Introduction: Navigating the Global Market for custom leather man jacket

Navigating the global market for custom leather man jackets presents unique challenges for B2B buyers seeking quality, style, and value. With a diverse range of suppliers and fluctuating prices, sourcing the ideal leather jacket that meets both aesthetic and functional requirements can be daunting. This guide aims to simplify the procurement process by providing a comprehensive overview of custom leather man jackets, including various types, applications, and essential factors for supplier vetting.

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe (notably Germany and Saudi Arabia), will find actionable insights on assessing quality materials, understanding pricing structures, and recognizing market trends. Additionally, we delve into customization options, allowing businesses to tailor products to their specific needs, enhancing brand identity and customer satisfaction.

By empowering B2B buyers with the knowledge needed to make informed purchasing decisions, this guide serves as a valuable resource in the competitive landscape of custom leather goods. Whether you are a retailer looking to expand your product line or a designer aiming to create unique pieces, understanding the nuances of the custom leather jacket market is crucial for success.

Table Of Contents

- Top 7 Custom Leather Man Jacket Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather man jacket

- Understanding custom leather man jacket Types and Variations

- Key Industrial Applications of custom leather man jacket

- 3 Common User Pain Points for ‘custom leather man jacket’ & Their Solutions

- Strategic Material Selection Guide for custom leather man jacket

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather man jacket

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather man jacket’

- Comprehensive Cost and Pricing Analysis for custom leather man jacket Sourcing

- Alternatives Analysis: Comparing custom leather man jacket With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather man jacket

- Navigating Market Dynamics and Sourcing Trends in the custom leather man jacket Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather man jacket

- Strategic Sourcing Conclusion and Outlook for custom leather man jacket

- Important Disclaimer & Terms of Use

Understanding custom leather man jacket Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Biker Jacket | Heavy-duty leather, asymmetrical zip, multiple pockets | Retail fashion, motorcycle gear suppliers | Pros: Durable, iconic style. Cons: May not suit all body types. |

| Bomber Jacket | Waist-length, ribbed cuffs and hem, often lined | Promotional merchandise, casual fashion brands | Pros: Versatile, comfortable. Cons: Less formal appeal. |

| Racer Jacket | Streamlined fit, minimalistic design, often features padding | Sportswear retailers, automotive brands | Pros: Aerodynamic, stylish. Cons: Limited color options. |

| Aviator Jacket | Classic collar, shearling lining, robust construction | Military surplus, fashion retailers | Pros: Timeless style, warm. Cons: Bulkier fit may not appeal to all. |

| Custom Tailored | Fully personalized fit and design, choice of materials | High-end fashion boutiques, bespoke services | Pros: Unique, perfect fit. Cons: Higher cost, longer lead times. |

What Are the Key Characteristics of Biker Jackets for B2B Buyers?

Biker jackets are crafted from heavy-duty leather, designed to withstand harsh conditions while providing a rugged aesthetic. Their asymmetrical zippers and multiple pockets cater to functionality, making them popular among motorcycle enthusiasts. B2B buyers in retail fashion and motorcycle gear sectors can leverage this iconic style to appeal to a dedicated customer base. However, it’s important to consider that the fit may not accommodate all body types, which could limit sales potential.

How Do Bomber Jackets Serve the Fashion Industry?

Bomber jackets feature a waist-length cut with ribbed cuffs and hems, often lined for added comfort. Their casual yet stylish appearance makes them a versatile choice for promotional merchandise and casual fashion brands. B2B buyers can benefit from the bomber’s broad appeal, as they can be marketed across various demographics. However, the less formal nature of these jackets may not suit all brand identities, which should be assessed before purchasing.

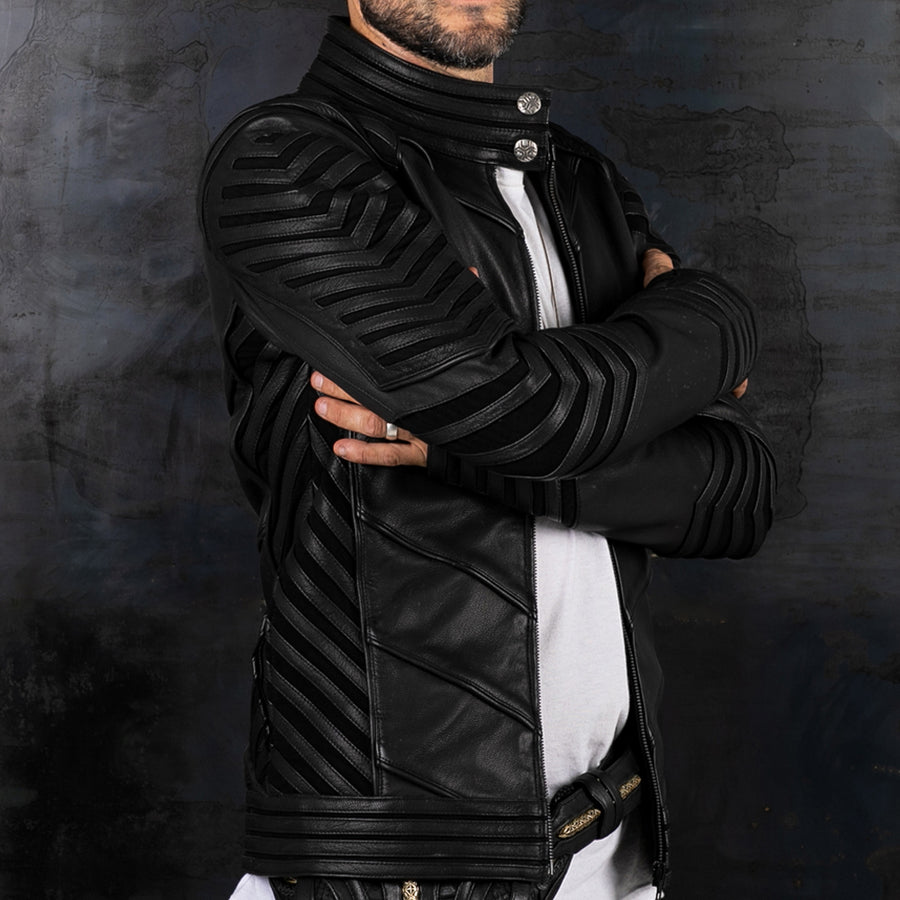

Illustrative image related to custom leather man jacket

Why Are Racer Jackets Ideal for Sportswear Retailers?

Racer jackets are characterized by their streamlined fit and minimalistic design, often featuring padding for added protection. This style is particularly suitable for B2B applications within sportswear retailers and automotive brands, as they convey a sense of speed and agility. Buyers should note that while racer jackets are stylish, they typically offer limited color options, which may restrict customization possibilities for certain markets.

What Makes Aviator Jackets a Timeless Choice?

Aviator jackets are defined by their classic collar, shearling lining, and robust construction, making them an enduring option in the leather jacket market. Their appeal spans military surplus outlets and fashion retailers, providing warmth and a timeless style. B2B buyers should consider the bulkier fit of aviator jackets, as it may not resonate with all consumers, potentially impacting sales.

How Can Custom Tailored Jackets Meet Diverse Market Needs?

Custom tailored jackets offer a fully personalized fit and design, allowing buyers to select materials and styles that reflect their brand’s identity. This bespoke option is particularly appealing to high-end fashion boutiques and bespoke services looking to differentiate themselves in a competitive market. While the uniqueness and perfect fit are significant advantages, B2B buyers must be prepared for higher costs and longer lead times associated with custom orders.

Key Industrial Applications of custom leather man jacket

| Industry/Sector | Specific Application of Custom Leather Man Jacket | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | Customized fashion lines for boutiques and brands | Differentiation in a saturated market, enhanced brand loyalty | Quality of leather, customization options, lead times |

| Automotive | Branded leather jackets for automotive events | Strong brand visibility, customer engagement | Branding capabilities, durability, and comfort |

| Film and Entertainment | Replicas of iconic jackets for film productions | Authenticity in costume design, increased sales potential | Precision in design replication, sourcing historical leathers |

| Corporate Branding | Custom jackets for employee uniforms or promotional gifts | Enhanced corporate identity, team cohesion | Customization options, cost-effectiveness, bulk order discounts |

| Outdoor and Adventure Gear | Jackets designed for extreme weather conditions | Functional protection, brand recognition in outdoor activities | Material quality, insulation options, and fit adjustments |

How is Custom Leather Man Jacket Used in the Fashion Retail Sector?

In the fashion retail industry, custom leather man jackets serve as a unique offering for boutiques and high-end brands. By allowing customers to personalize their jackets, businesses can stand out in a competitive market. This customization fosters brand loyalty as consumers appreciate the opportunity to express their individuality. Buyers should consider the quality of leather, available customization options, and lead times to ensure they meet consumer demands effectively.

Illustrative image related to custom leather man jacket

What Role Do Custom Leather Jackets Play in the Automotive Industry?

Automotive companies often utilize custom leather man jackets as promotional items during events, trade shows, or as part of their branding strategy. These jackets not only serve as functional apparel but also reinforce brand visibility and loyalty among customers. For B2B buyers in this sector, it is crucial to assess the branding capabilities of the jackets, their durability, and comfort to ensure they align with the brand’s image and customer expectations.

How Are Custom Leather Jackets Applied in Film and Entertainment?

In the film and entertainment industry, custom leather jackets are essential for replicating iconic looks for characters, enhancing authenticity in costume design. This application can significantly boost merchandise sales when fans seek to emulate their favorite characters. Buyers in this sector must focus on precision in design replication and the sourcing of historical leathers to ensure accuracy and appeal to target audiences.

What Benefits Do Custom Leather Jackets Offer for Corporate Branding?

For corporate branding, custom leather man jackets can be utilized as uniforms or promotional gifts that enhance corporate identity and foster team cohesion. This application allows businesses to present a unified image while rewarding employees or clients. When sourcing for this purpose, companies should prioritize customization options, cost-effectiveness, and bulk order discounts to maximize return on investment.

How Do Custom Leather Jackets Fit into Outdoor and Adventure Gear?

In the outdoor and adventure gear sector, custom leather man jackets are designed to withstand extreme weather conditions while providing functional protection. These jackets can help establish brand recognition among outdoor enthusiasts. Buyers should focus on the quality of materials, insulation options, and fit adjustments to ensure that the jackets meet the specific needs of their target audience, especially in diverse climates found in regions like Africa and South America.

Illustrative image related to custom leather man jacket

3 Common User Pain Points for ‘custom leather man jacket’ & Their Solutions

Scenario 1: Sizing Issues for Custom Leather Jackets

The Problem: One of the most significant challenges B2B buyers face when ordering custom leather jackets is ensuring accurate sizing. Many buyers struggle with the complexities of providing precise measurements, especially when dealing with a diverse customer base that may include varying body types. This can lead to dissatisfaction if the final product does not fit as expected, potentially resulting in returns or exchanges, which can be costly and time-consuming.

The Solution: To mitigate sizing issues, buyers should implement a standardized measurement guide that outlines the specific dimensions needed for custom orders. Offering a virtual fitting tool or an online consultation service can significantly enhance the accuracy of measurements. Encourage clients to take their measurements with a professional tailor or provide detailed instructional videos on how to measure correctly. Additionally, consider offering a “perfect fit guarantee” that allows for alterations or remakes, ensuring that customers feel secure in their purchase. This proactive approach not only builds trust but also fosters long-term relationships with clients.

Scenario 2: Concerns About Material Quality

The Problem: Buyers often worry about the quality of leather used in custom jackets, especially when sourcing from international manufacturers. Low-quality materials can lead to unsatisfactory products that don’t meet customer expectations, resulting in negative reviews and lost business. With so many options available, distinguishing between high-grade and inferior leather can be overwhelming, especially for those new to the industry.

The Solution: Establish partnerships with reputable suppliers who provide transparency about their sourcing practices and material specifications. Request samples of different leather types to assess their quality firsthand before placing bulk orders. Additionally, educate buyers about the various grades of leather, such as full grain versus top grain, so they can make informed decisions. Providing certification or documentation of the leather’s origin can further enhance buyer confidence. By emphasizing quality assurance, businesses can differentiate themselves in a competitive market and create a loyal customer base that values premium materials.

Scenario 3: Challenges with Customization Options

The Problem: Many B2B buyers encounter challenges when trying to navigate the myriad customization options available for leather jackets. From colors and styles to additional features like embroidery or hardware choices, the overwhelming number of possibilities can lead to confusion and decision fatigue. This is particularly true for fashion retailers looking to create unique designs that stand out in the market.

The Solution: To streamline the customization process, create a user-friendly online platform that allows buyers to visualize their options in real time. Implementing a configurator tool where buyers can see their selections come to life can greatly enhance the ordering experience. Providing design templates or inspiration boards can also help guide buyers in making choices that align with current fashion trends. Moreover, offering expert design consultations can assist clients in refining their ideas and ensuring that the final product meets their branding and aesthetic goals. By simplifying the customization process, businesses can encourage more orders and enhance customer satisfaction.

Strategic Material Selection Guide for custom leather man jacket

What Are the Key Properties of Common Materials Used in Custom Leather Man Jackets?

When selecting materials for custom leather man jackets, various options cater to different performance requirements and aesthetic preferences. Understanding the properties, advantages, and limitations of these materials is essential for B2B buyers looking to meet diverse customer needs.

What Are the Benefits of Full Grain Leather for Custom Jackets?

Full grain leather is often regarded as the highest quality leather available. It retains the natural grain pattern, providing a unique aesthetic that improves with age. Key properties include excellent breathability and durability, making it suitable for various climates. It can withstand significant wear and tear, offering a long lifespan, which is a critical consideration for buyers in regions with diverse weather conditions.

Pros: Full grain leather is highly durable, develops a rich patina over time, and is resistant to moisture. Its luxurious feel and appearance make it a popular choice among consumers who value quality.

Illustrative image related to custom leather man jacket

Cons: The primary drawback is its cost, which is relatively high compared to other leather types. Additionally, it requires specific care to maintain its appearance, which may not be ideal for all end-users.

For international buyers, especially in Europe and the Middle East, compliance with standards such as ASTM and DIN can be crucial, particularly regarding sourcing and manufacturing practices.

How Does Top Grain Leather Compare for Custom Leather Jackets?

Top grain leather is the second-highest quality leather, made by sanding the top layer of full grain leather to remove imperfections. This process results in a smoother finish that is still durable and flexible. It offers a good balance of quality and cost, making it a popular choice for custom jackets.

Pros: It is more affordable than full grain leather while still providing a premium look and feel. Its resistance to stains and easier maintenance are additional benefits.

Cons: While it is durable, it does not develop the same rich patina as full grain leather, which may be a disadvantage for some consumers. Additionally, it may not be as breathable due to the finishing process.

For buyers in Africa and South America, where climate can vary significantly, top grain leather offers a practical solution that balances aesthetics and functionality.

What Role Does Suede Play in Custom Leather Jacket Manufacturing?

Suede, made from the underside of animal hides, is known for its soft texture and unique appearance. It is lighter than traditional leather and offers a different aesthetic appeal, making it suitable for fashion-forward designs.

Pros: Suede is lightweight, offers a luxurious feel, and is available in a variety of colors. It is also relatively affordable compared to full and top grain leather.

Cons: Its primary limitation is its susceptibility to stains and moisture, which can affect its longevity. Suede requires special care and cleaning, which may deter some consumers.

International buyers should consider the implications of moisture exposure, especially in humid regions like parts of Africa and South America, where suede may not perform as well.

Why Is Faux Leather an Attractive Alternative for Custom Jackets?

Faux leather, or synthetic leather, is made from materials like polyurethane (PU) or polyvinyl chloride (PVC). It offers a cruelty-free alternative to traditional leather and is increasingly popular among environmentally conscious consumers.

Pros: It is generally more affordable than genuine leather and can be produced in various colors and textures. Faux leather is also easier to clean and maintain.

Illustrative image related to custom leather man jacket

Cons: While it can mimic the appearance of real leather, it does not offer the same durability or breathability. It may also have a shorter lifespan compared to genuine leather options.

For buyers in Europe and the Middle East, the growing trend toward sustainable and ethical fashion can make faux leather an appealing choice, aligning with consumer preferences for cruelty-free products.

Summary Table of Material Selection for Custom Leather Man Jackets

| Materiał | Typical Use Case for custom leather man jacket | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full Grain Leather | High-end jackets requiring durability and luxury | Exceptional durability and unique patina | High cost and requires careful maintenance | High |

| Top Grain Leather | Versatile jackets balancing quality and cost | Affordable yet premium look and feel | Less breathable and does not develop patina | Medium |

| Suede | Fashion-forward designs needing soft texture | Lightweight and luxurious feel | Susceptible to stains and moisture | Medium |

| Sztuczna skóra | Eco-friendly options for budget-conscious buyers | Affordable and easy to maintain | Less durable and shorter lifespan | Low |

This guide provides a comprehensive overview of the materials available for custom leather man jackets, enabling B2B buyers to make informed decisions based on performance, cost, and market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather man jacket

What Are the Main Stages of Manufacturing a Custom Leather Man Jacket?

The manufacturing of a custom leather man jacket is a meticulous process that involves several key stages. Understanding these stages helps B2B buyers ensure quality and consistency in their products.

Material Preparation: How Is Leather Selected and Prepared?

The first step in the manufacturing process involves selecting high-quality leather. Full-grain leather is often preferred for its durability and natural aesthetic. This leather is sourced from reputable tanneries, ensuring it meets international standards. The leather is then treated to enhance its properties, such as water resistance and color retention.

During this stage, suppliers often conduct initial inspections to assess the leather’s quality, looking for any defects or inconsistencies. Buyers should inquire about the types of leather used and the sourcing practices to ensure ethical and sustainable procurement.

Illustrative image related to custom leather man jacket

Forming: What Techniques Are Used to Shape the Jacket?

Once the leather is prepared, the next stage involves forming the jacket. This can be done using traditional handcrafting techniques or modern machinery, depending on the supplier’s capabilities. Custom patterns are created based on the buyer’s specifications, ensuring a tailored fit.

Key techniques in this stage include:

- Cutting: Precision cutting of leather pieces based on the design.

- Stitching: High-quality stitching techniques, often using strong polyester or nylon threads, to ensure durability.

Buyers should ensure that the manufacturer uses advanced cutting and stitching methods to avoid issues like fraying or uneven seams.

Assembly: How Are the Pieces Brought Together?

The assembly stage is where the individual leather pieces are brought together to form the jacket. This includes attaching components such as zippers, pockets, and lining. Quality manufacturers will often use high-standard zippers (like YKK) and hardware that not only serve a functional purpose but also add aesthetic value.

During this stage, it’s essential to have skilled artisans involved, as this ensures attention to detail. B2B buyers should verify the manufacturer’s workforce qualifications and experience in jacket assembly.

Illustrative image related to custom leather man jacket

Finishing: What Processes Enhance the Jacket’s Appearance?

Finishing processes include dyeing, polishing, and applying protective coatings to enhance the leather’s appearance and longevity. This stage may also involve adding custom features like embroidery or sublimation printing to personalize the jacket further.

Quality assurance checkpoints during this stage are critical. Buyers should request samples or prototypes before final production runs to assess quality and fit.

What Quality Control Measures Are Essential for Custom Leather Jackets?

Quality control (QC) is crucial in the leather jacket manufacturing process to ensure that the final product meets the desired standards. Various international and industry-specific standards guide these practices.

Which International Standards Should B2B Buyers Look For?

One of the most recognized international standards for quality management is ISO 9001. This certification ensures that the manufacturer maintains consistent quality throughout their processes, from material selection to final inspection. Additionally, industry-specific standards like CE marking may apply if the jackets are intended for specific markets or uses.

B2B buyers should inquire about the certifications held by their suppliers, as these serve as a benchmark for quality assurance.

Illustrative image related to custom leather man jacket

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are critical to maintaining high standards throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet predefined specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing help identify any issues early in the production process.

- Final Quality Control (FQC): A thorough inspection of the finished jackets, assessing for defects in stitching, finishing, and overall appearance.

B2B buyers should request documentation of these QC checkpoints to ensure adherence to quality standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that a supplier maintains high-quality standards, B2B buyers can implement several verification strategies:

Illustrative image related to custom leather man jacket

What Auditing Methods Are Effective for Supplier Verification?

Conducting regular audits of suppliers is an effective way to verify their manufacturing and quality control practices. These audits can be carried out by the buying company or through third-party inspection services. A comprehensive audit will assess the supplier’s compliance with international standards, production capabilities, and workforce skills.

What Documentation Should Buyers Request?

Buyers should request detailed QC reports from their suppliers, which should outline the inspection results at various checkpoints. These reports should include:

- Material inspection records

- Production process logs

- Final inspection certificates

This documentation provides transparency and helps in identifying potential quality issues before they reach the market.

What Are the QC and Certification Nuances for International B2B Buyers?

For international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certifications is vital.

How Do Customs and Import Regulations Affect Quality Control?

Different countries have varying regulations regarding import duties, taxes, and product standards. B2B buyers should familiarize themselves with local customs regulations to avoid unexpected charges or compliance issues. It is advisable to consult local customs offices to understand the implications of importing custom leather jackets.

What Should Buyers Consider About Ethical Manufacturing Practices?

Ethical manufacturing practices are increasingly important for B2B buyers. Ensuring that the leather is sourced as a byproduct of the meat industry and that workers are treated fairly can enhance a brand’s reputation. Buyers should inquire about the ethical standards upheld by their suppliers and seek certifications related to ethical manufacturing.

Conclusion: How to Ensure Quality in Custom Leather Jacket Manufacturing?

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures is essential for B2B buyers of custom leather man jackets. By focusing on material preparation, forming, assembly, and finishing, alongside robust quality control practices, buyers can ensure they receive high-quality products that meet international standards. Verifying supplier practices through audits and documentation will further enhance buyer confidence and satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather man jacket’

To assist B2B buyers in sourcing custom leather man jackets effectively, this practical guide provides a step-by-step checklist. It is essential to follow these steps to ensure quality, compliance, and satisfaction with your purchase.

Illustrative image related to custom leather man jacket

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s vital to establish clear technical specifications for the custom leather jackets. Consider factors such as material types (e.g., full-grain leather), design elements, and intended use (casual, formal, etc.). Defining these parameters will help you communicate your requirements effectively to potential suppliers.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in custom leather jackets. Look for companies with a strong presence in the leather goods market, particularly those that export to your target regions. Utilize industry directories, trade shows, and online platforms to compile a list of potential partners.

- Tip: Prioritize suppliers with positive reviews and a proven track record in delivering quality products.

Step 3: Evaluate Supplier Capabilities

Once you have a shortlist, assess each supplier’s capabilities. Request information about their production processes, quality control measures, and the range of customization options available. Understanding their manufacturing capabilities is crucial to ensure they can meet your specific requirements.

- Key Questions to Ask:

- What materials do you use, and can they be customized?

- How do you ensure quality throughout the production process?

Step 4: Request Samples and Prototypes

Before finalizing any orders, request samples or prototypes of the custom leather jackets. This step allows you to evaluate the craftsmanship, material quality, and overall fit. Ensure the sample reflects the specifications you require, as this will serve as a benchmark for your bulk order.

- Considerations:

- Check for consistency in color and texture.

- Assess the durability and comfort of the sample.

Step 5: Confirm Compliance with Standards

Verify that the suppliers adhere to international standards and regulations relevant to leather products. This may include safety certifications, ethical manufacturing practices, and environmental compliance. Ensuring that your suppliers meet these standards helps mitigate risks and enhances your brand’s reputation.

Illustrative image related to custom leather man jacket

- Important Standards:

- ISO certifications for quality management.

- Compliance with environmental regulations.

Step 6: Negotiate Terms and Conditions

Engage in discussions regarding pricing, payment terms, and delivery schedules. It’s crucial to establish clear terms that protect your interests while fostering a good relationship with the supplier. Be transparent about your expectations for quality and delivery timelines.

- Negotiation Points:

- Minimum order quantities (MOQs).

- Lead times and shipping arrangements.

Step 7: Establish a Quality Assurance Process

Once you’ve finalized your order, implement a quality assurance process to monitor production. This may involve regular check-ins with the supplier, on-site inspections, or third-party quality checks. Establishing this process ensures that the final product meets your expectations before shipping.

By following this checklist, B2B buyers can streamline their sourcing process for custom leather man jackets, ensuring a successful procurement experience that aligns with their business goals.

Illustrative image related to custom leather man jacket

Comprehensive Cost and Pricing Analysis for custom leather man jacket Sourcing

What Are the Key Cost Components in Custom Leather Man Jacket Sourcing?

When sourcing custom leather man jackets, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The quality of leather significantly impacts cost. Full-grain leather, considered the highest quality, tends to be more expensive than other grades. Additionally, the choice of lining, zippers, and hardware can affect the final price. Suppliers often offer various leather types that cater to different budgets, which can help in cost management.

-

Labor: Skilled labor is essential for crafting bespoke jackets. The complexity of the design and the level of customization required will dictate labor costs. Artisans with extensive experience may charge a premium, but their expertise can lead to superior product quality.

-

Manufacturing Overhead: This includes costs associated with operating the production facility, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help mitigate these costs, making it essential to partner with suppliers who emphasize operational efficiency.

-

Tooling: If unique patterns or molds are needed for custom designs, tooling costs can arise. This upfront investment can be significant but is necessary for creating high-quality, tailored products.

-

Quality Control (QC): Implementing a robust QC process ensures that each jacket meets the desired specifications and quality standards. This might involve additional testing or inspections, adding to the overall cost but ultimately safeguarding the product’s reputation.

-

Logistics: Shipping and handling costs can vary widely based on the destination and shipping method. Incoterms play a crucial role in determining who bears these costs, so understanding the logistics involved is vital for budgeting.

-

Margin: Suppliers will typically include a profit margin in their pricing. This can vary based on market demand, brand reputation, and the uniqueness of the product offered.

How Do Pricing Influencers Affect Custom Leather Jacket Costs?

Several factors can influence the final pricing of custom leather jackets:

-

Volume and Minimum Order Quantity (MOQ): Ordering in bulk can significantly reduce the unit price, as suppliers often provide discounts for larger orders. Understanding the MOQ can help buyers negotiate better terms.

-

Specifications and Customization: The more intricate the design or customization (e.g., embroidery, specialized linings), the higher the costs. Buyers should clearly define their specifications to obtain accurate quotes.

-

Materials and Quality Certifications: Jackets made from premium materials with certifications (like eco-friendly or sustainable leather) may have higher upfront costs but can offer long-term value through durability and brand reputation.

-

Supplier Factors: The reputation and reliability of the supplier play a significant role in pricing. Established suppliers with a track record of quality may charge more but offer peace of mind regarding product quality and delivery timelines.

-

Incoterms: Understanding the implications of shipping terms (like FOB, CIF, DDP) is crucial for calculating the total cost of ownership. Different Incoterms can shift responsibilities and costs between buyer and supplier, impacting the overall expense.

What Are Essential Buyer Tips for Cost-Efficiency in Custom Leather Jacket Sourcing?

B2B buyers should consider several strategies to enhance cost-efficiency in sourcing custom leather jackets:

-

Negotiate Wisely: Leverage your purchasing power by negotiating terms, especially if you are a repeat customer or can provide bulk orders. Establish clear communication about your needs and expectations.

-

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, consider all associated costs, including shipping, duties, and long-term maintenance. A higher-quality jacket may have a lower TCO due to its durability.

-

Understand Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of potential customs duties and taxes. Researching local regulations can prevent unexpected expenses.

-

Utilize Supplier Relationships: Build long-term relationships with suppliers to gain insights into upcoming trends and pricing. A reliable supplier can also provide flexibility in pricing based on market changes.

Disclaimer on Indicative Prices

While indicative prices for custom leather man jackets can range widely, it is essential to recognize that actual costs will vary based on the factors discussed above. Always obtain detailed quotes from suppliers to ensure accurate budgeting for your specific needs.

Illustrative image related to custom leather man jacket

Alternatives Analysis: Comparing custom leather man jacket With Other Solutions

Exploring Alternative Solutions for Custom Leather Jackets

When considering a custom leather man jacket, it’s essential to explore various alternatives that can meet similar needs for style, functionality, and personalization. This analysis will compare the custom leather jacket with two viable alternatives: synthetic leather jackets and ready-to-wear leather jackets. Each option presents distinct characteristics that may appeal to different B2B buyers based on their specific requirements.

| Comparison Aspect | Custom Leather Man Jacket | Synthetic Leather Jacket | Ready-to-Wear Leather Jacket |

|---|---|---|---|

| Performance | High durability and unique fit | Moderate durability, often less breathable | Good durability, standard fit |

| Cost | $398 – $502 | $100 – $300 | $200 – $600 |

| Ease of Implementation | Requires custom measurements and consultation | Off-the-shelf availability, no customization | Standard sizes available, limited customization |

| Maintenance | Requires specialized care for longevity | Easier to clean and maintain | Requires some care, but less than leather |

| Best Use Case | Unique branding, fashion-forward individuals, personalized gifts | Budget-conscious consumers, eco-friendly buyers | Quick procurement, general use in fashion |

What Are the Pros and Cons of Synthetic Leather Jackets?

Synthetic leather jackets, often made from polyurethane or PVC, provide a budget-friendly alternative to custom leather jackets. They typically cost less and are readily available, making them an attractive option for businesses looking to purchase in bulk. However, the trade-off is that synthetic materials may not offer the same level of durability or breathability as genuine leather. Moreover, while they can mimic the appearance of leather, they often lack the unique character and fit of a custom-made product. Therefore, synthetic leather jackets are best suited for companies targeting a price-sensitive market or those emphasizing eco-friendliness.

How Do Ready-to-Wear Leather Jackets Compare?

Ready-to-wear leather jackets offer a middle ground between custom solutions and off-the-shelf products. They are widely available in various styles and sizes, allowing for quick procurement. However, while they provide a decent level of quality and style, the fit is often generic, which may not meet the specific needs of all customers. Additionally, customization options are typically limited, which could hinder brand differentiation. These jackets are ideal for businesses that require a stylish yet practical solution without the time investment of a custom order.

Illustrative image related to custom leather man jacket

How Can B2B Buyers Choose the Right Solution?

Selecting the appropriate solution for leather jackets depends on various factors, including budget constraints, desired level of customization, and target market. For businesses aiming to create a unique brand identity or offer personalized gifts, investing in custom leather jackets can provide significant long-term value despite the higher upfront cost. Conversely, for those focused on immediate availability and cost-efficiency, synthetic or ready-to-wear options may suffice. Ultimately, understanding the specific needs of the target audience will guide buyers toward the most suitable choice.

Essential Technical Properties and Trade Terminology for custom leather man jacket

What Are the Key Technical Properties of a Custom Leather Man Jacket?

When dealing with custom leather man jackets, understanding the essential technical properties is crucial for B2B buyers. Here are some of the most significant specifications:

1. Material Grade

The material grade is a fundamental characteristic of leather jackets, determining quality, durability, and appearance. Full grain leather, for instance, is the highest quality, retaining the natural texture and imperfections of the hide. This type of leather ages beautifully, developing a unique patina over time. For B2B buyers, selecting high-grade materials ensures a premium product that meets customer expectations and enhances brand reputation.

2. Tolerance Levels

Tolerance levels refer to the acceptable variations in measurements during the manufacturing process. This is especially important for custom jackets, where precise fitting is essential. Tolerances are often expressed in millimeters or inches and can affect the jacket’s overall fit and comfort. For B2B buyers, understanding tolerance levels helps in ensuring that the final product meets the desired specifications, reducing the risk of returns due to poor fit.

Illustrative image related to custom leather man jacket

3. Stitching Techniques

The stitching technique used in leather jackets can significantly impact their durability and aesthetic appeal. Common methods include double stitching for added strength and decorative stitching for style. For B2B buyers, knowing the stitching techniques can provide insights into the jacket’s longevity and the craftsmanship involved, which can justify pricing and appeal to quality-conscious customers.

4. Hardware Quality

The quality of zippers, buttons, and other hardware components is crucial in custom leather jackets. YKK zippers, for example, are known for their reliability and durability. Hardware not only serves a functional purpose but also adds to the overall aesthetic. B2B buyers should prioritize suppliers who use high-quality hardware to ensure the longevity and functionality of the jackets.

5. Insulation Options

Insulation options, such as quilted lining, can enhance the functionality of leather jackets, especially in colder climates. Buyers should consider how insulation affects weight, bulk, and warmth. Offering jackets with varying insulation levels allows businesses to cater to different market needs and preferences.

What Are Common Trade Terms in Custom Leather Jacket Manufacturing?

Familiarity with industry-specific jargon is essential for effective communication in B2B transactions. Here are some common trade terms:

Illustrative image related to custom leather man jacket

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of custom leather jackets, an OEM might create the jackets based on designs provided by a fashion brand. Understanding OEM relationships can help buyers navigate their supply chain more effectively.

2. MOQ (Minimum Order Quantity)

MOQ signifies the smallest order quantity that a supplier is willing to accept. For custom leather jackets, MOQs can vary based on the complexity of the design and materials used. B2B buyers should be aware of MOQs to plan their inventory and manage costs effectively.

3. RFQ (Request for Quotation)

An RFQ is a formal process used by buyers to solicit price quotes from suppliers. It typically includes detailed specifications for the desired products. For buyers of custom leather jackets, issuing an RFQ can facilitate a competitive bidding process, ensuring they receive the best price and service.

4. Incoterms

Incoterms, or International Commercial Terms, are predefined trade terms used in international sales contracts. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is vital for B2B buyers engaged in cross-border transactions, as they clarify costs and liabilities.

5. Lead Time

Lead time is the duration it takes from placing an order to receiving the finished product. In the custom leather jacket industry, lead times can vary significantly based on design complexity and production capacity. B2B buyers should consider lead times when planning product launches and managing inventory levels.

By comprehending these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring successful partnerships and high-quality products in the custom leather jacket market.

Navigating Market Dynamics and Sourcing Trends in the custom leather man jacket Sector

What Are the Key Market Dynamics and Trends in the Custom Leather Man Jacket Sector?

The global custom leather man jacket market is experiencing significant growth, driven by increasing consumer demand for personalized fashion and a growing awareness of quality craftsmanship. In regions like Africa, South America, the Middle East, and Europe, the trend towards bespoke clothing is on the rise as consumers seek unique pieces that reflect their individuality. Key technological advancements, such as 3D modeling and virtual fitting rooms, are enhancing the customer experience, allowing buyers to visualize and customize their jackets before production. Moreover, the integration of online platforms for design consultations and order placements is streamlining the sourcing process for international B2B buyers.

Emerging trends indicate a shift towards hybrid models that combine online customization with local craftsmanship. Buyers are increasingly looking for suppliers that offer a blend of affordability and high-quality materials. The demand for full-grain leather—known for its durability and unique character—is also increasing, as buyers prioritize long-lasting products over fast fashion. Additionally, the market is seeing a rise in collaborations between fashion designers and bespoke leather manufacturers, which can lead to innovative styles and limited-edition releases, appealing to niche markets across various regions.

How Are Sustainability and Ethical Sourcing Impacting the Custom Leather Jacket Industry?

Sustainability and ethical sourcing have become critical considerations for B2B buyers in the custom leather man jacket sector. The environmental impact of leather production, including water usage and chemical processing, has led to an increased demand for eco-friendly practices. Buyers are prioritizing suppliers who demonstrate a commitment to sustainable sourcing, such as using vegetable-tanned leather and adhering to strict environmental regulations.

The importance of ethical supply chains is underscored by consumer preferences shifting towards brands that emphasize transparency and social responsibility. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are becoming crucial for manufacturers looking to attract conscientious buyers. These certifications ensure that leather is sourced responsibly, minimizing the ecological footprint and ensuring fair labor practices throughout the supply chain.

Moreover, businesses are increasingly adopting a circular economy approach, where leather waste is repurposed and recycled, thus reducing overall waste. This trend is particularly appealing to international buyers in regions like Europe, where sustainability is highly valued. As such, B2B buyers are encouraged to partner with manufacturers who prioritize eco-friendly materials and ethical practices to meet the growing consumer demand for sustainable fashion.

What is the Historical Context of Custom Leather Jackets in the B2B Market?

The custom leather jacket has a rich history that reflects broader fashion trends and cultural shifts. Originally designed for functionality and protection, leather jackets gained popularity in the mid-20th century as symbols of rebellion and individualism, particularly in the biker and rock music subcultures. Over the decades, these jackets have evolved into fashion staples, embraced by various demographics for their timeless appeal and versatility.

In the B2B context, the evolution of custom leather jackets has been significantly influenced by the rise of personalization in fashion. With advances in manufacturing technology and the growth of e-commerce, buyers can now easily source bespoke leather jackets tailored to specific styles and fits. This evolution has opened new avenues for international trade, particularly in emerging markets where demand for unique, high-quality apparel is on the rise. As the market continues to evolve, understanding this historical context can provide B2B buyers with valuable insights into consumer preferences and sourcing strategies.

Illustrative image related to custom leather man jacket

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather man jacket

-

1. How do I ensure the quality of custom leather man jackets when sourcing internationally?

To ensure quality, establish a thorough vetting process for suppliers. Request samples of their work and verify the materials used, such as full-grain leather, which is the highest quality. Engage in direct communication regarding production methods and ethical sourcing practices. It’s also beneficial to visit the supplier’s facility if possible or request third-party inspections to verify quality control measures. Having clear quality assurance standards outlined in your contract can further protect your interests. -

2. What is the best approach to customizing leather jackets for my target market?

Start by researching your target market’s preferences, including popular styles, colors, and sizes. Collaborate with your supplier to understand the range of customization options available, such as fabric types, hardware, and design features. Offering bespoke services can differentiate your brand, so consider integrating local cultural elements or trends into your designs. Conducting surveys or focus groups can also provide insights into what potential customers value in custom leather jackets. -

3. What are the common minimum order quantities (MOQs) for custom leather jackets?

MOQs can vary significantly between suppliers, typically ranging from 50 to 100 units per design. When negotiating, consider your budget and storage capabilities. Some manufacturers may offer lower MOQs for initial orders or sample runs, especially if you can demonstrate a commitment to future orders. Establishing a long-term relationship with a supplier can also lead to more flexible MOQs as trust builds over time. -

4. What payment terms should I expect when ordering custom leather jackets?

Payment terms can vary widely, but common practices include a 30% deposit upon order confirmation, with the balance due upon completion or before shipment. Ensure you clarify these terms upfront and consider using secure payment methods that offer buyer protection. Additionally, inquire about the possibility of payment in installments for larger orders, which can ease cash flow concerns. -

5. How do I manage logistics and shipping for international orders of custom leather jackets?

Work with suppliers who have experience in international shipping and can provide logistics support. Discuss shipping options, including air freight for quicker deliveries or sea freight for cost efficiency. Ensure your supplier can handle customs documentation and provide insights into any duties or taxes applicable in your country. Establishing a reliable logistics partner can streamline this process and ensure timely delivery to your location. -

6. What quality assurance practices should I implement for custom leather jackets?

Incorporate a multi-step quality assurance process that includes initial sample approval, mid-production inspections, and final product evaluations. Clearly communicate your quality standards to your supplier and request reports or images during production. Consider third-party inspections before shipment to verify that products meet your specifications and standards. Documenting these quality checks can help resolve disputes if issues arise. -

7. How can I effectively communicate my design requirements to suppliers?

Provide detailed specifications for your designs, including sketches, color swatches, and material samples. Utilize digital tools like CAD software to create precise designs that can be easily interpreted. Regular communication through video calls or messaging platforms can clarify any uncertainties and foster collaboration. Establish a timeline for feedback and revisions to keep the project on track, ensuring that your vision is accurately represented in the final product. -

8. What are the best practices for marketing custom leather jackets in international markets?

Understand the cultural nuances and fashion trends of your target markets. Utilize social media platforms to showcase your products and engage with potential customers through visually appealing content. Collaborate with local influencers or fashion bloggers to expand your reach. Attend trade shows and exhibitions in your target regions to network and present your products directly to buyers, enhancing brand visibility and credibility.

Top 7 Custom Leather Man Jacket Manufacturers & Suppliers List

1. Varsity Made – Customizable Varsity Jackets

Domain: varsitymade.co

Registered: 2022 (3 years)

Introduction: Fully Customizable Varsity Jacket, Free Shipping on all Varsity Jackets, Affordable pricing, Financing Available, Fast Delivery (ships within 5-7 weeks), High-quality materials, Custom interior lining upload option, Patch placement & embroidery customization, Group discounts available, 10% off first order for newsletter sign-up.

2. Aero Leather Clothing – Custom Leather Jackets

Domain: aeroleatherclothing.com

Registered: 1997 (28 years)

Introduction: Custom leather jackets made to order, hand-crafted by Aero Leather Jackets since 1981. Extensive range of vintage designs from the 1920s to 1960s, with over 100 classic coats available. Customization options include various leather and lining combinations, stitch color, and more. Known for high-quality craftsmanship and unique personalization. Available for order through the website or by contacti…

3. Momentec – Holloway Varsity Jacket Configurator

Domain: momentecbrands.com

Registered: 2024 (1 years)

Introduction: Holloway Configurator allows customization of wool varsity jackets. Users can choose from stock jackets for immediate delivery or design their own by selecting categories such as Adult, Ladies, Youth, and Juniors. The online builder facilitates customization of style, fabric, and colors. Previous designs can be saved and retrieved for consistency. Customer support is available for assistance with …

4. LeatherCult – Custom Leather Apparel

Domain: leathercult.com

Registered: 2010 (15 years)

Introduction: LeatherCult offers a wide range of custom leather apparel for men, women, and boys, including leather jackets, blazers, long coats, vests, suits, pants, shorts, and chaps. Accessories include leather pocket squares, wristbands, hoods, belts, caps, bows, and ties. The products are handmade from premium leather, ensuring a perfect fit and high-quality craftsmanship. Sizes range from XS to 4XL, and t…

5. Stewart & Strauss – Premium Varsity Jackets

Domain: jacketshop.com

Registered: 1999 (26 years)

Introduction: Stewart & Strauss offers premium varsity jackets and sweaters, with a sale ending on October 31st. They have the world’s largest selection of varsity letterman jackets and sweaters since 1977. Customers can design their own jackets and sweaters, with options including in-stock jackets, full leather jackets, satin bomber jackets, letter sweaters, custom lettering, patches, and kids jackets. They pr…

6. Novo Jackets – Premium Custom Varsity and Bomber Jackets

Domain: novojackets.com

Registered: 2015 (10 years)

Introduction: Top Quality Varsity Jackets, Bomber Jackets, Custom Varsity Jackets, Customize Varsity Letterman Jackets, High School Letterman Jackets, Custom Bomber Jackets, Premium Custom Jackets. Key features include: Superior materials (melton wool, genuine cowhide, sheep leather, high-quality polyester satin), expert craftsmanship, traditional and contemporary styling, personalized designs, easy-to-use Jack…

7. Varsity Base – High-Quality Varsity & Letterman Jackets

Domain: varsitybase.com

Registered: 2018 (7 years)

Introduction: Varsity Base offers a variety of high-quality varsity and letterman jackets suitable for both men and women. Key product details include:

– Men’s Classic Wool & Leather Jackets

– Women’s Classic Wool & Leather Jackets

– All-Wool Jackets

– Wool & Faux Leather Jackets

– Lightweight Jackets

– Satin Jackets

– Coats

– Customization options for letterman jackets including name, number, and desig…

Strategic Sourcing Conclusion and Outlook for custom leather man jacket

In the competitive landscape of custom leather jackets, strategic sourcing is pivotal for B2B buyers seeking high-quality products that align with market demands. By prioritizing ethical manufacturing practices and direct sourcing from reputable tanneries, businesses can ensure they offer unique, bespoke products that resonate with consumers’ desire for individuality and quality. The use of full-grain leather, combined with customizable options, not only enhances product appeal but also establishes a strong brand identity that can drive customer loyalty.

International buyers from Africa, South America, the Middle East, and Europe are uniquely positioned to leverage these insights. Embracing a tailored approach in sourcing can differentiate your offerings in diverse markets, catering to specific cultural preferences and fashion trends.

As we look ahead, the demand for custom leather jackets is expected to rise, fueled by a growing consumer base that values both craftsmanship and personalization. Now is the time to take action—invest in strategic partnerships with reliable manufacturers who can deliver high-quality products that meet your specifications. Empower your brand by providing customers with jackets that not only tell a story but also stand the test of time.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.