Introduction: Navigating the Global Market for custom leather die cutter

The global market for custom leather die cutters presents a unique set of challenges for B2B buyers, particularly those sourcing high-quality materials and equipment across diverse regions such as Africa, South America, the Middle East, and Europe. As businesses aim to streamline production processes while maintaining precision and quality, understanding the nuances of custom leather die cutters becomes imperative. This guide is designed to empower international buyers by providing comprehensive insights into the various types of die cutters available, their applications across different industries, and the critical factors to consider when vetting suppliers.

Navigating the complexities of sourcing these specialized tools can be daunting, especially when factoring in cost, lead times, and the intricacies of design specifications. Buyers will gain valuable knowledge about the latest advancements in die cutting technology, best practices for submitting design patterns, and the importance of selecting suppliers who offer robust support and quality assurance. From understanding the differences between steel rule dies and laser-cut options to exploring the advantages of custom designs tailored to specific project needs, this guide serves as an essential resource. By leveraging the insights provided, B2B buyers can make informed purchasing decisions that enhance their operational efficiency and product quality in competitive markets.

Table Of Contents

- Top 5 Custom Leather Die Cutter Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather die cutter

- Understanding custom leather die cutter Types and Variations

- Key Industrial Applications of custom leather die cutter

- 3 Common User Pain Points for ‘custom leather die cutter’ & Their Solutions

- Strategic Material Selection Guide for custom leather die cutter

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather die cutter

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather die cutter’

- Comprehensive Cost and Pricing Analysis for custom leather die cutter Sourcing

- Alternatives Analysis: Comparing custom leather die cutter With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather die cutter

- Navigating Market Dynamics and Sourcing Trends in the custom leather die cutter Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather die cutter

- Strategic Sourcing Conclusion and Outlook for custom leather die cutter

- Important Disclaimer & Terms of Use

Understanding custom leather die cutter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Steel Rule Die Cutters | Made from hardened steel, high precision, customizable sizes | Leather goods manufacturing, crafts | Pros: Durable, precise cuts; Cons: Higher initial cost |

| Acrylic Mounted Dies | Easy alignment, reduces material waste, optional engraving | Small-scale production, custom crafts | Pros: User-friendly, versatile; Cons: Limited to softer materials |

| Pre-Sharpened Clicker Dies | Ready-to-use, consistent quality, CAD-designed | Mass production of leather items | Pros: Time-efficient, reliable; Cons: May require bulk orders |

| Custom Laser Engraved Dies | High precision, intricate designs, quick turnaround | Branding, detailed leather products | Pros: Unique designs, fast production; Cons: Higher cost for complexity |

| Hydraulic Press Dies | Designed for heavy-duty use, compatible with hydraulic presses | Industrial applications, large quantities | Pros: High efficiency, suitable for thick materials; Cons: Requires specialized equipment |

What Are Steel Rule Die Cutters and Their Applications?

Steel rule die cutters are known for their durability and precision. Constructed from hardened steel, these dies are customizable in size and shape, making them ideal for various applications in leather goods manufacturing and crafts. When purchasing, consider the thickness of the materials you’ll be cutting, as this affects the die’s effectiveness. The higher initial investment is often justified by the long-term reliability and quality of cuts.

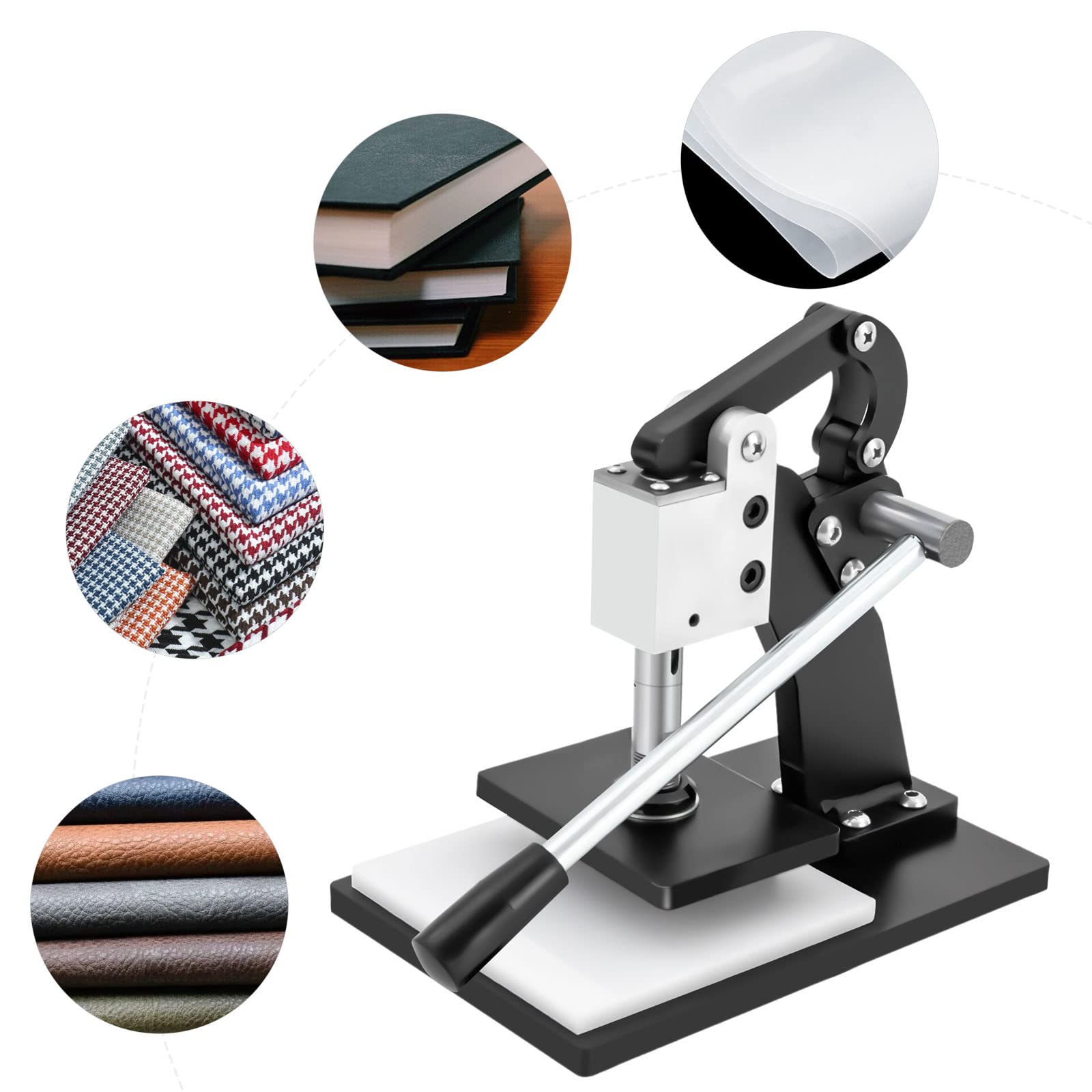

How Do Acrylic Mounted Dies Enhance Cutting Efficiency?

Acrylic mounted dies are designed for easy alignment, which minimizes material waste during production. They are particularly advantageous for small-scale productions or custom crafts where precision is essential. Buyers should note that while these dies are user-friendly, they may be limited to softer materials. Consider the specific requirements of your production process to determine if this type is suitable.

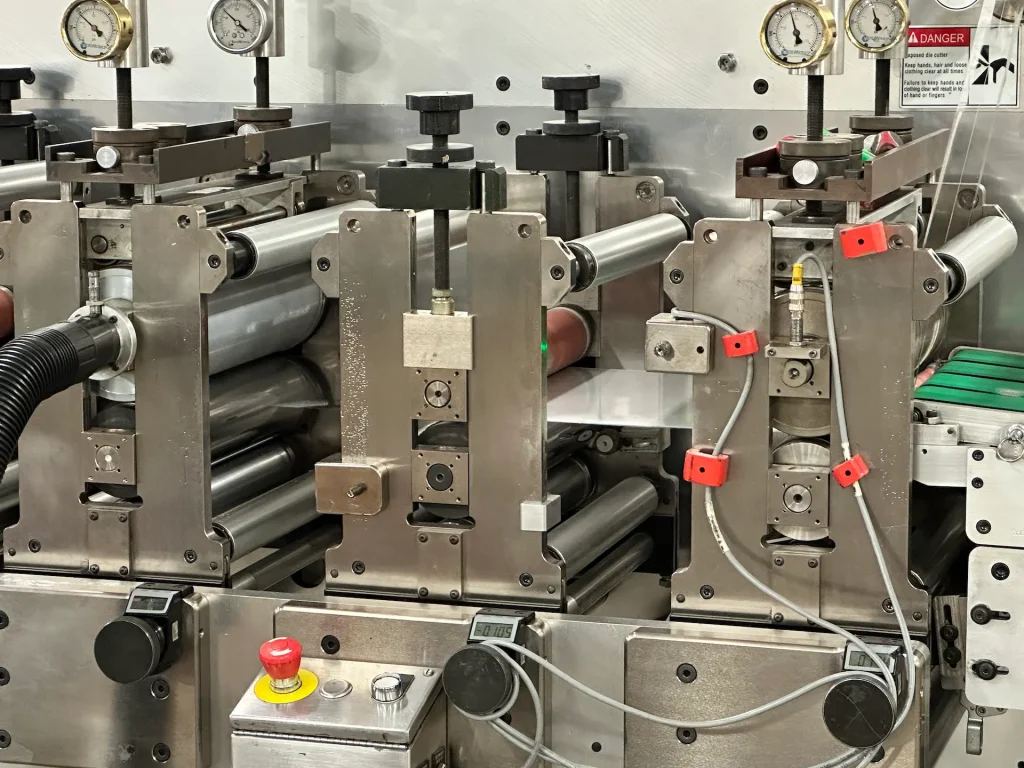

Illustrative image related to custom leather die cutter

What Benefits Do Pre-Sharpened Clicker Dies Offer for Mass Production?

Pre-sharpened clicker dies are constructed for maximum dependability and efficiency in mass production settings. These dies are typically CAD-designed to ensure high accuracy, making them a preferred choice for businesses looking to streamline their leather cutting processes. While they save time and maintain quality, buyers should be aware of the minimum order requirements, which may necessitate larger upfront investments.

How Can Custom Laser Engraved Dies Help in Branding?

Custom laser engraved dies allow for intricate designs and unique branding opportunities on leather products. With quick turnaround times, these dies are ideal for businesses looking to differentiate their offerings in the marketplace. However, the complexity of the design can drive up costs, so it’s essential to balance the need for uniqueness with budget considerations when making a purchase.

What Are the Considerations for Hydraulic Press Dies in Industrial Applications?

Hydraulic press dies are specifically designed for heavy-duty use, making them suitable for industrial applications where large quantities of leather parts need to be cut efficiently. These dies require specialized equipment, which may be a barrier for smaller businesses. Buyers should evaluate their production capabilities and the types of materials they work with to determine if hydraulic press dies align with their operational needs.

Key Industrial Applications of custom leather die cutter

| Industry/Sector | Specific Application of custom leather die cutter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Custom patterns for leather garments and accessories | Enhanced design precision and reduced material waste | Ensure high precision tolerances and quick turnaround times |

| Automotive | Cutting leather for upholstery and interior finishes | Improved production efficiency and quality assurance | Look for dies capable of handling thick materials |

| Leather Goods Manufacturing | Creating intricate designs for bags and wallets | Customization options that attract niche markets | Evaluate the supplier’s capability for complex designs |

| Footwear | Designing soles and upper parts for shoes | Streamlined production processes and consistent quality | Confirm compatibility with various leather thicknesses |

| Craft and Hobby Supplies | Producing DIY leather craft kits and templates | Ability to cater to a growing market for personalized goods | Assess the supplier’s support for small batch orders |

How is Custom Leather Die Cutter Used in the Fashion and Apparel Industry?

In the fashion and apparel sector, custom leather die cutters are essential for producing unique patterns for garments and accessories. By allowing designers to create intricate shapes and sizes, these die cutters minimize material waste and enhance design accuracy. For international buyers, especially in regions like Europe and the Middle East, sourcing from manufacturers who can deliver high precision and rapid turnaround times is crucial to meet fast-paced market demands.

What Role Does Custom Leather Die Cutter Play in the Automotive Industry?

Automotive manufacturers utilize custom leather die cutters for crafting upholstery and interior finishes. These die cutters ensure that leather pieces fit perfectly, enhancing both aesthetics and durability of vehicle interiors. Buyers should prioritize suppliers capable of handling thicker materials and providing dies that maintain sharpness and durability under repeated use, particularly in emerging markets like South America and Africa.

Illustrative image related to custom leather die cutter

How Does Custom Leather Die Cutter Benefit Leather Goods Manufacturing?

In leather goods manufacturing, custom die cutters are used to create intricate designs for products like bags and wallets. This capability allows for extensive customization, which can attract niche markets and enhance product offerings. International buyers should consider suppliers who have experience in producing complex designs and can provide support for small to medium production runs, ensuring flexibility in meeting consumer preferences.

What Advantages Does Custom Leather Die Cutter Offer Footwear Production?

For the footwear industry, custom leather die cutters are instrumental in designing shoe soles and upper parts. They streamline production processes by ensuring consistent quality and reducing manual cutting errors. Buyers should verify that the suppliers can accommodate various leather thicknesses and provide dies that are robust enough for high-volume production, especially in regions with a growing footwear market.

How Can Craft and Hobby Suppliers Leverage Custom Leather Die Cutters?

Craft and hobby suppliers benefit from custom leather die cutters by producing DIY leather craft kits and templates. This application caters to the rising consumer demand for personalized and handmade goods. Suppliers should assess the capability of their manufacturers to support small batch orders and provide design assistance, which can be crucial for hobbyists looking to create unique projects.

3 Common User Pain Points for ‘custom leather die cutter’ & Their Solutions

Scenario 1: Difficulty in Achieving Precision and Consistency

The Problem:

B2B buyers often face challenges with precision and consistency when utilizing custom leather die cutters. In industries like fashion or leather goods manufacturing, the need for intricate designs that maintain uniformity across multiple pieces is crucial. Any deviation in the die’s accuracy can lead to wasted materials, increased production costs, and ultimately, a compromise in product quality. For instance, if a buyer orders a die cutter for a unique pattern but receives a product that varies by even a fraction of a millimeter, it can throw off the entire production line.

The Solution:

To combat these issues, buyers should prioritize suppliers who utilize advanced CAD (Computer-Aided Design) technology for die creation. This ensures that every pattern is meticulously drawn and checked for symmetry and accuracy before manufacturing. When placing an order, it is essential to provide high-quality design files in formats like .ai or .pdf, as these can be directly utilized for die production. Additionally, buyers should request a sample die cutter before committing to a full order. This allows for testing and verification of precision, enabling businesses to ensure that the cutter meets their exact specifications before scaling up production.

Illustrative image related to custom leather die cutter

Scenario 2: Long Lead Times Affecting Production Schedules

The Problem:

Lead times for receiving custom leather die cutters can be a significant pain point for B2B buyers, especially in fast-paced markets. Many suppliers may have a standard processing time of several weeks, which can disrupt production schedules and delay product launches. This is particularly problematic for businesses that operate on tight timelines or need to respond quickly to market demands, such as those in the fashion industry or seasonal retail.

The Solution:

To mitigate this issue, B2B buyers should actively seek suppliers that offer expedited services. Many manufacturers provide rush order options for an additional fee, which can significantly reduce lead times. When requesting a quote, buyers should clearly communicate their timeline requirements and ask about the possibility of faster production and shipping. Furthermore, establishing a relationship with a reliable supplier who understands your business’s specific needs can facilitate quicker turnaround times in the future. Buyers can also consider developing a stock of standard dies for frequently used designs, allowing for immediate availability and reducing reliance on custom orders.

Scenario 3: Misalignment of Expectations Between Design and Final Product

The Problem:

Another common challenge is the misalignment between the initial design expectations and the final product delivered. Buyers often provide detailed specifications for their custom leather die cutters, but discrepancies can arise due to variations in material thickness, die construction, or even the cutting machinery used. This misalignment can lead to significant rework, dissatisfaction, and financial losses.

The Solution:

To ensure alignment of expectations, buyers should engage in thorough communication with their suppliers from the outset. This includes discussing material specifications, desired cutting depths, and any unique features required for the die. Buyers should also request detailed prototypes or mock-ups, if available, to visualize how the final product will perform. Additionally, providing a comprehensive design brief, including specific dimensions, tolerances, and examples of similar products, can help manufacturers understand the requirements better. Following up with a clear feedback loop during the production process can also ensure that any potential issues are addressed before the final product is delivered, minimizing the risk of misalignment.

By proactively addressing these pain points, B2B buyers can enhance their experience with custom leather die cutters, leading to improved production efficiency and product quality.

Illustrative image related to custom leather die cutter

Strategic Material Selection Guide for custom leather die cutter

When selecting materials for custom leather die cutters, it’s essential to consider various factors such as performance properties, cost-effectiveness, and suitability for specific applications. Here, we analyze four common materials used in the manufacturing of custom leather die cutters, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

What are the Key Properties of Steel in Custom Leather Die Cutters?

Steel is a popular choice for die cutting due to its strength and durability. It typically features high tensile strength, allowing it to withstand significant pressure without deformation. Steel dies can be pre-sharpened for precise cuts and have a corrosion resistance that can be enhanced through various treatments.

Pros: Steel dies offer exceptional durability and longevity, making them suitable for high-volume production. They can handle a variety of materials, including leather, paper, and some plastics, ensuring versatility in applications.

Illustrative image related to custom leather die cutter

Cons: The initial cost of steel dies can be high, particularly for intricate designs. Additionally, manufacturing complexity increases with the need for precise machining and finishing processes.

Impact on Application: Steel’s compatibility with various media makes it ideal for diverse cutting needs, but it requires careful handling to avoid rusting, especially in humid environments.

How Does Acrylic Enhance the Performance of Die Cutters?

Acrylic is often used as a mounting material for steel rule dies. It provides a lightweight, durable base that aids in the alignment of materials during the cutting process. Acrylic mounts can be customized to different thicknesses, enhancing the die’s performance by reducing material waste.

Pros: The use of acrylic allows for easy alignment and setup, which can significantly reduce production time. It is also less expensive than steel, making it a cost-effective option for businesses.

Cons: Acrylic may not be as durable as steel, particularly under high-pressure applications. It can also be prone to scratching and may require more frequent replacement.

Impact on Application: Acrylic’s lightweight nature makes it suitable for smaller operations or businesses just starting with die cutting. However, it may not be ideal for large-scale manufacturing where durability is paramount.

What Role Does Wood Play in Custom Leather Die Cutters?

Wood is sometimes used in conjunction with steel for die cutting applications, particularly for less demanding tasks or prototyping. Wooden dies are typically lighter and easier to manufacture, making them a budget-friendly option.

Pros: The low cost of wooden dies makes them an attractive option for small businesses or those testing new designs. They can be easily customized and are suitable for less intricate cuts.

Cons: Wooden dies have a limited lifespan and are not suitable for high-volume production due to their susceptibility to wear and tear. They also lack the precision of metal dies.

Impact on Application: Wooden dies are best suited for softer materials or lower production volumes, making them ideal for crafts or smaller businesses in emerging markets.

Illustrative image related to custom leather die cutter

Why is Rubber Important in Die Cutting Applications?

Rubber is often used as a cushioning material in die cutting applications, particularly for ejection purposes. It helps in the smooth removal of cut pieces from the die, reducing the risk of damage.

Pros: Rubber provides excellent cushioning and can improve the efficiency of the cutting process. It is also relatively inexpensive and can be easily integrated into existing die systems.

Cons: While rubber enhances the ejection process, it may not withstand high temperatures or pressures, limiting its application in more demanding environments.

Illustrative image related to custom leather die cutter

Impact on Application: Businesses operating in regions with variable climates, such as Africa and South America, should consider the thermal properties of rubber when selecting materials for their die cutters.

Summary of Material Selection for Custom Leather Die Cutters

| Materiał | Typical Use Case for custom leather die cutter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | High-volume production of leather and other materials | Exceptional durability and precision | High initial cost and manufacturing complexity | High |

| Acrylic | Mounting for steel rule dies | Easy alignment reduces waste | Less durable than steel, prone to scratches | Medium |

| Wood | Prototyping and low-volume production | Low cost and easy customization | Limited lifespan, not suitable for high volumes | Low |

| Rubber | Ejection cushioning in die cutting | Improves efficiency and reduces damage | Limited temperature/pressure resistance | Medium |

This strategic material selection guide provides valuable insights for B2B buyers in diverse international markets, helping them make informed decisions based on their specific needs and operational contexts.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather die cutter

What Are the Key Stages in the Manufacturing Process of Custom Leather Die Cutters?

The manufacturing of custom leather die cutters involves several critical stages, each essential for producing high-quality dies that meet precise specifications. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

1. Material Preparation: What Materials Are Typically Used?

The primary materials used in the production of custom leather die cutters include high-carbon steel, acrylic for mounting, and sometimes wood. High-carbon steel is preferred for its durability and ability to maintain sharp cutting edges. The selection of materials is vital, as it directly impacts the die’s performance and longevity. Quality suppliers will source materials that comply with international standards to ensure consistency.

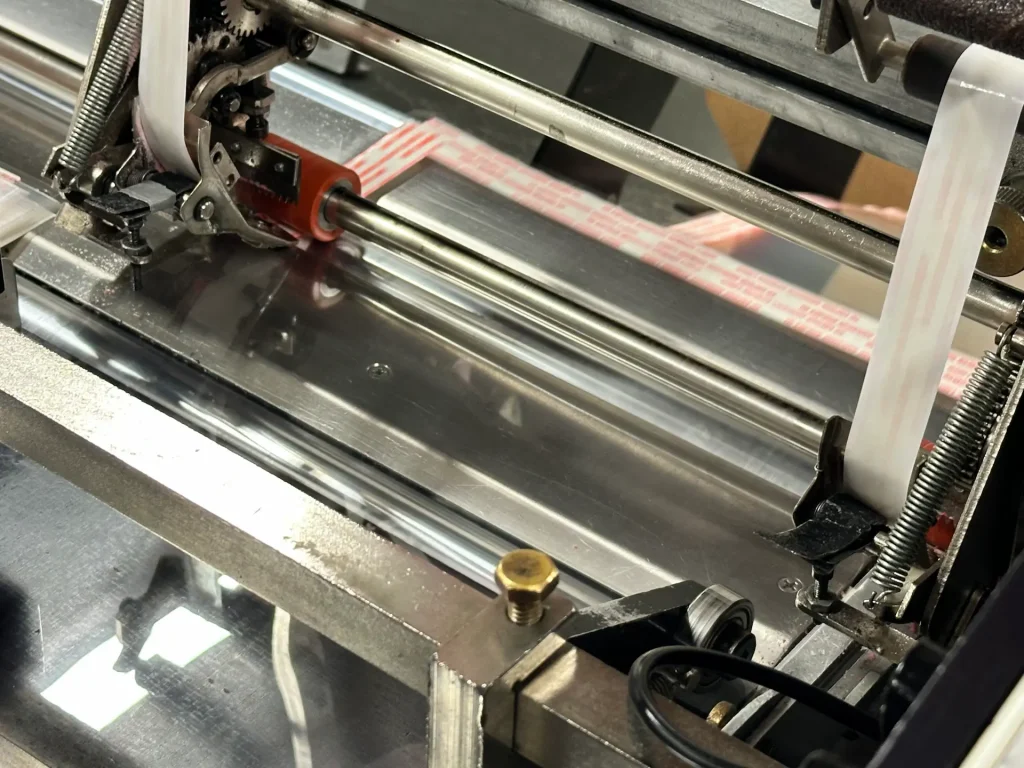

2. Forming: How Are Die Shapes Created?

The forming stage involves creating the die’s shape, which is typically done using CAD (Computer-Aided Design) software. This allows for precision in the design process, ensuring that the die will accurately replicate the intended pattern. The design is then transferred to a laser engraver, which produces a physical template that serves as a guide for cutting the steel. This step is crucial for ensuring that all measurements and angles are exact, which directly affects the die’s cutting performance.

3. Assembly: What Happens During Assembly?

After the cutting process, the individual components of the die cutter are assembled. This may include attaching the cutting blade to an acrylic or wooden mount for added stability. The assembly process often involves precision fitting to ensure that all parts align perfectly, which is essential for optimal cutting performance. Skilled craftsmen typically oversee this stage, leveraging their experience to avoid common pitfalls that could affect the die’s functionality.

4. Finishing: How Is the Die Prepared for Use?

The finishing stage involves several processes, including sharpening the cutting edges and applying protective coatings. A well-finished die will not only perform better but will also have a longer lifespan. Suppliers may also offer optional features, such as ejection rubber, to enhance the die’s usability by facilitating the easy release of cut pieces. A thorough inspection at this stage helps ensure that the product meets quality expectations before it is shipped.

What Quality Control Measures Are Implemented in Custom Leather Die Cutter Manufacturing?

Quality assurance is paramount in manufacturing, especially when dealing with custom products. For B2B buyers, understanding the quality control (QC) measures taken by suppliers can be a key factor in supplier selection.

1. What International Standards Should Buyers Look For?

Buyers should seek suppliers who adhere to international quality standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards indicates that the manufacturer has established processes for consistent quality and continuous improvement. Additionally, other certifications like CE (Conformité Européenne) may be relevant depending on the target market, particularly in Europe.

Illustrative image related to custom leather die cutter

2. What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control is typically divided into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified quality standards. Any materials that do not pass this inspection are rejected.

-

In-Process Quality Control (IPQC): During the manufacturing stages, periodic inspections are conducted to catch any deviations from the quality standards. This includes checking dimensions, alignment, and the integrity of the cutting edges.

-

Final Quality Control (FQC): Before shipping, a comprehensive inspection is conducted to verify that the finished products meet all specifications. This may include functional testing and visual inspections for defects.

3. What Common Testing Methods Are Used?

Testing methods can vary depending on the die’s intended use, but common practices include:

-

Dimensional Accuracy Testing: Using precision measuring tools to ensure that all dimensions align with the original CAD design.

-

Cutting Performance Testing: Assessing the die’s ability to cut through specified materials efficiently and cleanly.

-

Durability Testing: Subjecting the die to repeated use to evaluate its performance over time and under stress.

How Can B2B Buyers Verify Supplier Quality Control Processes?

Verifying a supplier’s quality control processes is crucial for B2B buyers, particularly when sourcing from international suppliers.

1. What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request detailed quality control reports and audit results from suppliers. These documents should outline the QC processes in place and any certifications obtained. A reputable supplier will be transparent about their quality assurance practices and willing to share audit findings from third-party inspections.

2. How Can Third-Party Inspections Enhance Quality Assurance?

Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes. These services typically include pre-shipment inspections and factory audits, ensuring that the products meet the required specifications before they leave the manufacturer. This can be particularly important for buyers in regions like Africa and South America, where local regulations may differ.

Illustrative image related to custom leather die cutter

What Are the Specific Quality Control Nuances for International B2B Buyers?

International buyers must navigate various challenges when sourcing custom leather die cutters. Understanding these nuances can help mitigate risks.

1. How Do Regional Standards Affect Quality Expectations?

Different regions may have distinct quality standards and regulations that suppliers must adhere to. For instance, products sold in the European market may require CE certification, while buyers in the Middle East might have different compliance requirements. It’s essential for buyers to communicate their specific quality needs and confirm that suppliers can meet them.

2. What Shipping and Customs Considerations Should Be Made?

When sourcing from overseas, buyers should also consider the logistics of shipping and customs. Ensuring that the supplier can provide necessary documentation for customs clearance can prevent delays and additional costs. Understanding the shipping timelines and potential risks associated with international transport is also crucial for maintaining project schedules.

By thoroughly assessing the manufacturing processes and quality assurance practices of potential suppliers, B2B buyers can ensure they partner with reliable manufacturers capable of delivering high-quality custom leather die cutters tailored to their specific needs.

Illustrative image related to custom leather die cutter

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather die cutter’

This guide aims to equip international B2B buyers with a structured approach to sourcing custom leather die cutters. By following these steps, you can ensure that your procurement process is efficient, cost-effective, and aligned with your specific production needs.

Step 1: Define Your Technical Specifications

Understanding your requirements is the first step in sourcing a custom leather die cutter. Determine the type of materials you will be cutting, the thickness of the leather, and the complexity of the designs. Be specific about dimensions, tolerances, and any unique features you may need, such as hole punches or engraving options.

- Material Compatibility: Ensure the cutter can handle various materials if needed, such as leather, paper, or felt.

- Precision Requirements: Specify tolerances to guarantee that the die cutter meets your production standards.

Step 2: Research Potential Suppliers

Thorough research is essential to identify suppliers who specialize in custom leather die cutters. Look for companies with a proven track record and positive reviews from previous clients.

- Industry Experience: Opt for suppliers with extensive experience in the leather industry, as they will understand the nuances of your requirements.

- Product Range: Assess their offerings to ensure they can accommodate various designs and sizes.

Step 3: Evaluate Supplier Certifications and Quality Assurance

Before making a commitment, verify that the suppliers have the necessary certifications and quality assurance processes in place. This step is crucial for ensuring that the products meet international standards.

- Certifications: Look for ISO certifications or similar credentials that indicate adherence to quality standards.

- Quality Control Processes: Inquire about their quality control measures, including how they handle defects and ensure consistency.

Step 4: Request Samples and Prototypes

To assess the quality of the die cutters, request samples or prototypes based on your specifications. This step allows you to test the cutter’s performance and ensure it meets your expectations.

- Testing: Evaluate the sample with your materials to ensure it cuts effectively and accurately.

- Feedback Loop: Use the prototype to gather feedback from your production team to confirm it aligns with your operational needs.

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers and compare them carefully. Pricing can vary significantly based on factors like complexity, material, and lead time, so ensure you understand what is included in each quote.

- Hidden Costs: Be aware of additional costs, such as shipping fees or charges for design modifications.

- Payment Terms: Clarify payment options and terms to avoid any misunderstandings later in the procurement process.

Step 6: Assess Customer Support and Communication

Evaluate the level of customer support offered by potential suppliers. Strong communication is vital for addressing concerns and ensuring a smooth procurement process.

- Responsiveness: Assess how quickly they respond to inquiries and how effectively they communicate.

- After-Sales Support: Inquire about support options for maintenance, repairs, or re-sharpening of the dies.

Step 7: Finalize Your Order and Agreement

Once you have selected a supplier, finalize your order and ensure all terms are documented in a contract. This step protects both parties and clarifies expectations.

- Contract Details: Include specifics about delivery timelines, warranties, and return policies.

- Follow-Up: Establish a timeline for follow-ups to ensure the order is on track and any issues are addressed promptly.

By following these steps, you can confidently navigate the process of sourcing custom leather die cutters, ensuring that your selection aligns with your business needs and production goals.

Illustrative image related to custom leather die cutter

Comprehensive Cost and Pricing Analysis for custom leather die cutter Sourcing

What Are the Key Cost Components for Custom Leather Die Cutters?

When sourcing custom leather die cutters, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. Common materials include steel for the cutting blades and acrylic for the mounts. High-quality materials can enhance durability but will also raise the initial price.

-

Labor: Skilled labor is required for the precision manufacturing of die cutters. Labor costs vary by region, with specialized craftsmen often commanding higher wages.

-

Manufacturing Overhead: This encompasses costs related to facilities, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize these overhead costs.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. These costs include the creation of molds and die patterns, which are essential for producing high-quality die cutters.

-

Quality Control (QC): Ensuring that the dies meet specified tolerances and quality standards adds an additional layer of cost. Regular inspections and testing are necessary to maintain quality.

-

Logistics: Shipping and handling costs must be factored in, particularly for international shipments. These can vary based on the size and weight of the dies, as well as the shipping method chosen.

-

Margin: Suppliers typically apply a margin to cover their operational costs and profit. The margin can vary based on the supplier’s market position and the level of customization required.

How Do Price Influencers Affect Custom Leather Die Cutter Costs?

Several factors influence the pricing of custom leather die cutters:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit costs due to economies of scale. Suppliers may offer discounts for bulk orders, making it beneficial for businesses with larger production needs.

-

Specifications and Customization: The complexity of the design and specific customization requests can significantly affect pricing. Intricate designs typically require more time and resources to produce, increasing costs.

-

Material Quality and Certifications: Selecting higher-grade materials or those with specific certifications (e.g., environmental sustainability) can lead to increased costs. However, investing in quality materials can reduce long-term operational costs.

-

Supplier Factors: The supplier’s reputation, experience, and manufacturing capabilities can impact pricing. Established suppliers may charge more due to their proven track record and reliability.

-

Incoterms: The terms of shipping (Incoterms) can influence the total cost. Understanding who bears the costs and risks of shipping can help buyers negotiate better terms.

What Are Some Effective Buyer Tips for Sourcing Custom Leather Die Cutters?

When sourcing custom leather die cutters, B2B buyers should consider the following tips to enhance cost-efficiency and value:

-

Negotiate Wisely: Always engage in negotiations with suppliers. Discuss volume discounts, payment terms, and delivery timelines to secure favorable conditions.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the long-term costs associated with maintenance, quality issues, and potential production downtimes.

-

Understand Pricing Nuances for International Purchases: International buyers from regions like Africa, South America, the Middle East, and Europe should be aware of potential tariffs, taxes, and import duties that may affect overall pricing.

-

Request Detailed Quotes: Obtain comprehensive quotes that itemize costs for materials, labor, logistics, and any additional services. This transparency allows for better comparisons across suppliers.

-

Leverage Technology for Design Submission: Utilize digital formats (e.g., CAD files) for design submissions to streamline the production process and reduce errors, which can lead to cost savings.

-

Consider Local Suppliers: If feasible, sourcing from local suppliers can mitigate shipping costs and reduce lead times, enhancing supply chain efficiency.

By understanding these cost components and pricing influencers, B2B buyers can make informed decisions when sourcing custom leather die cutters, ultimately leading to better procurement strategies and enhanced profitability.

Alternatives Analysis: Comparing custom leather die cutter With Other Solutions

Understanding Alternatives for Custom Leather Die Cutting Solutions

When it comes to cutting leather, businesses have several options beyond custom leather die cutters. Understanding these alternatives is crucial for international B2B buyers looking to optimize their production processes. This comparison will explore the performance, cost, ease of implementation, maintenance, and best use cases for custom leather die cutters and alternative solutions.

| Comparison Aspect | Custom Leather Die Cutter | Clicker Press Machine | Laser Cutting Machine |

|---|---|---|---|

| Performance | High precision; suitable for intricate designs | High throughput; ideal for bulk cutting | Extremely precise; versatile for various materials |

| Cost | Moderate initial investment; varies by design complexity | Higher upfront cost; often requires additional equipment | Higher operational costs; equipment and maintenance can be expensive |

| Ease of Implementation | Requires design files and consultation for production | Setup can be time-consuming; training needed | Requires skilled operators for programming and operation |

| Maintenance | Low maintenance; occasional sharpening needed | Moderate maintenance; regular checks essential | High maintenance; requires skilled technicians for upkeep |

| Best Use Case | Custom designs with low to medium production volume | High volume production of consistent shapes | Complex shapes and patterns; suitable for a variety of materials |

Detailed Breakdown of Alternatives

Clicker Press Machine

Clicker press machines are designed for high-volume production, making them an ideal choice for businesses that need to cut many pieces quickly and consistently. They can handle various materials and are particularly effective for basic shapes. However, the initial investment can be significant, and companies may need to invest in additional equipment and training for their operators. While they offer efficiency in bulk cutting, they may lack the flexibility needed for intricate designs.

Illustrative image related to custom leather die cutter

Laser Cutting Machine

Laser cutting machines provide unmatched precision and versatility, making them suitable for a wide range of materials beyond leather, including fabric and plastics. The technology allows for complex patterns and fine details, which can significantly enhance product designs. However, the operational costs can be high, and these machines often require skilled technicians for setup and maintenance. Additionally, the initial cost of purchasing a laser cutter can be prohibitive for smaller businesses, making it a less accessible option.

Conclusion: Choosing the Right Solution for Your Leather Cutting Needs

Selecting the right cutting solution depends on your specific business needs, production volume, and budget. Custom leather die cutters are ideal for businesses requiring precision and customization in smaller batches. In contrast, clicker press machines are suited for high-volume production of simpler shapes, while laser cutting machines excel in versatility and detail but come with higher costs. B2B buyers should assess their unique requirements and operational capabilities to make an informed decision that aligns with their production goals.

Essential Technical Properties and Trade Terminology for custom leather die cutter

What Are the Key Technical Properties of Custom Leather Die Cutters?

When selecting a custom leather die cutter, understanding its technical specifications is crucial for ensuring product quality and operational efficiency. Here are some essential properties to consider:

Illustrative image related to custom leather die cutter

-

Material Grade

The primary material for die cutters is typically hardened steel. This material is favored for its durability and ability to maintain sharpness over time. The grade of steel used can significantly affect the die’s performance; higher-grade steel provides better longevity, which is critical for businesses aiming for cost-effectiveness in production. -

Tolerance Levels

Tolerance refers to the permissible limit of variation in a physical dimension. For custom leather die cutters, a tolerance of ±0.2mm is common and indicates the precision of the cutting die. This is important in B2B transactions as it directly affects the accuracy of the cuts, influencing the overall quality of the final product. High precision reduces material waste and the need for rework, which is vital for maximizing profitability. -

Cutting Depth

The effective cutting depth, usually ranging up to 8.8mm for various materials, determines the thickness of leather or other materials that can be processed. Knowing the cutting depth helps buyers select a die cutter that meets their specific production needs, ensuring compatibility with their material choices. -

Height of Die Cut

The height of the die cut is an important specification, often around 23-24mm. This height affects how the die interacts with the cutting press and ultimately influences the ease of use and efficiency in production. A well-designed height can facilitate smoother operations and reduce operator fatigue. -

Engraving and Customization Options

Many manufacturers offer options for text engraving and additional features such as hole punches. These customizations allow businesses to tailor their die cutters to specific applications, enhancing the versatility of the equipment. This adaptability is particularly important in industries with diverse product lines.

What Are Common Trade Terms Related to Custom Leather Die Cutters?

Understanding industry jargon can facilitate smoother negotiations and clearer communications with suppliers. Here are some common terms used in the context of custom leather die cutters:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of custom leather die cutters, an OEM might supply the dies that are then used by leather goods manufacturers. Understanding OEM relationships can help buyers assess quality and reliability. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. For custom die cutters, this is particularly relevant as it may affect pricing and inventory management for businesses. Knowing the MOQ allows buyers to plan their production schedules and budget accordingly. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and other information for specific products or services. In the leather industry, submitting an RFQ can help businesses compare options and negotiate better terms, ensuring they receive the best value for their investment. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers as they clarify shipping costs, risks, and responsibilities, helping to prevent misunderstandings in cross-border trade. -

Lead Time

This term refers to the time taken from placing an order to its delivery. In the context of custom leather die cutters, understanding lead times is critical for managing production schedules and meeting market demands. Buyers should inquire about standard lead times and options for expedited services when necessary.

By grasping these technical specifications and trade terms, B2B buyers can make informed decisions when sourcing custom leather die cutters, ultimately enhancing their operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the custom leather die cutter Sector

What are the Key Market Trends in the Custom Leather Die Cutter Sector?

The custom leather die cutter market is witnessing significant growth, driven by the rising demand for personalized leather products across various industries, including fashion, automotive, and accessories. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe seek unique designs, the ability to customize die cutters is becoming increasingly important. A notable trend is the integration of advanced technologies, such as CAD (Computer-Aided Design), which enhances precision and efficiency in die production. This shift not only reduces turnaround times but also minimizes material waste, aligning with the needs of manufacturers focused on cost-effectiveness.

Additionally, the market is adapting to the growing trend of e-commerce, with suppliers offering online platforms for easy ordering and customization. This accessibility allows businesses to streamline their procurement processes and source dies more efficiently, catering to varying production scales. The demand for quick turnaround times is another emerging trend, with many suppliers now offering expedited services for urgent orders, a critical factor for B2B buyers operating in fast-paced markets.

How Can Sustainability and Ethical Sourcing Impact the Custom Leather Die Cutter Industry?

Sustainability is becoming a cornerstone of the custom leather die cutter sector, as both consumers and businesses increasingly prioritize environmental responsibility. The production of leather and the associated cutting processes can have significant environmental impacts, prompting B2B buyers to seek out suppliers that adopt sustainable practices. This includes using eco-friendly materials and processes, reducing waste, and implementing energy-efficient manufacturing techniques.

Ethical sourcing is equally important, as buyers are increasingly concerned about the origins of the materials they use. Suppliers who can demonstrate transparency in their supply chains and offer certifications for sustainable practices, such as the use of vegetable-tanned leather or recycled materials, are becoming more attractive to international buyers. By prioritizing sustainability and ethical sourcing, businesses not only enhance their brand reputation but also appeal to a growing market segment that values responsible manufacturing.

What is the Historical Context of Custom Leather Die Cutters in B2B Markets?

The evolution of custom leather die cutters has been marked by significant technological advancements and changing market demands. Historically, die cutting was a labor-intensive process that relied heavily on manual techniques. However, the introduction of steel rule dies in the mid-20th century revolutionized the industry, enabling faster and more precise cutting of leather. As the demand for bespoke leather goods grew, so did the need for customization in die cutting, leading to innovations such as CAD technology.

In recent years, the proliferation of e-commerce and digital design tools has further transformed the landscape, allowing B2B buyers to easily communicate their design requirements and receive tailored solutions. This evolution reflects broader trends within the manufacturing sector, where efficiency, precision, and customization are increasingly valued, aligning closely with the expectations of today’s international buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather die cutter

-

How do I choose the right custom leather die cutter for my business needs?

Selecting the right custom leather die cutter involves assessing your production requirements, including the types of materials you’ll be cutting, the complexity of designs, and volume needs. Evaluate suppliers based on their expertise in creating dies for specific applications, such as leather, paper, or silicone. Request samples or prototypes to gauge quality and precision. Additionally, consider the turnaround time for production and shipping, especially if your projects have tight deadlines. -

What is the best material for custom leather die cutters?

The best material for custom leather die cutters is typically hardened steel, as it offers durability and precision in cutting. Steel dies can withstand repeated use without losing their cutting edge, making them suitable for high-volume production. Some suppliers also offer dies with acrylic mounts for easier alignment, which can reduce material waste. When evaluating options, consider the thickness of the die and its compatibility with the materials you intend to cut. -

What are the minimum order quantities (MOQs) for custom leather die cutters?

Minimum order quantities for custom leather die cutters can vary significantly between suppliers, often depending on the complexity of the design and the material used. Some suppliers may have a low MOQ for simpler geometric shapes, while more intricate designs may require larger orders to justify production costs. It’s advisable to communicate directly with suppliers to clarify their MOQ policies and explore options for smaller runs if necessary. -

How can I ensure quality assurance (QA) for my custom leather dies?

To ensure quality assurance for custom leather dies, request detailed specifications and production samples before finalizing your order. Many reputable suppliers will use CAD programs to create precise designs and may offer guarantees that the dies will meet your specifications. Additionally, inquire about their quality control processes, such as inspections during and after production, to ensure that the dies are manufactured to the highest standards. -

What should I know about payment terms when sourcing custom leather die cutters?

Payment terms can vary by supplier, so it’s important to discuss them upfront. Common practices include a deposit upon order confirmation, with the balance due before shipment. Some suppliers may offer credit terms for established businesses, while others might require full payment in advance. Be sure to understand the payment methods accepted, such as credit cards or wire transfers, and inquire about any potential fees associated with international transactions. -

What shipping options are available for international orders of custom leather die cutters?

Shipping options for international orders typically include standard shipping and express services. Standard shipping may take longer but is often more cost-effective, while express services provide faster delivery, usually within a few business days. When placing an order, confirm the shipping costs and estimated delivery times, and ensure that the supplier can accommodate any specific logistics needs, such as customs clearance or tracking. -

How can I vet suppliers for custom leather die cutters?

Vetting suppliers involves researching their reputation, experience, and capabilities. Look for reviews and testimonials from previous clients, particularly those in your industry. Request samples of their work to assess quality and consistency. It’s also beneficial to inquire about their production processes, lead times, and customer service responsiveness. Engaging in direct communication can provide insights into their professionalism and reliability. -

What customization options are typically available for leather die cutters?

Customization options for leather die cutters often include variations in size, shape, and design features. Many suppliers allow you to submit your designs in various formats, such as CAD files or sketches, for tailored production. Additional features may include text engraving, hole punches, or specific cutting depths. Discuss your specific needs with the supplier to explore all available customization options that can enhance your production efficiency.

Top 5 Custom Leather Die Cutter Manufacturers & Suppliers List

1. Weaver Leather Supply – Custom Leather Cutting Dies

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Custom Leather Clicker & Cutting Dies by Weaver Leather Supply are made from hardened, pre-sharpened steel for quality and dependability. They are available in 3 mm and 4 mm thicknesses, with heights of 3/4″ or 1-1/4″ (recommended for maximum strength). Each die is constructed with attention to detail and is guaranteed to meet specifications or your money back. The die shop offers a consultation s…

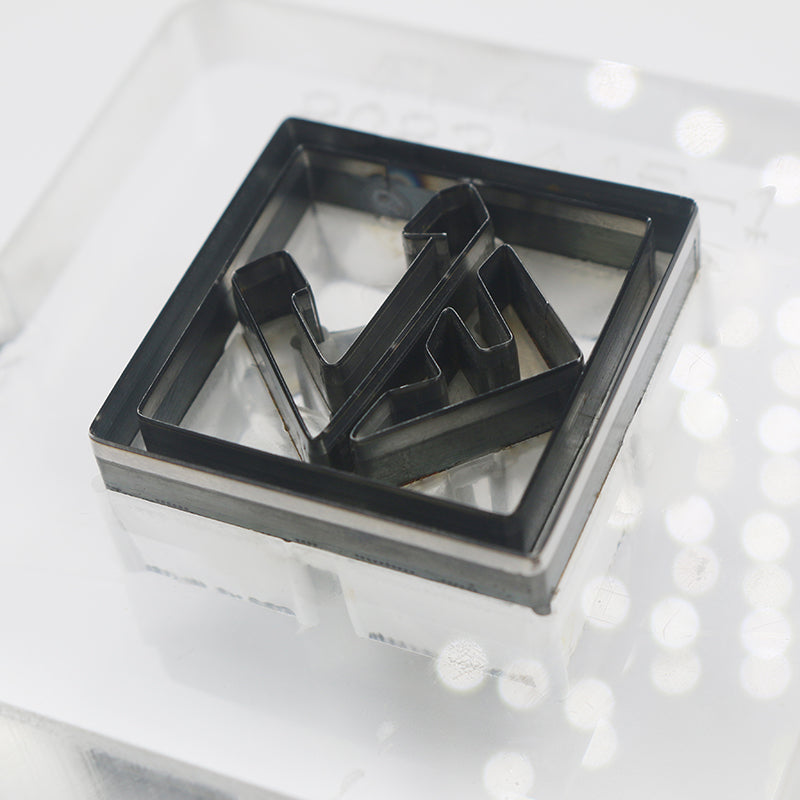

2. LW Leathers – Leather Die Cut with Acrylic Mount

Domain: lwleathers.com

Registered: 2012 (13 years)

Introduction: {“product_name”: “Leather Die Cut with Acrylic Mount for Leather Cutting and Paper Cutting”, “regular_price”: “US$138.00”, “sale_price”: “US$138.00”, “available_sizes”: [“Up to 3×3 inch”, “Up to 4×4 inch”, “Up to 5×5 inch”, “Up to 6×6 inch”], “description”: “Custom made laser engraved leather die cut / steel rule die cut for cutting leather, paper, card stock, silicone, thin magnet, etc. Acrylic m…

3. DM Leather Studio – Custom Leather Cutting Dies

Domain: dmleatherstudio.com

Registered: 2017 (8 years)

Introduction: {“product_name”: “Custom Leather Cutting Dies”, “product_type”: “Steel Die for Cutting Leather”, “product_code”: “X09-LCD”, “price”: “$2.00”, “availability”: “Many in stock”, “materials”: [“wood”, “steel”], “default_height”: “24mm (0.95in)”, “usage”: [“leather”, “paper”, “felt cloth”], “custom_order”: “Accepted”, “design_file_formats”: [“.ai”, “.eps”, “.pdf”, “.jpg”, “.png”], “shipping_options”: {…

4. Texas Custom Dies – Custom Die Cutting Services

Domain: usacuttingdie.com

Registered: 2009 (16 years)

Introduction: Texas Custom Dies offers custom die cutting services, including saddle dies, small key fobs, and coaster dies. They also provide die cutting services for customers without a press. The company emphasizes honesty, quality, and value in their die making.

5. Leather Stamp Maker – Custom Steel Leather Cutting Dies

Domain: leatherstampmaker.com

Registered: 2015 (10 years)

Introduction: Steel Leather Cutting Dies by Leather Stamp Maker, Made in the USA. Custom Leather Cutting Dies available. Full Letter Sets include: A trio of each letter A-Z, three copies of numbers 0-9, special characters (period, comma, at symbol, ampersand, hash, slash, dash, exclamation mark), four blank spacers, a stamping handle, and a 4-inch holder. Mini Font Sets include: full set of 26 uppercase letters…

Strategic Sourcing Conclusion and Outlook for custom leather die cutter

In navigating the intricate landscape of custom leather die cutting, international B2B buyers stand to gain substantial advantages through strategic sourcing. Partnering with reputable suppliers ensures access to high-quality materials and precision-engineered dies tailored to specific manufacturing needs. The ability to customize designs, along with the option for rapid production and delivery, minimizes waste and maximizes operational efficiency—critical factors in maintaining competitiveness in diverse markets.

Illustrative image related to custom leather die cutter

Moreover, understanding the nuances of pricing—where complexity and size dictate costs—enables buyers to make informed purchasing decisions. As the demand for personalized leather products grows, leveraging advanced technologies like CAD for die design can significantly enhance accuracy and reduce lead times.

As you consider your sourcing strategy, remember that aligning with suppliers who prioritize service and quality will yield long-term benefits. The future of leather crafting lies in innovation and collaboration, making now the ideal time to invest in custom leather die cutters. By embracing these opportunities, businesses in Africa, South America, the Middle East, and Europe can position themselves at the forefront of a thriving industry. Engage with suppliers today to explore tailored solutions that will elevate your production capabilities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.