Catalog

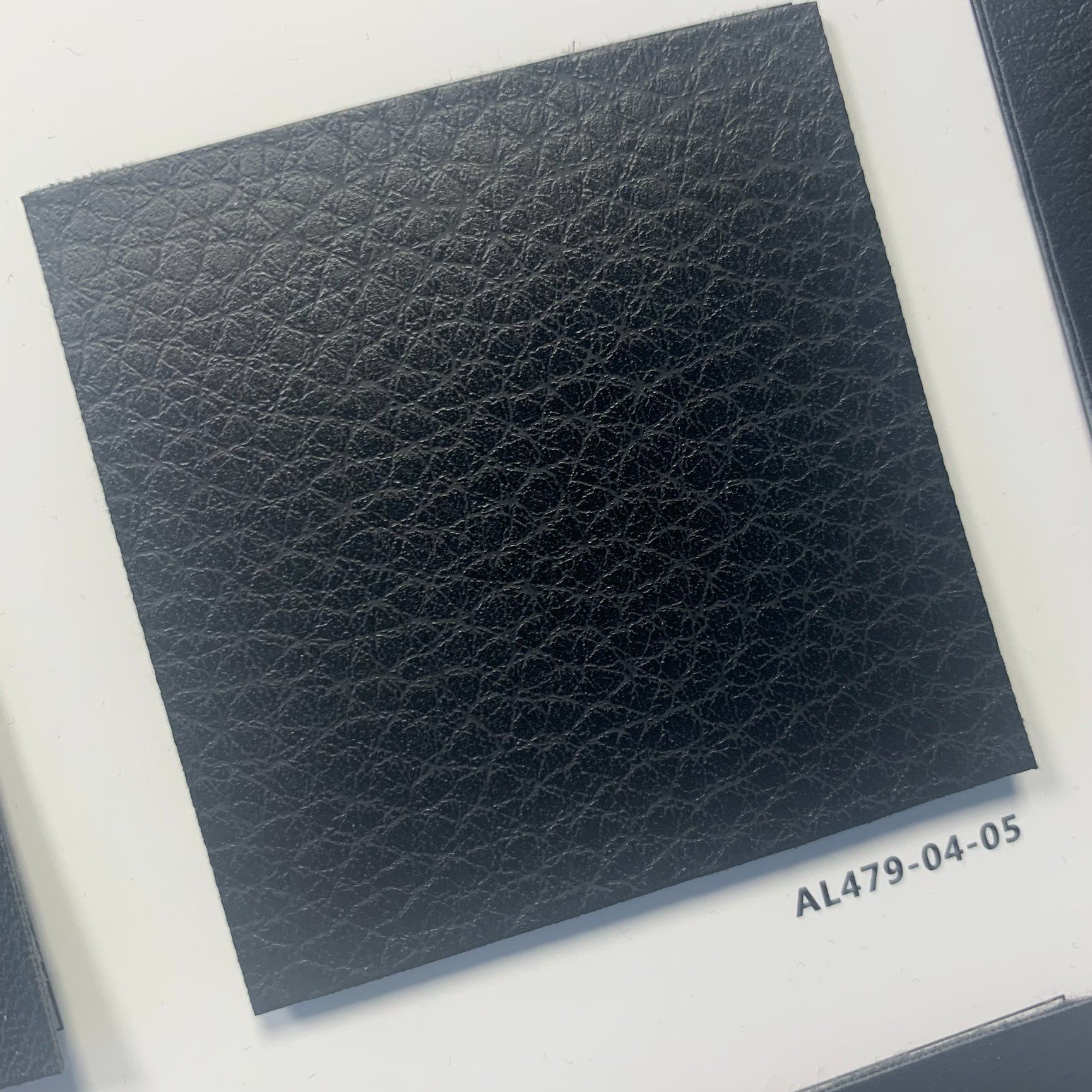

Material Insight: Custom Printed Faux Leather

B2B Product Guide: Custom Printed Faux Leather Solutions

In today’s competitive market, brand differentiation through unique, high-impact material finishes is essential. Custom printed faux leather offers unparalleled design flexibility for applications ranging from luxury packaging and furniture upholstery to automotive interiors and fashion accessories. Unlike traditional materials, it enables intricate patterns, photorealistic imagery, and precise brand color replication at scale—transforming ordinary surfaces into compelling brand touchpoints.

Why Faux Leather is the Optimal Choice for Custom Printing

Real leather’s natural inconsistencies—scars, grain variations, and thickness deviations—create significant challenges for precision printing, often resulting in uneven ink absorption, misaligned patterns, and wasted material. Faux leather solves these issues with engineered consistency:

- Uniform Surface Structure: Provides a perfectly smooth, non-porous base for sharp, vibrant prints without ink bleeding or texture interference.

- Predictable Color Accuracy: Ensures 100% color fidelity across large production runs, critical for brand compliance.

- Waste Reduction: Minimal material rejection due to surface flaws lowers costs and supports lean manufacturing.

- Eco-Efficiency: Eliminates the water-intensive tanning processes and chemical runoff associated with real leather, aligning with circular economy principles.

- Design Freedom: Enables complex digital prints (e.g., marble, wood, abstract art) impossible on organic hides, accelerating time-to-market for trend-responsive products.

Introducing WINIW: Your Sustainable Innovation Partner

WINIW has pioneered advanced synthetic leather solutions for over 20 years, serving global B2B clients in automotive, furniture, and luxury goods industries. We combine deep material science expertise with a commitment to planetary responsibility:

- Proven Reliability: 20+ years of R&D focused on performance-driven faux leather, with ISO 9001/14001-certified manufacturing.

- Eco-Advanced Formulations: Our base materials integrate recycled content (up to 30% PCR) and water-based, solvent-free coatings—reducing carbon footprint by 40% vs. conventional synthetics.

- End-to-End Customization: From substrate engineering to print-ready finishing, we co-develop solutions meeting exact aesthetic, durability (Martindale >50,000 cycles), and regulatory needs (REACH, OEKO-TEX®).

- Scalable Sustainability: Partner with us to achieve ESG targets without compromising on quality, cost, or design ambition.

Elevate your product’s visual storytelling while advancing sustainability—WINIW delivers the precision, performance, and planet-positive credentials modern brands require. Explore our full technical specifications and sample library to begin your custom printed project.

Technical Performance & Standards

WINIW Custom Printed Faux Leather – B2B Product Guide

WINIW’s custom printed faux leather is engineered for businesses seeking a sustainable, high-performance alternative to genuine leather. Designed for durability and visual appeal, our product combines advanced manufacturing techniques with eco-conscious materials, making it ideal for industries such as automotive interiors, furniture, fashion accessories, and retail display solutions.

Our proprietary production process ensures consistent quality and customization without compromising on cost-efficiency. WINIW’s commitment to compliance and innovation is reflected in every batch, meeting international standards for safety and performance.

Technical Advantages

-

Cost-Effective Production

WINIW’s custom printed faux leather reduces material waste and eliminates the inconsistencies associated with natural leather. The roll-good format and high yield per production run lower unit costs, especially for large-volume orders. No need for extensive post-processing further enhances cost efficiency. -

Superior Durability

Engineered with a high-density polyurethane (PU) coating and reinforced backing, our faux leather resists abrasion, cracking, and fading. It maintains integrity under repeated flexing and exposure to UV light, making it suitable for both indoor and semi-outdoor applications. -

Fully Customizable Colors & Patterns

WINIW offers digital printing technology that supports unlimited color options and precise pattern replication. Clients can match brand-specific Pantone colors or develop exclusive textures (e.g., matte, glossy, embossed). Minimum order quantities remain flexible without sacrificing print quality. -

REACH Compliant

Our materials are rigorously tested to meet REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations. Free from SVHCs (Substances of Very High Concern), WINIW’s faux leather ensures safe handling and end-use across European and global markets. -

ISO9001-Certified Manufacturing

WINIW operates under an ISO9001-certified quality management system, ensuring every stage—from raw material sourcing to final inspection—is monitored for consistency, traceability, and performance.

Product Specifications

| Specyfikacja | Detail |

|---|---|

| Base Material | High-tenacity polyester fabric |

| Coating | Thermoplastic polyurethane (TPU/PU) |

| Thickness Range | 0.6 mm – 1.2 mm (customizable) |

| Width per Roll | 137 cm, 140 cm (custom widths available) |

| Roll Length | Standard 30 m, 50 m (custom lengths) |

| Color Customization | Full digital printing, Pantone matching |

| Abrasion Resistance | >50,000 cycles (Martindale test) |

| Lightfastness | ISO 105-B02, Grade 6–7 (40+ hours UV) |

| Cold Crack Resistance | Passes -20°C bend test |

| REACH Compliance | Fully compliant, SVHC-free |

| Fire Resistance | Available with BS5852/CAL117 options |

| Eco-Friendly Certification | REACH, ISO9001, RoHS |

WINIW’s custom printed faux leather delivers a balanced solution for B2B clients who demand quality, sustainability, and design flexibility. By integrating precision manufacturing with environmental responsibility, we support long-term partnerships across global supply chains.

Why Choose Synthetic over Real Leather

WINIW B2B Product Guide: Custom Printed Faux Leather vs. Real Leather

For forward-thinking manufacturers and designers seeking sustainable, high-performance materials, WINIW provides premium synthetic leather solutions. This guide objectively compares custom printed faux leather (specifically WINIW’s advanced PU/PVC-based synthetics) against traditional real leather across critical commercial parameters. Understanding these differences empowers brands to make informed, responsible sourcing decisions aligned with modern market demands.

Key Differentiators for Commercial Applications

- Design Flexibility & Customization: WINIW custom printed faux leather offers unparalleled design freedom. Achieve exact Pantone matches, intricate patterns, photorealistic imagery, and complex branding directly on the surface with digital printing technology. Real leather printing is severely limited by its natural grain, scars, and inconsistent absorbency, often resulting in muted colors and unpredictable outcomes.

- Consistency & Yield: WINIW synthetics provide uniform texture, color, and thickness roll-to-roll, minimizing waste during cutting and production. Real leather exhibits significant natural variation (scars, stretch marks, grain differences), leading to higher material waste (typically 15-25%) and inconsistent end-product appearance.

- Ethical & Traceable Sourcing: WINIW materials are entirely animal-free, eliminating ethical concerns associated with livestock farming and tanning. Our supply chain is fully traceable and adheres to strict environmental standards (OEKO-TEX® STANDARD 100, ISO 14001). Real leather sourcing involves complex, often opaque supply chains with documented animal welfare and deforestation issues.

- Maintenance & Performance: WINIW custom printed surfaces are inherently stain-resistant, easy to clean, and maintain their printed integrity. Real leather requires specialized conditioning, is susceptible to staining and water damage, and printed/dyed surfaces can fade or wear unevenly.

Comparative Analysis: Cost, Durability & Eco-Friendliness

The table below details key performance metrics relevant to commercial procurement and product lifecycle management:

| Parametr | Custom Printed WINIW Faux Leather | Real Leather (Full-Grain) |

|---|---|---|

| Cost (Per Sq. Ft) | $8.50 – $15.00 (Stable pricing; includes printing). Lower waste rates improve effective cost. | $12.00 – $35.00+ (Highly variable; excludes printing complexity). Significant waste (15-25%) increases effective cost. |

| Trwałość | Excellent surface abrasion resistance (50,000+ Martindale). Consistent performance. Resists stains, moisture, & UV fading. Printed layer is integral to surface. | Good structural integrity but variable surface wear. Prone to scratches, water stains, & color fading. Printing/dyeing wears unevenly; requires frequent conditioning. |

| Eco-Friendliness | High (WINIW Standard). Animal-free. Lower water/energy use in production (vs. tanning). Recyclable (specific grades). OEKO-TEX® certified (non-toxic). Traceable, closed-loop manufacturing. | Low-Moderate. Requires resource-intensive livestock farming & polluting chrome tanning (80%+ of leather). High water/land use. Non-recyclable at end-of-life. Toxic chemicals common in tanning/dyeing. |

Why WINIW Custom Printed Faux Leather is the Strategic B2B Choice

Choosing WINIW for custom printed synthetic leather delivers tangible advantages for your brand and bottom line:

- Accelerate Time-to-Market: Rapid digital printing enables quick sample iterations and low minimum order quantities (MOQs), ideal for trend-responsive collections.

- Enhance Brand Sustainability: Leverage verifiable eco-credentials (certifications, traceability) to meet consumer ESG expectations and comply with tightening regulations (e.g., EU Green Deal).

- Optimize Production Efficiency: Consistent material properties and high yields reduce waste, lower labor costs for finishing, and ensure predictable quality control.

- Future-Proof Your Supply Chain: Eliminate volatility linked to hide availability, tanning capacity, and ethical controversies inherent in the animal leather market.

WINIW partners with B2B clients to transform design visions into durable, sustainable, and commercially viable products. Our custom printed faux leather solutions offer the performance, ethics, and innovation required to lead in today’s conscious marketplace. Contact our technical team for sample kits and lifecycle assessment data.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, delivering innovative and sustainable materials to global markets. With a strong foundation in research, production excellence, and international compliance, WINIW supports B2B partners across industries such as fashion, automotive, furniture, and accessories.

Our manufacturing capabilities are anchored in a state-of-the-art facility spanning 100,000 square meters. This expansive production base integrates advanced automation and eco-conscious processing lines, enabling high-volume output without compromising quality or sustainability. The facility is designed to support flexible production cycles, ensuring timely delivery for large-scale orders and custom developments.

Key strengths of WINIW’s factory operations include:

- A dedicated R&D team of over 100 technical experts focused on material innovation, durability enhancement, and environmental performance. The team continuously develops new textures, functional properties (such as water resistance, abrasion resistance, and breathability), and sustainable formulations.

- Strict quality control protocols implemented throughout the production process. Each batch undergoes rigorous testing for color fastness, tensile strength, thickness consistency, and chemical compliance, meeting international standards including REACH, RoHS, and OEKO-TEX®.

- In-house testing laboratory equipped with advanced instrumentation for real-time quality monitoring and long-term performance validation.

- Environmentally responsible manufacturing practices, including low-VOC emissions, water-based PU systems, and waste reduction initiatives, aligning with global ESG goals.

WINIW exports to key markets worldwide, with established distribution and compliance in Europe and the USA. Our products are trusted by premium brands seeking durable, cruelty-free, and sustainable alternatives to genuine leather. With scalable production, technical expertise, and a commitment to quality, WINIW serves as a reliable long-term partner for B2B clients demanding performance and sustainability in synthetic leather solutions.

Contact Us for Samples

WINIW Premium Custom Printed Microfiber Leather: Elevate Your Brand with Sustainable Sophistication

WINIW leads the industry in high-performance, eco-conscious synthetic leather solutions designed for demanding B2B applications. Our proprietary microfiber technology delivers exceptional durability, aesthetic versatility, and a significantly reduced environmental footprint compared to traditional leather and inferior synthetics. We specialize in empowering brands to create truly unique products through our advanced custom printing capabilities—turning your vision into a tactile, market-differentiating reality.

Why Choose WINIW Custom Printed Microfiber Leather?

- Unmatched Customization: Achieve precise brand colors, intricate patterns, realistic textures (wood, stone, exotic grains), or exclusive digital designs directly integrated into the leather surface.

- Superior Performance: Engineered for longevity with high abrasion resistance (50,000+ double rubs), excellent color fastness, UV stability, and resistance to cracking, peeling, and staining.

- Eco-Certified Sustainability: Made from 60%+ recycled content (post-consumer PET bottles) and 100% solvent-free, water-based PU. OEKO-TEX® STANDARD 100 certified, REACH compliant, and free from harmful phthalates, AZO dyes, and heavy metals.

- Resource Efficiency: 90% less water usage and 70% lower CO2 emissions versus bovine leather production. Fully recyclable at end-of-life through our take-back program.

- B2B Production Ready: Optimized for seamless integration into high-volume manufacturing (upholstery, automotive, fashion accessories, case goods) with consistent roll-to-roll quality and standard widths (1.37m / 1.42m).

Technical Specifications: Standard vs. Custom Printed

| Property | Standard WINIW Microfiber | Custom Printed WINIW Microfiber | Test Method |

|---|---|---|---|

| Basis Weight (g/m²) | 350 – 650 | 380 – 680 | ISO 9073-1 |

| Thickness (mm) | 0.6 – 1.8 | 0.7 – 1.9 | ISO 2424 |

| Tensile Strength (N/5cm) | ≥ 200 (Warp), ≥ 180 (Weft) | ≥ 190 (Warp), ≥ 170 (Weft) | ISO 1766 |

| Color Fastness (Light) | Grade 5-6 | Grade 5 | ISO 105-B02 |

| Martindale Abrasion | ≥ 50,000 rubs | ≥ 45,000 rubs | ISO 12947-2 |

| Eco-Certifications | OEKO-TEX®, REACH, GRS | OEKO-TEX®, REACH, GRS | Third-Party Labs |

Applications Driving Market Success

- Premium Automotive Interiors: Custom-branded seat inserts, dash accents, and door panels with OEM durability.

- High-End Furniture: Signature upholstery fabrics for sofas, chairs, and headboards with exclusive designer prints.

- Luxury Accessories: Distinctive handbags, wallets, and watch straps featuring bespoke patterns and logos.

- Retail & Hospitality: Branded wall panels, reception desks, and lounge seating that reinforce identity.

- Tech & Electronics: Custom-cased tablets, laptop sleeves, and speaker covers with tactile, protective finishes.

Why WINIW Stands Apart in Sustainable Customization

We move beyond basic printing. Our digital sublimation and direct-to-substrate processes embed designs within the microfiber structure—not just on the surface—ensuring color integrity remains vibrant through years of use. Combined with our closed-loop water treatment and renewable energy-powered facilities, we deliver true cradle-to-cradle responsibility without compromising on performance or aesthetics.

Bring Your Vision to Life—Request Free Samples Today

Experience the texture, depth, and quality of WINIW Custom Printed Microfiber Leather firsthand. Our technical team will collaborate with you to optimize your design for production, ensuring flawless color matching and performance validation for your specific application.

→ Request Complimentary Samples & Technical Dossier:

Contact WINIW Marketing: MKT88@MicrofiberLeather.com

Specify your target application, required width, and preferred design concept for a tailored sample kit.

WINIW: Engineered Responsibility. Uncompromised Design. Your Sustainable Edge.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.