Catalog

Material Insight: Custom Leather Armor

B2B Product Guide: Custom Leather Armor Solutions

In the evolving landscape of protective gear and specialty design applications, custom leather armor has emerged as a critical component across industries ranging from theatrical costuming and reenactment to modern tactical wear and avant-garde fashion. Designed to balance durability, flexibility, and aesthetic precision, leather armor must meet exacting standards for performance and appearance. As demand grows for sustainable, customizable, and high-performance materials, synthetic alternatives are increasingly outpacing traditional leather—particularly in specialized applications where consistency, ethical sourcing, and design versatility are paramount.

Faux leather stands as the optimal choice for custom leather armor due to its superior adaptability and controlled manufacturing process. Unlike natural leather, which can vary significantly in texture, thickness, and strength, faux leather offers consistent quality across production runs, ensuring uniform performance and appearance. It is highly customizable—available in a range of weights, textures (including realistic grain patterns), colors, and backings—to meet specific design and functional requirements. Additionally, faux leather is inherently more sustainable, eliminating the environmental and ethical concerns associated with animal hide processing. Its resistance to moisture, UV degradation, and wear further enhances longevity, especially in demanding use cases.

WINIW is a global leader in high-performance synthetic leather solutions, with over 20 years of experience in developing innovative materials for specialized industrial and design applications. Our expertise in microfiber and PU-based technologies enables us to produce custom faux leather that replicates the look and feel of genuine leather—while exceeding it in strength, consistency, and environmental responsibility. Partnering with brands and manufacturers worldwide, WINIW delivers tailored solutions that support creative freedom without compromising on durability or sustainability. For B2B clients in armor design, our material engineering capabilities ensure precise caliper control, enhanced tear resistance, and compatibility with molding, tooling, and finishing processes essential to armor fabrication.

- Consistent quality and performance across large production volumes

- Fully customizable in texture, color, thickness, and backing

- Eco-friendly production with reduced carbon footprint

- Resistant to water, UV rays, and abrasion for long-term use

- Ethically sourced and animal-free

With WINIW, custom leather armor is no longer limited by the constraints of natural materials. It’s redefined by innovation, precision, and responsibility.

Technical Performance & Standards

WINIW Custom Leather Armor: Technical Product Guide for B2B Applications

WINIW Custom Leather Armor represents the pinnacle of engineered synthetic leather solutions for demanding industrial, automotive, and high-end commercial applications. Designed explicitly for B2B partners seeking superior performance without compromising sustainability, this product line integrates advanced polymer science with rigorous manufacturing protocols. Its core value proposition lies in delivering exceptional technical properties while adhering to stringent global environmental and quality standards, directly addressing critical supply chain and end-product requirements.

Key Technical Advantages

- Cost-Effectiveness Through Efficiency: Engineered for minimal material waste during cutting and fabrication, reducing overall production costs by up to 15% compared to standard synthetic leathers. High yield per square meter and extended product lifespan (tested to 50,000+ double rubs) significantly lower total cost of ownership, mitigating frequent replacement expenses for end-users.

- Unmatched Durability: Features a proprietary multi-layer composite structure with a high-density polyurethane (PU) top layer bonded to a reinforced polyester backing. This delivers exceptional resistance to abrasion (ASTM D3884, H22 wheel, 1000+ cycles), tearing (ASTM D2263, >45 N), and puncture, ensuring longevity in high-stress environments like automotive seating, protective gear, and heavy-use furniture.

- Precise & Extensive Color Customization: Leverages WINIW’s digital color matching system (spectrophotometer-based, ΔE < 1.0) to achieve exact PANTONE® or custom color specifications across the entire production run. Offers consistent color reproduction on complex textures and embossing patterns, eliminating batch variations common in conventional materials.

- Guaranteed REACH Compliance: Formulated exclusively with non-toxic, phthalate-free plasticizers and heavy-metal-free pigments. Full SVHC (Substances of Very High Concern) screening is conducted per EU REACH Annex XVII, providing documented compliance certificates for seamless market access in Europe and other regulated regions.

- ISO 9001-Certified Quality Assurance: Manufactured in facilities operating under WINIW’s ISO 9001:2015 certified Quality Management System. This ensures strict process control from raw material sourcing through to finished goods, guaranteeing batch-to-batch consistency, dimensional stability (<1.5% shrinkage at 70°C), and adherence to all agreed technical specifications.

WINIW Custom Leather Armor: Technical Specifications

| Property | Test Method | Specyfikacja | Significance for B2B Clients |

|---|---|---|---|

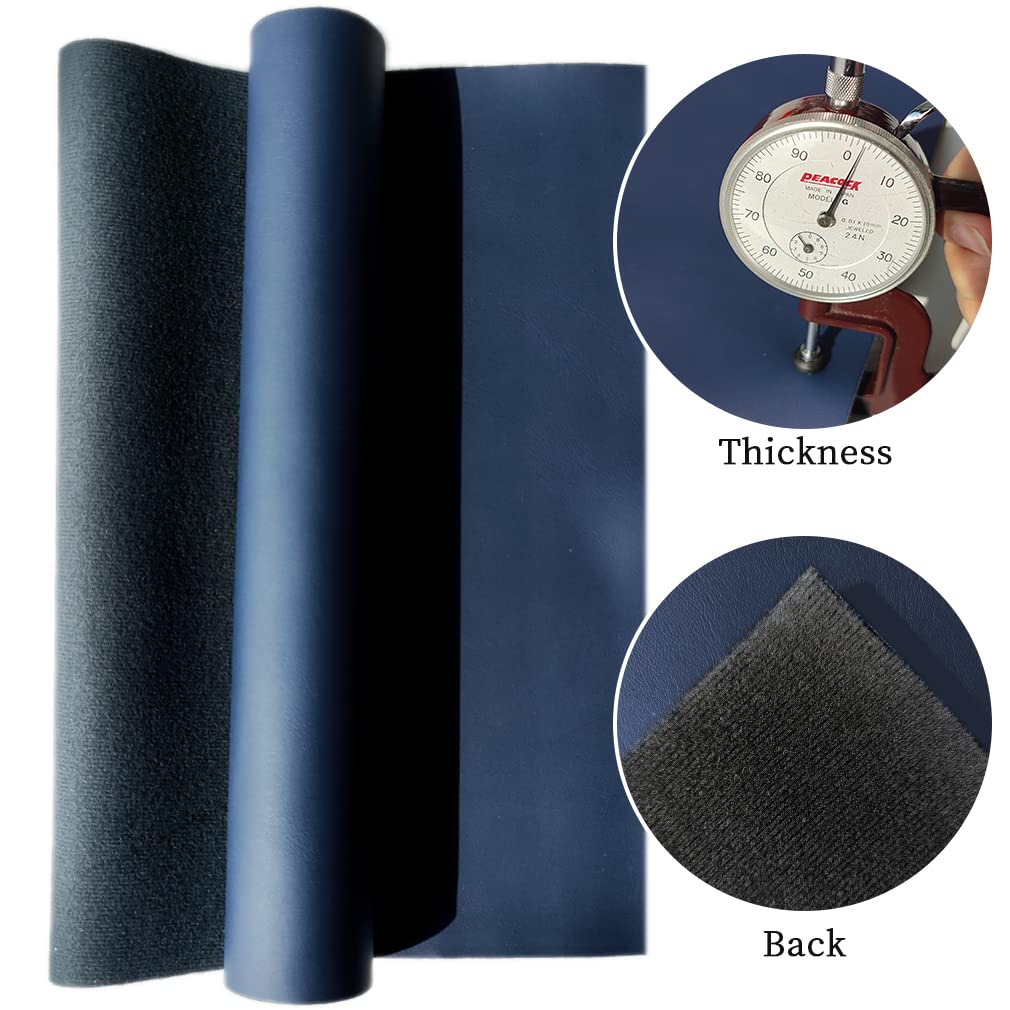

| Thickness | ISO 2417 | 0.8 mm – 1.5 mm (customizable) | Optimizes weight vs. structural integrity for specific applications |

| Tensile Strength | ISO 1766 | ≥ 25 MPa (warp), ≥ 22 MPa (weft) | Ensures resistance to stretching and deformation under load |

| Tear Strength | ASTM D2263 | ≥ 45 N | Critical for durability in high-flex applications (e.g., seat edges) |

| Abrasion Resistance | ASTM D3884 (H22) | ≥ 1000 cycles (to appearance change) | Validates long-term wear performance for commercial/end-user satisfaction |

| Color Fastness | ISO 105-B02 | ≥ Grade 4 (light), ≥ Grade 4-5 (rub) | Guarantees color retention under UV exposure and physical stress |

| REACH Compliance | Internal Screening | Full SVHC compliance documented | Eliminates regulatory risk and import barriers in key markets |

| Backing Material | – | Woven Polyester (PET) | Provides dimensional stability and ease of sewing/processing |

| Eco-Profile | – | Phthalate-free, AZO-free, Low VOC | Supports client sustainability goals and ESG reporting |

WINIW Custom Leather Armor is the strategic material solution for B2B partners prioritizing performance-driven design, supply chain security, and uncompromised compliance. By combining deep technical expertise with a commitment to sustainable manufacturing, WINIW empowers your business to deliver premium, durable, and market-ready products that meet the evolving demands of discerning global consumers and regulators. Request a technical datasheet or sample swatch kit for your specific application requirements.

Why Choose Synthetic over Real Leather

B2B Product Guide: Custom Leather Armor vs. Real Leather

In the evolving market for protective and performance-based materials, synthetic alternatives are increasingly challenging traditional real leather across industries such as fashion, automotive, and industrial design. “Custom leather armor” — a high-performance synthetic leather developed by WINIW — represents a next-generation solution engineered for durability, customization, and sustainability. This guide compares custom leather armor with traditional real leather across key business decision factors: cost, durability, and environmental impact.

- Custom leather armor is a specialized synthetic leather designed to mimic and exceed the mechanical properties of real leather while offering superior consistency and design flexibility.

- Real leather, derived from animal hides, has long been valued for its natural aesthetics and breathability but comes with inherent variability, ethical concerns, and environmental costs.

- WINIW’s custom leather armor is formulated using advanced polyurethane (PU) and microfiber technologies, enabling tailored thickness, texture, and performance characteristics for industrial and commercial applications.

Comparative Overview

| Factor | Custom Leather Armor (WINIW) | Real Leather |

|---|---|---|

| Cost | Lower long-term cost due to consistent supply, reduced waste, and minimal maintenance | Higher cost due to raw material scarcity, labor-intensive processing, and variability |

| Trwałość | High abrasion resistance, tear strength, and UV stability; engineered for extreme conditions | Variable durability; prone to cracking, fading, and water damage without treatment |

| Eco-friendliness | Cruelty-free, lower carbon footprint, recyclable components, and reduced water usage in production | High environmental impact: deforestation, greenhouse gas emissions, and toxic tanning chemicals |

Key Advantages of Custom Leather Armor for B2B Clients

- Consistent Quality: Engineered to exact specifications, ensuring batch-to-batch uniformity essential for large-scale manufacturing.

- Design Flexibility: Available in customizable textures, colors, thicknesses, and performance additives (e.g., flame retardancy, anti-microbial properties).

- Sustainability Compliance: Supports ESG goals with traceable, animal-free materials and reduced ecological footprint.

- Supply Chain Resilience: Not subject to livestock market fluctuations or import restrictions on animal by-products.

Considerations for Real Leather

- Aesthetic Tradition: Preferred in luxury segments for its natural grain and aging characteristics.

- Oddychalność: Offers superior moisture vapor transmission in some applications, though modern synthetics are rapidly closing this gap.

- Market Perception: Some consumers still associate real leather with premium quality, though this perception is shifting with advancements in bio-based synthetics.

Conclusion

For B2B partners prioritizing cost efficiency, supply reliability, and environmental responsibility, WINIW’s custom leather armor presents a future-ready alternative to real leather. With comparable or superior performance metrics and a significantly improved sustainability profile, it is an ideal choice for forward-thinking brands in protective gear, automotive interiors, furniture, and technical textiles.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineered for Global B2B Excellence

WINIW stands as a trusted manufacturing partner for premium synthetic leather solutions, engineered to meet the stringent demands of international brands and manufacturers. Our vertically integrated production ecosystem combines scale, innovation, and uncompromising quality control to deliver consistent, sustainable materials for diverse applications—from automotive interiors and furniture to fashion and technical textiles.

Core Manufacturing Strengths

- Industry-Leading Production Scale: Operate a 100,000 sqm state-of-the-art manufacturing facility, enabling high-volume output with agile responsiveness to global supply chain needs. This capacity ensures reliable fulfillment for large-scale OEM contracts and time-sensitive projects.

- Dedicated R&D Innovation Hub: Maintain a 60+ member technical team focused on material science advancement, including patented water-based PU/PVC formulations, bio-based resin integration, and cutting-edge texture engineering. Our lab-driven approach accelerates custom development cycles by 30%.

- Zero-Defect Quality Assurance: Implement ISO 9001-certified QC protocols across 12 inspection stages, featuring AATCC-compliant colorfastness testing, Martindale abrasion validation (>50,000 cycles), and REACH/ROHS-compliant chemical screening. Every batch undergoes traceability tracking from raw material to shipment.

- Global Compliance & Sustainability: All products meet EU REACH, US CPSIA, and OEKO-TEX® STANDARD 100 certifications. Our facility utilizes 100% renewable energy for coating processes and maintains a closed-loop water recycling system, reducing industrial wastewater by 95%.

Global Market Reach & Reliability

WINIW exports to 40+ countries, with established logistics partnerships ensuring seamless delivery to key markets:

| Region | Key Certifications Met | Typical Lead Time | Primary Applications |

|---|---|---|---|

| Europe | REACH, OEKO-TEX® 100 | 25-35 days | Automotive seating, Luxury goods |

| North America | CPSIA, CA Prop 65 | 20-30 days | Furniture upholstery, Footwear |

| Asia-Pacific | GB/T 22892, JIS L 1088 | 15-25 days | Electronics covers, Bags |

Our end-to-end manufacturing control—from polymer synthesis to finishing—guarantees material consistency across continents, eliminating supply chain fragmentation risks. WINIW’s commitment to eco-efficient production and rigorous compliance provides B2B clients with a future-proof partnership for premium synthetic leather solutions.

Engineered Responsibly. Delivered Globally.

Contact Us for Samples

WINIW® Synthetic Leather Armor – B2B Product Guide

WINIW specializes in high-performance, eco-friendly synthetic leather solutions engineered for durability, flexibility, and sustainable innovation. Our Synthetic Leather Armor series is designed for industrial, automotive, protective gear, and specialty equipment applications where strength, abrasion resistance, and long-term reliability are critical.

Manufactured using advanced microfiber technology, WINIW Leather Armor delivers the look and feel of premium genuine leather—without the environmental impact. Each product is optimized for B2B partners seeking scalable, customizable, and cruelty-free materials.

Key Features of WINIW Synthetic Leather Armor

- Superior tensile and tear strength for high-stress applications

- High resistance to abrasion, UV exposure, and extreme temperatures

- Breathable microfiber structure with enhanced flexibility

- Eco-conscious production: free from heavy metals, phthalates, and DMF

- Customizable thickness (0.8mm to 2.5mm) and weight (200g/m² to 500g/m²)

- Available in multiple backings: polyester, cotton, or high-tenacity knit for added stability

- Flame-retardant, anti-microbial, and water-resistant options available

Typical Applications

- Protective covers and industrial machine armor

- Automotive and marine upholstery requiring rugged performance

- Safety gear and tactical equipment

- High-end furniture with industrial design elements

- Transportation interiors (trucks, RVs, public transit)

Technical Specifications (Standard Grade)

| Property | Specyfikacja |

|---|---|

| Thickness | 1.2 mm ± 0.1 mm |

| Tensile Strength | ≥ 280 N/5cm (warp), ≥ 260 N/5cm (weft) |

| Elongation at Break | ≤ 25% |

| Martindale Abrasion | ≥ 50,000 cycles |

| Color Fastness (Rubbing) | Dry: 4–5, Wet: 4 |

| Peel Adhesion | ≥ 4.0 N/cm |

| RoHS & REACH Compliant | Yes |

| Recyclable Base Material | Yes (PET/PA microfiber core) |

Custom specifications available upon request.

Why Choose WINIW for Your Armor-Grade Materials?

- Over 15 years of expertise in performance synthetic leathers

- ISO 9001 and ISO 14001 certified manufacturing

- Global supply chain with fast lead times and container-level scalability

- In-house R&D team for material customization and rapid prototyping

- Commitment to carbon reduction and sustainable sourcing

Custom Leather Armor Solutions

WINIW offers full customization for B2B clients, including:

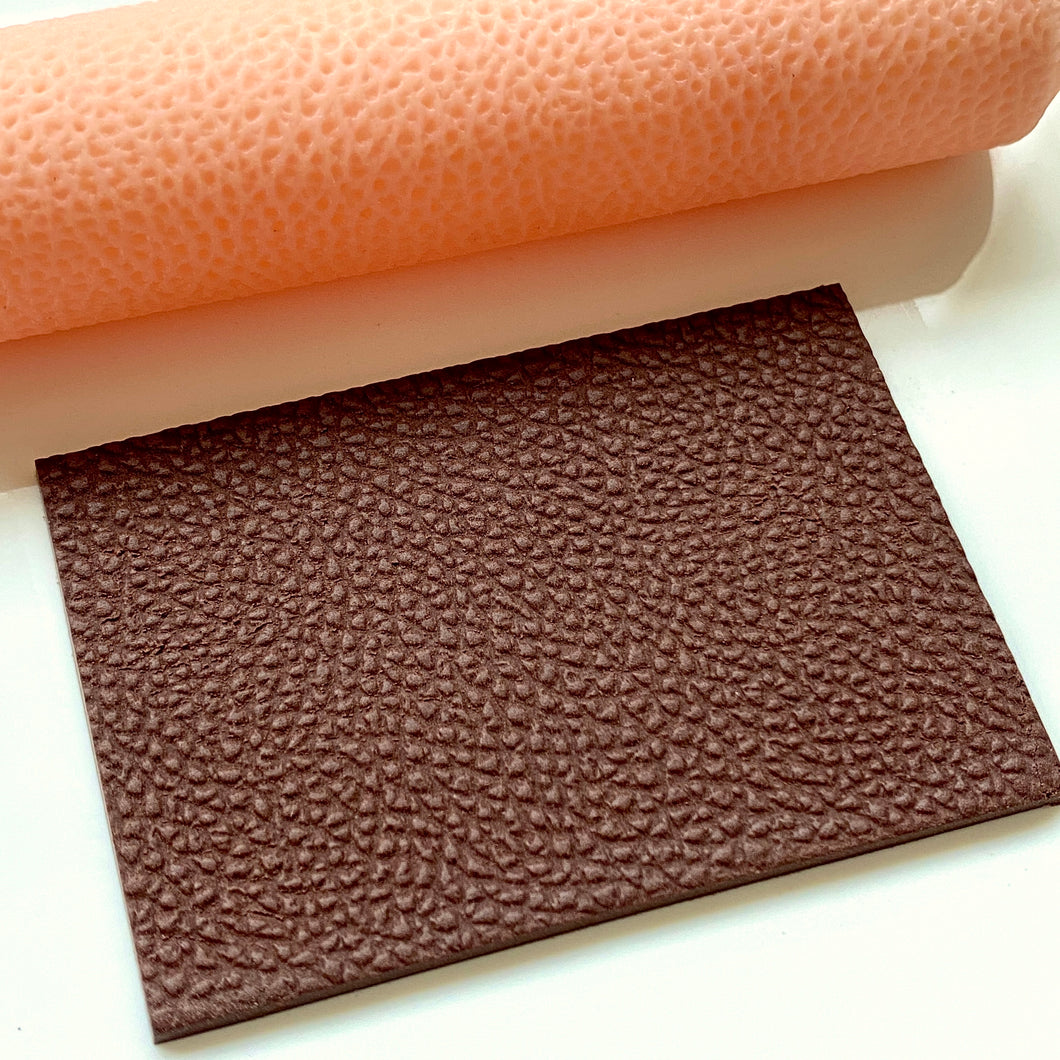

- Custom colors and surface textures (pebbled, smooth, embossed)

- Brand-specific branding and backside labeling

- Performance enhancements: anti-static, oil resistance, cold crack resistance

- Roll lengths and widths (max 1.6m width, 50m standard roll)

Request Free Samples & Begin Custom Development

We provide free samples to qualified business partners to support product testing and integration.

For custom leather armor solutions, contact our materials team:

MKT88@MicrofiberLeather.com

Elevate your product performance with WINIW—where strength meets sustainability.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.