Introduction: Navigating the Global Market for yellow faux leather fabric

In the ever-evolving landscape of international trade, sourcing high-quality yellow faux leather fabric presents a unique set of challenges for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. With the demand for vibrant, durable, and cost-effective materials on the rise, businesses must navigate a market filled with options that vary significantly in quality, pricing, and supplier reliability. This guide aims to empower international buyers by providing a comprehensive overview of yellow faux leather fabric, including its diverse types, practical applications, and key considerations for supplier vetting.

From upholstery in the furniture industry to fashion accessories and automotive interiors, yellow faux leather is increasingly popular for its aesthetic appeal and versatility. Buyers will find insights into the latest trends, material specifications, and maintenance requirements that can significantly impact their purchasing decisions. Additionally, this guide will cover essential factors such as cost analysis, import regulations, and sustainability practices, equipping businesses with the knowledge to make informed choices that align with their operational needs.

By addressing these critical aspects, this resource serves as a valuable tool for B2B buyers looking to enhance their sourcing strategies and establish long-term partnerships in the global market for yellow faux leather fabric.

Table Of Contents

- Top 7 Yellow Faux Leather Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for yellow faux leather fabric

- Understanding yellow faux leather fabric Types and Variations

- Key Industrial Applications of yellow faux leather fabric

- 3 Common User Pain Points for ‘yellow faux leather fabric’ & Their Solutions

- Strategic Material Selection Guide for yellow faux leather fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for yellow faux leather fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘yellow faux leather fabric’

- Comprehensive Cost and Pricing Analysis for yellow faux leather fabric Sourcing

- Alternatives Analysis: Comparing yellow faux leather fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for yellow faux leather fabric

- Navigating Market Dynamics and Sourcing Trends in the yellow faux leather fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of yellow faux leather fabric

- Strategic Sourcing Conclusion and Outlook for yellow faux leather fabric

- Important Disclaimer & Terms of Use

Understanding yellow faux leather fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PVC Faux Leather | Made from polyvinyl chloride, durable, easy to clean | Upholstery, automotive interiors, bags | Pros: Cost-effective, versatile; Cons: Less breathable than genuine leather. |

| PU Faux Leather | Polyurethane-based, softer feel, more environmentally friendly | Fashion apparel, upholstery, accessories | Pros: Softer texture, more eco-friendly; Cons: Generally higher cost than PVC. |

| Mustard Yellow Faux Leather | Specific color variant, often thicker, resistant to wear | Furniture, automotive interiors, fashion | Pros: Attractive color, durable; Cons: Limited availability in some markets. |

| Embossed Faux Leather | Features raised patterns, adds texture and visual appeal | Fashion items, upholstery, decorative accents | Pros: Unique designs, enhances aesthetics; Cons: May be pricier due to design complexity. |

| Marine Vinyl Faux Leather | Waterproof, UV resistant, durable for outdoor use | Marine applications, outdoor furniture | Pros: Ideal for outdoor settings, easy maintenance; Cons: Heavier than other types. |

What are the Characteristics and Suitability of PVC Faux Leather?

PVC faux leather is a synthetic material made from polyvinyl chloride, known for its durability and ease of maintenance. This type is highly resistant to scratches and wear, making it suitable for high-traffic environments such as upholstery for furniture and automotive interiors. When purchasing PVC faux leather, buyers should consider its thickness and texture, as these factors can affect its overall quality and longevity. It is a cost-effective solution, especially for projects requiring bulk materials.

How Does PU Faux Leather Differ from Other Types?

PU faux leather, or polyurethane faux leather, offers a softer and more luxurious feel compared to PVC. It is considered a more environmentally friendly option as it does not contain harmful chemicals found in some PVC products. PU is ideal for fashion apparel and accessories, where a high-end look is essential. Buyers should consider the intended use when selecting PU faux leather, as its softness can make it less durable for heavy-duty applications, but it excels in aesthetic appeal.

What Makes Mustard Yellow Faux Leather Unique?

Mustard yellow faux leather is a specific color variant that stands out for its vibrant hue and thickness. This type is often used in furniture and automotive applications, where color plays a significant role in design. Its resistance to wear and tear makes it a practical choice for upholstery. Buyers should be aware of regional availability, as certain color variants may be less common in some markets, potentially impacting sourcing and supply chain logistics.

Why Choose Embossed Faux Leather for Decorative Uses?

Embossed faux leather features raised patterns that add texture and visual appeal, making it a popular choice for fashion items and decorative upholstery. This type enhances the aesthetic value of products, allowing businesses to differentiate themselves in a competitive market. However, embossed faux leather can be pricier due to the complexity of its manufacturing process. Buyers should weigh the benefits of unique designs against their budget constraints when considering this option.

What are the Benefits of Marine Vinyl Faux Leather?

Marine vinyl faux leather is specifically designed to withstand outdoor conditions, being both waterproof and UV resistant. This makes it an excellent choice for marine applications and outdoor furniture. Its durability and ease of maintenance are significant advantages for businesses looking to invest in long-lasting materials. However, its heavier weight compared to other faux leather types may influence shipping costs and handling, which buyers should factor into their purchasing decisions.

Key Industrial Applications of yellow faux leather fabric

| Industry/Sector | Specific Application of yellow faux leather fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for sofas and chairs | Durable and easy-to-clean material enhances longevity and aesthetics of furniture. | Ensure compliance with local regulations on materials; assess colorfastness and stain resistance. |

| Automotive | Interior trim and seat covers | Offers a premium look at a lower cost compared to genuine leather while being easy to maintain. | Evaluate UV resistance and wear properties for automotive applications. |

| Fashion and Apparel | Clothing items and accessories | Provides a stylish, eco-friendly alternative to leather, appealing to environmentally conscious consumers. | Consider flexibility and breathability for garments; assess color variations and texture. |

| Medical Equipment | Upholstery for medical chairs and equipment | Easy to sanitize, durable, and resistant to wear, ensuring hygiene in medical settings. | Focus on antimicrobial properties and compliance with health regulations in target markets. |

| Event and Exhibition Design | Decorative elements for booths and displays | Bright colors like yellow can attract attention, enhancing brand visibility and engagement. | Check for lightweight options and ease of installation; assess durability for repeated use. |

How is Yellow Faux Leather Fabric Used in Furniture Manufacturing?

In the furniture manufacturing sector, yellow faux leather fabric is extensively utilized for upholstering sofas, chairs, and other seating options. Its durability and ease of cleaning make it a preferred choice for both residential and commercial furniture. This fabric effectively solves the problem of maintaining aesthetic appeal while ensuring longevity, making it ideal for high-traffic environments such as hotels and restaurants. For international buyers, sourcing considerations include ensuring compliance with local regulations regarding materials and assessing the fabric’s colorfastness and stain resistance to meet market demands.

What Role Does Yellow Faux Leather Play in Automotive Interiors?

In the automotive industry, yellow faux leather fabric is commonly used for interior trim, seat covers, and door panels. This synthetic material offers a luxurious appearance at a fraction of the cost of genuine leather, appealing to manufacturers looking to balance quality with affordability. Additionally, its ease of maintenance helps vehicle owners keep interiors looking pristine. Buyers should consider the fabric’s UV resistance and wear properties, especially in regions with intense sunlight, to ensure the longevity of the vehicle’s interior.

Why Choose Yellow Faux Leather for Fashion and Apparel?

The fashion and apparel industry increasingly embraces yellow faux leather fabric for clothing items and accessories. Its stylish look, combined with being an eco-friendly alternative to traditional leather, resonates with consumers who prioritize sustainability. This fabric can be used in jackets, skirts, and bags, offering versatility in design. Buyers should evaluate the fabric’s flexibility and breathability to ensure comfort in garments, as well as assess color variations and texture to align with current fashion trends.

How is Yellow Faux Leather Beneficial in Medical Equipment?

In the medical equipment sector, yellow faux leather fabric is utilized for the upholstery of medical chairs and equipment. Its properties make it easy to sanitize, durable, and resistant to wear, which is crucial in maintaining hygiene standards in healthcare settings. This fabric addresses the need for materials that can withstand the rigors of daily use while remaining visually appealing. International buyers must focus on the fabric’s antimicrobial properties and ensure compliance with health regulations specific to their markets.

What Are the Advantages of Using Yellow Faux Leather in Event Design?

Yellow faux leather fabric finds application in event and exhibition design, where it is used for decorative elements in booths and displays. Its vibrant color can attract attention, enhancing brand visibility and engagement at trade shows and events. This fabric is lightweight and easy to handle, making it ideal for temporary installations. Buyers should check for options that are durable enough for repeated use and assess the ease of installation to ensure a smooth setup process for events.

3 Common User Pain Points for ‘yellow faux leather fabric’ & Their Solutions

Scenario 1: Difficulty in Matching Color and Texture for Upholstery Projects

The Problem: B2B buyers often face challenges when sourcing yellow faux leather fabric that matches their specific project needs, particularly in terms of color and texture. For instance, a furniture manufacturer in Nigeria might require a specific shade of mustard yellow that aligns with their branding and existing products. However, the variability in dye lots and finishes can lead to discrepancies in color and texture, making it difficult to achieve a cohesive look across multiple items.

The Solution: To mitigate this issue, buyers should consider requesting fabric samples before making bulk purchases. Suppliers often provide small swatches that can be evaluated in the intended environment. Additionally, establishing a strong communication line with suppliers about specific requirements, including color codes or Pantone references, can ensure better alignment. Implementing a quality control process upon receiving shipments can also help identify any mismatches early, allowing for timely resolutions.

Scenario 2: Concerns About Durability and Maintenance of Yellow Faux Leather

The Problem: Another common pain point for B2B buyers is the concern over the durability and maintenance of yellow faux leather fabric, particularly in high-traffic applications like automotive interiors or public seating areas. Buyers may fear that the fabric will wear down quickly or become discolored, which can lead to increased costs and customer dissatisfaction.

The Solution: Buyers should prioritize sourcing yellow faux leather that is specifically labeled as durable and easy to clean. Look for materials that feature protective coatings or treatments, such as UV resistance and scratch resistance. Additionally, investing in a thorough understanding of the fabric care instructions is crucial. Suppliers can often provide cleaning guidelines tailored to the fabric type, which can significantly extend the lifespan of the upholstery. Consider conducting tests on a small scale before committing to larger orders to ensure that the material meets durability expectations.

Scenario 3: Navigating Supply Chain and Import Challenges with Yellow Faux Leather

The Problem: B2B buyers, particularly those in regions like South America or the Middle East, may encounter significant supply chain disruptions when importing yellow faux leather fabric. Delays, fluctuating prices, and customs complications can complicate project timelines and budgets, leading to frustration and potential loss of business.

The Solution: To navigate these challenges, buyers should establish relationships with multiple suppliers to create a more resilient supply chain. Diversifying sourcing options can reduce dependence on a single supplier and improve flexibility. Additionally, working with local distributors who understand regional logistics can streamline the import process. Buyers should also stay informed about international trade regulations and tariffs that may affect costs. Utilizing technology for real-time tracking of shipments can help manage expectations and improve communication with stakeholders involved in the project.

Strategic Material Selection Guide for yellow faux leather fabric

When selecting yellow faux leather fabric for various applications, it is crucial to understand the different materials available and their respective properties. This analysis focuses on three common materials used in yellow faux leather production: PVC (Polyvinyl Chloride), PU (Polyurethane), and Microfiber. Each material offers unique advantages and disadvantages that can significantly influence the decision-making process for B2B buyers, especially in diverse markets such as Africa, South America, the Middle East, and Europe.

What Are the Key Properties of PVC Faux Leather?

PVC faux leather is widely recognized for its affordability and durability. It typically features a thickness of around 0.8 mm and can withstand temperatures ranging from -20°C to 60°C. Its resistance to moisture makes it suitable for both indoor and outdoor applications. However, PVC is less flexible than other materials, which may limit its use in applications requiring high elasticity.

Pros: PVC is cost-effective, easy to clean, and resistant to wear and tear, making it ideal for upholstery in furniture and automotive sectors.

Cons: Its rigidity can be a drawback for applications needing flexibility, and it may not be as environmentally friendly as other options.

How Does PU Faux Leather Compare in Performance?

PU faux leather is another popular choice, known for its soft texture and high-end appearance. It offers better breathability than PVC, making it suitable for apparel and furniture that require comfort. PU leather can typically endure temperatures from -10°C to 50°C and has a good resistance to tearing and abrasion.

Pros: PU is more environmentally friendly than PVC and provides a luxurious feel, making it ideal for high-end applications.

Cons: It is generally more expensive than PVC and may require more careful maintenance to prevent wear over time.

Why Consider Microfiber Faux Leather for Your Projects?

Microfiber faux leather is composed of ultra-fine synthetic fibers, offering exceptional durability and a soft, suede-like feel. It is highly resistant to stains and is easy to clean, making it suitable for various applications, including upholstery, clothing, and accessories. Microfiber can withstand temperatures from -20°C to 60°C and is often preferred for its lightweight properties.

Pros: Microfiber is highly durable, lightweight, and offers a premium look and feel, making it suitable for luxury markets.

Cons: It can be more expensive than both PVC and PU, and its manufacturing process may be more complex, potentially affecting lead times.

What Are the Specific Considerations for International B2B Buyers?

International buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should consider compliance with local standards such as ASTM, DIN, and JIS. For example, buyers in Nigeria and Saudi Arabia may have specific regulations regarding the use of materials in upholstery and automotive applications. Additionally, understanding the local market preferences for material properties, such as durability, ease of maintenance, and aesthetic appeal, is crucial for successful procurement.

Summary Table of Material Selection for Yellow Faux Leather Fabric

| Materiał | Typical Use Case for yellow faux leather fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Upholstery, automotive interiors | Cost-effective and durable | Less flexible, environmental concerns | Low |

| PU | Apparel, high-end furniture | Luxurious feel and better breathability | More expensive, requires careful maintenance | Medium |

| Mikrofibra | Luxury upholstery, clothing, accessories | Highly durable and lightweight | Higher cost, complex manufacturing process | High |

In conclusion, understanding the properties, advantages, and limitations of different faux leather materials is essential for B2B buyers. By considering these factors, businesses can make informed decisions that align with their product requirements and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for yellow faux leather fabric

What Are the Key Manufacturing Processes for Yellow Faux Leather Fabric?

The production of yellow faux leather fabric involves several critical stages that ensure the final product meets quality and performance standards. Understanding these stages can help B2B buyers assess potential suppliers and their capabilities.

1. Material Preparation: What Raw Materials Are Used?

The primary raw materials for yellow faux leather are polyvinyl chloride (PVC) or polyurethane (PU). PVC is often favored for its durability and cost-effectiveness, while PU offers a more environmentally friendly option with a softer feel.

The manufacturing process begins with the preparation of these materials, which may include mixing with additives like plasticizers and stabilizers to enhance flexibility and longevity. The color yellow is introduced through dyeing or pigmentation processes, which can be done during the mixing phase or applied later.

2. Forming: How Is Faux Leather Created?

Once the materials are prepared, the next stage is forming. This involves the extrusion of the PVC or PU mixture into sheets. The sheets are then embossed with patterns or textures to mimic genuine leather, adding aesthetic appeal.

Advanced techniques like calendaring are often used in this stage, where the material is passed through rollers to achieve the desired thickness and finish. The thickness typically ranges from 0.5 mm to 2 mm, depending on the intended application, whether for upholstery, apparel, or accessories.

3. Assembly: What Steps Are Taken to Create the Final Product?

After forming, the faux leather sheets are cut into specific shapes and sizes based on customer requirements. This stage may involve sewing or bonding the fabric to other materials, such as foam or lining, to enhance comfort and durability.

Automated cutting machines are frequently employed for precision, ensuring that each piece meets the required specifications. Additionally, ultrasonic welding techniques may be utilized for seamless bonding, particularly in applications where aesthetics are paramount, such as fashion and automotive interiors.

4. Finishing: How Is the Faux Leather Enhanced?

The finishing stage involves applying coatings or treatments to improve the fabric’s performance characteristics. This can include water-resistant coatings, UV protection, or anti-scratch treatments.

The finishing process also encompasses quality checks to ensure that the fabric meets industry standards. The final product is then rolled or folded and prepared for shipment, with attention to packaging that preserves quality during transport.

What Quality Assurance Practices Are Important for Faux Leather Manufacturing?

Quality assurance is a critical component of the manufacturing process for faux leather fabric. It ensures that the products meet international standards and customer expectations.

International Standards: Which Certifications Should B2B Buyers Look For?

B2B buyers should look for suppliers that comply with international quality management standards, such as ISO 9001. This certification indicates that the manufacturer has established quality management systems in place to consistently produce high-quality products.

In addition to ISO certifications, industry-specific certifications like CE (Conformité Européenne) for safety and environmental standards, or API (American Petroleum Institute) for materials used in oil and gas applications, may also be relevant depending on the end-use of the faux leather.

QC Checkpoints: What Are the Key Stages of Quality Control?

Quality control in faux leather manufacturing typically involves several checkpoints:

-

Incoming Quality Control (IQC): This is the initial inspection of raw materials upon arrival at the manufacturing facility. Suppliers should verify that the materials meet specified standards before they are used in production.

-

In-Process Quality Control (IPQC): During production, regular inspections are conducted to monitor the manufacturing process. This includes checking for defects during forming, assembly, and finishing stages.

-

Final Quality Control (FQC): Once the product is completed, a thorough inspection is performed to ensure that it meets all specifications and quality standards before shipping.

Common Testing Methods: How Are Quality Standards Verified?

Several testing methods are commonly employed to ensure the quality of faux leather fabric:

-

Physical Testing: This includes tests for tensile strength, tear resistance, and abrasion resistance to ensure durability.

-

Chemical Testing: Suppliers may perform tests to check for harmful substances, particularly if the fabric is intended for clothing or products that come in contact with skin.

-

Visual Inspection: Aesthetic qualities, such as color consistency and surface texture, are assessed visually to meet customer expectations.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control processes of their suppliers, ensuring they receive high-quality products.

1. Conducting Supplier Audits: What Should Be Included?

Buyers should consider conducting on-site audits of potential suppliers. This allows them to evaluate the manufacturing processes, quality control measures, and overall operational efficiency. During the audit, it’s vital to review documentation related to quality management systems, certifications, and previous inspection reports.

2. Requesting Quality Reports: What Information Is Essential?

Buyers can request quality assurance reports from suppliers, which should detail the results of inspections and tests conducted during the manufacturing process. These reports should include data on defect rates, compliance with international standards, and any corrective actions taken in response to quality issues.

3. Utilizing Third-Party Inspections: How Can This Enhance Assurance?

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These services can conduct inspections at various stages of production, offering peace of mind to buyers concerned about quality consistency.

What Are the Unique Quality Control Nuances for International Buyers?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control in the context of local regulations and market expectations is essential.

1. Compliance with Local Regulations: What Should Buyers Know?

Buyers should be aware of local regulations regarding the import of textiles and leather products, as these can vary significantly by region. Compliance with safety standards and environmental regulations in the destination country is crucial to avoid penalties and ensure market access.

2. Addressing Cultural Preferences: How Does This Impact Quality Expectations?

Cultural preferences can influence the quality and design expectations for faux leather fabric. For example, buyers in the Middle East may prioritize UV-resistant materials for outdoor applications, while European buyers might focus on eco-friendly manufacturing processes. Understanding these preferences can enhance supplier relationships and product alignment.

Conclusion: Why Understanding Manufacturing Processes and Quality Assurance is Essential for B2B Buyers

For B2B buyers, particularly those sourcing yellow faux leather fabric, a comprehensive understanding of manufacturing processes and quality assurance practices is vital. By evaluating suppliers based on their manufacturing capabilities, adherence to international standards, and quality control measures, buyers can ensure they receive high-quality products that meet their specific needs and market demands. This diligence not only safeguards investments but also enhances brand reputation and customer satisfaction in competitive markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘yellow faux leather fabric’

Wprowadzenie

This guide serves as a practical checklist for B2B buyers looking to source yellow faux leather fabric. With the growing demand for sustainable and cost-effective materials across various industries, understanding the sourcing process is essential. This checklist will help ensure you make informed decisions, securing high-quality fabric that meets your business needs.

Step 1: Define Your Technical Specifications

Before initiating your sourcing process, it’s vital to establish the technical specifications of the yellow faux leather fabric you require. Consider factors such as the fabric’s thickness, weight, texture, and intended application (e.g., upholstery, apparel, or accessories). Defining these parameters will guide your search and help you communicate effectively with potential suppliers.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify reputable suppliers of yellow faux leather fabric. Look for manufacturers and distributors with a strong presence in your target markets, particularly in Africa, South America, the Middle East, and Europe. Utilize online platforms, trade shows, and industry directories to compile a list of potential suppliers who meet your criteria.

Step 3: Evaluate Supplier Certifications

Verify that your shortlisted suppliers possess relevant certifications and compliance with international quality standards. Certifications such as ISO, OEKO-TEX, or REACH indicate a commitment to quality and sustainability. These assurances are crucial for maintaining product integrity and meeting regulatory requirements in your target markets.

Step 4: Request Samples for Quality Assessment

Before placing a bulk order, request samples of the yellow faux leather fabric from your selected suppliers. This allows you to assess the material’s quality, color accuracy, and texture firsthand. Pay attention to the fabric’s durability, flexibility, and ease of maintenance, as these factors will impact your final product’s performance.

Step 5: Understand Pricing and Payment Terms

Clarify the pricing structure and payment terms with your chosen suppliers. Inquire about bulk order discounts, shipping costs, and any additional fees that may apply. Understanding the total cost of procurement will help you budget effectively and avoid unexpected expenses during the sourcing process.

Step 6: Negotiate Contracts and Delivery Terms

Once you’ve selected a supplier, negotiate the terms of the contract, including delivery timelines and return policies. Ensure that you have a clear agreement on the expected lead times, quality assurance procedures, and liability in case of defects. A well-defined contract protects your interests and establishes accountability.

Step 7: Establish Ongoing Communication and Feedback

After procurement, maintain open lines of communication with your supplier. Providing feedback on the fabric’s performance and any issues that arise will foster a positive relationship and help ensure future orders meet your expectations. Regular communication can also lead to better pricing and priority service in future transactions.

Comprehensive Cost and Pricing Analysis for yellow faux leather fabric Sourcing

What Are the Key Cost Components in Sourcing Yellow Faux Leather Fabric?

When considering the sourcing of yellow faux leather fabric, it’s essential to analyze the various cost components that contribute to the final price. These include:

-

Materials: The primary component is the synthetic leather itself, typically made from PVC or PU (polyurethane). Prices can vary based on the quality and finish of the material. For instance, premium options may incorporate additional treatments for durability and aesthetics, which can increase costs.

-

Labor: Labor costs involve the workforce required for manufacturing and assembling the fabric. Regions with lower labor costs may offer competitive pricing, but the quality of craftsmanship should also be evaluated.

-

Manufacturing Overhead: This includes costs related to the operation of the manufacturing facility, such as utilities, rent, and equipment maintenance. Efficient factories with modern machinery can produce fabrics at a lower overhead cost, which can be passed on to buyers.

-

Tooling: If custom patterns or finishes are required, tooling costs can be significant. This includes the expenses for molds or specialized machinery needed to produce unique designs.

-

Quality Control (QC): Ensuring that the fabric meets industry standards requires investment in quality control processes. This may add to the overall cost but is essential for maintaining product reliability.

-

Logistics: Shipping and handling costs are critical, especially for international transactions. Factors like distance, shipping method, and customs duties can significantly influence total costs.

-

Margin: Suppliers will add a profit margin to cover their operational costs and ensure profitability. Understanding the typical margins in the industry can aid in negotiations.

How Do Price Influencers Affect Sourcing Decisions for Yellow Faux Leather Fabric?

Several factors can influence the pricing of yellow faux leather fabric, which buyers should consider:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer tiered pricing based on order size. Larger orders can secure lower per-unit prices, making it crucial for buyers to assess their needs carefully.

-

Specifications and Customization: Customized products may incur higher costs due to the additional resources required for development. Buyers should weigh the importance of specific features against their budget.

-

Material Quality and Certifications: Fabrics that comply with international quality standards or sustainability certifications may command higher prices. Buyers should evaluate whether these certifications align with their brand values.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a track record of quality may charge more, but they also provide assurance regarding product consistency.

-

Incoterms: Understanding shipping terms is vital. Different Incoterms (e.g., FOB, CIF) affect the distribution of costs and responsibilities, influencing the overall pricing structure.

What Are the Best Practices for Negotiating Prices on Yellow Faux Leather Fabric?

For B2B buyers, particularly in diverse regions like Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant cost savings:

-

Understand Total Cost of Ownership (TCO): Beyond the purchase price, consider all associated costs, including shipping, storage, and potential waste. This holistic view can guide better purchasing decisions.

-

Leverage Volume Discounts: If your business model allows for larger orders, negotiate for discounts based on volume. Suppliers often appreciate larger commitments and may offer better pricing.

-

Be Open to Alternatives: If a particular type of yellow faux leather is too expensive, explore alternative materials or styles that may meet your needs at a lower cost.

-

Cultivate Long-term Relationships: Building a solid partnership with suppliers can lead to better pricing over time. Loyal customers often receive preferential treatment, including improved terms and prices.

-

Market Research: Stay informed about market trends and price fluctuations. Understanding the competitive landscape can empower you during negotiations.

Conclusion

Sourcing yellow faux leather fabric involves navigating a complex landscape of costs and pricing factors. By understanding the various cost components, recognizing price influencers, and employing strategic negotiation tactics, B2B buyers can make informed decisions that optimize their procurement processes. Always remember that indicative prices may vary based on market conditions and supplier relationships, so thorough research and preparation are essential.

Alternatives Analysis: Comparing yellow faux leather fabric With Other Solutions

Understanding Alternatives for Yellow Faux Leather Fabric

When considering materials for upholstery and other applications, yellow faux leather fabric emerges as a popular choice due to its aesthetic appeal and functionality. However, several alternatives can provide similar benefits, depending on specific project requirements. This analysis will compare yellow faux leather fabric against two viable alternatives: genuine leather and other synthetic fabrics such as polyurethane (PU) leather.

Comparison Table

| Comparison Aspect | Yellow Faux Leather Fabric | Genuine Leather | Polyurethane (PU) Leather |

|---|---|---|---|

| Performance | Durable, easy to clean | Highly durable, natural feel | Water-resistant, flexible |

| Cost | Moderate | High | Lower than genuine leather |

| Ease of Implementation | Simple to work with | Requires skilled craftsmanship | Easy to sew and manipulate |

| Maintenance | Low maintenance, stain-resistant | Requires conditioning | Low maintenance, wipe clean |

| Best Use Case | Upholstery, fashion items | High-end furniture, luxury goods | Casual wear, furniture, automotive |

Detailed Breakdown of Alternatives

Genuine Leather: Is it Worth the Investment?

Genuine leather is often considered the gold standard in upholstery materials due to its unmatched durability and luxurious feel. It ages well, developing a unique patina over time. However, the high cost can be a significant barrier for many businesses, especially in regions where budgets are tight. Additionally, genuine leather requires regular maintenance and conditioning to prevent cracking and drying, making it less suitable for high-traffic areas where low maintenance is desired.

Polyurethane (PU) Leather: A Cost-Effective Synthetic Option

Polyurethane leather serves as a popular alternative to both yellow faux leather and genuine leather, offering a similar aesthetic at a lower price point. PU leather is water-resistant and flexible, making it an ideal choice for various applications, including casual wear and automotive interiors. Its ease of cleaning is a significant advantage, especially in environments prone to spills and stains. However, it may not offer the same level of durability as genuine leather over the long term and may not be as environmentally friendly due to the chemical processes involved in its production.

Conclusion: How to Choose the Right Solution for Your Needs

For B2B buyers, the choice between yellow faux leather fabric, genuine leather, and polyurethane leather should be guided by specific project requirements, budget considerations, and maintenance capabilities. Yellow faux leather fabric stands out for its balance of durability, aesthetic appeal, and low maintenance, making it suitable for a wide range of applications. However, if a luxurious feel is paramount and budget allows, genuine leather may be worth the investment. Conversely, if cost is a primary concern, PU leather offers a practical and stylish alternative. Assessing the unique needs of your project will enable you to make an informed decision that aligns with your operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for yellow faux leather fabric

What Are the Key Technical Properties of Yellow Faux Leather Fabric?

When sourcing yellow faux leather fabric for various applications, understanding its technical properties is essential for making informed purchasing decisions. Here are some critical specifications to consider:

1. Material Composition

Yellow faux leather is typically made from polyvinyl chloride (PVC) or polyurethane (PU). PVC is known for its durability and cost-effectiveness, while PU offers a softer, more leather-like feel. The choice between these materials can affect the fabric’s application, longevity, and aesthetic appeal, making it crucial for buyers to specify their needs based on end-use.

2. Fabric Width

The standard width for faux leather fabrics usually ranges from 54 to 60 inches (137 to 152 cm). This dimension is vital for ensuring that the fabric meets the requirements of specific projects, such as upholstery or apparel manufacturing. Wider fabrics can reduce the amount of waste during cutting, thus optimizing material use.

3. Weight and Thickness

The weight of yellow faux leather is often expressed in grams per square meter (GSM), with common weights ranging from 300 to 600 GSM. Thicker materials (e.g., 540 GSM) tend to be more durable and suitable for high-wear applications such as upholstery, while lighter weights may be used for fashion items. Thickness is also measured in millimeters, with typical values around 0.8 mm, which influences flexibility and drape.

4. Durability and Resistance Properties

Durability features like tear resistance, waterproofing, and UV stability are critical for the longevity of faux leather products. Fabrics that are resistant to tearing and fading are ideal for outdoor applications or high-traffic areas. Buyers should inquire about specific testing standards to ensure the fabric meets their durability requirements.

5. Ease of Maintenance

One of the significant advantages of faux leather is its ease of cleaning. Many yellow faux leather fabrics are designed to be stain-resistant and can be wiped clean with a damp cloth. This property is especially appealing for applications in the hospitality and automotive industries, where cleanliness is paramount.

What Trade Terminology Should B2B Buyers Know Regarding Yellow Faux Leather Fabric?

Understanding industry-specific jargon can streamline communication and negotiation in B2B transactions. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of faux leather, buyers may work directly with OEMs to source specific materials tailored to their brand needs, ensuring that product quality aligns with their standards.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to understand as it impacts inventory management and cost efficiency. For faux leather fabrics, MOQs can vary significantly depending on the supplier and the type of fabric.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and availability for specific products. When sourcing yellow faux leather fabric, submitting an RFQ can help buyers compare prices and terms from multiple suppliers, facilitating better purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms can help buyers clarify shipping responsibilities, risk management, and costs associated with the transportation of yellow faux leather fabric.

5. Lead Time

Lead time refers to the time it takes from placing an order to the delivery of the product. In the fabric industry, lead times can vary based on the supplier’s location, production capabilities, and stock levels. Buyers should consider lead times when planning their projects to ensure timely delivery.

By familiarizing themselves with these technical specifications and trade terms, B2B buyers can make more informed decisions when purchasing yellow faux leather fabric, ultimately enhancing their product offerings and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the yellow faux leather fabric Sector

What Are the Key Market Dynamics and Trends in the Yellow Faux Leather Fabric Sector?

The yellow faux leather fabric market is witnessing significant growth, driven by a combination of aesthetic appeal, versatility, and cost-effectiveness. Global demand is bolstered by various industries, including automotive, furniture, fashion, and interior design. In regions like Africa, South America, the Middle East, and Europe, the trend leans toward customizable and vibrant colors such as mustard yellow, which can enhance product appeal and align with local cultural aesthetics.

Emerging technologies in sourcing, such as digital platforms for fabric procurement, are transforming how B2B buyers interact with suppliers. These platforms offer transparency in pricing and facilitate direct connections, reducing the need for intermediaries. Additionally, innovations in fabric treatment technologies have improved the durability and ease of maintenance of faux leather, making it a preferred choice for many businesses. International buyers are increasingly looking for suppliers who can provide not just quality products but also responsiveness in service and flexibility in order quantities.

How Important Is Sustainability and Ethical Sourcing in the Yellow Faux Leather Fabric Market?

Sustainability is becoming a critical consideration in the sourcing of yellow faux leather fabric. The environmental impact of traditional leather production has prompted buyers to seek more sustainable alternatives. Yellow faux leather, typically made from PVC or polyurethane, offers a less harmful option, but its production still involves environmental considerations.

Ethical sourcing practices are gaining traction, with buyers prioritizing suppliers who demonstrate commitment to responsible manufacturing processes. Certifications such as OEKO-TEX and Global Recycle Standard (GRS) are valuable indicators of a supplier’s dedication to sustainability. These certifications ensure that the materials used are free from harmful substances and are produced in an environmentally friendly manner. B2B buyers should actively seek out suppliers that can provide transparency regarding their supply chains and the sustainability of their materials.

What Has Been the Evolution of Yellow Faux Leather Fabric in B2B Context?

The evolution of yellow faux leather fabric reflects broader trends in material innovation and consumer preferences. Initially developed as a more affordable alternative to genuine leather, faux leather has evolved significantly in quality and application. The introduction of advanced synthetic materials has enhanced its durability and aesthetic appeal, making it suitable for high-end applications.

In recent years, the demand for vibrant colors like yellow has surged, driven by fashion and design trends that favor bold and expressive choices. This shift indicates a broader acceptance of faux leather in various sectors, from luxury fashion to practical upholstery, catering to diverse market needs. As consumer awareness of sustainability grows, the faux leather sector is poised to adapt further, aligning with ethical sourcing practices and innovative production techniques.

Frequently Asked Questions (FAQs) for B2B Buyers of yellow faux leather fabric

-

How do I choose the right yellow faux leather fabric for my project?

When selecting yellow faux leather fabric, consider the intended use, durability, and aesthetic appeal. Fabrics vary in texture, thickness, and flexibility, which can influence their suitability for upholstery, apparel, or other applications. Check specifications such as GSM (grams per square meter) for weight and thickness, as heavier materials tend to offer more durability. Additionally, assess the cleaning and maintenance requirements, especially if the fabric will be used in high-traffic areas or outdoor settings. -

What are the key benefits of using yellow faux leather fabric?

Yellow faux leather fabric offers several advantages, including cost-effectiveness, ease of maintenance, and versatility. It mimics the appearance of genuine leather while being more affordable and resistant to wear and tear. Faux leather is also waterproof, making it suitable for both indoor and outdoor applications. The vibrant yellow color can enhance aesthetic appeal, making it an excellent choice for furniture, fashion, and automotive interiors. -

What is the typical minimum order quantity (MOQ) for yellow faux leather fabric?

MOQs for yellow faux leather fabric can vary by supplier, but they generally range from 50 to 500 yards. Some manufacturers may offer lower MOQs for custom or specialty orders, while larger quantities can lead to better pricing and discounts. When sourcing, inquire directly with potential suppliers to clarify their MOQ policies and negotiate if necessary, especially if you are a smaller business or testing new products. -

How can I ensure the quality of yellow faux leather fabric when sourcing internationally?

To ensure quality, request samples from suppliers before placing a bulk order. Assess the samples for texture, durability, and color consistency. Additionally, consider suppliers with certifications or quality assurance processes in place. Conduct background checks and read reviews or testimonials from other buyers. Engaging with local agents in the supplier’s country can also help in verifying the supplier’s credibility and quality standards. -

What payment terms should I expect when sourcing yellow faux leather fabric?

Payment terms can vary widely among suppliers. Common terms include a deposit (typically 30-50%) upon order confirmation, with the balance due before shipment or upon delivery. It’s advisable to negotiate terms that suit your cash flow, and consider using secure payment methods like letters of credit or escrow services to protect your investment. Always clarify payment terms in advance to avoid misunderstandings. -

What are the shipping options for importing yellow faux leather fabric?

Shipping options depend on the supplier’s location and your destination. Common methods include air freight for faster delivery and sea freight for cost-effectiveness on larger shipments. Discuss shipping terms, including lead times, freight costs, and insurance, with your supplier. Be aware of customs duties and regulations in your country to ensure a smooth import process. Partnering with a reliable freight forwarder can also simplify logistics. -

Can I customize yellow faux leather fabric in terms of design or texture?

Yes, many suppliers offer customization options for yellow faux leather fabric. You can request specific patterns, textures, or finishes to align with your project requirements. However, customization often comes with higher costs and longer lead times. It’s essential to communicate your needs clearly and confirm that the supplier can meet your specifications before placing an order. -

What should I consider regarding compliance and regulations when importing faux leather?

When importing yellow faux leather, ensure that it complies with your country’s regulations regarding materials and safety standards. Check for certifications related to environmental impact and material safety, especially if the fabric will be used in products for children or medical applications. Understanding import duties and tariffs is also crucial to avoid unexpected costs. Consulting with a trade expert or legal advisor can help navigate these complexities effectively.

Top 7 Yellow Faux Leather Fabric Manufacturers & Suppliers List

1. Naugahyde – US322 SPIRIT MILLENNIUM SUN YELLOW

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: Yellow Faux Leather Upholstery Vinyl available from various brands including Naugahyde and Boltaflex. Products can be ordered by the yard or roll at wholesale prices. Key products include:

1. US322 Naugahyde SPIRIT MILLENNIUM US322 SUN YELLOW – $33.95 per yard, 13 yards in stock.

2. RWH42 RAWHIDE MUSTARD – $14.95 per yard, 30 yards in stock.

3. LDR36 LANDERS YELLOW – $14.95 per yard, 32 yards in …

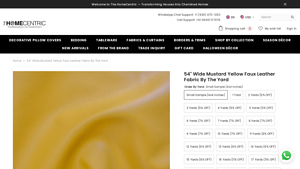

2. The Home Centric – 54 Wide Mustard Yellow Faux Leather

Domain: thehomecentric.com

Registered: 2007 (18 years)

Introduction: {“name”: “54” Wide Mustard Yellow Faux Leather By The Yard”, “width”: “54 inches”, “color”: “Mustard Yellow”, “material”: “Faux Leather”, “pricing”: [{“quantity”: “Small Sample (4×4 inches)”, “price”: “$14.16 USD”}, {“quantity”: “1 Yard”, “price”: “$54.87 USD”}, {“quantity”: “2 Yards (5% OFF)”, “price”: “$104.26 USD”}, {“quantity”: “3 Yards (5% OFF)”, “price”: “$156.39 USD”}, {“quantity”: “4 Yards…

3. Fabric Bistro – Yellow Marine Faux Leather Vinyl

Domain: fabricbistro.com

Registered: 2015 (10 years)

Introduction: {“product_name”: “Yellow Indoor Outdoor Marine Faux Leather Upholstery Vinyl”, “regular_price”: “$40.00”, “sale_price”: “$24.00”, “width”: “55 inches”, “usage”: “indoor/outdoor marine upholstery”, “material”: “faux leather”, “price_per”: “per yard”, “location”: “Columbia, South Carolina”}

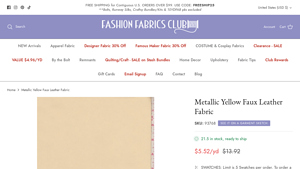

4. Fashion Fabrics Club – Metallic Yellow Faux Leather

Domain: fashionfabricsclub.com

Registered: 1999 (26 years)

Introduction: {‘name’: ‘Metallic Yellow Faux Leather Fabric’, ‘SKU’: ‘93768’, ‘price’: ‘$5.52’, ‘original_price’: ‘$13.92’, ‘stock’: ‘21.5 in stock, ready to ship’, ‘color’: ‘Yellow, Gold’, ‘care_instructions’: ‘Wipe Clean with Damp Cloth’, ‘material’: ‘100% Polyurethane face, 100% polyester back’, ‘width’: ’58 inches’, ‘weight’: ‘Heavy’, ‘transparency’: ‘Non-sheer’, ‘hand’: ‘Cool, smooth, slick’, ‘back’: ‘soft…

5. DuroLast® – Yellow Solid Soft Vinyl Fabric

Domain: bigzfabric.com

Registered: 2010 (15 years)

Introduction: {“Product Name”: “Yellow Solid Soft Vinyl Fabric”, “Brand”: “DuroLast®”, “Price”: “$7.34”, “Material”: “100% Vinyl”, “Width”: “54 inches”, “Stretch”: “No Stretch”, “Features”: [“Lightweight”, “Water Resistant”, “Durable”, “Glossy Finish”, “Low Maintenance”, “Easy to Clean”], “Uses”: [“Upholstery”, “Pillows”, “Bags”, “Frames”, “Headboards”, “Purses”, “Shoe Accessories”, “Clothing Accessories”, “Oth…

6. Fabric Warehouse – Yellow Vinyl Collection

Domain: fabricwarehouse.com

Registered: 1996 (29 years)

Introduction: Yellow Vinyl collection includes various types of vinyl fabrics suitable for marine, automotive, and upholstery projects. Key products include: 1. SEAQUEST Lemon Peel Yellow Marine & Automotive Vinyl Fabric (PSQ-012) – 54″ wide, high UV stability, 49 yards in stock, starting at $19.98 per yard. 2. SEAQUEST Sunflower Yellow Marine & Automotive Vinyl Fabric (PSQ-114) – 54″ wide, high UV stability, 3…

7. Burlap Fabric – 54 Yellow Leather-like Upholstery Vinyl

Domain: burlapfabric.com

Registered: 2004 (21 years)

Introduction: {“name”:”54 Yellow Leather-like Upholstery Vinyl”,”model”:”FL-YELLOW”,”price”:”$10.99″,”original_price”:”$15.00″,”discount”:”27%”,”width”:”54 inches”,”color”:”Yellow”,”texture”:”Leather-like”,”shipping_weight”:”2 lbs”,”available_units”:”1000″,”description”:”Bright yellow color with a leather-like texture, suitable for upholstery, furniture refurbishing, and various crafting projects.”}

Strategic Sourcing Conclusion and Outlook for yellow faux leather fabric

In the evolving landscape of the textile industry, yellow faux leather fabric presents a significant opportunity for international B2B buyers. Its durability, ease of maintenance, and aesthetic appeal make it an ideal choice for various applications, from upholstery to fashion. As sourcing strategies increasingly emphasize sustainability and cost-effectiveness, faux leather stands out as a practical alternative to genuine leather, offering similar visual and tactile qualities without the associated ethical concerns.

Strategic sourcing of yellow faux leather can lead to enhanced supply chain efficiencies and reduced costs, particularly for businesses in regions like Africa, South America, the Middle East, and Europe. By leveraging wholesale pricing and diverse product offerings, buyers can meet market demands while optimizing their procurement processes.

Looking ahead, the market for yellow faux leather is poised for growth, driven by innovative designs and an expanding range of applications. B2B buyers are encouraged to engage with suppliers who prioritize quality, sustainability, and trend responsiveness. Now is the time to capitalize on this trend—consider integrating yellow faux leather into your product lines to stay competitive and appeal to a broader customer base.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.