Catalog

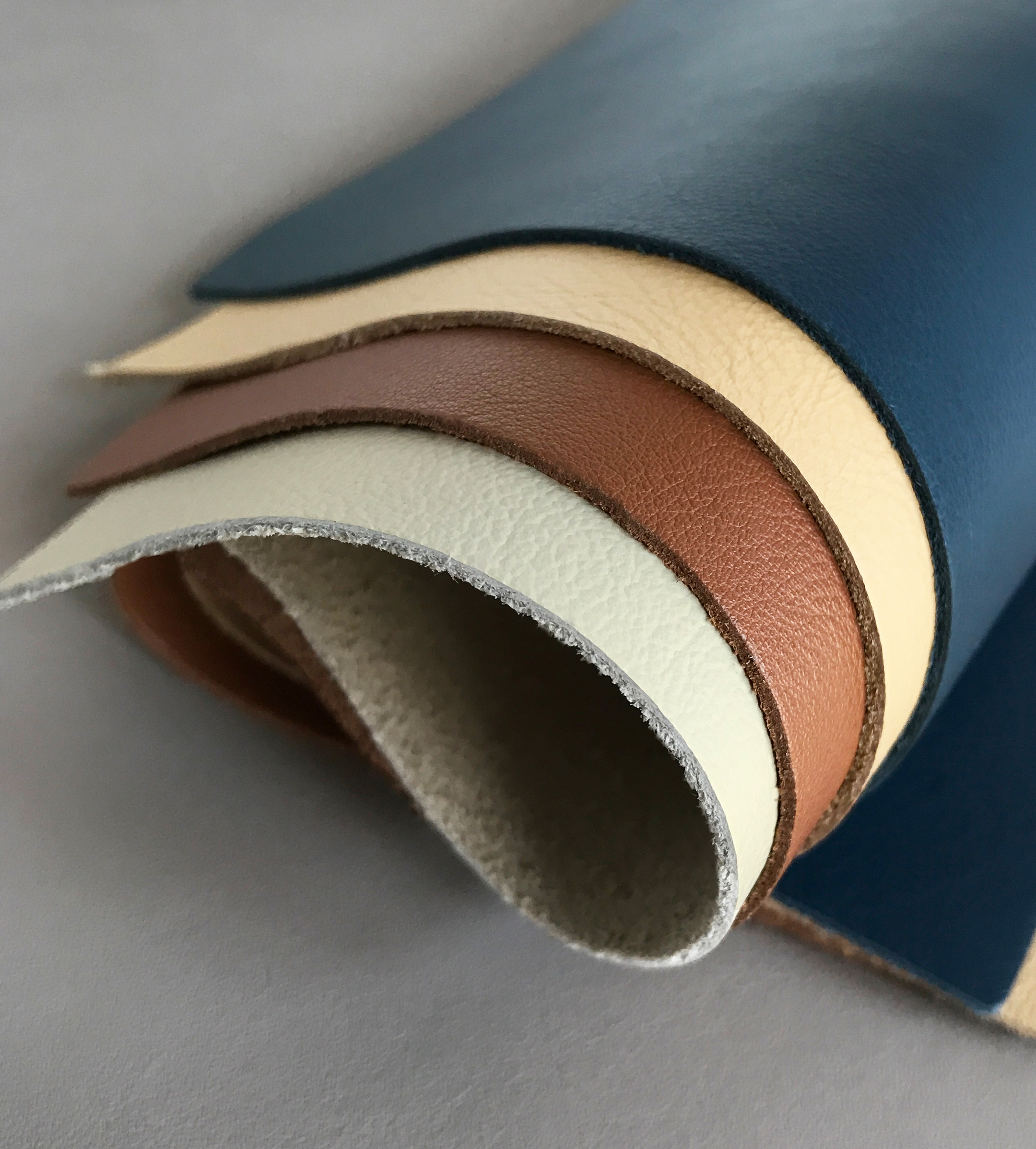

Material Insight: Leather Goods Manufacturer Italy

B2B Product Guide: Premium Faux Leather for Italian Leather Goods Manufacturers

Italy has long been synonymous with excellence in leather craftsmanship. From luxury handbags to high-end footwear and accessories, Italian manufacturers set the global standard for design, durability, and sophistication. As sustainability and ethical sourcing become increasingly important in the fashion and accessories industries, many leading manufacturers are turning to innovative alternatives—without compromising on quality. This shift has positioned premium faux leather as a strategic material choice for modern leather goods production.

Faux leather offers a compelling advantage for Italian manufacturers seeking to balance tradition with innovation. Unlike traditional leather, which involves resource-intensive tanning processes and variable hide quality, faux leather delivers consistent texture, color, and performance across batches. It is also highly customizable—available in a wide range of finishes, weights, and embossing options—to meet the exact aesthetic and functional requirements of high-end product lines. With growing consumer demand for cruelty-free and eco-conscious materials, faux leather supports brand integrity and aligns with global sustainability goals.

Environmental responsibility is no longer optional—it’s a competitive advantage. Faux leather significantly reduces water consumption, chemical usage, and carbon emissions compared to animal leather production. For Italian manufacturers committed to preserving their heritage while embracing the future, it represents a forward-thinking evolution in material selection.

Introducing WINIW

WINIW is a globally recognized leader in high-performance synthetic leather solutions, with over 20 years of expertise in developing innovative materials for premium applications. We specialize in PU (polyurethane) and microfiber leather that emulate the look, feel, and drape of genuine leather—while surpassing it in consistency, sustainability, and versatility. Our R&D-driven approach ensures that every batch meets strict European standards for durability, colorfastness, and eco-compliance.

- Designed for high-end fashion, accessories, and footwear

- OEKO-TEX® and REACH certified materials

- Custom development services: colors, textures, thicknesses, and performance features

- Sustainable production with low-VOC emissions and recyclable content options

- Trusted partner to B2B clients across Europe, North America, and Asia

For Italian leather goods manufacturers, WINIW delivers the perfect fusion of artisanal quality and modern innovation—enabling brands to craft exceptional products that meet today’s ethical and environmental expectations.

Technical Performance & Standards

WINIW Synthetic Leather: Technical Specification Guide for Italian Leather Goods Manufacturers

WINIW delivers premium, eco-conscious synthetic leather engineered specifically for high-end Italian leather goods manufacturers. Our materials combine European design sensibilities with advanced manufacturing, offering a sustainable alternative without compromising on luxury, performance, or compliance. Ideal for handbags, accessories, and upholstery, WINIW provides a strategic advantage in cost control, durability, and regulatory adherence.

Key Technical Advantages

-

Cost-Effective Production

Reduces material waste by up to 30% compared to genuine leather through precise roll-goods consistency and minimal grading variations. Eliminates seasonal price volatility and sourcing uncertainties associated with animal hides, ensuring stable budget forecasting. -

Exceptional Durability

Engineered with high-density PU/PVC backings and reinforced fibers to withstand 50,000+ double-rub cycles (Martindale test). Resists cracking, peeling, and UV degradation, maintaining structural integrity under rigorous Italian craftsmanship standards and daily use. -

Customizable Color Precision

Offers 100% Pantone® color matching with ±0.5 DE tolerance. Advanced pigment dispersion technology ensures batch-to-batch color consistency across large production runs, critical for luxury brand collections. Matte, gloss, and textured finishes available. -

Full REACH Compliance

Rigorously tested for all SVHCs (Substances of Very High Concern) per EU REACH Annex XVII. Zero detectable levels of DMF, AZO dyes, phthalates (DEHP, BBP, DBP), or heavy metals (Cd, Pb). Full documentation (including SGS reports) provided for seamless EU market access. -

ISO 9001-Certified Quality Control

Integrated quality management system ensures traceability from raw material to finished roll. Each batch undergoes 12+ in-line inspections for thickness, colorfastness, and physical properties, guaranteeing adherence to luxury segment tolerances.

WINIW Premium Synthetic Leather: Technical Specifications

| Parametr | Specyfikacja | Test Standard |

|---|---|---|

| Thickness Range | 0.6mm – 1.8mm (customizable) | ISO 2424 |

| Weight | 280g/m² – 650g/m² | ISO 2286-2 |

| Abrasion Resistance | ≥ 50,000 cycles (no visible wear) | ISO 12947-2 (Martindale) |

| Colorfastness to Rubbing | Grade 4-5 (wet/dry) | ISO 105-X12 |

| Light Fastness | ≥ 6 (Blue Wool Scale) | ISO 105-B02 |

| Tensile Strength | ≥ 35 N/mm² (warp & weft) | ISO 13934-1 |

| Eco-Certifications | REACH SVHC Compliant, OEKO-TEX® STANDARD 100 | EU Regulation 1907/2006 |

| Base Material | Recycled PET backing (up to 40% rPET) | GRS Certified |

WINIW empowers Italian manufacturers to elevate sustainability credentials while meeting uncompromising quality demands. Our technical team collaborates directly with your design and production units to optimize material specifications for your unique工艺 (craftsmanship), ensuring seamless integration into existing workflows. Request a sample kit with full compliance documentation to validate performance for your next collection.

Why Choose Synthetic over Real Leather

B2B Product Guide: Comparing Italian Leather Goods Manufacturers vs. Real Leather

When sourcing materials for premium products, brands must evaluate both origin-based craftsmanship and material authenticity. A common point of confusion lies in distinguishing between products labeled as “leather goods manufacturer Italy” — often referring to high-end, traditionally crafted goods — and “real leather,” a broad category encompassing all genuine animal hide materials regardless of origin. This guide clarifies the differences from a B2B perspective, focusing on cost, durability, and eco-friendliness.

Italian leather goods manufacturers are renowned for their artisanal techniques, strict quality control, and use of premium raw materials. These manufacturers typically process real leather — primarily bovine hides — using time-honored tanning methods such as vegetable tanning. The result is a high-performance, aesthetically superior product favored by luxury fashion houses and high-end accessory brands.

In contrast, “real leather” is a material classification, not a geographic or craftsmanship indicator. It includes a wide spectrum of leathers — from low-cost corrected grain to full-grain hides — produced globally using various tanning processes, including chrome tanning, which is faster but less environmentally sustainable.

Key considerations for B2B buyers include:

- Origin & Craftsmanship: Italian manufacturers emphasize traceability, skilled labor, and design innovation, adding value beyond the raw material.

- Material Quality: While all Italian leather goods use real leather, not all real leather meets the consistency and finish standards of Italian production.

- Market Positioning: Brands leveraging Italian manufacturing can command premium pricing due to perceived quality and heritage.

The following table compares Italian leather goods manufacturers and generic real leather across three critical business metrics:

| Criteria | Leather Goods Manufacturer (Italy) | Real Leather (Generic, Global) |

|---|---|---|

| Cost | High (€80–€200+/sqm) due to craftsmanship, labor, and import logistics | Low to moderate (€20–€80/sqm), varies by grade and tanning method |

| Trwałość | Exceptional – full-grain hides, vegetable-tanned, with high abrasion resistance and aging properties | Variable – depends on type (e.g., bonded leather less durable than top-grain) |

| Eco-friendliness | High – widespread use of vegetable tanning, regulated effluent treatment, and increasing use of renewable energy | Low to moderate – chrome tanning common, higher chemical runoff, inconsistent sustainability practices |

Strategic Recommendations for B2B Buyers

- Partner with Italian leather goods manufacturers when brand positioning, longevity, and sustainability certifications are critical.

- Consider generic real leather only for cost-sensitive lines, ensuring full transparency on tanning methods and sourcing.

- Evaluate total cost of ownership: Italian leather may have a higher upfront cost but offers longer product life and stronger eco-labeling potential.

WINIW supports sustainable innovation in material sourcing, offering eco-engineered alternatives that combine the performance of real leather with enhanced environmental benefits. For B2B partners seeking scalable, ethical solutions without compromising aesthetics, synthetic leathers with certified biodegradability and low carbon footprint present a compelling alternative.

WINIW Factory Capabilities

WINIW Synthetic Leather: B2B Manufacturing Excellence

WINIW operates one of the most advanced and vertically integrated synthetic leather manufacturing facilities globally, engineered to deliver consistent quality, innovation, and reliability for discerning B2B partners. Our infrastructure and processes are built to meet the highest international standards while prioritizing sustainable production.

Core Manufacturing Capabilities

- Industry-Leading Scale: A 100,000 sqm state-of-the-art factory enabling high-volume production without compromising agility. This scale ensures stable supply chains and rapid fulfillment for global orders, including emergency capacity for urgent client needs.

- Dedicated R&D Innovation Hub: An in-house team of 50+ material scientists and engineers continuously develops next-generation eco-friendly substrates, finishes, and performance technologies. Annual R&D investment exceeds 5% of revenue, focused on circularity and functional advancements.

- Zero-Compromise Quality Control: Multi-stage QC protocols aligned with ISO 9001, ISO 14001, and OEKO-TEX® STANDARD 100. Every batch undergoes 12+ physical/durability tests and chemical screenings for restricted substances (REACH, CPSIA, CA Prop 65).

Global Compliance & Market Access

WINIW’s production ecosystem is certified for seamless entry into regulated markets:

| Certification | Relevance to B2B Clients | Target Markets |

|---|---|---|

| OEKO-TEX® STANDARD 100 | Guarantees absence of harmful chemicals | EU, USA, Japan |

| GRS (Global Recycled Standard) | Validates recycled content (up to 60% PCR) | EU, North America |

| ISO 14001 | Certified environmental management systems | Global |

| SCS Recycled Content | Third-party verification of recycled material claims | USA, Canada |

Why Global Brands Partner With WINIW

- Supply Chain Resilience: 15+ years exporting to Tier-1 automotive, furniture, and fashion brands in Europe and the USA, with 99.6% on-time delivery rate.

- Eco-Performance Balance: Proprietary water-based PU/TPU formulations reduce VOC emissions by 70% vs. industry averages while meeting Martindale abrasion >50,000 cycles.

- Customization Velocity: From concept to bulk production in 25 days, supported by digital color matching and small-lot sampling (min. 500 meters).

WINIW’s factory is engineered for partnership—where scalability meets uncompromised sustainability and precision. We empower B2B clients to lead with materials that align with both performance demands and evolving ESG commitments.

Production capacity: 12 million meters annually | Lead time: 20-30 days for 50,000m+ orders | MOQ: 500 meters

Contact Us for Samples

WINIW® Microfiber Leather – Premium Synthetic Leather for Luxury Leather Goods

WINIW is a global leader in the development and production of high-performance synthetic leather, delivering sustainable, durable, and luxurious alternatives to genuine leather. Our advanced microfiber materials are engineered to meet the exacting standards of premium leather goods manufacturers, particularly within the European luxury market. With a focus on innovation, environmental responsibility, and performance, WINIW supports Italian and international brands in creating elegant, eco-conscious products without compromise.

Designed for high-end fashion, accessories, and upholstery, WINIW microfiber leather offers exceptional softness, tear strength, abrasion resistance, and color fastness—making it ideal for handbags, wallets, footwear, watch straps, and interior applications.

Key Advantages of WINIW Microfiber Leather

- Superior durability and wear resistance compared to traditional PU and lower-grade synthetics

- Breathable, lightweight, and flexible—ideal for intricate designs and delicate craftsmanship

- Consistent thickness and grain pattern for enhanced production efficiency

- Eco-friendly manufacturing with low-VOC emissions and compliance with REACH, RoHS, and Oeko-Tex standards

- Available in a wide range of textures, including smooth, pebbled, nubuck, and custom embossing

- High color fastness and resistance to UV, heat, and moisture

- Customizable backing (polyester, cotton, knit, or adhesive) for diverse applications

Product Specifications Overview

| Property | WINIW Standard Range | WINIW Premium (Luxury Grade) |

|---|---|---|

| Thickness | 0.6 – 1.2 mm | 0.8 – 1.5 mm |

| Weight | 200 – 350 g/m² | 250 – 400 g/m² |

| Tensile Strength | ≥ 25 N/mm² | ≥ 35 N/mm² |

| Elongation at Break | ≥ 80% | ≥ 100% |

| Martindale Abrasion | 30,000+ cycles | 50,000+ cycles |

| Backing Options | Knit, woven, non-woven | Custom textile composites |

| Certifications | REACH, RoHS, Oeko-Tex | Full traceability & LCA reports |

Ideal Applications for Italian Leather Goods Makers

- Luxury handbags and clutches

- Small leather goods (wallets, cardholders, keychains)

- High-end footwear and boot linings

- Watch bands and eyewear cases

- Furniture and automotive interiors

WINIW partners with leading leather goods manufacturers in Italy to deliver custom-tailored microfiber leather solutions that align with artisanal craftsmanship and sustainable innovation. Our technical team works closely with clients to match color, texture, drape, and performance to brand-specific requirements.

Request Free Samples for Your Production Line

Experience the quality and versatility of WINIW microfiber leather firsthand. We offer complimentary sample kits to qualified leather goods manufacturers in Italy.

For collaboration and sample requests, contact:

MKT88@MicrofiberLeather.com

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.