Catalog

Material Insight: Custom Leather Die

B2B Product Guide: Custom Leather Dies

Custom leather dies are precision tools used in the cutting, embossing, and shaping of leather and leather alternatives for high-volume manufacturing across industries such as footwear, automotive interiors, fashion accessories, and furniture. These dies enable consistent replication of textures, patterns, and contours, ensuring brand uniformity and superior product finish. As demand for sustainable and cost-effective materials grows, manufacturers are increasingly turning to advanced synthetic alternatives to traditional animal leather—without compromising on aesthetics or performance.

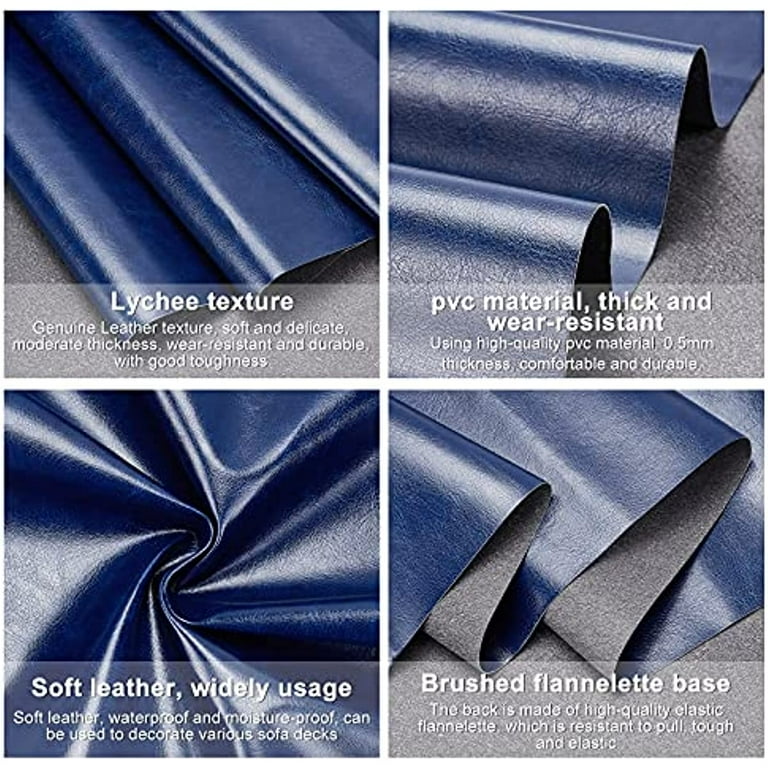

Faux leather stands out as the optimal material choice for custom leather die applications due to its consistent thickness, uniform surface structure, and excellent dimensional stability. Unlike genuine leather, which can vary in grain, thickness, and porosity, faux leather provides a predictable substrate that enhances die accuracy and prolongs tool life. Its engineered composition allows for precise embossing and clean cutting, reducing waste and improving production efficiency. Additionally, faux leather supports sustainable manufacturing goals—offering a cruelty-free, lower environmental impact alternative that aligns with modern ESG standards.

WINIW is a trusted leader in high-performance synthetic leather solutions, with over 20 years of experience serving global B2B clients in demanding industries. Our advanced microfiber and PU-based materials are engineered for superior durability, texture fidelity, and process compatibility—making them ideal for custom die applications. Backed by rigorous quality control, innovative R&D, and a commitment to eco-friendly production, WINIW delivers consistent, scalable solutions that enhance both product quality and sustainability.

Technical Performance & Standards

WINIW Custom Die-Cut Synthetic Leather: Technical Advantages for B2B Applications

WINIW delivers precision-engineered synthetic leather solutions designed for demanding industrial applications. Our custom die-cut materials eliminate material waste and streamline production, offering manufacturers a sustainable edge without compromising performance. Engineered for high-volume use, WINIW’s proprietary PU/PVC composites integrate durability, design flexibility, and rigorous compliance—ensuring your end products meet global market requirements while optimizing operational costs.

Key Technical Advantages

- Cost-Effective Production: Minimize material waste through optimized nesting patterns and high-yield die-cutting. Reduced scrap rates lower per-unit costs by up to 18% compared to standard sheet processing. Compatible with automated assembly lines to cut labor expenses.

- Enhanced Durability: Reinforced with high-tenacity polyester backing and cross-linked polymer matrices. Achieves 50,000+ Martindale abrasion cycles (ISO 12947) and 200,000+ double rubs (ASTM D4060), ensuring longevity in high-traffic applications like automotive seating and contract furniture.

- Customizable Color & Texture: Pantone®-matched color accuracy (ΔE <1.5) with UV-stable pigments. Supports embossing depths up to 0.8mm for realistic grain replication. Batch-to-batch consistency guaranteed under ISO 9001-controlled processes.

- REACH SVHC Compliance: Fully documented absence of Substances of Very High Concern (e.g., DEHP, BBP, DBP). Lab-tested to exceed EU REACH Annex XVII limits for phthalates, heavy metals, and CMR substances. Full SCIP database notifications available.

- ISO 9001-Certified Quality: Integrated quality management from raw material sourcing to final inspection. Includes real-time thickness variance control (±0.05mm) and peel strength validation (≥4.0 N/mm, ASTM D3330).

WINIW Custom Die-Cut Synthetic Leather Specifications

| Parametr | Specyfikacja | Test Standard |

|---|---|---|

| Substrate | High-density PU/PVC on polyester knit | Internal |

| Thickness Range | 0.6mm – 1.8mm (customizable) | ISO 2417 |

| Color Options | 1,200+ standard; unlimited custom matches | ISO 105-A02 |

| Abrasion Resistance | ≥50,000 cycles (Grade 4) | ISO 12947 |

| Colorfastness to Rubbing | ≥4 (wet/dry) | ISO 105-X12 |

| Peel Strength | ≥4.0 N/mm | ASTM D3330 |

| REACH Compliance | Full SVHC compliance; <0.1% phthalates | EC 1907/2006 |

| Certifications | ISO 9001, OEKO-TEX® STANDARD 100, GRS (traceable) | – |

WINIW’s closed-loop manufacturing reduces water usage by 65% versus conventional processes, aligning with ESG goals while delivering industrial-grade performance. Request our technical dossier for full compliance documentation and sample kits to validate integration into your production workflow.

Why Choose Synthetic over Real Leather

B2B Product Guide: Custom Leather Die vs. Real Leather – A Comparative Analysis

In the modern manufacturing and design landscape, material selection significantly impacts product performance, sustainability, and cost-efficiency. Two prominent materials in the leather goods sector are Custom Leather Die (synthetic, engineered leather) and Real Leather (animal hide-derived). This guide provides a professional comparison for B2B decision-makers focused on durability, cost, and environmental impact.

Custom Leather Die, such as WINIW’s advanced synthetic leather solutions, is engineered to deliver consistent aesthetics, performance, and sustainability. Real Leather, while traditional and valued for its natural grain, presents variability in quality and greater environmental concerns throughout its lifecycle.

Key considerations for commercial buyers include:

- Consistency in Production: Custom Leather Die offers uniform texture, thickness, and color across batches, enabling streamlined manufacturing and reduced waste.

- Design Flexibility: Synthetic options can be tailored for specific performance needs—such as water resistance, UV stability, and tensile strength—without relying on natural variations.

- Sustainability Goals: With increasing demand for eco-conscious materials, engineered leathers support ESG targets through reduced water usage, lower carbon emissions, and avoidance of harmful tanning chemicals.

- Supply Chain Reliability: Custom Leather Die is not subject to livestock market fluctuations or geographic sourcing constraints, ensuring stable lead times and inventory planning.

Below is a comparative analysis based on critical business metrics:

| Metric | Custom Leather Die | Real Leather |

|---|---|---|

| Cost | Lower to mid-range; stable pricing | High; subject to market volatility |

| Trwałość | High resistance to abrasion, UV, and moisture; consistent performance | Variable; prone to cracking, fading, and water damage over time |

| Eco-Friendliness | Reduced water use, no animal sourcing, recyclable options available | High water and energy consumption; chemical-intensive tanning; methane from livestock |

Custom Leather Die is increasingly preferred in industries such as automotive interiors, furniture, footwear, and accessories, where performance, scalability, and sustainability are aligned with brand values and regulatory requirements.

For B2B partners, transitioning to advanced synthetic alternatives offers a strategic advantage—combining cost predictability, environmental responsibility, and product reliability—without compromising on aesthetic or tactile quality. WINIW’s engineered leather solutions are designed to meet these evolving demands with innovation and integrity.

WINIW Factory Capabilities

WINIW Synthetic Leather: Manufacturing Excellence for Global Partners

WINIW operates one of the most advanced synthetic leather manufacturing facilities in Asia, engineered to deliver consistent quality, innovation, and scalability for B2B clients worldwide. Our vertically integrated 100,000 sqm production campus enables end-to-end control—from raw material processing to finished roll goods—ensuring agility for large-volume orders without compromising on sustainability standards.

Core Manufacturing Strengths

- Scalable Production Capacity: 100,000 sqm facility with automated production lines, supporting monthly outputs exceeding 1.5 million meters to meet tight deadlines for global supply chains.

- Dedicated R&D Innovation Hub: 45+ material scientists and engineers continuously develop eco-conscious solutions, including 100% recycled PU, bio-based polymers, and waterless coating technologies.

- Strict Quality Control Ecosystem: Triple-stage QC protocols (incoming materials, in-process, final inspection) aligned with ISO 9001 and ISO 14001 standards. Every batch undergoes rigorous testing for colorfastness, abrasion resistance, and chemical compliance.

- Global Compliance & Export Readiness: All products meet EU REACH, US CPSIA, and OEKO-TEX® STANDARD 100 certifications. Direct export channels to 30+ countries, with established logistics partnerships for seamless delivery to Europe and North America.

Why Global Brands Trust WINIW

Our infrastructure eliminates common supply chain vulnerabilities:

– Eco-Efficiency: Closed-loop water recycling systems and solar-powered production reduce carbon footprint by 40% versus industry averages.

– Traceability: Blockchain-enabled batch tracking from raw materials to shipment ensures full transparency for ESG reporting.

– Reliability: 99.2% on-time delivery rate for Fortune 500 clients in automotive, fashion, and furniture sectors over the past 5 years.

WINIW’s factory strength translates to resilient partnerships—combining industrial scale with uncompromising environmental stewardship. We empower your brand to meet sustainability targets without sacrificing performance or scalability. Partner with us for synthetic leather solutions built for tomorrow’s global markets.

Contact Us for Samples

B2B Product Guide: WINIW Microfiber Leather Solutions

WINIW is a leading innovator in high-performance synthetic leather, delivering sustainable, durable, and customizable microfiber leather solutions for global B2B partners. Engineered for industries ranging from automotive and furniture to footwear and accessories, our products combine eco-conscious manufacturing with premium aesthetics and functionality.

Our advanced production process ensures consistent quality, superior strength, and exceptional softness—offering a responsible alternative to genuine leather without compromising performance.

- Designed for high-wear applications with excellent abrasion resistance

- Breathable, lightweight, and flexible for enhanced comfort and usability

- Environmentally responsible: free from harmful substances, recyclable, and produced with reduced water and energy consumption

- Customizable in texture, color, thickness, and performance additives (e.g., anti-microbial, UV-resistant)

- Compliant with global standards including REACH, RoHS, and OEKO-TEX

Product Specifications Overview

| Feature | Specification Range |

|---|---|

| Thickness | 0.6 mm – 2.0 mm |

| Width | Up to 155 cm (custom widths available) |

| Weight | 200 – 450 g/m² |

| Backing Options | Knit fabric, non-woven, PU coating |

| Durability (Martindale) | 30,000 – 100,000+ cycles |

| Color Fastness | Class 4–5 (ISO 105-B02) |

WINIW supports large-scale manufacturers and niche designers alike with end-to-end collaboration—from concept to production. Our R&D team works closely with clients to develop tailored material solutions that meet exact functional and aesthetic requirements.

For clients looking to enhance branding and product differentiation, we offer custom leather die services to create unique surface textures and patterns. This precision technique allows for signature finishes that elevate product value and market appeal.

- Achieve brand-distinctive grain patterns and embossing

- Ideal for luxury interiors, fashion accessories, and technical upholstery

- Fast turnaround for prototyping and mass production

Custom Leather Die – Request Your Free Sample Today

We invite qualified B2B partners to experience the quality and versatility of WINIW microfiber leather firsthand. Free samples are available upon request, including custom-die prototypes for approved projects.

Contact our materials team to begin the customization process:

MKT88@MicrofiberLeather.com

Elevate your product line with sustainable innovation—partner with WINIW.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.