Introduction: Navigating the Global Market for leather jacket cowhide

Navigating the complexities of sourcing high-quality leather jacket cowhide can be a daunting task for international B2B buyers. With a global marketplace teeming with options, identifying reputable suppliers and ensuring the authenticity of the leather can pose significant challenges. This comprehensive guide addresses these hurdles by delving into the various types of cowhide leather jackets available, their applications across different industries, and effective strategies for vetting suppliers.

As buyers from Africa, South America, the Middle East, and Europe, including countries like Vietnam and Saudi Arabia, engage in this lucrative market, understanding the nuances of leather quality, pricing structures, and care requirements becomes paramount. This guide not only equips you with essential knowledge but also empowers you to make informed purchasing decisions that align with your business needs.

By exploring the factors influencing cost, the significance of leather grades, and the importance of proper maintenance, you will gain insights that enhance your sourcing strategy. Whether you’re looking to procure jackets for retail, fashion lines, or corporate gifts, this resource serves as your go-to reference for navigating the global market of leather jacket cowhide with confidence and success.

Table Of Contents

- Top 6 Leather Jacket Cowhide Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather jacket cowhide

- Understanding leather jacket cowhide Types and Variations

- Key Industrial Applications of leather jacket cowhide

- 3 Common User Pain Points for ‘leather jacket cowhide’ & Their Solutions

- Strategic Material Selection Guide for leather jacket cowhide

- In-depth Look: Manufacturing Processes and Quality Assurance for leather jacket cowhide

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather jacket cowhide’

- Comprehensive Cost and Pricing Analysis for leather jacket cowhide Sourcing

- Alternatives Analysis: Comparing leather jacket cowhide With Other Solutions

- Essential Technical Properties and Trade Terminology for leather jacket cowhide

- Navigating Market Dynamics and Sourcing Trends in the leather jacket cowhide Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather jacket cowhide

- Strategic Sourcing Conclusion and Outlook for leather jacket cowhide

- Important Disclaimer & Terms of Use

Understanding leather jacket cowhide Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Grain Cowhide | Retains the natural grain and imperfections; develops a rich patina over time. | High-end fashion brands, luxury retailers. | Pros: Exceptional durability, unique character. Cons: Higher price point. |

| Top Grain Cowhide | Sanded and buffed to remove imperfections; softer and more uniform appearance. | Mid-range fashion, everyday wear. | Pros: Good balance of quality and affordability. Cons: Less durable than full grain. |

| Corrected Grain | Made from lower-quality hides; surface is sanded and treated for uniformity. | Budget-friendly brands, fast fashion. | Pros: Cost-effective, appealing appearance. Cons: Less durable, may wear out quickly. |

| Bonded Leather | Made from scraps of leather bonded together; often coated for a leather-like appearance. | Promotional items, low-cost apparel. | Pros: Very affordable, lightweight. Cons: Not genuine leather, less longevity. |

| Vintage Cowhide | Distressed look, often pre-worn; typically full grain or top grain. | Niche fashion retailers, vintage markets. | Pros: Unique style, appeals to trendy consumers. Cons: Can be more expensive due to artisan craftsmanship. |

What are the Characteristics of Full Grain Cowhide Jackets?

Full grain cowhide is the highest quality leather available, characterized by its natural grain and imperfections. This type of leather ages beautifully, developing a unique patina that enhances its visual appeal over time. For B2B buyers, investing in full grain jackets can elevate brand prestige and cater to luxury markets, though the higher price point must be justified by the quality and durability offered.

How Does Top Grain Cowhide Compare to Full Grain?

Top grain cowhide is sanded and buffed to remove natural imperfections, resulting in a softer and more uniform appearance. It strikes a balance between quality and cost, making it suitable for mid-range fashion lines. B2B buyers should consider top grain for products targeting a broader audience, as it provides good durability and aesthetic appeal without the premium price of full grain leather.

Why Choose Corrected Grain Leather for Budget-Friendly Options?

Corrected grain leather is made from lower-quality hides that undergo extensive treatment to create a uniform surface. This type is ideal for budget-conscious brands looking to offer leather products at a lower price point. However, B2B buyers should be aware that while corrected grain may look appealing, it lacks the longevity and authenticity of higher-grade leather options.

What are the Benefits of Using Bonded Leather in Promotional Products?

Bonded leather is created from leather scraps that are bonded together, often coated to mimic genuine leather. It is an economical choice for promotional items and low-cost apparel. While it offers a leather-like appearance at a fraction of the price, B2B buyers should note that bonded leather lacks the durability and authenticity of real leather, which may affect customer satisfaction.

How Does Vintage Cowhide Appeal to Trendy Markets?

Vintage cowhide jackets are typically made from high-quality leather that has been intentionally distressed for a worn look. This style is particularly appealing to niche fashion retailers and vintage markets, as it resonates with consumers seeking unique and trendy items. B2B buyers should consider vintage options for their artisan craftsmanship and distinctive aesthetic, though pricing may be higher due to the specialized production process.

Key Industrial Applications of leather jacket cowhide

| Industry/Sector | Specific Application of leather jacket cowhide | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Production of high-end leather jackets | Enhances brand prestige and customer loyalty | Focus on full-grain quality, sourcing from reputable tanneries |

| Automotive | Upholstery for luxury vehicles | Provides durability and aesthetic appeal | Ensure compliance with automotive standards and regulations |

| Outdoor & Adventure Gear | Manufacturing of protective outdoor jackets | Offers weather resistance and longevity | Look for waterproof and breathable properties |

| Military & Tactical Gear | Design of tactical leather jackets | Ensures protection and functionality in the field | Verify material resilience and compliance with military specs |

| E-commerce & Retail | Online sales of custom leather jackets | Expands market reach and boosts sales potential | Consider logistics, shipping options, and customization capabilities |

How is Leather Jacket Cowhide Used in Fashion & Apparel?

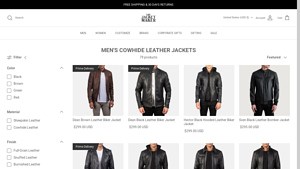

In the fashion and apparel industry, leather jacket cowhide is predominantly used to produce high-end leather jackets. These jackets not only serve a functional purpose but also enhance the brand’s prestige, appealing to consumers looking for luxury and durability. Buyers in this sector need to prioritize full-grain leather, which ages beautifully and develops a unique patina over time. Sourcing from reputable tanneries ensures quality and consistency, which is crucial in maintaining brand reputation.

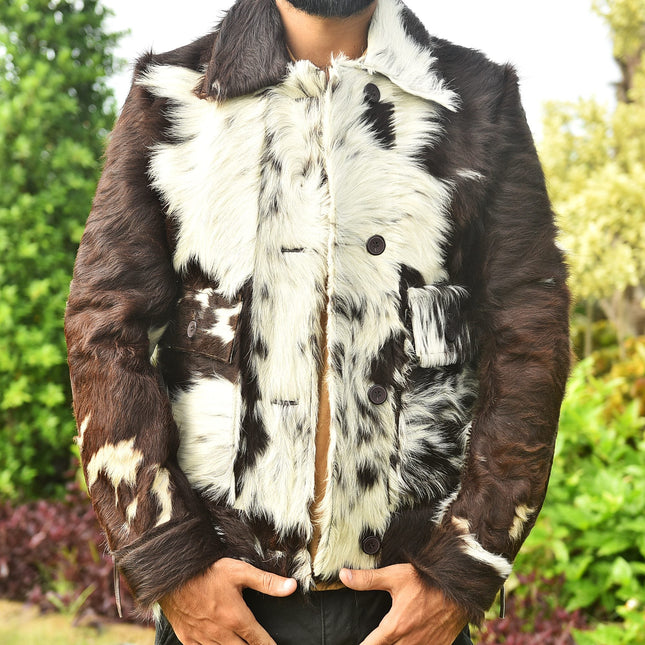

Illustrative image related to leather jacket cowhide

What Role Does Cowhide Play in Automotive Upholstery?

In the automotive sector, leather jacket cowhide is utilized for upholstery in luxury vehicles, providing a sophisticated aesthetic and long-lasting durability. The high-quality leather enhances the vehicle’s interior, making it more appealing to consumers. Buyers in this industry must ensure that the leather meets stringent automotive standards for safety and durability. Compliance with regulations related to emissions and material safety is also essential when sourcing cowhide for automotive applications.

How is Leather Jacket Cowhide Applied in Outdoor & Adventure Gear?

Outdoor and adventure gear manufacturers leverage leather jacket cowhide for protective jackets designed for various weather conditions. The inherent properties of cowhide, such as weather resistance and durability, make it an ideal choice for outdoor apparel. Buyers in this market should look for leather that offers both waterproof and breathable characteristics to ensure comfort during extended wear. Sourcing from suppliers who can guarantee these properties is vital for product performance.

What Benefits Does Cowhide Provide for Military & Tactical Gear?

In military and tactical applications, leather jacket cowhide is used to create durable and functional jackets that offer protection in challenging environments. The robust nature of cowhide ensures that these jackets can withstand wear and tear while providing the necessary mobility for personnel. Buyers must verify that the materials used comply with military specifications and standards to ensure optimal performance in the field. This includes checking the leather’s resilience to abrasions and environmental factors.

How Can E-commerce & Retail Benefit from Leather Jacket Cowhide?

E-commerce platforms and retail businesses often sell custom leather jackets made from cowhide, catering to a growing market for personalized apparel. This approach not only boosts sales potential but also expands market reach by appealing to diverse consumer preferences. When sourcing cowhide for this application, businesses should consider logistics and shipping options, especially for international markets. Additionally, the ability to offer customization options can set a retailer apart from competitors, making it crucial to partner with suppliers who can accommodate these needs.

3 Common User Pain Points for ‘leather jacket cowhide’ & Their Solutions

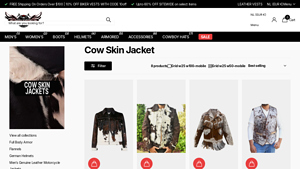

Scenario 1: Sourcing High-Quality Leather Jackets for Resale

The Problem: A B2B buyer from a retail chain in Africa is struggling to source high-quality cowhide leather jackets for their customers. They face challenges in distinguishing between various grades of leather and ensuring that the products meet the desired durability and aesthetic appeal. This uncertainty leads to concerns about customer satisfaction and potential returns, which can significantly impact their bottom line. With many suppliers offering low-quality alternatives at competitive prices, the buyer is torn between cost-effectiveness and quality assurance.

Illustrative image related to leather jacket cowhide

The Solution: To address this issue, the buyer should establish clear criteria for evaluating leather quality before engaging with suppliers. They should prioritize sourcing from manufacturers that provide detailed information about the leather’s grade, focusing on full-grain and top-grain options. Additionally, conducting factory visits or requesting samples will allow the buyer to assess the craftsmanship and durability firsthand. Building strong relationships with reputable suppliers can also facilitate better pricing without compromising quality. Utilizing industry certifications and standards as a benchmark will further aid in ensuring that the products meet both local and international quality expectations.

Scenario 2: Understanding Leather Care for Long-Term Investment

The Problem: A distributor in South America is concerned about the long-term maintenance of cowhide leather jackets. They have received feedback from retailers about the jackets showing signs of wear and tear, leading to customer dissatisfaction. The distributor worries that if the jackets do not hold up well over time, it could damage their reputation and affect future sales. The lack of comprehensive care guidelines from manufacturers complicates their ability to advise retailers and customers effectively.

The Solution: To mitigate this challenge, the distributor should collaborate with suppliers to obtain detailed care instructions that can be shared with retailers and consumers. These guidelines should cover essential maintenance practices, such as cleaning techniques, storage recommendations, and protective treatments. Providing this information as part of marketing materials can enhance customer confidence in the product. Additionally, the distributor could consider offering leather care products alongside the jackets, creating a bundled offering that promotes both sales and proper maintenance. Educating retailers on these care practices will empower them to provide better service, ultimately leading to increased customer satisfaction and loyalty.

Scenario 3: Navigating Sizing and Style Variability Across Markets

The Problem: A B2B buyer in the Middle East is facing issues with sizing and style variability of cowhide leather jackets when catering to diverse customer preferences. Different markets have varying expectations regarding fit and fashion trends, leading to inconsistent inventory turnover. The buyer is frustrated by excess stock of styles that do not resonate with local consumers, which ties up valuable resources and affects overall profitability.

The Solution: To effectively address these challenges, the buyer should conduct thorough market research to understand local fashion trends and sizing preferences. Partnering with local fashion consultants or leveraging data analytics can provide insights into popular styles and sizes in specific regions. The buyer should also consider offering a more diverse range of styles and customizable sizing options to cater to varying tastes. Implementing a feedback mechanism to gather insights from retailers and consumers can help refine inventory choices, ensuring that the product lineup aligns with market demands. By proactively adjusting their offerings based on customer preferences, the buyer can reduce excess inventory and improve sales efficiency.

Strategic Material Selection Guide for leather jacket cowhide

When selecting materials for leather jackets made from cowhide, international B2B buyers must consider various factors that influence product performance, cost, and compliance with regional standards. Below is an analysis of common materials used in cowhide leather jackets, focusing on their properties, advantages, disadvantages, and specific considerations for buyers from Africa, South America, the Middle East, and Europe.

Illustrative image related to leather jacket cowhide

What Are the Key Properties of Full Grain Cowhide Leather?

Full grain cowhide leather is the highest quality leather available, retaining the natural grain and imperfections of the hide. This material is known for its exceptional durability, breathability, and ability to develop a unique patina over time. Full grain leather can withstand significant wear and tear, making it suitable for jackets that are intended for long-term use. Additionally, it offers good thermal insulation, keeping the wearer warm in cooler climates.

What Are the Advantages and Disadvantages of Top Grain Cowhide Leather?

Top grain cowhide leather is slightly less durable than full grain but offers a more uniform appearance. This material is sanded and refinished to remove imperfections, making it ideal for those who prefer a sleek look. While it is still quite strong and resistant to wear, it may not develop the same depth of character as full grain leather. The cost of top grain leather is generally lower than that of full grain, but it may not provide the same longevity, which could be a consideration for buyers focused on long-term investment.

How Does Genuine Leather Compare in Terms of Suitability for Leather Jackets?

Genuine leather, often referred to as corrected grain leather, is made from the lower layers of the hide. It is more affordable but comes with significant trade-offs in terms of durability and aesthetic appeal. Genuine leather is typically less breathable and may not age as gracefully as higher-grade leathers. For buyers in regions where cost is a primary concern, genuine leather may be a suitable option, but it is essential to understand that it may not meet the same performance standards as full or top grain leather.

Illustrative image related to leather jacket cowhide

What Are the Implications of Using Bonded Leather for Leather Jackets?

Bonded leather is made from leftover scraps of leather that are bonded together with adhesives. This material is the least expensive and is often used in lower-quality products. While it can mimic the appearance of real leather, it lacks the durability and longevity of traditional leather options. For B2B buyers, particularly in emerging markets, bonded leather may be appealing due to its low cost, but it is crucial to consider the potential for increased replacement costs over time due to its inferior performance.

What Should International Buyers Consider When Selecting Leather Materials?

International buyers must be aware of compliance with local and international standards, such as ASTM, DIN, or JIS, which may dictate material quality and safety. Preferences for leather quality can vary significantly across regions; for instance, buyers in Europe may prioritize sustainability and ethical sourcing, while those in the Middle East may focus on luxury and durability. Understanding these regional preferences is vital for making informed purchasing decisions.

| Materiał | Typical Use Case for leather jacket cowhide | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full Grain Cowhide | High-end leather jackets | Exceptional durability and patina | Higher cost compared to other grades | High |

| Top Grain Cowhide | Fashion-forward leather jackets | Uniform appearance, good durability | Less character than full grain | Medium |

| Genuine Leather | Budget-friendly leather jackets | Lower cost | Less durable, may not age well | Low |

| Bonded Leather | Economical leather products | Very low cost | Poor durability and longevity | Low |

By understanding the properties and implications of these materials, B2B buyers can make informed decisions that align with their product goals and market demands.

Illustrative image related to leather jacket cowhide

In-depth Look: Manufacturing Processes and Quality Assurance for leather jacket cowhide

The production of high-quality leather jackets from cowhide involves a meticulous manufacturing process and stringent quality assurance measures. Understanding these processes is crucial for B2B buyers seeking reliable suppliers, particularly in regions such as Africa, South America, the Middle East, and Europe. This section provides an in-depth look at the key stages of manufacturing and the quality control mechanisms that ensure the final product meets international standards.

What Are the Main Stages of the Manufacturing Process for Cowhide Leather Jackets?

1. Material Preparation: How Is Cowhide Processed?

The manufacturing process begins with the selection and preparation of cowhide. This involves several critical steps:

- Sourcing: Quality cowhide is sourced from reputable tanneries that adhere to sustainable and ethical practices. The quality of the leather largely depends on the conditions in which the cows were raised and the processing methods used.

- Tanning: This step involves converting raw hides into durable leather. Common tanning methods include vegetable tanning and chrome tanning, each providing different characteristics to the leather. Vegetable tanning is environmentally friendly and results in a more natural finish, while chrome tanning is faster and produces more pliable leather.

- Conditioning: After tanning, the leather is conditioned to enhance its softness and flexibility. This step can involve the application of oils and waxes, which also contribute to the leather’s durability.

2. Forming: How Are Leather Jacket Patterns Created?

Once the cowhide is prepared, the next stage is forming, which includes:

- Pattern Making: Skilled artisans create patterns based on design specifications. These patterns dictate the cut of each leather piece, ensuring that they fit together seamlessly in the final product.

- Cutting: The leather is cut according to the patterns using precision cutting tools. This stage requires careful attention to detail to minimize waste and ensure consistency in size and shape.

- Stitching Preparation: Before assembly, edges are often treated to prevent fraying and ensure a polished look.

3. Assembly: What Techniques Are Used to Construct the Jackets?

The assembly stage is where the cut leather pieces come together to form the jacket. Key techniques include:

- Sewing: High-quality stitching is essential for durability. Double stitching is often employed in high-stress areas to reinforce seams.

- Fitting and Adjustment: Each jacket undergoes fitting adjustments to ensure that the final product meets design specifications and maintains comfort.

- Adding Hardware: Features such as zippers, buttons, and pockets are attached during this phase. The choice of hardware can significantly influence both aesthetics and functionality.

4. Finishing: How Is the Jacket Prepared for Market?

The finishing stage enhances the jacket’s appearance and durability. This involves:

- Dyeing and Treatment: Depending on the desired look, the leather may be dyed or treated with additional finishes to improve water resistance and sheen.

- Quality Inspection: Each jacket is inspected for defects, ensuring that only products meeting quality standards proceed to packaging.

- Final Packaging: Jackets are carefully packaged to prevent damage during shipping, often including care instructions for end-users.

What Quality Assurance Measures Are Implemented During Manufacturing?

International Standards: Which Quality Standards Should B2B Buyers Be Aware Of?

Quality assurance in the leather industry is vital, particularly for international B2B transactions. Key standards include:

- ISO 9001: This international standard outlines criteria for a quality management system, ensuring that manufacturers consistently meet customer and regulatory requirements. Compliance with ISO 9001 is a strong indicator of a supplier’s commitment to quality.

- CE Marking: Particularly relevant in the European market, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Certification: For suppliers dealing with specific industries, such as oil and gas, API certification may be necessary, ensuring products meet industry-specific standards.

Quality Control Checkpoints: What Are the Key Stages of QC?

Effective quality control involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial inspection assesses the quality of raw materials upon arrival at the facility. Only materials that meet quality specifications are allowed for production.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections ensure that the production process adheres to established standards and that any deviations are corrected immediately.

- Final Quality Control (FQC): Before packaging, finished products undergo thorough inspection to ensure they meet design and quality specifications. This includes checking for defects, measurements, and overall finish.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying the quality control processes of potential suppliers is essential. Here are some actionable steps:

- Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing and quality assurance processes. Buyers should request to see ISO certifications and audit reports to verify compliance with international standards.

- Request Quality Reports: Suppliers should be able to provide documentation of quality tests conducted on their products, including material specifications and testing results.

- Engage Third-Party Inspection Services: Utilizing third-party inspection services can offer an unbiased assessment of the manufacturing process and quality control measures, ensuring that the supplier adheres to the promised standards.

What Are the QC and Certification Nuances for International Buyers?

When engaging with suppliers from different regions, B2B buyers must be aware of certain nuances:

- Regional Standards: Different regions may have varying quality standards and certifications. Understanding these can help buyers ensure compliance and avoid potential trade barriers.

- Cultural Considerations: Different countries may have unique approaches to quality assurance and manufacturing practices. Building strong relationships with suppliers can facilitate better communication and understanding of quality expectations.

- Logistical Challenges: International shipping can complicate the quality assurance process. Buyers should consider the logistics of transporting goods and the potential for damage during transit. Proper packaging and labeling are essential to mitigate these risks.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for cowhide leather jackets equips B2B buyers with the knowledge needed to make informed purchasing decisions. By focusing on quality standards, inspection checkpoints, and the verification of supplier processes, buyers can ensure that they are sourcing high-quality products that meet international expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather jacket cowhide’

Wprowadzenie

This guide provides a practical checklist for B2B buyers looking to source high-quality cowhide leather jackets. As the market for leather goods continues to grow globally, understanding the nuances of sourcing, evaluating suppliers, and ensuring product quality is essential. This checklist will help streamline your procurement process and ensure you make informed decisions.

Step 1: Define Your Technical Specifications

Establish clear specifications for the leather jackets you intend to source. This includes determining the type of cowhide (e.g., full grain, top grain), desired styles (e.g., bomber, motorcycle), and any additional features (e.g., pockets, zippers). Defining these parameters will not only guide your supplier search but also ensure that the final product aligns with your brand’s vision and customer expectations.

Step 2: Research Market Trends

Understanding current market trends in leather jackets can provide insights into consumer preferences and pricing. Analyze factors such as popular styles, color palettes, and materials that are trending in your target regions (e.g., Africa, Europe). This knowledge will help you identify potential gaps in the market and tailor your offerings accordingly.

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, it’s crucial to conduct a thorough evaluation. Request company profiles, product catalogs, and references from other B2B buyers, especially those within your industry or geographical region. Pay attention to suppliers’ production capabilities, quality control processes, and their reputation in the market to ensure they meet your standards.

- Look for certifications: Verify if the supplier holds certifications related to quality management (e.g., ISO 9001) or sustainability (e.g., Leather Working Group certification).

- Assess production capacity: Ensure the supplier can meet your order quantities and timelines without compromising quality.

Step 4: Request Samples

Before placing a bulk order, always request samples of the leather jackets. This step allows you to assess the quality of the materials, craftsmanship, and overall fit. When evaluating samples, consider the texture, weight, and finish of the leather, as these factors contribute significantly to the product’s appeal.

Step 5: Negotiate Terms and Pricing

Once you’ve identified a suitable supplier, initiate negotiations on pricing, payment terms, and delivery schedules. Clear communication during this phase is vital to avoid misunderstandings later. Discuss minimum order quantities and any potential discounts for bulk purchases to optimize your costs.

- Be transparent about your budget: This will help suppliers provide options that align with your financial constraints.

- Inquire about warranty and return policies: Understanding these terms can protect your investment in case of defects or issues.

Step 6: Conduct Quality Assurance Checks

Establish a system for quality assurance checks upon receiving your order. This can include inspecting the leather for imperfections, ensuring that the jackets meet the specified dimensions, and checking for consistency in color and finish. Regular audits can help maintain product quality and supplier accountability.

Step 7: Plan for Ongoing Supplier Relationships

Building a strong relationship with your supplier can lead to more favorable terms and better collaboration over time. Maintain open lines of communication and provide feedback on product quality and delivery performance. Consider scheduling regular meetings to discuss potential improvements or new product developments.

By following this checklist, B2B buyers can navigate the complexities of sourcing cowhide leather jackets effectively, ensuring they procure high-quality products that satisfy their market’s demands.

Illustrative image related to leather jacket cowhide

Comprehensive Cost and Pricing Analysis for leather jacket cowhide Sourcing

What Are the Key Cost Components in Sourcing Cowhide Leather Jackets?

When sourcing cowhide leather jackets, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The type and quality of cowhide significantly influence pricing. Full-grain leather, known for its durability and aesthetic appeal, commands a higher price compared to lower grades. The sourcing of high-quality hides from reputable suppliers is critical.

-

Labor: Labor costs vary based on the region and the skill level required for crafting leather jackets. Artisans skilled in leatherwork may demand higher wages, but their expertise can lead to superior product quality.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, and indirect labor. Efficient manufacturing processes can help minimize overhead, impacting overall pricing.

-

Tooling: Initial setup and tooling costs for machinery and molds can be significant, especially for custom designs. These costs are often spread over the production run, influencing per-unit pricing.

-

Quality Control (QC): Implementing rigorous QC processes ensures that each jacket meets established standards. This may involve additional inspection costs but is crucial for maintaining a brand’s reputation.

-

Logistics: Transportation and shipping costs can vary widely depending on the origin of the materials and the destination market. International shipping may also introduce tariffs and customs fees.

-

Margin: Suppliers typically add a markup to cover their costs and desired profit. Understanding the typical margins in the leather goods industry can help buyers gauge fair pricing.

How Do Price Influencers Affect Leather Jacket Cowhide Costs?

Several factors can influence the pricing of cowhide leather jackets in B2B transactions:

-

Volume/MOQ: Minimum order quantities (MOQs) can greatly affect pricing. Larger orders typically yield lower per-unit costs due to economies of scale.

-

Specifications and Customization: Custom designs, colors, or additional features can drive up costs. Buyers should clearly define their specifications to receive accurate quotes.

-

Materials and Quality Certifications: Jackets made from certified materials (e.g., eco-friendly or ethically sourced) may carry a premium. Buyers should consider the importance of certifications in their sourcing decisions.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a proven track record may charge more but provide added assurance of quality and service.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international buyers. These terms define the responsibilities of buyers and sellers in shipping and logistics, affecting overall costs.

What Are Effective Buyer Tips for Cost-Efficient Sourcing of Leather Jackets?

B2B buyers can employ several strategies to ensure cost-effective sourcing of cowhide leather jackets:

-

Negotiation: Engage suppliers in discussions to negotiate better terms, especially for larger orders. Building a strong relationship can lead to favorable pricing and terms.

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the purchase price. Consider factors like durability, maintenance, and potential resale value to make informed purchasing decisions.

-

Pricing Nuances for International Buyers: International buyers should be aware of currency fluctuations, import duties, and local market conditions that may affect pricing. It’s advisable to conduct market research to understand competitive pricing in different regions.

-

Flexibility in Specifications: If possible, consider flexibility in design or material choices, as this can open up options for more cost-effective solutions.

-

Supplier Audits: Regularly auditing suppliers can ensure compliance with quality standards and help identify areas for cost savings.

Disclaimer on Indicative Prices

It is important to note that the prices associated with cowhide leather jackets can vary widely based on the aforementioned factors. Buyers are encouraged to conduct thorough market research and obtain multiple quotes to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing leather jacket cowhide With Other Solutions

Understanding Alternatives to Leather Jacket Cowhide

In the competitive market for outerwear, B2B buyers often seek alternatives to traditional materials, such as cowhide leather, to meet diverse consumer demands. While cowhide leather jackets are celebrated for their durability, aesthetic appeal, and timelessness, various alternatives exist that might better suit certain applications, target markets, or budget constraints. This section provides a comparative analysis of cowhide leather jackets against synthetic leather and canvas jackets, helping buyers make informed decisions.

Illustrative image related to leather jacket cowhide

Comparison Table

| Comparison Aspect | Leather Jacket Cowhide | Synthetic Leather | Canvas Jackets |

|---|---|---|---|

| Performance | High durability, excellent insulation, develops unique patina | Good durability, resistant to moisture, less breathable | Moderate durability, lightweight, breathable |

| Cost | Higher initial investment, generally $300-$600 | Mid-range, typically $100-$400 | Lower cost, usually $50-$200 |

| Ease of Implementation | Requires skilled craftsmanship for production | Easier to produce, can be mass-produced | Simple manufacturing process, widely available |

| Maintenance | Requires regular care and conditioning | Low maintenance, easy to clean | Easy to clean, machine washable |

| Best Use Case | Fashion-forward markets, luxury segments | Eco-conscious consumers, budget-friendly segments | Casual wear, outdoor activities, promotional uses |

Detailed Breakdown of Alternatives

Synthetic Leather

Synthetic leather, also known as faux leather, is made from plastic polymers and is designed to mimic the look and feel of genuine leather.

Pros:

– More affordable than cowhide, making it accessible to a wider audience.

– Resistant to water and stains, requiring minimal maintenance.

– Ethical choice for consumers concerned about animal welfare.

Cons:

– Generally less durable than cowhide; can wear out or tear more easily.

– Lacks the unique aging process of real leather, which can affect long-term appeal.

– May not provide the same level of insulation or breathability, impacting comfort in colder climates.

Canvas Jackets

Canvas jackets are made from heavy-duty cotton or linen fabric, often used for outdoor apparel.

Pros:

– Cost-effective option, appealing to budget-conscious consumers.

– Lightweight and breathable, making them suitable for warm climates or casual settings.

– Often machine washable, which simplifies care and maintenance.

Cons:

– Less durable than cowhide; prone to wear and tear over time.

– Offers limited insulation, which can be a drawback in colder environments.

– Lacks the premium aesthetic associated with leather, which may not appeal to high-end markets.

Conclusion: How to Choose the Right Solution for Your Needs

When evaluating alternatives to leather jacket cowhide, B2B buyers should consider their target market, budget constraints, and the intended use of the jackets. Cowhide leather remains a premium choice for luxury and fashion-focused segments, while synthetic leather provides a viable option for eco-conscious consumers looking for affordability. Canvas jackets, on the other hand, are ideal for casual wear and outdoor activities. By understanding the unique benefits and limitations of each material, buyers can strategically select the best solution to meet their specific needs and align with their brand values.

Essential Technical Properties and Trade Terminology for leather jacket cowhide

What Are the Key Technical Properties of Leather Jacket Cowhide?

Understanding the technical properties of cowhide used in leather jackets is crucial for B2B buyers, as these factors directly impact product quality, durability, and customer satisfaction. Here are some essential specifications to consider:

1. Material Grade

Cowhide leather is categorized into various grades, with full grain being the highest quality. Full grain leather retains the natural imperfections and characteristics of the hide, making it both durable and aesthetically appealing. For B2B buyers, selecting full grain cowhide ensures a product that ages well and develops a unique patina over time, which can enhance perceived value.

Illustrative image related to leather jacket cowhide

2. Tolerance Levels

Tolerance refers to the acceptable variations in leather thickness and quality. Typical cowhide thickness ranges from 1.1 to 1.5 mm. Understanding these tolerances is essential for manufacturers to maintain consistency in production and meet customer specifications. Buyers should seek suppliers who adhere to strict tolerance levels to ensure uniformity across their product lines.

3. Finish Type

The finish applied to cowhide can significantly affect its look and feel. Common finishes include aniline (dyed but not coated) and pigmented (dyed and coated), each offering different benefits. Aniline leather is softer and retains natural features, while pigmented leather is more durable and resistant to stains. Buyers should consider the intended use of the leather jacket when selecting the appropriate finish type.

4. Weight

The weight of cowhide leather can influence the jacket’s drape and comfort. Typically, heavier leathers (around 1.5 mm) are used for more rugged styles, while lighter leathers (around 1.1 mm) are often employed in fashion-forward designs. B2B buyers should align weight specifications with their target market’s preferences to ensure customer satisfaction.

Illustrative image related to leather jacket cowhide

5. Breathability

Breathability is a crucial property for leather jackets, particularly in warmer climates. Cowhide that has been properly processed retains its natural pores, allowing air circulation while still providing durability. For international buyers, especially in regions with varying climates, selecting breathable cowhide is vital for ensuring comfort and usability.

What Are Common Trade Terms Related to Leather Jacket Cowhide?

Navigating the leather industry requires familiarity with specific terminology. Here are some common terms that are essential for B2B transactions:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the leather industry, it often pertains to manufacturers who create leather goods for brands under their specifications. Understanding OEM relationships is vital for buyers looking to establish partnerships and ensure product quality.

2. MOQ (Minimum Order Quantity)

MOQ defines the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers as it affects inventory management and cost-efficiency. Knowing the MOQ helps businesses plan their purchasing strategy and manage cash flow effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing information on specific products. This process is essential for B2B buyers to compare costs and make informed purchasing decisions. Crafting a detailed RFQ ensures that suppliers provide accurate quotes tailored to the buyer’s needs.

Illustrative image related to leather jacket cowhide

4. Incoterms (International Commercial Terms)

Incoterms are a set of standardized trade terms used in international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for B2B buyers to mitigate risks and clarify obligations in cross-border transactions.

5. Lead Time

Lead time is the duration from placing an order to the delivery of the product. Understanding lead times is essential for effective inventory management and customer satisfaction. B2B buyers should consider lead times when planning their supply chain and marketing strategies.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing cowhide leather jackets, ultimately leading to better product offerings and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the leather jacket cowhide Sector

What are the Current Trends Influencing the Cowhide Leather Jacket Market?

The cowhide leather jacket market is experiencing a dynamic shift driven by several global factors. Firstly, the rise in consumer demand for high-quality, durable apparel is a significant driver. B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are increasingly seeking products that combine quality with style, emphasizing full-grain leather for its longevity and aesthetic appeal. This trend is supported by the growing popularity of vintage and retro styles, which often feature cowhide jackets as key fashion staples.

Another important trend is the integration of technology in sourcing and production processes. B2B platforms are enabling international buyers to connect directly with manufacturers, facilitating more transparent supply chains and reducing lead times. Innovations such as digital design tools and 3D modeling are also becoming prevalent, allowing for customized offerings that cater to specific market needs. Additionally, the rise of e-commerce has transformed traditional retail, prompting buyers to explore online channels for sourcing leather jackets, thus expanding their market reach.

Illustrative image related to leather jacket cowhide

Sustainability is increasingly shaping market dynamics, with buyers prioritizing eco-friendly materials and ethical manufacturing practices. This reflects a broader consumer trend towards sustainability, compelling manufacturers to adopt more responsible sourcing and production methods.

How is Sustainability Shaping the Sourcing of Cowhide Leather Jackets?

The environmental impact of leather production has become a critical concern in the cowhide leather jacket sector. Traditional tanning processes can be harmful to both the environment and public health, leading to a demand for more sustainable practices. B2B buyers are now prioritizing suppliers who can demonstrate a commitment to ethical sourcing and environmental stewardship. This includes using vegetable-tanned leather, which is less harmful than chrome-tanned options, and implementing waste reduction practices throughout the production cycle.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing the sourcing of raw materials, seeking certifications that guarantee humane treatment of livestock and fair labor practices. Certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) are becoming essential for suppliers looking to appeal to conscientious buyers. These certifications not only enhance brand reputation but also cater to a growing segment of consumers who prefer products that align with their values.

In addition, the push for circular economy practices is gaining traction, with initiatives aimed at recycling and upcycling leather products. B2B buyers are encouraged to explore partnerships with manufacturers who embrace these sustainable practices, as they can enhance product value and appeal to environmentally-conscious consumers.

What is the Historical Context of Cowhide Leather Jackets in the B2B Market?

The use of cowhide leather for jackets has a rich history that dates back centuries, rooted in practicality and durability. Initially, leather jackets were predominantly worn by military personnel and aviators for their protective qualities. Over time, these functional garments transitioned into fashion statements, gaining popularity in the mid-20th century with the rise of subcultures such as motorcycle and rock ‘n’ roll communities.

As the global market expanded, so did the variety and styles of cowhide leather jackets, catering to diverse consumer preferences. This evolution has laid the groundwork for the contemporary market, where quality and craftsmanship are paramount. Today’s international B2B buyers benefit from this rich heritage, as they seek to source jackets that not only offer durability but also tell a story, appealing to modern consumers’ desires for authenticity and style.

By understanding these dynamics, B2B buyers can navigate the cowhide leather jacket market more effectively, identifying opportunities that align with current trends and consumer demands.

Frequently Asked Questions (FAQs) for B2B Buyers of leather jacket cowhide

-

How do I assess the quality of cowhide leather jackets for my business?

To evaluate the quality of cowhide leather jackets, focus on several key factors: grade, appearance, texture, and price. Full grain leather is the highest quality, while lower grades include genuine and bonded leather. Inspect the surface for natural imperfections, which indicate authenticity. High-quality leather should feel soft and pliable, with slight flexibility when pressed. Finally, be wary of prices that seem too low; they often signal lower quality. Request samples from suppliers to make informed decisions. -

What is the best type of cowhide leather for jackets in various markets?

The best type of cowhide leather for jackets largely depends on your target market and customer preferences. Full grain leather is preferred for its durability and unique aging characteristics, making it ideal for high-end markets in Europe and the Middle East. For budget-conscious consumers in Africa or South America, top grain leather may be more appropriate as it offers a balance of quality and affordability. Consider regional climate and style preferences when choosing the leather type. -

What are the common minimum order quantities (MOQs) for cowhide leather jackets?

Minimum order quantities (MOQs) for cowhide leather jackets can vary widely based on the supplier and the customization involved. Typically, MOQs range from 50 to 300 units per style, but some manufacturers may accept lower quantities for initial orders or samples. It’s advisable to discuss MOQs upfront with potential suppliers to ensure they align with your business needs and budget. -

How can I customize cowhide leather jackets for my brand?

Customization options for cowhide leather jackets often include alterations in design, color, size, and branding elements like logos. When sourcing from suppliers, inquire about their customization capabilities and processes. Many manufacturers offer bespoke services, but ensure you have clear specifications and a design template to avoid miscommunication. Additionally, factor in lead times for custom orders, as they may extend delivery schedules. -

What payment terms should I expect when sourcing cowhide leather jackets internationally?

Payment terms can differ significantly among suppliers, but common practices include a deposit of 30% upfront and the remaining 70% prior to shipment. Some suppliers may offer payment through letters of credit or escrow services for added security. Always negotiate terms that protect your interests while remaining competitive. It’s advisable to establish a payment schedule that aligns with your cash flow and operational needs. -

How do I vet suppliers for cowhide leather jackets?

Vetting suppliers is crucial to ensure quality and reliability. Begin by researching potential suppliers through trade shows, online directories, and industry referrals. Request references and check reviews to assess their reputation. Additionally, ask for product samples and certifications that verify their leather quality and ethical sourcing practices. Conducting a factory visit, if feasible, can provide further insights into their production capabilities and standards. -

What logistics considerations should I keep in mind when importing cowhide leather jackets?

When importing cowhide leather jackets, consider shipping methods, customs regulations, and potential tariffs. Work with experienced freight forwarders familiar with your target markets to streamline the logistics process. Ensure that all required documentation, such as commercial invoices and certificates of origin, is prepared to avoid delays at customs. Additionally, assess insurance options for shipments to safeguard against potential loss or damage during transit. -

How can I ensure quality assurance (QA) for cowhide leather jackets?

To ensure quality assurance for cowhide leather jackets, establish clear quality standards and inspection protocols with your suppliers. Implement a pre-shipment inspection process to verify that the products meet your specifications before they leave the factory. Consider hiring third-party quality control services, especially for larger orders. Regular communication with suppliers during production can also help address any issues early on and maintain product quality.

Top 6 Leather Jacket Cowhide Manufacturers & Suppliers List

1. Buffalo Jackson – Legacy Men’s Leather Jacket

Domain: buffalojackson.com

Registered: 2011 (14 years)

Introduction: Buffalo Jackson offers a range of cow leather jackets for men, crafted from full grain leather, which is the highest quality leather available. The jackets are designed to develop a unique patina over time, enhancing their character. Key products include the Legacy men’s leather jacket, a vintage-inspired flight jacket made from brown full grain cow leather, featuring zippered sleeve cuffs, chest …

2. The Jacket Maker – Full-Grain Leather Jackets

Domain: thejacketmaker.com

Registered: 2013 (12 years)

Introduction: Full-grain Cowhide Leather Jackets for Men, Free Shipping, 30 Days Returns, Size Chart Updated, Various Styles Available: Bomber Jackets, Biker Jackets, Hooded Leather Jackets, Leather Vests, Leather Coats, Leather Blazers, Aviator Jackets, Winter Coats, Trench Coats, and more. Price Range: $220 to $395. Customization options available. Multiple colors and finishes: Black, Brown, Green, Red; Full-…

3. MARA Leather – Cowhide Jackets Collection

Domain: maraleatherstore.com

Registered: 2022 (3 years)

Introduction: Cow Skin Jacket – MARA Leather

– Types: Men’s Genuine Cowhide Skin Leather Motorcycle Jacket, Men’s Cowhide Leather Jacket Genuine Pony Skin, Men’s Cowhide Western Fringe Jacket, Men’s Hair On Cowhide Vest, Men’s Cow Skin Hair On Brown Leather Vest, Men’s White Hair On Cowhide Jacket, Men’s Hair On Pony Skin Leather Jacket, Men’s Hair On Cowhide Leather Jacket.

– Price Range: €162,95 – €289,95.

– …

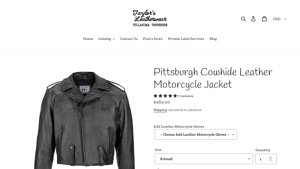

4. Taylor’s Leatherwear – Pittsburgh Cowhide Leather Motorcycle Jacket

Domain: taylorsleatherwear.com

Registered: 1997 (28 years)

Introduction: Product Name: Pittsburgh Cowhide Leather Motorcycle Jacket

Brand: Taylor’s Leatherwear, Inc.

Price: $489.00

Best Seller: Yes

Original Use: Worn by the Pittsburgh PA Police Department

Material: Soft and Durable Top Grain Leather (Drum Dyed Black Cowhide)

Lining: 3M™ Thinsulate™ Zip-out Quilted Liner

Style Name: Pittsburgh

Style Number: 4473Z

Length of Size Large Regular: Approx 25″

Cechy:

– All …

5. Aero Leather – Horsehide & Cowhide Jackets

Domain: aeroleatherclothing.com

Registered: 1997 (28 years)

Introduction: Horsehide and cowhide are two popular types of leather used for jackets. Cowhide is more widely available, flexible, lighter in weight, and has more natural blemishes. It comes from female cows used for breeding or milk production. Horsehide is less common, known for its strength, durability, and abrasion resistance, with significant variations in thickness and unusual grain patterns. Horsehide ha…

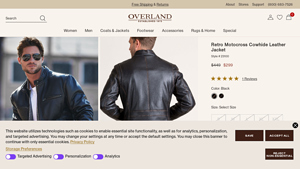

6. Overland – Retro Motocross Cowhide Leather Jacket

Domain: overland.com

Introduction: Retro Motocross Cowhide Leather Jacket, Model: 23100, Material: Cowhide leather, Features: Classic design, Durable construction, Suitable for motocross and casual wear, Available sizes: S, M, L, XL, Color options: Black, Brown, Care instructions: Professional leather clean only.

Strategic Sourcing Conclusion and Outlook for leather jacket cowhide

The strategic sourcing of cowhide for leather jackets is pivotal for international B2B buyers aiming to enhance product quality and market competitiveness. By prioritizing high-grade full grain leather, businesses can ensure that their offerings not only meet consumer expectations for durability and aesthetics but also stand out in a crowded marketplace. Understanding the nuances of leather quality—such as the differences between full grain and lower-grade alternatives—enables buyers to make informed purchasing decisions that align with their brand values and target demographics.

Moreover, effective sourcing strategies should incorporate sustainable practices and strong supplier relationships. This not only mitigates risks related to supply chain disruptions but also appeals to the growing consumer demand for ethically sourced materials. As markets in Africa, South America, the Middle East, and Europe continue to evolve, there is a significant opportunity for businesses to leverage these insights for growth.

Illustrative image related to leather jacket cowhide

Looking ahead, international buyers are encouraged to embrace innovative sourcing solutions and explore emerging markets. By doing so, they can position themselves at the forefront of the leather goods industry, driving both profitability and sustainability. Engage with reliable suppliers today to secure a competitive edge in the dynamic landscape of leather jacket cowhide production.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.