Introduction: Navigating the Global Market for material synthetic leather

Navigating the complexities of sourcing material synthetic leather can be a daunting task for international B2B buyers, particularly when considering factors such as quality, sustainability, and cost-effectiveness. As the demand for eco-friendly alternatives to genuine leather surges across Africa, South America, the Middle East, and Europe, understanding the nuances of synthetic leather becomes essential. This guide offers an in-depth exploration of the various types of synthetic leather available, their applications across diverse industries, and effective strategies for vetting suppliers to ensure quality and reliability.

Buyers will gain insights into the production processes, including the materials used—ranging from traditional PVC to innovative plant-based alternatives—enabling them to make informed decisions aligned with their sustainability goals. Additionally, we address pricing structures and how to navigate the global market, particularly focusing on leading producers such as China and emerging markets.

By the end of this guide, B2B buyers will be equipped with the knowledge to confidently source synthetic leather solutions that meet their specific needs, paving the way for successful partnerships and sustainable practices in an increasingly competitive landscape. Whether you are in the fashion, automotive, or furniture industries, this comprehensive resource is designed to enhance your purchasing strategy and drive your business forward.

Table Of Contents

- Top 6 Material Synthetic Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for material synthetic leather

- Understanding material synthetic leather Types and Variations

- Key Industrial Applications of material synthetic leather

- 3 Common User Pain Points for ‘material synthetic leather’ & Their Solutions

- Strategic Material Selection Guide for material synthetic leather

- In-depth Look: Manufacturing Processes and Quality Assurance for material synthetic leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘material synthetic leather’

- Comprehensive Cost and Pricing Analysis for material synthetic leather Sourcing

- Alternatives Analysis: Comparing material synthetic leather With Other Solutions

- Essential Technical Properties and Trade Terminology for material synthetic leather

- Navigating Market Dynamics and Sourcing Trends in the material synthetic leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of material synthetic leather

- Strategic Sourcing Conclusion and Outlook for material synthetic leather

- Important Disclaimer & Terms of Use

Understanding material synthetic leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Polyurethane (PU) | Soft texture, higher durability, more breathable | Upholstery, fashion accessories, automotive interiors | Pros: Eco-friendlier than PVC; Cons: Higher cost than PVC. |

| Polyvinyl Chloride (PVC) | Cost-effective, water-resistant, less breathable | Budget furniture, outdoor seating, fashion items | Pros: Affordable; Cons: Less durable and can emit harmful chemicals. |

| Vegetable-based Leather | Made from plant materials, biodegradable | Eco-friendly fashion, sustainable furniture | Pros: Biodegradable; Cons: Limited availability and higher costs. |

| Naugahyde | Durable, versatile, and historically significant | Commercial upholstery, automotive, marine applications | Pros: Strong brand recognition; Cons: May not be as eco-friendly. |

| Skóra z mikrofibry | Ultra-soft, lightweight, and highly durable | Fashion, footwear, upholstery, and tech accessories | Pros: Excellent durability and feel; Cons: Can be more expensive. |

What Are the Characteristics of Polyurethane (PU) Synthetic Leather?

Polyurethane (PU) synthetic leather is recognized for its soft texture and higher durability compared to other types. It offers better breathability, making it suitable for applications where comfort is key, such as fashion accessories and automotive interiors. When considering B2B purchases, buyers should evaluate the cost versus the long-term benefits of durability and environmental impact, as PU is generally seen as a more eco-friendly option compared to PVC.

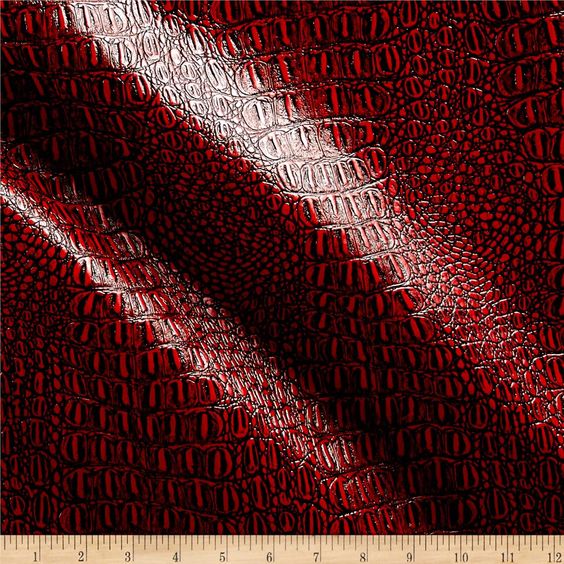

Illustrative image related to material synthetic leather

How Does Polyvinyl Chloride (PVC) Synthetic Leather Compare?

Polyvinyl Chloride (PVC) is a widely used synthetic leather due to its cost-effectiveness and water resistance. It is commonly found in budget furniture and outdoor seating products. However, while PVC is an economical choice, buyers must consider its lower durability and potential environmental concerns, including the emission of harmful chemicals during production. B2B buyers should weigh these factors against their specific application needs and market positioning.

Why Consider Vegetable-based Leather for Sustainable B2B Purchasing?

Vegetable-based leather represents a significant advancement in sustainable materials, being made from plant sources and offering biodegradability. This type is ideal for eco-friendly fashion and sustainable furniture markets. However, its limited availability and higher production costs can be a barrier for some businesses. B2B buyers focused on sustainability should assess their target market’s willingness to pay a premium for eco-friendly options.

What Makes Naugahyde a Popular Choice in B2B Markets?

Naugahyde is a durable synthetic leather that has been a staple in commercial upholstery and automotive applications. Its historical significance and strong brand recognition make it a trusted choice for businesses. While it offers versatility, buyers should consider its environmental impact and ensure that it aligns with their sustainability goals, as it may not be the most eco-friendly option available today.

Illustrative image related to material synthetic leather

How Does Microfiber Leather Stand Out in the Market?

Microfiber leather is known for its ultra-soft texture, lightweight nature, and exceptional durability, making it a popular choice for high-end fashion, footwear, and tech accessories. B2B buyers should recognize that while microfiber leather can be more expensive, its longevity and premium feel can justify the investment. Additionally, businesses targeting luxury markets may find microfiber leather enhances their brand appeal and product quality.

Key Industrial Applications of material synthetic leather

| Industry/Sector | Specific Application of material synthetic leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Car Upholstery | Cost-effective, lightweight, and easy to maintain | Ensure compliance with safety standards and durability requirements |

| Fashion & Apparel | Handbags and Footwear | Versatile design options and cruelty-free alternatives | Look for suppliers with eco-friendly production processes |

| Furniture | Sofas and Chairs | Durable and stain-resistant, ideal for high-traffic areas | Assess color fastness and ease of cleaning capabilities |

| Sports Equipment | Protective Gear (e.g., gloves, pads) | Enhanced durability and weather resistance | Verify material certifications for performance standards |

| Electronics & Accessories | Cases for Devices (phones, laptops) | Lightweight, customizable, and protective | Focus on suppliers with a variety of textures and finishes |

How is material synthetic leather used in the automotive industry?

In the automotive sector, material synthetic leather is primarily utilized for car upholstery, including seats, door panels, and dashboards. Its lightweight nature contributes to improved fuel efficiency, while its stain resistance makes it an ideal choice for vehicles frequently used in diverse climates, especially in regions like Africa and the Middle East. International buyers should prioritize suppliers who comply with stringent safety standards, as well as those who can provide durable materials that withstand wear and tear.

What are the applications of material synthetic leather in fashion and apparel?

In the fashion and apparel industry, material synthetic leather is widely used for creating handbags, footwear, and outerwear. This fabric offers a cruelty-free alternative to genuine leather, appealing to environmentally conscious consumers. Buyers from Europe and South America should consider suppliers that prioritize sustainable production processes and offer a range of colors and textures, ensuring alignment with current fashion trends while meeting ethical standards.

How does material synthetic leather benefit the furniture sector?

Material synthetic leather is an excellent choice for furniture applications, particularly for sofas and chairs. Its durability and stain resistance make it suitable for homes and commercial spaces with high foot traffic, such as restaurants and hotels. B2B buyers should evaluate the color fastness and cleaning capabilities of synthetic leather products, ensuring they can maintain a pristine appearance over time, especially in regions with varying humidity levels.

What role does material synthetic leather play in sports equipment?

In the sports equipment industry, material synthetic leather is commonly used in protective gear like gloves, pads, and sports bags. Its weather resistance and durability enhance the performance and longevity of these products, making them suitable for intense physical activities. Buyers should seek suppliers who can provide material certifications that meet specific performance standards, ensuring that the gear can withstand rigorous use across different sports environments.

How is material synthetic leather utilized in electronics and accessories?

Material synthetic leather is increasingly popular for protective cases for electronic devices, such as smartphones and laptops. It offers a lightweight, customizable solution that protects devices while providing a stylish appearance. International buyers should focus on suppliers that offer a variety of textures and finishes, allowing them to cater to diverse consumer preferences while ensuring the material’s protective qualities are not compromised.

3 Common User Pain Points for ‘material synthetic leather’ & Their Solutions

Scenario 1: Struggling with Quality and Durability Concerns in Synthetic Leather

The Problem: A B2B buyer sourcing synthetic leather for upholstery or fashion items often faces challenges related to quality and durability. Many products in the market vary significantly in their composition, leading to inconsistent performance. For instance, a buyer may invest in what appears to be a high-quality synthetic leather, only to discover that it quickly wears down, bubbles, or tears, resulting in high replacement costs and dissatisfied customers. This inconsistency can severely impact a company’s reputation, especially in competitive markets like Europe or South America, where consumers have high expectations for both aesthetics and durability.

The Solution: To navigate these quality concerns, B2B buyers should prioritize sourcing synthetic leather from reputable manufacturers with transparent production processes. Request detailed specifications and certifications, such as ISO or OEKO-TEX, which can assure the buyer of the material’s quality and safety. Additionally, conducting physical tests, such as abrasion resistance and tensile strength tests, before making a bulk purchase can help evaluate the material’s durability. Engaging in a sample order can also provide a firsthand look at the texture, weight, and overall feel of the synthetic leather, allowing buyers to make informed decisions that align with their product quality standards.

Scenario 2: Navigating Environmental Regulations and Sustainability Issues

The Problem: As global awareness of environmental sustainability increases, B2B buyers are increasingly pressured to ensure that their materials comply with stringent environmental regulations. Sourcing synthetic leather that is environmentally friendly can be particularly challenging. Buyers may face dilemmas when the synthetic leather they wish to purchase is made from PVC or other non-biodegradable materials, which can lead to reputational damage and legal challenges if found non-compliant with local or international environmental laws.

The Solution: To address these sustainability concerns, buyers should actively seek suppliers who offer eco-friendly synthetic leather options, such as those made from polyurethane (PU) or vegetable-based sources. Engaging with suppliers that prioritize sustainable practices and provide transparency regarding their sourcing and manufacturing processes is critical. Additionally, buyers can request Environmental Product Declarations (EPDs) or sustainability certifications to ensure compliance with environmental standards. By promoting the use of eco-friendly synthetic leather, businesses can not only mitigate risks but also appeal to a growing market segment that values sustainability.

Scenario 3: Overcoming Sizing and Customization Challenges

The Problem: B2B buyers often encounter challenges related to sizing and customization when sourcing synthetic leather for specific applications, such as automotive interiors or bespoke fashion items. Standardized materials may not meet unique design requirements or dimensions, leading to increased waste, higher costs, and delays in production. This situation can be particularly frustrating for manufacturers who require precise materials that align with their design specifications.

The Solution: To overcome sizing and customization challenges, buyers should collaborate closely with their suppliers during the design phase. Establishing a strong partnership allows for the customization of synthetic leather in terms of thickness, texture, and color. Buyers can leverage technology such as 3D modeling to communicate their specific needs effectively. Additionally, negotiating minimum order quantities (MOQs) that are flexible can enable buyers to experiment with custom materials without committing to excessive stock. This proactive approach not only saves costs but also fosters innovation in product design, enabling businesses to stand out in a competitive marketplace.

Strategic Material Selection Guide for material synthetic leather

What Are the Common Materials Used in Synthetic Leather Production?

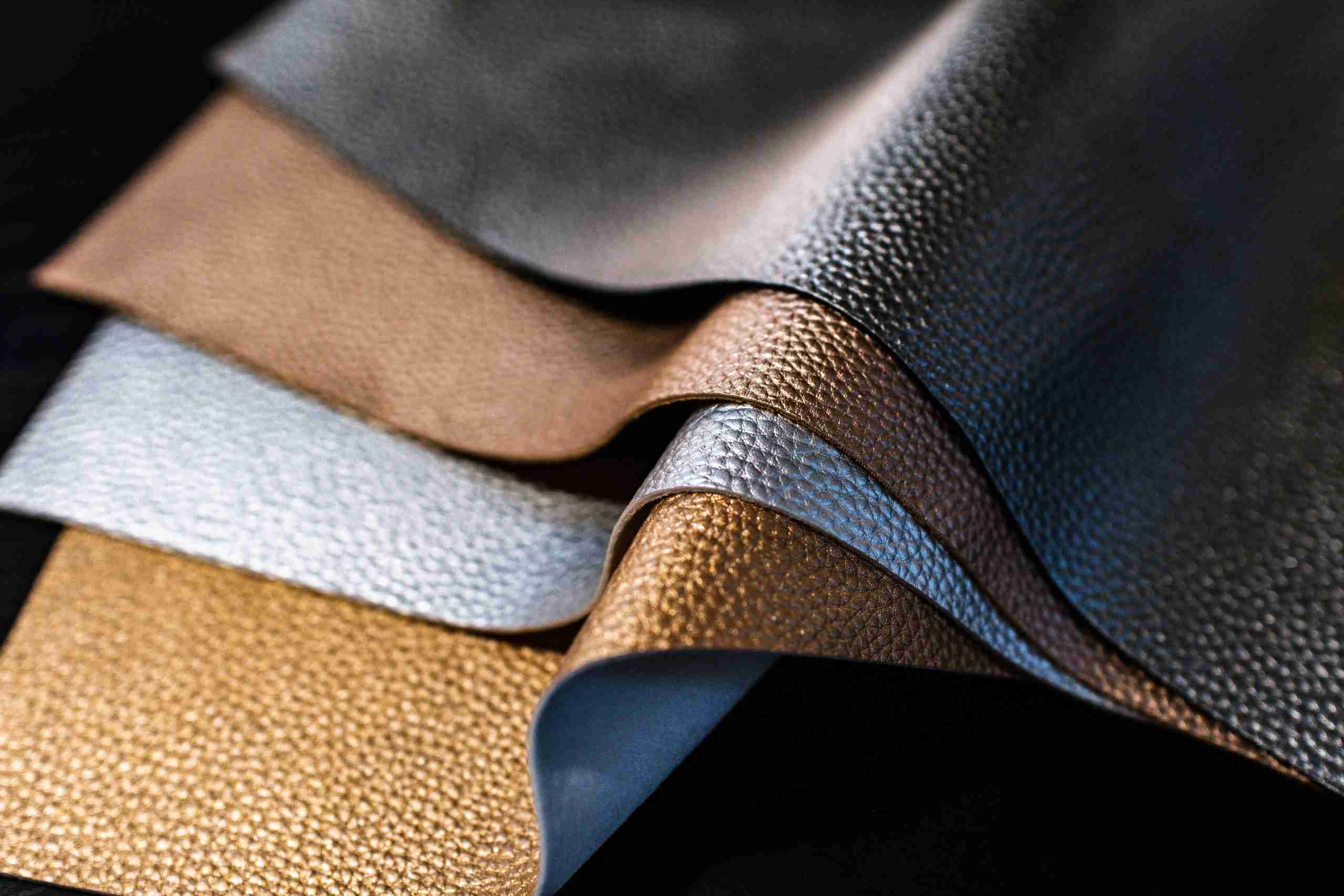

When selecting synthetic leather materials, B2B buyers must consider various factors that influence product performance, cost, and application suitability. The most common materials used in synthetic leather production include Polyvinyl Chloride (PVC), Polyurethane (PU), and bio-based alternatives. Each material has distinct properties and implications for use in different markets.

How Does Polyvinyl Chloride (PVC) Perform in Synthetic Leather Applications?

PVC is one of the most widely used materials for synthetic leather due to its versatility and cost-effectiveness. It offers low breathability and moisture-wicking abilities, making it suitable for applications where water resistance is critical, such as upholstery and outerwear. However, PVC has a high heat retention capacity, which can be a disadvantage in warmer climates.

Pros: PVC is durable and resistant to abrasions and cuts, making it ideal for high-wear applications. It is also relatively inexpensive to produce, which can lower overall product costs.

Illustrative image related to material synthetic leather

Cons: The environmental impact of PVC production is a significant concern, as it releases harmful chemicals. Additionally, its low breathability can lead to discomfort in certain applications, particularly in warmer regions.

Impact on Application: PVC is compatible with various media, including inks for printing, which allows for vibrant designs. However, international buyers should be aware of potential regulatory standards regarding PVC use, especially in regions with strict environmental regulations.

What Advantages Does Polyurethane (PU) Offer for Synthetic Leather?

PU is another popular material for synthetic leather, known for its softer texture and greater flexibility compared to PVC. This makes it suitable for high-end applications such as fashion accessories and luxury upholstery. PU has better breathability than PVC, which enhances comfort in garments.

Pros: The aesthetic appeal of PU, combined with its durability and resistance to wear, makes it a preferred choice for premium products. It also has a lower environmental impact than PVC, as it can be produced without harmful chemicals.

Cons: PU is generally more expensive than PVC, which can increase the final product cost. Additionally, while it is more breathable, it may not be as resistant to water as PVC, limiting its use in certain applications.

Impact on Application: PU’s compatibility with various dyes and finishes allows for a wide range of design options. Buyers should consider the specific performance characteristics required for their target market, especially in regions with varying climate conditions.

Are Bio-Based Alternatives to Synthetic Leather a Viable Option?

Emerging bio-based synthetic leathers, made from materials like plant oils, aim to address environmental concerns associated with traditional synthetic leathers. These materials are designed to be biodegradable and reduce reliance on petroleum-based products.

Pros: Bio-based synthetic leathers are often perceived as more sustainable, appealing to environmentally conscious consumers. They can also offer similar performance characteristics to traditional materials.

Cons: The production processes for bio-based alternatives can be more complex and costly, potentially leading to higher prices. Additionally, the availability of these materials may be limited, affecting supply chains.

Illustrative image related to material synthetic leather

Impact on Application: Bio-based synthetic leathers can be suitable for a variety of applications, but buyers should ensure compliance with international sustainability standards. Regions with a strong focus on eco-friendly products may see higher demand for these materials.

Summary of Material Selection for Synthetic Leather

| Materiał | Typical Use Case for material synthetic leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Upholstery, outerwear, footwear | Cost-effective and durable | Environmental concerns and low breathability | Low |

| PU | Fashion accessories, luxury upholstery | Soft texture and better breathability | Higher cost and lower water resistance | Med |

| Bio-based alternatives | Eco-friendly products, fashion | Sustainable and biodegradable | Higher production complexity and cost | High |

By understanding the properties, advantages, and limitations of these materials, international B2B buyers can make informed decisions that align with their product requirements and market expectations.

In-depth Look: Manufacturing Processes and Quality Assurance for material synthetic leather

What Are the Key Stages in the Manufacturing Process of Synthetic Leather?

The manufacturing process of synthetic leather involves several critical stages, each contributing to the final product’s quality and performance. Understanding these stages is essential for B2B buyers to make informed purchasing decisions.

Illustrative image related to material synthetic leather

1. Material Preparation: What Goes into Synthetic Leather?

The foundation of synthetic leather is the base material, typically made from cotton or polyester. Manufacturers begin by sourcing high-quality textiles that are porous and rough, ensuring they provide a good substrate for the synthetic coatings. In some cases, manufacturers may produce their own base materials, but it is more common to procure them from specialized suppliers.

Once the base fabric is obtained, the next step involves formulating the plastic material. The two most widely used plastics in synthetic leather production are Polyvinyl Chloride (PVC) and Polyurethane (PU). The preparation of these materials involves chemical processes where PVC is created from the combination of salt and petroleum products, while PU requires a more complex reaction involving isocyanates and polyols.

2. Forming: How Is Synthetic Leather Created?

The forming stage involves binding the prepared plastic to the base textile. This process generally employs techniques such as coating or laminating, where the plastic is melted and applied to the fabric surface. The specific method chosen can influence the texture, flexibility, and overall aesthetic of the synthetic leather.

For example, the coating process involves applying a liquid form of the plastic onto the fabric, which is then cured to create a strong bond. Alternatively, laminating involves using heat and pressure to fuse the two materials together, resulting in a durable and flexible product.

Illustrative image related to material synthetic leather

3. Assembly: What Are the Finishing Touches?

After forming, the synthetic leather is cut into desired shapes and sizes for various applications, such as upholstery or fashion accessories. This stage may involve additional treatments, such as embossing or printing, to enhance the visual appeal of the material.

Quality control measures are crucial at this stage to ensure that the cut pieces meet design specifications and quality standards before moving to the final assembly.

4. Finishing: How Is Quality Enhanced?

The finishing stage may involve applying protective coatings or treatments to enhance the synthetic leather’s resistance to stains, water, and abrasion. This is particularly important for products intended for high-use environments, such as automotive upholstery or furniture.

Illustrative image related to material synthetic leather

After finishing, the synthetic leather undergoes final inspection before packaging and shipping. This ensures that any defects are identified and addressed, maintaining the product’s integrity and performance.

What Quality Assurance Standards Are Relevant to Synthetic Leather Manufacturing?

Quality assurance is paramount in the synthetic leather industry, especially for international B2B buyers who require consistency and reliability in their supply chain. Several international standards and industry-specific certifications play a crucial role in ensuring quality.

ISO 9001: What Does It Mean for Synthetic Leather Quality?

ISO 9001 is a widely recognized quality management standard that outlines criteria for establishing an effective quality management system (QMS). Manufacturers of synthetic leather that hold ISO 9001 certification demonstrate their commitment to maintaining high-quality processes and continuous improvement. This certification is essential for B2B buyers, as it provides assurance of product reliability and consistency.

Illustrative image related to material synthetic leather

What Other Certifications Should B2B Buyers Consider?

In addition to ISO 9001, buyers should consider industry-specific certifications such as CE marking for products sold in the European market, which indicates compliance with health, safety, and environmental protection standards. Additionally, certifications from organizations like the American Petroleum Institute (API) may be relevant for specific applications, particularly in automotive and industrial sectors.

What Are the Key Quality Control Checkpoints in Synthetic Leather Production?

Effective quality control (QC) involves multiple checkpoints throughout the manufacturing process to ensure that the final product meets established standards.

Incoming Quality Control (IQC): How Is Material Quality Assessed?

IQC is the first line of defense in quality assurance. At this stage, raw materials, including base fabrics and plastic components, are inspected for defects and compliance with specifications. This process may involve visual inspections, dimensional checks, and laboratory testing to assess material properties.

Illustrative image related to material synthetic leather

In-Process Quality Control (IPQC): How Is Production Monitored?

During the manufacturing process, IPQC measures are implemented to monitor critical parameters such as temperature, humidity, and pressure. This ensures that the conditions are optimal for producing high-quality synthetic leather. Regular sampling and testing during production can help identify issues early, reducing waste and rework.

Final Quality Control (FQC): What Checks Are Conducted Before Shipment?

FQC is the last checkpoint before products are packaged and shipped. This stage includes comprehensive inspections to assess the finished product’s appearance, dimensions, and performance characteristics. Common testing methods at this stage may include abrasion resistance tests, colorfastness tests, and water resistance assessments.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying a supplier’s quality control processes is crucial to mitigating risks and ensuring product quality.

Illustrative image related to material synthetic leather

What Are the Best Practices for Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess a manufacturer’s quality control systems. Buyers should look for transparency in the supplier’s processes, including documentation of their quality management system, inspection protocols, and compliance with relevant standards.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control measures. These inspections often include on-site evaluations and product testing, offering buyers additional confidence in the supplier’s capabilities.

What Quality Control Nuances Should International Buyers Be Aware Of?

B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control that may vary by region.

How Do Cultural Differences Affect Quality Expectations?

Cultural differences can influence expectations around quality and communication. Buyers should establish clear specifications and quality expectations early in the negotiation process to ensure alignment with the supplier’s capabilities.

What Regulations Should Buyers Consider in Different Markets?

Each market may have specific regulations governing synthetic leather products, including environmental standards and safety requirements. Buyers should familiarize themselves with these regulations to ensure compliance and avoid potential legal issues.

Illustrative image related to material synthetic leather

In conclusion, understanding the manufacturing processes and quality assurance measures in the synthetic leather industry is vital for B2B buyers. By focusing on the key stages of production, relevant certifications, and effective quality control practices, buyers can make informed decisions that align with their business needs and market expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘material synthetic leather’

Wprowadzenie

This practical sourcing guide is designed to assist B2B buyers in procuring synthetic leather materials efficiently and effectively. By following this step-by-step checklist, you will ensure that your sourcing process is thorough, minimizing risks while maximizing the quality and suitability of the materials for your specific applications.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements for synthetic leather. This includes material composition (e.g., PVC or PU), thickness, texture, color, and any specific performance criteria such as durability or water resistance. By having a detailed specification, you can streamline your search and communicate your needs effectively to potential suppliers.

Step 2: Research Potential Suppliers

Conduct comprehensive research to identify reputable suppliers of synthetic leather. Look for manufacturers with a proven track record in the industry, particularly those who specialize in the specific types of synthetic leather you require. Utilize platforms such as trade shows, industry directories, and online marketplaces to compile a list of potential candidates.

- Considerations:

- Check the supplier’s production capacity and lead times.

- Evaluate their geographical location in relation to your logistics needs.

Step 3: Evaluate Supplier Certifications

It’s essential to verify that your potential suppliers possess relevant certifications. Certifications such as ISO 9001 for quality management systems and ISO 14001 for environmental management indicate a commitment to quality and sustainability. This step is crucial to ensure compliance with international standards and regulations.

- Documentation to Request:

- Copies of certifications.

- Evidence of compliance with environmental and safety regulations.

Step 4: Request Sample Materials

Once you have narrowed down your list of suppliers, request samples of the synthetic leather materials. This will allow you to assess the quality, texture, and overall suitability of the products for your applications. Pay attention to the feel, durability, and any specific features that meet your technical specifications.

Step 5: Assess Pricing and Payment Terms

Gather detailed pricing information from your shortlisted suppliers, including any bulk discounts or terms for long-term contracts. Evaluate the pricing against the quality of the materials offered. Additionally, clarify payment terms to avoid any misunderstandings later in the procurement process.

Illustrative image related to material synthetic leather

- Key Points:

- Compare pricing structures among suppliers.

- Look for transparency in payment terms and conditions.

Step 6: Conduct Factory Visits or Virtual Tours

If feasible, arrange factory visits or request virtual tours of the suppliers’ production facilities. This step allows you to observe manufacturing processes, quality control measures, and working conditions. It also provides an opportunity to build a personal relationship with the supplier, fostering better communication and collaboration.

Step 7: Finalize Contracts and Agreements

After selecting a supplier, ensure that all terms and conditions are clearly documented in a formal contract. Include specifications, pricing, delivery schedules, and penalties for non-compliance. This legal framework will protect both parties and provide clarity throughout the transaction.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing synthetic leather effectively, ensuring that they obtain high-quality materials that meet their specific needs.

Illustrative image related to material synthetic leather

Comprehensive Cost and Pricing Analysis for material synthetic leather Sourcing

What Are the Key Cost Components in Sourcing Synthetic Leather?

When sourcing synthetic leather, several cost components significantly influence the overall pricing structure. The primary elements include:

-

Materials: The cost of base textiles (commonly cotton or polyester) and the plastic (usually PVC or PU) is fundamental. Prices can fluctuate based on the quality of materials, with higher-grade plastics and eco-friendly options, such as vegetable-based alternatives, commanding premium prices.

-

Labor: Labor costs vary significantly across regions. For instance, manufacturing in countries like China may offer lower labor costs compared to Europe, affecting the overall price of synthetic leather.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and maintenance. Efficient manufacturing processes can lower overhead costs, making the final product more competitive.

-

Tooling: Initial tooling costs for specialized production lines can be substantial, especially for custom designs. These costs are typically amortized over large production runs, impacting the unit price.

-

Quality Control (QC): Implementing rigorous QC processes is essential to ensure product consistency and compliance with international standards. These costs, although sometimes overlooked, are crucial for maintaining quality and can influence pricing.

-

Logistics: Transportation and shipping costs are critical, especially for international buyers. Factors such as shipping distance, freight method, and potential tariffs can add to the total cost.

-

Margin: Suppliers will typically include a profit margin in their pricing, which can vary based on market demand and competition.

How Do Price Influencers Affect Synthetic Leather Sourcing?

Several factors influence the pricing of synthetic leather, particularly for international B2B buyers:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders often lead to bulk discounts, while smaller orders may incur higher per-unit costs.

-

Specifications and Customization: Tailored products with specific colors, patterns, or finishes can lead to increased costs. Customization often requires additional tooling and production time, which should be factored into the pricing.

-

Materials and Quality Certifications: The choice of materials directly impacts pricing. Eco-friendly certifications or high-quality materials can raise costs but may be necessary for certain markets or consumer demands.

-

Supplier Factors: The reputation and reliability of the supplier can also influence pricing. Established suppliers may charge a premium for their proven quality and service, while newer suppliers might offer lower prices to gain market entry.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital, as they define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. The choice of Incoterm can significantly affect the total landed cost of the product.

What Are the Best Buyer Tips for Cost-Efficiency in Synthetic Leather Sourcing?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, can adopt several strategies for effective sourcing:

-

Negotiate Wisely: Building a strong relationship with suppliers can lead to better pricing and terms. Don’t hesitate to negotiate on MOQs, payment terms, and delivery schedules to find a mutually beneficial arrangement.

-

Consider Total Cost of Ownership (TCO): Beyond the initial purchase price, evaluate the total cost of ownership, including logistics, quality assurance, and potential waste or returns. This holistic view can lead to better long-term decisions.

-

Stay Informed on Pricing Nuances: Global market trends, material shortages, and geopolitical factors can influence prices. Keeping abreast of these trends can provide leverage during negotiations.

-

Evaluate Supplier Capabilities: Assessing the supplier’s production capabilities and past performance can help ensure that they can meet your quality and delivery expectations, reducing the risk of costly delays or subpar products.

By understanding the intricate cost structure and pricing dynamics of synthetic leather sourcing, B2B buyers can make informed decisions that align with their business objectives and market demands.

Illustrative image related to material synthetic leather

Disclaimer: Prices mentioned in this analysis are indicative and can vary based on market conditions, negotiation outcomes, and specific project requirements. Always conduct thorough research and obtain multiple quotes before finalizing any procurement decisions.

Alternatives Analysis: Comparing material synthetic leather With Other Solutions

Introduction: Understanding Alternatives to Material Synthetic Leather

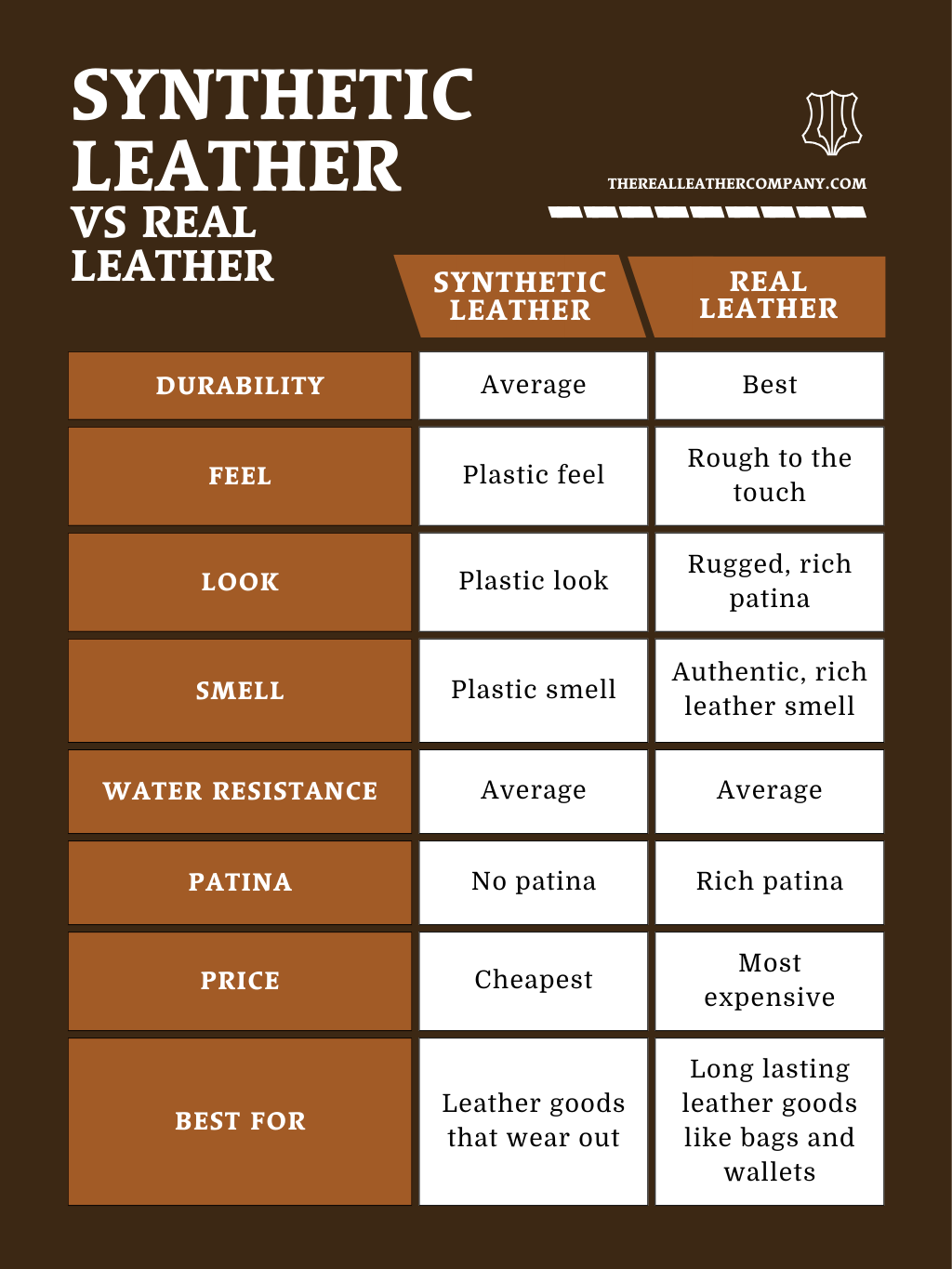

In the quest for sustainable and high-performance materials, businesses often explore alternatives to traditional synthetic leather. Material synthetic leather, known for its versatility and affordability, faces competition from various other solutions. This analysis provides a comparative overview of synthetic leather against two viable alternatives: natural leather and plant-based leather. By understanding the key differences, B2B buyers can make informed decisions that align with their operational needs and ethical considerations.

Comparison Table

| Comparison Aspect | Material Synthetic Leather | Natural Leather | Plant-Based Leather |

|---|---|---|---|

| Performance | Good durability, water-resistant; lower breathability | High durability, excellent breathability; requires care | Moderate durability; water-resistant; varies by type |

| Cost | Generally low cost | Higher cost due to sourcing and processing | Moderate to high cost depending on materials used |

| Ease of Implementation | Readily available, easy to process | Requires skilled labor for production | Requires specialized processes; still emerging in the market |

| Maintenance | Easy to clean; resistant to stains | Requires regular conditioning and care | Low maintenance; cleaning depends on specific materials |

| Best Use Case | Upholstery, apparel, accessories | Luxury goods, high-end fashion, durable goods | Eco-friendly products, fashion, and upholstery |

Detailed Breakdown of Alternatives

Natural Leather

Natural leather is derived from animal hides and is valued for its unique aesthetic and durability. It offers excellent breathability and a luxurious feel, making it the preferred choice for high-end products. However, natural leather comes with a higher price tag and requires more maintenance to preserve its quality. Additionally, ethical concerns surrounding animal welfare and environmental impact can deter some buyers. For businesses focused on luxury and quality, natural leather remains a strong option, albeit with implications for sustainability.

Illustrative image related to material synthetic leather

Plant-Based Leather

Plant-based leather, often made from materials like pineapple leaves, apple cores, or other agricultural by-products, is gaining traction as a sustainable alternative. It offers a lower environmental impact compared to traditional synthetic options and does not involve animal cruelty. However, the technology for producing plant-based leather is still evolving, which can lead to variability in durability and performance. While it presents an eco-friendly option, the cost can be higher, and availability may be limited. Businesses aiming for sustainability may find plant-based leather a compelling choice, particularly in the fashion and accessories sectors.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between material synthetic leather and its alternatives, B2B buyers should consider factors such as performance requirements, budget constraints, and ethical implications. Material synthetic leather offers affordability and ease of use, making it suitable for a wide range of applications. In contrast, natural leather appeals to luxury markets but comes with higher costs and maintenance needs. Plant-based leather provides a sustainable option but may not yet match the durability of its synthetic counterparts. Ultimately, the right choice will depend on the specific requirements of your business and the values you wish to uphold in your product offerings.

Essential Technical Properties and Trade Terminology for material synthetic leather

What Are the Key Technical Properties of Synthetic Leather?

Understanding the technical properties of synthetic leather is crucial for B2B buyers looking to procure materials that meet specific application needs. Here are some essential specifications:

1. Material Composition

Synthetic leather is primarily composed of polyurethane (PU) or polyvinyl chloride (PVC). PU is known for its superior softness and flexibility, making it suitable for high-end applications such as fashion apparel. In contrast, PVC offers durability and is often used in industrial applications. Knowing the material composition helps buyers assess the product’s suitability for various uses, from upholstery to automotive interiors.

Illustrative image related to material synthetic leather

2. Breathability

Breathability refers to the ability of synthetic leather to allow air and moisture to pass through. Most synthetic leathers have low breathability, which can lead to discomfort in clothing applications. For upholstery, however, low breathability can be advantageous as it helps maintain a clean and dry surface. Understanding breathability is vital for selecting the right material for garments versus furniture.

3. Abrasion Resistance

Abrasion resistance measures how well the material can withstand wear and tear from friction. Higher abrasion resistance is essential for products like car interiors and footwear, where durability is a priority. Buyers should seek materials with high abrasion resistance ratings to ensure longevity and reduce replacement costs over time.

4. Stretchability

Stretchability indicates how much a material can stretch without losing its shape. While some synthetic leathers offer moderate stretchability, others are more rigid. This property is particularly important in fashion applications, where a snug fit is desired. Assessing stretchability is crucial for buyers to ensure that the material meets the functional requirements of their products.

5. Heat Retention

Heat retention refers to the material’s ability to retain body heat. Synthetic leather generally has high heat retention, making it suitable for outerwear and cold-weather applications. Understanding this property is essential for buyers focused on performance apparel or insulation materials.

6. Environmental Impact

With growing concerns about sustainability, the environmental impact of synthetic leather production is increasingly important. Traditional PVC-based synthetic leathers are not biodegradable, while newer vegetable-based alternatives are emerging. Buyers should consider the environmental footprint of the materials they choose, which can also influence brand perception and customer loyalty.

Illustrative image related to material synthetic leather

What Are Common Trade Terms Used in the Synthetic Leather Industry?

Familiarity with industry terminology can streamline communication and negotiations for B2B buyers. Here are key trade terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that manufactures products that are sold under another company’s brand. In the synthetic leather industry, OEM partnerships are common, as many brands rely on third-party manufacturers to produce their goods. Understanding OEM relationships can help buyers evaluate the reliability and quality of their suppliers.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell in a single order. This term is crucial for buyers, as it affects inventory management and financial planning. Knowing the MOQ helps buyers assess whether a supplier meets their purchasing needs without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document sent by buyers to suppliers requesting pricing and terms for specific products. In the synthetic leather market, RFQs help buyers gather competitive pricing and ensure they understand the terms of trade. Crafting a clear RFQ can lead to more accurate quotes and better supplier relationships.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. They clarify who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers to avoid misunderstandings and ensure smooth transactions across borders.

5. Lead Time

Lead time is the period between placing an order and receiving the product. In synthetic leather procurement, understanding lead times can help buyers plan production schedules and manage customer expectations. Longer lead times may necessitate earlier ordering to avoid production delays.

Illustrative image related to material synthetic leather

6. Quality Assurance (QA)

Quality assurance refers to the systematic processes that ensure products meet specified standards. In the synthetic leather industry, QA processes help maintain consistency and reliability. Buyers should inquire about a supplier’s QA practices to ensure that the materials they receive meet their quality expectations.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their business objectives and market demands.

Navigating Market Dynamics and Sourcing Trends in the material synthetic leather Sector

What Are the Key Market Dynamics and Trends in the Material Synthetic Leather Sector?

The material synthetic leather market is experiencing notable growth driven by several global factors. Increasing consumer awareness regarding animal welfare and the environmental impact of traditional leather production is propelling demand for synthetic alternatives. Emerging markets in Africa and South America are witnessing a surge in demand due to rapid urbanization and economic growth, which is leading to higher disposable incomes and an affinity for fashion and lifestyle products. Additionally, the Middle East and Europe are seeing a shift towards synthetic leather in automotive and furniture upholstery, where durability and ease of maintenance are paramount.

Key B2B sourcing trends include the integration of technology in manufacturing processes. Advanced techniques such as digital printing and automated cutting are streamlining production, allowing for customization and quicker turnaround times. Furthermore, manufacturers are increasingly adopting sustainable practices, such as using recycled materials and innovative production methods that reduce waste. International buyers, particularly from Europe and Germany, are prioritizing suppliers that can provide transparency in their supply chains, ensuring quality and compliance with stringent regulations.

As global demand continues to rise, synthetic leather is projected to capture a more significant share of the overall leather market, particularly in emerging economies where the price advantage over genuine leather is a critical factor.

How Is Sustainability and Ethical Sourcing Transforming the Material Synthetic Leather Industry?

Sustainability is becoming a cornerstone of the material synthetic leather industry. Traditional synthetic leather production, primarily based on PVC and PU, poses environmental challenges, including non-biodegradability and harmful emissions during manufacturing. In response, many manufacturers are shifting towards eco-friendly alternatives, such as plant-based synthetic leathers that offer similar aesthetic and functional qualities without the environmental footprint.

For international B2B buyers, understanding the importance of ethical supply chains is crucial. Buyers are increasingly seeking suppliers who can provide certifications that validate their sustainability claims. Certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX® indicate that materials are produced with minimal environmental impact and adhere to strict safety and ethical standards.

Moreover, the emphasis on ethical sourcing extends beyond materials to include labor practices. Companies that prioritize fair labor conditions and transparency in their production processes are becoming more attractive to international buyers. As sustainability becomes a key differentiator in purchasing decisions, aligning sourcing strategies with these values will be essential for long-term success in the synthetic leather market.

What Is the Evolution and Historical Context of Material Synthetic Leather?

The evolution of material synthetic leather dates back to the early 20th century, with significant advancements shaping its current form. The first commercially successful synthetic leather, Naugahyde, was developed in the 1920s, primarily for use in handbags. Over the decades, innovations in polymer chemistry led to the widespread adoption of PVC and PU, which became the foundation for modern synthetic leathers.

The post-World War II era saw a surge in demand for synthetic alternatives as genuine leather became scarce and expensive. By the 1970s, environmental concerns began to surface, prompting manufacturers to explore more sustainable practices. Although the initial focus was primarily on cost-effectiveness and availability, the recent shift towards eco-friendly production methods signifies a new chapter in the synthetic leather industry. This historical context is critical for B2B buyers, as it highlights the ongoing transformation within the sector, driven by consumer demand for ethical and sustainable products.

Understanding these dynamics will enable international buyers to make informed sourcing decisions, aligning their procurement strategies with both market trends and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of material synthetic leather

-

How do I solve quality issues with synthetic leather products?

To address quality issues, establish clear specifications and quality standards with your supplier before production begins. Implement a thorough vetting process for potential manufacturers, including requesting samples and reviewing certifications for compliance with international quality standards. Regular communication during the production process and conducting on-site inspections or third-party quality assurance checks can also help identify and rectify issues before shipment. -

What is the best type of synthetic leather for upholstery applications?

For upholstery, polyurethane (PU) synthetic leather is often preferred due to its superior durability, aesthetic appeal, and comfort compared to PVC. PU leather offers better breathability and is generally softer to the touch, making it ideal for furniture that requires both style and practicality. Ensure that the chosen material meets fire safety and durability standards specific to your market. -

How can I customize synthetic leather materials for my products?

Customization options typically include color, texture, thickness, and finish. Discuss your specific requirements with potential suppliers, as many manufacturers offer bespoke services. Providing detailed specifications or even prototypes can help suppliers better understand your needs. Additionally, inquire about minimum order quantities (MOQs) for custom products, as these may vary by manufacturer. -

What are the typical minimum order quantities (MOQs) for synthetic leather?

MOQs for synthetic leather can vary significantly depending on the manufacturer and the specific type of material. Generally, MOQs range from 500 to 1,000 meters for standard products, while custom orders may require higher quantities. It’s essential to clarify MOQs during the initial discussions with suppliers to ensure they align with your production capabilities and market needs. -

What payment terms should I expect when sourcing synthetic leather internationally?

Payment terms can vary by supplier but are typically structured as a percentage of the total cost upfront, with the balance due upon shipment or delivery. Common practices include a 30% deposit with the order and 70% before shipping. Ensure to negotiate terms that provide adequate protection for both parties, and consider using secure payment methods such as letters of credit for larger transactions. -

How do I ensure timely logistics and delivery of synthetic leather?

To ensure timely logistics, establish a clear timeline with your supplier that includes production, quality checks, and shipping. Collaborate with logistics partners experienced in international shipping to navigate customs regulations and potential delays. Regular updates from your supplier regarding production progress can also help you anticipate and mitigate any logistical challenges. -

What certifications should I look for when sourcing synthetic leather?

When sourcing synthetic leather, look for certifications that confirm compliance with international safety and environmental standards, such as REACH, OEKO-TEX, or ISO certifications. These certifications indicate that the materials are free from harmful chemicals and produced sustainably. Request documentation from suppliers to verify these certifications and ensure that their products meet your quality expectations. -

How can I assess the credibility of a synthetic leather supplier?

To assess a supplier’s credibility, research their reputation through online reviews, industry forums, and trade shows. Request references from previous clients and inquire about their experience and satisfaction with the supplier’s products and services. Additionally, consider visiting the supplier’s facility if possible, or use third-party verification services to evaluate their production capabilities and quality control processes.

Top 6 Material Synthetic Leather Manufacturers & Suppliers List

1. Sewport – Faux Leather

Domain: sewport.com

Registered: 2015 (10 years)

Introduction: Faux leather, also known as synthetic leather, is a petroleum-based alternative to genuine leather. It is soft to the touch, water-resistant, and highly resistant to stains, making it easy to clean. While less durable than real leather, it is resistant to abrasions and cuts, ideal for upholstery in homes with children or pets. Faux leather can be produced in various colors and is popular for outer…

2. Sallie Tomato – Faux Leather Collection

Domain: sallietomato.com

Registered: 2015 (10 years)

Introduction: Faux Leather collection by Sallie Tomato includes 66 products available in various colors and textures. Colors include Beige, Black, Blue, Brown, Green, Grey, Navy, Orange, Pink, Purple, Red, Teal, White, and Yellow. Textures available are Alligator, Basket Weave, Crocodile, Legacy, Limited Edition, Lite, Ostrich, Pebble, Rugged, and Shimmer. The fabric is sold by quarter yard and is a vegan alter…

3. Decorative Fabrics Direct – PU Leather & Faux Leather

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: PU Leather & Faux Leather | Vinyl Upholstery Fabric. Terms: Free Shipping Coupon Code: SHIPFREE for Most $199 Orders. Available in various colors: Black, Gray, Blue, Turquoise, Aqua, Brown, Beige, Green, Orange, Coral, Purple, Red, Pink, White, Yellow, Gold. Uses include Furniture, Automotive, Marine. Brands include Naugahyde, Omnova Boltaflex, Nassimi, Spradling. Types include Vinyl (PVC), Uretha…

4. The Real Leather Company – Synthetic Leather Solutions

Domain: therealleathercompany.com

Registered: 2019 (6 years)

Introduction: Synthetic leather, also known as faux leather or vegan leather, is a man-made material designed to mimic the look and feel of real leather. It is typically composed of plastic-based materials such as polyurethane (PU) or polyvinyl chloride (PVC). Synthetic leather offers a cruelty-free alternative to traditional leather products but has its own sustainability concerns. It is produced through a pro…

5. Buffalo Jackson – Faux Leather Products

Domain: buffalojackson.com

Registered: 2011 (14 years)

Introduction: Faux leather, also known as synthetic leather, is made from a fabric base such as polyester, which is then treated with wax, dye, polyvinyl chloride (PVC), or polyurethane to create an imitation leather finish and texture. It is designed to look like real leather but has a uniform surface and feels cold and unnaturally even. Faux leather does not last as long as real leather and does not wear out …

6. Leathercult – Synthetic Leather Garments

Domain: leathercult.com

Registered: 2010 (15 years)

Introduction: Synthetic leather is a substitute for real leather, commonly used in garments like jackets, vests, and trousers. It is made of a coated base material such as nylon, rayon, or polyester, with a layer of polyurethane (PU) or polyvinyl chloride (PVC) applied. Synthetic leather is more susceptible to cracking than real leather due to its laminated construction. It emerged during World War 2, initially…

Strategic Sourcing Conclusion and Outlook for material synthetic leather

What Are the Key Takeaways for B2B Buyers in Synthetic Leather Sourcing?

In the evolving landscape of synthetic leather, strategic sourcing is essential for international B2B buyers. Understanding the characteristics of synthetic leather—such as its composition, durability, and applications—enables businesses to make informed decisions that align with market demands. With China as a dominant producer, exploring partnerships with manufacturers that prioritize eco-friendly practices can enhance your brand’s reputation and meet consumer expectations for sustainability.

How Can Strategic Sourcing Enhance Your Competitive Edge?

Investing in strategic sourcing not only reduces costs but also ensures access to high-quality materials. Buyers from Africa, South America, the Middle East, and Europe should leverage the diverse offerings in synthetic leather to differentiate their products in competitive markets. Engaging with suppliers who utilize innovative manufacturing processes can provide unique color and texture options that appeal to a broader customer base.

What Does the Future Hold for Synthetic Leather in Global Markets?

Looking ahead, the demand for synthetic leather is poised for growth as consumer preferences shift towards cruelty-free and environmentally conscious products. B2B buyers should proactively seek partnerships that align with these values, ensuring their offerings remain relevant and appealing. By embracing strategic sourcing practices today, businesses can position themselves for success in the dynamic future of synthetic leather.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.