Catalog

Material Insight: Faux Leather Durability

Faux Leather Durability: A B2B Product Guide

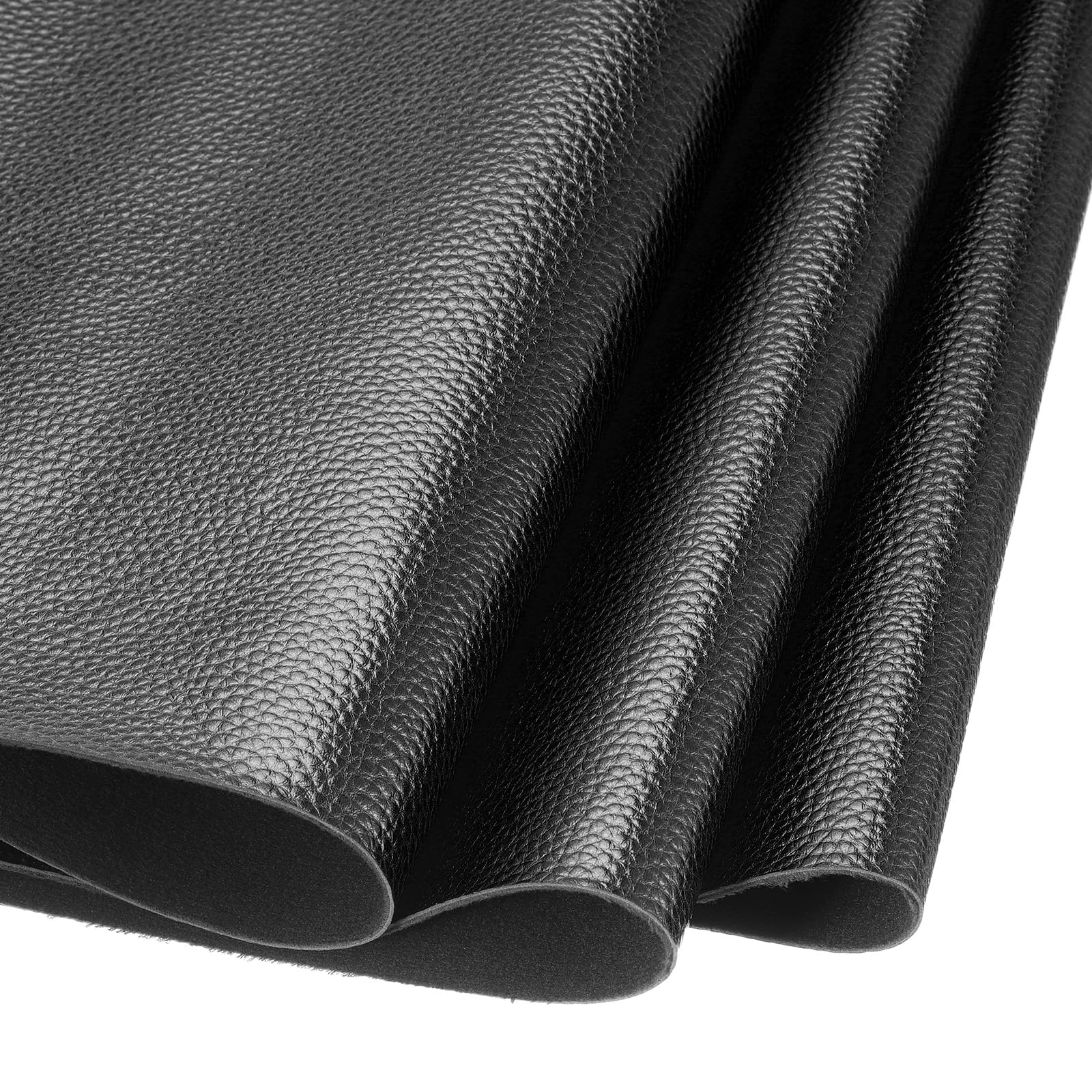

In commercial and industrial applications where performance, consistency, and longevity are paramount, material selection plays a critical role in long-term success. Faux leather—specifically high-performance synthetic leather—has emerged as a leading choice across industries such as furniture, transportation, healthcare, and consumer electronics. Engineered for resilience, modern faux leather delivers exceptional durability while meeting evolving demands for sustainability, cost-efficiency, and design flexibility.

Unlike natural leather, which can vary significantly in strength and consistency due to biological factors, faux leather offers uniform quality and predictable performance. It resists fading, cracking, and abrasion, and can be customized to meet specific requirements for tensile strength, seam strength, and resistance to UV, moisture, and chemicals. These attributes make it ideal for high-traffic environments and applications requiring low maintenance and long service life.

- Resists wear and tear in high-use settings

- Maintains appearance and integrity under UV exposure

- Offers consistent quality batch after batch

- Supports sustainable production with reduced environmental impact

At WINIW, we have been at the forefront of synthetic leather innovation for over 20 years. Our deep expertise in polyurethane (PU) and microfiber technologies enables us to deliver durable, eco-conscious faux leather solutions tailored to the exacting needs of B2B clients worldwide. By combining advanced manufacturing processes with rigorous quality control, WINIW ensures every roll meets the highest standards for performance and reliability.

When durability matters, WINIW’s faux leather provides a smarter, more sustainable alternative to natural leather—without compromising on aesthetics or functionality.

Technical Performance & Standards

WINIW Synthetic Leather: Engineered Durability for Demanding Applications

WINIW delivers premium synthetic leather solutions designed for commercial longevity and operational efficiency. Our proprietary manufacturing processes prioritize material science and sustainable chemistry, resulting in faux leather that outperforms conventional alternatives in high-use environments. This engineered durability translates directly to reduced total cost of ownership, minimized replacement cycles, and consistent aesthetic integrity for B2B partners across furniture, transportation, and accessory manufacturing.

Core Technical Advantages Driving Value

- Cost-Effective Longevity: WINIW substrates utilize high-density polyurethane (PU) matrices reinforced with microfiber layers, achieving abrasion resistance exceeding 50,000 cycles (Martindale test). This significantly extends product lifespan compared to standard faux leathers (typically 15,000-25,000 cycles), lowering lifetime material costs by up to 30% through reduced reupholstery and replacement needs.

- Unmatched Durability: Engineered tensile strength (≥ 25 MPa) and tear resistance (≥ 45 N) prevent seam splitting and surface damage under stress. Enhanced hydrolysis resistance ensures structural integrity in humid climates or marine environments, maintaining performance for 7+ years without degradation.

- True-to-Spec Color Customization: Our digital color matching system (ΔE < 1.0) supports Pantone® and RAL library replication with batch-to-batch consistency. Pigment integration within the PU layer eliminates fading risks from UV exposure (tested to 500+ hours QUV), ensuring brand color accuracy throughout the product lifecycle without costly post-production dyeing.

- REACH SVHC Compliance Guaranteed: WINIW materials are rigorously screened against the REACH Candidate List. All formulations are free from SVHCs (Substances of Very High Concern), phthalates, AZO dyes, and heavy metals (Cd, Pb, Hg, Cr⁶⁺), ensuring seamless compliance for EU and global markets. Full material disclosure (IMDS/SCIP) is provided.

- ISO 9001-Certified Quality Control: Every production batch undergoes real-time monitoring per ISO 9001:2015 standards. This guarantees consistent thickness tolerance (±0.1mm), color fastness (≥ Grade 4), and physical properties, eliminating production delays due to material variance.

WINIW Durability Performance Specifications

| Property | Test Standard | WINIW Performance | Industry Average | Advantage |

|---|---|---|---|---|

| Abrasion Resistance | ISO 12947 (Martindale) | ≥ 50,000 cycles | 15,000-25,000 cycles | 2-3x longer surface life |

| Tensile Strength | ISO 1728 | ≥ 25 MPa | 15-20 MPa | Superior tear resistance |

| Tear Strength | ISO 13937-1 | ≥ 45 N | 25-35 N | Reduced seam failure risk |

| Color Fastness (Light) | ISO 105-B02 (QUV) | Grade 7-8 (500+ hrs) | Grade 4-5 (200 hrs) | Fade resistance for 7+ yrs |

| Hydrolysis Resistance | ISO 1419 (70°C/95% RH) | Pass (35 days) | Fail (14-21 days) | Stable in high-moisture env |

| REACH SVHC Status | EC 1907/2006 | Compliant (None detected) | Varies | Guaranteed regulatory safety |

WINIW’s commitment to eco-engineering ensures these performance benchmarks are achieved without compromising environmental responsibility. Our closed-loop water systems and solvent-free coating processes reduce CO₂ emissions by 40% versus conventional methods, aligning durability with your ESG goals. Partner with WINIW to deploy synthetic leather that delivers measurable operational savings, uncompromised quality, and future-proof compliance.

Why Choose Synthetic over Real Leather

B2B Product Guide: Faux Leather vs. Real Leather – Performance and Sustainability Comparison

In commercial and industrial applications—from automotive interiors to furniture manufacturing—material selection significantly impacts product longevity, cost-efficiency, and environmental footprint. Two of the most widely used materials in these sectors are real leather and faux (synthetic) leather. Understanding the differences in durability, cost, and sustainability is essential for informed procurement decisions.

Durability Comparison

Durability in leather materials is assessed by resistance to abrasion, tearing, cracking, and exposure to UV light and moisture. Real leather, derived from animal hides, offers natural strength and breathability. Over time, it develops a patina, enhancing its aesthetic appeal. However, it is susceptible to fading, water damage, and requires regular conditioning to maintain performance.

Faux leather, particularly high-performance variants such as polyurethane (PU) leather like WINIW® advanced synthetic leather, offers consistent texture and enhanced resistance to environmental stressors. Modern manufacturing techniques have significantly improved the tensile strength and abrasion resistance of faux leather, often matching or exceeding that of lower- and mid-grade real leathers. Additionally, faux leather does not crack or fade as readily under UV exposure, making it ideal for applications in automotive and outdoor furniture.

- Faux leather maintains uniform quality across batches, ensuring predictable performance.

- Real leather varies in quality depending on hide source and tanning process.

- High-end PU leather resists staining and microbial growth better than untreated real leather.

- Faux leather is inherently more water-resistant, reducing long-term maintenance costs.

Cost and Sustainability Overview

From a B2B perspective, total cost of ownership includes material cost, processing, maintenance, and end-of-life impact. While real leather often carries a premium price tag due to sourcing and tanning complexity, faux leather offers scalable production with lower variability in cost.

Environmental responsibility is increasingly critical in material sourcing. The tanning of real leather, especially chrome-tanned varieties, involves hazardous chemicals and high water consumption. In contrast, advanced eco-friendly faux leathers are produced with low-emission processes, recyclable substrates, and reduced ecological impact.

The following table compares key performance and sustainability metrics:

| Criteria | Real Leather | Faux Leather (High-Grade PU) |

|---|---|---|

| Cost | High (raw material and processing) | Moderate to High (scales efficiently) |

| Trwałość | High (varies by grade); prone to moisture/UV damage | High; consistent resistance to abrasion, UV, and water |

| Eco-Friendliness | Low to Moderate (high water/chemical use, waste byproducts) | Moderate to High (especially with eco-PU and recycled backing) |

Conclusion

For B2B clients prioritizing consistent quality, lower maintenance, and environmental responsibility, high-performance faux leather presents a compelling alternative to real leather. Innovations in synthetic leather technology have closed the durability gap while offering greater design flexibility and sustainability benefits. WINIW® continues to lead in eco-conscious synthetic leather solutions, supporting manufacturers in meeting both performance standards and ESG goals.

WINIW Factory Capabilities

WINIW Synthetic Leather: Manufacturing Excellence for Global Partners

WINIW stands at the forefront of sustainable synthetic leather production, engineered to meet the rigorous demands of international B2B clients. Our vertically integrated manufacturing ecosystem combines scale, innovation, and uncompromising quality control to deliver premium materials for fashion, automotive, and furniture industries worldwide.

Core Manufacturing Capabilities

- 100,000 sqm Advanced Production Facility: Fully automated production lines operating under ISO 14001-certified environmental management systems, enabling annual output of 50+ million meters to support high-volume global supply chains.

- Dedicated R&D Team of 40+ Specialists: Proprietary material science expertise focused on eco-innovation, including water-based PU formulations, recycled content integration (up to 40% PCR), and bio-based alternatives. 15+ patents held for texture replication and low-impact finishing technologies.

- Triple-Layer Quality Assurance Protocol:

- Raw material screening via AI-powered spectrometry

- In-line robotic tensile/abrasion testing at 3 production stages

- Final batch validation against 200+ physical/chemical parameters (exceeding ISO 9001 standards)

Global Compliance & Export Infrastructure

WINIW materials consistently clear stringent regulatory barriers across key markets:

| Region | Key Compliance Standards Met | Primary Export Destinations |

|---|---|---|

| Europe | REACH SVHC, OEKO-TEX® STANDARD 100 Class I, EU Ecolabel | Germany, Italy, Sweden, France |

| North America | CPSIA, Prop 65, FDA 21 CFR 177 (food-contact grades) | USA, Canada, Mexico |

| APAC | GB/T 16799-2018, Japan SEK Mark | South Korea, Japan, Australia |

Why Global Brands Partner with WINIW

- Supply Chain Resilience: 99.2% on-time delivery rate across 50+ countries with dedicated logistics hubs in Rotterdam and Los Angeles.

- Eco-Performance Transparency: Full LCA reporting available; all facilities powered by 70% renewable energy with zero wastewater discharge.

- Customization Agility: Rapid prototyping (2-week turnaround) for texture, thickness (0.4–2.0mm), and performance attributes (anti-microbial, fire-retardant).

WINIW’s manufacturing infrastructure delivers not just product, but partnership assurance—where environmental responsibility and industrial-scale precision converge to elevate your brand’s material legacy. Partner with us to transform sustainable vision into tangible market advantage.

Contact Us for Samples

WINIW B2B Product Guide: High-Performance Faux Leather Solutions

WINIW specializes in advanced synthetic leather engineered for durability, sustainability, and superior performance across diverse industries. Our eco-conscious manufacturing process delivers premium-quality microfiber leather that meets the rigorous demands of automotive, furniture, footwear, and accessories sectors. With over two decades of innovation, we provide B2B partners with reliable, cruelty-free alternatives to genuine leather without compromising on strength or aesthetics.

Key Benefits of WINIW Faux Leather

- Exceptional tensile and tear strength for long-term use

- Superior resistance to abrasion, UV exposure, and environmental stress

- Eco-friendly production with low-VOC emissions and recyclable materials

- Consistent thickness and texture for streamlined manufacturing

- Customizable finishes, colors, and textures to match brand specifications

- Water-resistant and easy to clean—ideal for high-traffic applications

Durability Performance Comparison

| Property | WINIW Microfiber Leather | Standard PU Leather | Genuine Leather |

|---|---|---|---|

| Abrasion Resistance | >50,000 cycles (Martindale) | 10,000–20,000 cycles | 20,000–30,000 cycles |

| Tensile Strength | 30–45 MPa | 10–15 MPa | 20–35 MPa |

| Color Fastness (UV) | Grade 7–8 (ISO 105-B02) | Grade 4–5 | Grade 5–6 |

| Water Resistance | Doskonały | Moderate | Poor (without treatment) |

| Eco-Certifications | OEKO-TEX®, REACH, RoHS | Varies | Limited traceability |

Industries We Serve

- Automotive interiors (seating, dashboards, door panels)

- Contract and residential furniture

- Performance footwear and luxury accessories

- Hospitality and healthcare upholstery

Why Choose WINIW for Faux Leather Durability?

Our proprietary microfiber technology mimics the structural integrity of natural leather while surpassing it in critical durability metrics. WINIW’s materials are tested under industrial-grade conditions to ensure performance in extreme temperatures, humidity, and mechanical stress—making them ideal for global supply chains and demanding end-users.

Free samples are available for qualified B2B partners to evaluate performance firsthand.

Request your free sample today and test WINIW’s durability in your application.

For product specifications, technical data sheets, or custom development support, contact our materials team at MKT88@MicrofiberLeather.com.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.