Introduction: Navigating the Global Market for custom leather works

In today’s competitive landscape, sourcing high-quality custom leather works can be a daunting task for international B2B buyers. With varying standards, diverse supplier capabilities, and distinct market demands, navigating this intricate ecosystem is essential for making informed purchasing decisions. This guide provides a comprehensive overview of the custom leather market, covering the types of products available, their applications across different industries, effective supplier vetting processes, and cost considerations.

For businesses in Africa, South America, the Middle East, and Europe—including key markets like Germany and Nigeria—understanding the nuances of custom leather works is crucial. From bespoke handbags and wallets to specialized items like guitar straps and holsters, the potential applications are vast. This guide empowers you to make strategic choices by offering insights into reputable suppliers, ensuring that the products you source align with your brand’s quality standards and customer expectations.

By the end of this guide, you will be equipped with the knowledge to confidently navigate the global market for custom leather works, enabling you to enhance your product offerings and strengthen your competitive edge. Whether you are looking to collaborate on unique designs or seeking bulk production options, our detailed analysis will serve as your roadmap to success in this dynamic industry.

Table Of Contents

- Top 8 Custom Leather Works Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather works

- Understanding custom leather works Types and Variations

- Key Industrial Applications of custom leather works

- 3 Common User Pain Points for ‘custom leather works’ & Their Solutions

- Strategic Material Selection Guide for custom leather works

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather works

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather works’

- Comprehensive Cost and Pricing Analysis for custom leather works Sourcing

- Alternatives Analysis: Comparing custom leather works With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather works

- Navigating Market Dynamics and Sourcing Trends in the custom leather works Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather works

- Strategic Sourcing Conclusion and Outlook for custom leather works

- Important Disclaimer & Terms of Use

Understanding custom leather works Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Handcrafted Leather Goods | Unique, artisan quality with customization options | Retail, corporate gifting, promotional items | Pros: High quality, personalized service. Cons: Longer production times, higher cost. |

| Industrial Leather Products | Durable materials designed for heavy use and functionality | Industrial applications, tools, equipment | Pros: High durability, functional design. Cons: Limited customization options. |

| Fashion Leather Accessories | Trend-driven designs, often seasonal, appealing to fashion markets | Fashion retail, branded merchandise | Pros: Attractive designs, high market demand. Cons: Fast turnover, may require frequent updates. |

| Leather Cases & Covers | Custom-fit for specific items, often protective and stylish | Electronics, instruments, and personal items | Pros: Enhanced protection, tailored fit. Cons: May require precise specifications. |

| Specialty Leather Items | Unique items like holsters, saddles, and bespoke art pieces | Niche markets, collectors, and enthusiasts | Pros: Unique offerings, potential for high margins. Cons: Limited audience, longer lead times. |

What Are Handcrafted Leather Goods and Their B2B Suitability?

Handcrafted leather goods are characterized by their artisan quality and extensive customization options. These products, which include items such as wallets, handbags, and belts, are ideal for businesses looking to offer unique, high-quality merchandise. B2B buyers should consider the craftsmanship, material quality, and the ability to personalize products to meet their brand identity. While these goods can command higher prices, their unique appeal can lead to increased customer loyalty and brand differentiation.

How Do Industrial Leather Products Meet Business Needs?

Industrial leather products are designed for durability and functionality, making them suitable for heavy-duty applications such as tool belts, equipment covers, and protective gear. Businesses in sectors like construction and manufacturing often seek these products for their reliability and longevity. B2B buyers should evaluate the material specifications and the intended use to ensure they meet industry standards. While the customization options may be limited compared to handcrafted items, the durability often justifies the investment.

What Makes Fashion Leather Accessories a Smart Investment?

Fashion leather accessories are often trend-driven and cater to the fast-paced fashion market. These items, including bags and wallets, are popular among retailers and brands looking to enhance their product lines. B2B buyers should be aware of seasonal trends and consumer preferences when purchasing these items. While they can attract a high demand, the fast turnover rate requires businesses to stay ahead of trends, which can be both an opportunity and a challenge.

Why Are Leather Cases & Covers Essential for Protection?

Leather cases and covers are custom-fit products designed to protect valuable items like electronics and musical instruments. Their tailored design not only provides protection but also enhances the aesthetic appeal. B2B buyers should consider the specifications of the items being covered to ensure a perfect fit. While these products are often more expensive than generic options, the added protection and style can significantly enhance the product offering.

What Are the Advantages of Specialty Leather Items for Niche Markets?

Specialty leather items include unique products such as holsters, saddles, and bespoke art pieces, appealing to niche markets and collectors. These items often carry a higher price point and can yield significant margins for businesses. B2B buyers should assess the uniqueness and craftsmanship of these products, as well as their target audience, to maximize sales potential. However, the limited audience and longer lead times may pose challenges in inventory management and sales strategies.

Key Industrial Applications of custom leather works

| Industry/Sector | Specific Application of custom leather works | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Music and Entertainment | Custom guitar straps and covers | Enhances brand image and artist identity | Quality of leather, customization options, durability |

| Fashion and Accessories | Handcrafted leather handbags and wallets | Unique offerings that differentiate from competitors | Design flexibility, material sourcing, lead times |

| Defense and Security | Leather holsters and sheaths for firearms | Increased safety and functionality | Compliance with regulations, material strength, custom sizing |

| Corporate Gifts and Branding | Personalized leather portfolios and desk accessories | Strengthens client relationships and brand loyalty | Custom branding options, quality assurance, delivery times |

| Sports and Recreation | Custom leather sports gear (e.g., gloves, bags) | Improved performance and player comfort | Material performance, design specifications, pricing |

How is Custom Leather Works Utilized in the Music and Entertainment Industry?

In the music and entertainment sector, custom leather works are primarily used for crafting unique guitar straps and covers. These products not only serve a functional purpose but also enhance the brand image of artists. By opting for bespoke designs, musicians can create a distinct identity that resonates with fans. For international buyers, especially in regions like Europe and Africa, sourcing high-quality leather that withstands wear and tear is crucial, as is ensuring that the customization process aligns with their artistic vision.

What Role Does Custom Leather Play in Fashion and Accessories?

Custom leather goods such as handbags and wallets play a significant role in the fashion industry by offering unique, handcrafted items that stand out in a crowded market. These bespoke products allow brands to cater to niche markets and create exclusive collections, thereby enhancing their appeal. Buyers from South America and the Middle East should prioritize sourcing from artisans who can provide design flexibility and use premium materials, as this impacts the overall quality and marketability of the products.

How Are Custom Leather Works Applied in Defense and Security?

In the defense and security sectors, custom leather works are essential for creating holsters and sheaths that ensure the safe storage and accessibility of firearms. These products must meet stringent safety and regulatory standards, which makes sourcing from reputable manufacturers critical. International buyers need to consider the material strength and custom sizing to ensure that the leather goods not only comply with regulations but also cater to specific operational needs.

Why Are Custom Leather Items Important for Corporate Gifts and Branding?

Custom leather portfolios and desk accessories serve as valuable corporate gifts that can strengthen client relationships and enhance brand loyalty. These high-quality items convey professionalism and attention to detail, making them ideal for client presentations and gifting. B2B buyers in Europe and Africa should look for suppliers who offer extensive customization options and ensure quality assurance, as these factors significantly influence the perception of the brand.

How Do Custom Leather Products Improve Performance in Sports and Recreation?

In sports and recreation, custom leather gear such as gloves and bags is crucial for improving performance and comfort. Athletes benefit from tailored products that fit their specific needs, enhancing their ability to perform. Buyers in regions like Africa and South America should focus on sourcing durable materials that can withstand rigorous use, while also considering design specifications that align with the specific sport or activity, ensuring both functionality and style.

3 Common User Pain Points for ‘custom leather works’ & Their Solutions

Scenario 1: Navigating Quality Assurance in Custom Leather Goods

The Problem: B2B buyers often face challenges in ensuring the quality of custom leather works, especially when sourcing from different regions. The lack of uniform standards in leather quality can lead to discrepancies in product durability, appearance, and overall craftsmanship. Buyers may receive products that do not meet their expectations, resulting in wasted resources and potential damage to their brand reputation.

Illustrative image related to custom leather works

The Solution: To mitigate quality concerns, B2B buyers should establish clear specifications and quality benchmarks before placing orders. This includes detailed descriptions of the leather type, thickness, finish, and stitching methods. Requesting samples before committing to larger orders can also provide insight into the supplier’s craftsmanship. Additionally, working with suppliers who have a transparent production process, including traceability of materials, can ensure that buyers receive high-quality products that align with their brand standards. Regular communication with suppliers about quality expectations can foster stronger partnerships and ultimately lead to better outcomes.

Scenario 2: Meeting Tight Deadlines for Custom Orders

The Problem: In the fast-paced world of B2B transactions, buyers often face tight deadlines when ordering custom leather works. Delays in production or shipping can disrupt business operations and lead to missed opportunities, especially for businesses that require custom items for events, promotions, or client gifts.

The Solution: To effectively manage timelines, B2B buyers should initiate discussions with suppliers about lead times during the planning phase. Providing clear deadlines and understanding the supplier’s production capacity is crucial. It may be beneficial to establish a buffer period for unexpected delays. Additionally, opting for suppliers who offer express services or have a proven track record of timely deliveries can alleviate pressure. Implementing a project management tool to track order progress and maintain regular updates with the supplier can also help ensure that deadlines are met without sacrificing quality.

Illustrative image related to custom leather works

Scenario 3: Customization and Design Challenges

The Problem: Buyers often struggle with translating their vision into reality when ordering custom leather works. The challenge lies in effectively communicating design specifications and ensuring that the final product aligns with their expectations. Misunderstandings about design elements, such as color, texture, and functionality, can lead to dissatisfaction with the end product.

The Solution: To overcome design challenges, B2B buyers should invest time in creating comprehensive design briefs. This includes visual aids such as sketches, photographs, or digital mock-ups that illustrate the desired outcome. Utilizing collaborative tools that allow for real-time feedback during the design process can significantly improve communication between buyers and suppliers. Furthermore, establishing a clear revision process can help ensure that any necessary adjustments are made before production begins. Engaging with suppliers who offer design consultation services can also provide valuable insights and expertise, leading to a more successful outcome that meets the buyer’s vision.

Strategic Material Selection Guide for custom leather works

What Are the Key Properties of Common Leather Materials for Custom Works?

When selecting materials for custom leather works, understanding the properties of various leather types is crucial for ensuring the final product meets performance and aesthetic requirements. Here, we analyze four common leather materials: Full Grain Leather, Top Grain Leather, Suede, and Bonded Leather.

Full Grain Leather: What Makes It a Preferred Choice?

Full grain leather is the highest quality leather available, made from the top layer of the hide, which retains the natural grain. This material is known for its remarkable durability and breathability, making it ideal for high-end products such as luxury handbags and custom guitar straps. It can withstand significant wear and tear, offering a temperature range that allows for comfort in various climates.

Pros: Full grain leather is highly durable, develops a rich patina over time, and is resistant to moisture. It is suitable for high-end applications where longevity and aesthetics are paramount.

Cons: The cost is relatively high, which may deter budget-conscious buyers. Additionally, the manufacturing process can be complex, requiring skilled artisans to achieve the desired finish.

For international buyers, particularly from regions like Europe and the Middle East, compliance with standards such as ASTM and DIN for leather quality is essential. Buyers should also be aware of the sourcing and ethical considerations associated with full grain leather.

Illustrative image related to custom leather works

Top Grain Leather: Is It a Cost-Effective Alternative?

Top grain leather is the second-highest quality leather, made by sanding down the surface of full grain leather to remove imperfections. This process results in a more uniform appearance while still maintaining a degree of durability.

Pros: It is generally more affordable than full grain leather while still offering good durability and a refined look. Top grain leather is easier to work with, making it suitable for a variety of products, including wallets and belts.

Cons: While it is durable, it does not develop the same rich patina as full grain leather, and it can be more susceptible to scratches and wear over time.

For B2B buyers in Africa and South America, understanding the market demand for affordable yet quality leather products is crucial. Compliance with local regulations regarding leather sourcing and treatment should also be considered.

Illustrative image related to custom leather works

Suede: How Does It Perform in Custom Leather Applications?

Suede is made from the underside of the hide, giving it a soft, velvety texture. It is often used in fashion items like shoes and bags, where a luxurious feel is desired.

Pros: Suede is lightweight and offers a unique aesthetic appeal, making it a popular choice for trendy products. It is also relatively affordable compared to full grain and top grain leathers.

Cons: Suede is less durable and more susceptible to stains and water damage, which limits its use in high-wear applications. It requires special care to maintain its appearance.

International buyers should be aware of the specific care instructions for suede products, as well as the potential for variations in quality based on regional tanning practices. Compliance with environmental regulations regarding chemical treatments is also a consideration.

Bonded Leather: What Are Its Practical Applications?

Bonded leather is made from leftover scraps of leather that are bonded together with adhesives and then coated with polyurethane. This material is often used in budget-friendly products.

Pros: Bonded leather is significantly cheaper than genuine leather and can mimic the appearance of real leather. It is lightweight and can be produced in various colors and finishes.

Illustrative image related to custom leather works

Cons: It is less durable than traditional leather options and may peel or wear out quickly. Its lifespan is considerably shorter, making it less suitable for high-end applications.

For buyers in regions like Nigeria, where cost-effective solutions are often prioritized, bonded leather can serve as an entry point into the leather goods market. However, understanding the limitations of this material is essential for managing customer expectations.

Summary of Material Selection for Custom Leather Works

| Materiał | Typical Use Case for custom leather works | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full Grain Leather | Luxury handbags, custom guitar straps | Highly durable, develops rich patina | High cost, complex manufacturing | High |

| Top Grain Leather | Wallets, belts, bags | Affordable, good durability | Less patina, more susceptible to wear | Medium |

| Suede | Fashion items, shoes | Soft texture, unique aesthetic | Less durable, requires special care | Medium |

| Bonded Leather | Budget-friendly goods, office supplies | Cost-effective, lightweight | Less durable, shorter lifespan | Low |

This strategic material selection guide provides international B2B buyers with essential insights into the properties, advantages, and limitations of various leather types, aiding in informed purchasing decisions for custom leather works.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather works

What Are the Main Stages of the Manufacturing Process for Custom Leather Works?

The manufacturing process of custom leather works involves several critical stages, each contributing to the final product’s quality and uniqueness. Understanding these stages can empower B2B buyers to make informed decisions when selecting suppliers.

1. Material Preparation: Selecting the Right Leather

The first step in the manufacturing process is the careful selection of leather. Quality leather is typically sourced from reputable suppliers, with a focus on full-grain or top-grain varieties known for their durability and aesthetic appeal. B2B buyers should ensure that suppliers provide detailed information about the leather’s origin, tanning process, and any treatments applied to enhance longevity.

Illustrative image related to custom leather works

Once the leather is sourced, it undergoes preparation, which includes cutting it into manageable pieces and conditioning it to ensure flexibility and ease of handling. This stage is crucial, as the quality of the leather directly impacts the final product’s performance and appearance.

2. Forming: Crafting the Design

The forming stage involves translating the design specifications into physical shapes. Techniques such as hand tooling, die cutting, or laser cutting are commonly employed. For custom works, artisans may hand-tool designs into the leather, allowing for intricate detailing that reflects the buyer’s specifications.

For B2B buyers, understanding the techniques used in this stage can provide insight into the craftsmanship level. It’s advisable to request samples or images of previous work to gauge the supplier’s capabilities in executing specific designs.

3. Assembly: Bringing It All Together

During the assembly phase, the formed leather pieces are stitched, glued, or otherwise joined together. This process can vary widely depending on the product type—whether it’s a handbag, wallet, or guitar strap. High-quality leather goods often utilize double-stitching or other durable sewing techniques to enhance strength.

Buyers should inquire about the assembly methods used and ensure that they align with their quality expectations. Additionally, it’s beneficial to understand the skill level of the artisans involved, as this can directly affect the final product’s craftsmanship.

Illustrative image related to custom leather works

4. Finishing: Adding the Final Touches

Finishing is the final stage where products receive treatments to enhance aesthetics and durability. This can include dyeing, polishing, or applying protective coatings. For custom leather works, this stage is crucial as it determines the product’s final look and feel.

Buyers should consider discussing finishing options with suppliers, as variations in finishes can significantly affect product appeal. Understanding the materials used in finishing can also help assess the product’s longevity and maintenance needs.

How Is Quality Assurance Implemented in Custom Leather Works?

Quality assurance (QA) is a vital component of the manufacturing process for custom leather works. It ensures that products meet specific standards and customer expectations. Implementing a robust QA process involves several key elements.

International Standards: What Certifications Should B2B Buyers Look For?

Many suppliers adhere to international quality standards such as ISO 9001, which outlines requirements for a quality management system. This certification indicates that the supplier has established processes in place to maintain quality throughout the manufacturing process.

Additionally, industry-specific certifications may be relevant, particularly in sectors like fashion or automotive where compliance with standards such as CE (Conformité Européenne) or API (American Petroleum Institute) is essential. B2B buyers should request copies of these certifications to verify compliance.

Illustrative image related to custom leather works

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are strategically placed throughout the manufacturing process to catch defects early and ensure adherence to specifications:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival. It ensures that the leather and other components meet quality standards before production begins.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are conducted to monitor adherence to specifications and processes. This can involve visual inspections or measurements of key dimensions.

-

Final Quality Control (FQC): The final checkpoint occurs after assembly and finishing. Products are thoroughly inspected for defects, functionality, and overall quality before shipment.

B2B buyers should inquire about the frequency and methods of these quality checks to ensure that suppliers maintain high standards throughout production.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verification of a supplier’s quality control practices is crucial for mitigating risks associated with product quality. Here are several strategies for B2B buyers to consider:

1. Conducting Audits: What to Look For

Regular audits of potential suppliers can provide valuable insights into their manufacturing processes and quality assurance practices. Buyers should look for transparency in operations and compliance with established standards. Audits can be performed by the buyers themselves or through third-party organizations specializing in supply chain assessments.

Illustrative image related to custom leather works

2. Requesting Quality Reports: What Information to Include

Suppliers should be able to provide detailed quality reports that outline their QA processes, inspection results, and any corrective actions taken in response to defects. These reports should also include statistical data on defect rates, which can help buyers assess the supplier’s reliability over time.

3. Utilizing Third-Party Inspection Services: How They Enhance Trust

Engaging third-party inspection services can add an additional layer of assurance. These independent entities conduct inspections at various stages of production and provide unbiased assessments of quality. B2B buyers should consider incorporating this practice, especially when dealing with international suppliers to ensure compliance with their standards.

What Unique Quality Control Considerations Exist for International B2B Buyers?

International buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, face unique challenges in quality assurance. Understanding these nuances is essential for successful partnerships.

-

Cultural Differences in Quality Expectations: Different regions may have varying standards for quality and craftsmanship. B2B buyers should communicate their expectations clearly and ensure that suppliers understand and can meet these standards.

-

Logistical Challenges: Shipping and handling can impact product quality. Buyers should discuss packaging and transportation methods with suppliers to mitigate risks associated with damage during transit.

-

Regulatory Compliance: International buyers must be aware of local regulations that may affect product quality and safety standards. Suppliers should provide documentation demonstrating compliance with relevant regulations in the buyer’s region.

By understanding the manufacturing processes and quality assurance practices involved in custom leather works, B2B buyers can make informed decisions that align with their quality expectations and business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather works’

Wprowadzenie

Sourcing custom leather works can be a complex process, especially for B2B buyers seeking high-quality, bespoke products. This guide aims to streamline your procurement efforts by providing a step-by-step checklist to ensure you select the right suppliers and achieve your desired outcomes. Following these actionable steps will help you navigate the market effectively and secure exceptional custom leather goods tailored to your specifications.

Step 1: Define Your Project Requirements

Clearly outline the specifics of your custom leather project. Consider factors such as product type, dimensions, materials, and design features. This clarity will help potential suppliers understand your needs and provide accurate quotes.

- Product Types: Identify whether you need handbags, wallets, straps, or other items.

- Design Specifications: Include color preferences, branding elements, and any unique features.

Step 2: Research Potential Suppliers

Invest time in researching various suppliers to identify those who specialize in custom leather works. Look for companies with a strong portfolio and positive reviews from previous clients.

- Portfolio Review: Examine their past projects to gauge the quality and creativity of their work.

- Industry Reputation: Seek out testimonials or case studies, particularly from businesses in your region or sector.

Step 3: Evaluate Supplier Capabilities

Before committing to a supplier, assess their production capabilities. Ensure they have the necessary equipment and skilled artisans to meet your project’s demands.

- Craftsmanship: Investigate their production processes to confirm they prioritize quality and craftsmanship.

- Scalability: Determine if they can handle your order volume, especially if you anticipate future growth.

Step 4: Request Samples

Request samples of their previous work to evaluate the quality of materials and craftsmanship. This step is critical to ensuring that the final product meets your expectations.

- Material Quality: Assess the leather’s texture, durability, and finish.

- Design Accuracy: Check if the samples reflect the design specifications you provided.

Step 5: Verify Certifications and Compliance

Ensure that the suppliers adhere to relevant industry standards and certifications. This verification helps mitigate risks associated with quality and ethical sourcing.

- Sustainability Practices: Confirm if they use ethically sourced materials and environmentally friendly processes.

- Quality Certifications: Look for certifications that indicate adherence to quality standards, such as ISO or equivalent.

Step 6: Negotiate Terms and Pricing

Once you’ve identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Clear communication at this stage can prevent misunderstandings later on.

- Transparent Pricing: Ensure all costs are outlined, including potential additional fees for customizations.

- Delivery Timelines: Agree on realistic timelines for production and delivery to align with your project deadlines.

Step 7: Establish a Communication Plan

Effective communication is key to a successful partnership. Set up a plan for regular updates and check-ins throughout the production process.

- Point of Contact: Designate a representative from both sides to facilitate clear communication.

- Feedback Mechanisms: Create channels for providing feedback on samples and progress to ensure alignment with your expectations.

By following this checklist, B2B buyers can navigate the sourcing of custom leather works with confidence, ensuring they partner with the right suppliers for their unique needs.

Comprehensive Cost and Pricing Analysis for custom leather works Sourcing

What are the Key Cost Components in Custom Leather Works?

Understanding the cost structure is essential for international B2B buyers looking to source custom leather works. The main cost components include:

-

Materials: The type of leather used is a significant cost driver. Full-grain leather, for example, is more expensive than split leather but offers superior durability and aesthetics. Other materials, such as linings, thread, and hardware, can also impact costs.

-

Labor: Skilled craftsmanship is required for custom leather goods, which often leads to higher labor costs. Artisans with specialized skills command a premium, especially for intricate designs or hand-tooling.

-

Manufacturing Overhead: This encompasses costs related to utilities, rent, and equipment maintenance. Custom leather workshops often operate on a smaller scale, meaning overhead costs can be proportionately higher than in mass production.

-

Tooling: Customization often requires specific tools or molds, which can add to the initial costs. The more complex the design, the higher the tooling expenses.

-

Quality Control (QC): Ensuring the final product meets quality standards incurs additional costs. Rigorous QC processes can lead to higher costs but are essential for maintaining brand reputation.

-

Logistics: Shipping and handling costs can vary significantly based on the destination, weight, and dimensions of the goods. This is particularly important for international buyers who must consider customs duties and tariffs.

-

Margin: Suppliers typically add a profit margin to cover all costs and ensure sustainability. This margin can vary based on the supplier’s business model and market position.

How Do Price Influencers Affect Custom Leather Works?

Several factors can influence pricing in the custom leather sector:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes can lead to reduced costs per unit due to economies of scale. Suppliers may set MOQs, which can affect total pricing.

-

Specifications and Customization: Unique designs or specifications can drive up costs. The more tailored the product, the more labor and material considerations come into play.

-

Materials and Quality Certifications: Premium materials and certifications (like eco-friendly or sustainable sourcing) can significantly influence pricing. Buyers must balance their desire for quality with budget constraints.

-

Supplier Factors: The reputation and experience of the supplier can impact pricing. Established suppliers with a track record may charge more due to their expertise and reliability.

-

Incoterms: The agreed terms of delivery (Incoterms) affect total costs. Understanding whether costs include shipping, insurance, and duties is crucial for budgeting.

What Tips Can Help Buyers Negotiate Better Prices for Custom Leather Works?

When navigating the complexities of sourcing custom leather goods, consider the following buyer tips:

Illustrative image related to custom leather works

-

Negotiate Smartly: Always inquire about bulk discounts, flexible payment terms, or other cost-saving opportunities. Building a relationship with suppliers can lead to more favorable terms.

-

Prioritize Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes not just the purchase price but also maintenance, durability, and potential resale value. High-quality products may cost more upfront but save money in the long run.

-

Understand Pricing Nuances for International Markets: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, regional tariffs, and import regulations. These factors can significantly affect overall costs.

-

Request Samples: Before committing to larger orders, request samples to assess quality and craftsmanship. This helps in making informed decisions and can serve as a negotiation tool if quality does not meet expectations.

-

Stay Informed: Keep abreast of market trends and pricing shifts. Understanding the competitive landscape can provide leverage during negotiations.

Disclaimer on Indicative Prices

Prices for custom leather works can vary widely based on the aforementioned factors. The information provided serves as a guideline, and buyers should engage directly with suppliers for accurate quotes tailored to their specific needs and requirements.

Alternatives Analysis: Comparing custom leather works With Other Solutions

Understanding Alternatives in Custom Leather Works

When considering custom leather works, it’s essential for B2B buyers to explore various alternative solutions that could meet their needs. These alternatives may offer different advantages, such as cost-effectiveness, faster turnaround times, or unique features that custom leather goods might not provide. This analysis will compare custom leather works against two viable alternatives: synthetic leather products and mass-produced leather goods.

Comparison Table

| Comparison Aspect | Custom Leather Works | Synthetic Leather Products | Mass-Produced Leather Goods |

|---|---|---|---|

| Performance | High durability, tailored fit | Moderate durability, variable quality | Good durability, but less customization |

| Cost | Higher initial investment | Generally lower cost | Lower cost due to economies of scale |

| Ease of Implementation | Requires skilled artisans, longer lead times | Easier to produce, quick to market | Quick to source, widely available |

| Maintenance | Requires care to maintain quality | Low maintenance | Varies, but often less durable |

| Best Use Case | Unique, high-end items for special occasions | Cost-effective solutions for bulk needs | Standard items for mass market appeal |

Detailed Breakdown of Alternatives

Synthetic Leather Products

Synthetic leather, commonly known as faux leather, is made from various materials like polyurethane or PVC. Its primary advantage is cost-effectiveness; it is typically less expensive than custom leather works and can be produced quickly, making it a suitable option for businesses looking for bulk items. However, while synthetic leather can mimic the appearance of real leather, it often lacks the durability and aesthetic appeal that genuine leather provides. Additionally, it may not be as environmentally friendly, depending on the production methods used.

Mass-Produced Leather Goods

Mass-produced leather goods are manufactured using streamlined processes that allow for lower costs and quicker availability. These products are ideal for businesses needing a large volume of standardized items, such as promotional giveaways or corporate gifts. The downside, however, is the lack of customization; buyers cannot tailor these products to their brand or specific needs. Furthermore, the quality can be inconsistent, and mass-produced items may not have the same level of craftsmanship or longevity as custom leather works.

Conclusion: Choosing the Right Solution for Your Business Needs

In deciding between custom leather works and its alternatives, B2B buyers must assess their specific requirements, budget, and the intended use of the products. If uniqueness and craftsmanship are paramount, custom leather works provide unparalleled value despite the higher cost and longer lead times. Conversely, if budget constraints and quick turnaround are the primary concerns, synthetic leather or mass-produced leather goods might be more appropriate. Evaluating these factors will enable businesses to select the solution that aligns best with their objectives and market demands.

Essential Technical Properties and Trade Terminology for custom leather works

What Are the Key Technical Properties of Custom Leather Works?

When engaging in custom leather works, understanding specific technical properties is crucial for ensuring quality and meeting buyer expectations. Here are the essential properties to consider:

1. Material Grade

Material grade refers to the classification of leather based on its quality and characteristics. Common grades include full-grain, top-grain, genuine leather, and bonded leather. Full-grain leather, for instance, is the highest quality, retaining the natural texture and durability. This distinction is vital for B2B buyers as it impacts the product’s longevity, aesthetics, and price point, making it essential to select the appropriate grade for the intended application.

2. Thickness

Leather thickness is typically measured in ounces or millimeters. Thicker leather offers greater durability and protection, making it ideal for items like belts and holsters, while thinner leather is better suited for wallets and bags. Specifying the right thickness is crucial for manufacturers to ensure the final product meets functional and aesthetic requirements, directly influencing customer satisfaction.

3. Tolerance

Tolerance refers to the allowable variation in dimensions during the manufacturing process. In custom leather works, tight tolerances are often necessary to ensure that parts fit together seamlessly, especially for items like guitar straps or cases. Understanding tolerance specifications helps maintain product quality and reduces the risk of defects, which can lead to costly rework and delays.

4. Finish

The finish of leather determines its texture and appearance. Options range from natural finishes that highlight the leather’s grain to more processed finishes that provide a uniform look. B2B buyers should consider the desired finish for their products, as it affects both the aesthetic appeal and the leather’s resistance to wear and moisture. Selecting the right finish can enhance the product’s marketability.

5. Colorfastness

Colorfastness is the ability of leather to retain its color when exposed to light, moisture, and abrasion. This property is particularly important for custom leather goods that may be subjected to varying environmental conditions. B2B buyers need to ensure that the leather used in their products meets industry standards for colorfastness to avoid issues with fading or discoloration, which can impact brand reputation.

What Are the Common Trade Terminology and Concepts in Custom Leather Works?

Understanding industry jargon is essential for effective communication in the custom leather market. Here are key terms that B2B buyers should be familiar with:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of custom leather works, buyers may engage with OEMs for specialized leather components, ensuring compatibility with their brand’s offerings.

Illustrative image related to custom leather works

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is critical for B2B buyers as it can influence inventory management and overall purchasing strategies. It ensures that buyers align their orders with supplier capabilities and their market demand.

3. RFQ (Request for Quotation)

An RFQ is a formal document issued by a buyer to solicit price quotes from suppliers for specific products or services. Including detailed specifications in an RFQ helps suppliers provide accurate pricing and timelines, facilitating smoother negotiations and procurement processes.

4. Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in shipping and delivery. Familiarity with these terms helps B2B buyers understand shipping costs, insurance, and liability, ensuring clarity in international transactions, especially in regions like Africa, South America, and the Middle East.

5. Customization

Customization in the leather industry refers to tailoring products to meet specific client needs, whether in design, color, or functionality. This term is central to B2B transactions in custom leather works, as it directly relates to the value proposition and competitive advantage of the products offered.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing custom leather goods, ensuring quality and alignment with their brand’s standards.

Illustrative image related to custom leather works

Navigating Market Dynamics and Sourcing Trends in the custom leather works Sector

What Are the Key Market Dynamics and Trends in the Custom Leather Works Sector?

The global custom leather works market is witnessing significant growth driven by various factors including rising disposable incomes, increasing consumer preference for personalized products, and a burgeoning demand for high-quality, artisanal leather goods. This trend is particularly evident in regions such as Africa, South America, the Middle East, and Europe, where the appreciation for craftsmanship and uniqueness is growing. For international B2B buyers, the emphasis on customization is a critical driver, as businesses seek to offer tailored solutions that resonate with local tastes and cultural nuances.

Emerging technologies are also reshaping sourcing practices within the sector. The adoption of digital platforms for design and prototyping allows manufacturers to streamline processes and enhance collaboration with buyers. Virtual reality (VR) and augmented reality (AR) tools are beginning to play a role in product visualization, enabling buyers to experience products before making purchasing decisions. Furthermore, supply chain transparency is becoming increasingly important, with buyers prioritizing manufacturers who can provide visibility into their sourcing and production practices.

How Is Sustainability Shaping the Custom Leather Works Sector?

Sustainability is a pivotal concern in the custom leather works industry, significantly influencing buyer preferences and sourcing decisions. The environmental impact of leather production, particularly in terms of water usage and chemical waste, has led to a heightened awareness among consumers and businesses alike. As a result, B2B buyers are increasingly inclined to partner with suppliers who prioritize ethical sourcing and sustainable practices.

The importance of ethical supply chains cannot be overstated. Buyers are actively seeking manufacturers who use ‘green’ certifications and sustainable materials, such as vegetable-tanned leather, which minimizes harmful chemical usage. Certifications from organizations like the Leather Working Group (LWG) can serve as a benchmark for assessing a supplier’s commitment to environmentally responsible practices. Additionally, the integration of recycled materials and innovative production methods further enhances the appeal of a supplier’s offerings in a market that values sustainability.

Illustrative image related to custom leather works

What Is the Evolution of Custom Leather Works and Its Importance for B2B Buyers?

The custom leather works sector has a rich history, evolving from traditional craftsmanship to a modern industry that embraces both artistry and technology. Historically, leather goods were handcrafted for specific needs, often passed down through generations. Today, while the artisanal aspect remains vital, advancements in production techniques and design tools have transformed how businesses operate.

For B2B buyers, understanding this evolution is crucial. It highlights the balance between heritage and innovation, enabling businesses to appreciate the value of traditional skills while also leveraging modern technology to meet contemporary demands. This duality not only enhances product quality but also allows for greater customization, catering to the unique preferences of diverse markets. As the sector continues to evolve, international buyers must stay informed about these dynamics to make strategic sourcing decisions that align with their brand values and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather works

-

How do I ensure the quality of custom leather products from suppliers?

To ensure high-quality custom leather products, start by vetting potential suppliers thoroughly. Request samples to evaluate craftsmanship, leather quality, and durability. Look for reviews and testimonials from other B2B buyers. Additionally, inquire about the sourcing of their leather, production processes, and quality assurance practices. Establishing clear quality standards and specifications in your contract can also help maintain product integrity throughout the manufacturing process. -

What is the best way to communicate my custom design needs to a leather supplier?

Effective communication is key to achieving your desired custom leather products. Start by providing detailed specifications, including dimensions, colors, materials, and design inspirations. Utilize sketches or digital mockups to illustrate your vision. Schedule a meeting or video call to discuss your requirements and address any questions. Maintaining an open line of communication throughout the design process will help ensure that the final product aligns with your expectations. -

What are typical minimum order quantities (MOQs) for custom leather works?

Minimum order quantities (MOQs) for custom leather works can vary significantly based on the supplier and the complexity of the designs. Generally, MOQs can range from as low as 50 units for simpler items to several hundred for more intricate customizations. It’s essential to discuss MOQs upfront with potential suppliers to ensure they align with your budget and production needs. Some suppliers may offer flexibility for first-time orders or larger contracts. -

What payment terms should I expect when sourcing custom leather goods?

Payment terms can vary among suppliers, but many will require a deposit upfront, typically ranging from 30% to 50% of the total order value. The remaining balance is usually due upon completion or before shipping. Ensure you clarify payment methods accepted, such as bank transfers, letters of credit, or online payment platforms. It’s advisable to negotiate terms that offer protection for both parties, especially for larger orders or long-term contracts. -

How can I verify the legitimacy of a custom leather supplier?

To verify the legitimacy of a custom leather supplier, conduct thorough research. Check their business registration details, and assess their online presence, including website quality and social media engagement. Request references from previous clients and reach out to them for feedback. Additionally, consider visiting the supplier’s facility if possible, or utilize third-party verification services that can audit and validate the supplier’s operations. -

What logistics considerations should I keep in mind when importing custom leather goods?

When importing custom leather goods, consider logistics aspects such as shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder who can assist with documentation and ensure compliance with international trade laws. Be aware of lead times for production and shipping to avoid delays. Additionally, ensure your supplier provides tracking information and updates throughout the shipping process for better transparency. -

What are the common customization options available for leather products?

Common customization options for leather products include selecting different leather types (full grain, top grain, etc.), colors, textures, and finishes. You can also request personalized features such as embossing, stitching patterns, and hardware choices. Discuss your specific needs with the supplier to explore all available options and create a unique product that aligns with your brand identity. -

How do I handle quality assurance and control for custom leather orders?

To manage quality assurance for custom leather orders, establish clear quality standards and inspection protocols before production begins. Schedule regular updates and checkpoints with the supplier during the production process. Upon receipt, conduct a thorough inspection of the products against your specifications. If any discrepancies arise, address them promptly with the supplier to resolve issues and ensure future orders meet your quality expectations.

Top 8 Custom Leather Works Manufacturers & Suppliers List

1. JP Custom Leather Works – Breast Cancer Awareness Radio Strap Combo

Domain: jpcustomleatherworks.com

Registered: 2016 (9 years)

Introduction: {“products”:[{“name”:”Breast Cancer Awareness Radio Strap Combo”,”msrp”:”$184.99″,”price”:”$184.99″},{“name”:”Custom Radio Strap”,”msrp”:”$99.99″,”price”:”$99.99″},{“name”:”Chin Strap RTS”,”msrp”:”$29.99″,”price”:”$29.99″},{“name”:”Custom Chin Strap”,”msrp”:”$39.99″,”price”:”$39.99″},{“name”:”Custom Glove Strap”,”msrp”:”$29.99″,”price”:”$29.99″},{“name”:”Custom Locker Tag”,”msrp”:”$36.99″,”price”:…

2. Axe and Awl Leatherworks – Custom Leather Radio Strap

Domain: axeandawlleatherworks.com

Registered: 2015 (10 years)

Introduction: Current Lead Times: 8-12 weeks (Custom Radio Straps) | Handmade in the USA | Contact: 828.246.0996 | Product Categories: Durable Goods, Firefighter Leather, Apparel, Accessories | Key Products: Custom Leather Radio Strap ($95.00), Two Piece Leather Chin Strap ($37.00), The Daily Belt ($70.00), Inverted Flashlight Strap ($45.00), The Comrade Leather Toiletry Bag ($95.00), Monarch Leather Tote ($310…

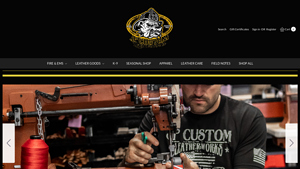

3. Great Point Custom Leather – Unique Leather Goods

Domain: greatpointcustomleather.com

Registered: 2015 (10 years)

Introduction: Great Point Custom Leather specializes in crafting unique leather goods tailored to customer specifications. Key products include hand-tooled leather guitar covers, guitar straps, handbags, wallets, gun holsters, belts, valet trays, tablet covers, portfolios, and knife sheaths. Each piece is handcrafted from the finest leathers, ensuring meticulous attention to detail. The brand has a strong prese…

4. Collier Custom Leather – Holsters & Accessories

Domain: colliercustomleather.com

Registered: 2017 (8 years)

Introduction: Belts, Bible Covers, Checkbook Covers, Chest Holsters, Holsters, Knife Scabbards, Notebooks, Gun Belts

5. Candle Leather – Custom Handcrafted Leather Goods

Domain: candbleather.com

Registered: 2021 (4 years)

Introduction: Custom leather work handcrafted with quality. Handmade leather items made in traditional ways of Western American Saddle Makers. Specializes in personalized items including custom notebooks, designer handbags, money clips with geometric designs, floral pendant, Celtic Trinity Knot notebooks, and floral clutch wallets.

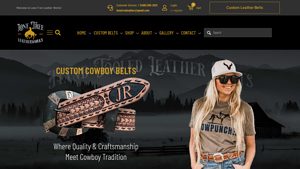

6. Lone Tree Leather Works – Custom Leather Cowboy Belts

Domain: lonetreeleatherworks.com

Registered: 2015 (10 years)

Introduction: Lone Tree Leather Works specializes in custom leather cowboy belts, crafted from premium leather by dedicated artisans. The company has over a decade of experience (since 2012) and has produced more than 6,000 bespoke belts. Each belt is designed to embody the spirit of the cowboy lifestyle, emphasizing quality, craftsmanship, and durability. The belts are personalized, allowing customers to choos…

7. Fully Involved Leatherworks – Leather Helmet Bands

Domain: fullyinvolvedleatherworks.com

Registered: 2014 (11 years)

Introduction: Fully Involved Leatherworks offers a range of leather products specifically designed for firefighters and emergency services. Key products include:

1. **Leather Helmet Bands**

2. **Leather Radio Straps & Accessories**

3. **PPE Accessories**

4. **Leather Fire Helmet Shields**

5. **Leather Firefighter Suspenders**

6. **Leather SCBA Mask Covers**

7. **Leather Locker Tags**

8. **Leather Glove…

8. Amish Leatherworks – Handmade Classic Leather Guitar Strap

Domain: amishleatherworks.com

Registered: 2017 (8 years)

Introduction: [{‘name’: ‘Leather Guitar Strap’, ‘color’: ‘Brown’, ‘style’: ‘Handmade Classic Style’, ‘features’: ‘Personalized Engraved, Full Grain Leather’, ‘made_in’: ‘USA’}, {‘name’: ‘Deluxe Flask with Buffalo Leather’, ‘made_in’: ‘USA’}, {‘name’: ‘Handmade Leather Sling Bag’, ‘type’: ‘Crossbody Travel Pouch’, ‘features’: ‘Secure Cross Carry, Phone Slot’, ‘made_in’: ‘USA’, ‘price’: ‘$169.99’}, {‘name’: ‘Delu…

Strategic Sourcing Conclusion and Outlook for custom leather works

What Are the Key Takeaways for B2B Buyers in Custom Leather Works?

As we conclude our exploration of custom leather works, it is essential to recognize the value of strategic sourcing in this niche market. By leveraging partnerships with skilled artisans, businesses can obtain high-quality, tailored leather products that meet specific requirements. This approach not only enhances product offerings but also fosters brand loyalty through unique, personalized items that resonate with customers.

Additionally, understanding regional preferences and market trends is crucial for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. By aligning sourcing strategies with cultural nuances and consumer demands, businesses can effectively tap into new markets and drive sales growth.

How Can You Position Your Business for Success in the Custom Leather Market?

Looking ahead, the custom leather industry is poised for innovation, with advancements in sustainable practices and customization technology. International buyers are encouraged to seek out suppliers who prioritize ethical sourcing and craftsmanship, ensuring that their products not only stand out but also reflect a commitment to quality and responsibility.

Illustrative image related to custom leather works

Now is the time to engage with trusted manufacturers and designers to create distinctive leather goods that will capture your target audience’s attention. By investing in strategic sourcing, you can elevate your brand and secure a competitive edge in the dynamic world of custom leather works.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.