Catalog

Material Insight: Stretchable Leather Fabric

B2B Product Guide: Stretchable Leather Fabric

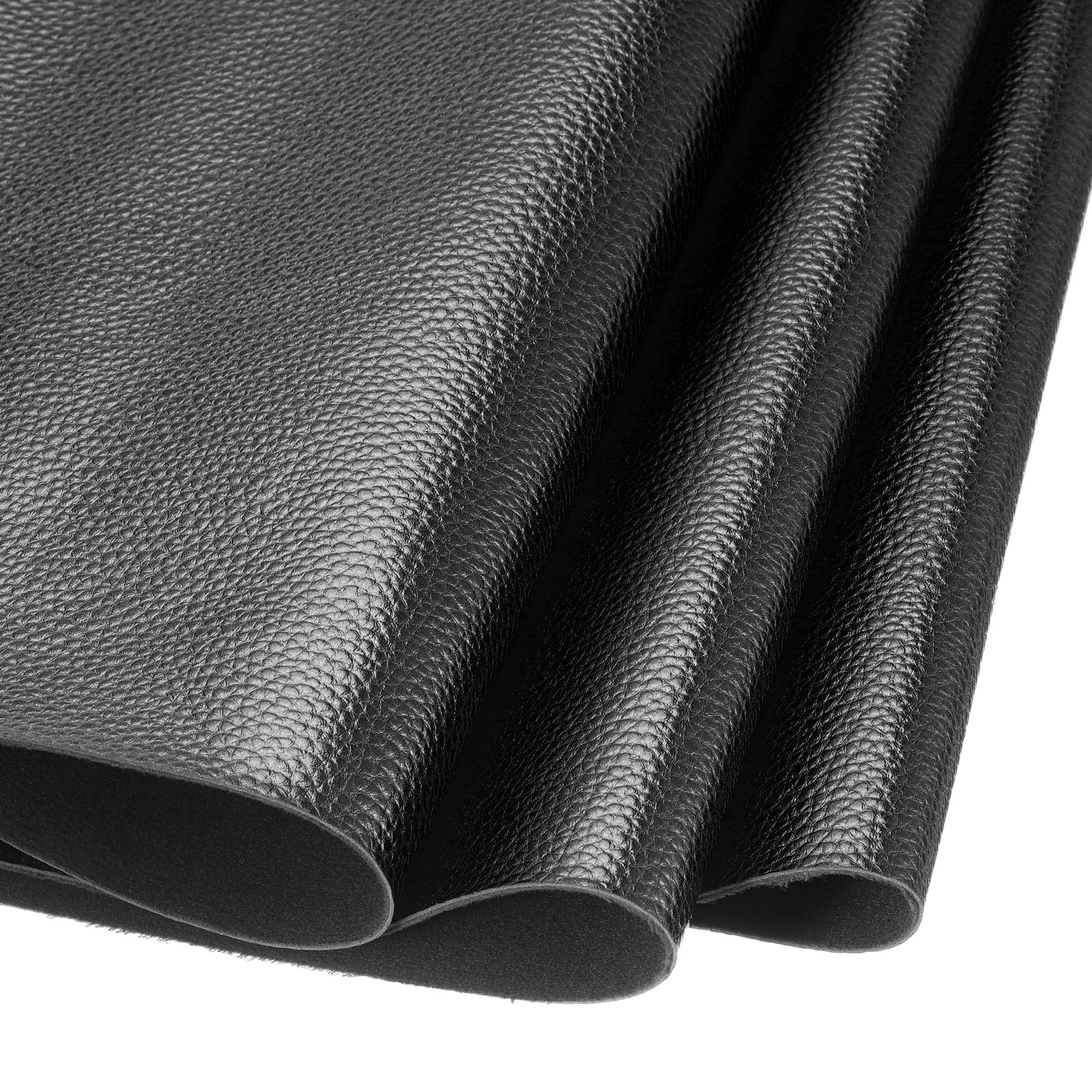

Stretchable leather fabric has become a critical material in modern design and manufacturing across industries such as automotive interiors, performance apparel, footwear, furniture, and medical devices. Combining the luxurious aesthetic of genuine leather with enhanced flexibility, durability, and design versatility, stretchable leather offers manufacturers a high-performance alternative that meets both functional and aesthetic demands. This material enables seamless integration into contoured surfaces, ergonomic designs, and dynamic applications where traditional leather falls short.

Faux leather stands out as the best choice for stretchable applications due to its engineered composition. Unlike natural leather, which has inherent limitations in elasticity and consistency, faux leather can be precisely formulated to deliver uniform stretch, improved tensile strength, and long-term resilience. It offers excellent control over thickness, texture, and performance properties—critical for high-volume, precision-driven B2B production. Additionally, faux leather supports sustainable manufacturing practices by reducing reliance on animal hides and enabling eco-conscious production cycles.

WINIW is a leading innovator in high-performance synthetic leather solutions, with over 20 years of expertise in research, development, and industrial application. Specializing in microfiber and polyurethane-based materials, WINIW delivers stretchable leather fabrics that meet rigorous international standards for durability, environmental safety, and aesthetic quality. Our products are engineered for superior breathability, abrasion resistance, and UV stability, making them ideal for demanding commercial applications. Trusted by global brands and manufacturers, WINIW combines technical excellence with a commitment to sustainability—offering eco-friendly formulations, low-VOC emissions, and recyclable material options.

Partner with WINIW to access advanced stretchable leather fabrics designed for performance, scalability, and long-term value.

Technical Performance & Standards

WINIW Stretchable Leather Fabric: Technical Product Guide

WINIW’s Stretchable Leather Fabric delivers superior performance for demanding B2B applications in automotive interiors, furniture upholstery, and performance apparel. Engineered for resilience and efficiency, this synthetic leather solution eliminates traditional material limitations while meeting rigorous environmental and quality standards. Key technical advantages include optimized production costs, extended product lifecycle, and seamless integration into high-volume manufacturing.

Core Technical Advantages

- Cost-Effective Production: Reduces material waste by 15–20% versus conventional leathers due to precise roll-good consistency and high cutting yields. Eliminates pre-stretching processes, lowering labor and energy costs in fabrication.

- Exceptional Durability: Withstands 200,000+ double rubs (Martindale ASTM D4966) and maintains structural integrity after 50,000+ flex cycles (ISO 7854). Resists UV degradation (5,000+ hours QUV testing), preventing fading or cracking in prolonged sunlight exposure.

- Customizable Color System: Offers 500+ standard color options with <7-day lead time for custom Pantone matches (MOQ: 500m). Pigment integration during base-layer extrusion ensures uniform color depth and eliminates batch variation.

- REACH Compliance: Fully adheres to EU REACH Regulation (EC 1907/2006), with zero SVHCs (Substances of Very High Concern). Certificates available upon request for all chemical constituents.

- ISO 9001-Certified Quality: Manufactured under WINIW’s ISO 9001:2015-certified quality management system, ensuring consistent thickness, tensile strength, and stretch recovery across all production batches.

Technical Specifications

| Property | Specyfikacja | Test Method |

|---|---|---|

| Thickness | 0.8–1.2 mm (customizable) | ISO 2424 |

| Stretch Ratio (Warp) | 120–140% | ASTM D5035 |

| Tensile Strength | ≥ 25 N/mm² | ISO 1767 |

| Abrasion Resistance | ≥ 200,000 double rubs | ASTM D4966 |

| Color Fastness (Light) | Grade 7–8 (ISO Blue Scale) | ISO 105-B02 |

| Cold Crack Resistance | ≤ -30°C | ISO 1770 |

| REACH Status | Fully compliant, SVHC-free | Internal Audit + 3rd Party Lab |

| Quality Certification | ISO 9001:2015 | WINIW Certificate #Q-2024-087 |

WINIW’s stretchable leather fabric enables designers to achieve complex 3D forms without delamination or stress marks, while its closed-loop water-based coating process reduces VOC emissions by 90% versus solvent-based alternatives. All materials are traceable through WINIW’s digital supply chain platform, providing full compliance documentation for global regulatory frameworks. For volume pricing and technical datasheets, contact WINIW’s B2B Solutions Team.

Why Choose Synthetic over Real Leather

B2B Product Guide: Stretchable Leather Fabric vs. Real Leather

In the evolving landscape of material selection for fashion, upholstery, and technical applications, manufacturers and designers are increasingly evaluating alternatives to traditional materials. One such comparison gaining relevance is between stretchable leather fabric—often a synthetic or semi-synthetic engineered material—and real (animal-derived) leather. This guide provides a professional comparison focused on cost, durability, and eco-friendliness to support informed B2B decision-making.

Overview of Materials

- Stretchable Leather Fabric: Typically made from a polyurethane (PU) or polyvinyl chloride (PVC) base layered with a fabric backing that allows for flexibility and stretch. Often developed using advanced coating and lamination techniques, such as those pioneered by WINIW, to mimic the texture and performance of real leather while offering enhanced design versatility.

- Real Leather: Derived from animal hides (commonly bovine, ovine, or porcine), real leather undergoes tanning and finishing processes to improve durability and appearance. It is valued for its natural grain, breathability, and premium tactile qualities.

Key Differences

- Stretchable leather fabric is engineered for consistent thickness, color, and performance, making it ideal for applications requiring precision and scalability.

- Real leather features natural variations in grain and texture, which are often considered desirable in luxury markets but can complicate mass production.

- Stretchable leather offers greater design freedom, including elasticity, making it suitable for form-fitting products such as athletic footwear, ergonomic furniture, and wearable tech.

- Real leather generally has higher breathability and develops a patina over time, which some consumers perceive as a mark of authenticity and quality.

Performance and Sustainability Comparison

| Factor | Stretchable Leather Fabric | Real Leather |

|---|---|---|

| Cost | Lower to moderate | High |

| Trwałość | High resistance to cracking and abrasion; consistent performance | Variable; prone to drying, cracking if not maintained |

| Eco-friendliness | Higher potential (especially water-based PU); recyclable options available; lower carbon footprint | High environmental cost: land use, water, chemicals in tanning (especially chrome tanning) |

Sustainability Notes

- Modern stretchable leather fabrics, particularly those made with water-based PU systems, significantly reduce VOC emissions and are aligned with global environmental standards (e.g., REACH, OEKO-TEX®).

- Real leather, while a byproduct of the meat industry, contributes to deforestation, greenhouse gas emissions, and water pollution due to resource-intensive processing.

- WINIW’s stretchable leather solutions are designed with circularity in mind, supporting brands in achieving ESG goals through sustainable material innovation.

Conclusion

For B2B clients focused on scalability, consistent quality, and environmental responsibility, stretchable leather fabric presents a compelling alternative to real leather. While real leather retains its niche in premium and traditional markets, engineered leather solutions offer superior performance in elasticity, cost-efficiency, and sustainability—making them ideal for forward-thinking brands in footwear, automotive interiors, furniture, and fashion.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineered Excellence for Global Partners

WINIW stands at the forefront of sustainable synthetic leather manufacturing, delivering performance-driven materials to premium brands worldwide. Our vertically integrated capabilities ensure unmatched consistency, innovation, and reliability for B2B partners demanding excellence.

Unmatched Manufacturing Capacity

Our state-of-the-art facility spans 100,000 square meters (equivalent to 14 international football fields), enabling scalable production without compromising agility. This scale supports:

– High-volume output for global supply chain demands

– Dedicated production lines for specialized material formulations

– Streamlined logistics with integrated warehousing and shipping coordination

– Reduced lead times through optimized in-house processes

Innovation-Driven R&D Excellence

WINIW’s 85+ member R&D team pioneers next-generation sustainable materials, translating market needs into technical solutions:

– Proprietary bio-based polyurethane (PU) and polyamide (PA) formulations

– Custom development for performance attributes (abrasion resistance, hydrolysis stability, color fastness)

– Collaborative co-creation with brand partners from concept to commercialization

– Continuous improvement of eco-footprint through waterless dyeing and recycled content integration

Rigorous Quality Assurance Framework

Every meter of WINIW synthetic leather undergoes uncompromising quality control:

– Triple-stage inspection: raw material intake, in-process monitoring, final product validation

– AQL 1.0 standard compliance (exceeding industry benchmarks)

– Full traceability via blockchain-enabled batch tracking

– Independent laboratory testing for global regulatory adherence (REACH, CPSIA, OEKO-TEX®)

Global Compliance & Market Penetration

WINIW materials meet the highest international standards for safety and sustainability:

| Certification | Scope | Key Markets Validated |

|---|---|---|

| ISO 14001 | Environmental Management | EU, USA, Japan |

| ISO 9001 | Quality Management | Global |

| OEKO-TEX® STANDARD 100 | Harmful Substance Screening | EU, North America |

| GRS (Global Recycled Standard) | Recycled Content Verification | EU, USA |

We actively serve Tier-1 partners across Europe and North America, with 68% of annual production exported to these regions. Our compliance infrastructure ensures seamless integration into demanding supply chains, including automotive, luxury goods, and performance apparel sectors.

WINIW combines industrial scale with artisanal precision—transforming sustainability commitments into technically superior materials that empower your brand’s market leadership. Partner with us to future-proof your material supply chain.

Contact Us for Samples

B2B Product Guide: Stretchable Leather Fabric by WINIW

WINIW is a leading innovator in high-performance synthetic leather solutions, delivering sustainable, durable, and versatile materials tailored for industries ranging from automotive and furniture to fashion and sports apparel. Our stretchable leather fabric combines the luxurious look and feel of genuine leather with the functional advantages of advanced microfiber technology—offering elasticity, resilience, and eco-conscious manufacturing.

Engineered for performance and design flexibility, WINIW’s stretchable leather is ideal for applications requiring form-fitting materials, dynamic movement, and long-term durability. Whether used in seating systems, footwear, or technical apparel, our material provides consistent quality and superior adaptability.

Key Features of WINIW Stretchable Leather Fabric

- High elasticity with excellent recovery—ideal for contour-hugging designs

- Soft hand feel with a natural leather aesthetic

- Breathable, lightweight, and abrasion-resistant

- Eco-friendly production with low-VOC emissions and recyclable components

- Available in multiple thicknesses (0.6mm to 1.2mm) and custom widths

- UV and color-fast rated for long-term indoor and outdoor use

- Compatible with standard cutting, sewing, and laminating processes

Industry Applications

- Automotive interiors (steering wheels, seats, dashboards)

- Performance footwear and wearable accessories

- Upholstered furniture and modular seating

- Sports and outdoor gear (gloves, protective padding)

- Medical and mobility devices requiring flexible coverings

Technical Specifications (Typical Values)

| Property | Specyfikacja |

|---|---|

| Thickness | 0.8 mm ± 0.1 mm |

| Tensile Strength | ≥ 25 MPa (warp & weft) |

| Elongation at Break | ≥ 120% |

| Color Fastness (ISO 105) | ≥ Grade 4 |

| Martindale Abrasion | ≥ 30,000 cycles |

| RoHS & REACH Compliant | Yes |

| Base Material | Polyester/polyurethane microfiber |

All products are customizable in color, texture, backing fabric, and stretch direction (4-way or 2-way stretch options available).

Why Choose WINIW?

- Sustainable manufacturing with reduced water and energy consumption

- Global supply chain reliability with ISO 9001 and OEKO-TEX® certified facilities

- R&D support for co-developing application-specific materials

- Fast turnaround for samples and bulk production

Request Free Samples

Experience the performance and quality of WINIW stretchable leather fabric firsthand. Free samples are available for qualified B2B partners.

For inquiries and sample requests, contact:

MKT88@MicrofiberLeather.com

Elevate your product design with a smarter, sustainable alternative to traditional leather.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.