Catalog

Material Insight: Custom Leather Upholstery

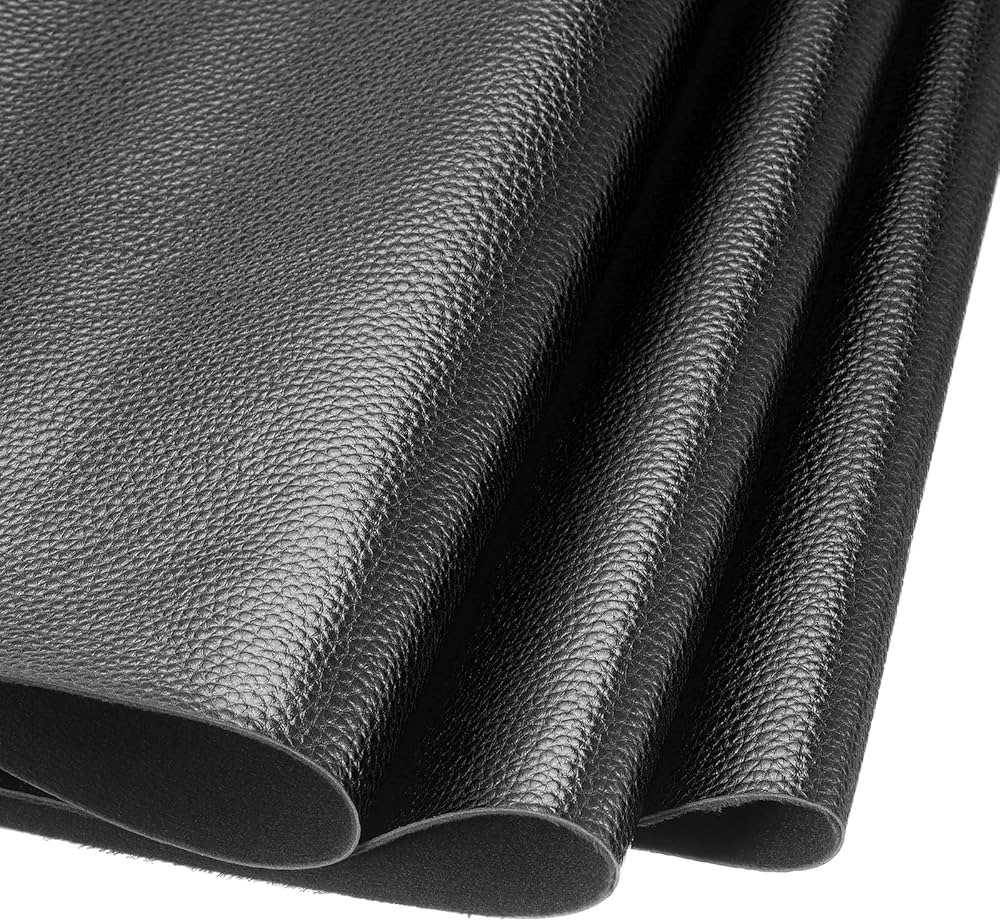

Custom Leather Upholstery: Precision Craftsmanship for Demanding Applications

In today’s competitive furniture, automotive, and hospitality markets, custom leather upholstery transcends aesthetics—it defines brand identity, ensures longevity, and meets rigorous performance standards. Selecting the right material is critical, as upholstery must endure daily wear, environmental stressors, and evolving sustainability expectations while maintaining visual appeal. Synthetic leather emerges as the optimal solution for custom applications, offering unparalleled consistency, design flexibility, and responsible manufacturing—without compromising on the luxurious feel and durability clients demand.

Why Synthetic Leather is the Superior Choice for Custom Upholstery:

– Consistent Quality & Efficiency: Unlike natural leather, synthetic variants eliminate grain variations, scars, and thickness inconsistencies, ensuring uniform appearance across entire production runs and reducing material waste by up to 30%.

– Tailored Performance: Engineered for specific needs—whether extreme abrasion resistance for public transit seating, flame retardancy for hospitality, or soft-touch finishes for premium automotive interiors.

– Sustainable Innovation: Modern synthetics use 60–100% recycled content (e.g., PET bottles), water-based PU coatings, and low-VOC processes, aligning with global ESG goals and certifications like OEKO-TEX® Standard 100.

– Design Freedom: Achieve exact color matching (Pantone®), textures (suede, pebble, exotic grains), and widths (up to 152 cm) without minimum order constraints, accelerating time-to-market.

– Total Cost Control: Predictable pricing, no hide grading costs, and simplified logistics streamline budgeting versus volatile natural leather markets.

Since 2003, WINIW has partnered with forward-thinking manufacturers to solve complex upholstery challenges. With over 20 years of R&D in high-performance synthetic leather, we combine deep material science expertise with a commitment to circular design principles. Our vertically integrated production—from recycled raw materials to finished roll goods—ensures traceability, compliance, and innovation that meets the strictest global safety and ecological standards. When you choose WINIW, you gain a collaborative engineering partner dedicated to elevating your custom upholstery with solutions that perform, endure, and respect our planet.

Technical Performance & Standards

WINIW Custom Leather Upholstery – Technical Product Guide

WINIW’s custom leather upholstery is engineered for high-performance applications across commercial furniture, transportation, hospitality, and healthcare sectors. Designed with innovation and sustainability at its core, our synthetic leather delivers exceptional durability, safety, and aesthetics—without compromising environmental responsibility. Each product is tailored to meet exact client specifications, ensuring optimal fit, finish, and functionality.

Key Technical Advantages

-

Fire Retardant Performance (UK/US Standards Compliant)

WINIW’s custom leather meets stringent fire safety regulations in both the UK and US markets. Our formulations comply with BS 5852 (ignition source 0 & 1) and California Technical Bulletin 117 (CA TB 117), ensuring safe use in public and commercial environments. The intrinsic fire-retardant properties are engineered into the material matrix, offering long-term reliability without surface coatings that may wear off. -

Easy to Clean & Maintain

The tightly bonded polyurethane surface resists stains, spills, and microbial growth. Routine cleaning requires only mild soap and water, making it ideal for high-traffic and hygiene-sensitive settings. No special polishes or conditioners are needed, reducing lifecycle maintenance costs. -

Superior Soft Touch & Aesthetic Quality

WINIW’s micro-porous structure replicates the natural breathability and tactile comfort of premium animal leather. With advanced embossing and finishing techniques, our material offers customizable textures and colors while maintaining a consistently soft hand feel. -

REACH Compliant Chemistry

All formulations adhere to EU REACH regulations (Registration, Evaluation, Authorization, and Restriction of Chemicals). WINIW guarantees the absence of SVHCs (Substances of Very High Concern) and restricted phthalates, ensuring product safety for users and the environment. -

ISO9001-Certified Manufacturing

Our production processes are governed by ISO9001 quality management systems, ensuring consistency, traceability, and continuous improvement. Every batch undergoes rigorous in-line and final inspection to maintain dimensional accuracy, color fastness, and mechanical performance.

Product Specifications

| Property | Specyfikacja |

|---|---|

| Base Material | High-performance polyurethane (PU) on polyester knit or woven backing |

| Thickness Range | 0.6 mm – 1.2 mm (customizable) |

| Width | Up to 155 cm (custom roll lengths available) |

| Fire Resistance | BS 5852 Source 0 & 1, CA TB 117 compliant |

| Color Fastness (Xenon) | ≥ Grade 4 (ISO 105-B02) |

| Martindale Abrasion | ≥ 50,000 cycles (ISO 12947) |

| Tensile Strength | ≥ 90 N/5cm (warp & weft, ISO 13934-1) |

| Tear Strength | ≥ 10 N (ASTM D2261) |

| REACH Compliance | Fully compliant, SVHC-free |

| Cleaning | Water and mild detergent; no solvent required |

| Environmental Profile | PVC-free, low-VOC emissions, recyclable at end-of-life |

| Quality Management | ISO9001:2015 certified production facility |

WINIW’s custom leather upholstery combines technical excellence with sustainable manufacturing practices, offering B2B clients a reliable, compliant, and premium alternative to traditional leather. Partner with us to develop tailored solutions that meet your performance, design, and regulatory requirements.

Why Choose Synthetic over Real Leather

B2B Product Guide: Synthetic Leather vs. Real Leather for Upholstery Applications

Selecting the right upholstery material is critical for commercial furniture, automotive interiors, and hospitality projects. WINIW specializes in premium, eco-conscious synthetic leather solutions engineered for performance and sustainability. Below is a comparative analysis focused on key decision drivers for B2B procurement.

Key Differences: WINIW Synthetic Leather vs. Real Leather

- Material Origin & Consistency

- WINIW Synthetic Leather: Precision-engineered from plant-based and recycled polymers (e.g., PU, PVC-free options). Uniform texture, color, and thickness across all batches—eliminating natural defects.

-

Real Leather: Sourced from animal hides. Inherent variations in grain, scars, and thickness require extensive grading, leading to material waste (up to 30%) during cutting.

-

Customization & Production Efficiency

- WINIW Synthetic Leather: Fully customizable in color, texture, thickness (0.6–1.2mm), and performance (e.g., flame resistance, UV stability). Rapid production scaling with no lead-time delays from hide availability.

-

Real Leather: Limited color/texture options due to natural constraints. Custom dyeing adds cost and time. Supply chain volatility (e.g., livestock market fluctuations) disrupts production schedules.

-

Total Cost of Ownership

While real leather has a lower initial material cost per hide, WINIW’s synthetic solutions reduce total project costs through: - Near-zero waste in cutting (optimized pattern nesting)

- No secondary finishing processes (e.g., stain masking)

- 40–60% lower maintenance costs over product lifecycle

Comparative Performance Metrics

| Factor | WINIW Synthetic Leather | Real Leather |

|---|---|---|

| Cost (per sqm) | 25–40% lower upfront cost* | Higher initial material cost |

| Long-term savings via 95%+ material yield & reduced labor | Waste costs: 20–30% of hide value lost in grading/cutting | |

| Trwałość | Superior abrasion resistance (50,000+ double rubs) | Moderate (20,000–30,000 double rubs; prone to cracking) |

| Consistent performance in humidity/UV exposure | Requires conditioning; fades/cracks under UV/stress | |

| Eco-Friendliness | 60% lower water usage vs. leather tanning | Tanning consumes 45,000–100,000 L water/ton hides |

| Recyclable at end-of-life (closed-loop programs available) | Non-recyclable; landfill-bound post-use | |

| Carbon footprint 3x lower (no livestock methane) | High emissions from livestock + chemical tanning |

*Based on commercial furniture production data (2023, WINIW Lifecycle Analysis)

Why WINIW Synthetic Leather Wins for B2B Applications

- Sustainability Compliance: Meets EU REACH, OEKO-TEX® STANDARD 100, and LEED v4.1 material credits—critical for ESG reporting.

- Risk Mitigation: Avoids ethical controversies (animal welfare) and supply chain disruptions (e.g., hide export bans).

- Design Freedom: Achieve brand-specific aesthetics without compromising on durability or eco-credentials.

WINIW delivers not just a material, but a strategic partnership for scalable, future-proof upholstery solutions. Request our technical datasheets and sample kits to validate performance for your next project.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, serving global clients with innovative, sustainable, and premium-quality materials. Our vertically integrated production ecosystem and advanced manufacturing capabilities position us as a trusted partner in the B2B market.

Our state-of-the-art manufacturing facility spans over 100,000 square meters, making it one of the largest synthetic leather production bases in Asia. This expansive infrastructure supports large-scale output while maintaining precision, consistency, and fast turnaround times to meet the demands of international clients.

Key strengths of the WINIW factory include:

-

Advanced R&D team: Comprising over 100 technical experts, our research and development department drives continuous innovation in material science, focusing on eco-friendly formulations, durability, and application-specific performance. We invest heavily in developing low-VOC, recyclable, and bio-based synthetic leathers to align with global sustainability standards.

-

Strict quality control (QC) system: WINIW implements a comprehensive QC process across all production stages—from raw material inspection to final product testing. Our facility is certified under ISO 9001, ISO 14001, and OEKO-TEX® STANDARD 100, ensuring compliance with international safety and environmental regulations.

-

Global export capability: WINIW exports to key markets including Europe and the USA, supplying industries such as automotive, furniture, apparel, and luggage. Our logistics network ensures reliable delivery, while our compliance with REACH, RoHS, and CPSIA standards facilitates smooth customs clearance and market access.

-

In-house testing laboratory: Equipped with advanced instrumentation, our lab conducts rigorous tests on abrasion resistance, color fastness, tensile strength, and chemical content, guaranteeing that every batch meets or exceeds client specifications.

| Feature | Specyfikacja |

|---|---|

| Factory Size | 100,000 sqm |

| R&D Team | 100+ engineers and technicians |

| Key Certifications | ISO 9001, ISO 14001, OEKO-TEX® STANDARD 100, REACH, RoHS |

| Main Export Regions | Europe, USA, Southeast Asia |

| Production Capacity | Over 30 million meters annually |

WINIW combines scale, innovation, and quality to deliver synthetic leather solutions that support the evolving needs of global brands and manufacturers. Our factory strength ensures reliability, consistency, and long-term partnership value in the competitive B2B marketplace.

Contact Us for Samples

WINIW Premium Synthetic Leather: B2B Product Guide for Upholstery Solutions

WINIW delivers high-performance, eco-conscious synthetic leather engineered specifically for demanding B2B upholstery applications. Our materials combine exceptional durability, design versatility, and certified sustainability—eliminating the environmental burden of traditional leather without compromising on quality. Trusted by leading furniture manufacturers, automotive OEMs, and contract interior designers globally, WINIW provides scalable solutions aligned with modern ESG commitments.

Why WINIW for Commercial Upholstery?

- Eco-Certified Performance: OEKO-TEX® STANDARD 100 Class I (skin-safe), ISO 14001-compliant production, and 30–60% lower carbon footprint vs. bovine leather.

- Engineered Durability: 50,000+ double-rubs (Martindale), UV-stable pigments, and abrasion resistance for high-traffic commercial use.

- Design Flexibility: 200+ stock colors/finishes (matte, pebble, embossed) + full customization for texture, thickness, and color matching.

- Seamless Integration: Consistent roll widths (54″/137cm, 60″/152cm) with minimal batch variation; compatible with standard cutting/sewing workflows.

- Regulatory Ready: REACH, RoHS, and CA TB 117-2013 compliant for global market access.

Core Product Specifications (Standard Upholstery Grade)

| Property | WINIW EcoLux™ Series | WINIW AutoFlex™ Series | WINIW ContractPro™ Series |

|---|---|---|---|

| Thickness | 0.8–1.2mm | 0.7–1.0mm | 1.0–1.5mm |

| Width | 54″ / 60″ (137/152cm) | 54″ / 60″ (137/152cm) | 54″ / 60″ (137/152cm) |

| Weight (g/m²) | 320–450 | 300–400 | 400–550 |

| Martindale Rubs | 50,000+ | 60,000+ | 70,000+ |

| Eco-Certifications | OEKO-TEX®, GRS | OEKO-TEX®, UL ECOLOGO® | OEKO-TEX®, ISO 14001 |

| Primary Use Case | Furniture, Hospitality | Automotive, Transport | Healthcare, Public Spaces |

Sustainable Innovation at Scale

WINIW’s closed-loop water recycling system reduces freshwater use by 90% versus industry averages. Our PU/PVC-free EcoLux™ series utilizes plant-based polyols (30% bio-content), while recycled polyester backings incorporate post-consumer PET bottles. Every roll is traceable via blockchain for full supply chain transparency—ensuring your sustainability claims are verifiable.

Elevate Your Upholstery Project with Custom Solutions

WINIW partners with B2B clients to develop tailored synthetic leather that meets exact performance, aesthetic, and sustainability requirements. Whether scaling luxury furniture lines, designing automotive interiors, or outfitting high-occupancy commercial spaces, our R&D team optimizes materials for your specific workflow and market demands.

→ Request Free Physical Samples & Custom Quotes

Experience WINIW’s quality firsthand. Contact our B2B Solutions Team for:

– Complimentary 6″x6″ samples of any stock or custom finish

– Technical data sheets and fire/safety compliance documentation

– Volume pricing and lead time consultation

Email: MKT88@MicrofiberLeather.com

Response within 24 business hours. MOQs start at 500 linear meters.

WINIW: Engineered Responsibility. Uncompromised Performance.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.