Introduction: Navigating the Global Market for automobile upholstery fabric

In today’s competitive landscape, sourcing high-quality automobile upholstery fabric poses a significant challenge for international B2B buyers. As the automotive industry evolves, so do the demands for upholstery materials that not only enhance aesthetics but also offer durability, comfort, and sustainability. This comprehensive guide serves as a vital resource for stakeholders in Africa, South America, the Middle East, and Europe—regions where the automotive market is thriving and evolving.

Throughout this guide, we delve into the various types of upholstery fabrics available, including leather, vinyl, and innovative synthetic options, each with distinct benefits tailored to different applications. We address critical factors such as supplier vetting processes, cost considerations, and the importance of aligning material choices with specific automotive needs. By providing actionable insights and expert recommendations, this guide empowers B2B buyers to make informed purchasing decisions that enhance both the functionality and appeal of their vehicles.

Whether you are a manufacturer, distributor, or retailer, navigating the complexities of the global market for automobile upholstery fabric requires a strategic approach. This guide is designed to equip you with the knowledge and tools needed to optimize your sourcing strategies, ensuring you remain competitive in a rapidly changing industry.

Table Of Contents

- Top 8 Automobile Upholstery Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for automobile upholstery fabric

- Understanding automobile upholstery fabric Types and Variations

- Key Industrial Applications of automobile upholstery fabric

- 3 Common User Pain Points for ‘automobile upholstery fabric’ & Their Solutions

- Strategic Material Selection Guide for automobile upholstery fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for automobile upholstery fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘automobile upholstery fabric’

- Comprehensive Cost and Pricing Analysis for automobile upholstery fabric Sourcing

- Alternatives Analysis: Comparing automobile upholstery fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for automobile upholstery fabric

- Navigating Market Dynamics and Sourcing Trends in the automobile upholstery fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of automobile upholstery fabric

- Strategic Sourcing Conclusion and Outlook for automobile upholstery fabric

- Important Disclaimer & Terms of Use

Understanding automobile upholstery fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

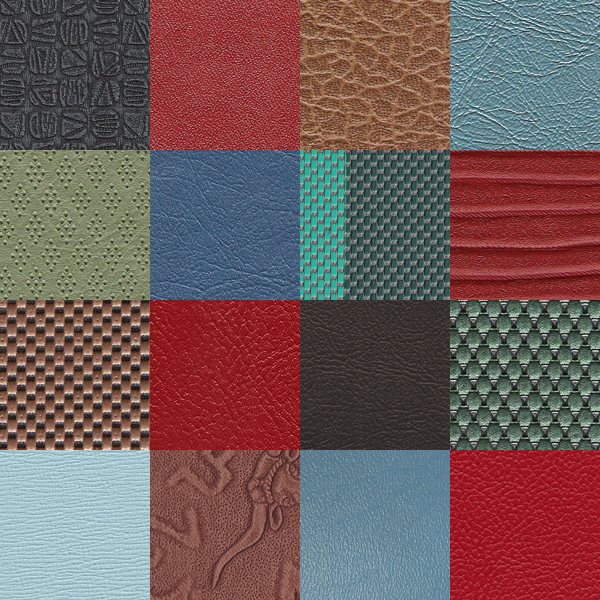

| Leather Upholstery | Luxurious feel, durable, ages well, easy to clean | High-end vehicles, luxury car restorations | Pros: Long-lasting, sophisticated look. Cons: Expensive, requires maintenance. |

| Vinyl Upholstery | Affordable alternative to leather, stain-resistant | Fleet vehicles, budget-conscious markets | Pros: Cost-effective, easy to maintain. Cons: Less breathable, can feel sticky in heat. |

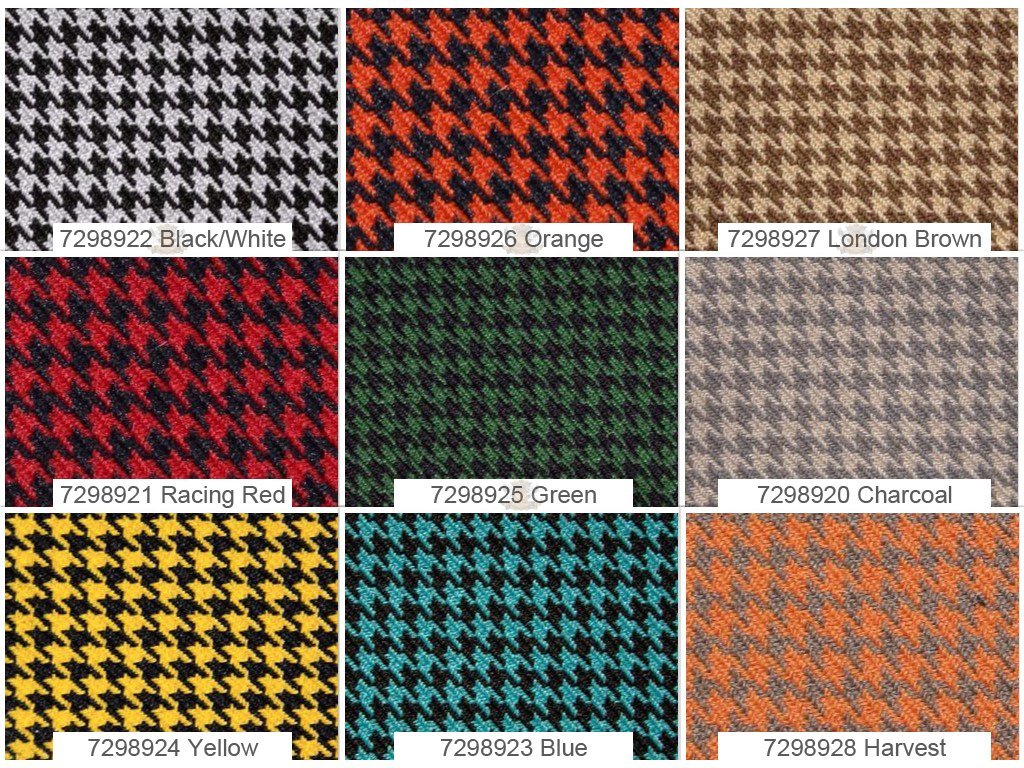

| Fabric Upholstery | Soft, breathable, customizable in colors and patterns | Family vehicles, custom interiors | Pros: Comfortable, versatile. Cons: Prone to staining, may wear out faster. |

| Synthetic Fabrics | Soft feel, durable, stain-resistant, budget-friendly | Mass-market vehicles, aftermarket upgrades | Pros: Affordable, easy to clean. Cons: Less luxurious, potential for wear over time. |

| Mikrofibra | Ultra-soft, high durability, resistant to stains | Luxury vehicles, custom upholstery | Pros: Luxurious feel, great durability. Cons: Can be more expensive than other synthetics. |

What are the Characteristics of Leather Upholstery for B2B Buyers?

Leather upholstery is often regarded as the pinnacle of luxury in automobile interiors. Its distinguishing features include a sophisticated appearance and exceptional durability, making it a popular choice for high-end vehicles and luxury restorations. When considering leather, B2B buyers should note that while it offers a long-lasting and easy-to-clean solution, it comes with a higher price point and requires regular maintenance to keep it looking pristine. This makes it ideal for businesses aiming to enhance their brand image through premium vehicle interiors.

How Does Vinyl Upholstery Serve Budget-Conscious Markets?

Vinyl upholstery stands out as a cost-effective alternative to leather, providing a similar aesthetic without the hefty price tag. It is particularly well-suited for fleet vehicles and budget-conscious markets, where durability and ease of maintenance are paramount. Vinyl is stain-resistant and easy to clean, making it an excellent choice for vehicles that see heavy use. However, buyers should consider that while vinyl is practical, it lacks breathability, which can lead to discomfort in hot climates.

Why is Fabric Upholstery Popular Among Family Vehicle Manufacturers?

Fabric upholstery is characterized by its soft, breathable nature and wide range of customizable colors and patterns. This makes it a favored choice for family vehicles and businesses that prioritize comfort and personalization. While fabric offers excellent versatility and comfort, B2B buyers must be aware that it is more susceptible to staining and may require more frequent replacements than leather or vinyl. The trade-off between comfort and maintenance costs is a crucial consideration for companies looking to balance quality and budget.

What Advantages Do Synthetic Fabrics Offer in Mass-Market Vehicles?

Synthetic fabrics, including options like polyester and nylon, provide a soft feel combined with impressive durability and stain resistance. These materials are commonly used in mass-market vehicles and aftermarket upgrades, where cost-effectiveness is essential. B2B buyers should appreciate that synthetic fabrics often offer a good balance of affordability and performance, making them suitable for high-volume production. However, they may not deliver the same luxurious feel as leather or microfiber, which could influence buyer decisions based on market positioning.

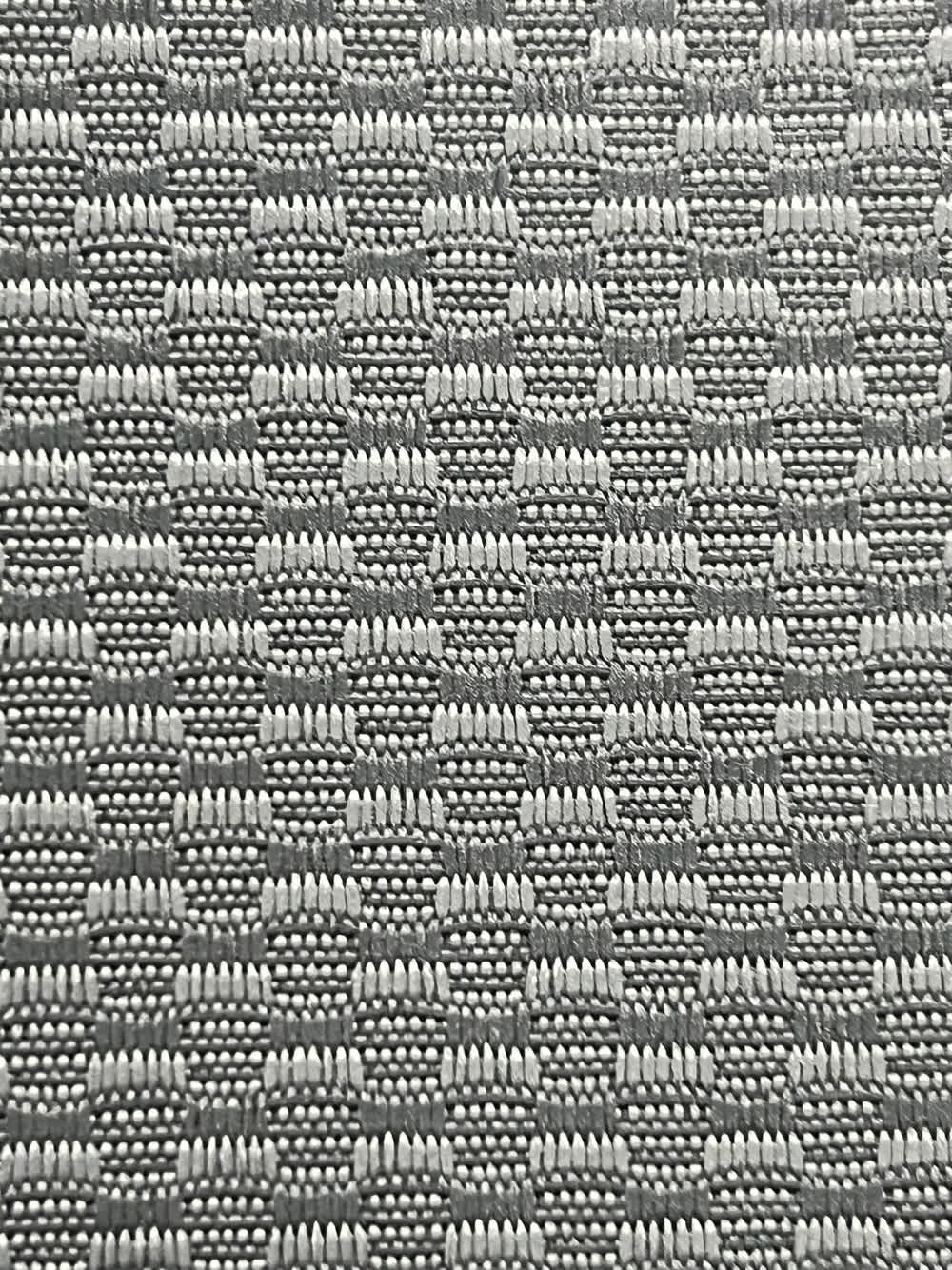

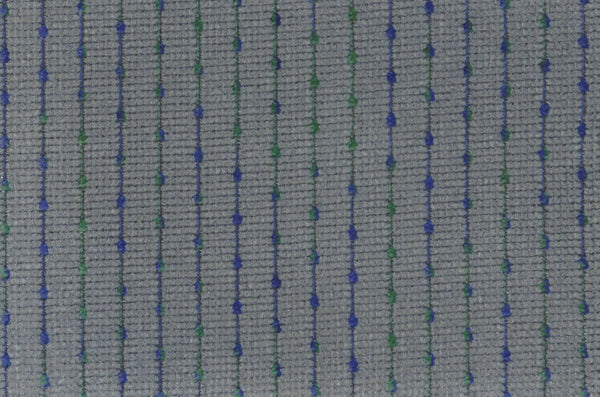

Illustrative image related to automobile upholstery fabric

What Makes Microfiber a Luxurious Choice for Custom Upholstery?

Microfiber is an ultra-soft synthetic fabric that boasts high durability and excellent stain resistance, making it a compelling choice for luxury vehicles and custom upholstery projects. Its luxurious feel can elevate the interior experience while still being practical for everyday use. For B2B buyers, the key consideration is the balance between the initial investment and the long-term benefits of durability and ease of maintenance. While microfiber may carry a higher price tag than other synthetic options, its performance and aesthetic appeal can justify the expense in premium markets.

Key Industrial Applications of automobile upholstery fabric

| Industry/Sector | Specific Application of automobile upholstery fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Interior seating for vehicles | Enhances vehicle comfort and aesthetic appeal | Durability, compliance with safety standards |

| Commercial Transport | Upholstery for buses and coaches | Improves passenger comfort and vehicle branding | Stain resistance, ease of maintenance |

| Automotive Restoration | Custom upholstery for classic cars | Increases resale value and aesthetic quality | Authenticity of materials, customization options |

| Fleet Management | Upholstery for company vehicles | Ensures durability and professional appearance | Cost-effectiveness, bulk purchasing options |

| Luxury Vehicle Production | High-end upholstery for premium vehicles | Elevates brand perception and customer satisfaction | Material quality, sourcing from sustainable suppliers |

How is Automobile Upholstery Fabric Used in Automotive Manufacturing?

In the automotive manufacturing sector, upholstery fabric is primarily utilized for the interior seating of vehicles. This application not only enhances passenger comfort but also plays a critical role in the vehicle’s overall aesthetic appeal. Buyers in this sector need to consider the durability of fabrics, as well as compliance with safety standards, ensuring that materials can withstand wear and tear while providing a visually appealing interior. International buyers should also be aware of local regulations regarding vehicle interiors, particularly in regions like Europe, where stringent safety guidelines are enforced.

What Role Does Upholstery Fabric Play in Commercial Transport?

For the commercial transport industry, upholstery fabric is essential in buses and coaches, where it enhances passenger comfort and contributes to the vehicle’s branding. Durable and stain-resistant fabrics are crucial, as these vehicles often experience high traffic and require easy maintenance. Buyers must prioritize materials that can withstand frequent cleaning and heavy usage. Additionally, understanding regional preferences for colors and patterns can help businesses better cater to local markets, particularly in diverse regions such as Africa and South America.

Illustrative image related to automobile upholstery fabric

Why is Automobile Upholstery Important for Automotive Restoration?

In the automotive restoration industry, custom upholstery fabric is vital for revamping classic cars. This application not only increases the vehicle’s resale value but also enhances its aesthetic quality. Buyers in this sector typically seek authenticity in materials to maintain the original charm of the vehicle. Customization options are also essential, allowing restorers to match the original upholstery as closely as possible. International buyers should consider sourcing from suppliers who specialize in vintage materials to ensure quality and authenticity.

How Does Upholstery Fabric Benefit Fleet Management?

Fleet management companies utilize upholstery fabric for their company vehicles to ensure a professional appearance and durability. The choice of fabric can significantly impact the vehicle’s longevity and overall maintenance costs, making it crucial for buyers to focus on cost-effectiveness and bulk purchasing options. Additionally, selecting materials that offer easy cleaning and maintenance can lead to significant time and cost savings. Buyers from regions with varying climates, such as the Middle East, should also consider temperature resistance and breathability of the fabrics.

What is the Significance of High-End Upholstery in Luxury Vehicle Production?

In luxury vehicle production, high-quality upholstery fabric is a key element that elevates brand perception and enhances customer satisfaction. Premium materials are often chosen for their luxurious feel and durability, which can significantly affect the vehicle’s marketability. Buyers in this sector must prioritize sourcing from suppliers who provide exceptional quality and sustainable materials, as eco-conscious consumers are increasingly influencing purchasing decisions. Understanding the latest trends in luxury upholstery can also help businesses stay competitive in the European and South American markets.

3 Common User Pain Points for ‘automobile upholstery fabric’ & Their Solutions

Scenario 1: Navigating Material Durability for High-Use Vehicles

The Problem: B2B buyers often face challenges in selecting upholstery fabrics that can withstand the rigors of high-use environments, such as commercial vehicles or cars frequently transporting families or pets. The wrong choice can lead to rapid wear and tear, resulting in costly replacements and dissatisfied customers. Buyers may struggle to balance aesthetic appeal with durability, often leading to a compromise that affects the vehicle’s interior longevity and overall value.

Illustrative image related to automobile upholstery fabric

The Solution: To effectively address this pain point, buyers should prioritize sourcing materials specifically designed for high-traffic use. Conduct thorough research on upholstery fabrics that emphasize durability, such as high-denier synthetic fibers or treated leather options that resist stains and fading. Collaborating with suppliers who provide detailed product specifications and performance testing results can help buyers make informed decisions. Additionally, consider investing in protective treatments or coatings for fabrics that enhance their resistance to spills and abrasions. This proactive approach not only extends the lifespan of the upholstery but also enhances customer satisfaction, as the vehicles will maintain their appearance and functionality over time.

Scenario 2: Balancing Cost and Quality in Upholstery Selection

The Problem: B2B buyers often encounter the challenge of balancing cost with quality when selecting automobile upholstery fabrics. While budget constraints are a reality, compromising too much on quality can lead to poor customer experiences and increased return rates. Buyers may feel pressure to opt for cheaper materials, which can affect the overall reputation of their offerings in the market.

The Solution: To navigate this delicate balance, buyers should adopt a strategic sourcing approach that includes evaluating the total cost of ownership rather than just the upfront price. This involves considering factors such as durability, maintenance needs, and the expected lifespan of the upholstery. Buyers can engage with suppliers who offer samples or trial periods for their fabrics, allowing for real-world testing in various conditions. Additionally, forming partnerships with manufacturers who provide warranties or guarantees can ensure that investments in higher-quality materials are protected. This way, buyers can confidently choose fabrics that enhance their product offerings while remaining within budget constraints.

Scenario 3: Customization Challenges for Diverse Markets

The Problem: International B2B buyers often face difficulties in sourcing upholstery fabrics that meet diverse cultural preferences and local market demands. Different regions may have varying aesthetic standards, climate conditions, and functional requirements, making it challenging to find a fabric that appeals to a broad audience. This can lead to stock discrepancies and missed sales opportunities if the offerings do not resonate with local customers.

The Solution: To overcome these challenges, buyers should implement a localized approach to fabric selection by conducting market research to understand regional trends and preferences. Engaging local designers or upholsterers can provide valuable insights into popular colors, patterns, and materials that resonate within specific markets. Additionally, buyers should consider building relationships with flexible suppliers who can offer a range of customizable options, allowing for tailored solutions that meet local demands. By embracing a more localized strategy in their upholstery sourcing, buyers can enhance their competitiveness and ensure that their products align with customer expectations across different regions.

Illustrative image related to automobile upholstery fabric

Strategic Material Selection Guide for automobile upholstery fabric

What Are the Key Properties of Common Materials Used in Automobile Upholstery Fabric?

When selecting materials for automobile upholstery, it is essential to consider their properties, advantages, and limitations. Here, we analyze four common materials: leather, vinyl, fabric (cloth), and synthetic fabrics. Each material has unique characteristics that cater to different needs and preferences in the automotive industry.

How Does Leather Perform as an Upholstery Material?

Leather is renowned for its luxurious appearance and durability. It typically boasts a high temperature tolerance, making it suitable for various climates. Leather is resistant to wear and tear, and it ages well, developing a unique patina over time. However, it requires regular maintenance to prevent cracking and fading, particularly in extreme temperatures.

Pros: Leather offers a high-end aesthetic, is easy to clean, and has excellent durability. Its ability to withstand daily use makes it a preferred choice for premium vehicles.

Cons: The initial cost of leather is high, and it may require professional cleaning and conditioning. Additionally, it can become uncomfortable in extreme heat or cold without proper ventilation.

Impact on Application: Leather is compatible with luxury vehicles and high-end models, enhancing their resale value. However, it may not be ideal for budget-conscious applications.

Considerations for International Buyers: Buyers from regions with varying climates, such as Africa and the Middle East, should consider the maintenance requirements of leather. Compliance with international standards like ASTM for durability testing is crucial.

What Are the Benefits of Vinyl Upholstery in Automobiles?

Vinyl is a synthetic alternative to leather that provides a similar aesthetic at a lower cost. It is highly durable, resistant to stains, and easy to clean, making it an excellent choice for families and commercial vehicles. Vinyl can withstand a range of temperatures, although it may not be as breathable as leather.

Pros: Vinyl is budget-friendly, available in various colors and textures, and requires minimal maintenance. Its durability makes it suitable for high-traffic areas.

Cons: Vinyl can feel sticky in hot weather and may lack the luxurious feel of leather. Over time, it can show signs of wear, such as cracking.

Impact on Application: Vinyl is often used in vehicles that require easy maintenance and durability, such as taxis or family cars. It is suitable for high-usage applications.

Considerations for International Buyers: Buyers should ensure that the vinyl meets regional compliance standards, such as DIN in Europe, for safety and durability.

Illustrative image related to automobile upholstery fabric

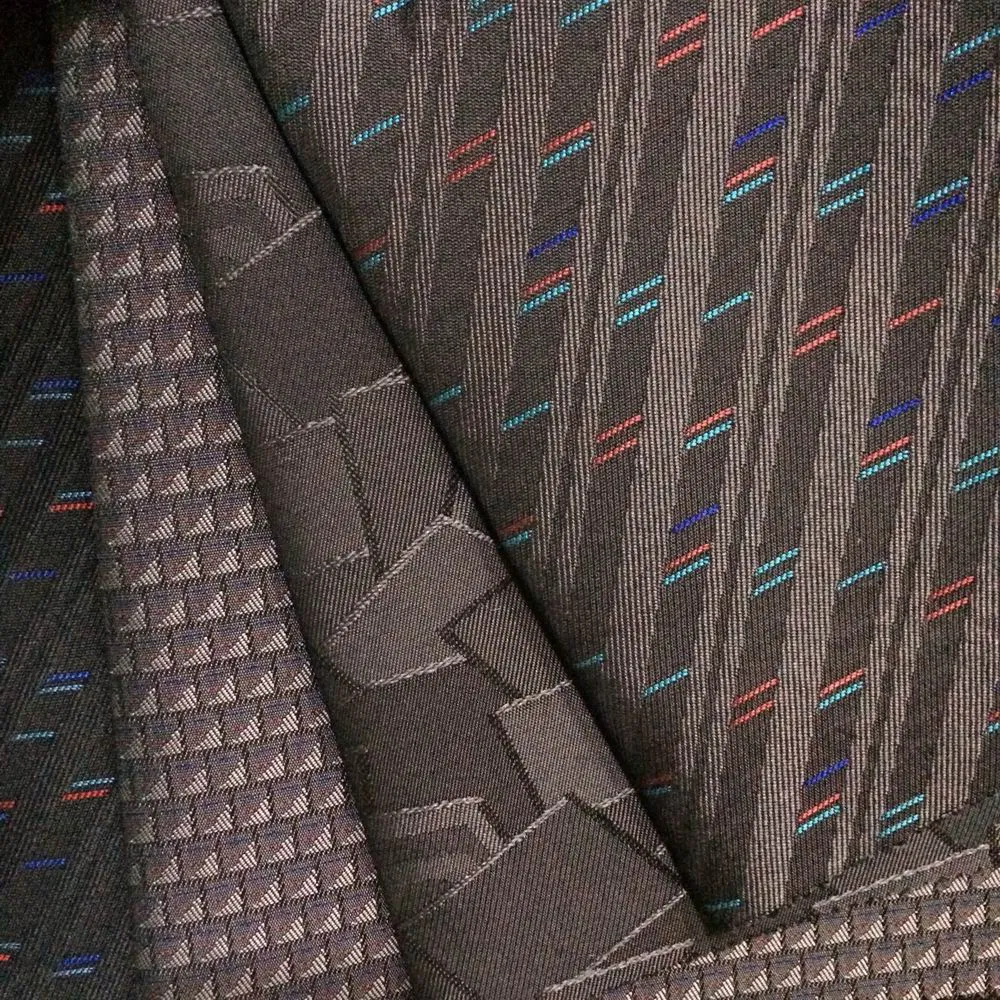

How Does Fabric Upholstery Compare in Terms of Comfort and Customization?

Fabric upholstery, typically made from polyester or cotton blends, is known for its comfort and breathability. It is available in a wide range of colors and patterns, allowing for significant customization. While fabric can be less durable than leather or vinyl, modern treatments have improved its stain resistance and longevity.

Pros: Fabric is comfortable, customizable, and generally more affordable than leather. It provides a cozy feel, making it ideal for long drives.

Cons: Fabric can stain easily and may require more frequent cleaning. It is generally less durable than leather or vinyl, leading to potential wear over time.

Impact on Application: Fabric is well-suited for family vehicles and models targeting younger demographics, where comfort and aesthetics are prioritized.

Illustrative image related to automobile upholstery fabric

Considerations for International Buyers: Buyers should assess the fabric’s compliance with international standards for fire resistance and durability, especially in regions with stringent regulations.

What Advantages Do Synthetic Fabrics Offer for Automobile Upholstery?

Synthetic fabrics, such as microfiber and polyester, combine the softness of natural fibers with enhanced durability. These materials are often treated to be stain-resistant and easy to clean, making them practical for various applications. They can mimic the look of leather while being more affordable.

Pros: Synthetic fabrics are budget-friendly, easy to maintain, and resistant to stains. They provide a soft feel and are available in various designs.

Cons: While they offer durability, synthetic materials may not provide the same luxurious feel as leather. They can also show wear over time.

Impact on Application: Synthetic fabrics are suitable for budget-conscious applications and vehicles that require frequent cleaning, such as fleet vehicles.

Considerations for International Buyers: Buyers should check for compliance with local environmental regulations, as some synthetic materials may not be eco-friendly.

Summary Table of Material Selection for Automobile Upholstery Fabric

| Materiał | Typical Use Case for automobile upholstery fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Luxury vehicles, high-end models | High durability and aesthetic appeal | High cost, requires maintenance | High |

| Vinyl | Family cars, commercial vehicles | Budget-friendly and easy to clean | Less breathable, can wear over time | Medium |

| Fabric (Cloth) | Family vehicles, customizable interiors | Comfortable and highly customizable | Prone to staining, less durable | Low |

| Synthetic Fabrics | Budget-conscious applications, fleet vehicles | Soft, stain-resistant, affordable | May lack luxury feel, shows wear | Low to Medium |

This guide provides a comprehensive overview of common materials used in automobile upholstery, helping international B2B buyers make informed decisions that align with their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for automobile upholstery fabric

What Are the Main Stages in the Manufacturing Process of Automobile Upholstery Fabric?

The manufacturing process of automobile upholstery fabric involves several key stages, each critical to ensuring the final product meets quality and performance standards. Here’s a breakdown of the main stages:

Illustrative image related to automobile upholstery fabric

Material Preparation: How Are Raw Materials Processed for Upholstery Fabric?

The journey begins with the selection and preparation of raw materials. Common materials include natural fibers (like cotton and wool), synthetic fibers (such as polyester and nylon), and leather.

- Sourcing: Manufacturers must ensure that materials are sourced from reputable suppliers to maintain quality.

- Testing: Raw materials undergo testing for strength, color fastness, and durability before production begins. This ensures they meet industry standards.

- Pre-Treatment: Natural fibers may be treated to enhance their properties, such as dye absorption or resistance to mold and mildew.

Forming: What Techniques Are Used to Create Upholstery Fabric?

Once materials are prepared, the next stage is forming the fabric. This involves several processes:

- Weaving/Knitting: The chosen fibers are woven or knitted into fabric. Weaving is common for upholstery due to its durability, while knitting can provide stretch and flexibility.

- Coating: Some upholstery fabrics are coated with a protective layer to enhance stain resistance or water repellency. Techniques include applying a polymer or using lamination processes.

- Dyeing: Fabrics are dyed using various methods, including piece dyeing and solution dyeing, depending on the desired color and finish. Consistency in color is crucial for aesthetic appeal.

Assembly: How Are Upholstery Fabrics Prepared for Installation?

Assembly involves cutting and sewing the fabric into specific patterns that will be used in vehicles.

- Cutting: Using precision cutting tools, the fabric is cut according to the patterns created from the vehicle’s specifications. This stage is critical for ensuring the fabric fits perfectly.

- Sewing: Skilled labor or automated sewing machines stitch the pieces together, focusing on durability and aesthetics. Techniques include double stitching and reinforced seams to enhance longevity.

- Quality Checks: At this stage, initial quality checks are performed to catch any defects in stitching or fabric integrity before moving to finishing.

Finishing: What Processes Ensure the Upholstery Fabric Meets Quality Standards?

The final stage is finishing, which enhances the fabric’s performance and appearance.

- Post-Treatment: Fabrics may undergo additional treatments, such as anti-static or anti-stain coatings, to improve functionality.

- Inspection: Each batch of fabric is inspected for defects, color consistency, and overall quality. This is crucial to ensure the product meets the specifications set by the automotive industry.

- Packaging: Finally, the upholstery fabric is rolled or folded and packaged for shipping. Proper packaging is essential to prevent damage during transport.

What Quality Assurance Practices Are Essential for Automobile Upholstery Fabric?

Quality assurance (QA) is vital in ensuring that the upholstery fabric meets international and industry-specific standards. Here are the key aspects of QA relevant to B2B buyers:

Which International Standards Should B2B Buyers Consider for Upholstery Fabric?

B2B buyers should be aware of various international quality standards that manufacturers may adhere to:

- ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers consistently meet customer and regulatory requirements.

- CE Marking: Required in the European market, CE marking indicates that the product meets EU safety, health, and environmental protection standards.

- API Standards: For specific applications, particularly in high-performance vehicles, manufacturers may follow American Petroleum Institute (API) standards for materials that come into contact with automotive fluids.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integral to maintaining high standards throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials upon arrival. Any substandard materials are rejected.

- In-Process Quality Control (IPQC): During the manufacturing stages, random checks are conducted to ensure processes are followed correctly and defects are caught early.

- Final Quality Control (FQC): Before packaging, a comprehensive inspection assesses the finished products for defects, ensuring they meet all quality and safety standards.

What Common Testing Methods Are Used for Upholstery Fabric?

Testing methods play a crucial role in validating the quality and durability of upholstery fabrics:

- Abrasion Resistance Testing: Measures the fabric’s durability against wear and tear.

- Color Fastness Testing: Evaluates how well the fabric maintains its color when exposed to various conditions, including sunlight and washing.

- Flammability Testing: Ensures the fabric complies with safety regulations regarding fire resistance.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying the quality control practices of suppliers is critical in establishing a trustworthy relationship. Here are some strategies:

- Supplier Audits: Conducting regular audits of suppliers can help assess their adherence to quality standards and manufacturing processes.

- Quality Reports: Request detailed quality reports from suppliers that outline their QC processes, testing results, and compliance with international standards.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices and product quality.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

- Regulatory Compliance: Different regions may have varying regulations that affect material sourcing and product standards. Buyers should ensure their suppliers comply with local regulations.

- Cultural Expectations: Buyers should understand cultural expectations related to quality and performance. For example, European buyers may place a higher emphasis on eco-friendliness and sustainability.

- Logistical Considerations: Quality control measures should also account for the logistics of transporting upholstery fabric across borders, including packaging and handling to prevent damage.

By understanding the manufacturing processes and quality assurance measures in place for automobile upholstery fabric, B2B buyers can make informed decisions when selecting suppliers and materials, ultimately enhancing the quality and appeal of their automotive offerings.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automobile upholstery fabric’

To effectively source automobile upholstery fabric, B2B buyers must navigate a range of considerations that influence both the quality of materials and the reliability of suppliers. This checklist provides a structured approach to ensure you make informed decisions and procure the best upholstery options for your needs.

Step 1: Define Your Technical Specifications

Before beginning the procurement process, clearly outline your technical specifications for the upholstery fabric. Consider factors such as durability, aesthetics, comfort, and functionality. Knowing these details will help you communicate effectively with suppliers and ensure that the materials meet your operational needs.

Step 2: Conduct Market Research

Understanding the current market landscape is crucial. Investigate various fabric types, trends, and pricing in different regions, particularly focusing on your target markets in Africa, South America, the Middle East, and Europe. This research will empower you to identify competitive pricing and innovative materials that align with your specifications.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers who have a proven track record in quality and reliability, ensuring they can meet your volume requirements and delivery timelines.

- Supplier Certifications: Verify if the suppliers have relevant certifications that demonstrate compliance with industry standards, such as ISO or other quality management systems.

Step 4: Request Samples and Test Materials

Always request samples of the upholstery fabric before making a bulk purchase. Testing the samples for durability, comfort, and appearance will give you a tangible sense of what to expect. This step is vital to ensure the fabric meets your standards and is suitable for the intended application in automobiles.

Step 5: Negotiate Pricing and Terms

Once you have selected potential suppliers, engage in negotiations. Discuss pricing, payment terms, and delivery schedules to establish a mutually beneficial agreement. It’s essential to ensure that the cost aligns with your budget while also considering the long-term value of the fabric.

Step 6: Assess Logistics and Supply Chain

Evaluate the logistics capabilities of your selected suppliers. Consider their shipping methods, lead times, and how they manage inventory. A reliable supply chain is crucial to avoid delays and ensure that your upholstery projects can proceed as planned.

Step 7: Establish Quality Control Measures

Finally, establish quality control protocols for incoming materials. Implement inspection processes to ensure that the upholstery fabric received meets your specifications and quality standards. This step helps mitigate risks associated with defective materials and ensures customer satisfaction in your finished products.

By following this checklist, B2B buyers can streamline their procurement process for automobile upholstery fabric, ensuring they source high-quality materials that meet their business needs effectively.

Comprehensive Cost and Pricing Analysis for automobile upholstery fabric Sourcing

What Are the Key Cost Components in Automobile Upholstery Fabric Sourcing?

When sourcing automobile upholstery fabric, understanding the cost structure is vital for making informed purchasing decisions. The primary components that contribute to the overall cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of upholstery fabric significantly influences cost. High-end materials such as leather will naturally incur higher expenses compared to synthetic options like vinyl or polyester. The quality of the fabric, including certifications like flame resistance or eco-friendliness, also impacts pricing.

-

Labor: Labor costs vary based on the complexity of the manufacturing process. Custom upholstery solutions may require skilled artisans, leading to increased labor costs. Standardized products may have lower labor expenses due to streamlined production processes.

-

Manufacturing Overhead: This includes costs associated with utilities, rent, and equipment maintenance. Manufacturers may pass these overhead costs onto buyers, especially if operating in regions with higher operational expenses.

-

Tooling: Custom tooling for specialized designs or fabric cuts can add to the initial costs. This is particularly relevant for bespoke upholstery projects, where unique patterns or specifications are required.

-

Quality Control (QC): Rigorous QC processes ensure that the fabric meets industry standards and client specifications. This additional step can introduce costs but is essential for maintaining product integrity and customer satisfaction.

-

Logistics: Shipping costs can vary significantly based on distance, weight, and the chosen Incoterms. International shipping may involve tariffs and customs duties, which can further affect the overall price.

-

Margin: Suppliers typically include a profit margin that reflects their operational costs and market positioning. Understanding the expected margin can help buyers gauge the reasonableness of pricing.

How Do Price Influencers Affect Automobile Upholstery Fabric Costs?

Several factors influence the pricing of automobile upholstery fabric, which can vary depending on market conditions and buyer specifications.

-

Volume/MOQ: Purchasing in bulk often results in lower unit prices. Buyers should inquire about minimum order quantities (MOQ) and negotiate terms that maximize cost efficiency.

-

Specifications/Customization: Custom orders generally attract higher prices due to additional labor and tooling costs. Buyers should weigh the benefits of customization against their budget constraints.

-

Materials: The type and quality of materials directly affect pricing. Buyers should consider long-term costs associated with durability and maintenance when selecting materials.

-

Quality/Certifications: Fabrics that meet specific industry certifications, such as UV resistance or eco-friendly standards, may command higher prices. Investing in certified fabrics can reduce long-term costs associated with replacements and repairs.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can influence pricing. Established suppliers may offer more reliable products but at a premium.

-

Incoterms: Understanding shipping terms is crucial for cost management. Different Incoterms can impact the total landed cost, including who bears the cost of shipping, insurance, and tariffs.

What Buyer Tips Can Help Optimize Costs in Upholstery Fabric Sourcing?

B2B buyers can adopt several strategies to optimize their sourcing costs for automobile upholstery fabric, particularly in diverse international markets.

-

Negotiation Strategies: Leverage volume purchases or long-term contracts to negotiate better terms. Building a relationship with suppliers can also lead to favorable pricing and priority service.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership rather than just the upfront price. Consider factors such as durability, maintenance, and potential for resale when assessing the value of upholstery materials.

-

Understand Pricing Nuances: Be aware of regional pricing differences, especially when sourcing from suppliers in Africa, South America, the Middle East, or Europe. Currency fluctuations and local economic conditions can affect costs, so keep abreast of market trends.

-

Stay Informed on Regulations: Compliance with local regulations regarding automotive materials can affect costs. Ensure that sourced fabrics meet all necessary standards to avoid costly compliance issues.

-

Request Samples: Before making large orders, request samples to assess material quality and suitability. This step can prevent costly mistakes and ensure that the chosen fabric aligns with expectations.

Disclaimer

The pricing information provided is indicative and may vary based on supplier negotiations, market conditions, and specific buyer requirements. Always conduct thorough research and engage in direct discussions with suppliers to obtain the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing automobile upholstery fabric With Other Solutions

Introduction to Alternatives in Automobile Upholstery Solutions

When it comes to enhancing vehicle interiors, automobile upholstery fabric is a popular choice among B2B buyers. However, it’s essential to consider alternative solutions that may offer distinct advantages depending on the specific needs of the project. This analysis examines automobile upholstery fabric against two viable alternatives: leather upholstery and synthetic leather options. Each solution comes with its unique benefits and drawbacks, which can influence the decision-making process for businesses in the automotive industry.

Comparison Table

| Comparison Aspect | Automobile Upholstery Fabric | Leather Upholstery | Synthetic Leather |

|---|---|---|---|

| Performance | Good durability; soft feel | High durability; luxurious look | Moderate durability; resistant to wear |

| Cost | Generally budget-friendly | Higher cost due to quality | Mid-range cost, less than leather |

| Ease of Implementation | Easy to install; customizable | Requires skilled labor for installation | Simple to install; often pre-formed |

| Maintenance | Requires regular cleaning | Needs conditioning; easy to clean | Low maintenance; easy to wipe down |

| Best Use Case | Ideal for customizable interiors; family vehicles | Luxury vehicles; high-end markets | Cost-effective alternative for budget-conscious projects |

Detailed Breakdown of Alternatives

Leather Upholstery

Leather upholstery is synonymous with luxury and durability. Its high-end appearance and feel make it a preferred choice for premium vehicles. While leather offers exceptional longevity and a sophisticated aesthetic, it typically comes with a higher upfront cost. Maintenance is also a consideration; leather requires regular conditioning to prevent cracking and fading, which may not suit all buyers. However, for businesses targeting the luxury market or seeking to enhance the resale value of vehicles, leather upholstery can be a worthwhile investment.

Synthetic Leather

Synthetic leather, often made from polyurethane or PVC, provides a visually appealing alternative to genuine leather. It is designed to mimic the look and feel of leather while being more budget-friendly. Synthetic leather is easier to maintain, as it can be wiped clean with minimal effort, making it suitable for family vehicles or high-traffic areas. However, it may not deliver the same level of durability or luxury as real leather. For businesses focused on cost-effectiveness or those catering to a wider audience, synthetic leather presents a compelling option without sacrificing style.

Conclusion: How to Choose the Right Upholstery Solution

Selecting the appropriate upholstery solution requires a careful assessment of your specific needs, budget, and the target market. For businesses prioritizing luxury and durability, leather upholstery may be the best fit, despite its higher cost and maintenance requirements. Conversely, if customization and budget-friendliness are paramount, automobile upholstery fabric stands out as a versatile choice. Synthetic leather serves as an excellent middle-ground option, combining affordability with a stylish appearance. Ultimately, understanding the pros and cons of each solution will empower B2B buyers to make informed decisions that align with their business objectives and customer expectations.

Essential Technical Properties and Trade Terminology for automobile upholstery fabric

What Are the Key Technical Properties of Automobile Upholstery Fabric?

When selecting automobile upholstery fabric, understanding the technical specifications is crucial for making informed purchasing decisions. Here are some essential properties that B2B buyers should consider:

1. Material Grade

Material grade refers to the quality classification of the fabric based on its composition and performance characteristics. Common grades include premium leather, high-performance synthetics, and standard fabrics. Higher-grade materials generally offer better durability, aesthetics, and longevity, which can significantly impact the overall quality of the vehicle’s interior.

2. Tolerance

Tolerance in upholstery fabric refers to the allowable variation in dimensions and properties. This can include aspects like thickness, weight, and color consistency. For manufacturers, maintaining tight tolerances ensures that materials fit perfectly during installation and that the finished product meets quality standards. This is especially important in high-volume production environments where consistency is key.

3. Abrasion Resistance

Abrasion resistance measures how well a fabric can withstand wear and tear from friction. This property is quantified using the Martindale test, which simulates the rubbing action that upholstery experiences over time. Fabrics with high abrasion resistance are essential for applications in vehicles that experience heavy use, ensuring that the upholstery maintains its appearance and integrity over its lifespan.

4. UV Resistance

UV resistance indicates how well a fabric can withstand exposure to sunlight without degrading. This property is particularly important for vehicles used in sunny climates, as UV rays can cause fading and material breakdown. Fabrics with high UV resistance help maintain the aesthetic appeal of vehicle interiors while prolonging the lifespan of the upholstery.

Illustrative image related to automobile upholstery fabric

5. Flame Retardancy

Flame retardancy is a critical safety feature in automobile upholstery. It refers to the fabric’s ability to resist ignition and prevent the spread of flames. Compliance with industry standards for flame retardancy is crucial for manufacturers, especially in regions with stringent safety regulations. Selecting flame-retardant materials can enhance the safety profile of vehicles, making them more appealing to buyers.

What Are Common Trade Terms Used in the Automobile Upholstery Fabric Industry?

Familiarizing oneself with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are several key terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of upholstery, OEM fabrics are those originally supplied with the vehicle, ensuring compatibility with the vehicle’s design and specifications. B2B buyers often seek OEM materials to maintain brand integrity and quality.

2. MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it impacts inventory management and cash flow. Suppliers may set MOQs based on production costs and material availability, so negotiating favorable terms can lead to cost savings for bulk purchases.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to potential suppliers to request pricing and other relevant information for a specific quantity of goods. In the upholstery fabric industry, issuing an RFQ allows buyers to compare offers, negotiate terms, and select the best supplier for their needs.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs, helping to avoid misunderstandings and disputes. Familiarity with Incoterms is vital for B2B buyers engaging in cross-border purchases of upholstery fabric.

5. Lead Time

Lead time is the time taken from placing an order until the product is delivered. Understanding lead times is critical for planning production schedules and inventory management. Buyers should factor in lead times when negotiating contracts and placing orders to ensure timely delivery of upholstery materials.

By grasping these technical properties and trade terms, B2B buyers can navigate the automobile upholstery fabric market more effectively, making informed decisions that align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the automobile upholstery fabric Sector

What Are the Key Market Trends Influencing the Automobile Upholstery Fabric Sector?

The automobile upholstery fabric market is witnessing significant transformations driven by globalization and evolving consumer preferences. Key factors such as increasing disposable incomes in emerging economies, notably in Africa and South America, are leading to heightened demand for premium and customizable upholstery options. In regions like Europe, particularly Germany, the focus is shifting towards high-performance fabrics that offer durability and aesthetic appeal.

Illustrative image related to automobile upholstery fabric

Emerging technologies are also reshaping the sourcing landscape. Digital platforms are streamlining the procurement process, enabling B2B buyers to access a broader range of suppliers and materials with greater efficiency. Innovations in fabric technology, such as the development of stain-resistant and easy-to-clean materials, are increasingly appealing to consumers who prioritize both aesthetics and functionality. Additionally, the rise of smart textiles—fabrics integrated with technology for added functionality—presents new opportunities for differentiation in the marketplace.

Another trend is the growing emphasis on sustainability, with buyers increasingly seeking eco-friendly materials. The global push for greener solutions is compelling manufacturers to adopt sustainable practices, from material sourcing to production processes. As a result, B2B buyers must stay abreast of these trends to make informed sourcing decisions that align with both market demands and their own corporate sustainability goals.

How Are Sustainability and Ethical Sourcing Shaping the Automobile Upholstery Fabric Market?

Sustainability and ethical sourcing are becoming paramount in the automobile upholstery fabric sector. The environmental impact of traditional upholstery materials, such as leather and synthetic fabrics, has prompted a shift towards eco-friendly alternatives. B2B buyers are now more inclined to seek upholstery options that minimize ecological footprints, such as fabrics made from recycled materials or those produced with reduced water and energy consumption.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing the sourcing practices of their suppliers, favoring those that demonstrate a commitment to fair labor practices and environmental stewardship. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® can serve as indicators of a supplier’s dedication to sustainability, providing assurance to buyers about the environmental and social credentials of the materials they purchase.

In addition to enhancing brand reputation, adopting sustainable practices can also lead to cost savings in the long run. By investing in durable, high-quality materials, buyers can reduce the frequency of replacements and repairs. Ultimately, aligning sourcing strategies with sustainability goals not only meets consumer expectations but also positions businesses favorably in a competitive market.

What Is the Historical Context of the Automobile Upholstery Fabric Industry?

The automobile upholstery fabric industry has evolved significantly since the early 20th century. Initially dominated by leather, the sector has diversified to include a wide array of materials such as vinyl, fabric blends, and synthetic options. The introduction of synthetic fabrics in the mid-20th century revolutionized the market, offering cost-effective and durable alternatives to leather.

As consumer preferences shifted towards customization and personalization, upholstery options expanded to include a variety of colors, textures, and patterns. The late 20th century saw a growing emphasis on performance fabrics that offered enhanced durability and resistance to wear and tear, catering to the needs of families and commercial vehicle operators alike.

Illustrative image related to automobile upholstery fabric

Today, the industry is at the forefront of innovation, with advancements in fabric technology leading to smart textiles and sustainable materials, reflecting broader trends in consumer awareness and environmental responsibility. This evolution underscores the importance of staying informed about historical and current trends for B2B buyers looking to make strategic sourcing decisions in the automobile upholstery fabric market.

Frequently Asked Questions (FAQs) for B2B Buyers of automobile upholstery fabric

-

How do I choose the right auto upholstery fabric for my project?

Selecting the right auto upholstery fabric involves assessing your specific needs, such as durability, aesthetics, and functionality. Consider the environment in which the vehicle will be used; for instance, if it will be exposed to heavy wear from children or pets, choose materials like synthetic fabrics or vinyl for their durability and ease of cleaning. Additionally, evaluate the look you want to achieve—whether luxurious leather or vibrant fabric. Collaborating with suppliers who offer samples can also help you visualize how different materials will fit your design. -

What types of auto upholstery fabrics are most durable?

The most durable auto upholstery fabrics include leather, vinyl, and high-quality synthetic options like microfiber and polyester. Leather is renowned for its longevity and luxurious feel, making it a popular choice among premium vehicles. Vinyl is a more affordable alternative that is also resistant to stains and wear, ideal for high-traffic use. Synthetic fabrics often combine durability with a softer feel, providing a versatile option that can withstand everyday use while maintaining comfort. -

What are the minimum order quantities (MOQs) for automotive upholstery fabric?

Minimum order quantities can vary significantly between suppliers, typically ranging from 50 to 500 yards, depending on the fabric type and supplier policies. For bulk buyers, it’s essential to discuss MOQs early in the negotiation process to ensure that your order meets the supplier’s requirements while aligning with your project needs. Some suppliers may offer flexibility or discounts on larger orders, so it’s worth exploring these options to optimize your procurement strategy. -

How can I verify the quality of upholstery fabric before purchasing?

To verify the quality of upholstery fabric, request samples from potential suppliers. This allows you to assess the fabric’s texture, durability, and color in person. Additionally, inquire about the fabric’s specifications, such as abrasion resistance, colorfastness, and warranty terms. Certifications from recognized industry standards can also provide assurance of quality. Building relationships with reputable suppliers who have a track record in the industry can further ensure that you are sourcing high-quality materials. -

What payment terms should I expect when sourcing upholstery fabric internationally?

Payment terms can vary widely based on the supplier and the nature of the transaction. Common practices include upfront payments, deposits (typically 30-50%), and balance payments upon delivery. For international transactions, consider using secure payment methods like letters of credit or escrow services to protect your investment. It’s crucial to establish clear terms before finalizing any agreement, including currency, payment timeline, and any penalties for late payments, to avoid misunderstandings. -

What customization options are available for upholstery fabric?

Many suppliers offer extensive customization options for upholstery fabric, including color, texture, and design patterns. You can often request specific blends of materials or treatments for enhanced durability, stain resistance, or eco-friendliness. Additionally, some manufacturers may provide the option for custom prints or embroidery to reflect your brand identity. Discussing your customization needs early in the sourcing process can help ensure that the supplier can accommodate your requirements. -

How do I assess the reliability of a fabric supplier?

To assess the reliability of a fabric supplier, conduct thorough research, including checking their industry experience, client testimonials, and any certifications or awards. Request references from previous customers to gain insights into their experiences. Additionally, consider visiting the supplier’s facility if possible or arranging virtual tours to evaluate their production capabilities. Engaging in direct communication about your specific needs and their willingness to address them can also indicate a supplier’s reliability and customer service quality. -

What logistics considerations should I keep in mind when sourcing upholstery fabric internationally?

When sourcing upholstery fabric internationally, logistics play a crucial role in ensuring timely and cost-effective delivery. Consider factors like shipping methods, customs regulations, and potential tariffs that could impact your overall costs. Work with suppliers who have experience in international shipping and can provide guidance on documentation and compliance. Additionally, plan for contingencies such as delays in shipping or customs clearance to minimize disruptions to your supply chain.

Top 8 Automobile Upholstery Fabric Manufacturers & Suppliers List

1. Midwest Fabrics – Automotive Upholstery & OEM Fabrics

Domain: midwestfabrics.com

Registered: 1999 (26 years)

Introduction: Automotive Upholstery Fabric, Original OEM Detroit Number Fabrics, GM, Ford, Chrysler, Honda, Toyota, Mazda, Nissan OEM Fabric, Heavy Duty Flock fabric, various Culp Contract fabrics, Marine Vinyl, Automotive Vinyl, Endurasoft Core Program, Carbon Fiber, Brushed Aluminum, multiple Morbern Vinyl options, Upholstery Supplies including thread, staples, zippers, adhesives, and foam.

2. A·1 Foam & Fabrics – 555 Portfolio Tweed Collection

Domain: a1foamandfabrics.com

Registered: 2003 (22 years)

Introduction: Automotive Car Interior Fabrics available at A·1 Foam & Fabrics include a variety of options such as Velvets, Suedes, and Tweeds suitable for automotive, RV, and trucking applications. Key products include: 1. 555 Portfolio Tweed Collection – Abrasion resistance: 50,000+ DR #10 Cotton Duck, Flame Retardancy: California T.B. 117 Section E-Class 1 (Pass), NFPA 260-Class 1 (Pass), UFAC Class 1 (Pass)…

3. Original Auto Fabric – Vintage & New Upholstery Materials

Domain: oemautofabric.com

Registered: 2018 (7 years)

Introduction: Original Auto Fabric offers a wide selection of vintage and new auto upholstery materials, including specialty car cloths, marine and automotive vinyls, custom carpets, floor mats, and vinyl tops. They provide over 230 licensed logos for floor mats, molded carpet to OEM specifications, and specialize in high-end imported luxury carpets. Their product categories include Auto Cloths (686 options), L…

4. JJ Auto Fabrics – Automotive and Marine Vinyl Supplies

Domain: jjautofabrics.com

Registered: 2001 (24 years)

Introduction: Automotive-Marine Vinyl and Upholstery Supplies including Classic Automotive Vinyl, Heavy Weight Vinyl, SoftSide/SoftTouch Automotive Vinyl, various specialty vinyls (e.g., JJ Ostrich, JJ Wild CROC), automotive carpet options (e.g., Dorsett Loop, Wilton Wool), padding and sound control materials, headliner materials, marine vinyl options (e.g., Morbern Mellowhide), marine carpet (e.g., Aquaturf), …

5. Scotland Shop – Plaid and Tweed Car Upholstery Fabric Guide

Domain: scotlandshop.com

Registered: 2002 (23 years)

Introduction: Plaid and Tweed Car Upholstery Fabric Guide

– Fabric Types: Pure wool, Polyviscose

– Fabric Weights: 11oz to 16oz

– Recommended Uses: Lighter use, Regular use, Heavy use

– Care Instructions: Dry clean only for most wool fabrics, Machine washable at 30 degrees for Polyviscose

– Widths: Ranges from 140cm to 150cm (54 inches to 60 inches)

– Custom Tartan Design Service available

– Over 500 Scottish p…

6. SMS Auto Fabrics – Classic Auto Interiors

Domain: smsautofabrics.com

Registered: 2000 (25 years)

Introduction: SMS Auto Fabrics offers a large selection of classic auto interiors, including cloth, vinyl, leather, door panels, headliners, vinyl tops, and carpets for American cars from the 1930s to the 1990s. Featured products include various plaid fabrics for Chevrolet models from 1972 and 1973, as well as door panels for models such as the 1956 Ford Fairlane Sunliner, 1968 Dodge Polara Convertible, and 197…

7. MiamiCorp – Auto Upholstery Fabrics

Domain: miamicorp.com

Registered: 2001 (24 years)

Introduction: This company, MiamiCorp – Auto Upholstery Fabrics, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

8. Sailrite – Vinyl Automotive Upholstery Fabrics

Domain: sailrite.com

Registered: 1996 (29 years)

Introduction: Our Favorite Vinyl Automotive Upholstery Fabrics – Sailrite

– Vinyl is durable, waterproof, and easy to clean.

– High-quality vinyl resembles real leather in texture and graining.

– Economical alternative to leather, easier to maintain.

– Easy to clean: loose dirt vacuums easily, spills wipe up effortlessly.

– Waterproof, preventing odors from food spills.

– Long-lasting and abrasion resistant wit…

Strategic Sourcing Conclusion and Outlook for automobile upholstery fabric

In summary, the strategic sourcing of automobile upholstery fabric is essential for enhancing vehicle interiors while balancing cost, durability, and aesthetics. Buyers should prioritize materials that align with their specific market needs—whether that’s the luxurious appeal of leather, the practicality of vinyl, or the versatility of synthetic fabrics. Understanding the nuances of each material will empower B2B buyers to make informed decisions that not only meet their immediate requirements but also enhance their product offerings.

As the automotive industry continues to evolve, staying ahead of trends in upholstery materials and customer preferences will be crucial. International buyers, particularly from Africa, South America, the Middle East, and Europe, should leverage strategic sourcing to build partnerships with reliable suppliers who can offer innovative and eco-friendly options.

By embracing a forward-thinking approach to sourcing, businesses can position themselves competitively in the market. Now is the time to explore diverse upholstery solutions that not only elevate vehicle aesthetics but also contribute to sustainability efforts in the automotive sector. Engage with suppliers today to ensure your upholstery offerings meet the demands of tomorrow’s consumers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.