Introduction: Navigating the Global Market for l’agence leather blazer

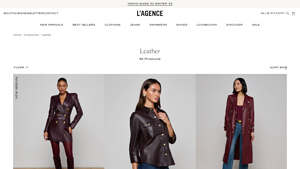

Navigating the global market for L’AGENCE leather blazers presents unique challenges for international B2B buyers seeking to source high-quality, fashionable apparel. With an increasing demand for stylish yet durable outerwear, buyers from regions such as Africa, South America, the Middle East, and Europe, including Vietnam and Nigeria, are tasked with finding products that not only meet aesthetic expectations but also align with their market demands. This comprehensive guide addresses critical factors such as types of leather blazers, their various applications, supplier vetting processes, and cost considerations, empowering buyers to make informed purchasing decisions.

The L’AGENCE leather blazer, crafted from luxurious lambskin leather, is not merely a wardrobe staple; it’s an investment piece that enhances any outfit, making it a sought-after item across diverse markets. Understanding the nuances of sourcing these blazers—from identifying reliable suppliers to evaluating quality and price—can significantly impact your business’s success. This guide will equip you with actionable insights and strategies to navigate the complexities of the leather apparel market, ensuring that you can confidently meet the demands of your clientele while maximizing your return on investment. By leveraging this information, B2B buyers can effectively position themselves in the competitive fashion landscape, ultimately driving growth and profitability.

Table Of Contents

- Top 2 L’Agence Leather Blazer Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for l’agence leather blazer

- Understanding l’agence leather blazer Types and Variations

- Key Industrial Applications of l’agence leather blazer

- 3 Common User Pain Points for ‘l’agence leather blazer’ & Their Solutions

- Strategic Material Selection Guide for l’agence leather blazer

- In-depth Look: Manufacturing Processes and Quality Assurance for l’agence leather blazer

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘l’agence leather blazer’

- Comprehensive Cost and Pricing Analysis for l’agence leather blazer Sourcing

- Alternatives Analysis: Comparing l’agence leather blazer With Other Solutions

- Essential Technical Properties and Trade Terminology for l’agence leather blazer

- Navigating Market Dynamics and Sourcing Trends in the l’agence leather blazer Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of l’agence leather blazer

- Strategic Sourcing Conclusion and Outlook for l’agence leather blazer

- Important Disclaimer & Terms of Use

Understanding l’agence leather blazer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Double-Breasted Blazer | Strong shoulders, peaked lapels, and sophisticated hardware | Corporate environments, formal events | Pros: Timeless style, versatility. Cons: Higher price point. |

| Tailored Leather Blazer | Fitted silhouette, elegant design, often with feminine detailing | Business meetings, upscale gatherings | Pros: Professional appearance, flattering fit. Cons: Limited casual use. |

| Cropped Leather Blazer | Shorter length, edgy style, often featuring unique embellishments | Fashion-forward retail, casual outings | Pros: Trendy, youthful vibe. Cons: Less suitable for formal occasions. |

| Shearling-Lined Blazer | Insulated with shearling, luxurious feel, ideal for colder climates | Winter collections, luxury boutiques | Pros: Warmth, comfort. Cons: Seasonal use, higher maintenance. |

| Embellished Leather Blazer | Decorative zippers, bold hardware, and unique textures | Fashion shows, creative industries | Pros: Statement piece, attracts attention. Cons: Niche appeal, may not suit all markets. |

What Are the Key Characteristics of Double-Breasted Blazers from L’AGENCE?

Double-breasted blazers from L’AGENCE are characterized by their strong shoulders and peaked lapels, which create a powerful silhouette. These blazers often feature high-quality lambskin leather and meticulous craftsmanship, making them ideal for corporate environments and formal events. B2B buyers should consider their versatility and timeless appeal, which allows for a seamless transition from day to evening wear. However, the higher price point may require justification in budget-conscious markets.

How Do Tailored Leather Blazers Enhance Professional Wardrobes?

Tailored leather blazers offer a fitted silhouette that enhances the wearer’s shape while maintaining an elegant design. This style is particularly suitable for business meetings and upscale gatherings, where a polished appearance is paramount. B2B buyers looking to invest in professional attire will find that these blazers elevate any outfit, making them a staple in high-end fashion retail. The only downside is their limited casual applicability, which may restrict their use in more relaxed settings.

Why Are Cropped Leather Blazers Popular Among Younger Consumers?

Cropped leather blazers present a trendy, youthful vibe with their shorter length and edgy styling. Often adorned with unique embellishments, they are perfect for fashion-forward retail environments and casual outings. B2B buyers targeting a younger demographic should consider these blazers for their ability to resonate with contemporary fashion trends. However, their less formal nature may make them unsuitable for traditional corporate settings, limiting their market reach.

What Advantages Do Shearling-Lined Blazers Offer in Cold Weather?

Shearling-lined blazers combine luxury with functionality, providing warmth and comfort during colder months. This style is ideal for winter collections and luxury boutiques, appealing to consumers who prioritize both style and practicality. B2B buyers should note that while these blazers are a great investment for seasonal offerings, their higher maintenance needs and limited wearability outside of winter months could pose challenges in inventory management.

How Can Embellished Leather Blazers Make a Statement in Fashion?

Embellished leather blazers stand out due to their decorative zippers, bold hardware, and unique textures, making them a popular choice in fashion shows and creative industries. These statement pieces attract attention and are perfect for buyers looking to curate distinctive collections. However, the niche appeal of embellished designs may limit their suitability in more conservative markets, necessitating careful market research before procurement.

Illustrative image related to l’agence leather blazer

Key Industrial Applications of l’agence leather blazer

| Industry/Sector | Specific Application of l’agence leather blazer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion Retail | High-end women’s fashion collections featuring leather blazers | Enhances brand prestige and attracts discerning customers | Focus on quality, craftsmanship, and sustainable sourcing practices |

| Corporate Fashion | Professional attire for executive women in corporate environments | Elevates employee appearance and fosters a strong company image | Ensure availability in various sizes and styles to meet diverse needs |

| Event Management | Outfits for staff at upscale events and fashion shows | Creates a cohesive and stylish look that enhances brand visibility | Consider seasonal trends and color options for versatility |

| E-commerce | Online sales of luxury leather blazers | Expands market reach and caters to global clientele | Optimize for international shipping and return policies |

| Hospitality | Uniforms for front-of-house staff in luxury hotels and restaurants | Contributes to an upscale ambiance and customer experience | Prioritize comfort and durability for daily wear |

How is the l’agence leather blazer utilized in the fashion retail industry?

In the fashion retail sector, l’agence leather blazers serve as essential pieces in high-end women’s collections. Retailers can leverage these blazers to attract style-conscious customers who seek luxury and quality. The blazers’ unique design features, such as sharp lapels and tailored fits, enhance the overall aesthetic of a fashion line, making them a staple for upscale boutiques. International buyers must consider the latest trends and the importance of sustainable sourcing to align with consumer expectations in various markets.

What role does the l’agence leather blazer play in corporate fashion?

For corporate environments, l’agence leather blazers are ideal for professional attire, particularly for executive women. These blazers provide a polished appearance that reflects professionalism and authority. By integrating high-quality leather pieces into their dress code, companies can enhance their corporate image and ensure employees feel confident and empowered. Buyers should focus on the availability of different sizes and styles to accommodate diverse body types and preferences.

How can event management companies benefit from l’agence leather blazers?

Event management companies can utilize l’agence leather blazers for staff uniforms at upscale events and fashion shows. These blazers not only promote a cohesive and sophisticated look but also elevate the overall brand visibility during high-profile gatherings. The durability and luxury of leather make these blazers suitable for various occasions, ensuring staff members present a polished image. When sourcing, companies should consider seasonal trends and color options to ensure versatility and relevance.

In what ways can e-commerce platforms leverage l’agence leather blazers?

E-commerce platforms can benefit from offering l’agence leather blazers as part of their luxury fashion selections. These blazers appeal to a global audience, allowing online retailers to expand their market reach. High-quality product images and detailed descriptions are essential for attracting international buyers. Additionally, optimizing shipping and return policies for global customers can enhance customer satisfaction and drive repeat purchases, making it a critical consideration for online sellers.

How do hospitality businesses incorporate l’agence leather blazers into their operations?

In the hospitality industry, l’agence leather blazers can be used as uniforms for front-of-house staff in luxury hotels and restaurants. These blazers contribute to an upscale ambiance, enhancing the overall customer experience. The combination of style and comfort is crucial, as staff members are often on their feet for long periods. Buyers in this sector should prioritize sourcing options that ensure durability and ease of care, as well as the ability to accommodate various sizes and fits for diverse staff members.

3 Common User Pain Points for ‘l’agence leather blazer’ & Their Solutions

Scenario 1: Sourcing Quality Leather Blazers for Diverse Markets

The Problem: B2B buyers often face the challenge of sourcing high-quality leather blazers that meet the varied tastes and preferences of different markets, particularly in regions like Africa, South America, and the Middle East. The disparity in climate, cultural styles, and fashion trends can complicate the selection process. For instance, a blazer that resonates with buyers in Europe may not appeal to clients in Nigeria or Brazil, where styles and fabric preferences can differ significantly. Additionally, concerns about the authenticity and quality of leather can lead to apprehension during the purchasing process.

The Solution: To effectively address these challenges, B2B buyers should establish a robust communication channel with suppliers like L’AGENCE to discuss market-specific trends and demands. Conducting market research to understand regional preferences can also be invaluable. For example, buyers might focus on lighter leather options for warmer climates or seek out vibrant colors and unique designs favored in South American markets. Additionally, leveraging L’AGENCE’s expertise in lambskin leather can ensure buyers receive products that are not only stylish but also durable. Setting up sample orders for different styles can also help gauge market reactions before committing to larger purchases.

Illustrative image related to l’agence leather blazer

Scenario 2: Managing Logistics and Shipping Challenges

The Problem: International shipping presents significant challenges, especially when dealing with luxury items like leather blazers. B2B buyers often grapple with high shipping costs, lengthy delivery times, and potential customs complications, which can delay inventory availability and impact sales. Furthermore, understanding the return policies for international orders can be confusing, particularly when the garments may need to be returned due to sizing issues or defects.

The Solution: To mitigate these logistics challenges, buyers should work closely with L’AGENCE to understand their shipping policies and explore options for bulk purchasing that can reduce per-item shipping costs. Implementing a comprehensive logistics strategy that includes partnering with reliable freight forwarders can also streamline the shipping process. Buyers should consider opting for a consolidated shipping method to save costs and ensure faster delivery times. Additionally, establishing clear communication with suppliers regarding their return policies can help buyers feel more secure in their purchases, allowing them to confidently address any potential issues that may arise after delivery.

Scenario 3: Ensuring Proper Care and Maintenance for Leather Blazers

The Problem: Leather products require specific care and maintenance, which can be a concern for B2B buyers and their customers. Mismanagement can lead to premature wear, affecting the product’s appeal and longevity. This is particularly critical in regions with varying climates, where humidity and temperature can affect leather quality. Buyers may find themselves in a position where they need to educate their customers on how to maintain their leather blazers properly, which can be a daunting task.

The Solution: B2B buyers should proactively provide care instructions and maintenance tips when selling L’AGENCE leather blazers. This can include guidance on dry cleaning practices, recommended products for leather care, and tips on storage to prevent damage. Collaborating with L’AGENCE to create informative content, such as care guides or instructional videos, can help educate end customers and enhance their purchasing experience. Buyers can also consider offering leather care kits as an add-on sale, which can further elevate customer satisfaction and promote the longevity of the blazers. By prioritizing customer education, buyers can foster loyalty and encourage repeat business.

Strategic Material Selection Guide for l’agence leather blazer

What Are the Key Materials Used in L’agence Leather Blazers?

When considering the materials for L’agence leather blazers, several key options stand out, each with unique properties and implications for performance, durability, and market suitability. This analysis focuses on lambskin leather, vegan leather, shearling, and suede, providing actionable insights for international B2B buyers.

How Does Lambskin Leather Perform in L’agence Leather Blazers?

Lambskin leather is the primary material used in L’agence leather blazers. Known for its softness and luxurious feel, lambskin has a high tensile strength, making it durable yet lightweight. It typically performs well in various temperatures, providing comfort in both cooler and warmer climates. However, lambskin is less resistant to abrasion compared to other leathers, which may affect its longevity in high-wear situations.

Pros: The primary advantages of lambskin include its luxurious appearance, softness, and ability to mold to the wearer’s body over time. It is also relatively easy to dye, allowing for vibrant colors and patterns.

Cons: The main drawback is its susceptibility to scratches and stains, which can require careful maintenance. Additionally, lambskin is generally more expensive than other leather types, which may impact pricing strategies for B2B buyers.

International buyers should consider the care requirements for lambskin, as it typically requires dry cleaning by a leather specialist. Compliance with local regulations regarding leather sourcing and treatment is also essential, particularly in regions with strict environmental standards.

What About Vegan Leather as an Alternative Material?

Vegan leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), has gained popularity as a sustainable alternative to traditional leather. It is generally water-resistant and easy to clean, making it suitable for various climates. However, the durability of vegan leather can vary significantly based on manufacturing quality.

Pros: The key advantages of vegan leather include its ethical appeal and lower environmental impact during production. It is also typically less expensive than lambskin, making it an attractive option for budget-conscious buyers.

Cons: On the downside, vegan leather may not offer the same breathability and comfort as natural leather. Its longevity can also be questionable, particularly under rigorous use.

B2B buyers in regions like Africa and South America may find vegan leather appealing due to its lower cost and ethical considerations. However, they should be aware of potential compliance issues with local regulations regarding synthetic materials.

How Does Shearling Enhance L’agence Leather Blazers?

Shearling, a type of sheepskin with the wool still attached, provides excellent insulation and warmth, making it ideal for colder climates. Its natural properties allow for breathability, ensuring comfort during wear. Shearling is also durable, providing a rugged yet stylish look.

Pros: The primary advantages of shearling include its warmth and comfort, making it suitable for winter collections. Its unique texture also adds a luxurious touch to the blazers.

Cons: The main limitation is the higher cost associated with shearling, as well as specific care requirements, which often involve professional cleaning.

For international buyers, particularly in colder regions, shearling can be a strong selling point. However, they must consider compliance with animal welfare regulations and sourcing standards.

Illustrative image related to l’agence leather blazer

What Role Does Suede Play in L’agence Leather Blazers?

Suede, made from the underside of animal hides, offers a unique texture and aesthetic appeal. It is softer than traditional leather and provides a distinctive look. However, suede is less durable and more susceptible to staining and water damage.

Pros: Suede’s softness and luxurious feel make it a desirable option for fashion-forward designs. It can also be dyed easily, allowing for a variety of color options.

Cons: The main drawbacks include its lower durability and higher maintenance needs, as it can be easily damaged by moisture.

International B2B buyers should consider the market demand for suede in their regions. Compliance with sourcing standards and consumer preferences for sustainable materials will also influence purchasing decisions.

Summary Table of Materials for L’agence Leather Blazers

| Materiał | Typical Use Case for l’agence leather blazer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Lambskin Leather | Main material for blazers | Softness and luxurious feel | Susceptible to scratches and stains | High |

| Skóra wegańska | Sustainable alternative | Ethical appeal and lower cost | Durability varies | Medium |

| Shearling | Winter collections | Excellent insulation and warmth | Higher cost and care requirements | High |

| Suede | Fashion-forward designs | Unique texture and aesthetic appeal | Less durable and moisture-sensitive | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the various materials used in L’agence leather blazers, aiding in informed purchasing decisions tailored to regional preferences and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for l’agence leather blazer

What Are the Key Manufacturing Processes for L’AGENCE Leather Blazers?

The manufacturing of L’AGENCE leather blazers involves a meticulous process that ensures each piece meets high standards of quality and craftsmanship. The main stages of production include material preparation, forming, assembly, and finishing.

How Is Material Prepared for L’AGENCE Leather Blazers?

The journey begins with the selection of premium lambskin leather, renowned for its softness and durability. Sourcing from reputable tanneries, the leather undergoes rigorous quality checks to ensure it meets L’AGENCE’s specifications for texture and color consistency. Once the leather is selected, it is hand-sanded to create a vintage feel, enhancing its aesthetic appeal. This preparation stage is critical as it lays the foundation for the overall quality of the finished blazer.

What Techniques Are Used in Forming and Assembly?

In the forming stage, skilled artisans cut the leather into precise patterns using both traditional techniques and modern technology such as CAD (Computer-Aided Design). This ensures accuracy and minimizes waste. The assembly process involves sewing the individual pieces together, where attention to detail is paramount. Techniques such as double-stitching are often employed to enhance durability, particularly in areas subject to stress, such as seams and pockets.

During assembly, features like peaked lapels, embossed dome buttons, and decorative zippers are added. Each blazer is then fitted to ensure a flattering silhouette, which is crucial for the brand’s identity. This phase is essential for creating a product that not only meets aesthetic standards but also provides comfort and functionality.

What Finishing Processes Are Applied to L’AGENCE Leather Blazers?

The finishing stage includes several steps to ensure each blazer is polished and ready for the market. This involves quality checks for stitching, alignment, and overall appearance. Additionally, each blazer is fully lined to enhance comfort and durability. Final inspections include testing for color fastness and ensuring that all hardware functions properly.

Illustrative image related to l’agence leather blazer

The blazers are then carefully packed, often with protective materials to prevent damage during shipping. This attention to detail in the finishing process reflects L’AGENCE’s commitment to quality, making each piece an investment for buyers.

What Quality Assurance Standards Are Followed for L’AGENCE Leather Blazers?

Quality assurance is integral to the manufacturing of L’AGENCE leather blazers. The company adheres to international standards such as ISO 9001, which focuses on quality management systems. This certification ensures that the manufacturing processes consistently meet customer and regulatory requirements.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are established at various stages of the production process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting the raw materials, such as leather and hardware, for defects before they enter the production line.

-

In-Process Quality Control (IPQC): Throughout the assembly process, random inspections are conducted to ensure that each stage adheres to quality standards. This includes checks for stitching accuracy, alignment, and the functionality of components like zippers and buttons.

-

Final Quality Control (FQC): After the blazers are completed, a comprehensive inspection is performed. This includes examining the overall appearance, fit, and function of the blazer. Any product that does not meet the established criteria is either reworked or discarded.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are some actionable strategies:

-

Conduct Audits: Regular audits of suppliers can help assess compliance with quality standards. Buyers should request audit reports that detail the supplier’s adherence to ISO 9001 and other relevant certifications.

-

Request Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including test results and QC checkpoint records. This transparency builds trust and ensures accountability.

-

Engage Third-Party Inspections: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These services can conduct random inspections and provide detailed reports on compliance and quality metrics.

What Are the Nuances of Quality Control for International Buyers?

International buyers face unique challenges when sourcing products like leather blazers. Factors such as varying regulatory standards, cultural expectations, and logistics must be considered. For instance, buyers from Africa and South America may encounter different quality expectations compared to European markets.

Understanding local regulations regarding leather products, including any environmental considerations and import restrictions, is essential. Buyers should also familiarize themselves with the specific quality certifications that are recognized in their region to ensure compliance and acceptance in their markets.

In conclusion, the manufacturing and quality assurance processes for L’AGENCE leather blazers emphasize meticulous craftsmanship and adherence to international quality standards. By understanding these processes, B2B buyers can make informed decisions, ensuring they source high-quality products that meet their market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘l’agence leather blazer’

Wprowadzenie

This sourcing guide is designed for international B2B buyers interested in procuring L’AGENCE leather blazers. It outlines essential steps to ensure a successful procurement process, from understanding product specifications to evaluating suppliers and managing logistics. By following this checklist, buyers can make informed decisions that align with their business needs and market demands.

1. Identify Your Market Needs

Understanding your target market’s preferences is crucial. Research fashion trends and customer demographics in your region—Africa, South America, the Middle East, or Europe. This information will help you determine which styles, colors, and sizes of L’AGENCE leather blazers will be most appealing to your customers.

2. Define Your Technical Specifications

Establish clear technical specifications for the leather blazers you intend to source. Consider factors such as material quality (e.g., 100% lambskin leather), design features (e.g., double-breasted, zippered pockets), and size ranges. This step ensures that the products you source meet your quality standards and customer expectations.

3. Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of L’AGENCE products. Look for suppliers with a proven track record in the fashion industry, particularly those specializing in leather goods. Utilize online directories, trade shows, and industry publications to compile a list of potential partners.

4. Evaluate Supplier Credentials

Before proceeding, vet potential suppliers to ensure they meet your business standards. Request documentation such as business licenses, certifications, and references from existing clients. It’s essential to verify their capability to deliver high-quality products consistently and understand their production processes.

Illustrative image related to l’agence leather blazer

5. Request Product Samples

Always request samples of the leather blazers before placing a bulk order. Assess the craftsmanship, material quality, and fit to ensure they align with your specifications. This step is vital for evaluating the supplier’s ability to meet your quality expectations and helps avoid costly mistakes later.

6. Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Clear terms can prevent misunderstandings and ensure a smooth transaction. Be sure to discuss minimum order quantities and potential discounts for larger orders, which can impact your overall cost.

7. Plan for Logistics and Distribution

Consider the logistics involved in transporting the blazers to your target market. Evaluate shipping options, customs regulations, and potential tariffs that may apply. Establishing a reliable distribution plan is crucial for timely delivery and maintaining inventory levels in line with demand.

By adhering to this checklist, B2B buyers can effectively source L’AGENCE leather blazers that meet market demands and enhance their product offerings.

Comprehensive Cost and Pricing Analysis for l’agence leather blazer Sourcing

What Are the Key Cost Components for Sourcing L’AGENCE Leather Blazers?

When considering the sourcing of L’AGENCE leather blazers, it is essential to understand the various cost components that contribute to the final price. The primary elements include:

-

Materials: The blazers are made from 100% lambskin leather, a premium material known for its softness and durability. The cost of high-quality leather can fluctuate based on market demand and availability, impacting the overall product price.

-

Labor: Skilled craftsmanship is crucial in the production of leather garments. Labor costs vary significantly by region, with countries offering lower labor rates potentially providing a more cost-effective solution. However, this may come at the expense of quality.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing practices can help mitigate these costs.

-

Tooling: Initial tooling costs for creating patterns and molds can be substantial, especially for custom designs. These costs are typically amortized over larger production runs.

-

Quality Control (QC): Ensuring the quality of leather blazers through rigorous QC processes is vital. This includes inspections at various stages of production, which adds to the overall cost but is necessary to maintain brand reputation.

-

Logistics: Shipping costs can significantly influence the pricing structure. International shipping, especially to regions like Africa or South America, may involve additional tariffs and taxes, which should be factored into the total cost.

-

Margin: The profit margin for suppliers can vary widely, influenced by brand positioning and market competition. Understanding the supplier’s margin can provide insights into potential negotiation points.

How Do Price Influencers Affect the Sourcing of Leather Blazers?

Several factors can influence the pricing of L’AGENCE leather blazers:

-

Volume/MOQ: Minimum Order Quantities (MOQ) can significantly affect pricing. Larger orders typically result in lower per-unit costs, making it advantageous for buyers to consolidate orders.

-

Specifications and Customization: Custom designs or specific features can lead to increased costs. Buyers should weigh the benefits of unique specifications against potential price hikes.

-

Material Quality and Certifications: Certifications for ethical sourcing and sustainability can add to costs but may appeal to certain markets. Buyers should consider the long-term value of sourcing certified products.

-

Supplier Factors: The reputation and reliability of suppliers play a crucial role. Established suppliers may charge a premium for their services but often provide better quality assurance and support.

-

Incoterms: Understanding International Commercial Terms (Incoterms) is vital for international buyers. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can influence the total landed cost of goods.

What Are Effective Buyer Tips for Negotiating Leather Blazer Prices?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation and cost management strategies are essential:

-

Negotiate Wisely: Build relationships with suppliers to facilitate better pricing. Leverage volume orders and long-term contracts to negotiate favorable terms.

-

Focus on Cost Efficiency: Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also logistics, handling, and potential return costs. This holistic view can lead to better purchasing decisions.

-

Understand Pricing Nuances: Be aware of the market dynamics and seasonal trends that can affect leather prices. For instance, demand spikes during fashion seasons can lead to higher costs.

-

Leverage Local Insights: Utilize local agents or experts who understand the market landscape and can provide insights into the best sourcing practices.

-

Stay Informed: Regularly monitor changes in material costs and labor markets. Being informed can give buyers an edge in negotiations and help them make timely purchasing decisions.

By comprehensively understanding these cost components, price influencers, and effective negotiation strategies, B2B buyers can make informed decisions when sourcing L’AGENCE leather blazers, ensuring they achieve the best value for their investment.

Alternatives Analysis: Comparing l’agence leather blazer With Other Solutions

Introduction to Alternative Solutions for Leather Blazers

When evaluating options for leather blazers, B2B buyers must consider various alternatives that can meet their specific needs in terms of style, functionality, and budget. While the L’Agence leather blazer is a high-quality option known for its luxurious materials and craftsmanship, alternatives exist that may offer different advantages. This analysis will compare the L’Agence leather blazer with two notable alternatives: the AllSaints leather blazer and the Mango faux leather blazer.

Comparison Table

| Comparison Aspect | L’Agence Leather Blazer | AllSaints Leather Blazer | Mango Faux Leather Blazer |

|---|---|---|---|

| Performance | High durability and style; crafted from 100% lambskin leather, ensuring a luxurious feel. | Good durability; made from sheep leather, providing a rugged but chic look. | Moderate durability; faux leather offers a stylish appearance but may not last as long as genuine leather. |

| Cost | Premium pricing ($1,350 – $2,200) reflecting high-quality materials and craftsmanship. | Mid-range pricing ($800 – $1,200) offering a balance between quality and affordability. | Budget-friendly ($50 – $150) making it accessible for larger orders or cost-sensitive buyers. |

| Ease of Implementation | Requires careful handling and professional dry cleaning, which may complicate upkeep. | Similar care requirements but may offer more robust wearability for everyday use. | Easy to maintain; can be machine washed, appealing for casual use. |

| Maintenance | High maintenance; necessitates specialized care to maintain appearance and longevity. | Moderate maintenance; requires regular cleaning but is generally more forgiving. | Low maintenance; simple cleaning processes, suitable for casual or everyday wear. |

| Best Use Case | Ideal for upscale events and professional settings where a polished look is essential. | Suitable for both casual and semi-formal occasions, providing versatility. | Best for everyday wear and casual outings, appealing to budget-conscious buyers. |

Detailed Breakdown of Alternatives

AllSaints Leather Blazer

The AllSaints leather blazer is a strong contender, made from sheep leather that offers a slightly more rugged aesthetic compared to the L’Agence option. It is priced more moderately, making it a viable choice for businesses looking for quality without the premium price tag. While it requires similar care to maintain its appearance, it is often viewed as more versatile for various occasions. However, it may not provide the same level of luxury or softness as lambskin leather.

Mango Faux Leather Blazer

For buyers with a limited budget, the Mango faux leather blazer presents an attractive alternative. Priced significantly lower, it allows for bulk purchases without a considerable financial commitment. It is easy to care for, making it ideal for businesses that prioritize practicality over luxury. However, the faux leather may not offer the same durability or upscale appearance as real leather options, making it less suitable for formal settings.

Conclusion: Choosing the Right Leather Blazer for Your Needs

When selecting the appropriate leather blazer for your business, consider factors such as budget, intended use, and maintenance requirements. The L’Agence leather blazer stands out for its premium materials and sophisticated style, making it perfect for high-end events. However, if cost is a primary concern, AllSaints provides a balance between quality and affordability, while Mango offers a budget-friendly, low-maintenance option. Assessing these alternatives will help B2B buyers make informed decisions that align with their specific needs and brand image.

Essential Technical Properties and Trade Terminology for l’agence leather blazer

What Are the Key Technical Properties of L’AGENCE Leather Blazers?

When considering a purchase of L’AGENCE leather blazers, understanding their technical properties is crucial for B2B buyers. Here are several key specifications that define the quality and appeal of these products:

-

Material Composition: What Makes L’AGENCE Leather Blazers Stand Out?

L’AGENCE leather blazers are primarily made from 100% lambskin leather. This material is favored for its softness, durability, and luxurious feel. Lambskin is known for its fine grain and lightweight properties, making it a premium choice for high-end fashion. For B2B buyers, this means investing in products that not only look great but also offer longevity and comfort, essential for customer satisfaction and brand reputation. -

Construction Quality: How Is Craftsmanship Reflected in the Product?

Each blazer features meticulous craftsmanship, with elements like expertly handled flap pockets and reinforced seams. The double-breasted style, strong shoulders, and fitted waist provide a structured silhouette. For businesses, understanding the construction quality is vital as it directly impacts the product’s durability and overall aesthetic appeal. A well-constructed blazer translates to fewer returns and higher customer loyalty. -

Fit and Sizing: Why Is Accurate Sizing Important for B2B Purchases?

L’AGENCE blazers come in various sizes, and their tailored fit is designed to enhance the wearer’s silhouette. Accurate sizing is essential for reducing returns and ensuring customer satisfaction. For international buyers, knowing the sizing standards and fit of the blazers can help in making informed purchasing decisions, leading to better inventory management. -

Care Instructions: What Maintenance Is Required for Longevity?

The care instructions for L’AGENCE leather blazers typically recommend professional dry cleaning. This information is crucial for B2B buyers, as it affects the product’s maintenance and lifespan. Understanding care requirements helps businesses set realistic expectations for their customers and aids in promoting proper care practices. -

Design Features: What Elements Contribute to the Blazer’s Style?

Key design features of L’AGENCE leather blazers include embossed dome buttons, decorative zippers, and unique shoulder designs. These elements not only add to the aesthetic appeal but also differentiate the product in a competitive market. For B2B buyers, recognizing these design characteristics can inform marketing strategies and help in positioning the product effectively.

What Common Trade Terms Should B2B Buyers Know When Purchasing L’AGENCE Leather Blazers?

Understanding industry terminology is essential for navigating B2B transactions effectively. Here are several common terms relevant to purchasing L’AGENCE leather blazers:

-

OEM (Original Equipment Manufacturer): What Does It Mean in Fashion?

OEM refers to a company that produces products or components that are used in another company’s end product. In the fashion industry, this can relate to manufacturers that create garments for brands like L’AGENCE. Knowing about OEM can help buyers understand sourcing options and quality control processes. -

MOQ (Minimum Order Quantity): Why Is This Important?

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding MOQ is crucial for budgeting and inventory planning. L’AGENCE may have specific MOQs that influence purchasing decisions, especially for smaller retailers. -

RFQ (Request for Quotation): How Do You Use It?

An RFQ is a document used to invite suppliers to bid on specific products or services. For buyers interested in L’AGENCE leather blazers, issuing an RFQ can help gather pricing and availability information, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms): What Do They Cover?

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms is essential for B2B buyers, particularly when importing L’AGENCE blazers, as they dictate shipping responsibilities, costs, and risk management. -

Lead Time: What Should You Expect?

Lead time refers to the amount of time from placing an order to its delivery. Understanding lead time is vital for inventory management and planning marketing strategies. B2B buyers must consider this when ordering L’AGENCE products to ensure timely availability for their customers.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing L’AGENCE leather blazers, ultimately enhancing their product offerings and customer satisfaction.

Illustrative image related to l’agence leather blazer

Navigating Market Dynamics and Sourcing Trends in the l’agence leather blazer Sector

What Are the Current Market Trends Influencing the L’AGENCE Leather Blazer Sector?

The leather blazer market, particularly in the context of L’AGENCE products, is witnessing a significant evolution driven by global fashion trends and consumer preferences. As international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, begin to explore these offerings, several key trends emerge. Firstly, there is a growing demand for luxury leather apparel that combines aesthetics with functionality. High-quality lambskin, as used in L’AGENCE blazers, is increasingly favored for its durability and sophisticated appeal.

Additionally, the influence of e-commerce is reshaping how buyers source these products. Digital platforms facilitate direct access to manufacturers and brands, allowing for streamlined purchasing processes and enhanced visibility into product offerings. B2B buyers are also leveraging data analytics to understand consumer preferences better, enabling them to make informed purchasing decisions based on market insights. The rise of social media marketing has further amplified brand visibility, creating a direct link between fashion trends and consumer behavior.

Lastly, the demand for customization is on the rise, as buyers look for unique products that resonate with their brand identity. This trend is particularly relevant for the L’AGENCE leather blazer, where distinctive designs and personalized features can set businesses apart in competitive markets.

How Is Sustainability Shaping the Sourcing of L’AGENCE Leather Blazers?

Sustainability and ethical sourcing have become paramount considerations in the leather apparel industry. As B2B buyers become increasingly conscientious about environmental impact, sourcing from brands that prioritize sustainable practices is essential. L’AGENCE is committed to responsible production methods, utilizing leather sourced from suppliers who adhere to strict environmental standards. This focus not only enhances brand reputation but also meets the growing consumer demand for sustainable fashion.

The importance of ethical supply chains cannot be overstated. Buyers are now seeking suppliers who can provide transparency in their sourcing processes, ensuring that materials are obtained in a manner that respects both human rights and environmental integrity. Brands that offer certifications for eco-friendly practices, such as the use of vegetable-tanned leather or adherence to fair labor standards, are more likely to attract B2B partnerships.

Moreover, the integration of innovative materials, such as vegan leather alternatives, is becoming a viable option for buyers looking to align with sustainable initiatives without compromising on quality or style. This shift towards greener materials and ethical production methods is not just a trend; it represents a fundamental transformation in how businesses approach sourcing and manufacturing.

What Is the Historical Context Behind L’AGENCE’s Leather Blazer Offerings?

L’AGENCE has established itself as a prominent player in the luxury fashion sector, particularly known for its high-quality leather apparel. The brand’s history reflects a commitment to craftsmanship and timeless design, with a focus on creating pieces that transcend seasonal trends. Since its inception, L’AGENCE has embraced the essence of modern femininity, integrating classic silhouettes with contemporary materials.

The evolution of the leather blazer within the brand’s portfolio showcases a blend of tradition and innovation. By utilizing premium lambskin and employing meticulous construction techniques, L’AGENCE has positioned its leather blazers as staple items in the wardrobes of discerning buyers. This legacy of quality and style has not only solidified L’AGENCE’s reputation but has also paved the way for international B2B partnerships, as retailers seek to offer their customers luxury products that reflect both sophistication and ethical considerations in sourcing.

Frequently Asked Questions (FAQs) for B2B Buyers of l’agence leather blazer

-

How can I ensure the quality of L’AGENCE leather blazers before purchasing?

To guarantee the quality of L’AGENCE leather blazers, consider requesting samples from the supplier. Inspect the leather for suppleness and craftsmanship, including stitching and hardware quality. Additionally, verify if the products adhere to your country’s quality standards and regulations. Establishing a clear communication channel with the supplier for quality assurance checks can further ensure that the products meet your expectations. -

What are the typical lead times for ordering L’AGENCE leather blazers?

Lead times for L’AGENCE leather blazers can vary based on factors such as order size and customization requirements. Generally, expect a lead time of 4 to 8 weeks for bulk orders. For customized items, this may extend to 10 weeks or longer. It’s advisable to discuss and confirm specific timelines with your supplier to align expectations and avoid potential delays. -

What is the minimum order quantity (MOQ) for L’AGENCE leather blazers?

The minimum order quantity (MOQ) for L’AGENCE leather blazers typically starts at 10 to 20 units, depending on the model and customization options. For bulk orders, many suppliers offer tiered pricing, where larger quantities can yield better rates. Always confirm MOQs directly with the supplier, as they can vary by product line and availability. -

Can I customize L’AGENCE leather blazers to meet my brand’s specifications?

Yes, many suppliers allow customization of L’AGENCE leather blazers, which can include adjustments to size, color, and design features. Customization options may depend on order volume and specific supplier capabilities. Ensure you communicate your needs clearly and obtain samples of customizations to assess quality before placing a full order. -

What payment terms are typically offered for purchasing L’AGENCE leather blazers?

Payment terms can vary widely among suppliers but often include options like 30% upfront payment with the balance due upon shipment or delivery. Some suppliers may also accept letters of credit for larger orders. It is crucial to clarify payment terms during negotiations to ensure that they align with your cash flow and budgeting processes. -

How do I vet a supplier for sourcing L’AGENCE leather blazers?

To vet a supplier effectively, start by checking their business credentials, such as registration and certifications. Request references from previous clients and review customer feedback online. Consider visiting the supplier’s facility if feasible, or conduct a virtual tour. Understanding their production capabilities and quality assurance processes will also help assess their reliability. -

What logistics considerations should I keep in mind when importing L’AGENCE leather blazers?

When importing L’AGENCE leather blazers, factor in logistics aspects such as shipping methods, customs clearance, and duties. Choose a reliable freight forwarder experienced in handling fashion goods. Additionally, understand the import regulations of your country, as they can affect delivery times and costs. Clear communication with your supplier regarding shipping timelines is also essential for smooth operations. -

What are the best practices for marketing L’AGENCE leather blazers in international markets?

To successfully market L’AGENCE leather blazers in international markets, conduct thorough market research to understand local consumer preferences and trends. Utilize social media and influencer partnerships to enhance brand visibility. Highlight unique selling points, such as quality craftsmanship and sustainable sourcing, in your promotional materials. Tailoring your marketing strategy to resonate with local cultures will enhance engagement and drive sales.

Top 2 L’Agence Leather Blazer Manufacturers & Suppliers List

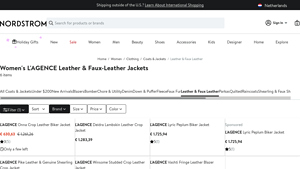

1. L’Agence – Women’s Leather Jackets & Clothing Collection

Domain: lagence.com

Registered: 1999 (26 years)

Introduction: Women’s Leather Jackets & Clothing collection includes 54 products categorized into various types such as Belts (19), Blazers (7), Blouses (1), Jackets (11), Outerwear (3), Pants (5), and Shirts (1). The collection features new arrivals and allows sorting by featured items, best selling, alphabetically, and by price. It includes options for evening and workwear styles, with specific styles like st…

2. Nordstrom – Winsome Studded Crop Leather Jacket

Domain: nordstrom.com

Registered: 1994 (31 years)

Introduction: This company, Nordstrom – Winsome Studded Crop Leather Jacket, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for l’agence leather blazer

In conclusion, strategic sourcing for L’AGENCE leather blazers presents a significant opportunity for international B2B buyers seeking high-quality, stylish leather apparel. The brand’s commitment to meticulous craftsmanship and the use of premium lambskin leather ensures that each piece not only meets aesthetic standards but also offers durability and timeless appeal. By focusing on the distinctive features of L’AGENCE’s blazers, such as tailored silhouettes, luxurious finishes, and versatile styling options, buyers can cater to a diverse clientele eager for sophisticated fashion solutions.

As the demand for premium leather goods continues to rise across markets in Africa, South America, the Middle East, and Europe, strategic partnerships with brands like L’AGENCE can enhance product offerings and drive sales. Buyers are encouraged to leverage these insights to make informed purchasing decisions that align with market trends and consumer preferences.

Looking ahead, the potential for growth in the leather fashion segment remains robust. International B2B buyers should act proactively to secure their inventory, ensuring they are well-positioned to capitalize on emerging trends and consumer demands. Explore the L’AGENCE collection today to elevate your brand’s offerings and meet the evolving needs of your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.