Introduction: Navigating the Global Market for automotive leather

Navigating the complex landscape of the automotive leather market can be daunting for international B2B buyers, particularly those from emerging economies in Africa, South America, the Middle East, and Europe. With increasing demand for high-quality automotive interiors, sourcing the right automotive leather that balances luxury, durability, and cost-effectiveness is crucial. This guide provides a comprehensive overview of the automotive leather industry, covering the various types of leather, their applications, and essential considerations for supplier vetting.

In addition to exploring the nuances of leather grades and finishes, we delve into pricing structures, trends in sustainability, and the growing popularity of eco-friendly alternatives. Understanding these factors is essential for making informed purchasing decisions that align with your business needs and customer expectations.

By equipping B2B buyers with actionable insights and practical tips, this guide empowers you to navigate the global automotive leather market with confidence. Whether you are looking to source materials for luxury vehicles, commercial fleets, or custom projects, our expert analysis will help you identify reliable suppliers and make strategic choices that enhance your product offerings. Together, let’s transform your procurement process into a streamlined and effective strategy that drives success in the automotive industry.

Table Of Contents

- Top 9 Automotive Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for automotive leather

- Understanding automotive leather Types and Variations

- Key Industrial Applications of automotive leather

- 3 Common User Pain Points for ‘automotive leather’ & Their Solutions

- Strategic Material Selection Guide for automotive leather

- In-depth Look: Manufacturing Processes and Quality Assurance for automotive leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘automotive leather’

- Comprehensive Cost and Pricing Analysis for automotive leather Sourcing

- Alternatives Analysis: Comparing automotive leather With Other Solutions

- Essential Technical Properties and Trade Terminology for automotive leather

- Navigating Market Dynamics and Sourcing Trends in the automotive leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of automotive leather

- Strategic Sourcing Conclusion and Outlook for automotive leather

- Important Disclaimer & Terms of Use

Understanding automotive leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Grain Leather | Retains the natural grain and texture; highly durable | Luxury vehicles, high-end restorations | Pros: Premium quality, excellent durability. Cons: Higher cost, may require more maintenance. |

| Top Grain Leather | Sanded and finished for a smooth surface; less durable than full grain | Mid-range to luxury vehicles | Pros: Affordable luxury, easier to clean. Cons: Less durable than full grain, can show wear faster. |

| Bonded Leather | Made from leather scraps and fibers bonded together | Budget vehicles, commercial fleets | Pros: Cost-effective, environmentally friendly. Cons: Lower durability, less luxurious appearance. |

| Alcantara | Synthetic suede-like material; soft and breathable | Performance vehicles, luxury interiors | Pros: Lightweight, easy to maintain. Cons: Not as durable as leather, can be prone to staining. |

| Vintage Leather | Authentic aged leather; unique character and patina | Classic cars, restoration projects | Pros: Unique aesthetic, highly sought after. Cons: Availability issues, higher cost. |

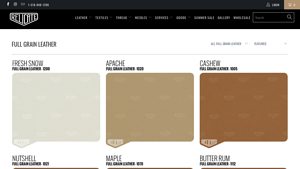

What are the Characteristics of Full Grain Leather for Automotive Applications?

Full grain leather is celebrated for its durability and natural beauty. It retains the animal’s original grain, providing a unique texture and a luxurious feel. This type of leather is ideal for high-end vehicles where quality and longevity are paramount. When purchasing full grain leather, buyers should consider the sourcing and tanning processes, as these factors significantly impact the leather’s quality and performance over time.

Illustrative image related to automotive leather

How Does Top Grain Leather Compare in Quality and Cost?

Top grain leather is sanded to remove imperfections, resulting in a smoother surface. While it offers a more affordable luxury option compared to full grain leather, it is less durable and can show signs of wear more quickly. B2B buyers should weigh the trade-off between cost and longevity, particularly for vehicles that may experience heavy use, ensuring that the choice aligns with their customer expectations.

Why Choose Bonded Leather for Budget-Friendly Options?

Bonded leather is made from leftover leather scraps that are glued together, making it a cost-effective choice for budget-conscious applications. While it offers a leather-like appearance, its durability is significantly lower than that of full or top grain leather. Buyers should consider bonded leather for commercial fleets or entry-level vehicles, where aesthetics are important but budget constraints prevail.

What Are the Advantages of Using Alcantara in Automotive Interiors?

Alcantara is a synthetic material that mimics the softness of suede and offers a modern aesthetic. It is lightweight, breathable, and easy to maintain, making it a popular choice for performance vehicles and luxury interiors. However, it is essential for buyers to consider the potential for staining and the overall durability compared to traditional leather options, especially in high-traffic areas.

How Does Vintage Leather Enhance Classic Car Restorations?

Vintage leather provides an authentic touch to classic car restorations, featuring unique character and a rich patina that tells a story. This type of leather is often sought after by collectors and enthusiasts. B2B buyers should be aware of potential supply challenges and the higher costs associated with sourcing genuine vintage leather, which can affect project budgets and timelines.

Key Industrial Applications of automotive leather

| Industry/Sector | Specific Application of Automotive Leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Luxury Vehicle Interiors | Enhances brand image and customer satisfaction | Quality certification, customization options, color matching |

| Custom Vehicle Upgrades | Custom Upholstery for Classic Cars | Adds value to restorations and bespoke builds | Availability of vintage styles, material durability |

| Commercial Vehicle Interiors | Fleet Vehicle Cabins | Improves comfort and reduces maintenance costs | Bulk purchasing options, stain resistance, easy cleaning |

| Aviation and Marine | High-End Seating and Interiors | Provides lightweight, durable, and luxurious finishes | Compliance with safety regulations, fire resistance |

| Furniture and Home Décor | Specialty Automotive Leather Furniture | Unique aesthetic appeal and high-end market positioning | Sustainability of sourcing, availability of diverse colors |

How is Automotive Leather Used in Luxury Vehicle Interiors?

In the automotive manufacturing sector, automotive leather is predominantly used for luxury vehicle interiors. This application not only enhances the aesthetic appeal of the vehicle but also elevates the overall customer experience. Luxury brands rely on high-quality leather to convey exclusivity and sophistication. International buyers, especially from regions like Europe and the Middle East, should consider sourcing leather with certifications that guarantee quality, such as ISO or other industry standards, to maintain their brand image.

What Role Does Automotive Leather Play in Custom Vehicle Upgrades?

In the custom vehicle upgrades market, automotive leather is essential for creating bespoke interiors in classic cars and hot rods. This application allows car enthusiasts to personalize their vehicles, significantly adding to their value. Buyers should prioritize sourcing leather that mimics vintage styles while ensuring durability and ease of maintenance. Customization options, such as color and texture variations, are critical for meeting specific design requirements.

How Does Automotive Leather Benefit Commercial Vehicle Interiors?

For commercial vehicle interiors, automotive leather is increasingly used to enhance fleet vehicle cabins. This application improves passenger comfort while reducing long-term maintenance costs due to leather’s stain-resistant properties. International buyers, particularly from South America and Africa, should seek suppliers that offer bulk purchasing options and warranties, ensuring that they receive quality materials capable of withstanding heavy use in diverse environments.

Illustrative image related to automotive leather

In What Ways is Automotive Leather Utilized in Aviation and Marine Industries?

In the aviation and marine sectors, automotive leather is favored for high-end seating and interiors due to its lightweight and durable nature. This application provides a luxurious finish that meets the stringent safety regulations of these industries. Buyers in these fields should focus on sourcing leather that complies with fire resistance standards and is suitable for high-humidity environments, ensuring longevity and safety in their applications.

How is Automotive Leather Integrated into Furniture and Home Décor?

Automotive leather is also finding its way into furniture and home décor, particularly in creating unique pieces that stand out in high-end markets. This application combines the durability of automotive leather with innovative design, appealing to luxury consumers. Buyers should consider the sustainability of sourcing practices and the availability of diverse color options to align with current market trends and consumer preferences.

3 Common User Pain Points for ‘automotive leather’ & Their Solutions

Scenario 1: Sourcing High-Quality Automotive Leather for Diverse Markets

The Problem: B2B buyers often struggle to find high-quality automotive leather that meets their specific requirements, especially when catering to diverse markets such as Africa, South America, the Middle East, and Europe. Variations in climate, consumer preferences, and automotive standards can complicate sourcing decisions. Buyers may face challenges with inconsistent quality, limited availability of preferred colors or textures, and the risk of dealing with untrustworthy suppliers. This can lead to delays in production and dissatisfaction among end customers.

The Solution: To address these challenges, buyers should establish strong relationships with reputable suppliers who specialize in automotive leather. It’s essential to conduct thorough research and vet potential suppliers based on their track record, quality certifications, and product range. Request samples of various leather types and colors to ensure they align with market expectations. Additionally, consider suppliers that offer custom dyeing services to match specific color requirements. Leveraging suppliers that operate globally can provide access to a broader selection, ensuring you find the right leather for your target market while maintaining quality and consistency.

Scenario 2: Managing Leather Maintenance and Longevity Concerns

The Problem: Another pain point for B2B buyers is the challenge of ensuring that automotive leather maintains its appearance and durability over time. Many buyers are concerned about the leather’s susceptibility to wear, tear, and staining, which can negatively impact customer satisfaction and brand reputation. This issue is particularly pressing in regions with extreme weather conditions, where leather may degrade faster without proper care.

Illustrative image related to automotive leather

The Solution: To combat these issues, buyers should prioritize sourcing leather that is treated for durability and ease of maintenance. Look for leather products that come with protective coatings that repel stains and resist fading. Additionally, provide end-users with comprehensive care instructions tailored to the specific type of leather used. Offering leather care kits, including conditioners and protectants, can also enhance the longevity of the product. Educating customers on the importance of regular maintenance will not only ensure the leather looks great but also reinforces the value of investing in high-quality materials.

Scenario 3: Balancing Cost and Quality in Automotive Leather Procurement

The Problem: B2B buyers frequently face the dilemma of balancing cost and quality when procuring automotive leather. In a competitive market, there is pressure to minimize costs while still providing high-quality materials that meet consumer expectations. This can lead to sourcing cheaper alternatives that may not perform as well, resulting in higher long-term costs due to replacements or repairs.

The Solution: To achieve an effective balance between cost and quality, buyers should engage in strategic sourcing practices. This involves analyzing the total cost of ownership rather than just the initial purchase price. Invest time in understanding the lifecycle of the leather, including its durability and maintenance needs. Additionally, consider establishing long-term contracts with suppliers for bulk purchasing, which can lower costs without sacrificing quality. Collaborating with suppliers who can provide insights into industry trends and advancements in leather technology can also lead to better investment decisions, ultimately benefiting both the buyer and the end customer.

Strategic Material Selection Guide for automotive leather

What Are the Key Properties of Common Automotive Leather Materials?

When selecting automotive leather, understanding the properties of various materials is crucial for B2B buyers. The following analysis covers four common materials used in automotive leather production: full-grain leather, top-grain leather, synthetic leather (PU), and Alcantara. Each material has unique characteristics that can impact performance, cost, and suitability for specific applications.

What Are the Key Properties of Full-Grain Leather?

Full-grain leather is renowned for its durability and natural appearance. It retains the hide’s original texture, making it highly breathable and resistant to wear. This material can withstand high temperatures and pressures, making it ideal for high-performance vehicles. However, full-grain leather requires regular maintenance to prevent drying and cracking, which can be a disadvantage for some manufacturers.

Illustrative image related to automotive leather

Pros: Exceptional durability, luxurious appearance, and natural breathability.

Cons: Higher cost and maintenance requirements.

Impact on Application: Suitable for luxury vehicles where aesthetics and durability are paramount.

Considerations for International Buyers: Compliance with international standards like ASTM for leather quality and environmental regulations is essential, particularly in regions like Europe where sustainability is prioritized.

How Does Top-Grain Leather Compare in Performance?

Top-grain leather is a step down from full-grain, as it has been sanded and treated to remove imperfections. This results in a more uniform appearance and a softer texture, making it easier to clean and maintain. It offers good durability but is less resistant to scratches compared to full-grain leather. Top-grain leather is often used in mid-range vehicles.

Pros: Easier to maintain and more affordable than full-grain leather.

Cons: Less durable and may not age as well.

Impact on Application: Ideal for vehicles that require a balance between luxury and practicality.

Considerations for International Buyers: Buyers should ensure that top-grain leather meets local quality standards, especially in markets like Brazil, where consumer preferences lean towards cost-effective yet stylish options.

What Are the Advantages of Synthetic Leather (PU)?

Synthetic leather, particularly polyurethane (PU), has gained popularity due to its affordability and versatility. It is resistant to stains and easy to clean, making it a practical choice for vehicles with high passenger turnover. However, while PU leather can mimic the look of genuine leather, it lacks the breathability and durability of natural leathers.

Illustrative image related to automotive leather

Pros: Cost-effective, easy maintenance, and wide color options.

Cons: Less durable and can wear out faster than natural leather.

Impact on Application: Suitable for budget-friendly vehicles and fleet cars.

Considerations for International Buyers: Buyers should verify the environmental impact of synthetic leathers, especially in regions where eco-friendliness is a selling point, such as in parts of Europe.

Why Is Alcantara a Preferred Choice for Luxury Interiors?

Alcantara is a synthetic material that combines the look and feel of suede with enhanced durability. It is often used in high-end vehicles due to its luxurious appearance and soft texture. Alcantara is resistant to fading and staining, making it ideal for automotive applications. However, it may require specialized cleaning products to maintain its appearance.

Pros: Luxurious feel, excellent durability, and stain resistance.

Cons: Higher cost and specific cleaning requirements.

Impact on Application: Perfect for luxury and performance vehicles where aesthetics are critical.

Considerations for International Buyers: Compliance with international quality standards and consumer preferences for luxury materials are vital, especially in markets like Saudi Arabia, where luxury automotive features are highly valued.

Summary Table of Automotive Leather Materials

| Materiał | Typical Use Case for Automotive Leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | Luxury vehicles | Exceptional durability and breathability | Higher cost and maintenance needs | High |

| Top-Grain Leather | Mid-range vehicles | Easier maintenance and affordability | Less durable than full-grain | Medium |

| Synthetic Leather (PU) | Budget-friendly vehicles and fleet cars | Cost-effective and easy to clean | Less durable than natural leather | Low |

| Alcantara | High-end and performance vehicles | Luxurious feel and stain resistance | Higher cost and specific cleaning needs | High |

This guide provides a comprehensive overview of key materials used in automotive leather, helping international B2B buyers make informed decisions based on their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for automotive leather

What Are the Key Stages in the Manufacturing Process of Automotive Leather?

The manufacturing of automotive leather is a meticulous process that involves several critical stages, ensuring that the final product meets the high standards expected by the automotive industry. Here’s a breakdown of the main stages involved:

Material Preparation: How Is Raw Leather Processed?

The journey of automotive leather begins with the selection of high-quality hides, typically from cattle. These hides undergo a rigorous curing process to prevent decomposition. Common methods include:

- Salt Curing: The hides are salted to draw out moisture, which helps to preserve them.

- Pickling: Hides are treated with acidic solutions to prepare them for tanning.

- Tanning: This crucial process transforms raw hides into durable leather. Various tanning methods are utilized, including vegetable tanning and chrome tanning, each imparting distinct characteristics to the leather.

Once tanned, the hides are cleaned, and excess flesh is removed to prepare them for the next stage.

Forming: What Techniques Are Used to Shape Automotive Leather?

After preparation, the leather goes through forming, which includes cutting and shaping to fit specific automotive applications. Key techniques during this stage involve:

- Die Cutting: Precision die cutting machines are used to ensure consistent shapes and sizes, allowing for mass production without compromising quality.

- Stitching and Assembly: Skilled artisans may hand-stitch certain components, while automated stitching machines handle more straightforward seams. This assembly process is crucial for parts like seat covers, door panels, and headliners.

The forming stage is integral to maintaining the aesthetic and functional qualities of the leather, ensuring it aligns with design specifications.

Finishing: How Is Automotive Leather Treated for Quality and Appearance?

The finishing stage is where the leather is treated to enhance its durability and visual appeal. This includes:

- Dyeing: Leather can be dyed in various colors to meet specific design requirements. Custom dyeing services are often available to match precise color specifications.

- Coating: A protective coating is applied to improve resistance to stains and wear. This might include polyurethane or acrylic finishes, which also add to the leather’s gloss and smoothness.

- Quality Control: Each hide undergoes a thorough inspection for defects such as scars, blemishes, or inconsistencies in color before it moves on to the final product.

What Quality Assurance Standards Are Relevant for Automotive Leather?

Quality assurance in automotive leather manufacturing is critical, particularly for B2B buyers who require reliable and durable products. Several international and industry-specific standards guide this process:

Which International Standards Should Buyers Be Aware Of?

- ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is essential for ensuring that suppliers maintain consistent quality in their products.

- ISO 14001: This environmental management standard is also relevant, particularly for companies focused on sustainable practices in their supply chain.

What Industry-Specific Standards Are Important for Automotive Leather?

- CE Marking: Products that comply with European health, safety, and environmental protection standards must have CE marking, which is crucial for automotive leather sold in Europe.

- API Standards: For suppliers involved in the automotive industry, adhering to API (American Petroleum Institute) standards may also be relevant, especially when leather is treated with chemical processes.

What Are the Checkpoints in Quality Control for Automotive Leather?

Quality control (QC) is a multi-stage process involving various checkpoints to ensure that the leather meets established standards:

What Are the Key QC Checkpoints in the Manufacturing Process?

- Incoming Quality Control (IQC): This stage involves inspecting the raw hides upon arrival. Any defects must be documented and addressed before processing.

- In-Process Quality Control (IPQC): Throughout the tanning, forming, and finishing stages, regular inspections are conducted. This includes checking for consistency in dyeing and ensuring that stitching meets quality standards.

- Final Quality Control (FQC): Before shipping, finished products undergo a final inspection to ensure they meet all specifications and standards. This may include physical tests for durability, colorfastness, and resistance to wear.

How Can B2B Buyers Verify Supplier Quality Control?

When sourcing automotive leather from international suppliers, B2B buyers should take proactive steps to verify the supplier’s quality control measures:

What Are Effective Methods for Verifying Supplier QC?

- Supplier Audits: Conducting regular audits of suppliers can provide insight into their manufacturing processes and quality assurance practices. This includes reviewing their adherence to ISO and other relevant standards.

- Quality Reports: Requesting detailed quality control reports can help buyers understand the QC measures implemented by the supplier, including any testing methods used and the results.

- Third-Party Inspections: Engaging independent third-party inspectors can ensure that the products meet specified standards before shipment. This is particularly valuable for buyers in regions like Africa and South America, where local regulations may differ significantly.

What Are the QC and Certification Nuances for International Buyers?

B2B buyers, particularly from diverse markets such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances related to quality control and certification:

- Local Regulations: Buyers must familiarize themselves with local regulations and standards that may differ from international norms. This is especially relevant in regions with strict environmental or safety regulations.

- Cultural Considerations: Understanding cultural nuances can also aid in effective communication with suppliers regarding quality expectations and practices.

By navigating the complexities of manufacturing processes and quality assurance, B2B buyers can make informed decisions and ensure they source the highest quality automotive leather for their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automotive leather’

In the competitive landscape of automotive manufacturing, sourcing high-quality leather is essential for creating luxurious vehicle interiors. This guide provides a practical checklist for B2B buyers looking to procure automotive leather, ensuring that you make informed decisions that align with your project requirements and business goals.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications of the leather you need. Consider factors such as thickness, grain type, color, and finish. This will guide your selection and ensure that the leather meets the aesthetic and functional requirements of your automotive design.

- Grain Types: Full grain, top grain, and corrected grain each offer different qualities and appearances.

- Finish Options: Decide whether you need a matte, glossy, or textured finish to complement your vehicle’s design.

Step 2: Identify Reputable Suppliers

Research and compile a list of potential suppliers known for their automotive leather offerings. Look for suppliers with a strong reputation in the industry, particularly those with experience catering to the automotive sector.

- Certifications: Ensure that suppliers have relevant industry certifications, such as ISO or environmental compliance, which can indicate quality assurance.

- Experience: Prioritize suppliers who have a proven track record with reputable automotive brands.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website.

- Quality Assurance: Ask about their quality control processes and how they handle defects or inconsistencies.

- Customer Feedback: Seek testimonials or reviews from other businesses that have sourced leather from them.

Step 4: Request Samples

Once you’ve narrowed down your list of suppliers, request samples of the leather you are considering. This step allows you to assess the material’s quality, texture, and color in person.

- Physical Assessment: Evaluate the samples for durability, flexibility, and overall appearance.

- Color Matching: Ensure that the colors align with your design specifications and can be matched if custom orders are necessary.

Step 5: Negotiate Terms and Pricing

Engage in discussions with your selected suppliers about pricing, minimum order quantities, and lead times. Establish clear terms to avoid misunderstandings later.

- Volume Discounts: Inquire about pricing structures for bulk orders, as many suppliers offer discounts for larger quantities.

- Delivery Timelines: Confirm expected delivery times to align with your production schedules.

Step 6: Verify Compliance and Sustainability Practices

Ensure that your chosen supplier adheres to ethical sourcing practices and complies with industry regulations. This is increasingly important for companies focused on sustainability.

- Environmental Impact: Inquire about the tanning processes used and whether they utilize environmentally friendly methods.

- Traceability: Check if the leather can be traced back to sustainable sources, which can enhance your brand’s reputation.

Step 7: Finalize Contracts and Place Orders

Once you are satisfied with your supplier’s quality, terms, and compliance, finalize contracts. Ensure that all details are clearly documented to protect your interests.

- Contract Details: Include specifications, payment terms, and delivery schedules in the contract.

- Order Confirmation: After placing the order, obtain a confirmation to ensure that all parties are aligned.

By following this checklist, B2B buyers can effectively navigate the sourcing process for automotive leather, ensuring that they select high-quality materials that meet their specific needs.

Comprehensive Cost and Pricing Analysis for automotive leather Sourcing

Understanding the cost structure and pricing analysis for automotive leather sourcing is crucial for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. This section delves into the various cost components, price influencers, and provides actionable tips for buyers to optimize their procurement strategies.

What Are the Key Cost Components in Automotive Leather Sourcing?

The cost structure of automotive leather encompasses several critical components:

-

Materials: The primary cost driver is the quality of leather itself. Full-grain leather typically commands higher prices due to its durability and aesthetic appeal, while lower grades, such as corrected grain, are more economical but may compromise on longevity and appearance.

-

Labor: Skilled labor is essential for the tanning and finishing processes. Labor costs can vary significantly depending on the region, with higher costs generally associated with countries that have stringent labor laws or where skilled artisans are in demand.

-

Manufacturing Overhead: This includes costs related to the operation of manufacturing facilities, utilities, and indirect labor. Overhead can be influenced by the scale of production and the efficiency of the manufacturing processes.

-

Tooling: Customization requires specific tools and molds, which can add to initial costs. For buyers looking for unique specifications, tooling costs must be factored into the total price.

-

Quality Control (QC): Ensuring that leather meets industry standards and buyer specifications incurs additional costs. This is particularly important for automotive applications where safety and durability are paramount.

-

Logistics: Transporting leather from tanneries to manufacturers can be costly, especially for international shipments. Factors such as distance, shipping method, and customs duties play a significant role in this component.

-

Margin: Suppliers typically add a markup to cover their operational costs and profit margin. This can vary widely based on market dynamics and the supplier’s position in the value chain.

What Influences the Pricing of Automotive Leather?

Several factors affect the pricing of automotive leather, which buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often yield discounts. Understanding a supplier’s MOQ can help buyers negotiate better pricing.

-

Specifications and Customization: Customized leather solutions typically incur higher costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Premium leather with certifications (e.g., eco-friendly tanning processes) can attract higher prices. Buyers should assess the value of these certifications in their purchasing decision.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a track record of quality may charge more, but they often provide better consistency and service.

-

Incoterms: Understanding the terms of shipping (e.g., FOB, CIF) is crucial as they affect the total landed cost. Buyers should clarify these terms during negotiations to avoid hidden costs.

How Can B2B Buyers Optimize Their Automotive Leather Procurement?

-

Negotiation Tactics: Engage suppliers in discussions about pricing structures. Highlighting long-term partnerships or bulk purchasing can leverage better pricing.

-

Focus on Total Cost of Ownership (TCO): Beyond the initial purchase price, consider factors such as durability, maintenance, and lifecycle costs. Higher quality leather may incur a higher upfront cost but could lead to savings in the long run.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, tariffs, and regional pricing differences that can impact costs. Establishing contracts in stable currencies can mitigate some risks.

-

Leverage Technology: Utilize digital platforms for sourcing and supplier comparison. Online marketplaces can provide insights into pricing trends and supplier reliability.

-

Request Samples: Before committing to large orders, requesting samples allows buyers to assess quality and suitability, helping to avoid costly mistakes.

Disclaimer

Pricing for automotive leather can fluctuate due to market conditions, supplier policies, and regional factors. The information provided is indicative and should be verified with suppliers for the most accurate and up-to-date pricing.

Alternatives Analysis: Comparing automotive leather With Other Solutions

Exploring Alternatives to Automotive Leather: What Are the Best Options?

In the automotive industry, the choice of materials for interior finishes significantly impacts vehicle aesthetics, performance, and customer satisfaction. While automotive leather has long been the gold standard for luxury and durability, several alternative solutions have emerged. This section compares automotive leather with synthetic alternatives, specifically faux leather and Alcantara, to assist B2B buyers in making informed decisions tailored to their specific needs.

Illustrative image related to automotive leather

| Comparison Aspect | Skóra samochodowa | Sztuczna skóra | Alcantara |

|---|---|---|---|

| Performance | High durability, luxurious feel, and excellent aging properties | Less durable than leather, but can mimic appearance well | Excellent durability, soft texture, and good resistance to wear |

| Cost | Generally higher price point due to sourcing and processing | More affordable, especially in bulk | Mid-range pricing, often competitive with high-quality leather |

| Ease of Implementation | Requires skilled labor for installation | Easier to work with and install | Installation may require specialized skills but is manageable |

| Maintenance | Requires conditioning and care to maintain appearance | Easy to clean, resistant to stains | Simple to clean, but can be prone to staining if not treated |

| Best Use Case | Luxury vehicles, high-end models where quality is paramount | Budget vehicles, fleet cars, or where cost is a primary concern | Sports cars, luxury vehicles where a unique aesthetic is desired |

What Are the Advantages and Disadvantages of Faux Leather?

Faux leather, also known as synthetic leather, is crafted from materials like polyurethane (PU) or polyvinyl chloride (PVC). The primary advantage of faux leather is its cost-effectiveness, making it a popular choice for budget-conscious manufacturers. Additionally, it is easier to clean and maintain, appealing to buyers who prioritize convenience. However, faux leather may not offer the same level of durability and luxury feel as genuine leather, which can impact the overall perception of the vehicle’s quality.

Why Choose Alcantara Over Automotive Leather?

Alcantara is a unique alternative that combines the luxurious appearance of suede with the durability required for automotive applications. It is soft to the touch and offers excellent resistance to wear, making it suitable for high-performance vehicles. One of the significant benefits of Alcantara is its ability to resist stains and maintain its appearance over time, provided it is properly cared for. However, Alcantara typically requires specialized cleaning products, and its price can be a consideration for budget-sensitive projects.

How Can B2B Buyers Make the Right Choice?

When selecting the right material for automotive interiors, B2B buyers should consider various factors, including target market, budget constraints, and the desired aesthetic. Automotive leather remains an unparalleled choice for luxury and performance, while faux leather offers a more economical option that is easier to maintain. Alcantara stands out as a premium alternative that balances luxury with practicality. Ultimately, the decision should align with the brand’s values and customer expectations, ensuring that the chosen material enhances the overall vehicle experience.

Essential Technical Properties and Trade Terminology for automotive leather

What Are the Key Technical Properties of Automotive Leather?

Understanding the technical properties of automotive leather is crucial for B2B buyers who want to ensure that they are purchasing high-quality materials suitable for automotive applications. Here are some essential specifications to consider:

1. Material Grade

Material grade refers to the classification of leather based on its quality and characteristics. Common grades include full-grain, top-grain, and corrected grain. Full-grain leather is the highest quality, retaining the natural grain, while corrected grain has been sanded and treated for uniformity. For B2B buyers, selecting the appropriate material grade is vital for meeting customer expectations regarding durability, aesthetics, and price point.

Illustrative image related to automotive leather

2. Thickness

The thickness of automotive leather is typically measured in millimeters (mm) or ounces. Common thickness ranges for automotive applications vary from 0.8 mm to 1.4 mm. Thicker leather often provides greater durability and resistance to wear and tear, making it a preferred choice for high-traffic areas in vehicles. Buyers must assess the intended use to choose the right thickness that balances comfort and durability.

3. Tensile Strength

Tensile strength is a measure of how much force the leather can withstand before breaking. It is crucial for automotive applications where the material is subjected to stretching and pressure. A higher tensile strength indicates a more durable product, which is essential for maintaining the integrity of upholstery over time. Buyers should request tensile strength data to ensure that the leather can handle the demands of automotive environments.

4. Color Fastness

Color fastness refers to the leather’s ability to retain its color when exposed to light, water, and abrasion. This property is particularly important in automotive applications where sunlight and moisture can cause fading. B2B buyers should prioritize suppliers that provide leather with high color fastness ratings to ensure long-lasting aesthetics in their vehicle interiors.

5. Flame Resistance

Flame resistance is a critical property for automotive leather, particularly in regions where safety regulations are stringent. This characteristic measures how well the material resists ignition and flame spread. Buyers must verify that the leather meets the necessary fire safety standards, especially for vehicles that require compliance with specific regulations.

Illustrative image related to automotive leather

What Are Common Trade Terms in the Automotive Leather Industry?

Familiarity with industry jargon can significantly enhance communication and negotiation in the automotive leather supply chain. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products to be sold under another company’s brand name. In the context of automotive leather, OEM leather is supplied to vehicle manufacturers for use in new cars. Understanding OEM specifications is crucial for buyers looking to maintain brand integrity in their upholstery offerings.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum amount of product a supplier is willing to sell. This term is vital for B2B buyers to consider when planning inventory and procurement. Understanding MOQ helps buyers manage their budgets and stock levels effectively while ensuring they meet supplier requirements.

Illustrative image related to automotive leather

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products or services. This process is essential for establishing clear expectations and obtaining competitive pricing. B2B buyers should prepare detailed RFQs to receive accurate and tailored responses from suppliers.

4. Incoterms (International Commercial Terms)

Incoterms are a set of standardized terms that define the responsibilities of buyers and sellers in international trade. Familiarity with these terms helps buyers understand shipping costs, risk, and insurance responsibilities. Clear communication of Incoterms can prevent misunderstandings and ensure smoother transactions.

5. Custom Dying

Custom dying refers to the process of matching and producing leather colors based on specific customer requirements. This term is particularly relevant for buyers looking for unique color options that align with branding or design needs. Suppliers that offer custom dying services can provide tailored solutions that enhance the overall product offering.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the right automotive leather to meet their specific requirements.

Navigating Market Dynamics and Sourcing Trends in the automotive leather Sector

What Are the Current Market Dynamics and Key Trends in the Automotive Leather Sector?

The automotive leather market is experiencing significant transformation driven by several global factors. The rising demand for luxury vehicles across emerging markets in Africa, South America, and the Middle East is a primary growth driver. Countries like Brazil and Saudi Arabia are witnessing a surge in consumer spending on premium automotive interiors, emphasizing quality and aesthetics. Furthermore, the increasing incorporation of advanced technologies in manufacturing processes is reshaping sourcing trends. Digital platforms are facilitating more streamlined procurement channels, enabling international B2B buyers to access diverse suppliers and materials with greater efficiency.

Illustrative image related to automotive leather

Sourcing trends are evolving with a noticeable shift towards customization and personalization. Buyers are increasingly seeking unique leather finishes and colors tailored to specific vehicle models, which is becoming a significant differentiator in the competitive landscape. Additionally, the growing trend of electric vehicles (EVs) has introduced new materials and designs that prioritize lightweight and sustainable options, further impacting sourcing decisions.

Another dynamic to consider is the fluctuation in raw material prices, influenced by environmental regulations and the availability of hides. Buyers must stay informed on market pricing trends and potential supply chain disruptions, particularly in regions heavily reliant on livestock farming. Strategic partnerships with reliable suppliers that offer transparency in their sourcing practices are becoming essential for mitigating risks.

How Is Sustainability and Ethical Sourcing Shaping the Automotive Leather Industry?

Sustainability has emerged as a crucial consideration in the automotive leather sector, influencing both consumer preferences and regulatory frameworks. The environmental impact of traditional leather production methods, including deforestation and chemical waste, has led to a growing demand for sustainable practices. B2B buyers are increasingly prioritizing suppliers who adhere to ethical sourcing standards and demonstrate a commitment to reducing their carbon footprint.

The importance of ethical supply chains cannot be overstated. Buyers are now scrutinizing their suppliers for certifications such as the Leather Working Group (LWG) certification, which ensures responsible sourcing and environmental stewardship. Furthermore, the trend towards ‘green’ materials is gaining traction, with innovative alternatives such as plant-based leather and recycled materials entering the market. These alternatives not only reduce environmental impact but also cater to the rising consumer demand for eco-friendly products.

For B2B buyers, aligning with suppliers who implement sustainable practices can enhance brand reputation and appeal to environmentally conscious consumers. Establishing partnerships with manufacturers that prioritize sustainability can also offer long-term cost benefits, as regulatory compliance becomes increasingly stringent.

What Is the Evolution of the Automotive Leather Market?

The automotive leather market has undergone significant evolution over the decades, transitioning from purely functional materials to luxury elements that enhance vehicle interiors. Initially, leather was predominantly used in high-end vehicles, but advancements in tanning and finishing processes have made it more accessible across various vehicle segments.

Historically, the industry relied heavily on traditional tanning methods, which often involved harsh chemicals and significant environmental impact. However, the late 20th century saw the introduction of more sustainable tanning processes, such as vegetable tanning, which have gained popularity among manufacturers and consumers alike. This shift not only improved the environmental footprint of leather production but also elevated the status of leather as a premium material choice in the automotive sector.

As the market continues to evolve, the focus remains on innovation and sustainability, with technological advancements driving the development of new materials that meet the changing demands of consumers and regulatory bodies alike.

Frequently Asked Questions (FAQs) for B2B Buyers of automotive leather

-

1. How do I ensure the quality of automotive leather before purchasing?

To ensure the quality of automotive leather, request samples from suppliers and evaluate the texture, finish, and durability. Look for full-grain leather, which is the highest quality and most durable option. Additionally, check for compliance with international standards, such as ISO certifications, and inquire about the tanning process, which can impact both quality and environmental sustainability. Establishing relationships with trusted suppliers and seeking testimonials from other businesses can also provide insights into product quality. -

2. What types of automotive leather are best for luxury vehicles?

For luxury vehicles, full-grain and top-grain leathers are the best options. Full-grain leather retains the natural grain and is highly durable, making it ideal for high-end applications. Top-grain leather is slightly more processed but still offers a luxurious feel and appearance. Both types can be customized in terms of color and finish, allowing for a tailored aesthetic that enhances the vehicle’s overall design. Suppliers specializing in luxury automotive leather often provide a variety of textures and colors to suit specific brand identities. -

3. How can I customize automotive leather for my vehicle’s interior?

Customization options for automotive leather typically include color matching, embossing, and selecting specific finishes. Many suppliers offer custom dyeing services to match any color reference you provide. Additionally, you can request specific textures or patterns that align with your design vision. Engaging with suppliers who specialize in custom orders can ensure you receive high-quality materials tailored to your specifications. Be sure to discuss minimum order quantities (MOQs) and lead times for customization to align with your project timeline. -

4. What are the typical minimum order quantities (MOQs) for automotive leather?

Minimum order quantities (MOQs) for automotive leather can vary significantly by supplier and type of leather. Generally, MOQs can range from half a hide (approximately 25 square feet) to several hundred square feet for larger bulk orders. It’s essential to clarify MOQs during initial discussions with suppliers, especially if you’re a smaller business or are testing a new product line. Some suppliers may offer flexibility for first-time buyers or smaller projects, so negotiating terms may be beneficial. -

5. What payment terms should I expect when sourcing automotive leather internationally?

Payment terms for international orders can vary widely among suppliers. Common terms include upfront payment, partial payment with the balance due upon delivery, or credit terms based on your relationship with the supplier. It’s crucial to discuss these terms upfront to avoid misunderstandings. Additionally, consider using secure payment methods such as letters of credit or escrow services to protect your investment, especially when dealing with new suppliers or larger orders. -

6. How do I vet suppliers for automotive leather?

Vetting suppliers involves assessing their reputation, product quality, and reliability. Start by researching their history and customer reviews, focusing on businesses within your region or industry. Request references from other B2B buyers to gauge their experiences. Additionally, visit the supplier’s facility if possible, or request detailed information about their manufacturing processes and quality assurance measures. Certifications such as ISO or environmental standards can further validate their credibility. -

7. What logistics considerations should I keep in mind when importing automotive leather?

When importing automotive leather, consider logistics factors such as shipping methods, customs regulations, and lead times. Understand the import duties and taxes applicable to your country, as these can significantly impact total costs. Partnering with a freight forwarder familiar with international trade can streamline the shipping process and ensure compliance with all regulations. Additionally, plan for adequate storage conditions upon arrival, as leather can be sensitive to temperature and humidity. -

8. How can I address potential issues with leather quality upon delivery?

To address potential quality issues with leather upon delivery, conduct a thorough inspection immediately upon receipt. Check for defects such as discoloration, tears, or inconsistent texture. Document any issues with photographs and contact the supplier promptly to discuss returns or replacements. Familiarizing yourself with the supplier’s return policy during the initial agreement can help facilitate a smoother resolution process. Establishing a clear communication channel with your supplier can also expedite any necessary corrective actions.

Top 9 Automotive Leather Manufacturers & Suppliers List

1. Leather Hide Store – Quality Auto Upholstery Leather

Domain: leatherhidestore.com

Registered: 2010 (15 years)

Introduction: Quality auto upholstery leather for cars and trucks. Features include:

– Color fastness standards (UV resistance) for aftermarket auto use.

– Essentials Line: Durable, soft, and supple.

– Market Street: Smoother leather with a buttery feel and rich color.

– Urban: Heavier weight material with lots of grain, extra luxurious.

– Dakota line: High performance distressed leathers for statement pro…

2. Hydes Leather – Automotive, Marine & Aviation Leather

Domain: hydesleather.com

Registered: 2006 (19 years)

Introduction: Hydes Leather offers a diverse collection of automotive, marine, and aviation leather, including:

– Automotive Leather: Astro Bomber, Distressed Buffalo, OEM Leather, Pelle Fresco, Prima Nappa, Roser 2 Tone, Royal Steering Wheel Leather, Thema Vintage, Vintage OEM Leather, Vision Woven Leather.

– Alcantara: Automotive Alcantara Cover (backed), Panel (unbacked), Multilayer (steering wheels), Perfo…

3. Relicate – Full Grain Leather Options

Domain: relicate.com

Registered: 2013 (12 years)

Introduction: Full Grain Leather options include Solid Color Leather, Nappa Italia Leather, Napali Leather, and various Black Leather types. OEM Auto Leather colors are available for brands like BMW®, Ferrari®, Lamborghini®, Porsche®, Rolls Royce®, and American Cars. Distressed & Heritage Leather types include Legacy Distressed Leather, Heritage Hide Leather, Matte Distressed Leather, Vintage Distressed Leather…

4. Apex Leather – High-Performance Auto Upholstery Supplies

Domain: apexleather.com

Registered: 2005 (20 years)

Introduction: Apex Leather offers a variety of high-performance auto upholstery supplies including: Smooth Grain Leather, Distressed Leather, Natural Grain Leather, Heavyweight Leather, Ultra Square Weave Carpet, Microsuede, Thread, CNC Panels, and Custom Color Matching services. They provide industry-leading products for custom car and truck interiors, catering to auto upholstery professionals.

5. Auto Leather Dye – Leather & Vinyl Repair Kits

Domain: autoleatherdye.com

Registered: 2015 (10 years)

Introduction: Luxury Leather Repair’s Leather & Vinyl Repair Kits are designed for DIY customers, offering over 2000 OEM automotive leather and vinyl dye colors. Each kit includes necessary application tools and detailed instructions for effective leather restoration. The product range includes: 1. Leather & Vinyl Dye – $29.95 2. Leather & Vinyl Prep and Dye Bundle – $54.95 3. Leather & Vinyl Dye Kit – $59.95 4…

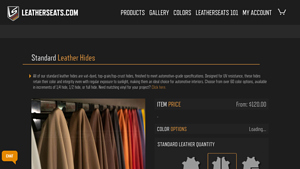

6. LeatherSeats.com – Automotive Leather Hides

Domain: leatherseats.com

Registered: 2000 (25 years)

Introduction: Automotive Leather Hides for interior car upholstery available at LeatherSeats.com. The product includes standard leather hides and ecstasy leather hides. It is suitable for various vehicle makes and models, offering a range of upholstery kits and materials. The site also provides DIY installation tools, upholstery supplies, and maintenance products. Customers can find matching materials, includin…

7. Moore & Giles – Natural Automotive Leathers

Domain: mooreandgilesleather.com

Registered: 2022 (3 years)

Introduction: Moore & Giles offers a range of natural automotive leathers available in various colors and textures, suitable for customizing or restoring vehicles. The leathers can be filtered by finish types including Aniline Plus, Nubuck, Pigmented, Semi-Aniline, and Suede. There are 13 different leather options available for comparison, including Apollo, Berkshire, Burnham, Carlyle, Castello, Dresden, Eden, …

8. Midwest Fabrics – Upholstery Leather

Domain: midwestfabrics.com

Registered: 1999 (26 years)

Introduction: Upholstery Leather: Art of Sophistication

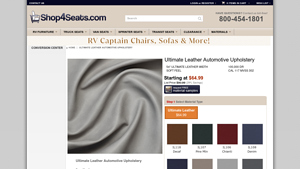

9. Shop4Seats – Ultimate Leather Automotive Upholstery

Domain: shop4seats.com

Registered: 2013 (12 years)

Introduction: {“Product Name”: “Ultimate Leather Automotive Upholstery”, “Width”: “54 inches”, “Thickness”: “50 ga”, “Weight”: “25 oz per linear yard”, “Abrasion Resistance”: “100,000 DR”, “Flame Resistance”: “CAL 117 SECT E MVSS 302”, “UV Resistance”: “1000 Hours”, “Mildew Resistance”: “Back and face conforms with ASTM G21”, “Material Composition”: “100% premium polyurethane”, “Price”: “$64.99”, “List Price”: …

Strategic Sourcing Conclusion and Outlook for automotive leather

In the competitive landscape of automotive leather sourcing, strategic partnerships and informed decision-making are paramount. Buyers from diverse regions, including Africa, South America, the Middle East, and Europe, must focus on quality, sustainability, and customization to meet evolving consumer demands. Understanding the unique characteristics of various leather types—from full grain to Alcantara—enables businesses to select materials that not only enhance vehicle aesthetics but also ensure durability and comfort.

Building relationships with reputable suppliers is crucial. By leveraging trade-only suppliers that offer a wide range of luxury and vintage OEM leathers, businesses can access high-quality materials that elevate their product offerings. The emphasis on allergy-friendly and easy-to-maintain materials can further differentiate brands in a saturated market.

As the automotive industry continues to evolve, embracing innovation in sourcing practices will be essential. International buyers are encouraged to stay ahead of trends by actively seeking out suppliers who can provide tailored solutions to meet specific needs. By prioritizing strategic sourcing now, companies can position themselves for sustained success in the dynamic automotive leather market. Engage with suppliers who understand your vision and can help you realize it—your next breakthrough in automotive design awaits.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.