Catalog

Material Insight: Kinds Of Leather

B2B Product Guide: Understanding Kinds of Leather

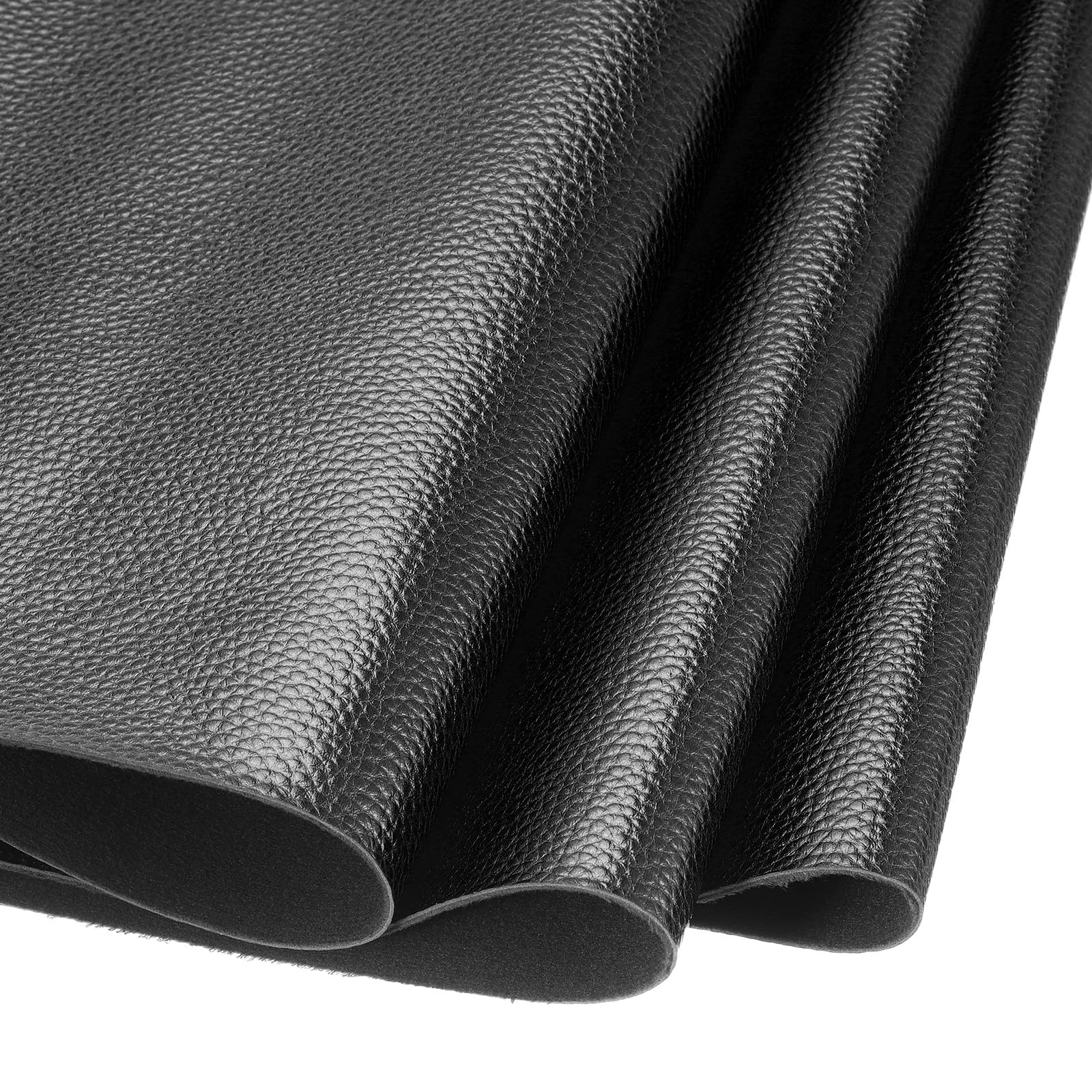

Leather has long been a cornerstone material across industries including fashion, automotive, furniture, and accessories, valued for its durability, aesthetic appeal, and tactile quality. Traditionally, leather is categorized into two primary types: genuine (animal hide-based) and faux (synthetic or lab-created). Genuine leather includes full-grain, top-grain, corrected grain, and genuine split leather—each varying in quality, cost, and performance. While natural leather offers unique characteristics, it also presents challenges such as inconsistent supply, high environmental impact, and ethical concerns related to animal sourcing.

In contrast, faux leather—also known as synthetic or artificial leather—offers a sustainable, consistent, and ethically responsible alternative. Made primarily from polyurethane (PU) or polyvinyl chloride (PVC) on a fabric backing, modern faux leather replicates the look and feel of genuine leather while providing enhanced control over physical properties such as thickness, color fastness, abrasion resistance, and breathability.

Why Faux Leather is the Best Choice for Modern Applications

Today’s manufacturers and brands are increasingly turning to faux leather for both performance and sustainability reasons. Faux leather excels in applications where consistency, scalability, and environmental responsibility are critical. Key advantages include:

- Consistent Quality: Unlike natural leather, which varies by hide, faux leather offers uniform texture, thickness, and color batch after batch.

- Eco-Friendly Production: Advanced PU-based faux leathers, like those developed by WINIW, significantly reduce water usage, eliminate harmful tanning chemicals, and lower carbon emissions.

- Animal-Free & Ethical: Faux leather supports cruelty-free manufacturing and aligns with global animal welfare standards.

- Design Flexibility: Available in a wide range of textures, colors, and finishes—including embossed, matte, glossy, and custom patterns—faux leather enables greater creative freedom.

- Durability & Performance: Engineered to resist cracking, fading, and abrasion, high-quality faux leather meets or exceeds the performance standards of natural leather in demanding environments.

Introducing WINIW: Innovating Sustainable Leather Solutions

WINIW is a leading B2B supplier of high-performance synthetic leather, with over 20 years of expertise in material science and eco-conscious manufacturing. Specializing in PU and microfiber leather solutions, WINIW serves global markets including automotive interiors, upholstery, footwear, and fashion accessories. Our commitment to innovation, quality, and sustainability has positioned us as a trusted partner for brands seeking durable, ethical, and scalable materials.

At WINIW, we combine advanced coating technologies with environmentally responsible practices—using water-based PU systems, recyclable backings, and low-VOC emissions processes—to deliver premium faux leather that meets international standards (REACH, RoHS, OEKO-TEX®). With in-house R&D, global logistics support, and customizable production capabilities, WINIW empowers manufacturers to future-proof their supply chains while reducing environmental impact.

Technical Performance & Standards

WINIW Synthetic Leather: Technical Advantages for Industrial Applications

WINIW delivers high-performance synthetic leather solutions engineered for demanding B2B manufacturing environments. Our product lines balance ecological responsibility with uncompromising technical specifications, ensuring cost efficiency, longevity, and regulatory compliance for automotive, furniture, electronics, and fashion accessories sectors.

Core Technical Advantages

- Cost-Effective Production: Reduced material waste (up to 15% vs. genuine leather) through consistent roll widths (1.38m–1.42m) and uniform thickness. Eliminates grain variation sorting, lowering processing costs by 20–30% in high-volume production.

- Superior Durability: Engineered for 100,000+ double-rub tests (Martindale), UV resistance (500+ hrs QUV), and tear strength exceeding 35N. Maintains integrity under extreme flexing (-30°C to +80°C), critical for automotive and outdoor furniture.

- Customizable Color Systems: 50+ standard colors with ±0.5 DE color tolerance. Full Pantone® matching capability and batch-to-batch consistency (ΔE < 1.0) via digital color management, reducing rework in multi-component assemblies.

- REACH & Eco-Compliance: Zero phthalates, AZO dyes, or heavy metals (Cd, Pb, Hg). Fully traceable raw materials with SGS-certified documentation. Compliant with EU REACH Annex XVII, OEKO-TEX® STANDARD 100, and Proposition 65.

- ISO 9001-Qualified Consistency: Rigorous in-line thickness control (±0.05mm tolerance), coating weight uniformity (±3%), and humidity-stable performance (8–12% moisture regain) validated under ISO 9001:2015 frameworks.

WINIW Product Line Specifications

All materials meet ISO 9001:2015 and REACH Annex XVII standards. Thickness range: 0.6mm–2.0mm.

| Product Line | Base Material | Abrasion Resistance (Martindale) | Color Options | Key Applications | Eco-Certifications |

|---|---|---|---|---|---|

| WINIW Microfiber | Polyester/Polyamide | 150,000+ cycles | 60+ standard + custom | Automotive seats, luxury goods | bluesign®, GRS (min. 30% rPET) |

| WINIW PU | Polyurethane | 80,000–120,000 cycles | 50+ standard + Pantone® matching | Furniture, electronics, footwear | OEKO-TEX® STANDARD 100 |

| WINIW Eco | Bio-based PU | 60,000–90,000 cycles | 40+ earth-tone palette | Sustainable fashion, eco-furniture | USDA BioPreferred®, GRS (50%+) |

Why WINIW for Industrial Sourcing?

- Supply Chain Resilience: 98% on-time delivery rate with 15,000+ meter monthly capacity per line. No seasonal sourcing volatility.

- Waste Reduction: Precision-engineered widths minimize cutting waste; recyclable production scraps (up to 95% recovery rate).

- Technical Partnership: Dedicated engineering support for substrate adhesion, seam strength optimization, and regulatory documentation.

- Lifecycle Value: 3–5x longer service life than standard synthetics in abrasion-prone applications, verified via ASTM D4157 testing.

WINIW transforms sustainability mandates into competitive advantage—delivering certified, customizable performance without compromising on cost or durability. Request our full technical dossier and sample kit to validate specifications for your production workflow.

Why Choose Synthetic over Real Leather

B2B Product Guide: Synthetic vs. Real Leather – A Comparative Overview

In the modern manufacturing and design landscape, material selection plays a critical role in product performance, sustainability, and cost-efficiency. Leather—both real and synthetic—remains a preferred material across industries such as automotive, fashion, furniture, and accessories. Understanding the differences between real leather and various kinds of synthetic leather is essential for businesses aiming to balance quality, environmental impact, and economic viability.

Real leather is derived from animal hides, primarily bovine, and undergoes tanning and finishing processes to enhance durability and appearance. While it offers natural grain and long-term aging characteristics, it comes with ethical, environmental, and consistency challenges.

Synthetic leather, including polyurethane (PU) and polyvinyl chloride (PVC) leather, is engineered to replicate the look and feel of real leather. Advanced iterations, such as WINIW® microfiber synthetic leather, offer high performance, design flexibility, and improved sustainability profiles. These materials are ideal for B2B clients seeking consistent quality, reduced environmental impact, and compliance with animal-free standards.

Key differences between real leather and synthetic leather include:

- Source & Ethics: Real leather relies on animal agriculture, raising ethical and traceability concerns. Synthetic leather is animal-free and offers greater transparency in sourcing.

- Consistency: Real leather varies in grain, thickness, and defects due to its natural origin. Synthetic leather provides uniform thickness, color, and texture—ideal for mass production.

- Customization: Synthetic leather can be engineered for specific performance needs (e.g., abrasion resistance, UV stability, breathability), whereas real leather has inherent limitations.

- Environmental Impact: Real leather production involves high water consumption, greenhouse gas emissions, and hazardous chemicals in tanning. Modern synthetic leathers, especially PU-based and bio-based variants, offer lower carbon footprints and recyclability options.

- Maintenance & Performance: Synthetic leather is generally more resistant to fading, staining, and moisture, requiring less maintenance than real leather.

The following table compares real leather and common synthetic leather types across key business decision factors:

| Material Type | Cost (per sqm) | Durability (Years) | Eco-Friendliness (Scale: 1–10) | Notes |

|---|---|---|---|---|

| Real Leather (Full-Grain) | High | 10–15 | 4 | High environmental cost; variable supply; long aging period |

| PVC Synthetic Leather | Low | 3–5 | 2 | Contains phthalates; poor biodegradability; limited breathability |

| PU Synthetic Leather | Medium | 5–8 | 6 | More flexible and breathable than PVC; lower VOC emissions |

| Microfiber Synthetic Leather (e.g., WINIW®) | Medium-High | 8–12 | 8 | High tensile strength; water-resistant; recyclable; bio-based options available |

For forward-thinking B2B partners, microfiber synthetic leather represents the optimal balance of performance, sustainability, and design control. It supports circular economy goals and meets increasing market demand for cruelty-free, traceable materials without compromising on luxury or longevity.

Choosing the right leather alternative is no longer just a cost or aesthetic decision—it is a strategic move toward responsible innovation. WINIW specializes in high-performance synthetic leather solutions tailored for industrial applications, offering scalable production, global compliance, and eco-conscious material science.

WINIW Factory Capabilities

WINIW Synthetic Leather: Engineered for Global Excellence

WINIW stands at the forefront of sustainable synthetic leather manufacturing, delivering premium materials that meet the exacting demands of international B2B clients. Our vertically integrated production ecosystem, grounded in environmental responsibility and technical innovation, ensures consistent quality and scalability for brands committed to both performance and planetary stewardship.

Core Manufacturing Strengths

- 100,000 sqm Advanced Production Facility: Strategically located in China, our state-of-the-art campus integrates raw material processing, coating, finishing, and logistics under one roof, enabling end-to-end control and rapid order fulfillment for volumes up to 50 million meters annually.

- Dedicated R&D Innovation Hub: A 120+ member technical team, including polymer scientists and material engineers, drives continuous advancement in eco-materials. We hold 47 patents for water-based PU/PE technologies, bio-content formulations (up to 30% recycled content), and performance-enhancing surface treatments.

- Zero-Compromise Quality Assurance: Every batch undergoes 18-stage QC protocols aligned with EU REACH, US CPSIA, and OEKO-TEX® STANDARD 100. Our on-site ISO/IEC 17025-certified lab conducts abrasion, colorfastness, and eco-toxicity testing, ensuring <0.5% defect rates.

Global Market Leadership

WINIW materials empower leading brands across 60+ countries, with 78% of exports serving regulated markets:

| Key Export Regions | Primary Applications | Compliance Standards Met |

|---|---|---|

| Europe | Automotive upholstery, Luxury goods | EU REACH, EN 14363, ZDHC MRSL v3.0 |

| North America | Furniture, Footwear, Apparel | CPSIA, CAL TB 117-2013, Prop 65 |

| Japan & South Korea | Electronics, Medical | JIS K 6400, KCLP, GOTS |

Our closed-loop production system reduces water usage by 65% versus industry averages and utilizes 100% renewable energy in finishing processes, directly supporting client ESG targets without sacrificing durability or aesthetic versatility. Partner with WINIW to transform sustainable material specifications into competitive market advantage—backed by industrial-scale reliability and uncompromised integrity.

Contact Us for Samples

Premium Synthetic Leather Solutions by WINIW – B2B Product Guide

WINIW is a trusted global manufacturer of high-performance synthetic leather, serving industries such as automotive, furniture, fashion, and footwear. Our advanced microfiber technology delivers durable, sustainable, and cost-effective alternatives to genuine leather—without compromising on quality, texture, or aesthetics.

Engineered for performance and designed for versatility, WINIW synthetic leather meets rigorous international standards for abrasion resistance, color fastness, and environmental safety. With a strong commitment to sustainability, our materials are REACH-compliant, phthalate-free, and produced using eco-conscious processes.

Key Advantages of WINIW Synthetic Leather

- Superior durability and wear resistance for high-use applications

- Consistent thickness and width for optimized production efficiency

- Customizable textures, colors, and finishes to match brand specifications

- Lightweight and flexible—ideal for complex designs and ergonomic products

- Breathable, soft-touch surfaces that emulate the feel of natural leather

- Environmentally responsible: reduced carbon footprint and no animal sourcing

Industry Applications

- Automotive interiors (seats, dashboards, door panels)

- Upholstered furniture and office seating

- Luxury handbags, footwear, and accessories

- Sports and protective gear requiring high abrasion resistance

- Hospitality and contract furnishings

Customization Capabilities

WINIW supports OEM and ODM partnerships with full-service customization:

- Matte, glossy, soft-feel, or embossed surface finishes

- Wide range of standard and Pantone-matched colors

- Variable thickness (0.6mm to 2.0mm) and roll width (1.37m standard)

- Flame-retardant, anti-bacterial, and UV-resistant options available

Discover the Kinds of Leather We Offer

From ultra-suede to grain leather and performance-focused technical hides, WINIW delivers tailored solutions for every industrial need.

Contact us today to explore our full range:

MKT88@MicrofiberLeather.com

Free samples available upon request—ideal for prototyping, quality testing, and design validation.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.