Catalog

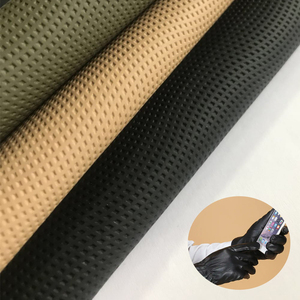

Material Insight: Leather Designer Fabric

Leather Designer Fabric: The Modern Material Standard

For designers and manufacturers demanding exceptional aesthetics, performance, and responsibility, leather designer fabric represents the pinnacle of surface material innovation. This category transcends traditional upholstery and finishing applications, requiring materials that deliver precise color matching, intricate texture replication, superior durability, and alignment with evolving sustainability mandates. In this demanding landscape, high-performance faux leather (synthetic leather) has emerged not merely as an alternative, but as the optimal choice for forward-thinking design projects.

Why Faux Leather is the Superior Choice for Designer Fabric Applications

Faux leather surpasses both genuine leather and inferior synthetics in critical areas essential for premium design:

- Unmatched Design Freedom: Achieve exact color consistency, repeatable complex textures (from ultra-smooth nappa to deep embossed patterns), and bespoke finishes impossible with natural hide variations.

- Ethical & Traceable Sourcing: Eliminate concerns over animal welfare and opaque supply chains; our materials are certified cruelty-free and produced under strict ethical manufacturing standards.

- Superior Performance Consistency: Deliver uniform thickness, strength, and wear resistance across every meter, batch after batch, ensuring flawless production and long-term product integrity.

- Enhanced Sustainability Profile: Utilize significantly less water and land than leather tanning, incorporate recycled content (e.g., ocean-bound plastics, post-industrial fibers), and offer end-of-life recyclability pathways – aligning with circular economy goals.

- Tailored Technical Properties: Engineer specific characteristics like enhanced UV resistance, flame retardancy (meeting global standards), cold crack resistance, and ease of cleaning – critical for automotive, hospitality, and high-traffic commercial use.

Introducing WINIW: Your Trusted Partner in Premium Synthetic Leather (20+ Years Expertise)

WINIW is a global leader in the research, development, and production of high-end synthetic leather solutions, serving discerning B2B clients across automotive interiors, luxury furniture, consumer electronics, and aviation for over two decades. We don’t just supply materials; we provide engineered surface solutions grounded in deep material science expertise.

Our commitment drives every innovation:

– Decades of Specialized R&D: Leveraging 20+ years of focused experience to solve complex material challenges and anticipate industry shifts.

– Eco-Conscious Manufacturing: Pioneering waterless coating technologies, utilizing certified recycled resources (GRS, RCS), and maintaining ISO 14001-certified facilities to minimize environmental impact.

– Collaborative Partnership Approach: Working closely with your design and engineering teams from concept to量产 to ensure our leather designer fabric perfectly integrates with your product vision and production processes.

– Global Quality Assurance: Rigorous in-house testing against international standards (ISO, ASTM, OEM specs) guarantees reliability, safety, and longevity in the most demanding applications.

Choose WINIW leather designer fabric to elevate your products with the perfect fusion of aesthetic excellence, uncompromising performance, and authentic sustainability – the definitive choice for the modern design professional.

Technical Performance & Standards

WINIW Leather Designer Fabric – B2B Product Guide

WINIW’s Leather Designer Fabric is engineered for commercial clients seeking a high-performance, sustainable, and aesthetically versatile alternative to traditional leather. Designed for industries ranging from furniture and automotive interiors to fashion accessories and retail displays, this synthetic leather delivers premium quality with enhanced production efficiency and environmental responsibility.

Key Technical Advantages

-

Cost-Effective Production

WINIW’s manufacturing process optimizes material yield and reduces waste, resulting in lower overall production costs. The fabric requires no animal sourcing, tanning, or water-intensive processes, significantly cutting input expenses and lead times. -

Superior Durability

Reinforced with high-tenacity polyester backings and wear-resistant polyurethane (PU) coatings, the material exhibits excellent abrasion resistance, tear strength, and dimensional stability. Suitable for high-traffic commercial applications, it maintains integrity under prolonged use and challenging conditions. -

Customizable Colors & Finishes

WINIW offers full color customization through digital shade matching (Pantone, RAL, or custom references). Clients can also select from a variety of textures (suede, grain, smooth, embossed) and surface treatments (matte, glossy, anti-scratch) to align with brand-specific design requirements. -

REACH-Compliant Chemistry

Formulated without SVHCs (Substances of Very High Concern), phthalates, heavy metals, or azo dyes, WINIW’s Leather Designer Fabric meets EU REACH regulations. This ensures safe handling, reduced environmental impact, and compliance with global market standards. -

ISO 9001-Certified Quality Management

Every stage of production—from raw material sourcing to final inspection—is governed by ISO 9001 standards. This guarantees consistent product quality, traceability, and process reliability across all batches and order volumes.

Technical Specifications

| Property | Specyfikacja |

|---|---|

| Base Material | High-tenacity polyester fabric |

| Coating | Polyurethane (PU) with optional PE backing |

| Thickness Range | 0.6 mm – 1.2 mm |

| Weight Range | 280 g/m² – 450 g/m² |

| Abrasion Resistance | >50,000 cycles (Martindale test) |

| Color Fastness to Rubbing | Grade 4–5 (dry), Grade 4 (wet) |

| Light Fastness | >4 (Blue Scale, ISO 105-B02) |

| Tensile Strength | ≥80 N/5 cm (warp and weft) |

| Tear Strength | ≥8 N (Elmendorf test) |

| REACH Status | Compliant (SVHC-free) |

| ISO Certification | ISO 9001:2015 |

| Customization Options | Full color, texture, and width (up to 1.5 m) |

WINIW’s Leather Designer Fabric combines industrial efficiency with eco-conscious innovation, offering B2B partners a scalable, reliable, and sustainable material solution. With in-house R&D and rapid prototyping capabilities, we support OEMs and designers in accelerating time-to-market while maintaining strict environmental and quality benchmarks.

Why Choose Synthetic over Real Leather

B2B Product Guide: Synthetic Leather vs. Real Leather for Commercial Applications

As a leader in sustainable material innovation, WINIW provides high-performance synthetic leather solutions engineered for demanding commercial sectors including automotive, furniture, and contract interiors. Understanding the critical differences between synthetic leather (“leather designer fabric”) and real leather is essential for strategic procurement, cost management, and sustainability compliance. Below is an objective comparison focused on key operational metrics.

Core Comparison: Synthetic Leather vs. Real Leather

| Metric | Synthetic Leather (WINIW) | Real Leather |

|---|---|---|

| Cost Efficiency | 20-40% lower material cost; consistent pricing unaffected by hide scarcity or tannery volatility. Predictable bulk-order pricing. | 30-50% higher base cost; subject to significant fluctuations due to livestock markets, hide quality variance, and complex tanning logistics. |

| Durability & Performance | Engineered for uniform strength; resistant to UV fading, moisture, stains, and abrasion. No splitting or grain damage. Ideal for high-traffic/commercial use. | Natural variations in hide strength; susceptible to cracking, water damage, and fading without rigorous maintenance. Requires conditioning to prevent degradation. |

| Eco-Friendliness | 70% less water used in production; zero animal agriculture footprint; 100% phthalate-free & REACH-compliant. Recyclable at end-of-life (WINIW closed-loop programs). | High water/land use in livestock; toxic tannery effluents (chromium); methane emissions. Non-recyclable; landfill-bound at end-of-life. |

Strategic Advantages of WINIW Synthetic Leather for B2B Partners

- Supply Chain Resilience: Eliminate hide scarcity risks and tannery bottlenecks with consistent, scalable production.

- Design Flexibility: Rapid customization of colors, textures, and performance specs (e.g., fire resistance, antimicrobial) without minimum order constraints.

- Total Cost of Ownership: Lower maintenance costs (no conditioning/polishing), reduced waste from inconsistent hides, and longer functional lifespan in harsh environments.

- Compliance Assurance: Meet stringent EU Ecolabel, LEED, and corporate ESG targets with traceable, audited eco-certifications (e.g., OEKO-TEX® STANDARD 100).

- Ethical Sourcing: Zero animal welfare concerns; align with global biodiversity and circular economy mandates.

WINIW’s synthetic leather delivers uncompromised luxury aesthetics while addressing the operational and sustainability imperatives of modern B2B procurement. Partner with us to future-proof your supply chain with materials engineered for performance, planet, and profitability. Request our technical datasheets for sector-specific validation data.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative, sustainable materials for global B2B markets. With a strong commitment to quality and environmental responsibility, WINIW serves industries ranging from automotive and furniture to fashion and technical textiles.

The company operates from a state-of-the-art manufacturing facility spanning 100,000 square meters, making it one of the largest production bases for synthetic leather in Asia. This extensive facility integrates advanced production lines with automated systems to ensure high efficiency, consistent output, and scalability for large-volume orders.

Key strengths of WINIW’s factory operations include:

-

Advanced R&D Team: A dedicated research and development team of over 150 experts drives continuous innovation. The team focuses on eco-friendly formulations, performance enhancement, and custom material solutions tailored to client specifications. WINIW invests significantly in material science, regularly launching new products that meet evolving industry standards.

-

Strict Quality Control (QC) System: WINIW implements a comprehensive QC process at every stage of production—from raw material inspection to final product validation. The facility is ISO 9001 and IATF 16949 certified, ensuring adherence to international quality benchmarks. All products undergo rigorous testing for durability, color fastness, abrasion resistance, and chemical compliance (including REACH, RoHS, and CPSIA).

-

Sustainability Integration: The factory utilizes water-based, solvent-free production technologies to minimize environmental impact. Waste reduction, energy efficiency, and closed-loop water systems are embedded into daily operations, aligning with global ESG goals.

WINIW exports to key markets worldwide, with a strong presence in Europe and the USA. Its products are trusted by major automotive OEMs, premium furniture brands, and eco-conscious fashion labels. The company maintains regional logistics hubs to ensure fast, reliable delivery and responsive customer support.

| Feature | Specyfikacja |

|---|---|

| Factory Size | 100,000 sqm |

| R&D Team | 150+ specialists |

| Certifications | ISO 9001, IATF 16949, REACH, RoHS, CPSIA |

| Production Capacity | 30 million meters/year |

| Export Regions | Europe, USA, Japan, South Korea, Southeast Asia |

With a proven track record in innovation, quality, and global compliance, WINIW stands as a strategic partner for businesses seeking high-performance, sustainable synthetic leather solutions.

Contact Us for Samples

WINIW Microfiber Leather: Premium Designer Fabric for Sustainable Innovation

WINIW delivers high-performance synthetic leather engineered for discerning B2B partners in fashion, automotive, and furniture design. Our microfiber leather solutions combine luxury aesthetics with uncompromising eco-credentials, supporting your brand’s sustainability goals without sacrificing durability or tactile excellence. All materials are REACH-compliant, OEKO-TEX® STANDARD 100 certified, and incorporate up to 40% recycled content.

Core Advantages for Design Partners

- Superior Performance: 50,000+ double-rub abrasion resistance (ASTM D4157), 20% higher tear strength vs. conventional PU leather

- Eco-Integrity: Water-based manufacturing, zero DMF solvents, and 30% lower carbon footprint than traditional leather

- Design Flexibility: 1,200+ color/texture options including vegan embossing, metallic finishes, and custom printability

- End-of-Life Responsibility: Fully recyclable through WINIW’s closed-loop take-back program

Product Line Specifications

| Product Series | Thickness (mm) | Weight (g/m²) | Key Applications | Sustainability Highlight |

|---|---|---|---|---|

| WINIW ECO-LUX | 0.6–1.2 | 280–420 | Handbags, Footwear | 100% recycled polyester base |

| WINIW AUTO-GRADE | 1.0–1.8 | 450–620 | Automotive Interiors | Low-VOC, flame-retardant (FMVSS 302) |

| WINIW HOME-TEXTURE | 0.8–1.5 | 350–500 | Upholstery, Wall Panels | OEKO-TEX® certified, antimicrobial |

Why Partner with WINIW?

- Speed to Market: 15-day sample turnaround from digital color request

- Scalable Production: 300,000+ linear meters monthly capacity

- Technical Collaboration: Dedicated R&D team for custom substrate development

- Certified Transparency: Full LCA reports and GRSS chain-of-custody documentation

Elevate your design portfolio with materials that meet tomorrow’s sustainability standards today. WINIW microfiber leather delivers the aesthetic richness of premium hide with the ethical assurance modern consumers demand.

Request Free Samples for Your Next Collection

Contact our Material Innovation Team:

MKT88@MicrofiberLeather.com

Specify “Designer Fabric Sample Kit” in your inquiry. Complimentary 30cm x 30cm swatches available for qualified B2B partners.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.