Introduction: Navigating the Global Market for polyurethane leather paint

The global market for polyurethane leather paint presents a unique set of challenges for B2B buyers, particularly those seeking high-quality solutions for leather restoration and color change. As industries across Africa, South America, the Middle East, and Europe increasingly embrace eco-friendly and durable materials, the demand for polyurethane leather paint is on the rise. However, navigating this market can be daunting, with a multitude of options available and varying supplier capabilities.

This comprehensive guide is designed to empower international B2B buyers by providing insights into the different types of polyurethane leather paints, their applications across various sectors—from automotive to furniture—and essential supplier vetting processes. We will also explore factors influencing pricing, ensuring that buyers can make informed decisions that align with their operational needs and budget constraints.

By delving into critical aspects such as color matching services, application techniques, and performance characteristics like scuff resistance and flexibility, this guide offers actionable insights that can enhance product offerings and improve customer satisfaction. Whether you are a manufacturer, distributor, or retailer, understanding the nuances of polyurethane leather paint will enable you to source the right products effectively and remain competitive in the global marketplace.

Table Of Contents

- Top 5 Polyurethane Leather Paint Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for polyurethane leather paint

- Understanding polyurethane leather paint Types and Variations

- Key Industrial Applications of polyurethane leather paint

- 3 Common User Pain Points for ‘polyurethane leather paint’ & Their Solutions

- Strategic Material Selection Guide for polyurethane leather paint

- In-depth Look: Manufacturing Processes and Quality Assurance for polyurethane leather paint

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘polyurethane leather paint’

- Comprehensive Cost and Pricing Analysis for polyurethane leather paint Sourcing

- Alternatives Analysis: Comparing polyurethane leather paint With Other Solutions

- Essential Technical Properties and Trade Terminology for polyurethane leather paint

- Navigating Market Dynamics and Sourcing Trends in the polyurethane leather paint Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of polyurethane leather paint

- Strategic Sourcing Conclusion and Outlook for polyurethane leather paint

- Important Disclaimer & Terms of Use

Understanding polyurethane leather paint Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Water-Based PU Paint | Non-harmful, flexible, high color coverage | Furniture, automotive interiors, fashion | Pros: Safe to use, easy application. Cons: May require additional topcoat for durability. |

| Solvent-Based PU Paint | High durability, excellent adhesion, and strong scuff resistance | Industrial applications, footwear, automotive | Pros: Long-lasting, suitable for high-wear surfaces. Cons: More hazardous, requires ventilation. |

| Matte Finish PU Paint | Soft, natural look, adjustable gloss levels | Fashion accessories, upholstery | Pros: Aesthetic appeal, customizable finish. Cons: May show wear faster than glossy finishes. |

| Gloss Finish PU Paint | High shine, enhances color vibrancy | Luxury goods, automotive interiors | Pros: Eye-catching, enhances durability. Cons: Can highlight imperfections on surfaces. |

| Specialty PU Paint | Custom formulations for specific applications | Equestrian gear, sports equipment | Pros: Tailored solutions for niche markets. Cons: Higher cost and longer lead times. |

What are the Characteristics of Water-Based PU Paints?

Water-based polyurethane (PU) paints are known for their non-toxic formulation and flexibility, making them ideal for a wide range of applications, including furniture and automotive interiors. These paints provide excellent color coverage and are easy to apply using various methods such as spraying or brushing. For B2B buyers, the safety aspect is crucial, especially in environments where chemical exposure is a concern. However, it may require a protective topcoat to enhance durability, which should be factored into overall project costs.

How Do Solvent-Based PU Paints Compare?

Solvent-based polyurethane paints offer exceptional durability and adhesion, making them suitable for industrial applications and high-wear items like footwear and automotive parts. They are formulated to withstand harsh conditions and provide a robust finish that resists scratches and scuffs. B2B buyers should consider the need for proper ventilation during application due to the hazardous nature of solvents. While these paints provide long-lasting results, their environmental impact and safety concerns must be weighed against their performance benefits.

What Advantages Do Matte Finish PU Paints Offer?

Matte finish polyurethane paints provide a soft, natural appearance that is highly sought after in fashion accessories and upholstery. They allow for customizable gloss levels, catering to varying aesthetic preferences. For B2B buyers, the appeal of a matte finish lies in its ability to create a sophisticated look while still being functional. However, matte finishes can be more prone to showing wear compared to glossy alternatives, necessitating careful consideration in high-traffic applications.

Why Choose Gloss Finish PU Paints?

Gloss finish polyurethane paints are favored for their vibrant color enhancement and eye-catching shine, making them a popular choice for luxury goods and automotive interiors. Their glossy surface not only adds aesthetic value but also increases durability against everyday wear and tear. B2B buyers should note that while gloss finishes can make products more appealing, they may also highlight imperfections on the surface, requiring meticulous preparation before application.

What Are Specialty PU Paints and Their Benefits?

Specialty polyurethane paints are custom-formulated for specific applications, such as equestrian gear and sports equipment. These tailored solutions can address unique challenges, such as flexibility and resistance to environmental factors. For B2B buyers, the advantage of specialty PU paints lies in their ability to meet niche market demands, though they often come with higher costs and longer lead times. It’s essential for businesses to assess whether the performance benefits justify the investment for their specific applications.

Key Industrial Applications of polyurethane leather paint

| Industry/Sector | Specific Application of polyurethane leather paint | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Interior restoration and customization of vehicle seats | Enhances aesthetic appeal and extends product lifespan | Durability, color matching capabilities, and compliance with safety standards |

| Furniture | Restoration of leather upholstery in sofas and chairs | Cost-effective solution for refurbishing high-value items | Availability of diverse colors, ease of application, and fast drying times |

| Fashion and Apparel | Customization and repair of leather garments and accessories | Allows brands to offer personalized products, boosting customer loyalty | Flexibility in application methods and compatibility with various leather types |

| Equestrian | Maintenance and enhancement of saddles and riding gear | Increases product durability and maintains high-end appearance | Resistance to wear and tear, water resistance, and easy cleaning properties |

| Home Decor | Revitalization of leather decorative items | Adds value to home furnishings and prolongs their life cycle | Eco-friendly formulations, colorfastness, and ease of use in various environments |

How is Polyurethane Leather Paint Used in the Automotive Industry?

In the automotive sector, polyurethane leather paint is utilized for restoring and customizing vehicle interiors, particularly seats and trim. Its high durability ensures resistance against wear, scuffs, and scratches, making it ideal for high-traffic areas. For international buyers, especially in regions like South America and Africa, sourcing paints that comply with local regulations and offer color-matching services is crucial. Additionally, paints that dry quickly and provide a soft finish enhance both the aesthetic and tactile experience for end-users.

What Role Does Polyurethane Leather Paint Play in Furniture Restoration?

For the furniture industry, polyurethane leather paint serves as a vital tool for restoring leather upholstery on sofas and chairs. It provides a cost-effective solution for businesses looking to refurbish high-value items, allowing them to maintain or even enhance their aesthetic appeal. Buyers from Europe and the Middle East should prioritize sourcing products that offer high color coverage and easy application methods, ensuring a seamless restoration process. The ability to select from a wide range of colors and finishes further assists businesses in meeting diverse customer preferences.

How Can Fashion Brands Benefit from Using Polyurethane Leather Paint?

In the fashion and apparel sector, polyurethane leather paint is used for the customization and repair of leather garments and accessories. This application allows brands to offer personalized products, increasing customer loyalty and satisfaction. For B2B buyers in regions such as Vietnam and Brazil, it’s essential to consider the flexibility of application methods—whether by sponge, brush, or spray—alongside the paint’s compatibility with various leather types. This adaptability enhances the creativity and innovation that fashion brands can deliver to their clientele.

What Advantages Does Polyurethane Leather Paint Offer in Equestrian Gear Maintenance?

Within the equestrian industry, polyurethane leather paint is essential for maintaining and enhancing saddles and riding gear. Its durability and resistance to wear ensure that high-end equipment remains functional and visually appealing over time. Businesses should focus on sourcing paints that provide water resistance and are easy to clean, which is vital for maintaining gear used in various weather conditions. Buyers should also look for eco-friendly options to align with growing sustainability trends in the equestrian community.

How Does Polyurethane Leather Paint Enhance Home Decor Items?

In home decor, polyurethane leather paint is used to revitalize leather decorative items, such as cushions and wall hangings. This application not only adds aesthetic value but also prolongs the life cycle of these furnishings, making them more appealing to consumers. Buyers from diverse regions should consider sourcing paints that are eco-friendly and offer colorfastness to ensure long-lasting results. The ease of use in various environments is another critical factor, as it allows businesses to cater to a broader audience looking for DIY solutions.

3 Common User Pain Points for ‘polyurethane leather paint’ & Their Solutions

Scenario 1: Struggling with Color Consistency in Bulk Orders

The Problem: Many B2B buyers face the challenge of maintaining color consistency when ordering polyurethane leather paint in bulk for large projects. This inconsistency can lead to mismatched products, ultimately affecting the overall aesthetic and quality of the final goods. Buyers often find that different batches of paint can slightly vary in hue or texture, causing frustration and potential financial loss if products need to be reworked or replaced.

The Solution: To ensure color consistency, it is crucial to establish a strong relationship with suppliers who can provide reliable color matching services. Before placing a bulk order, request a color sample and compare it under various lighting conditions to ensure it meets your expectations. Additionally, consider utilizing a supplier that maintains a comprehensive database of colors and can guarantee that future orders will match previous ones. When submitting orders, specify that you need products from the same batch, and inquire about the supplier’s process for color consistency checks. This proactive approach can significantly minimize discrepancies and enhance customer satisfaction with the final products.

Scenario 2: Difficulty in Achieving Proper Adhesion on Various Leather Types

The Problem: B2B buyers often encounter issues with polyurethane leather paint not adhering properly to different types of leather, such as aniline or pigmented leathers. This challenge can lead to peeling, flaking, or uneven finishes, which can be particularly problematic in industries such as automotive or furniture manufacturing where durability is paramount. Buyers may also struggle with ensuring that the surface is adequately prepared before application, further complicating the process.

The Solution: To enhance adhesion, it is essential to follow a meticulous surface preparation routine. Start by thoroughly cleaning the leather with a suitable leather cleaner to remove any dirt, oils, or residues that could interfere with adhesion. After cleaning, consider using a dedicated adhesion promoter specifically designed for polyurethane paints, especially on more challenging leather types. Additionally, always conduct a test application on a small, inconspicuous area to assess how well the paint adheres before proceeding with the entire project. By taking these steps, buyers can achieve a more durable and professional finish, thus increasing the longevity of the products they create.

Scenario 3: Navigating Environmental Regulations and Safety Concerns

The Problem: International B2B buyers, particularly those operating in regions with stringent environmental regulations, may experience difficulties sourcing polyurethane leather paints that comply with local laws and safety standards. The challenge is not only to find a product that performs well but also to ensure it is safe for use in various environments, minimizing health risks for workers and consumers alike.

The Solution: To navigate these complexities, it is vital to partner with reputable suppliers who provide transparent information about their products’ compliance with international safety and environmental standards. Request detailed product data sheets that outline the chemical composition and any relevant certifications. Additionally, consider adopting a proactive approach by staying informed about regional regulations and trends related to polyurethane products. Engage with suppliers who are committed to sustainability and can offer eco-friendly options that meet both performance and safety requirements. This diligence will not only ensure compliance but also enhance your company’s reputation as a responsible and forward-thinking business.

Illustrative image related to polyurethane leather paint

Strategic Material Selection Guide for polyurethane leather paint

When selecting materials for polyurethane leather paint, it is crucial to consider the properties, advantages, and limitations of various components. The following analysis focuses on four common materials used in polyurethane leather paint formulations, providing insights tailored for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Polyurethane Resins in Leather Paint?

Polyurethane resins are the backbone of polyurethane leather paint. They offer a unique combination of flexibility, durability, and chemical resistance. These resins typically have a high-temperature resistance, often rated up to 80°C (176°F), and can withstand various environmental conditions. Their corrosion resistance makes them suitable for applications in diverse climates, which is particularly important for buyers in regions with extreme weather variations.

What Are the Advantages and Disadvantages of Using Polyurethane Resins?

Pros: The primary advantage of polyurethane resins is their exceptional durability and flexibility, making them ideal for leather applications that require a soft touch and high wear resistance. Additionally, they provide excellent adhesion to various substrates and are available in a range of formulations to suit different needs.

Cons: However, the manufacturing complexity can be a drawback. The production process may require specialized equipment and expertise, which can increase costs. Furthermore, while polyurethane resins are versatile, they may not be suitable for all types of leather finishes, particularly those that require a more natural look.

Illustrative image related to polyurethane leather paint

How Do Plasticizers Impact the Performance of Polyurethane Leather Paint?

Plasticizers are often added to polyurethane formulations to enhance flexibility and workability. They help lower the glass transition temperature, making the paint easier to apply and more adaptable to the substrate.

Pros: The incorporation of plasticizers can significantly improve the softness and flexibility of the final product, making it more comfortable for end-users. This is particularly beneficial for applications in fashion and automotive interiors where a soft feel is desired.

Cons: On the downside, plasticizers can sometimes lead to issues such as migration over time, which may affect the paint’s longevity and performance. Additionally, certain plasticizers may not comply with international safety standards, which is a critical consideration for B2B buyers in regulated markets.

What Role Do Additives Play in Enhancing Polyurethane Leather Paint?

Additives such as UV stabilizers, anti-foaming agents, and thickeners are critical in formulating polyurethane leather paint. These additives enhance the paint’s performance characteristics, including UV resistance and application ease.

Pros: The use of additives can improve the paint’s resistance to fading and degradation, which is essential for products exposed to sunlight. They can also enhance the application process, making it smoother and more efficient.

Cons: However, the addition of multiple components can complicate the formulation process and increase costs. Furthermore, ensuring compliance with international standards can be challenging, especially for buyers in regions with strict regulations.

What Are the Compliance Considerations for International Buyers?

For B2B buyers, compliance with international standards such as ASTM, DIN, and JIS is paramount. Different regions may have specific regulations regarding VOC emissions and the use of hazardous materials. Buyers from Africa, South America, the Middle East, and Europe should ensure that their selected polyurethane leather paint formulations meet these standards to avoid legal complications and ensure market acceptance.

| Materiał | Typical Use Case for polyurethane leather paint | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane Resins | Automotive interiors, furniture upholstery | Exceptional durability and flexibility | Manufacturing complexity can increase costs | Medium |

| Plasticizers | Fashion accessories, soft leather goods | Enhances softness and flexibility | Potential migration affecting longevity | Medium |

| Additives | UV protection in outdoor leather products | Improves resistance to UV and fading | Complicates formulation and compliance | Medium |

| Colorants | Restoration and color change in leather items | High color coverage and fastness | May require multiple applications for full effect | Low |

This strategic material selection guide aims to equip B2B buyers with essential insights into the materials used in polyurethane leather paint, enabling informed purchasing decisions that align with their operational needs and market requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for polyurethane leather paint

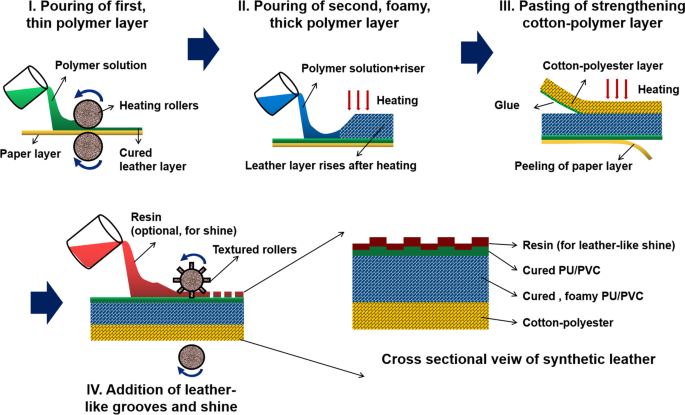

What Are the Key Stages in the Manufacturing Process of Polyurethane Leather Paint?

Manufacturing polyurethane leather paint involves several critical stages, each of which is essential for ensuring high-quality and durable products.

Material Preparation: What Raw Materials Are Used?

The initial stage involves sourcing and preparing raw materials, which typically include polyurethane resins, pigments, solvents, and additives such as stabilizers and cross-linking agents. The selection of high-quality raw materials is crucial as they directly affect the paint’s performance, such as adhesion, durability, and colorfastness. Suppliers should ensure that the materials conform to industry standards and are sourced from reputable manufacturers to minimize quality issues.

Forming: How Is Polyurethane Leather Paint Formulated?

Once the raw materials are prepared, they are mixed in precise ratios to achieve the desired formulation. This process often takes place in controlled environments to maintain consistency. Key techniques in this phase include high-shear mixing and dispersion, which ensure that pigments and additives are evenly distributed throughout the mixture. Advanced technology may also be employed to monitor viscosity and other critical parameters in real-time, ensuring that the formulation is stable before moving to the next stage.

Assembly: What Does the Application Process Involve?

After formulation, the polyurethane leather paint is packaged for distribution or application. In a B2B context, this may include bulk packaging for manufacturers or smaller containers for retailers. The assembly stage must ensure that the paint is sealed properly to prevent contamination or degradation during transportation. Additionally, specific application equipment may be supplied, such as spray guns or rollers, to assist end-users in applying the paint effectively.

Finishing: How Is Quality Enhanced?

The finishing stage involves adding any necessary protective coatings or treatments that enhance the paint’s properties. This may include UV inhibitors to prevent fading, anti-scratch additives for durability, and gloss agents to achieve the desired sheen. The final product should undergo thorough mixing and quality checks to ensure it meets the specifications required for various applications, such as automotive interiors or furniture.

What Quality Assurance Practices Are Essential for Polyurethane Leather Paint?

Quality assurance (QA) is integral to the manufacturing process, ensuring that the final product meets both regulatory and customer expectations.

Which International Standards Should B2B Buyers Be Aware Of?

B2B buyers should look for manufacturers that comply with international quality standards such as ISO 9001, which outlines criteria for a quality management system (QMS). Additionally, compliance with CE marking requirements may be necessary, especially in Europe, indicating that products meet health, safety, and environmental protection standards. For specialized applications, adherence to specific industry standards like API (American Petroleum Institute) may also be relevant.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) is typically implemented at various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint focuses on inspecting raw materials before they enter the production line. Ensuring the quality of inputs reduces the risk of defects in the final product.

-

In-Process Quality Control (IPQC): This phase involves monitoring the manufacturing process itself. Techniques such as real-time viscosity testing and color matching are used to ensure that the paint meets specifications as it is being produced.

-

Final Quality Control (FQC): The last checkpoint occurs before the product is packaged for shipment. This includes a thorough inspection of the final product for consistency in color, viscosity, and other performance attributes. Testing methods may include adhesion tests, rub fastness tests, and chemical resistance evaluations.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s QC practices is crucial to maintaining product quality and compliance. Here are several actionable steps:

Illustrative image related to polyurethane leather paint

-

Conduct Supplier Audits: Schedule regular audits to assess the supplier’s manufacturing processes and QC systems. This provides firsthand insight into their practices and adherence to quality standards.

-

Request Quality Reports: Ask suppliers to provide documentation of their QC processes, including testing results and compliance certifications. This transparency can help build trust and ensure accountability.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased assessment of the supplier’s quality management practices. These inspectors can validate compliance with international standards and provide detailed reports.

-

Evaluate QC Certifications: Ensure that suppliers have relevant QC certifications, such as ISO 9001 or CE marking, which can serve as indicators of their commitment to quality.

What Are the Specific QC Considerations for International Buyers from Africa, South America, the Middle East, and Europe?

International buyers must navigate various regulatory environments and market expectations. Here are some nuanced considerations:

-

Regional Regulations: Different countries may have unique regulations concerning chemical safety and environmental impact. Buyers should familiarize themselves with local laws to ensure compliance.

-

Supply Chain Reliability: In regions with less stable supply chains, consider suppliers with robust logistics capabilities to mitigate risks associated with delays or quality fluctuations.

-

Cultural Sensitivity in Communication: Establishing clear communication channels can help overcome language barriers and ensure that expectations regarding quality and performance are clearly articulated and understood.

-

Sustainability Practices: Increasingly, buyers are prioritizing suppliers that implement sustainable manufacturing practices. This may include using eco-friendly materials or processes that minimize waste and environmental impact.

In conclusion, understanding the manufacturing processes and quality assurance practices for polyurethane leather paint is essential for B2B buyers seeking reliable suppliers. By focusing on quality control checkpoints, international standards, and supplier verification methods, businesses can ensure they partner with manufacturers that meet their quality expectations and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘polyurethane leather paint’

Wprowadzenie

This practical sourcing guide aims to assist B2B buyers in effectively procuring polyurethane leather paint. By following this step-by-step checklist, you can ensure that you choose the right product for your specific applications, while also partnering with reliable suppliers that meet your quality and compliance standards.

Illustrative image related to polyurethane leather paint

Step 1: Define Your Technical Specifications

Clearly outline the specific requirements for the polyurethane leather paint you need. Consider factors such as color options, flexibility, durability, and environmental compliance. Knowing these specifications upfront will streamline your sourcing process and help you communicate effectively with potential suppliers.

Step 2: Research Market Trends and Standards

Stay informed about the latest trends in the polyurethane leather paint market, including advancements in formulations and applications. Understanding industry standards, such as VOC regulations, will help you identify products that not only meet performance expectations but are also compliant with environmental regulations in your target markets.

Step 3: Identify Potential Suppliers

Compile a list of potential suppliers specializing in polyurethane leather paint. Utilize trade shows, online directories, and industry publications to find reputable manufacturers. Look for suppliers with a proven track record and positive reviews from other businesses in your sector.

Illustrative image related to polyurethane leather paint

Step 4: Evaluate Supplier Certifications

Verify the certifications and quality standards of each potential supplier. Key certifications may include ISO 9001 for quality management and specific environmental certifications relevant to your region. This step ensures that the products meet international quality benchmarks and align with your company’s sustainability goals.

Step 5: Request Product Samples

Before making a bulk purchase, request samples of the polyurethane leather paint to evaluate its quality and performance. Test the samples under real-world conditions relevant to your application, such as flexibility, adhesion, and resistance to wear and tear. This hands-on assessment is critical to confirming that the product meets your expectations.

Step 6: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in negotiations regarding pricing, delivery schedules, and payment terms. Be prepared to discuss order quantities, potential discounts for bulk purchases, and any additional services such as color matching or technical support. Clear agreements will mitigate misunderstandings and establish a strong business relationship.

Step 7: Establish a Quality Assurance Process

Implement a quality assurance process for incoming shipments of polyurethane leather paint. This should include checking for consistency in color, performance characteristics, and compliance with the agreed specifications. Regular audits and feedback loops with your supplier will help maintain quality and address any issues proactively.

By following these steps, you can ensure a thorough and effective sourcing process for polyurethane leather paint, ultimately leading to successful partnerships and high-quality products for your business needs.

Comprehensive Cost and Pricing Analysis for polyurethane leather paint Sourcing

What Are the Key Cost Components in Sourcing Polyurethane Leather Paint?

When sourcing polyurethane leather paint, understanding the cost structure is essential for making informed purchasing decisions. Key components include:

-

Materials: The primary ingredient in polyurethane leather paint is polyurethane resin, which can vary in cost depending on its quality and formulation. Additives such as pigments, solvents, and stabilizers also contribute to the material costs. It’s crucial to evaluate the specific materials used, as higher-quality components may lead to better performance and durability.

-

Labor: Labor costs encompass the workforce involved in production, quality control, and packaging. Skilled labor may command higher wages, particularly if the paint requires specialized mixing or application techniques.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and equipment depreciation associated with production facilities. Efficient manufacturing processes can help reduce overhead costs, which can be a point of negotiation with suppliers.

-

Tooling: If customized formulations or packaging are required, tooling costs can be significant. These costs should be factored into the overall pricing, especially for smaller orders.

-

Quality Control (QC): Ensuring that the paint meets specified standards necessitates a robust QC process, which can add to the overall cost. Buyers should inquire about the QC measures in place and how they impact pricing.

-

Logistics: Shipping and handling costs vary based on the origin of the materials and the destination market. Factors like freight costs, customs duties, and warehousing should be considered when calculating total expenses.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary significantly based on market demand, competition, and the perceived value of their products.

How Do Price Influencers Affect the Cost of Polyurethane Leather Paint?

Several factors influence the pricing of polyurethane leather paint:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly impact pricing. Larger orders usually lead to lower per-unit costs due to economies of scale.

-

Specifications and Customization: Custom colors, formulations, or packaging can increase costs. Buyers should clarify their needs upfront to receive accurate quotes.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., eco-friendly or safety certifications) may come at a premium. Buyers should evaluate whether these certifications align with their market demands.

-

Supplier Factors: The supplier’s reputation, experience, and geographic location can influence pricing. Established suppliers may offer more reliable products but at a higher price point.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can affect logistics costs and responsibilities. Understanding these terms is vital for accurate cost forecasting.

What Tips Can Help International B2B Buyers Optimize Their Sourcing Costs?

-

Negotiation: Engage in negotiations with suppliers to secure better pricing, particularly for larger orders. Building a good relationship can often lead to favorable terms.

-

Cost-Efficiency: Look for suppliers that offer value-added services, such as color matching or technical support, which can reduce the total cost of ownership.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with using the paint, including application, maintenance, and potential rework.

-

Pricing Nuances for Different Regions: Buyers in Africa, South America, the Middle East, and Europe should be aware of regional market dynamics. Currency fluctuations, local regulations, and varying demand can all influence pricing strategies.

-

Disclaimer for Indicative Prices: Pricing can vary widely based on the factors mentioned above. It is essential to obtain detailed quotes from multiple suppliers to ensure competitiveness.

By understanding these cost structures and pricing influences, international B2B buyers can make strategic decisions that optimize their sourcing of polyurethane leather paint, ensuring both quality and cost-effectiveness in their operations.

Alternatives Analysis: Comparing polyurethane leather paint With Other Solutions

In today’s competitive marketplace, B2B buyers are presented with various solutions for leather restoration and finishing. While polyurethane leather paint is a popular choice, it’s essential to consider alternatives that may better suit specific requirements. This section explores how polyurethane leather paint compares with other viable solutions, providing insights to help businesses make informed decisions.

| Comparison Aspect | Polyurethane Leather Paint | Leather Recolouring Balm | Acrylic Leather Paint |

|---|---|---|---|

| Performance | High durability, flexible, excellent color retention | Good for restoring color on absorbent leather | Moderate durability, less flexible than PU paint |

| Cost | Moderate ($21.95 per liter) | Low ($15.00 per 250ml) | Moderate ($20.00 per liter) |

| Ease of Implementation | Easy application via sponge, brush, or spray | Simple, requires minimal preparation | Requires surface preparation and priming |

| Maintenance | Low; resistant to scratches and fading | Moderate; may require reapplication over time | High; prone to wear and tear, may need frequent touch-ups |

| Best Use Case | Ideal for automotive and furniture applications | Best for aniline and semi-aniline leather | Suitable for decorative leather items or crafts |

What Are the Pros and Cons of Leather Recolouring Balm?

Leather recolouring balm is particularly beneficial for restoring color on absorbent leathers such as aniline and semi-aniline types. Its formulation allows it to penetrate the leather, providing a natural feel and appearance. However, while it effectively restores color, it may not be as durable as polyurethane leather paint, requiring more frequent reapplication. This solution is cost-effective, making it attractive for businesses looking to minimize expenses, but it is best suited for specific leather types, limiting its versatility.

How Does Acrylic Leather Paint Compare?

Acrylic leather paint offers a more artistic approach, allowing for intricate designs and color applications. It is available in various colors and finishes, making it suitable for decorative leather items and crafts. However, its durability is moderate compared to polyurethane leather paint, and it may not withstand heavy use as effectively. Acrylic paint also requires proper surface preparation, which can complicate the application process. While it is moderately priced, the need for frequent touch-ups can increase long-term costs, making it less appealing for high-traffic applications.

How Can B2B Buyers Choose the Right Leather Solution?

When selecting a leather restoration solution, B2B buyers should carefully assess their specific needs. Polyurethane leather paint is ideal for applications requiring durability and resistance to wear, such as automotive interiors and furniture. On the other hand, leather recolouring balm is a great choice for businesses focused on restoring softer leathers, while acrylic leather paint can cater to creative projects. Ultimately, understanding the characteristics and limitations of each option will enable buyers to make choices that align with their operational requirements and budget constraints.

Essential Technical Properties and Trade Terminology for polyurethane leather paint

What Are the Key Technical Properties of Polyurethane Leather Paint?

Polyurethane leather paint is essential for a variety of applications, particularly in the automotive, furniture, and fashion industries. Understanding its technical properties can greatly influence purchasing decisions and ensure the right product is selected for specific needs.

Illustrative image related to polyurethane leather paint

1. Flexibility and Durability

Polyurethane leather paint is designed to be extremely flexible, with the ability to withstand over 100,000 flexes without cracking or degrading. This property is crucial for applications where the material will be subjected to frequent movement, such as in automotive upholstery or furniture. A durable paint reduces the frequency of reapplication, thus lowering long-term costs.

2. Color Coverage and Fastness

High pigment concentration allows for excellent color coverage, often requiring fewer applications to achieve the desired hue. Additionally, polyurethane paints exhibit high rub fastness, meaning colors resist fading and wear over time. For B2B buyers, this translates to reduced maintenance and enhanced product longevity, making it a more economical choice in the long run.

3. Adhesion Properties

Strong adhesion is vital for ensuring that the paint bonds effectively to various leather substrates, including aniline, pigmented, and synthetic leathers. Poor adhesion can lead to peeling or flaking, which is detrimental for any brand’s reputation. Buyers should look for products that come with guarantees on adhesion performance.

Illustrative image related to polyurethane leather paint

4. Environmental Compliance

Many polyurethane leather paints are water-based, making them non-harmful and compliant with environmental regulations. This property is increasingly important for companies aiming to reduce their ecological footprint. Buyers should prioritize products that emphasize sustainability, as this can also enhance their brand’s image.

5. Application Versatility

Polyurethane leather paint can be applied using various methods such as spraying, brushing, or sponging. This versatility allows manufacturers to choose the most effective application method for their specific production processes. Understanding the application options helps businesses optimize their workflows and reduce labor costs.

6. Shelf Life and Storage Requirements

The shelf life of polyurethane leather paint typically ranges from one year once opened, requiring proper storage conditions (ideally between 8°C and 30°C). Buyers need to ensure that they purchase quantities that align with their production schedules to minimize waste and ensure quality.

What Are Common Trade Terms Related to Polyurethane Leather Paint?

Familiarity with trade terminology can facilitate smoother transactions and clearer communication among international buyers and suppliers.

Illustrative image related to polyurethane leather paint

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is crucial for buyers seeking to maintain brand consistency and quality in their finished products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps businesses manage inventory levels and budgeting effectively, ensuring they don’t overcommit financially.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing and other terms for a particular quantity of products. This term is vital for B2B buyers to initiate procurement and negotiate better terms.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with these terms helps buyers understand their obligations and mitigate risks in cross-border trade.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. For buyers, knowing the lead time is essential for planning production schedules and managing customer expectations.

6. Bespoke Solutions

Bespoke solutions refer to customized products tailored to specific customer requirements. This term is significant for buyers looking for unique colors or finishes in polyurethane leather paint, allowing for differentiation in their offerings.

By understanding these technical properties and industry terms, B2B buyers can make informed decisions that align with their operational needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the polyurethane leather paint Sector

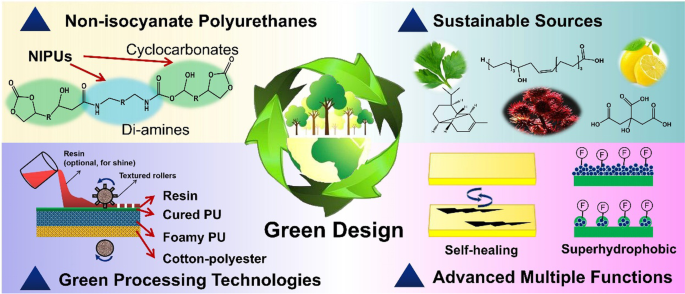

What Are the Current Market Dynamics and Key Trends in Polyurethane Leather Paint?

The polyurethane leather paint market is currently shaped by several global drivers, including rising consumer demand for durable and high-quality leather alternatives. As industries such as automotive, furniture, and fashion increasingly prioritize aesthetics and longevity, the need for polyurethane leather paint—known for its excellent flexibility, color retention, and resistance to wear and tear—has surged. Emerging trends indicate a strong shift towards customization, with suppliers offering extensive color matching services and tailored solutions to meet specific client needs. This trend is particularly relevant for B2B buyers in diverse markets such as Africa, South America, the Middle East, and Europe, where unique color specifications can set a brand apart.

Technological advancements in application methods, such as spray guns and automated systems, are also transforming the sourcing landscape. These innovations enhance efficiency and reduce labor costs, making it easier for manufacturers to adopt polyurethane leather paint. Additionally, the increasing digitization of supply chains allows international buyers to source products more effectively, facilitating smoother transactions and real-time inventory management.

How Is Sustainability Influencing Sourcing Trends in the Polyurethane Leather Paint Market?

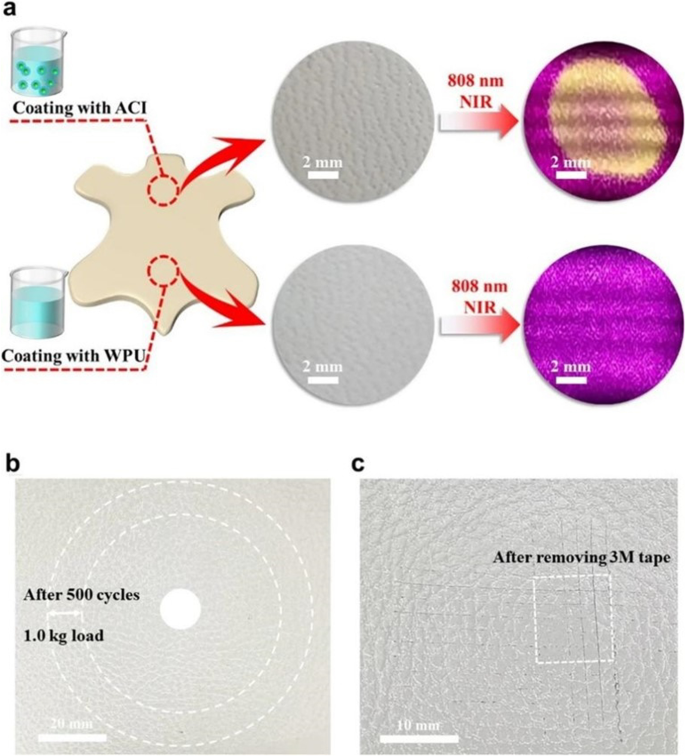

Sustainability has become a pivotal factor in the sourcing of polyurethane leather paint, driven by both regulatory pressures and consumer expectations. B2B buyers are increasingly seeking suppliers that adhere to environmentally friendly practices and provide eco-certified materials. The impact of polyurethane production on the environment, particularly in terms of VOC emissions and waste management, has led many companies to explore greener alternatives, including water-based formulations that minimize harm.

Ethical sourcing is also gaining traction, as businesses aim to build transparent supply chains that emphasize fair labor practices and sustainable resource management. Certifications such as ISO 14001 for environmental management and other green credentials are becoming essential for suppliers looking to engage with discerning international buyers. Implementing these practices not only enhances brand reputation but also mitigates risks associated with non-compliance in various markets.

What Is the Brief Evolution of Polyurethane Leather Paint in the B2B Sector?

The evolution of polyurethane leather paint can be traced back to its initial use in the automotive industry, where durability and flexibility were paramount. Over the years, advancements in chemistry have led to the development of high-performance polyurethane formulations that offer superior resistance to abrasions and environmental stressors. This evolution has expanded its applications beyond automotive interiors to include furniture, fashion, and various consumer goods.

In recent years, the focus has shifted towards customization and sustainability, reflecting broader industry trends. The rise of eco-conscious consumers has prompted manufacturers to invest in research and development of environmentally friendly formulations, ensuring that polyurethane leather paint remains relevant and competitive in a rapidly changing marketplace. As international B2B buyers continue to seek innovative solutions that align with their values, the sector is poised for ongoing growth and transformation.

Frequently Asked Questions (FAQs) for B2B Buyers of polyurethane leather paint

-

How do I select the right polyurethane leather paint for my needs?

Choosing the appropriate polyurethane leather paint involves assessing the specific application requirements, such as the type of leather, desired color finish, and durability expectations. Consider factors like flexibility, colorfastness, and ease of application. It’s beneficial to request samples or conduct small test patches before placing a bulk order. Engaging with suppliers who offer color matching services can also ensure that the paint meets your exact specifications, particularly for custom projects. -

What is the best method for applying polyurethane leather paint?

The application method for polyurethane leather paint can vary based on the product type and the surface area. Generally, it can be applied using a sponge, brush, or spray gun for even coverage. Prior to application, ensure the leather is clean and properly prepared to enhance adhesion. Following the initial application, multiple thin coats are recommended, with adequate drying time in between to achieve a smooth finish. Always refer to the manufacturer’s guidelines for specific instructions. -

What are the minimum order quantities (MOQs) for polyurethane leather paint?

Minimum order quantities for polyurethane leather paint can vary significantly between suppliers. Typically, MOQs may range from a few liters to larger bulk orders, depending on the manufacturer’s production capabilities and your specific needs. When sourcing, it’s advisable to communicate your projected usage to negotiate favorable terms. Suppliers often offer flexibility for first-time buyers or ongoing partnerships, so establishing a good rapport can lead to customized solutions. -

How can I ensure the quality of polyurethane leather paint before purchasing?

To ensure the quality of polyurethane leather paint, request product samples and review technical data sheets that outline the paint’s properties, such as adhesion, flexibility, and resistance to wear. Additionally, inquire about certifications or compliance with international quality standards. Evaluating customer reviews and case studies can provide insights into performance in real-world applications. Establishing a relationship with reputable suppliers known for high-quality products can also mitigate risks. -

What payment terms should I expect when sourcing polyurethane leather paint internationally?

Payment terms for international purchases of polyurethane leather paint can vary widely. Common options include upfront payment, partial payment upon order confirmation, and the balance upon shipment. Letter of Credit (LC) is often used for larger transactions to ensure security for both parties. It’s essential to discuss and agree on payment terms upfront to avoid misunderstandings. Additionally, consider the impact of currency fluctuations and transaction fees when budgeting for your purchase. -

How do I handle logistics and shipping for polyurethane leather paint orders?

Managing logistics for polyurethane leather paint requires careful planning. Coordinate with suppliers to determine the best shipping method based on your location and order size, whether by air or sea freight. Ensure that you understand customs regulations and import duties applicable in your country. Work with experienced freight forwarders to streamline the process and minimize delays. It’s also wise to establish clear communication channels with your supplier for tracking shipments and addressing potential issues. -

What customization options are available for polyurethane leather paint?

Many suppliers offer customization options for polyurethane leather paint, including color matching and formulation adjustments to meet specific application needs. You can often choose from a variety of finishes, such as matte or gloss, and request unique colors that align with your brand. Engaging directly with suppliers about your requirements and requesting samples can help you visualize the final product. Customization typically requires discussing MOQs and lead times to ensure timely delivery. -

What should I look for in a supplier of polyurethane leather paint?

When vetting suppliers for polyurethane leather paint, consider their reputation, experience in the industry, and product range. Look for suppliers who provide detailed product information, including technical data sheets and safety data sheets. Assess their customer service responsiveness and willingness to accommodate special requests or modifications. Additionally, verify their adherence to quality standards and any certifications that may apply to their products. Establishing a partnership with a reliable supplier can significantly enhance your sourcing experience.

Top 5 Polyurethane Leather Paint Manufacturers & Suppliers List

1. Furniture Clinic – Leather Colorant

Domain: furnitureclinic.com

Registered: 2004 (21 years)

Introduction: Leather Colorant – Furniture Clinic

– Extremely Flexible: Withstands 100,000 flexes.

– Hard wearing & high color coverage.

– Soft, delicate & natural look & feel.

– Available in 16 standard colors or over 10,000 custom colors.

– Color matching service available.

– Price: From $21.95

– Ships nationwide with fast shipping available.

– Water-based polyurethane colorants, non-harmful and non-hazardou…

2. Angelus – Leather Paint & Dye

Domain: angelusdirect.com

Registered: 2013 (12 years)

Introduction: Angelus Leather Paint: Vibrant, flexible, and durable acrylic paints for customizing shoes, bags, canvas, wood, and more. Available in over 120 colors. 4-Coat Urethane Clear Coat: Durable and flexible scratch-resistant finish. Low VOC Leather Dye: Permanent, non-flammable formula for leather. Suede Dye: Alcohol-based, industry-strength dye with vibrant colors. Cleaning Products: Includes Shoe Crea…

3. Angelus – Leather Paint

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Angelus – Leather Paint, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. WikiHow – Acrylic and Leather Paint

Domain: wikihow.com

Registered: 2004 (21 years)

Introduction: 1. Acrylic Paint: Available in a range of colors, including metallic and glittery shades, adheres well to faux leather, does not fade easily, and is flexible to prevent cracking. 2. Leather Paint: Acrylic-based, specifically formulated for real and artificial leather, costs between $2 and $8 for a small bottle, less likely to chip or fade. 3. Chalk-Based Paint: Offers a shabby chic, distressed loo…

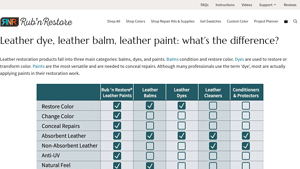

5. RubnRestore – Leather Balms

Domain: rubnrestore.com

Registered: 2010 (15 years)

Introduction: Leather restoration products fall into three main categories: balms, dyes, and paints.

Leather Balms:

– Brands: Furniture Clinic, Fortivo, Clydes, Coconix

– Consistency: Thick, creamy paste

– Contain: Oils and waxes; some also contain dyes

– Great For: Absorbent leather that is dry and faded

– Avoid: Vinyl, areas that repel liquids

– Pros: Moisturizes dry, absorbent leather; semi-transpare…

Strategic Sourcing Conclusion and Outlook for polyurethane leather paint

In the dynamic landscape of polyurethane leather paint, strategic sourcing emerges as a critical factor for success. International B2B buyers across Africa, South America, the Middle East, and Europe must prioritize partnerships with suppliers who offer high-performance, environmentally friendly products that meet diverse market needs. The growing demand for durable, customizable, and safe leather colorants presents significant opportunities for businesses to enhance their offerings while ensuring customer satisfaction.

By leveraging a robust sourcing strategy, companies can access innovative polyurethane solutions that not only provide superior color coverage and flexibility but also demonstrate remarkable resistance to wear and tear. This adaptability is particularly important in regions where climatic conditions may affect product performance.

As the market continues to evolve, buyers should remain proactive in exploring new suppliers, engaging in color-matching services, and investing in quality assurance processes. The future is bright for businesses that embrace these trends, positioning themselves as leaders in the polyurethane leather paint sector. Now is the time to act—evaluate your sourcing strategies and partner with suppliers who align with your vision for growth and sustainability in the coming years.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.