Catalog

Material Insight: Leather Garment Fabric

B2B Product Guide: Leather Garment Fabric Solutions

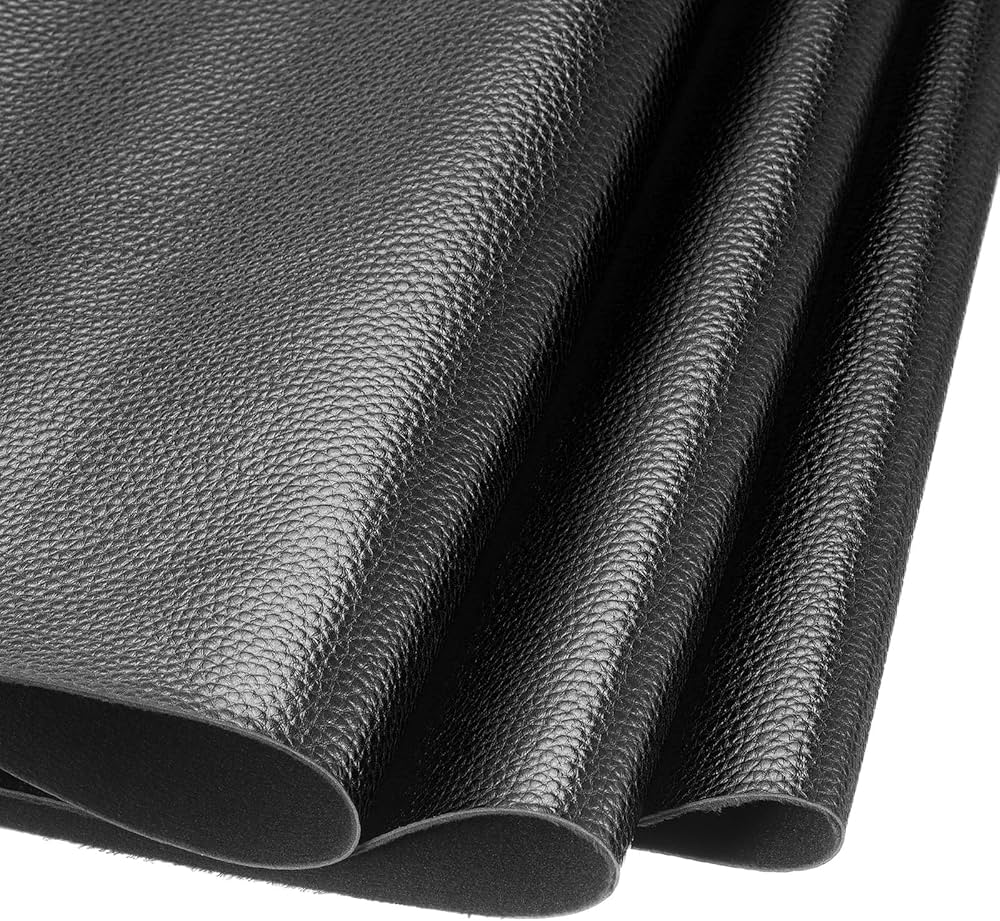

The global fashion industry demands innovative materials that balance aesthetic excellence, ethical responsibility, and operational efficiency. For designers and manufacturers creating leather garments—from jackets and skirts to accessories—faux leather (synthetic leather) has emerged as the strategic material of choice. Unlike traditional leather, modern faux leather delivers consistent quality, design versatility, and alignment with evolving sustainability mandates without compromising on the luxurious look and feel essential to high-end apparel.

Why Faux Leather is the Optimal Choice for Garment Applications

- Ethical & Traceable Sourcing: Eliminates reliance on animal hides, addressing growing consumer and regulatory pressure for cruelty-free supply chains. Full material transparency is achievable from production to finished garment.

- Design Precision & Consistency: Offers uniform texture, color, and thickness across every batch, eliminating natural hide variations. Enables intricate embossing, digital printing, and custom finishes critical for fashion-forward collections.

- Performance Tailored for Apparel: Engineered for superior flexibility, breathability, and drape—key requirements for wearable garments. Resists cracking during movement and maintains integrity through repeated wear and washing cycles.

- Sustainability Integration: Significantly reduces water consumption, chemical usage, and land impact compared to conventional leather tanning. Compatible with recycled PET, plant-based polyols, and bio-PU technologies for measurable carbon footprint reduction.

- Cost & Supply Chain Efficiency: Mitigates volatility in raw hide markets and complex tanning lead times. Streamlines production with predictable roll goods and reduced waste through precise cutting.

Introducing WINIW: Your Trusted Partner in Advanced Synthetic Leather

With over 20 years of specialized expertise in developing high-performance synthetic leather for the global fashion and apparel industry, WINIW is a leader in innovation and sustainable material science. We partner with forward-thinking brands to transform design visions into market-ready garments through:

- Deep Technical Collaboration: Our R&D team works directly with your designers to customize weight, hand feel, colorfastness, and functional properties (e.g., water resistance, stretch recovery) for specific garment applications.

- Eco-Conscious Manufacturing: All WINIW faux leather is produced in ISO 14001-certified facilities using bluesign® approved processes. Our portfolio includes premium options with >30% recycled content and PFC-free finishes.

- Reliable Scale & Quality: Serving Tier-1 fashion brands worldwide, we guarantee batch-to-batch consistency and on-time delivery for collections of any volume, backed by rigorous QC protocols.

- Future-Forward Innovation: Continuously investing in next-gen materials like bio-based PU and circular economy solutions to help brands exceed evolving ESG targets.

For the fashion industry, faux leather is no longer a compromise—it’s the intelligent foundation for creating desirable, responsible, and commercially viable leather garments. WINIW empowers your brand to lead with materials that deliver uncompromised quality, ethics, and environmental stewardship. Let’s redefine the future of leather apparel, together.

Technical Performance & Standards

WINIW Leather Garment Fabric – B2B Product Guide

WINIW specializes in high-performance synthetic leather fabrics engineered for the fashion and apparel industry. Our leather garment fabric combines technical innovation with sustainable manufacturing practices, offering brands a premium alternative to genuine leather. Designed for cost efficiency, long-term durability, and full customization, WINIW’s fabric supports eco-conscious production without compromising on quality or aesthetics.

Key Technical Advantages

-

Cost-Effective Production: WINIW’s manufacturing process reduces material waste and energy consumption, translating into lower production costs for partners. The fabric requires no animal sourcing, tanning, or extensive water use, significantly lowering input costs compared to traditional leather.

-

Superior Durability: Engineered with high-tenacity polyurethane and reinforced backings, WINIW’s fabric offers excellent abrasion resistance, tensile strength, and dimensional stability. It withstands repeated flexing and environmental exposure, ensuring longevity in garments such as jackets, pants, and accessories.

-

Customizable Colors and Finishes: We offer full color customization with precise Pantone matching and a wide range of surface textures (matte, glossy, embossed, soft-touch). Our digital color management system ensures batch-to-batch consistency across large production runs.

-

REACH Compliant: WINIW’s leather garment fabric is fully compliant with EU REACH regulations (Registration, Evaluation, Authorization, and Restriction of Chemicals). All dyes, pigments, and additives are rigorously tested to exclude SVHCs (Substances of Very High Concern), ensuring safety for consumers and the environment.

-

ISO 9001 Certified Quality Management: Our production facilities are ISO 9001 certified, guaranteeing consistent quality control, traceability, and continuous improvement across all stages of manufacturing—from raw material sourcing to finished roll goods.

Technical Specifications

| Property | Specyfikacja |

|---|---|

| Base Material | High-density polyester knit + PU coating |

| Thickness | 0.6 mm – 1.2 mm (customizable) |

| Weight | 280 – 450 g/m² |

| Tensile Strength (MD) | ≥ 80 N/3cm |

| Elongation at Break (MD) | ≤ 25% |

| Color Fastness (Rubbing) | Dry: 4–5, Wet: 4 (ISO 105-X12) |

| Light Fastness | ≥ 4–5 (ISO 105-B02) |

| Martindale Abrasion | ≥ 30,000 cycles |

| REACH SVHC Status | Compliant (No restricted substances detected) |

| ISO Certification | ISO 9001:2015 |

| Eco-Friendly Processing | Azo-free, low-VOC, water-based coating |

WINIW’s leather garment fabric is ideal for fashion brands seeking sustainable, high-quality materials without sacrificing performance or design flexibility. Our B2B model supports bulk orders, rapid prototyping, and co-development opportunities to meet evolving market demands.

Why Choose Synthetic over Real Leather

B2B Product Guide: Synthetic Leather Garment Fabric vs. Real Leather

As a leader in sustainable material innovation, WINIW provides this objective comparison to support informed procurement decisions for fashion and apparel brands. “Leather garment fabric” in this context refers to high-performance synthetic alternatives (primarily PU/PVC-based), engineered specifically for garment applications, distinct from lower-grade faux leathers. Real leather denotes full-grain or top-grain bovine hides processed through traditional tanning.

Key Differentiators Summary

- Material Origin: Synthetic leather garment fabric is derived from polymer bases (e.g., PU, recycled PET) with advanced finishing; real leather is a natural byproduct of the meat industry.

- Application Suitability: Synthetics offer consistent thickness, dyeability, and design flexibility critical for complex garment patterns; real leather varies naturally in grain and texture.

- Sustainability Leverage: Modern synthetics like WINIW’s eco-series drastically reduce water/chemical use versus conventional tanning, aligning with circular economy goals.

Comparative Analysis: Core Attributes

| Attribute | Real Leather | Synthetic Leather Garment Fabric (WINIW Grade) |

|---|---|---|

| Cost | Higher raw material cost (€25-€80/m²). Significant labor/waste in cutting due to hide irregularities. Long-term value via aging patina. | Lower upfront cost (€12-€35/m²). Near-zero waste in precision cutting. Lower logistics cost (lighter weight). Total cost of ownership often 20-30% lower at scale. |

| Trwałość | High tensile strength; develops character with use but prone to water damage, staining, and irreversible stretching. Requires specialized care. | Consistent abrasion resistance (WINIW: 50,000+ Martindale cycles). Resists water, stains, and UV fading. Minimal stretching. Easy-care (machine-washable options available). |

| Eco-Friendliness | High environmental burden: 15,000-20,000L water/finished hide, toxic chrome tanning (70% of global production), methane from landfills. Biodegradable but slow (decades). | WINIW Eco-Series: 90% less water, zero chrome, 40-60% lower CO2 vs. chrome-tanned leather. Uses recycled content (e.g., 30% rPET). Fully recyclable via closed-loop systems. Biodegradability varies by formulation (WINIW offers TÜV-certified compostable grades). |

Strategic Advantages for B2B Partners

- Supply Chain Resilience: Synthetic leather avoids hide scarcity/volatility; WINIW guarantees 99.5% batch-to-batch color/texture consistency.

- Design Agility: Enables ultra-thin weights (0.3-0.6mm), 3D embossing, and digital printing unachievable with real leather.

- Compliance Assurance: Meets EU REACH, ZDHC, and GRS standards out-of-the-box; eliminates deforestation/land-use risks associated with leather.

- End-of-Life Management: WINIW’s circular solutions (e.g., take-back programs) support brand EPR obligations, unlike leather’s limited recycling infrastructure.

WINIW’s synthetic leather garment fabrics deliver performance parity with real leather while addressing critical ESG mandates. For brands scaling sustainable collections without compromising quality, our engineered materials provide a future-proof alternative validated by global apparel leaders. Request our technical datasheets for ISO-certified performance metrics.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative, eco-friendly materials for global B2B clients. With a strong foundation in research, production excellence, and international compliance, WINIW serves diverse industries including automotive, fashion, furniture, and sports.

Our manufacturing capabilities are anchored in a state-of-the-art production facility spanning 100,000 square meters. This expansive campus integrates advanced manufacturing lines with sustainable practices, enabling high-volume output without compromising quality or environmental responsibility.

Key strengths of the WINIW factory include:

- Large-Scale Production Capacity: The 100,000 sqm facility supports end-to-end manufacturing, from resin synthesis and coating to finishing and testing, ensuring consistent supply for global partners.

- Dedicated R&D Team: A professional research and development team of over 100 engineers drives continuous innovation, developing new textures, performance features, and eco-conscious materials such as water-based and recycled PU leather.

- Strict Quality Control System: WINIW implements a comprehensive QC process at every stage—from raw material inspection to final product validation. Our lab conducts rigorous testing for durability, color fastness, chemical compliance (REACH, RoHS, CA Prop 65), and environmental standards.

- Global Export Expertise: WINIW products are exported to Europe, the USA, Japan, and other key markets, meeting stringent international regulations and client-specific requirements. Our logistics network ensures reliable, on-time delivery worldwide.

WINIW is committed to sustainable innovation and operational excellence, making us a trusted partner for brands seeking high-quality, responsible synthetic leather solutions.

Contact Us for Samples

WINIW Microfiber Leather: Premium Synthetic Leather for High-End Garment Manufacturing

WINIW Microfiber Leather delivers uncompromising quality, sustainability, and performance for fashion brands committed to ethical production. Engineered specifically for demanding garment applications—from tailored jackets and skirts to contemporary accessories—our material replicates the luxurious drape, softness, and durability of premium genuine leather while eliminating environmental and ethical concerns. As a leader in eco-conscious synthetics, WINIW supports B2B partners in achieving circular design goals without sacrificing aesthetic or functional excellence.

Core Advantages for Garment Production

- Superior Softness & Drape: Ultra-fine microfiber structure mimics natural grain movement, ensuring seamless tailoring and comfort in finished garments.

- Consistent Quality: Eliminates hide variations (scars, stretch marks), reducing waste and streamlining cutting efficiency by up to 15%.

- Eco-Engineered Composition: Made from 60%+ recycled polyester and water-based PU resins; free of DMF, heavy metals, and PVC.

- Trwałość: 50,000+ double rubs (Martindale test), resistant to cracking, peeling, and UV degradation—ideal for long-lasting apparel.

- Oddychalność: Micro-porous backing enhances moisture management, critical for wear comfort in all-season garments.

- Designer Flexibility: Customizable weight (0.6–1.2mm), thickness, embossing, and color matching (Pantone®/RAL) for brand-specific needs.

Performance Comparison: WINIW vs. Traditional Materials

| Property | WINIW Microfiber Leather | Genuine Leather | Conventional PVC Leather |

|---|---|---|---|

| Sustainability | 60%+ recycled content; OEKO-TEX® STANDARD 100 certified | Resource-intensive (land/water); tanning pollutants | Non-recyclable; contains phthalates & chlorine |

| Water Absorption | ≤ 8% (controlled breathability) | High (requires conditioning) | Near-zero (non-breathable) |

| Tensile Strength | 25–35 N/mm² | 15–25 N/mm² | 10–20 N/mm² |

| Eco-Certifications | GRS, OEKO-TEX®, ISO 14001 | Limited (leather working group tiered) | Rarely certified |

| Waste Reduction | Uniform roll goods; ≤5% cutting waste | Hide defects; 20–30% waste | Moderate defects; 10–15% waste |

Why Global Fashion Brands Choose WINIW

- Supply Chain Resilience: Stable pricing and availability unaffected by livestock market volatility.

- Circularity Support: Compatible with chemical recycling programs; biodegradable under industrial composting (EN 13432).

- Compliance Ready: Meets EU REACH, CPSIA, and Japan’s Chemical Substances Control Law (CSCL) out-of-box.

- Sample Efficiency: Request cut-to-size swatches (15x15cm) for immediate design validation.

Elevate Your Garment Line with Sustainable Luxury

Discover how WINIW Microfiber Leather transforms design potential while advancing your ESG commitments. Request free cut-to-size samples for your next collection development cycle:

→ Contact WINIW’s B2B Solutions Team: MKT88@MicrofiberLeather.com

Specify “Leather Garment Fabric Inquiry” for priority processing. Samples ship within 48 hours.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.