Catalog

Material Insight: Custom Leather Work

B2B Product Guide: Elevating Custom Leather Work with Precision & Purpose

Custom leather work represents a strategic investment for brands seeking distinctive product identity, enhanced user experience, and market differentiation. Whether for premium automotive interiors, bespoke furniture, specialized protective gear, or high-end accessories, the material foundation directly impacts durability, aesthetics, sustainability credentials, and production efficiency. Selecting the right material partner is therefore critical to project success and brand alignment.

Faux leather (synthetic leather) has become the unequivocal material of choice for demanding custom applications, outperforming traditional leather in key areas essential to modern B2B manufacturing:

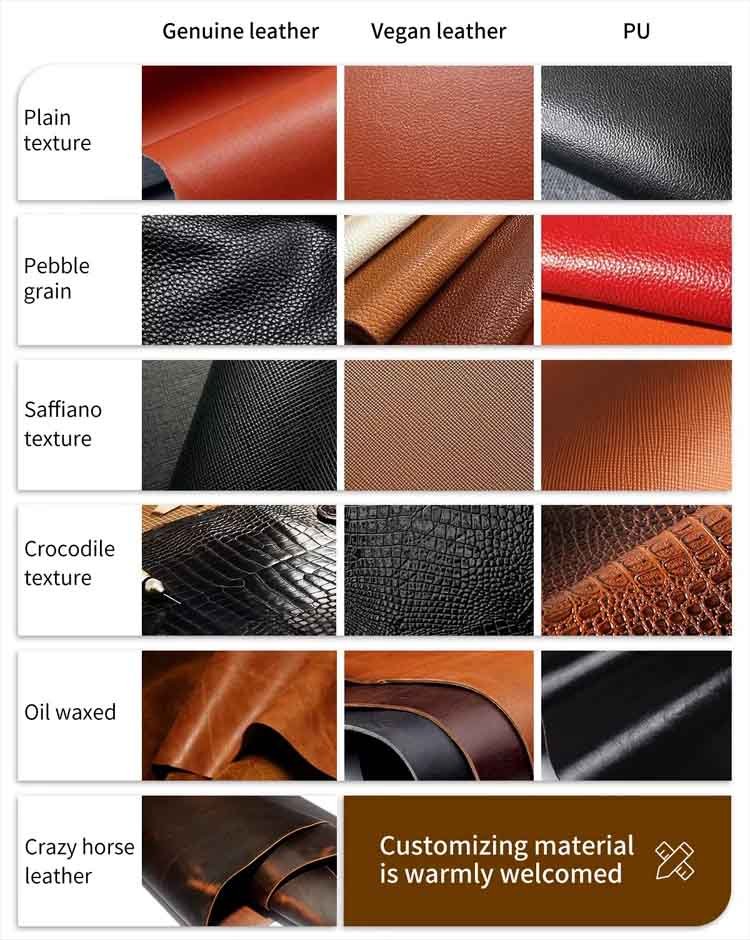

- Design Freedom & Consistency: Achieve exact color matches, unique textures (suede, pebble, exotic embosses), and seamless large-format panels impossible with natural hide variability. Eliminate costly waste from leather grading inconsistencies.

- Accelerated Time-to-Market: Bypass lengthy leather sourcing cycles and tanning lead times. WINIW’s engineered materials are produced on-demand with reliable, predictable schedules.

- Superior Performance Properties: Engineered for enhanced abrasion resistance, UV stability, cold crack resistance, and chemical resilience – critical for automotive, aviation, and commercial furniture sectors.

- Radical Sustainability: Eliminate land/water use, methane emissions, and toxic tanning chemicals associated with animal leather. WINIW utilizes recycled content (e.g., PET bottles, pre-consumer waste) and water-based, solvent-free production.

- Cost Predictability & Optimization: Avoid volatile leather market pricing and hide defect-related yield loss. Achieve higher material utilization rates and streamlined production.

- Ethical Assurance: Guarantee 100% animal-free production with full traceability, meeting stringent corporate ESG mandates and conscious consumer expectations.

Introducing WINIW: Your Engineered Leather Authority

For over 20 years, WINIW has been at the forefront of synthetic leather innovation, dedicated exclusively to serving B2B manufacturers with technically superior, eco-conscious solutions. We transcend the limitations of traditional materials through relentless R&D in polymer science and sustainable manufacturing. Our global production footprint ensures scalability while maintaining rigorous quality control, and our technical teams collaborate deeply with clients – from concept sketch to mass production – to solve complex material challenges. WINIW isn’t just a supplier; we are your strategic partner in building better products, responsibly. Partner with us to transform your custom leather vision into a tangible asset for your brand and the planet.

Technical Performance & Standards

WINIW Custom Leather Work – B2B Product Guide

WINIW specializes in high-performance synthetic leather solutions engineered for industrial and commercial applications. Our custom leather work combines advanced material science with sustainable manufacturing practices to deliver a product line that meets the rigorous demands of modern B2B clients. Designed for versatility across sectors—including automotive interiors, furniture, footwear, and technical textiles—WINIW’s synthetic leather offers a compelling alternative to natural leather without compromising on quality, aesthetics, or environmental responsibility.

Technical Advantages of WINIW Custom Leather Work

-

Cost-Effective Production

WINIW’s synthetic leather reduces material waste and production cycle times compared to traditional leather. With consistent thickness and fewer defects, it enables higher yield in cutting and sewing operations. This consistency lowers downstream processing costs and supports scalable manufacturing. -

Superior Durability

Engineered with high-tensile strength polyurethane and reinforced backings, WINIW leather resists abrasion, tearing, and cracking. It maintains structural integrity under repeated flexing and exposure to UV, humidity, and temperature fluctuations—making it ideal for long-life applications. -

Customizable Colors and Finishes

We offer full color customization with precise Pantone matching and batch consistency. Clients can select from matte, glossy, textured, or embossed finishes. Our digital color management system ensures repeatable results across large-volume orders. -

REACH Compliance

All WINIW synthetic leather products are manufactured in compliance with EU REACH regulations (EC 1907/2006). Our materials are free from SVHC (Substances of Very High Concern) and routinely tested by third-party laboratories to ensure chemical safety throughout the supply chain. -

ISO 9001-Certified Quality Management

WINIW operates under an ISO 9001-certified quality management system, ensuring standardized processes from raw material sourcing to finished goods. This certification guarantees consistent product quality, traceability, and continuous improvement in production efficiency.

WINIW Custom Leather Work – Technical Specifications

| Property | Specyfikacja |

|---|---|

| Base Material | High-density polyurethane (PU) or polyvinyl chloride (PVC) with fabric backing |

| Thickness Range | 0.6 mm – 2.0 mm (customizable) |

| Weight Range | 180 g/m² – 450 g/m² |

| Tensile Strength | ≥ 80 N/5cm (warp), ≥ 70 N/5cm (weft) |

| Elongation at Break | ≤ 25% |

| Color Fastness (ISO 105-B02) | ≥ Grade 4 (after 40 hrs xenon exposure) |

| Martindale Abrasion | ≥ 30,000 cycles (for standard grades) |

| Cold Crack Resistance | Passes at -20°C |

| REACH SVHC Status | Compliant (no listed substances) |

| ISO Certification | ISO 9001:2015 |

| Eco-Friendly Options | Available (low-VOC, solvent-free coating) |

WINIW’s custom leather work delivers a balanced combination of economic efficiency, long-term performance, and regulatory compliance. By integrating client-specific design requirements with sustainable manufacturing, we empower B2B partners to innovate confidently in competitive markets.

Why Choose Synthetic over Real Leather

WINIW Synthetic Leather: B2B Product Guide for Sustainable Material Selection

Selecting the right material is critical for product performance, brand alignment, and long-term operational efficiency. Within the leather alternatives market, “custom leather work” (engineered synthetic leather solutions like WINIW’s) offers distinct advantages over traditional real leather, particularly for brands prioritizing sustainability, cost control, and design flexibility. Below is an objective comparison focusing on key decision-making factors for B2B partners.

Key Comparison: Custom Synthetic Leather Work vs. Real Leather

| Metric | Custom Synthetic Leather Work (e.g., WINIW) | Real Leather |

|---|---|---|

| Cost | Predictable pricing; lower volatility. No dependency on livestock markets or tanning chemical fluctuations. Bulk customization reduces waste and labor costs. | High volatility due to raw hide supply, tanning chemical costs, and labor-intensive processing. Significant waste (30-40% unusable hide) increases effective cost. |

| Trwałość | Consistent performance: High abrasion resistance (tested to 50,000+ Martindale cycles), UV stability, water resistance, and colorfastness. Engineered for specific use cases (e.g., automotive, furniture). | Variable quality: Susceptible to cracking, fading, and water damage without ongoing maintenance. Durability heavily dependent on hide origin and tanning process. |

| Eco-Friendliness | Significantly lower environmental footprint: 90% less water used, zero animal agriculture impact, Cradle-to-Cradle Certified™ options available. WINIW uses recycled content (up to 50%) and OEKO-TEX® Standard 100 materials. Traceable, ISO 14001-certified production. | High environmental cost: 15,000+ liters of water per kg of leather, toxic tanning chemicals (chromium), methane emissions from livestock, and deforestation for grazing. Limited end-of-life recyclability. |

Why WINIW’s Custom Synthetic Leather Work Delivers B2B Value

- Supply Chain Resilience

- Eliminate dependency on volatile hide markets and ethical concerns in animal farming.

-

Achieve consistent lead times with regional production hubs (Asia, Europe, Americas).

-

Design & Performance Precision

- Tailor thickness, texture, color, and functional properties (e.g., fire resistance, antimicrobial) to exact product specifications.

-

Maintain uniform quality across global production runs—no natural hide imperfections.

-

Authentic Sustainability Credentials

- Meet corporate ESG targets with verifiable data: Full LCAs (Life Cycle Assessments), GRS (Global Recycled Standard) certification, and PEF (Product Environmental Footprint) compliance support.

-

Reduce Scope 3 emissions by up to 60% compared to real leather, critical for net-zero commitments.

-

Total Cost of Ownership Advantage

- Lower waste in cutting (pattern efficiency up to 95% vs. 60-70% for real leather).

- Eliminate maintenance costs for end-users (e.g., conditioning, waterproofing).

WINIW empowers forward-thinking brands to future-proof their material strategy without compromising on luxury, performance, or ethics. Our custom-engineered solutions deliver measurable operational savings while advancing circular economy principles—proving that responsible manufacturing is the cornerstone of premium product design. Partner with us to co-create materials that meet today’s standards and tomorrow’s expectations.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, dedicated to delivering innovative and sustainable materials for global B2B clients. With a strong foundation in research, production excellence, and environmental responsibility, WINIW serves diverse industries including automotive, fashion, furniture, and technical textiles.

Our manufacturing capabilities are anchored in a state-of-the-art facility spanning 100,000 square meters. This expansive production base integrates advanced automation and eco-conscious processes to ensure high output without compromising quality or sustainability.

Key strengths of the WINIW factory include:

- A dedicated R&D team of over 100 professionals focused on material innovation, durability testing, and eco-friendly solutions. The team continuously develops new textures, finishes, and functional properties to meet evolving market demands.

- Strict quality control protocols implemented at every stage of production, from raw material selection to final inspection. All processes adhere to international standards, including ISO 9001 and OEKO-TEX® certifications.

- In-house testing laboratory equipped to conduct abrasion resistance, color fastness, tensile strength, and environmental compliance assessments, ensuring consistent product reliability.

- Sustainable manufacturing practices, including water-based PU formulations, low-VOC emissions, and waste reduction initiatives, supporting our clients’ ESG goals.

WINIW exports to key markets worldwide, with a strong presence in Europe and the USA. Our global logistics network ensures timely delivery and regulatory compliance with regional standards, including REACH and CPSIA.

| Feature | Specyfikacja |

|---|---|

| Factory Size | 100,000 sqm |

| R&D Team | 100+ specialists |

| Quality Standards | ISO 9001, OEKO-TEX®, REACH, CPSIA |

| Primary Export Regions | Europe, USA, Asia |

| Production Capacity | Customized output for large-scale B2B orders |

With vertical integration, technical expertise, and a commitment to sustainability, WINIW stands as a trusted partner for brands seeking high-quality, eco-conscious synthetic leather solutions.

Contact Us for Samples

WINIW Premium Synthetic Leather: Your Sustainable Material Partner for High-Performance Applications

WINIW delivers cutting-edge, eco-conscious synthetic leather solutions engineered for demanding B2B applications across furniture, automotive, fashion, and technical goods. Our advanced microfiber technology replicates the luxury, durability, and tactile qualities of premium genuine leather while exceeding environmental and ethical standards. Partner with us for materials that align with your sustainability goals without compromising on performance or aesthetics.

Core Product Advantages

- Superior Performance: Exceptional abrasion resistance (>50,000 cycles Martindale), color fastness (Grade 4-5), and tear strength for long-lasting product integrity.

- Eco-Certified Production: OEKO-TEX® STANDARD 100, ISO 14001, and REACH compliant. Zero toxic solvents (DMF-free) and 30% lower carbon footprint vs. conventional synthetics.

- Design Flexibility: 500+ stock colors/finishes; custom embossing, textures, and thicknesses (0.6mm–2.0mm) available.

- Resource Efficiency: Water-based PU coating reduces processing waste; 40% lighter weight cuts logistics emissions.

WINIW Product Series Overview

| Series | Primary Applications | Key Technical Features | Eco-Certifications |

|---|---|---|---|

| WINIW EcoLuxe | Upholstery, Luxury Furniture | Breathable mesh backing, stain-resistant topcoat | OEKO-TEX® 100, GRS (Recycled) |

| WINIW AutoFlex | Automotive Interiors | Flame-retardant (FMVSS 302), anti-scratch | ISO/TS 16949, UL 94 HB |

| WINIW TechWeave | Technical Apparel, Bags | Waterproof (5,000mm H₂O), 4-way stretch | Bluesign® approved, PFC-free |

| WINIW SoftTouch | Fashion, Footwear | Ultra-soft hand feel, matte finish | OEKO-TEX® STeP, Vegan Society |

Why WINIW Meets Modern B2B Demands

- Supply Chain Transparency: Full traceability from raw material to finished roll; audited ethical manufacturing.

- Regulatory Assurance: Compliant with EU Ecolabel, California Proposition 65, and global chemical restrictions.

- Circular Economy Support: Recyclable at end-of-life; 25% post-industrial recycled content in EcoLuxe series.

- Cost Efficiency: Reduced waste via precision cutting (optimized yield patterns) and lower maintenance costs vs. genuine leather.

Request Custom Leather Solutions Today

Elevate your product line with WINIW’s tailored synthetic leather engineered for your exact specifications. Our technical team collaborates closely with B2B partners to develop materials matching your performance, aesthetic, and sustainability requirements.

- Free physical samples available for qualified businesses to validate quality and suitability.

- Dedicated project management from concept to bulk production (MOQ: 500 linear meters).

Contact WINIW’s Material Innovation Team

Email: MKT88@MicrofiberLeather.com

Subject Line: “Custom Leather Inquiry – [Your Company Name]”

Response within 24 business hours. Specify application, volume needs, and target certifications.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.