outdoor gear, upholstery | Quick drying and water resistant | Environmental concerns | Medium |

| Suede | Footwear, jackets, accessories | Unique texture and aesthetic appeal | Susceptible to stains | Medium |

| Nubuck | High-end fashion items | Soft and comfortable | Requires regular maintenance | High |

This strategic material selection guide provides valuable insights for B2B buyers in various regions, helping them make informed decisions when sourcing leather materials from Tandy Leather factory locations.

Illustrative image related to tandy leather factory locations

In-depth Look: Manufacturing Processes and Quality Assurance for tandy leather factory locations

What Are the Main Stages of Manufacturing Processes at Tandy Leather Factory Locations?

Tandy Leather has established a comprehensive manufacturing process that reflects its commitment to quality and efficiency. The typical stages involved in leather production include material preparation, forming, assembly, and finishing. Each stage is crucial in ensuring that the final products meet the high standards expected by B2B buyers.

How Does Material Preparation Work in Leather Manufacturing?

The manufacturing process begins with material preparation, where raw leather hides are sourced from reputable suppliers. Tandy Leather prioritizes high-quality hides, often utilizing vegetable-tanned and chrome-tanned leathers. In this stage, hides are inspected for defects, sorted based on quality, and conditioned to ensure they are ready for subsequent processes. This careful selection is vital for maintaining the integrity of the final products.

What Techniques Are Used in the Forming and Assembly Processes?

Once the materials are prepared, the next step is forming. This involves cutting the leather into specific shapes required for various products, such as bags, belts, and accessories. Advanced cutting techniques, including die-cutting and laser cutting, are employed to enhance precision and reduce waste.

The assembly phase follows, where the cut pieces are stitched or bonded together. Tandy Leather utilizes both traditional hand-stitching methods and modern sewing machines, ensuring durability and aesthetic appeal. Attention to detail in this stage is paramount, as it directly impacts the product’s functionality and appearance.

Illustrative image related to tandy leather factory locations

What Are the Finishing Techniques Applied to Tandy Leather Products?

Finishing is the final stage of the manufacturing process, which includes dyeing, sealing, and applying protective coatings. Tandy Leather employs various finishing techniques to enhance the leather’s appearance and longevity. This may involve hand-painting, embossing, or applying eco-friendly dyes, which not only provide a distinctive look but also cater to the increasing demand for sustainable products. Quality checks are integrated into this stage to ensure that each item meets Tandy’s strict standards.

How Does Quality Assurance Work at Tandy Leather Factory Locations?

Quality assurance is a critical component of Tandy Leather’s manufacturing process. The company adheres to various international standards, including ISO 9001, which ensures consistent quality management practices across its operations. This commitment to quality is not only beneficial for Tandy but also reassures B2B buyers of the reliability of their products.

What International Standards and Industry-Specific Certifications Are Relevant?

For B2B buyers, understanding the certifications held by suppliers is essential. Tandy Leather complies with international standards such as ISO 9001, which focuses on quality management systems, and industry-specific certifications like CE (Conformité Européenne) for products sold in the European market. Additionally, Tandy Leather may adhere to standards relevant to specific markets, such as API (American Petroleum Institute) for products used in industrial applications.

What Are the Quality Control Checkpoints in the Manufacturing Process?

Quality control at Tandy Leather involves several critical checkpoints throughout the manufacturing process. These include:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified quality standards.

-

In-Process Quality Control (IPQC): During the manufacturing stages, continuous monitoring is conducted to identify any deviations from quality standards. This may include inspecting stitching, verifying dimensions, and checking for defects.

-

Final Quality Control (FQC): Once products are completed, a final inspection ensures that they meet the desired specifications before being shipped. This step is crucial for maintaining customer satisfaction and brand integrity.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers seeking to verify the quality control processes of Tandy Leather can take several proactive steps. Conducting supplier audits is one of the most effective ways to assess the manufacturing environment and practices. Buyers should request access to quality control reports, which detail the results of various inspections and tests conducted throughout the manufacturing process.

Illustrative image related to tandy leather factory locations

Additionally, engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality assurance practices. These inspections typically include a thorough review of manufacturing processes, material quality, and adherence to international standards. Buyers from regions such as Africa, South America, the Middle East, and Europe should ensure that suppliers are prepared to provide documentation and certifications that verify their compliance with relevant quality standards.

What Are the Common Testing Methods Employed in Quality Assurance?

Tandy Leather employs various testing methods to ensure the quality and durability of its products. Common testing techniques include:

-

Physical Testing: Assessing the strength, flexibility, and durability of the leather through tensile and tear tests.

-

Chemical Testing: Evaluating the leather for resistance to water, oils, and other substances that may affect its longevity.

-

Visual Inspection: Conducting thorough visual checks for defects such as scratches, color inconsistencies, and stitching errors.

These testing methods are integral to maintaining high-quality standards and ensuring that Tandy Leather products meet the expectations of B2B buyers.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control is crucial, especially when dealing with suppliers from different regions. Buyers should be aware of the specific certifications that may be required in their respective markets and ensure that suppliers can provide proof of compliance.

Moreover, cultural differences in quality perception and practices may exist, making it essential for buyers to communicate their quality expectations clearly. Establishing a strong partnership with suppliers can also facilitate better quality control practices, leading to enhanced product satisfaction.

Illustrative image related to tandy leather factory locations

In conclusion, Tandy Leather’s robust manufacturing processes and stringent quality assurance measures ensure that their products meet the highest standards. By understanding these processes, B2B buyers can make informed decisions and foster successful partnerships with Tandy Leather factory locations globally.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tandy leather factory locations’

When sourcing products from Tandy Leather, particularly for international B2B buyers, a structured approach can streamline the process and ensure you make informed decisions. This guide provides a step-by-step checklist to help you effectively navigate the procurement of leather goods from Tandy Leather factory locations.

Step 1: Identify Your Leather Requirements

Understanding your specific leather needs is the first step in the sourcing process. Determine the type of leather (e.g., veg-tan, chrome-tan), thickness, and finishes you require based on your end products. This clarity will guide your interactions with suppliers and ensure you receive the appropriate materials.

Step 2: Research Tandy Leather Locations

Utilize Tandy Leather’s store locator to identify nearby factory locations or distribution centers. Knowing where your nearest factory is can significantly reduce shipping times and costs. Furthermore, visiting a location may provide opportunities to see products firsthand and engage with knowledgeable staff.

- Explore Store Offerings: Each location may have unique in-store specials or exclusive products not available online.

Step 3: Evaluate Supplier Reliability

Before proceeding with any purchase, it’s essential to assess the reliability of Tandy Leather and its individual locations. Check for customer reviews, testimonials, and case studies from other B2B buyers. This step builds confidence that you are dealing with a reputable supplier.

- Inquire About Certifications: Ensure that the factory adheres to international quality standards and ethical sourcing practices.

Step 4: Confirm Product Availability and Lead Times

Once you have identified potential suppliers, confirm the availability of your required products and their lead times. Understanding how quickly you can receive materials is vital for planning production schedules and meeting customer demands.

- Ask About Minimum Order Quantities (MOQs): Some factories may have specific MOQs that could affect your purchasing decisions.

Step 5: Negotiate Terms and Conditions

Engaging in negotiations with Tandy Leather regarding pricing, payment terms, and delivery schedules can yield favorable outcomes. Clear terms can prevent misunderstandings and ensure a smooth procurement process.

- Consider Long-Term Contracts: If you foresee ongoing needs, negotiating a long-term contract could lead to better pricing and reliability.

Step 6: Establish Communication Protocols

Effective communication is crucial throughout the sourcing process. Establish clear channels for discussing orders, addressing issues, and providing feedback. This proactive approach can enhance your relationship with the supplier.

- Utilize Technology: Consider using project management tools or communication platforms that facilitate real-time updates and exchanges.

Step 7: Plan for Quality Assurance

After receiving your leather products, implement a quality assurance process to inspect the materials. This step ensures that the products meet your specifications and standards before they are used in production.

Illustrative image related to tandy leather factory locations

- Document Findings: Keep records of any discrepancies or quality issues to address with the supplier for future orders.

By following this structured checklist, B2B buyers can effectively source leather products from Tandy Leather factory locations, ensuring that they meet their business needs while fostering successful supplier relationships.

Comprehensive Cost and Pricing Analysis for tandy leather factory locations Sourcing

What Are the Key Cost Components in Sourcing from Tandy Leather Factory Locations?

Understanding the cost structure of sourcing from Tandy Leather factory locations involves several critical components. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The primary cost component is raw leather, which varies in price based on type (e.g., veg-tan, chrome-tanned) and quality. Tandy Leather offers a range of materials, and prices fluctuate depending on the grade and availability. Buyers should consider bulk purchases to optimize costs.

-

Labor: Labor costs at Tandy Leather facilities reflect local wage rates, which can vary significantly across different regions. In markets like Brazil or Saudi Arabia, understanding the local labor market can influence the total cost.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses. Tandy Leather’s operational efficiency can impact these costs, affecting overall pricing for buyers.

-

Tooling and Quality Control: The investment in specialized machinery and tools, along with rigorous QC processes, adds to the overall cost. Tandy Leather emphasizes quality, which may result in higher initial costs but can lead to reduced returns on defective products.

-

Logistics: Shipping and handling costs can vary based on location and the chosen Incoterms. International buyers must factor in these logistics costs when evaluating total expenditures.

-

Margin: Profit margins for Tandy Leather are influenced by the competitive landscape and the demand for leather products. Understanding these margins can provide insight into pricing strategies.

How Do Price Influencers Affect Sourcing Decisions?

Several factors influence pricing that B2B buyers should be aware of:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit prices. Buyers should negotiate MOQs to maximize cost efficiency.

-

Specifications and Customization: Custom orders may incur additional costs due to unique tooling and processing requirements. Buyers should clearly define their needs to avoid unexpected expenses.

-

Materials and Quality Certifications: The choice of materials and any associated certifications (e.g., eco-friendly practices) can impact costs. Buyers focused on sustainability may need to budget for premium pricing.

-

Supplier Factors: Tandy Leather’s reputation and reliability as a supplier can influence pricing. Establishing a strong relationship may lead to better terms and pricing.

-

Incoterms: Understanding Incoterms is crucial for international transactions. These terms dictate who is responsible for shipping, insurance, and tariffs, significantly affecting the total landed cost.

What Tips Can Help B2B Buyers Optimize Their Sourcing Strategy?

To navigate the complexities of sourcing from Tandy Leather, consider these buyer tips:

-

Negotiation: Always negotiate terms with suppliers. Discuss pricing, payment terms, and delivery schedules to align on mutually beneficial conditions.

-

Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), which includes purchase price, shipping, handling, and potential waste or defects. A lower purchase price does not always equate to lower overall costs.

-

Pricing Nuances for International Buyers: B2B buyers from regions like Africa, South America, and the Middle East should be aware of currency fluctuations, import duties, and local market conditions that may influence pricing.

-

Stay Informed: Regularly review market trends and Tandy Leather’s pricing updates to remain competitive. Engage with industry forums or local trade shows to gather insights.

Conclusion

Sourcing from Tandy Leather factory locations requires a thorough understanding of cost structures and pricing influencers. By leveraging these insights, international B2B buyers can optimize their purchasing strategies, ensuring they achieve the best value and quality in their leathercraft endeavors. While the pricing details discussed are indicative, they serve as a foundation for informed decision-making in the leather sourcing landscape.

Illustrative image related to tandy leather factory locations

Alternatives Analysis: Comparing tandy leather factory locations With Other Solutions

Exploring Alternatives to Tandy Leather Factory Locations for Leather Supply Needs

In the competitive landscape of leather crafting and supply, businesses often evaluate various sourcing solutions to meet their specific needs. While Tandy Leather Factory locations provide an established and trusted option for purchasing leather and related supplies, other alternatives may offer different advantages. This section compares Tandy Leather Factory locations with two viable alternatives: online leather suppliers and local artisan cooperatives. Each solution has its unique strengths and weaknesses, which can influence decision-making for B2B buyers.

| Comparison Aspect | Tandy Leather Factory Locations | Online Leather Suppliers | Local Artisan Cooperatives |

|---|---|---|---|

| Performance | High-quality, consistent products and hands-on assistance available. | Variable quality; depends on supplier. Limited hands-on experience. | Unique, handcrafted items with local authenticity. |

| Cost | Competitive pricing with occasional in-store promotions. | Often lower prices due to direct sourcing. | Prices can be higher due to craftsmanship. |

| Ease of Implementation | Accessible locations and knowledgeable staff enhance purchasing experience. | Convenient online ordering; delivery can vary by location. | Requires local outreach and may have limited availability. |

| Maintenance | Regular inventory updates and classes for skill enhancement. | Self-service; ongoing relationship management needed. | Community-based; fosters relationships but may lack consistency. |

| Best Use Case | Ideal for bulk purchases and learning opportunities. | Best for cost-sensitive buyers seeking variety. | Perfect for bespoke projects requiring unique materials. |

What Are the Advantages and Disadvantages of Online Leather Suppliers?

Online leather suppliers present a modern approach to sourcing leather. These suppliers often provide a wide range of products at competitive prices, benefiting from lower overhead costs associated with physical storefronts. However, the variability in product quality and the lack of physical inspection before purchase can pose risks. Additionally, while convenience is a significant advantage, the absence of personal interaction may limit the buyer’s ability to seek guidance on product selection.

How Do Local Artisan Cooperatives Compare to Tandy Leather Locations?

Local artisan cooperatives specialize in handcrafted leather goods and materials, fostering a unique connection to regional craftsmanship. This option is ideal for businesses seeking distinctive products that reflect local culture. However, the cost of artisan goods can be higher due to the labor-intensive nature of production. Moreover, availability may be inconsistent, as these cooperatives might not stock the same range of products as larger suppliers like Tandy.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right solution for leather supply hinges on understanding specific business needs and objectives. Buyers should consider factors such as budget, desired product quality, and the importance of local craftsmanship versus convenience. Tandy Leather Factory locations provide a reliable source for high-quality products and educational resources, making them suitable for businesses that prioritize hands-on experiences and bulk purchases. In contrast, online suppliers may appeal to those looking for cost-effective solutions, while local artisan cooperatives can offer unique products that enhance brand storytelling. Ultimately, evaluating these aspects will enable B2B buyers to make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for tandy leather factory locations

What are the Essential Technical Properties of Tandy Leather Products?

When sourcing leather and related products from Tandy Leather factory locations, it is crucial for B2B buyers to understand specific technical properties that can significantly impact their purchasing decisions. Here are some key specifications to consider:

-

Material Grade

The material grade indicates the quality of leather being offered, typically categorized into grades such as A, B, C, and D. Higher grades (A) represent premium quality leather with fewer imperfections, making them ideal for high-end products. Understanding material grades helps buyers align their product offerings with customer expectations and market demands. -

Leather Weight and Thickness

Leather weight is often measured in ounces or millimeters, which directly correlates to its durability and suitability for various applications. For instance, heavier leather (8-10 oz) is preferred for saddlery and heavy-duty goods, while lighter options (2-4 oz) are ideal for garments and linings. Buyers should assess the specific requirements of their projects to select the appropriate leather weight, ensuring optimal performance and longevity. -

Tanning Process

The tanning process affects the leather’s characteristics, including its texture, colorfastness, and resistance to wear and tear. Common tanning methods include chrome tanning and vegetable tanning, each imparting distinct properties. For example, vegetable-tanned leather is more environmentally friendly and develops a rich patina over time, making it desirable for artisan goods. Buyers should inquire about the tanning process to ensure it meets their sustainability and quality standards. -

Finishing Options

Finishing techniques, such as dyeing, painting, or embossing, enhance the aesthetic appeal and usability of leather products. The finish can affect the leather’s water resistance, gloss, and texture. Buyers should understand the available finishing options to make informed decisions about the end products they wish to create, ensuring they align with their brand image. -

Tolerance Levels

Tolerance levels indicate the allowable variations in dimensions and properties of leather. This is essential for manufacturers who require precise cuts for specific applications, such as automotive interiors or high-fashion apparel. Being aware of tolerance specifications helps buyers avoid production issues and ensures consistency in their product offerings.

What are Common Trade Terms Associated with Tandy Leather Factories?

Familiarity with industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some common trade terms relevant to Tandy Leather factory locations:

Illustrative image related to tandy leather factory locations

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the leather industry, this could mean that a Tandy Leather factory supplies leather components for various brands. Understanding OEM relationships can help buyers identify potential partnerships and supply chain opportunities. -

MOQ (Minimum Order Quantity)

MOQ is the minimum quantity of a product that a supplier is willing to sell. Tandy Leather factories may set MOQs to optimize production costs and streamline inventory management. Buyers should be aware of MOQs to plan their orders effectively, ensuring they meet the supplier’s requirements while managing their own inventory levels. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request a quote from suppliers for specific products or services. This is particularly important in the leather industry, where prices can fluctuate based on material availability and quality. Submitting a comprehensive RFQ helps buyers receive accurate pricing and terms from Tandy Leather factories. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, outlining the responsibilities of buyers and sellers in international transactions. Understanding these terms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is crucial for B2B buyers to clarify shipping costs and risk responsibilities when sourcing from Tandy Leather factories. -

Lead Time

Lead time refers to the time taken from placing an order until it is delivered. In the leather industry, lead times can vary based on factors like order complexity and production capacity. Buyers should factor in lead times when planning their production schedules to avoid delays in bringing their products to market.

By grasping these essential technical properties and trade terminologies, B2B buyers can make more informed decisions when engaging with Tandy Leather factory locations, enhancing their purchasing strategy and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the tandy leather factory locations Sector

What Are the Key Market Dynamics and Trends Affecting Tandy Leather Factory Locations?

The leather industry is undergoing significant transformation driven by globalization, technological advancements, and changing consumer preferences. For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for effective sourcing. The demand for premium leather products continues to rise, fueled by the growth of the fashion, automotive, and furniture industries. Emerging markets are witnessing increased investment in leather goods, with countries like Brazil and Saudi Arabia positioning themselves as key players in leather manufacturing and export.

A notable trend in the sector is the adoption of digital technologies in sourcing and procurement processes. B2B platforms are streamlining supply chain management, allowing buyers to access a broader range of products and suppliers with ease. Additionally, the use of data analytics is enhancing decision-making, enabling buyers to identify market trends and optimize inventory management. The shift towards e-commerce is also reshaping the way businesses engage with suppliers, providing more options for sourcing raw materials, including those from Tandy Leather factory locations.

Furthermore, the market is experiencing a growing emphasis on customization and personalization, with buyers seeking unique leather goods that cater to specific consumer preferences. As a result, manufacturers and suppliers are responding by offering a wider array of customizable options, from leather types to design features. This trend presents opportunities for international buyers to collaborate with Tandy Leather locations to develop tailored solutions that meet local market demands.

How Are Sustainability and Ethical Sourcing Influencing Tandy Leather Factory Locations?

Sustainability and ethical sourcing have become central themes in the leather industry, reflecting a broader global shift towards responsible production practices. For B2B buyers, particularly those in environmentally conscious markets, sourcing leather from Tandy Leather factory locations that prioritize sustainability can enhance brand reputation and consumer trust. The environmental impact of leather production, including water usage, chemical processing, and waste generation, has prompted companies to adopt greener practices.

Illustrative image related to tandy leather factory locations

Buyers should look for suppliers that adhere to recognized sustainability certifications and standards, such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS). These certifications ensure that the leather is sourced from environmentally responsible facilities that prioritize waste reduction and resource conservation. Additionally, many Tandy Leather locations are increasingly offering eco-friendly products, such as vegetable-tanned leather and water-based dyes, which align with sustainable practices.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing the sourcing practices of their suppliers to ensure fair labor practices and humane treatment of workers. By partnering with Tandy Leather, which emphasizes transparency and ethical sourcing, international buyers can confidently promote their commitment to social responsibility in their markets.

What Is the Historical Context of Tandy Leather and Its Relevance to Today’s B2B Landscape?

Tandy Leather has a rich history that dates back to 1919, establishing itself as a leader in the leather crafting industry. Founded in Fort Worth, Texas, the company has evolved significantly, expanding its product offerings from basic leather supplies to a comprehensive range of tools, kits, and educational resources for leathercrafters. This legacy of quality and innovation has solidified Tandy Leather’s reputation as a trusted partner for B2B buyers.

Illustrative image related to tandy leather factory locations

The company’s long-standing commitment to customer education through workshops and classes underscores its role as not just a supplier but also a valuable resource for buyers looking to enhance their leatherworking skills. This focus on community engagement and support is especially relevant in today’s B2B environment, where businesses prioritize partnerships that offer added value beyond mere transactions. By leveraging Tandy Leather’s extensive expertise, international buyers can enhance their own product offerings and build stronger connections with their customers.

Frequently Asked Questions (FAQs) for B2B Buyers of tandy leather factory locations

-

How can I find the nearest Tandy Leather factory location for bulk purchases?

To locate the nearest Tandy Leather factory or retail outlet, visit the Tandy Leather store locator on their official website. You can input your region or country to see available locations. For bulk purchases, it’s advisable to contact the store directly to confirm stock availability and any specific offerings for B2B clients. Additionally, consider reaching out to their customer service for inquiries about larger orders or specific product lines. -

What are the benefits of sourcing leather from Tandy Leather locations?

Sourcing leather from Tandy Leather provides access to a well-established supplier known for high-quality materials and tools. They offer a variety of leather types, including vegetable-tanned and chrome-tanned options. B2B buyers can benefit from competitive pricing, bulk purchase discounts, and in-store support for product demonstrations and hands-on experience with tools. Furthermore, Tandy provides educational resources to enhance your leathercraft skills, ensuring you make informed purchasing decisions. -

What customization options are available for leather products at Tandy Leather?

Tandy Leather offers various customization options, including different leather types, colors, and finishes. Depending on your order size, you may request specific cuts, shapes, or treatments for the leather. For large-scale projects, consider discussing your requirements directly with a Tandy representative to explore bespoke solutions that fit your business needs. Custom orders might require additional lead time, so it’s best to plan accordingly. -

What are the minimum order quantities (MOQ) for bulk purchases at Tandy Leather?

Minimum order quantities can vary depending on the product type and location. Tandy Leather typically accommodates bulk orders, but it is essential to confirm specifics with the local store or distribution center. For international orders, the MOQ might also be influenced by shipping considerations and local regulations. Establishing a direct line of communication with Tandy’s sales team will help clarify these details. -

What payment terms does Tandy Leather offer for international B2B buyers?

Tandy Leather’s payment terms may vary based on the location and size of the order. Generally, options include credit card payments, bank transfers, and possibly net terms for established accounts. For international buyers, it’s crucial to discuss payment methods that accommodate currency exchange and transaction fees. Directly contacting Tandy Leather’s sales team will provide the most accurate and tailored information regarding payment terms. -

How does Tandy Leather ensure quality assurance for its products?

Tandy Leather implements a rigorous quality assurance process that involves inspecting raw materials and finished products for consistency and durability. They prioritize customer satisfaction by adhering to industry standards and guidelines. B2B buyers can request samples or quality certifications for specific products to ensure they meet their requirements before making bulk purchases. -

What logistics support does Tandy Leather provide for international shipments?

Tandy Leather collaborates with various logistics partners to facilitate international shipping. They can assist buyers in navigating customs regulations and provide information about shipping costs and delivery timelines. It’s advisable for B2B buyers to discuss their shipping needs directly with Tandy to ensure a smooth logistics process tailored to their order size and destination. -

How can I stay updated on Tandy Leather’s new products and promotions?

To stay informed about new products, promotions, and special offers, consider subscribing to Tandy Leather’s newsletter or following them on social media platforms. Regularly checking their website for updates and visiting your local store will also keep you in the loop regarding exclusive B2B deals and upcoming events, including workshops that can enhance your product knowledge and skills.

Top 3 Tandy Leather Factory Locations Manufacturers & Suppliers List

1. Tandy Leather – Leather Shapes & Kits

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Leather Shapes & Kits, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Tandy Leather – Leatherworking Supplies

Domain: tandyleather.irpass.com

Registered: 2002 (23 years)

Introduction: Tandy Leather Factory, Inc. is a specialty retailer offering a broad product line including leather, leatherworking tools, buckles and adornments for belts, leather dyes and finishes, saddle and tack hardware, and do-it-yourself kits.

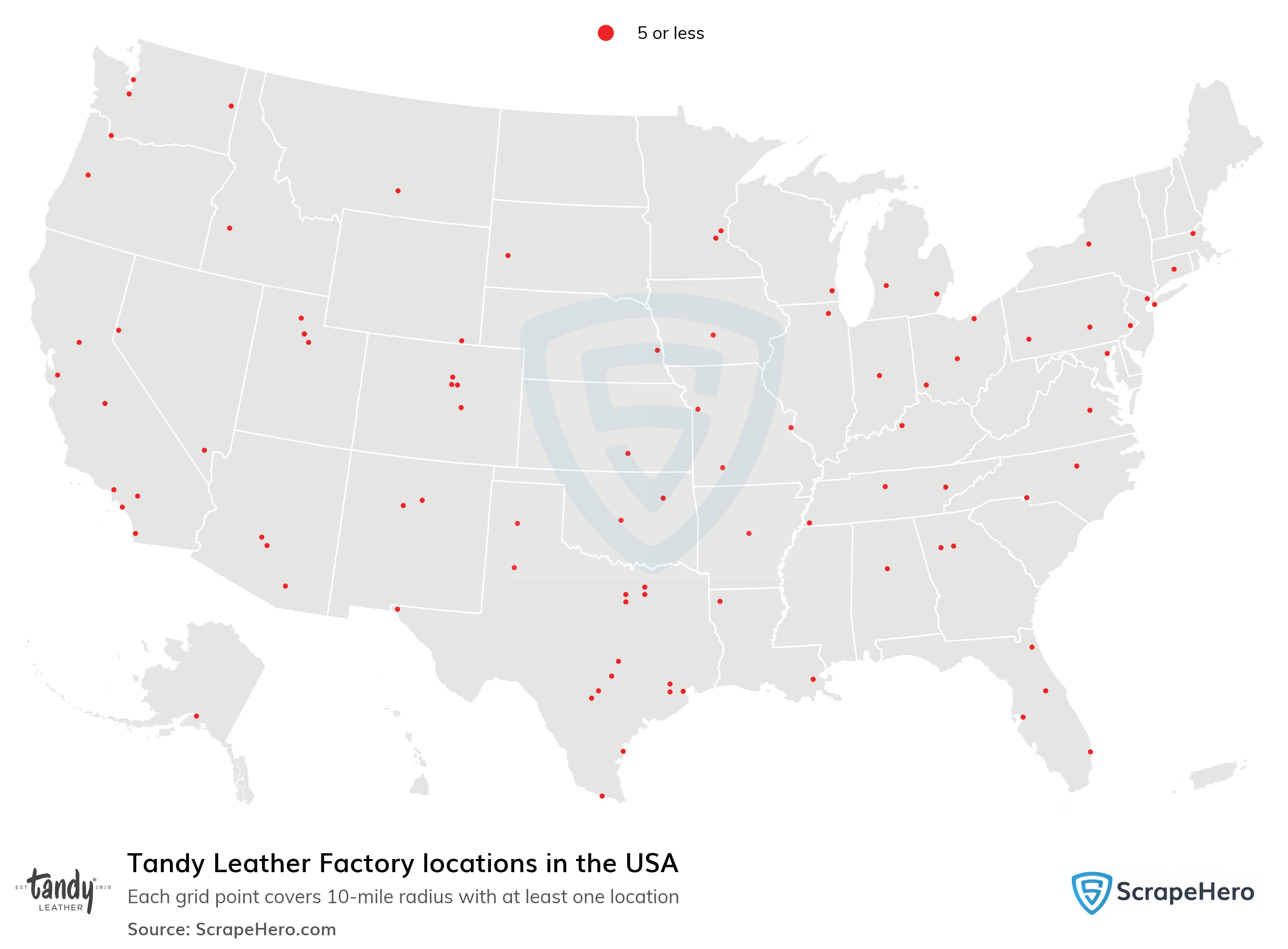

3. Tandy Leather – Location Directory

Domain: scrapehero.com

Registered: 2014 (11 years)

Introduction: {“title”: “Tandy Leather Factory locations in the USA”, “price”: “$55”, “number_of_locations”: “92”, “last_updated”: “August 28, 2024”, “description”: “Complete list of all Tandy Leather Factory locations in the US with geocoded address, phone number, open hours, stock ticker etc for instant download.”, “data_fields”: [“Store No.”, “Zip Code”, “Status”, “Name”, “Phone”, “Stock Ticker”, “Provider”,…

Strategic Sourcing Conclusion and Outlook for tandy leather factory locations

How Can Tandy Leather’s Global Locations Enhance Your Supply Chain?

In conclusion, Tandy Leather’s extensive network of factory and retail locations provides an invaluable resource for international B2B buyers. The company’s commitment to quality leather products, tools, and educational resources positions it as a strategic partner in your sourcing endeavors. By leveraging Tandy’s diverse offerings, businesses across Africa, South America, the Middle East, and Europe can access premium materials that elevate their leathercraft projects, ultimately driving profitability and innovation.

Strategic sourcing from Tandy Leather not only enhances your supply chain efficiency but also ensures that you stay competitive in the global market. The ability to connect with knowledgeable staff at local stores for personalized support and insights into the latest industry trends is a significant advantage. Moreover, Tandy’s commitment to customer engagement through workshops and classes fosters a deeper understanding of leathercraft, empowering your team to maximize product potential.

Looking ahead, we encourage international buyers to explore partnerships with Tandy Leather. As the company continues to expand its footprint and adapt to market needs, aligning your sourcing strategies with Tandy can unlock new avenues for growth and success in the leather industry. Embrace this opportunity to elevate your business today!

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.