Introduction: Navigating the Global Market for custom leather fire helmet shields

In the dynamic landscape of firefighting equipment, sourcing custom leather fire helmet shields presents unique challenges for international B2B buyers. With the demand for durable, high-quality shields that reflect departmental identity and pride, navigating the myriad options available in the global market can be daunting. This guide aims to illuminate the diverse types of custom leather fire helmet shields, from traditional designs to fully customizable options that cater to specific needs and preferences.

We’ll delve into key aspects such as the applications of these shields in various firefighting scenarios, the essential criteria for vetting suppliers, and an analysis of cost structures to help you make informed decisions. Whether you are operating in Nigeria, Brazil, or any country in the Middle East or Europe, understanding the nuances of this market is crucial.

By equipping you with actionable insights and practical recommendations, this guide empowers B2B buyers to confidently select the right custom leather fire helmet shields that meet both performance and aesthetic requirements. Ultimately, it serves as a valuable resource to enhance your procurement strategy, ensuring that your firefighting team is not only well-equipped but also proudly represented on the front lines.

Table Of Contents

- Top 2 Custom Leather Fire Helmet Shields Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather fire helmet shields

- Understanding custom leather fire helmet shields Types and Variations

- Key Industrial Applications of custom leather fire helmet shields

- 3 Common User Pain Points for ‘custom leather fire helmet shields’ & Their Solutions

- Strategic Material Selection Guide for custom leather fire helmet shields

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather fire helmet shields

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather fire helmet shields’

- Comprehensive Cost and Pricing Analysis for custom leather fire helmet shields Sourcing

- Alternatives Analysis: Comparing custom leather fire helmet shields With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather fire helmet shields

- Navigating Market Dynamics and Sourcing Trends in the custom leather fire helmet shields Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather fire helmet shields

- Strategic Sourcing Conclusion and Outlook for custom leather fire helmet shields

- Important Disclaimer & Terms of Use

Understanding custom leather fire helmet shields Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Issue Helmet Shields | Traditional designs, often featuring department insignia | Fire departments, uniform procurement | Pros: Cost-effective, widely accepted; Cons: Limited customization options. |

| Custom Logo Helmet Shields | Incorporates department logos and unique designs | Branding for fire departments | Pros: Enhances department identity; Cons: Higher price point for customization. |

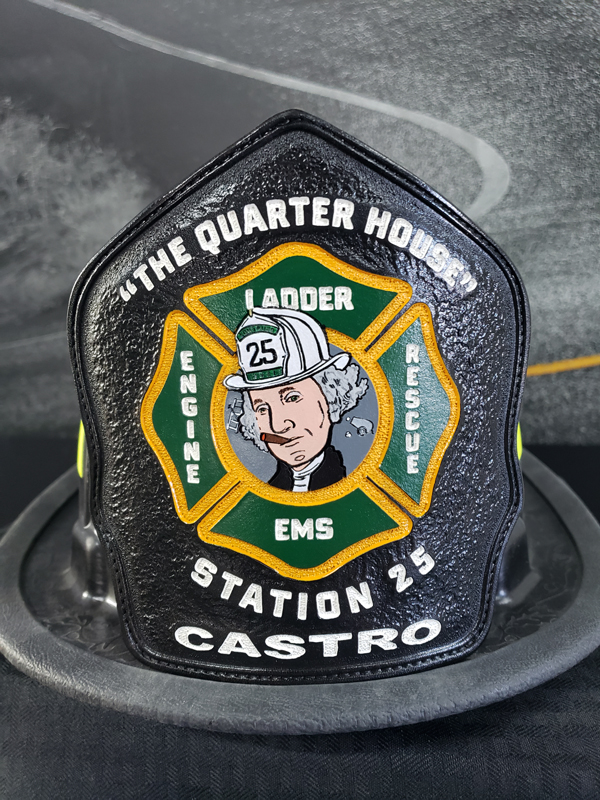

| Maltese Cross Helmet Shields | Iconic design symbolizing firefighting heritage | Ceremonial events, awards | Pros: Strong tradition appeal; Cons: May not suit all operational environments. |

| Passport Helmet Shields | Flexible inserts for quick changes in identification | Departments with changing personnel | Pros: Easy to update; Cons: May lack durability compared to solid shields. |

| Specialty & Custom Art Shields | Unique, handcrafted designs tailored to individual preferences | Personal use, special recognition | Pros: Highly personalized; Cons: Longer lead times and potentially higher costs. |

What Are the Key Characteristics of Standard Issue Helmet Shields?

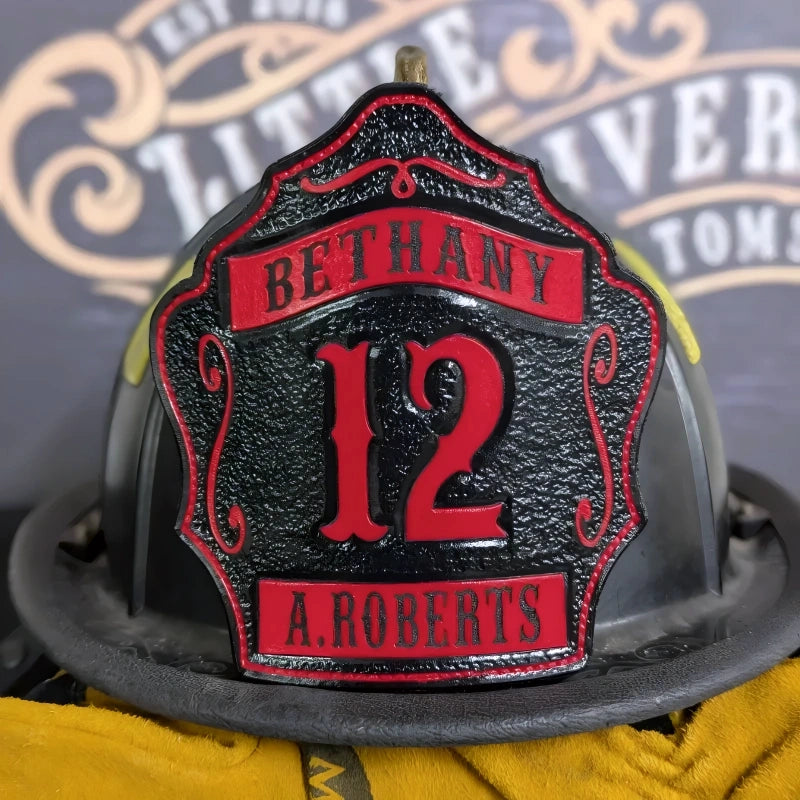

Standard issue helmet shields are the backbone of firefighter identification. These shields typically feature a traditional design that prominently displays the department insignia and rank. They are widely accepted across various fire departments, making them an ideal choice for uniform procurement. While they are cost-effective, buyers should note that customization options are limited, which may not cater to departments seeking a unique identity.

How Do Custom Logo Helmet Shields Enhance Department Branding?

Custom logo helmet shields allow fire departments to incorporate their unique branding elements, such as logos and specific designs. This not only enhances the visual identity of the department but also fosters a sense of pride among firefighters. While these shields are ideal for branding, they often come with a higher price point due to the customization involved. B2B buyers should consider their budget and the importance of brand representation in their purchasing decisions.

Why Choose Maltese Cross Helmet Shields for Ceremonial Events?

Maltese cross helmet shields are steeped in firefighting tradition, making them particularly popular for ceremonial events and awards. Their iconic design symbolizes bravery and commitment, appealing to departments that value heritage. However, while they are visually striking, these shields may not be suitable for all operational environments due to their decorative nature. B2B buyers should assess the intended use before opting for this style.

What Advantages Do Passport Helmet Shields Offer for Changing Personnel?

Passport helmet shields are designed for flexibility, allowing departments to quickly change identification elements as personnel shift. This feature is particularly beneficial for departments with frequent changes in staff or ranks. While they provide ease of use, buyers should be aware that these shields may not match the durability of solid shields, which could be a consideration for those in high-demand environments.

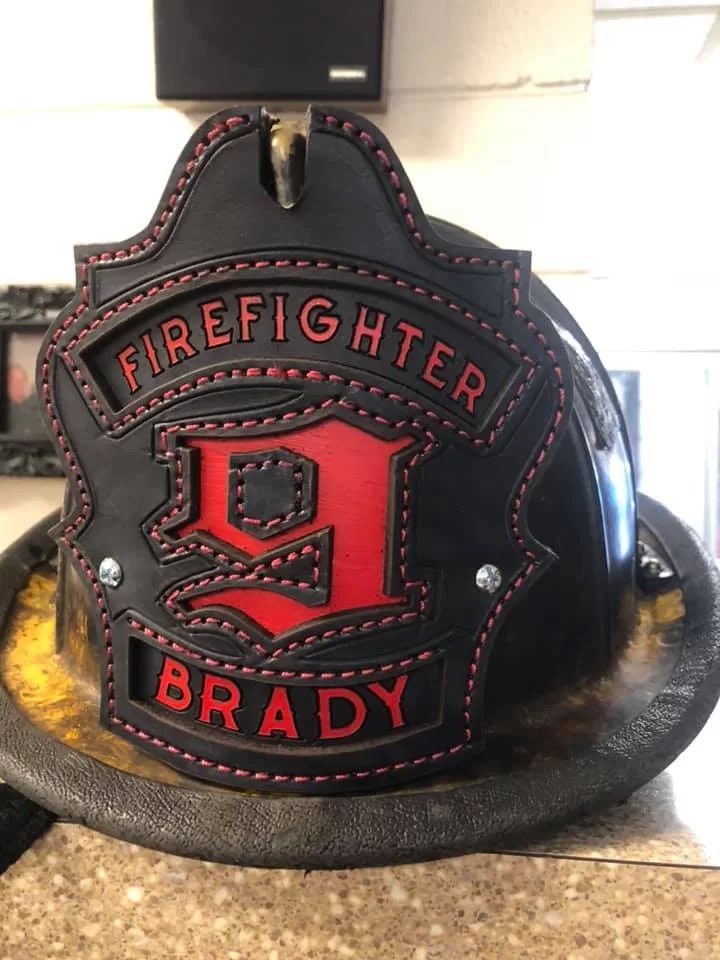

How Do Specialty & Custom Art Shields Reflect Individual Preferences?

Specialty and custom art shields provide a unique opportunity for personalization, enabling firefighters to express their individuality through handcrafted designs. These shields can be tailored to specific preferences, making them ideal for personal use or special recognition. However, potential buyers should be prepared for longer lead times and higher costs associated with custom orders. B2B purchasers should evaluate the balance between uniqueness and practicality when considering these options.

Key Industrial Applications of custom leather fire helmet shields

| Industry/Sector | Specific Application of custom leather fire helmet shields | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Firefighting Services | Identification and rank display for firefighters | Enhances crew identity and morale, promotes professionalism | Customization options, durability against heat and smoke |

| Emergency Response Organizations | Custom shields for rescue teams | Provides clear identification in chaotic environments | Compatibility with various helmet types, bulk order discounts |

| Oil and Gas Industry | Safety and identification for emergency response teams | Improves safety by ensuring quick recognition of team members | Compliance with industry standards, bespoke design features |

| Military and Security Services | Custom insignia for firefighting units | Fosters unit pride and enhances operational efficiency | Material quality, customization for unit insignia |

| Industrial Manufacturing | Fire safety training and drills | Supports training initiatives with realistic gear | Availability of training-specific designs, cost-effectiveness |

How Are Custom Leather Fire Helmet Shields Used in Firefighting Services?

Custom leather fire helmet shields serve as essential identification tools for firefighters, displaying rank, department, and personal insignia. This enhances team morale and fosters a sense of pride among crew members, which is particularly vital in high-stress environments. For international buyers, especially in regions like Africa and South America, sourcing durable options that withstand extreme conditions is crucial. Customization options allow departments to maintain a consistent look, which can be vital for brand identity and recognition in the community.

What Role Do Custom Shields Play in Emergency Response Organizations?

In emergency response organizations, custom leather fire helmet shields are vital for identifying rescue team members quickly during crises. These shields enhance visibility and clarity, allowing for immediate recognition of roles in chaotic situations. Buyers from the Middle East and Europe should consider the compatibility of shields with various helmet models and the availability of bulk order discounts, which can help streamline procurement processes and reduce costs for large teams.

Why Are Custom Leather Shields Important in the Oil and Gas Industry?

Within the oil and gas sector, custom leather fire helmet shields are used by emergency response teams to ensure quick identification during emergencies. These shields not only signify rank and unit but also improve safety by allowing for rapid recognition of team members. For B2B buyers in this industry, ensuring compliance with safety standards while sourcing bespoke designs is critical. The shields must also be durable enough to withstand the harsh conditions often found on oil rigs.

How Do Custom Shields Benefit Military and Security Services?

Military and security services utilize custom leather fire helmet shields to display unit insignia and rank, fostering unit pride and cohesion. These shields contribute to operational efficiency by making it easier to identify team members during missions. Buyers in this sector should focus on sourcing high-quality materials that can endure rigorous use, as well as customization options that reflect the specific needs of their units.

Illustrative image related to custom leather fire helmet shields

What Is the Application of Custom Leather Shields in Industrial Manufacturing?

In industrial manufacturing, custom leather fire helmet shields are employed during safety training and drills to provide realistic scenarios for employees. These shields support training initiatives by familiarizing workers with the equipment they might encounter in real emergencies. Buyers should prioritize the availability of training-specific designs that are also cost-effective, ensuring that they can equip their teams without compromising on quality.

3 Common User Pain Points for ‘custom leather fire helmet shields’ & Their Solutions

Scenario 1: Sizing and Compatibility Issues with Fire Helmet Shields

The Problem: A common challenge faced by B2B buyers is ensuring that custom leather fire helmet shields fit the specific helmet models used by their fire departments. Different helmets come in varying sizes and designs, leading to potential misfits that can affect not only the aesthetics but also the shield’s visibility and functionality. This situation can result in wasted resources and time, as incorrect orders may necessitate returns or replacements, complicating procurement processes and delaying operations.

The Solution: To mitigate sizing issues, buyers should first conduct thorough measurements of their existing helmets. It’s advisable to create a comprehensive sizing guide that includes specific dimensions for each helmet model in use. When sourcing custom shields, engage with manufacturers who offer detailed size charts and the ability to customize dimensions based on your specifications. Additionally, consider ordering a sample shield for testing before making bulk purchases. This proactive approach ensures compatibility, saving time and money while enhancing team cohesion through uniformity in appearance.

Illustrative image related to custom leather fire helmet shields

Scenario 2: Concerns Over Durability in Harsh Conditions

The Problem: Firefighters operate in extreme environments, and the durability of custom leather fire helmet shields is a significant concern for B2B buyers. Many buyers worry that the shields will degrade quickly when exposed to heat, smoke, and other harsh elements typical in firefighting scenarios. This degradation not only affects the shield’s appearance but can also compromise the identification function that is crucial during emergency operations.

The Solution: Buyers should prioritize sourcing shields made from high-quality, full-grain leather known for its resilience and ability to withstand extreme conditions. When evaluating suppliers, inquire about the materials used and request information about any protective finishes applied to the leather, such as water-resistant coatings. Furthermore, look for manufacturers who offer warranties or guarantees on their products, as this reflects their confidence in the durability of their shields. Regular maintenance, such as cleaning with a damp cloth and conditioning the leather to prevent cracking, can also prolong the life of the shields, making them a worthwhile investment.

Scenario 3: Customization and Brand Identity Challenges

The Problem: Another prevalent pain point is the need for customization to reflect the unique identity and values of different fire departments. B2B buyers often face difficulties in finding suppliers that can accommodate specific designs, logos, or insignias without compromising on quality. This challenge can hinder the department’s ability to foster pride among its members and represent its brand effectively during public engagements.

The Solution: To address this need for customization, B2B buyers should partner with manufacturers that specialize in bespoke designs for fire helmet shields. Look for companies that offer a wide range of customization options, including the ability to submit unique artwork or logos for incorporation into the shield design. Establish clear communication regarding your design vision and requirements, and request prototypes or digital mock-ups before finalizing orders. Additionally, consider bulk purchasing options that allow for variations in design across different teams or units, ensuring that every aspect of the department’s identity is represented while maintaining a cohesive look. This approach not only enhances team spirit but also reinforces the department’s brand in the community.

Strategic Material Selection Guide for custom leather fire helmet shields

What Are the Key Properties of Different Materials Used in Custom Leather Fire Helmet Shields?

When selecting materials for custom leather fire helmet shields, understanding the properties and performance characteristics of each option is crucial for ensuring durability and functionality in demanding environments. Below are analyses of several common materials used in the production of these shields.

How Does Full-Grain Leather Perform in Custom Fire Helmet Shields?

Full-grain leather is the highest quality leather available, retaining the natural grain and texture. It is known for its exceptional durability and resistance to wear and tear, making it ideal for high-stress applications like fire helmet shields. Full-grain leather can withstand high temperatures and is less likely to crack or peel compared to lower-grade leathers.

Pros: The key advantages of full-grain leather include its superior strength, aesthetic appeal, and natural resistance to moisture when treated properly. It also molds well to the shape of the helmet, providing a snug fit.

Cons: However, full-grain leather can be more expensive than other materials and may require more complex manufacturing processes, including dyeing and sealing. Additionally, it may not be as readily available in some regions.

Impact on Application: Full-grain leather is compatible with various environmental conditions, making it suitable for fire departments operating in diverse climates, from humid regions in South America to dry areas in the Middle East.

Illustrative image related to custom leather fire helmet shields

What Are the Benefits of Using Suede Leather for Fire Helmet Shields?

Suede leather, derived from the underside of the hide, offers a soft texture and a unique aesthetic. While it is less durable than full-grain leather, suede is lightweight and can provide a comfortable fit.

Pros: Suede is generally more affordable and easier to work with, allowing for intricate designs and customizations. It can also be treated to enhance its resistance to water and stains.

Cons: The main drawback is its lower durability, making it less suitable for environments with extreme heat or exposure to harsh chemicals. Suede may also require more frequent maintenance to keep it looking good.

Impact on Application: Suede is often favored for custom designs and artistic elements, appealing to fire departments looking to showcase their identity. However, buyers in regions with high humidity or heavy rainfall should consider its limited moisture resistance.

Illustrative image related to custom leather fire helmet shields

How Does Synthetic Leather Compare to Natural Leather for Helmet Shields?

Synthetic leather, often made from polyurethane or PVC, is an alternative that mimics the appearance of natural leather. It is typically less expensive and can be manufactured to have specific properties, such as enhanced water resistance.

Pros: The key advantages of synthetic leather include its affordability, ease of maintenance, and consistent quality. It is also available in a variety of colors and finishes, allowing for extensive customization.

Cons: However, synthetic leather may not offer the same level of durability or breathability as natural leather. It can also degrade more quickly under extreme heat or UV exposure, which is a critical consideration for fire helmet applications.

Impact on Application: Synthetic leather can be a viable option for budget-conscious departments, especially in regions where leather availability is limited. However, buyers should be aware of the potential for reduced longevity in harsh working conditions.

Illustrative image related to custom leather fire helmet shields

What Makes Top-Grain Leather a Compelling Choice for Custom Shields?

Top-grain leather is a step below full-grain leather in terms of quality, as it has been sanded and treated to remove imperfections. This process makes it more pliable and easier to work with, while still retaining many desirable properties.

Pros: Top-grain leather is less expensive than full-grain leather and offers a good balance of durability and aesthetics. It is also more resistant to stains and easier to clean.

Cons: The trade-off is that top-grain leather may not be as strong or long-lasting as full-grain leather. It is also more susceptible to wear over time, especially in high-stress applications.

Impact on Application: Top-grain leather is suitable for fire departments looking for a balance between quality and cost. It is particularly appealing to organizations in regions where budget constraints are a significant factor.

Summary Table of Material Selections for Custom Leather Fire Helmet Shields

| Materiał | Typical Use Case for custom leather fire helmet shields | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-performance, durable shields for extreme conditions | Exceptional durability and aesthetics | Higher cost and manufacturing complexity | High |

| Suede Leather | Custom artistic designs and lighter shields | Affordable and easy to customize | Lower durability and maintenance needs | Medium |

| Synthetic Leather | Budget-friendly options for various designs | Cost-effective and easy to maintain | Reduced durability under extreme conditions | Low |

| Top-Grain Leather | Balanced quality for cost-sensitive applications | Good aesthetics with easier cleaning | Less durable than full-grain leather | Medium |

This strategic material selection guide provides essential insights for international B2B buyers, helping them make informed decisions based on performance, cost, and regional preferences.

Illustrative image related to custom leather fire helmet shields

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather fire helmet shields

What Are the Key Stages in the Manufacturing Process of Custom Leather Fire Helmet Shields?

The manufacturing process for custom leather fire helmet shields involves several critical stages, each essential for ensuring the final product meets the high standards required by firefighters.

Material Preparation: What Types of Leather Are Used?

The first step in manufacturing is the selection and preparation of high-quality leather. Full-grain leather is often preferred due to its durability and ability to withstand harsh conditions, including heat and moisture. Manufacturers typically source leather from reputable tanneries to ensure consistency in quality. The leather is inspected for defects and graded accordingly. This initial quality control sets the foundation for the entire production process.

How Is the Leather Formed into Helmet Shields?

Once the leather is prepared, it undergoes a forming process. This typically involves cutting the leather into the desired shapes and sizes using precision cutting tools. Some manufacturers employ laser cutting technology to achieve intricate designs with high accuracy. After cutting, the leather pieces are moistened to make them pliable, allowing artisans to mold them into the specific shapes required for different helmet styles. This step is crucial for achieving a snug fit on the helmet while ensuring the shield’s structural integrity.

What Techniques Are Used for Assembly and Finishing?

The assembly of the helmet shields involves several techniques, including stitching, tooling, and painting. High-strength stitching is used to attach different leather components, ensuring durability during use. Hand tooling allows for the creation of custom designs, logos, or insignias, enhancing the visual appeal and personalization of each shield.

Finishing processes, such as dyeing and sealing, are applied to enhance the leather’s appearance and protect it from environmental factors. Manufacturers often use water-resistant finishes to ensure longevity, which is particularly important for shields exposed to heat and moisture during firefighting operations. This attention to detail in both assembly and finishing contributes to a product that not only looks professional but also performs reliably in the field.

What Quality Assurance Practices Are Implemented in the Production of Helmet Shields?

Quality assurance is a critical component of the manufacturing process for custom leather fire helmet shields. Various international and industry-specific standards guide the QC practices to ensure that products meet safety and performance criteria.

Illustrative image related to custom leather fire helmet shields

Which International Standards Are Relevant for Custom Leather Products?

ISO 9001 is a widely recognized standard that focuses on quality management systems. Manufacturers often seek certification to demonstrate their commitment to quality and customer satisfaction. Additionally, while custom leather helmet shields are not classified as safety equipment, adherence to CE marking and relevant local regulations can enhance credibility in international markets.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are integrated at various stages of production:

-

Incoming Quality Control (IQC): This step involves inspecting the leather and other materials upon arrival. Any defective materials are rejected to prevent downstream issues.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor the quality of workmanship and adherence to specifications. This includes checking stitching quality, tooling accuracy, and overall craftsmanship.

-

Final Quality Control (FQC): Before products are packaged and shipped, a comprehensive inspection is performed. This includes verifying dimensions, checking for defects, and ensuring that finishing processes meet the required standards.

What Testing Methods Are Commonly Used for Leather Helmet Shields?

Common testing methods for leather products include tensile strength tests, abrasion resistance tests, and water resistance evaluations. These tests ensure that the shields can withstand the rigors of firefighting and maintain their integrity over time. While specific certifications for helmet shields may not exist, these tests provide valuable data that can be shared with B2B buyers to instill confidence in product quality.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential to ensure product reliability.

What Steps Can Buyers Take to Audit Suppliers?

Buyers can conduct audits of potential suppliers to assess their manufacturing processes and quality control measures. This includes:

-

Factory Visits: If feasible, visiting the manufacturing facility allows buyers to observe production processes and quality checks in real-time.

-

Reviewing Quality Control Reports: Suppliers should provide documentation detailing their quality control procedures, testing results, and any certifications obtained. This transparency helps buyers gauge the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s operations and product quality. These inspections typically occur at various stages of production, providing assurance that the products meet the specified requirements.

What Are the Unique QC Considerations for International Buyers?

International buyers should be aware of potential differences in quality expectations and standards across regions. For example, while European markets may prioritize certain certifications, buyers in Africa or South America may focus more on durability and performance. Understanding these nuances can help buyers select suppliers that align with their specific needs.

Illustrative image related to custom leather fire helmet shields

Additionally, factors such as shipping logistics, import regulations, and regional compliance standards should be taken into account when establishing quality expectations. Clear communication regarding these aspects can enhance collaboration between buyers and suppliers, fostering a more effective partnership.

Conclusion: How Do Quality Manufacturing Processes Impact the Value of Custom Leather Fire Helmet Shields?

The manufacturing and quality assurance processes for custom leather fire helmet shields are integral to producing reliable, durable products that meet the needs of firefighters. By understanding the stages of production, quality control measures, and verification methods, B2B buyers can make informed purchasing decisions that ensure they receive high-quality shields tailored to their specifications. Investing in well-manufactured helmet shields not only enhances safety and performance but also contributes to the pride and identity of firefighting crews worldwide.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather fire helmet shields’

Wprowadzenie

In the competitive landscape of firefighting equipment procurement, selecting the right custom leather fire helmet shields is vital for branding, functionality, and crew identity. This guide serves as a step-by-step checklist for B2B buyers to ensure a thorough sourcing process, enabling you to find reliable suppliers who meet your specific needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, it’s essential to outline your specific requirements for the custom leather fire helmet shields. Consider factors such as size, design, and durability.

- Size: Ensure the shields fit the helmets your team uses, as different models may have unique dimensions.

- Material Quality: Look for full-grain leather options that withstand harsh conditions, including heat and smoke.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in custom leather fire helmet shields.

Illustrative image related to custom leather fire helmet shields

- Online Presence: Explore their websites for product offerings, customer testimonials, and case studies.

- Industry Reputation: Check industry forums and social media for reviews and feedback from other fire departments or organizations.

Step 3: Evaluate Supplier Experience and Expertise

Prioritize suppliers with a proven track record in the fire service industry.

- Years in Business: Suppliers with extensive experience are likely to understand the unique needs of firefighters.

- Custom Design Capabilities: Look for suppliers that offer bespoke designs, allowing you to incorporate department logos or unique artwork.

Step 4: Request Samples and Product Specifications

Before making a bulk order, ask for samples to assess quality and craftsmanship.

- Material Samples: This will help you gauge the leather quality and durability.

- Product Specifications: Request detailed information on the manufacturing process, including stitching methods and finishes.

Step 5: Verify Compliance and Certifications

Ensure that the supplier meets relevant industry standards, even if custom helmet shields are not classified as safety equipment.

- Quality Assurance: Check if the supplier follows quality control practices that ensure consistent product quality.

- Sustainability Practices: If applicable, inquire about their environmental practices, which can be a significant factor for many organizations today.

Step 6: Understand Pricing and Payment Terms

Discuss pricing structures and payment options with potential suppliers.

- Bulk Discounts: Inquire about discounts for larger orders, which can be beneficial for fire departments looking to outfit multiple helmets.

- Payment Terms: Clarify payment methods and terms to avoid any misunderstandings later in the procurement process.

Step 7: Establish a Clear Communication Channel

Set up a direct line of communication with your chosen supplier for a smooth procurement process.

- Point of Contact: Designate a specific representative for your order to streamline communication.

- Regular Updates: Ensure that the supplier provides updates on production timelines and shipping details, which is crucial for planning.

By following this checklist, B2B buyers can confidently navigate the procurement process for custom leather fire helmet shields, ensuring that their teams are equipped with quality, durable, and personalized gear.

Comprehensive Cost and Pricing Analysis for custom leather fire helmet shields Sourcing

What Are the Key Cost Components in Custom Leather Fire Helmet Shields?

Understanding the cost structure of custom leather fire helmet shields is crucial for B2B buyers seeking to make informed purchasing decisions. The primary cost components include:

-

Materials: The quality of leather used significantly impacts the overall cost. Full-grain leather, known for its durability and aesthetics, is typically more expensive than lower-grade options. Additional materials such as dyes, paints, and sealants also contribute to the final price.

-

Labor: Handcrafted products necessitate skilled labor, which can drive up costs. Artisans who carve, tool, and assemble the shields often command higher wages due to their expertise.

-

Manufacturing Overhead: This encompasses the costs of running production facilities, including utilities, equipment maintenance, and indirect labor. Higher overhead can be a reflection of better working conditions and more advanced manufacturing techniques.

-

Tooling: Custom designs may require specialized tools or molds, increasing the initial investment for a manufacturer. This cost is often amortized over larger production runs.

-

Quality Control (QC): Ensuring that each helmet shield meets stringent quality standards involves additional costs. This may include inspections and testing, which are particularly important for products used in high-stakes environments like firefighting.

-

Logistics: The cost of shipping and handling can vary significantly based on the destination. International shipping, especially to regions like Africa or South America, may incur higher fees and longer lead times.

-

Margin: Suppliers typically include a profit margin that reflects their business model and market conditions. This margin can vary based on the perceived value of the product and competitive landscape.

What Price Influencers Should Buyers Consider?

Several factors can influence the pricing of custom leather fire helmet shields:

-

Volume/MOQ (Minimum Order Quantity): Bulk orders often result in reduced per-unit costs. Suppliers may offer tiered pricing structures, making it advantageous for larger organizations to consolidate orders.

-

Specifications and Customization: Unique designs or additional features can elevate prices. Custom logos or specific artwork may incur extra charges, so clarity on requirements is essential before initiating orders.

-

Material Quality and Certifications: Higher-quality materials and certifications can justify premium pricing. Buyers should assess whether the added costs align with their operational needs and safety standards.

-

Supplier Factors: Reputation, reliability, and location of the supplier can impact costs. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding shipping terms can save costs. For instance, options like CIF (Cost, Insurance, and Freight) may offer more predictable expenses compared to FOB (Free on Board), where buyers assume more risk.

What Are the Best Buyer Tips for Cost-Efficiency?

To ensure a cost-efficient purchasing process, B2B buyers should consider the following strategies:

-

Negotiate Wisely: Engage suppliers in discussions about pricing and terms. Highlighting potential for repeat business or bulk orders can provide leverage for better deals.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial costs, consider the lifespan and durability of the shields. Investing in higher-quality products may reduce replacement frequency and overall expenditure.

-

Understand Pricing Nuances in International Markets: Buyers from regions like Africa, South America, and the Middle East should be aware of local economic conditions, currency fluctuations, and import duties that can affect total costs.

-

Request Detailed Quotes: Ensure that quotes include breakdowns of all costs associated with the product, including materials, labor, and logistics. This transparency allows for better comparison between suppliers.

-

Plan for Lead Times: Custom orders may require longer lead times. Planning ahead can mitigate rush fees and ensure timely delivery, which is crucial for operational readiness.

Conclusion

Navigating the cost and pricing landscape of custom leather fire helmet shields requires a comprehensive understanding of various components and influencing factors. By being informed, buyers can make strategic decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing custom leather fire helmet shields With Other Solutions

When considering the best options for fire helmet identification, it’s essential to evaluate the alternatives to custom leather fire helmet shields. While these shields offer unique benefits, there are other viable solutions that may better suit specific needs or preferences. Below, we compare custom leather fire helmet shields with two alternative solutions: vinyl helmet decals and embroidered patches.

| Comparison Aspect | Custom Leather Fire Helmet Shields | Vinyl Helmet Decals | Embroidered Patches |

|---|---|---|---|

| Performance | High durability, withstands heat and wear | Moderate durability, can fade over time | Durable but susceptible to fraying |

| Cost | Higher upfront cost ($60-$130) | Lower cost ($10-$30) | Moderate cost ($20-$50) |

| Ease of Implementation | Requires careful fitting and mounting | Easy application, self-adhesive | Requires sewing or heat press |

| Maintenance | Low maintenance; occasional cleaning | Moderate; may need replacement | Low; can wash but may fray |

| Best Use Case | Long-term use for professional firefighters | Budget-friendly for training or temporary use | Customizable for team identity and events |

What Are the Advantages and Disadvantages of Vinyl Helmet Decals?

Vinyl helmet decals are an attractive alternative for those looking for a cost-effective solution. They are lightweight and can be easily applied to helmets without the need for tools. However, they may not hold up as well under extreme conditions, leading to fading or peeling over time. Their affordability makes them a good choice for departments with tight budgets or for temporary identification during training exercises. Yet, they may not convey the same level of professionalism and tradition as leather shields.

How Do Embroidered Patches Compare to Custom Leather Shields?

Embroidered patches offer a unique and flexible way to display rank and identity. They can be customized to reflect a department’s logo or a firefighter’s rank and can be easily attached to various gear. While they are generally durable, they can fray or lose their appearance over time, especially with exposure to harsh environments. The cost is moderate, making them a viable option for departments wanting a blend of customization and affordability. However, they may require more maintenance than leather shields and may not provide the same level of protection against the elements.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the right helmet identification solution, B2B buyers should consider their specific needs, budget, and the environment in which their team operates. Custom leather fire helmet shields are ideal for those prioritizing durability and a professional appearance, making them suitable for frontline firefighters. Conversely, vinyl decals may be more appropriate for training scenarios or departments with budget constraints, while embroidered patches can offer a customizable option that balances identity and cost. Ultimately, the decision should align with the department’s culture, operational demands, and long-term goals.

Essential Technical Properties and Trade Terminology for custom leather fire helmet shields

What Are the Essential Technical Properties of Custom Leather Fire Helmet Shields?

When sourcing custom leather fire helmet shields, understanding the technical properties is crucial for making informed purchasing decisions. Here are some key specifications to consider:

1. Material Grade

The primary material used in custom leather fire helmet shields is full-grain leather. This grade is considered the highest quality, as it retains the natural grain and durability of the hide. Full-grain leather is essential for withstanding the demanding conditions firefighters face, such as heat, smoke, and wear over time. For B2B buyers, investing in high-grade leather ensures longevity and protects your investment.

Illustrative image related to custom leather fire helmet shields

2. Size and Fit Tolerance

Custom helmet shields come in various sizes, typically around 6.5 inches in height to fit standard helmets. However, the width can vary based on the specific helmet model, such as composite or leather helmets. It is essential to measure your helmet accurately to ensure a proper fit, as an ill-fitting shield can compromise visibility and functionality. B2B buyers should request precise sizing guides from manufacturers to avoid costly errors.

3. Water Resistance

A quality shield should be treated with a water-resistant finish to protect it from moisture and environmental factors. This property is crucial for maintaining the shield’s appearance and durability over time. For B2B buyers, ensuring that the shields are sealed appropriately can prevent deterioration and extend the life of the product, thereby reducing replacement costs.

4. Customization Options

Customization is a significant advantage of sourcing leather helmet shields. Buyers can select designs, colors, and even incorporate department logos or personal insignias. This property enhances brand identity and morale within fire departments. For B2B buyers, having a manufacturer that offers flexible customization options can be a deciding factor in choosing a supplier.

5. Durability Standards

Firefighter helmet shields must be built to withstand harsh conditions, including exposure to heat, smoke, and physical impacts. Buyers should inquire about the durability standards or testing methods used by manufacturers to ensure that their products meet the rigorous demands of firefighting. A durable shield not only protects the helmet but also represents the pride and professionalism of the fire service.

What Are Common Trade Terms Used in the Custom Leather Fire Helmet Shield Industry?

Understanding industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some common terms:

Illustrative image related to custom leather fire helmet shields

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are marketed under another company’s brand. In the context of custom leather fire helmet shields, an OEM may provide the raw materials or even the finished products for brands that wish to sell them under their own name. For buyers, knowing the OEM can provide insights into quality and reliability.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For custom leather fire helmet shields, MOQs can vary significantly among manufacturers. Understanding the MOQ is crucial for B2B buyers to plan their purchases effectively, especially when ordering for entire departments.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for a specific quantity of goods. For custom leather fire helmet shields, submitting an RFQ allows buyers to compare offers from different manufacturers, ensuring they secure the best deal while meeting their specifications.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in shipping goods. For buyers of custom leather fire helmet shields, understanding Incoterms helps clarify who is responsible for costs and risks at different stages of the shipping process, ensuring smoother international transactions.

Illustrative image related to custom leather fire helmet shields

5. Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. For custom products like leather helmet shields, lead times can vary based on customization complexity and manufacturing schedules. B2B buyers should factor in lead times when planning their inventory to avoid disruptions.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing custom leather fire helmet shields, ensuring they receive quality products that meet their specific needs.

Navigating Market Dynamics and Sourcing Trends in the custom leather fire helmet shields Sector

What Are the Current Market Dynamics and Key Trends in Custom Leather Fire Helmet Shields?

The custom leather fire helmet shields market is witnessing significant growth driven by several global factors. As fire departments across Africa, South America, the Middle East, and Europe increasingly prioritize personalization and branding, the demand for custom shields is surging. These products serve not only as functional items but also as symbols of pride and identity among firefighters. Technological advancements in leather crafting and customization techniques are enabling manufacturers to produce high-quality, durable shields that can withstand extreme conditions. Moreover, the rise of e-commerce platforms is facilitating easier access for international B2B buyers, allowing them to compare products, customize orders, and procure items more efficiently.

Emerging trends include a shift towards fully customized products, where buyers can tailor designs to reflect their department’s culture and branding. This customization extends beyond mere aesthetics; features such as heat resistance, water resistance, and durability are increasingly prioritized. Additionally, the integration of digital design tools in the procurement process allows buyers to visualize their custom shields before production, enhancing the overall purchasing experience. As a result, manufacturers who can leverage technology to offer flexible and user-friendly customization options are likely to stand out in the competitive landscape.

Illustrative image related to custom leather fire helmet shields

How Is Sustainability and Ethical Sourcing Impacting the Custom Leather Fire Helmet Shields Market?

Sustainability has become a crucial consideration in the custom leather fire helmet shields sector. The environmental impact of leather production, including resource use and waste generation, has prompted a shift towards more sustainable practices. B2B buyers are increasingly seeking suppliers who adopt ethical sourcing methods and utilize eco-friendly materials. This trend is particularly relevant for buyers in regions such as Europe, where regulatory frameworks and consumer expectations around sustainability are more stringent.

Incorporating “green” certifications into the supply chain can significantly enhance a manufacturer’s appeal. Certifications such as the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) demonstrate a commitment to responsible sourcing and production practices. Suppliers who can provide transparency in their sourcing processes and materials are likely to gain the trust of B2B buyers, particularly those with a focus on corporate social responsibility. Furthermore, using vegetable-tanned leather and other sustainable materials can reduce the environmental footprint and align with the values of eco-conscious customers.

What Is the Brief Evolution and History of Custom Leather Fire Helmet Shields?

The evolution of custom leather fire helmet shields reflects broader trends in firefighting gear and culture. Historically, helmet shields were simple, utilitarian designs that served primarily functional purposes. Over the decades, however, as firefighting became more recognized as a profession and community service, the shields evolved into symbols of identity, pride, and tradition within fire departments.

The shift towards customization began in the late 20th century when fire departments started to embrace unique designs that represented their local culture, history, and values. Today, custom leather fire helmet shields are not only functional pieces of equipment but also personal statements that reflect the individuality of the firefighter and the collective identity of the department. This trend continues to grow, driven by advancements in leatherworking technology and a greater emphasis on personalization in consumer goods, making these shields essential for modern firefighting teams.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather fire helmet shields

-

How do I customize my leather fire helmet shield effectively?

To effectively customize your leather fire helmet shield, begin by identifying your specific needs such as design, colors, and text. Most suppliers offer online customization tools that allow you to visualize your design in real time. Ensure to communicate any unique requirements, such as department logos or rank insignia, directly with the supplier. Request a sample if possible to assess the quality of materials and craftsmanship before finalizing your order. -

What is the best size for a custom leather fire helmet shield?

Choosing the right size for your custom leather fire helmet shield depends on the type of helmet you are using. Different helmet models, such as traditional or composite designs, may require different dimensions. Measure your helmet’s front area carefully and consult the supplier’s sizing guide to ensure a perfect fit. It’s crucial to confirm compatibility to avoid issues during installation. -

What are the minimum order quantities (MOQ) for custom helmet shields?

Minimum order quantities can vary significantly between suppliers. Many manufacturers set MOQs to optimize production efficiency, often starting at six shields for bulk orders. For larger departments, ordering in bulk not only ensures uniformity but can also unlock discounts. Always inquire about pricing structures and potential savings for larger orders to maximize your investment. -

What payment terms should I expect when ordering custom helmet shields internationally?

Payment terms for international orders may include upfront payments, partial deposits, or net terms based on the supplier’s policies. Common methods include bank transfers, credit cards, or escrow services for security. It’s advisable to clarify these terms upfront and confirm any additional costs like shipping or customs duties to prevent surprises during the transaction process. -

How can I ensure the quality of custom leather fire helmet shields?

To ensure quality, it’s essential to vet suppliers by reviewing their previous work, customer testimonials, and industry certifications. Request samples to assess the craftsmanship, materials, and durability of the shields. Additionally, inquire about their production processes and quality assurance measures to ensure they meet your expectations. Establishing a clear communication channel can also facilitate a better understanding of your requirements. -

What logistics considerations should I keep in mind for international orders of helmet shields?

When ordering internationally, consider logistics factors such as shipping methods, delivery times, and customs regulations. Work with suppliers who have experience in international shipping to minimize delays. It’s also wise to understand import duties and taxes applicable in your country to budget accordingly. Ensure the supplier provides tracking information for your shipment to monitor its progress. -

Can I order custom designs for my fire department?

Yes, most manufacturers offer the option to create custom designs tailored specifically for fire departments. This can include logos, specific colors, and unique layouts. Communicate your vision clearly to the supplier, providing any graphic files or design references. Collaborating closely with them can help bring your ideas to life while ensuring compliance with any regulations or standards specific to your region. -

How do I maintain and care for my leather fire helmet shield?

Maintaining your leather fire helmet shield is crucial for longevity. Regularly clean it with a damp cloth to remove dirt and grime, avoiding harsh chemicals that could damage the leather. Consider applying a leather conditioner occasionally to keep the material supple and prevent cracking. Store your helmet in a dry place away from direct sunlight to protect it from fading and ensure it remains in excellent condition for years of service.

Top 2 Custom Leather Fire Helmet Shields Manufacturers & Suppliers List

1. Fully Involved Leatherworks – Customizable Leather Fire Helmet Shields

Domain: fullyinvolvedleatherworks.com

Registered: 2014 (11 years)

Introduction: Leather Fire Helmet Shields are customizable, hand carved designs that are 6 1/2″ tall, fitting traditional style helmets including composite and leather types, as well as the Phoenix TL-2. The designs are carved, tooled, hand painted, and sewn with real stitching, sealed with a water resistant clear finish for durability. Products include: 1. Passport Leather Fire Helmet Shield Front – $22.95 (34…

2. Five Alarm Fronts – Custom Leather Gear

Domain: fivealarmfronts.com

Registered: 2012 (13 years)

Introduction: Five Alarm Fronts and Leatherworks specializes in custom leather work for fire departments, offering products such as Fire Helmet Fronts, Leather Suspenders, Radio Straps/Holsters, and Duty Belts. Each product is handmade to order by firefighters in the U.S.A. using 9/10oz leather, with a focus on quality and customization to meet customer visions. The current turnaround time for orders is 14-17 w…

Strategic Sourcing Conclusion and Outlook for custom leather fire helmet shields

In the competitive landscape of custom leather fire helmet shields, strategic sourcing is paramount for international B2B buyers. Leveraging quality craftsmanship and bespoke designs ensures that your fire department not only represents its identity but also prioritizes durability and functionality in high-stress environments. Key takeaways include the importance of selecting suppliers who offer customizable options, robust materials, and a clear understanding of the unique needs of your region, whether in Africa, South America, the Middle East, or Europe.

Investing in custom helmet shields is more than a purchase; it is a commitment to operational excellence and team pride. As you navigate your sourcing options, consider the long-term value of establishing partnerships with manufacturers who can provide not only products but also a shared vision of quality and tradition.

Looking ahead, the demand for personalized firefighting gear will only grow. Engage with suppliers who are ready to innovate alongside you, ensuring your department stands out with shields that embody your unique legacy. Take the next step in enhancing your firefighting capabilities by exploring the vast array of options available in the market today.

Illustrative image related to custom leather fire helmet shields

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.