Catalog

Material Insight: Automotive Seat Vinyl

B2B Product Guide: Automotive Seat Vinyl

Introduction to Automotive Seat Vinyl

Automotive seat vinyl is a high-performance synthetic leather engineered to meet the rigorous demands of modern vehicle interiors. As a durable, cost-effective, and sustainable alternative to genuine leather, automotive vinyl delivers exceptional resistance to abrasion, UV exposure, temperature fluctuations, and daily wear—making it ideal for both mass-market and premium vehicle manufacturing.

Increasingly, automotive designers and OEMs are turning to synthetic leather not only for its consistent quality and design flexibility but also for its alignment with environmental and ethical standards. Unlike natural leather, which involves resource-intensive tanning processes and variable raw material quality, synthetic vinyl offers controlled production, reduced environmental impact, and greater customization in texture, color, and performance.

Why Automotive Synthetic Leather is the Best Choice

- Durability & Longevity: Engineered to withstand millions of flex cycles, automotive vinyl resists cracking, fading, and peeling even under extreme conditions.

- Design Flexibility: Available in a wide range of textures (suede, grain, smooth), colors, and finishes to match brand-specific aesthetics.

- Consistency in Quality: Unlike natural leather, synthetic vinyl ensures uniform thickness, appearance, and performance across large production runs.

- Sustainability: Reduces reliance on animal products and lowers carbon footprint through water-based, low-VOC, and recyclable material options.

- Ease of Maintenance: Resistant to stains and spills, easily cleaned with mild detergents—ideal for high-traffic vehicle interiors.

- Cost Efficiency: Offers premium look and feel at a lower total cost, with reduced waste during cutting and upholstery processes.

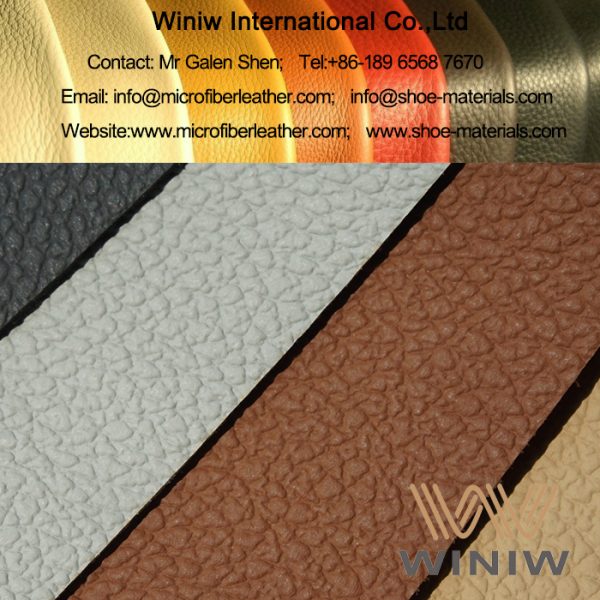

Introducing WINIW – Trusted Synthetic Leather Innovator

WINIW has been a leading manufacturer of high-performance synthetic leather for over 20 years, specializing in custom solutions for the automotive industry. With a strong focus on R&D, sustainability, and precision manufacturing, WINIW delivers premium automotive seat vinyl that meets global standards for safety, durability, and environmental responsibility.

Our products are engineered using advanced microfiber and polyurethane technologies, ensuring superior breathability, softness, and mechanical strength. WINIW partners with automotive OEMs and tier suppliers worldwide, offering scalable production, rapid prototyping, and compliance with international regulations including REACH, RoHS, and ISO 14001.

Backed by technical expertise and a commitment to innovation, WINIW empowers automotive brands to elevate interior comfort and style—responsibly and reliably.

Technical Performance & Standards

WINIW Automotive Seat Vinyl: Technical Performance Specification Guide

WINIW delivers premium synthetic leather engineered specifically for demanding automotive seating applications. Our advanced manufacturing process integrates rigorous environmental stewardship with uncompromising performance, providing Tier-1 suppliers and OEMs with a sustainable, high-durability solution that meets global regulatory standards and enhances cabin longevity.

Core Technical Advantages

- Exceptional Abrasion Resistance: Engineered with a proprietary polyurethane matrix and high-density backing, WINIW Automotive Seat Vinyl withstands rigorous use. Validated to exceed 500,000 cycles in ASTM D4157 (Wyzenbeek) testing, significantly outperforming standard automotive leathers (typically 150,000–300,000 cycles). This ensures long-term aesthetic retention and structural integrity in high-traffic seating zones.

- Superior UV & Lightfastness Stability: Formulated with advanced UV inhibitors and non-migrating pigments, our vinyl resists fading and degradation under prolonged solar exposure. Achieves Level 7–8 (excellent) per AATCC Test Method 16 and maintains color consistency after 1,000+ hours of accelerated weathering (SAE J2412), critical for sun-exposed vehicle interiors.

- True VOC-Free Composition: Manufactured using a 100% solvent-free process, WINIW vinyl emits <10 µg/g total VOCs (as measured by ISO 12219-2), well below stringent automotive cabin air quality thresholds (e.g., VDA 276). Eliminates off-gassing risks, ensuring occupant health compliance and odor-free cabins.

- Full REACH SVHC Compliance: Rigorously screened against the REACH Candidate List (Annex XIV). Contains zero Substances of Very High Concern (SVHCs) at or above 0.1% w/w. Comprehensive documentation and batch-specific certificates of analysis are provided for seamless supply chain transparency.

- ISO 9001-Certified Quality Assurance: Production adheres to WINIW’s ISO 9001-certified quality management system, ensuring consistent thickness, color, and physical properties across global production sites. Real-time in-line monitoring guarantees <2% batch-to-batch variance in critical metrics.

Performance Specifications Summary

| Property | Test Standard | WINIW Performance | Industry Benchmark |

|---|---|---|---|

| Abrasion Resistance | ASTM D4157 (Wyzenbeek) | ≥500,000 cycles | 150,000–300,000 cycles |

| Lightfastness (Color) | AATCC 16 | Level 7–8 | Level 5–6 |

| Total VOC Emission | ISO 12219-2 | <10 µg/g | <50 µg/g |

| Tensile Strength | ASTM D412 | ≥25 MPa | ≥18 MPa |

| Tear Strength | ASTM D2263 | ≥80 N | ≥50 N |

| Thickness Tolerance | ISO 2420 | ±0.05 mm | ±0.10 mm |

| REACH SVHC Status | EC 1907/2006 | 0 substances >0.1% | Varies |

| Production Certification | ISO 9001 | Certyfikowany | Common |

WINIW Automotive Seat Vinyl reduces lifecycle costs through extended service life, eliminates compliance risks in global markets, and supports ESG goals via its recyclable structure (up to 95% PUR content) and zero-hazardous-waste production. Partner with WINIW to integrate certified durability and sustainability into your next-generation seating platforms.

WINIW: Engineered Responsibility for Automotive Interiors.

Why Choose Synthetic over Real Leather

B2B Product Guide: Automotive Seat Vinyl vs. Real Leather

When selecting materials for automotive seating, manufacturers and suppliers must balance performance, cost, sustainability, and consumer appeal. Two of the most common choices are real leather and synthetic alternatives such as automotive seat vinyl. While both materials offer distinct advantages, understanding their differences in cost, durability, and environmental impact is essential for informed decision-making in the automotive supply chain.

Overview of Materials

-

Real Leather: A natural material derived from animal hides, typically bovine. It is valued for its premium look, breathability, and long-term patina. However, its production involves resource-intensive tanning processes and raises ethical and environmental concerns.

-

Automotive Seat Vinyl: A synthetic material, often based on polyvinyl chloride (PVC) or polyurethane (PU), engineered to mimic the appearance and feel of leather. Modern innovations, such as WINIW® Ultra Leather, offer high performance, design flexibility, and enhanced sustainability.

Key Comparison: Cost, Durability, and Eco-Friendliness

| Attribute | Real Leather | Automotive Seat Vinyl (PU-based) |

|---|---|---|

| Cost | High – raw material and processing are expensive; prices fluctuate with livestock markets | Lower to moderate – stable pricing due to synthetic base; scalable production |

| Trwałość | High tensile strength but prone to cracking and fading over time, especially with UV exposure; requires conditioning | Excellent resistance to cracking, fading, and abrasion; consistent performance in extreme temperatures |

| Eco-Friendliness | Low – high water and energy consumption; use of toxic tanning agents (e.g., chromium); significant carbon footprint | Moderate to High – especially with PU-based, solvent-free, and recycled-content options; lower water usage and emissions |

Advantages of Automotive Seat Vinyl in B2B Applications

- Consistent Supply Chain: Not subject to livestock availability or market volatility.

- Design Flexibility: Can be engineered in a wide range of textures, colors, and finishes to meet brand-specific requirements.

- Lower Maintenance: Resistant to stains, spills, and UV degradation—ideal for high-use commercial vehicles.

- Sustainability Compliance: Aligns with OEMs’ ESG goals; many vinyl alternatives are now recyclable and produced with renewable energy.

- Animal-Friendly: Appeals to markets with growing demand for cruelty-free materials.

Considerations for Real Leather

- Preferred in luxury segments for its tactile authenticity and heritage appeal.

- Requires rigorous quality control to avoid defects such as scars or uneven grain.

- Long-term care increases lifecycle costs for end users.

Conclusion

For B2B partners focused on scalability, cost-efficiency, and environmental responsibility, automotive seat vinyl—particularly advanced PU-based synthetics—offers a compelling alternative to real leather. While real leather maintains a niche in premium branding, synthetic solutions are increasingly matching or exceeding its performance while supporting sustainable manufacturing goals.

WINIW Factory Capabilities

WINIW Synthetic Leather: Industrial Manufacturing Excellence for Global Partners

WINIW operates a state-of-the-art manufacturing facility spanning 100,000 square meters, positioning us as a leading industrial-scale producer of high-performance synthetic leather for global B2B markets. Our integrated campus enables end-to-end control over production, ensuring consistent quality and capacity to support large-volume, long-term supply agreements. Key strengths underpinning our reliability include:

- Dedicated R&D Team: A specialized research and development unit of 50+ engineers and material scientists continuously innovates formulations, focusing on eco-conscious materials (including water-based PU and recycled content options), enhanced durability, and application-specific performance.

- Strict Multi-Stage Quality Control: Rigorous QC protocols are embedded at every production phase—from raw material inspection to finished roll testing—adhering to ISO 9001 standards and exceeding stringent regional requirements (e.g., REACH, CPSIA).

- Global Compliance & Export Readiness: WINIW maintains certified production processes for seamless entry into demanding markets, with established export channels supplying premium synthetic leather to tier-1 clients across Europe and the USA.

Manufacturing Capabilities Snapshot

| Capability | Specyfikacja | Client Benefit |

|---|---|---|

| Facility Size | 100,000 sqm (fully integrated campus) | Guaranteed supply continuity & scalability |

| R&D Focus | Eco-materials, performance innovation | Future-proof solutions & sustainable sourcing |

| Zapewnienie jakości | ISO 9001, multi-stage testing | Zero-defect consistency & regulatory compliance |

| Primary Export Regions | Europe, USA | Streamlined logistics for key global markets |

This combination of scale, technical expertise, and uncompromising quality positions WINIW as a strategic manufacturing partner for brands prioritizing ethical production, performance innovation, and supply chain resilience in the synthetic leather sector.

Contact Us for Samples

WINIW Automotive Seat Vinyl – Premium Synthetic Leather for Modern Vehicle Interiors

WINIW specializes in high-performance synthetic leather solutions engineered specifically for the automotive industry. Our automotive seat vinyl combines durability, aesthetic appeal, and eco-conscious manufacturing to meet the evolving demands of OEMs and Tier-1 suppliers. Designed for both interior comfort and long-term resilience, WINIW’s microfiber-based vinyl offers a sustainable alternative to traditional leather without compromising on quality.

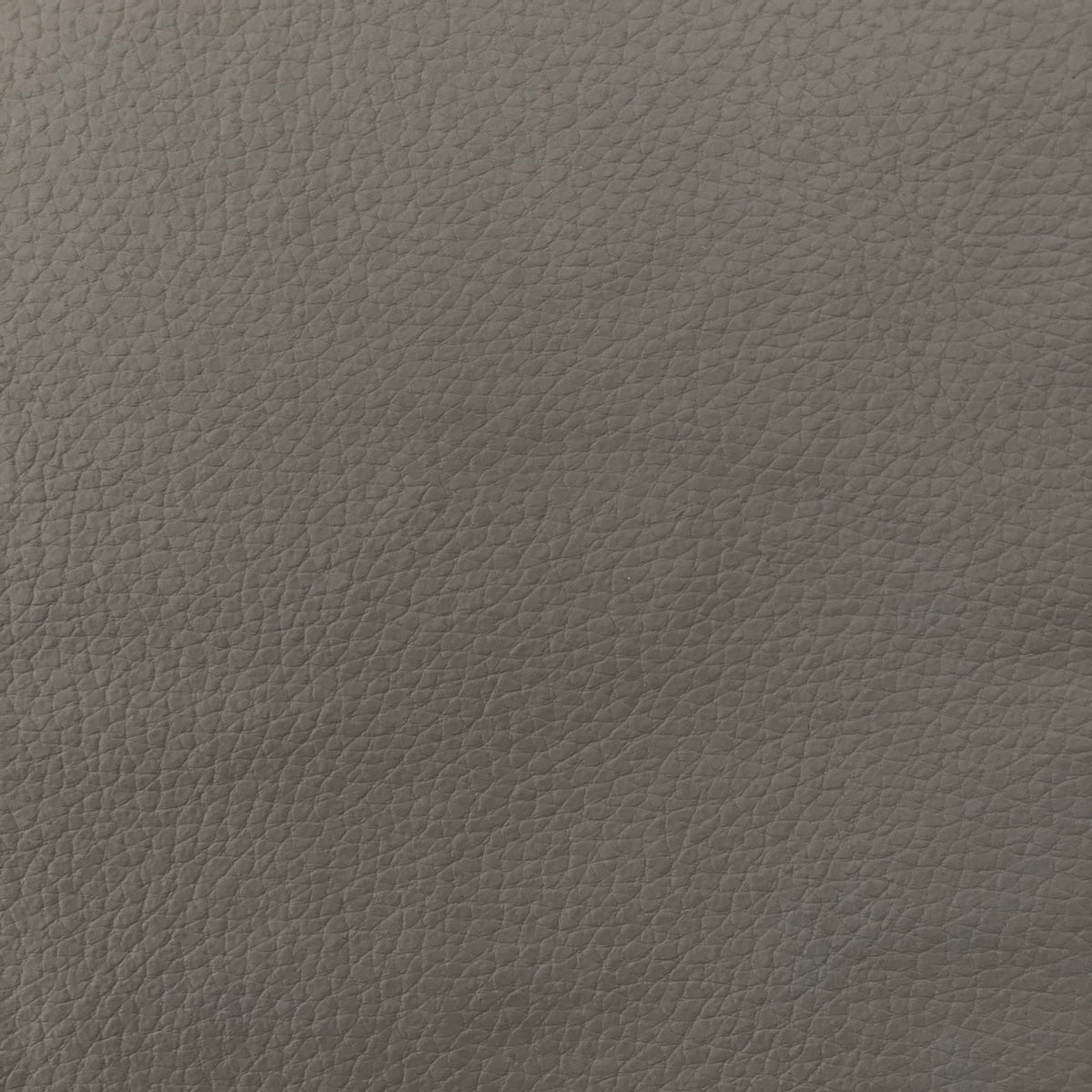

Ideal for car seats, bolsters, armrests, and door panels, our material delivers consistent texture, superior wear resistance, and excellent color fastness under UV exposure. With a focus on innovation and environmental responsibility, WINIW supports the shift toward greener mobility solutions.

Key Features of WINIW Automotive Seat Vinyl

- High tensile and tear strength for long-lasting seat upholstery

- Excellent abrasion resistance (tested up to 50,000+ double rubs)

- UV-stable pigments to prevent fading in direct sunlight

- Soft hand feel with customizable textures (matte, grain, embossed)

- Breathable structures available for enhanced passenger comfort

- Resistance to temperature extremes (-30°C to +85°C)

- Low VOC emissions, meeting global automotive air quality standards

- REACH and RoHS compliant – free from heavy metals and harmful phthalates

- Available in widths up to 1.5 meters for reduced seam lines

Technical Specifications

| Property | Standard Value |

|---|---|

| Thickness | 1.0 – 1.8 mm (customizable) |

| Weight | 450 – 650 g/m² |

| Breaking Strength | ≥ 100 N/5cm (warp & weft) |

| Elongation at Break | ≤ 25% |

| Color Fastness (Xenon) | ≥ Grade 4 (after 1000 hrs) |

| Martindale Abrasion | ≥ 50,000 cycles (no breakdown) |

| Fogging Performance | Low condensate (meets DIN 75201) |

Why Choose WINIW?

- Sustainable Production: Water-based PU coating and recycled fiber options reduce environmental impact.

- Customization: Tailored color matching, thickness, and surface finishes to match brand specifications.

- Global Supply Reliability: Scalable production capacity with ISO 9001 and IATF 16949 certified facilities.

- Innovation-Driven: Ongoing R&D focused on lightweighting and bio-based raw materials.

WINIW is committed to supporting automotive manufacturers in delivering premium, eco-friendly interiors that meet both regulatory requirements and consumer expectations.

Request Your Free Sample Today

Experience the quality and performance of WINIW automotive seat vinyl firsthand. Free samples are available for qualified B2B partners.

For inquiries and sample requests, contact:

MKT88@MicrofiberLeather.com

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.