Introduction: Navigating the Global Market for fabric flocking

In today’s competitive landscape, sourcing high-quality fabric flocking solutions poses a significant challenge for international B2B buyers. As the demand for innovative and aesthetically appealing products rises across diverse markets—from the bustling textiles of Vietnam to the vibrant manufacturing sectors in Brazil—understanding the intricacies of flocking becomes essential. This guide delves into the multifaceted world of fabric flocking, addressing various types and applications, supplier vetting strategies, and cost considerations, all tailored to meet the unique needs of buyers in Africa, South America, the Middle East, and Europe.

By exploring the essential aspects of flocking, including the processes, materials, and technologies involved, this comprehensive resource empowers businesses to make informed purchasing decisions. It provides actionable insights into selecting reliable suppliers, ensuring quality control, and navigating the complexities of international trade. Whether you’re in the automotive industry seeking durable flocked components or a fashion brand aiming to enhance product appeal, this guide will equip you with the knowledge necessary to capitalize on flocking’s potential.

Unlock the benefits of flocking for your business and stay ahead of market trends by leveraging this valuable resource. Your journey into the world of fabric flocking begins here, where informed choices lead to successful partnerships and enhanced product offerings.

Table Of Contents

- Top 4 Fabric Flocking Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for fabric flocking

- Understanding fabric flocking Types and Variations

- Key Industrial Applications of fabric flocking

- 3 Common User Pain Points for ‘fabric flocking’ & Their Solutions

- Strategic Material Selection Guide for fabric flocking

- In-depth Look: Manufacturing Processes and Quality Assurance for fabric flocking

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric flocking’

- Comprehensive Cost and Pricing Analysis for fabric flocking Sourcing

- Alternatives Analysis: Comparing fabric flocking With Other Solutions

- Essential Technical Properties and Trade Terminology for fabric flocking

- Navigating Market Dynamics and Sourcing Trends in the fabric flocking Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of fabric flocking

- Strategic Sourcing Conclusion and Outlook for fabric flocking

- Important Disclaimer & Terms of Use

Understanding fabric flocking Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electrostatic Flocking | Utilizes electrical charge to apply fibers uniformly | Apparel, automotive interiors, promotional items | Pros: High density, durable finish. Cons: Higher equipment costs. |

| Beater Bar Flocking | Mechanical vibration used for fiber application | Carpets, packaging, toys | Pros: Cost-effective for larger areas. Cons: Potential for fiber shedding. |

| Spray Flocking | Air compressor used for application | Large surface applications, decorative items | Pros: Quick application for extensive areas. Cons: Messy process, fibers can become airborne. |

| Cut Flock | Made from high-quality synthetic materials | High-end garments, luxury products | Pros: Consistent fiber length, superior feel. Cons: Higher material costs. |

| Milled Flock | Produced from textile waste, less uniform | Budget-friendly applications, craft projects | Pros: Lower cost, soft texture. Cons: Less durable, inconsistent quality. |

What are the Characteristics and Suitability of Electrostatic Flocking?

Electrostatic flocking is characterized by its ability to create a dense and uniform fiber application through an electrical charge. This method is particularly suitable for high-volume production in sectors such as apparel and automotive interiors, where durability and aesthetic appeal are paramount. Buyers should consider the initial investment in specialized equipment, which can be substantial but pays off in the long run through enhanced product quality and consistency.

How Does Beater Bar Flocking Compare to Other Methods?

Beater bar flocking employs mechanical vibration to apply fibers, making it a practical choice for larger surface areas like carpets and packaging. This method is cost-effective and suitable for bulk production. However, buyers need to be aware of potential fiber shedding, which can impact product quality and cleanliness during manufacturing. Ensuring proper operational controls can mitigate these issues.

In What Scenarios is Spray Flocking Most Effective?

Spray flocking is ideal for large surface applications and decorative items, allowing for quick coverage over expansive areas. The main advantage is its speed; however, the process can be messy, with fibers easily becoming airborne. Businesses considering this method should weigh the need for additional cleanup measures against the benefits of rapid application, especially in high-production environments.

What Advantages Does Cut Flock Offer for Premium Products?

Cut flock is made from high-quality synthetic materials, providing a consistent fiber length that enhances the tactile experience of high-end garments and luxury products. While the initial material costs are higher, the resulting quality can justify the investment. Buyers should evaluate the target market’s expectations for quality and feel, as this method can significantly elevate product perception.

Why Choose Milled Flock for Budget-Friendly Applications?

Milled flock, produced from textile waste, offers a softer texture at a lower cost, making it suitable for budget-friendly applications and craft projects. While it provides an economical option, the trade-off is in durability and consistency, which may not meet the standards of more demanding applications. Buyers should consider the intended use and lifespan of the product to ensure that milled flock aligns with their quality requirements.

Key Industrial Applications of fabric flocking

| Industry/Sector | Specific Application of fabric flocking | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Interior trim and components (e.g., glove compartments, door panels) | Enhances aesthetic appeal and provides sound insulation | Supplier reliability, material durability, and compliance with automotive standards |

| Consumer Electronics | Non-slip surfaces for remote controls and devices | Improves grip and user experience | Material compatibility with electronics, cost-effectiveness, and customization options |

| Textile and Apparel | Decorative elements on garments and accessories | Adds unique textures and visual appeal | Fiber quality, colorfastness, and adherence to fashion trends |

| Packaging | Luxury packaging for cosmetics and gifts | Creates a premium feel that enhances brand image | Sustainability of materials, custom design capabilities, and cost considerations |

| Home Furnishings | Flocked surfaces for upholstery and carpets | Offers comfort, style, and improved durability | Fabric type, maintenance requirements, and environmental impact |

How is Fabric Flocking Used in the Automotive Industry?

In the automotive sector, fabric flocking is extensively used for interior trim components such as glove compartments and door panels. The flocked surfaces not only provide an appealing velvety texture but also serve functional purposes like sound insulation and reduced condensation. B2B buyers in this industry should prioritize sourcing flock materials that meet stringent automotive safety and durability standards, ensuring long-lasting performance in various environments.

What are the Applications of Fabric Flocking in Consumer Electronics?

For consumer electronics, flocking is applied to create non-slip surfaces on remote controls and other handheld devices. This enhances user experience by providing a better grip, which is crucial for usability and comfort. International buyers should focus on sourcing materials that are compatible with electronic components, considering factors such as weight, cost, and the ability to customize textures and colors to align with branding strategies.

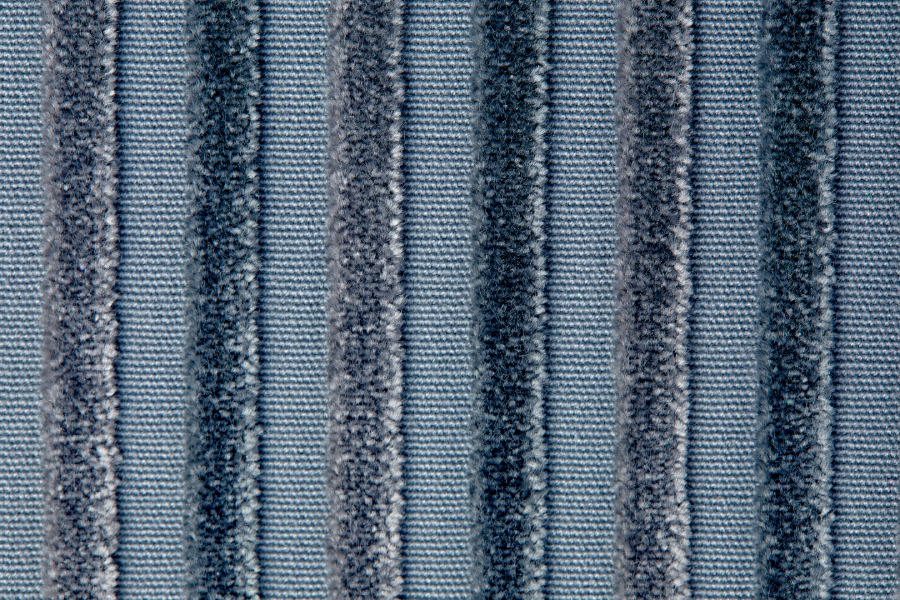

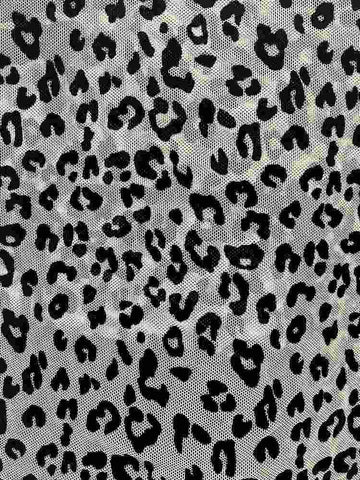

How is Fabric Flocking Transforming the Textile and Apparel Sector?

In the textile and apparel industry, fabric flocking is utilized for adding decorative elements to garments and accessories, giving them a unique texture that stands out in a competitive market. This technique allows brands to differentiate themselves by offering products with a luxurious feel. Buyers in this sector should ensure that the flock fibers are of high quality and that the adhesive used is colorfast to maintain the aesthetic appeal over time.

What Benefits Does Fabric Flocking Provide in Packaging?

Fabric flocking is increasingly being used in luxury packaging, particularly for cosmetics and high-end gifts. The flocked finish provides a premium look and feel, enhancing the perceived value of the product. B2B buyers should consider the sustainability of the materials used, as well as the supplier’s ability to create custom designs that align with brand aesthetics while keeping costs manageable.

Illustrative image related to fabric flocking

How is Fabric Flocking Applied in Home Furnishings?

In the home furnishings sector, flocking is commonly applied to upholstery and carpets, providing a soft touch and aesthetic appeal. This application not only enhances comfort but also improves the durability of the materials. Buyers should focus on sourcing flock that meets specific maintenance requirements and is environmentally friendly, considering the growing demand for sustainable products in the market.

3 Common User Pain Points for ‘fabric flocking’ & Their Solutions

Scenario 1: Quality Control Issues with Flock Adhesion

The Problem: Many B2B buyers experience challenges with the adhesion of flock to substrates, leading to inconsistent quality in finished products. This can occur due to a variety of factors, including improper adhesive application, subpar flock materials, or environmental conditions during the flocking process. Such inconsistencies can result in increased production costs, dissatisfied customers, and a tarnished brand reputation, especially in competitive markets like textiles and automotive.

The Solution: To mitigate adhesion issues, it’s crucial to invest in high-quality adhesives specifically formulated for flocking applications. Before initiating production, conduct a thorough assessment of the adhesive’s compatibility with both the flock material and the substrate. Ensure that the adhesive is applied in the correct thickness; too thin may lead to shedding, while too thick can cause clumping. Implement a quality control process that includes testing adhesion strength on sample pieces before full-scale production. Additionally, maintain a controlled environment during the flocking process to reduce variables like humidity and temperature, which can affect adhesion performance. Regular training for staff on proper application techniques can further enhance product quality.

Scenario 2: Inconsistent Flock Density and Texture

The Problem: Buyers often face challenges in achieving a consistent flock density and texture across their product lines. Inconsistent flocking can lead to visual discrepancies, affecting the aesthetic appeal and functionality of the end product. For instance, in the automotive industry, uneven flocking in interior components can detract from the overall luxury feel of the vehicle, impacting customer satisfaction and sales.

The Solution: To ensure uniform flock density, it is essential to utilize advanced flocking equipment that offers precise control over the flocking process. Electrostatic flocking systems are particularly effective, as they allow for the adjustment of voltage and distance between electrodes, optimizing the fiber application. Regular maintenance of the equipment is vital to prevent operational inconsistencies. Furthermore, consider conducting pre-production trials using different flock lengths and weights to identify the optimal settings for your specific materials. Implementing a standard operating procedure (SOP) for flock application will help maintain consistency and facilitate training for new staff, ensuring that everyone adheres to the same high standards.

Scenario 3: Environmental and Regulatory Compliance Concerns

The Problem: Buyers in regions like Europe and South America frequently encounter regulatory challenges regarding environmental compliance in their manufacturing processes. The flocking industry often involves the use of synthetic materials and adhesives that may not meet stringent environmental standards, leading to costly fines or restrictions on production capabilities.

The Solution: To navigate these compliance challenges, B2B buyers should prioritize sourcing eco-friendly flock materials and adhesives that adhere to local regulations. Conduct thorough research on suppliers’ certifications and their commitment to sustainable practices. Additionally, consider investing in water-based or low-VOC adhesives that minimize environmental impact while still delivering strong performance. Collaborate with suppliers to obtain the latest information on compliance requirements and best practices. Implementing an internal audit system can help track compliance with environmental standards and provide documentation for regulatory bodies, thereby reducing the risk of non-compliance penalties and enhancing your brand’s reputation as a socially responsible manufacturer.

Illustrative image related to fabric flocking

Strategic Material Selection Guide for fabric flocking

What Are the Key Properties of Common Flocking Materials?

When selecting materials for fabric flocking, it is essential to understand the properties that influence product performance. Here, we examine four common flocking materials: nylon, rayon, polyester, and cotton. Each material has distinct characteristics that impact its suitability for various applications.

How Does Nylon Perform in Fabric Flocking Applications?

Nylon is a synthetic fiber known for its excellent durability and strength. It has a high resistance to abrasion, making it suitable for applications that require longevity, such as automotive interiors and high-wear textiles. Nylon also offers good thermal stability, withstanding a wide range of temperatures without significant degradation. However, it can be more expensive than other materials, which may limit its use for budget-sensitive projects.

From a B2B perspective, nylon’s compatibility with various adhesives enhances its versatility. However, international buyers should consider compliance with local regulations regarding synthetic materials, particularly in regions like Europe, where environmental standards are stringent.

What Advantages Does Rayon Offer for Flocking?

Rayon is a semi-synthetic fiber derived from natural cellulose, providing a soft, luxurious feel. It is less expensive than nylon and offers good dyeability, making it popular for decorative applications. Rayon has moderate wear resistance, making it suitable for products like clothing and home textiles. However, it is less durable than nylon and can be prone to moisture absorption, which may lead to mold or mildew in humid climates.

For international buyers, particularly in humid regions like parts of South America and Africa, it’s crucial to consider the moisture resistance of rayon. Compliance with local textile standards, such as ASTM or JIS, is also important to ensure product safety and quality.

Why Is Polyester a Preferred Choice for Industrial Applications?

Polyester is a robust synthetic material known for its excellent resistance to chemicals and UV light. This makes it an ideal choice for industrial applications, such as automotive parts and outdoor textiles. Polyester’s durability and low moisture absorption rate contribute to its long lifespan. However, it may not provide the same luxurious feel as nylon or rayon, which could limit its use in high-end consumer products.

B2B buyers should be aware of polyester’s compatibility with various adhesives and flocking techniques. Additionally, compliance with international standards regarding chemical resistance is essential, especially for buyers in Europe and the Middle East, where regulations are increasingly stringent.

What Role Does Cotton Play in Flocking Materials?

Cotton is a natural fiber that offers a soft touch and is often used for cost-effective flocking solutions. Milled cotton flock is particularly popular due to its low cost and pleasant appearance. However, it has the least abrasion and wear resistance among flocking materials, making it less suitable for high-wear applications. Cotton is also more susceptible to moisture, which can lead to degradation over time.

International buyers should consider the environmental impact of cotton production, especially in regions where sustainability is a priority. Compliance with organic and fair-trade standards is increasingly important for consumers in Europe and North America.

Summary Table of Flocking Materials

| Materiał | Typical Use Case for fabric flocking | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | Automotive interiors, high-wear textiles | Excellent durability and abrasion resistance | Higher cost compared to other materials | High |

| Rayon | Decorative textiles, clothing | Soft feel and good dyeability | Moderate wear resistance and moisture absorption | Medium |

| Polyester | Industrial applications, outdoor textiles | Strong chemical and UV resistance | Less luxurious feel compared to nylon and rayon | Medium |

| Cotton | Cost-effective flocking solutions | Soft touch and low cost | Least abrasion resistance and moisture susceptibility | Low |

This strategic material selection guide aims to equip international B2B buyers with the insights needed to make informed decisions regarding fabric flocking materials. Understanding the properties, advantages, and limitations of each material can lead to optimized product performance and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for fabric flocking

What Are the Key Stages in the Manufacturing Process of Fabric Flocking?

The manufacturing process of fabric flocking is multifaceted, comprising several key stages that ensure high-quality, durable products. Understanding these stages is essential for B2B buyers looking to source flocked materials effectively.

Material Preparation: What Are the Initial Steps?

The initial phase in the flocking process begins with the selection and preparation of raw materials, including flock fibers and adhesives. Flock fibers, typically made from nylon, polyester, or rayon, are cleaned and dyed to the desired color. This is crucial because the dye must adhere well to the fibers for aesthetic consistency. The adhesives used must be compatible with the substrate and the flock fibers, and they are often pre-tested to ensure optimal performance.

Moreover, manufacturers must ensure that the adhesive’s viscosity is suitable for the application method being employed, whether it’s electrostatic, spraying, or beater bar techniques. Proper preparation of these materials lays the groundwork for a successful flocking process.

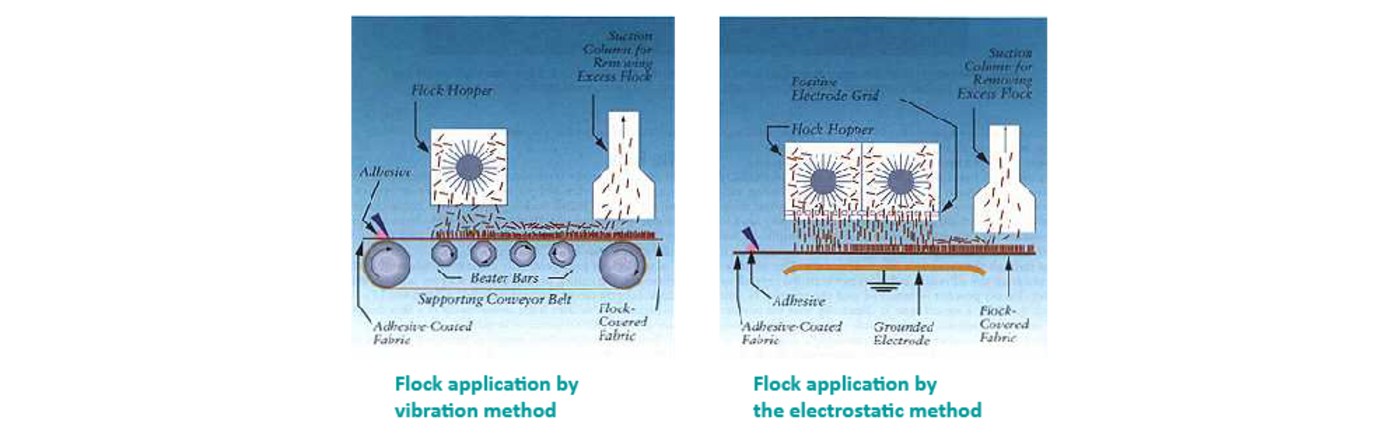

Forming: How Is the Flocking Process Executed?

Once the materials are prepared, the flocking process itself begins. The substrate—such as textiles, plastic, or metal—is coated with a layer of adhesive. The choice of application method significantly affects the final product’s quality. The most common methods include:

Illustrative image related to fabric flocking

-

Electrostatic Flocking: This method uses an electrical charge to propel the flock fibers into the adhesive-coated substrate, resulting in a dense and uniform flock layer. It is ideal for high-volume production and offers superior quality.

-

Beater Bar Flocking: In this mechanical method, the substrate is vibrated while flock fibers are dispensed, leading to random adherence of fibers. This technique is less precise but can be effective for large areas.

-

Spraying: This method is more suited for larger surfaces but can be messy, as airborne fibers can contaminate the workspace.

-

Flock Transfers: These are pre-made flock designs that can be applied easily, allowing for intricate patterns without extensive setup.

Each method requires specialized equipment, and the choice depends on production volume, desired quality, and substrate type.

Assembly: What Happens After Flocking?

After the flocking process, the flocked products undergo assembly, which may include cutting, sewing, or further finishing processes. This stage is vital for products like automotive interiors, where precision and durability are paramount.

Post-flocking, items may be subjected to additional treatments such as heat-setting or curing to enhance adhesion and durability. The goal is to ensure that the flocking remains intact under varying conditions, such as temperature fluctuations and mechanical wear.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is critical in the fabric flocking industry, ensuring that products meet international and industry-specific standards.

What Are the Relevant International Standards?

For B2B buyers, understanding quality standards is essential for sourcing reliable suppliers. The ISO 9001 standard is widely recognized and focuses on maintaining a quality management system (QMS). Compliance with ISO 9001 indicates that a manufacturer has established procedures to consistently provide products that meet customer and regulatory requirements.

Illustrative image related to fabric flocking

In addition to ISO standards, buyers should also look for compliance with industry-specific certifications such as CE marking for products sold in Europe, and API standards for products used in the petroleum industry. These certifications indicate adherence to safety and performance standards.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically divided into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This step verifies the quality of raw materials upon arrival. For flocking, this includes testing the fibers and adhesives for consistency and compliance with specifications.

-

In-Process Quality Control (IPQC): During production, continuous monitoring is necessary to ensure adherence to quality standards. This includes checking adhesive application thickness and the uniformity of flock density.

-

Final Quality Control (FQC): After the flocking process, finished products are inspected for defects, color consistency, and adherence to specifications. This final check is crucial for ensuring that the products meet customer expectations.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is vital. Here are some actionable strategies:

-

Conduct Supplier Audits: Regular audits can provide insights into a supplier’s manufacturing processes and QC practices. This can be done either by the buyer’s quality assurance team or through third-party inspection services.

-

Request Quality Reports: Suppliers should be able to provide documentation regarding their QC processes, including results from tests conducted during IQC, IPQC, and FQC.

-

Third-Party Inspections: Engaging third-party quality assurance firms can provide an unbiased evaluation of a supplier’s processes and products. This is particularly important for B2B buyers in regions like Africa or South America, where local regulations may vary.

What Are the Unique QC Considerations for International Buyers?

When sourcing flocked materials internationally, especially from regions like Africa, South America, the Middle East, and Europe, buyers should be aware of specific nuances in quality control.

For example, the availability of raw materials, adherence to local regulations, and differences in manufacturing practices can affect product quality. Buyers should also consider potential language barriers and cultural differences that may impact communication with suppliers.

Illustrative image related to fabric flocking

Additionally, it is advisable to establish clear specifications and quality expectations upfront, ensuring that suppliers are fully aware of the standards required. Building strong relationships with suppliers can also facilitate better quality assurance and responsiveness to issues that may arise.

Conclusion: Ensuring Quality in Fabric Flocking Manufacturing

In summary, the manufacturing processes for fabric flocking involve meticulous preparation, execution, and quality assurance. By understanding these processes and standards, B2B buyers can make informed decisions when sourcing flocked products. Verifying supplier quality control through audits, reports, and inspections will further ensure that the products meet their specifications and expectations, ultimately leading to successful business outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fabric flocking’

When sourcing fabric flocking materials, it’s essential to follow a structured approach to ensure quality, compliance, and alignment with your project needs. This checklist will guide international B2B buyers through the key steps to successfully procure fabric flocking.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline your technical requirements. This includes the type of flock material (e.g., nylon, rayon, polyester), desired fiber length, and application method (e.g., electrostatic, beater bar). Understanding these specifications is crucial as they directly impact the quality and performance of the flocked products.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers who specialize in fabric flocking. Look for companies with experience in your industry and region. Utilize online directories, trade shows, and industry forums to compile a list of potential suppliers. Pay attention to their reputation and customer reviews, as these can provide insights into their reliability.

Step 3: Evaluate Supplier Certifications

Ensure that your chosen suppliers possess relevant certifications that demonstrate compliance with international standards. This may include ISO certifications, environmental compliance, and quality assurance certifications. Valid certifications indicate that the supplier adheres to industry best practices, which is critical for ensuring product quality and sustainability.

Step 4: Request Samples for Testing

Before making bulk orders, request samples of the flocking materials. Testing these samples allows you to assess the texture, durability, and colorfastness, ensuring they meet your project requirements. Be specific about the conditions under which the samples will be used to ensure they are representative of the final product.

Step 5: Negotiate Pricing and Terms

Once you have identified potential suppliers and tested their products, initiate discussions about pricing and terms. Compare quotes from multiple suppliers to ensure competitive pricing. Additionally, clarify payment terms, minimum order quantities, and delivery timelines to avoid any misunderstandings later in the process.

Step 6: Verify Production Capabilities

Evaluate the production capabilities of your shortlisted suppliers. Inquire about their production capacity, lead times, and equipment used for flocking. This step is crucial to ensure that the supplier can meet your order volume within your required timeframe and that they have the necessary technology to achieve the desired quality.

Step 7: Establish a Communication Plan

Effective communication is vital throughout the sourcing process. Establish a clear communication plan with your supplier that includes regular updates on production status, shipping details, and any potential issues. Maintaining open lines of communication will help foster a strong partnership and ensure that any challenges are addressed promptly.

By following this checklist, B2B buyers can effectively navigate the sourcing process for fabric flocking, ensuring they select the right suppliers and materials for their needs.

Comprehensive Cost and Pricing Analysis for fabric flocking Sourcing

What Are the Key Cost Components in Fabric Flocking?

When evaluating the cost structure of fabric flocking, several components come into play that can significantly impact the overall pricing. The primary cost components include:

Illustrative image related to fabric flocking

-

Materials: The choice of flocking materials—nylon, rayon, or polyester—plays a crucial role in determining costs. Cut flock tends to be more expensive due to its uniformity and quality compared to milled flock, which is often made from textile waste and is less costly.

-

Labor: Labor costs can vary based on the complexity of the flocking process and the level of automation in the production facility. Manual flocking operations may incur higher labor costs than automated processes, especially when skilled workers are involved.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and facility costs. The overhead can be significant in regions with high operational costs, affecting the final price of flocked products.

-

Tooling: Initial tooling costs for flocking equipment can range widely. Hand-held units are more affordable, while advanced electrostatic systems can run into tens of thousands of dollars, impacting the pricing structure depending on the scale of production.

-

Quality Control (QC): Ensuring high-quality flocking requires stringent QC measures. The costs associated with testing and validating the flocking process can add to the overall expenses, especially for suppliers aiming to meet international standards.

-

Logistics: Shipping costs can fluctuate based on distance, volume, and the chosen Incoterms. Import duties and tariffs may also affect the total cost for international buyers.

-

Margin: Supplier profit margins vary significantly based on market conditions and competition. Understanding these margins can help buyers negotiate better prices.

How Do Price Influencers Affect Fabric Flocking Costs?

Several factors can influence the pricing of fabric flocking, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Higher volumes typically result in lower per-unit costs. Suppliers may offer tiered pricing structures based on order size, incentivizing larger purchases.

-

Specifications and Customization: Custom flocking designs or specifications can lead to increased costs. Buyers should weigh the need for customization against budget constraints.

-

Material Quality and Certifications: Higher quality materials and compliance with international certifications can raise costs. Buyers should consider whether the additional investment aligns with their product quality expectations.

-

Supplier Factors: The supplier’s reputation, reliability, and production capacity can influence pricing. Established suppliers may charge more but offer better quality assurance and service.

-

Incoterms: The chosen Incoterms can significantly affect the cost structure. Buyers should understand the implications of terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) to evaluate total landed costs.

What Tips Can Help Buyers Optimize Costs in Fabric Flocking?

To navigate the complexities of fabric flocking sourcing and pricing, buyers can adopt several strategies:

-

Negotiation: Engage suppliers in discussions to explore discounts for bulk orders or long-term contracts. Establishing a good relationship can also yield better pricing and terms.

-

Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO) rather than just upfront costs. Consider factors such as durability, maintenance, and potential waste to determine the true cost of flocked products.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations and local market conditions that can affect pricing. Understanding local regulations and import duties is crucial for accurate cost estimation.

-

Requesting Samples: Before committing to large orders, request samples to assess quality. This can prevent costly mistakes and ensure that the chosen flocking material meets expectations.

Disclaimer

The prices and cost structures discussed here are indicative and can vary based on market conditions, supplier specifics, and geographic factors. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing fabric flocking With Other Solutions

Understanding Alternatives to Fabric Flocking

In the competitive landscape of textile decoration and surface enhancement, fabric flocking stands out as a unique method. However, various alternatives can achieve similar aesthetic and functional results. B2B buyers must evaluate these options based on performance, cost, ease of implementation, maintenance, and best use cases to make informed decisions that align with their business objectives.

Illustrative image related to fabric flocking

Comparison Table

| Comparison Aspect | Fabric Flocking | Screen Printing | Embroidery |

|---|---|---|---|

| Performance | High durability, unique texture | Good color vibrancy, less texture | Excellent durability, textured look |

| Cost | Moderate to high | Low to moderate | High |

| Ease of Implementation | Requires specialized equipment | Relatively easy, minimal setup | Requires skilled labor and equipment |

| Maintenance | Low maintenance | Low maintenance | Moderate maintenance, thread replacement needed |

| Best Use Case | Specialty items, high-end applications | Promotional items, apparel | Workwear, uniforms, and durable goods |

In-Depth Analysis of Alternatives

What Are the Pros and Cons of Screen Printing?

Screen printing is a widely used method for transferring designs onto fabric. It offers vibrant colors and is cost-effective, especially for large production runs. The setup is relatively simple, requiring less specialized equipment than flocking. However, it lacks the textured feel that flocking provides, making it less suitable for high-end applications where tactile quality is crucial. Additionally, intricate designs may require multiple screens, increasing complexity and cost.

How Does Embroidery Compare to Fabric Flocking?

Embroidery is another popular alternative, particularly for items like uniforms and corporate apparel. It boasts exceptional durability and a premium look. The tactile texture of embroidered designs can enhance the perceived value of a product. However, the costs are generally higher due to the labor-intensive process and the need for specialized machinery. Embroidery may not be suitable for all fabrics, particularly those that are delicate or prone to fraying. Moreover, the time required for setup and execution can lead to longer production times compared to flocking.

What Is the Unique Value of Fabric Flocking?

Fabric flocking offers a unique aesthetic with its velvety texture and rich colors, making it ideal for specialty items and high-end products. It is durable and creates a soft touch that can enhance customer experience. While the initial investment in equipment may be higher than other methods, the long-lasting quality and minimal maintenance can offset these costs in the long run. Flocking is particularly effective in applications where a unique visual appeal is a competitive advantage, such as in luxury fashion or decorative home textiles.

How to Choose the Right Solution for Your Needs

B2B buyers should assess their specific needs and objectives when selecting a decoration method. Consider the product’s intended use, the desired aesthetic, and budget constraints. For high-end applications where texture and durability are paramount, fabric flocking may be the best choice. Conversely, if cost and speed are more critical, screen printing could be more appropriate. Embroidery may serve well for branding on uniforms or corporate apparel where durability and a premium look are essential. Ultimately, understanding the strengths and limitations of each method will enable buyers to make a strategic decision that aligns with their business goals.

Essential Technical Properties and Trade Terminology for fabric flocking

What Are the Key Technical Properties of Fabric Flocking?

Understanding the technical properties of fabric flocking is essential for making informed purchasing decisions. Here are some critical specifications that B2B buyers should consider:

Illustrative image related to fabric flocking

-

Material Grade

– The quality of the flock material—whether natural (like cotton) or synthetic (like nylon, rayon, or polyester)—affects durability, appearance, and cost. Higher-grade materials tend to offer better wear resistance and aesthetic appeal, making them suitable for high-end applications. -

Fibre Length and Diameter

– Flock fibres vary in length from 0.25 mm to 5 mm and can have diameters ranging from 1.7 to 22 dtex. The length and diameter influence the texture and feel of the flocked surface. Shorter fibres may result in a softer feel but can be more challenging to work with due to balling up, while longer fibres can create a more robust appearance. -

Adhesive Compatibility

– The choice of adhesive—whether single-part, two-part, plastisol, or water-based—plays a crucial role in the flocking process. Compatibility between the adhesive and the flock material is essential to ensure a durable bond and optimal performance. This consideration directly impacts the longevity and functionality of the final product. -

Application Method

– Different flocking application methods, such as electrostatic, beater bar/gravity, spraying, and transfers, have varying implications for production efficiency and cost. Understanding these methods helps in selecting the most suitable process for specific applications, influencing turnaround times and production costs. -

Flock Density

– The density of flocking refers to how closely the fibres are packed on the substrate. Higher density often leads to better aesthetic quality and tactile feel. However, achieving the right density requires careful control of both the adhesive application and the flocking process, impacting production efficiency. -

Moisture Content

– The moisture content of flock fibres is crucial for electrostatic flocking processes. A specific level of moisture enhances conductivity, which is essential for the fibres to adhere properly during application. Buyers should inquire about moisture management in the production process to ensure quality.

What Are Common Trade Terms in Fabric Flocking?

Navigating the fabric flocking industry involves understanding specific jargon and trade terms that are frequently used:

-

OEM (Original Equipment Manufacturer)

– This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of fabric flocking, OEMs may provide flocked materials or components for other brands’ products, ensuring quality and consistency. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This is particularly relevant in fabric flocking, where bulk orders may be necessary to justify production runs. Understanding MOQ helps buyers manage inventory and budget effectively. -

RFQ (Request for Quotation)

– An RFQ is a standard business process used to invite suppliers to bid on specific products or services. For buyers in the flocking industry, submitting an RFQ allows for comparative pricing and ensures that all specifications are met, facilitating better decision-making. -

Incoterms (International Commercial Terms)

– These are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers to understand shipping, insurance, and delivery obligations. -

Flock Transfer

– This term refers to a method where pre-fabricated flock designs are transferred onto substrates. It is a convenient option for businesses looking to add flocking without investing in complex equipment, making it an appealing choice for smaller operations. -

Electrostatic Flocking

– This advanced method uses electrical charges to propel flock fibres onto an adhesive-coated substrate. Understanding this term helps buyers recognize the benefits of this technique, such as uniformity and durability, when evaluating flocking options.

In summary, a solid grasp of these technical properties and trade terms will empower B2B buyers to make informed decisions in the fabric flocking market, fostering successful partnerships and enhancing product offerings.

Navigating Market Dynamics and Sourcing Trends in the fabric flocking Sector

What Are the Key Trends Driving the Fabric Flocking Market?

The fabric flocking market is witnessing a resurgence driven by several global trends. Increasing consumer demand for unique and textured products is pushing manufacturers to explore flocking as a decorative solution across various industries, including automotive, home textiles, and consumer goods. Notably, innovations in digital printing technologies and adhesives are enhancing the quality and efficiency of flocking applications. B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should note that advancements in electrostatic flocking methods are allowing for more intricate designs and sustainable production practices.

Illustrative image related to fabric flocking

Emerging technologies, such as automation and smart manufacturing, are also reshaping sourcing strategies. Companies are investing in advanced flocking equipment that can reduce waste and increase production speed, making it essential for international buyers to stay informed about these innovations. Additionally, the rise of e-commerce and digital marketplaces is facilitating easier access to flocking suppliers, enabling buyers to source materials from diverse geographies. This democratization of the supply chain means that companies can find competitive pricing and innovative products, fostering a more dynamic market environment.

How Is Sustainability Influencing Sourcing Decisions in Fabric Flocking?

Sustainability is becoming a cornerstone of sourcing decisions in the fabric flocking sector. As awareness of environmental issues grows, B2B buyers are increasingly prioritizing suppliers that adhere to ethical sourcing practices. The environmental impact of flocking materials, particularly synthetic fibers, necessitates a shift towards more sustainable options. This includes the use of recycled materials, such as recycled polyester, and natural fibers that minimize carbon footprints.

Buyers should also consider suppliers who hold green certifications, such as OEKO-TEX® or Global Recycled Standard (GRS), which signal a commitment to sustainable practices. These certifications assure that products are free from harmful substances and produced in environmentally friendly conditions. Furthermore, the implementation of closed-loop systems in manufacturing processes can significantly reduce waste, making it vital for B2B buyers to engage with suppliers who are adopting these practices. By prioritizing sustainability, companies not only meet regulatory requirements but also align with consumer preferences, enhancing brand loyalty and market competitiveness.

Illustrative image related to fabric flocking

How Has the Fabric Flocking Industry Evolved Over Time?

The history of fabric flocking dates back to ancient decorative techniques but saw significant advancements in the 1970s with the introduction of modern adhesives and electrostatic application methods. Initially popular for decorative purposes, flocking fell out of favor in the late 20th century due to competition from other textile decoration techniques. However, recent years have seen a revival driven by consumer demand for unique textures and enhanced aesthetics in everyday products.

As industries recognize the functional benefits of flocking—such as improved insulation properties and reduced noise in automotive applications—the technology has evolved to incorporate advanced materials and processes. This evolution has positioned flocking as a versatile solution in various sectors, making it an attractive option for B2B buyers looking to innovate their product offerings while meeting market demands for quality and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of fabric flocking

-

How do I choose the right flocking material for my products?

Choosing the right flocking material depends on the intended application and desired properties. Common materials include nylon, rayon, and polyester. For applications requiring durability and abrasion resistance, nylon is preferred. If cost is a primary concern, milled cotton flock is the most economical option, but it offers less wear resistance. Consider factors such as the aesthetic finish, texture, and application method to ensure compatibility with your product requirements. -

What are the key factors to consider when sourcing flocking suppliers?

When sourcing flocking suppliers, evaluate their experience, production capacity, and quality control measures. Verify certifications and compliance with international standards to ensure product safety and quality. Request samples to assess the quality of their flocking materials and adhesive systems. Additionally, consider their ability to customize products to meet your specific needs, such as color matching or unique textures. -

What minimum order quantities (MOQ) should I expect from flocking suppliers?

MOQs can vary significantly among suppliers. Generally, for custom flocking orders, expect MOQs ranging from 100 to 1,000 meters, depending on the material and complexity of the design. Some suppliers may offer lower MOQs for stock items or standard colors. Always discuss MOQs upfront to avoid potential delays in your production schedule, and consider negotiating terms that align with your business needs. -

What payment terms are typically offered by flocking suppliers?

Payment terms can vary widely, but common practices include a 30% deposit upon order confirmation and the balance before shipment. Some suppliers may offer net 30 or net 60 terms for established relationships. Always clarify payment terms during negotiations, and consider using secure payment methods to protect your transaction. Discussing terms in advance helps to prevent misunderstandings and ensures smoother transactions. -

How can I ensure quality assurance when sourcing flocking products?

To ensure quality assurance, request detailed specifications and samples before placing bulk orders. Establish clear quality control standards, including adherence to international norms. Many reputable suppliers conduct regular inspections and tests on their materials. You may also consider third-party quality audits or inspections prior to shipping to verify compliance with your requirements and specifications. -

What logistics considerations should I keep in mind when importing flocking materials?

When importing flocking materials, consider shipping costs, customs duties, and local regulations in your destination country. Familiarize yourself with import tariffs and ensure all documentation is in order, including invoices, packing lists, and certificates of origin. Partnering with a reliable freight forwarder can facilitate smoother logistics, ensuring timely delivery and compliance with local laws. -

Can flocking be customized to meet specific design needs?

Yes, flocking can be highly customized. Many suppliers offer options for color matching, fiber lengths, and adhesive formulations to meet specific design requirements. Discuss your design concepts with potential suppliers to explore customization possibilities. This can include multi-colored flocking, unique textures, or even specific patterns, allowing you to differentiate your products in the market. -

What are the environmental considerations when sourcing flocking materials?

When sourcing flocking materials, consider the environmental impact of the production processes and materials used. Look for suppliers that adhere to sustainable practices, such as using recycled fibers or eco-friendly adhesives. Certifications like OEKO-TEX or GOTS can indicate compliance with environmental standards. Discussing sustainability initiatives with your supplier not only enhances your brand image but also meets the growing demand for environmentally responsible products.

Top 4 Fabric Flocking Manufacturers & Suppliers List

1. Search for Fabric – Flocked Fabrics

Domain: searchforfabric.com

Registered: 2020 (5 years)

Introduction: Flocked fabrics are a unique textile innovation characterized by a velvet-like texture and intricate patterns. The flocking process involves applying minuscule fiber dust particles to fabric surfaces using adhesive and high voltage to create a tactile and visually appealing finish. Flocked fabrics are versatile and used across various industries, including automotive (for reducing glare in interio…

2. Flockit – Flocking Solutions

Domain: flockit.com

Registered: 2007 (18 years)

Introduction: Flocking is the application of millions of tiny fibers onto an adhesive-coated surface to create a velvet-like texture. It is commonly used in jewelry boxes, glove compartments, waterfowl decoys, and various decorative and functional applications. Flocking has a historical background dating back to 3000 years ago in China and became popular in the 19th century for wallpaper. In the 20th century, i…

3. AccTrims – Flocking Fabric

Domain: acctrims.com

Registered: 2021 (4 years)

Introduction: Flocking fabric is made by planting nylon or viscose fluff on various types of fabric, resulting in a soft, suede-like texture that is rich in color and unique in style. It is warm, fashionable, and favored by consumers.

Pros:

– Antifouling: Flocking fabric has excellent antifouling properties due to its nylon composition, allowing dirt to be easily wiped clean.

– Waterproof: The plush nylon pro…

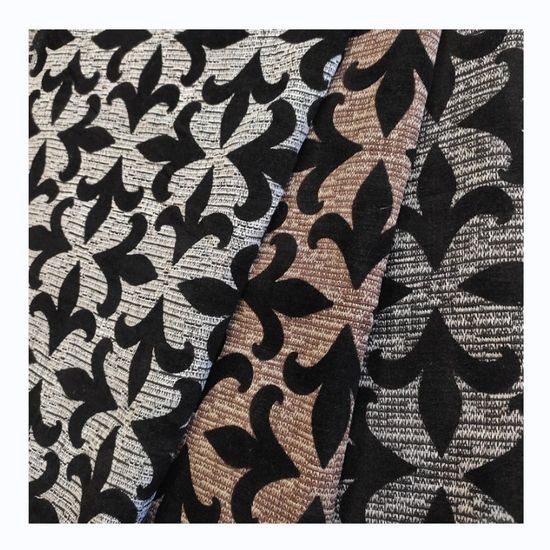

4. New Star Fabric – Damask Flocking Taffeta

Domain: newstarfabric.com

Registered: 2008 (17 years)

Introduction: Damask Flocking Taffeta is a luxurious fabric known for its intricate patterns and elegant texture. It is popular for uses such as event drapery, photography backdrops, wallpapers, and fancy clothing items like jackets, coats, skirts, and shirts. It is widely used by event planners and decorators to add sophistication to settings.

Strategic Sourcing Conclusion and Outlook for fabric flocking

In conclusion, the fabric flocking process presents a unique opportunity for international B2B buyers seeking to enhance their product offerings. The versatility of flocking, applicable to a wide range of substrates, allows businesses to tap into diverse markets—from automotive to fashion—by providing distinctive and textured finishes that appeal to consumers’ desire for novelty.

Strategic sourcing of high-quality flock materials and advanced flocking technologies can lead to significant cost savings and improved product differentiation. By leveraging reliable suppliers, buyers can ensure consistent quality and performance, which is crucial in maintaining competitive advantage in fast-evolving markets.

As we look ahead, the demand for innovative flocking applications is expected to grow, driven by consumer trends favoring customization and sustainability. B2B buyers in Africa, South America, the Middle East, and Europe should seize this moment to explore the possibilities that flocking offers. Collaborating with experienced suppliers and investing in cutting-edge flocking technologies will be essential steps to capitalize on this trend. Embrace the flocking revolution today to elevate your product line and meet the evolving needs of your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to fabric flocking