Introduction: Navigating the Global Market for nubuck leathe

The global market for nubuck leather presents a compelling opportunity for B2B buyers seeking high-quality materials for their products. However, sourcing the right nubuck leather can be challenging, particularly when navigating various suppliers, quality standards, and price points. This guide is designed to address these challenges by providing comprehensive insights into nubuck leather, including its types, applications, and key characteristics.

Throughout this guide, you will discover the intricacies of nubuck leather production, from the tanning processes to its unique texture and durability. We will also delve into practical applications across different industries, such as footwear, upholstery, and fashion accessories, ensuring you understand how to leverage nubuck leather effectively in your business.

Moreover, we will equip you with essential strategies for vetting suppliers, evaluating costs, and ensuring that the nubuck leather you choose meets your specific quality requirements. By the end of this guide, international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe—including countries like Vietnam and Germany—will feel empowered to make informed purchasing decisions. This resource aims to enhance your understanding of nubuck leather, enabling you to select the best materials that align with your business objectives and customer expectations.

Table Of Contents

- Top 4 Nubuck Leathe Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for nubuck leathe

- Understanding nubuck leathe Types and Variations

- Key Industrial Applications of nubuck leathe

- 3 Common User Pain Points for ‘nubuck leathe’ & Their Solutions

- Strategic Material Selection Guide for nubuck leathe

- In-depth Look: Manufacturing Processes and Quality Assurance for nubuck leathe

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘nubuck leathe’

- Comprehensive Cost and Pricing Analysis for nubuck leathe Sourcing

- Alternatives Analysis: Comparing nubuck leathe With Other Solutions

- Essential Technical Properties and Trade Terminology for nubuck leathe

- Navigating Market Dynamics and Sourcing Trends in the nubuck leathe Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of nubuck leathe

- Strategic Sourcing Conclusion and Outlook for nubuck leathe

- Important Disclaimer & Terms of Use

Understanding nubuck leathe Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Nubuck Cowhide | Made from the outer layer of cowhide, soft and durable texture. | Footwear, handbags, upholstery | Pros: High durability, luxurious feel. Cons: Expensive, requires maintenance. |

| Nubuck Calfskin | Sourced from young cattle, finer grain, softer texture. | Luxury fashion items, high-end accessories | Pros: Excellent softness, premium appearance. Cons: Higher cost, sensitive to moisture. |

| Nubuck Sheepskin | Lightweight, softer than cowhide, with a unique texture. | Fashion garments, interior design | Pros: Lightweight, comfortable. Cons: Less durable, more prone to wear. |

| Nubuck Bullhide | Thick and robust, ideal for heavy-duty applications. | Workwear, industrial products | Pros: Exceptional durability, resistant to wear. Cons: Heavier, less refined appearance. |

| Nubuck Vegetable Tanned | Tanned using natural methods, retains eco-friendly properties. | Eco-conscious products, artisanal goods | Pros: Environmentally friendly, unique patina. Cons: Longer tanning process, can be costly. |

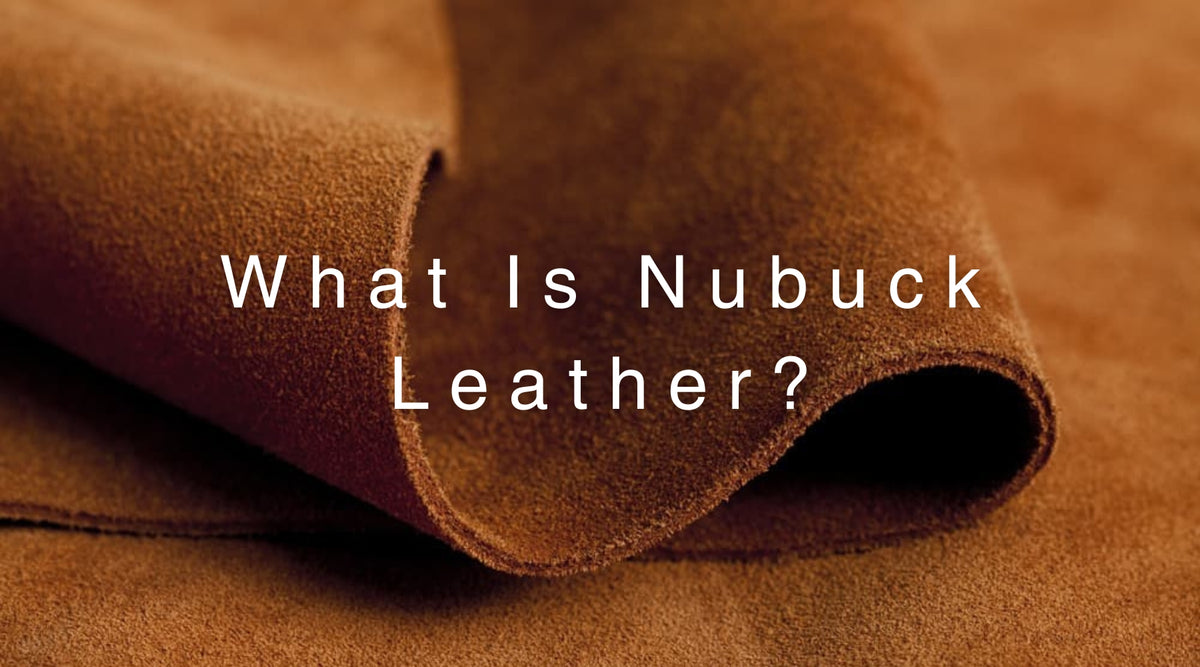

What Are the Key Characteristics of Nubuck Cowhide for B2B Buyers?

Nubuck cowhide is renowned for its durability and luxurious feel, making it a popular choice in the leather industry. Its production process involves sanding the outer layer of the cowhide, which results in a soft, velvety texture that maintains the natural grain characteristics. This type of nubuck is suitable for high-wear applications such as footwear and handbags, where durability is paramount. B2B buyers should consider its higher price point and maintenance requirements, as regular care is essential to prevent staining and water damage.

How Does Nubuck Calfskin Stand Out for Luxury Applications?

Nubuck calfskin is derived from younger cattle, offering a finer grain and softer texture compared to cowhide. This type of nubuck is particularly favored in the luxury fashion market, where its premium appearance enhances high-end accessories and garments. B2B purchasers should note that while calfskin provides exceptional softness and aesthetic appeal, it tends to be more sensitive to moisture and requires careful handling. Its elevated cost reflects its quality, making it a worthwhile investment for brands targeting upscale consumers.

What Makes Nubuck Sheepskin a Suitable Choice for Fashion Garments?

Nubuck sheepskin is lightweight and features a unique texture, making it ideal for fashion garments and interior design applications. Its softness provides comfort, which is a significant advantage for clothing items. However, B2B buyers must be aware that while it offers a luxurious feel, it is less durable than cowhide and can wear out more quickly. This trade-off between comfort and durability is critical for brands focused on fashion-forward products, especially in markets where style is prioritized over ruggedness.

Illustrative image related to nubuck leathe

Why Choose Nubuck Bullhide for Heavy-Duty Applications?

Nubuck bullhide is characterized by its thickness and robustness, making it an excellent option for heavy-duty applications such as workwear and industrial products. Its durability ensures it can withstand harsh conditions, appealing to businesses requiring reliable leather materials for demanding environments. However, B2B buyers should consider that its heavier weight and less refined appearance may not suit all fashion contexts. Understanding the specific needs of end-users will help in making informed purchasing decisions.

What Are the Benefits of Using Nubuck Vegetable Tanned Leather?

Nubuck vegetable-tanned leather is processed using natural methods, offering eco-friendly properties that appeal to environmentally conscious brands. This type of nubuck develops a unique patina over time, adding character to products. B2B buyers should be aware that the vegetable tanning process can be longer and more costly, but the resulting leather is often seen as a premium choice. This type is particularly suitable for artisanal goods and products aimed at sustainability-focused consumers, allowing brands to differentiate themselves in a competitive market.

Key Industrial Applications of nubuck leathe

| Industry/Sector | Specific Application of nubuck leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Footwear | High-end shoes and boots | Offers durability and a luxurious appearance, appealing to premium markets. | Ensure quality hides with minimal imperfections, focus on color options and finishing techniques. |

| Upholstery | Furniture and interior design | Provides a soft, elegant finish that enhances aesthetic appeal, suitable for luxury markets. | Source from reputable suppliers who offer consistent quality and sustainable tanning processes. |

| Fashion Accessories | Handbags and belts | Adds a touch of sophistication and uniqueness, catering to fashion-conscious consumers. | Look for unique textures and colors; verify the tanning process to ensure longevity. |

| Automotive | Car interiors and accessories | Enhances comfort and luxury, increasing the vehicle’s perceived value. | Assess durability against wear and tear, consider water-resistant treatments for maintenance. |

| Sporting Goods | High-end sports equipment and apparel | Combines style with performance, attracting premium clientele. | Ensure compliance with performance standards and seek eco-friendly tanning options. |

How is Nubuck Leather Used in the Footwear Industry?

Nubuck leather is extensively utilized in the production of high-end shoes and boots, valued for its luxurious feel and durability. This material’s fine texture and natural grain characteristics appeal to consumers seeking premium footwear. International B2B buyers must consider sourcing high-quality hides that meet specific color and finish requirements, as imperfections can detract from the product’s overall appeal. Additionally, understanding the tanning process is crucial for ensuring the longevity of the footwear.

What Role Does Nubuck Leather Play in Upholstery?

In the upholstery sector, nubuck leather is favored for its elegant appearance and soft texture, making it ideal for luxury furniture and interior design projects. Its ability to maintain a refined look while providing durability makes it a preferred choice among high-end manufacturers. Buyers should prioritize suppliers that offer consistent quality and sustainable tanning methods, as these factors significantly impact the final product’s quality and environmental footprint.

How is Nubuck Leather Utilized in Fashion Accessories?

The fashion industry often incorporates nubuck leather in the creation of handbags, belts, and other accessories due to its sophisticated look and unique texture. This material helps brands stand out in a competitive market, appealing to consumers who value both aesthetics and quality. B2B buyers should seek out diverse color options and unique textures while ensuring that the suppliers adhere to high standards of tanning and finishing to guarantee product longevity.

Illustrative image related to nubuck leathe

What Benefits Does Nubuck Leather Provide in Automotive Applications?

In the automotive sector, nubuck leather enhances the interiors of vehicles, contributing to a luxurious feel that elevates the overall customer experience. This leather is often used in seat covers, dashboards, and other interior accessories, appealing to consumers looking for comfort and style. Buyers must evaluate the leather’s durability against wear and tear, as well as its resistance to stains and moisture, to ensure that it meets the rigorous demands of automotive applications.

How is Nubuck Leather Applied in Sporting Goods?

Nubuck leather finds its place in high-end sports equipment and apparel, where it combines style with performance. Its unique texture and robustness make it suitable for products that require both aesthetic appeal and functional durability. B2B buyers in this sector should ensure that their sources comply with performance standards and consider eco-friendly tanning options, as sustainability is becoming increasingly important in the sporting goods market.

3 Common User Pain Points for ‘nubuck leathe’ & Their Solutions

Scenario 1: Struggling with Stains on Nubuck Leather Products

The Problem: One of the most significant challenges B2B buyers face when working with nubuck leather is its susceptibility to stains. Whether it’s for high-end footwear, upholstery, or bags, a single spill can lead to permanent damage if not addressed promptly. Buyers often worry that their investment in premium nubuck leather products will be compromised, leading to customer dissatisfaction and potential returns. This concern is particularly acute in markets where high humidity or rain is common, increasing the risk of water-related stains.

Illustrative image related to nubuck leathe

The Solution: To mitigate the risk of stains, buyers should invest in high-quality, protective treatments designed specifically for nubuck leather. These products often come in the form of sprays that create a water-repellent barrier without altering the leather’s natural appearance or texture. When sourcing nubuck leather, ensure the supplier offers treated options or recommend additional treatments to your customers. Additionally, providing care kits that include a soft brush and cleaning solution can empower your clients to maintain the appearance of their products. Regular maintenance and immediate attention to spills can significantly enhance the longevity and aesthetic appeal of nubuck leather items.

Scenario 2: Navigating the High Cost of Nubuck Leather

The Problem: Nubuck leather is often more expensive than other leather types, creating a financial burden for B2B buyers, especially small to medium-sized enterprises. This higher price point can lead to concerns about whether the investment will yield a sufficient return, particularly in competitive markets where price sensitivity is high. Buyers may struggle with justifying the cost to their management or stakeholders while competing against lower-priced alternatives.

The Solution: To address the cost issue, buyers should focus on the long-term benefits of investing in nubuck leather, such as its durability and luxurious appearance. Highlighting these attributes can help justify the initial expenditure. Furthermore, consider sourcing nubuck leather from reputable suppliers who offer bulk purchasing options or discounts for larger orders. Establishing a solid relationship with suppliers can also lead to better pricing over time. Lastly, educating your sales team on the value proposition of nubuck leather, including its appeal to high-end markets, can enhance customer buy-in and ultimately drive sales.

Scenario 3: Ensuring Quality Consistency in Nubuck Leather

The Problem: Quality inconsistency is a prevalent concern among B2B buyers, especially when sourcing nubuck leather from different suppliers or regions. Variations in texture, color, and finish can lead to mismatched products, which can tarnish a brand’s reputation and lead to increased returns or customer complaints. This challenge is particularly pronounced when dealing with international suppliers, where variations in tanning processes and quality standards may exist.

Illustrative image related to nubuck leathe

The Solution: To combat quality inconsistency, buyers should establish strict quality control measures throughout the sourcing process. This can include requesting samples from multiple suppliers and conducting thorough inspections before placing bulk orders. Implementing a standardized grading system for nubuck leather can help ensure that all products meet specific quality benchmarks. Additionally, developing strong partnerships with trusted suppliers who can consistently deliver high-quality materials is crucial. Consider also utilizing technology, such as digital color matching tools, to ensure that all batches of nubuck leather align with your specifications, minimizing the risk of inconsistencies in your final products.

Strategic Material Selection Guide for nubuck leathe

What Are the Key Materials Used in Nubuck Leather Production?

When selecting nubuck leather for various applications, understanding the materials involved is crucial for B2B buyers. Here, we analyze three common materials used in the production of nubuck leather, focusing on their properties, advantages, disadvantages, and implications for international buyers.

1. Cowhide Nubuck Leather

Key Properties:

Cowhide nubuck leather is derived from the outer grain side of the hide, offering a robust structure. It typically has a temperature tolerance suitable for a variety of environments, maintaining integrity under moderate pressure.

Illustrative image related to nubuck leathe

Pros & Cons:

The primary advantage of cowhide nubuck is its durability, making it ideal for high-end footwear and upholstery. However, it can be more expensive due to the quality of the raw material and the tanning process involved. Additionally, it requires careful maintenance to prevent staining and water damage.

Impact on Application:

Cowhide nubuck is particularly well-suited for products that experience frequent wear, such as shoes and bags. Its natural grain adds aesthetic value, but its susceptibility to moisture means that protective treatments are often necessary.

Considerations for International Buyers:

For buyers in regions like Africa and the Middle East, compliance with local standards regarding leather quality and environmental impact is essential. Understanding the tanning process, whether chrome or vegetable, can also influence purchasing decisions.

2. Calfskin Nubuck Leather

Key Properties:

Calfskin nubuck leather is softer and finer than cowhide, providing a luxurious feel while still maintaining a strong structure. Its temperature and pressure ratings are similar to those of cowhide, but it is generally lighter and more flexible.

Pros & Cons:

The key advantage of calfskin nubuck is its superior softness and aesthetic appeal, making it ideal for high-fashion items. However, it is less durable than cowhide, which may limit its use in heavy-duty applications. The cost is typically higher, reflecting the quality and processing involved.

Impact on Application:

Calfskin nubuck is often used in luxury handbags and high-end apparel, where appearance and texture are paramount. Its sensitivity to moisture necessitates additional care and treatment.

Considerations for International Buyers:

Buyers from Europe, particularly in fashion-centric markets like Germany, may prioritize calfskin for its prestige. Compliance with EU regulations on leather sourcing and environmental sustainability is also critical.

3. Sheepskin Nubuck Leather

Key Properties:

Sheepskin nubuck leather is known for its lightweight and soft texture, derived from the outer layer of sheep hides. It offers moderate temperature resistance and is less robust than cowhide or calfskin.

Pros & Cons:

The main advantage of sheepskin nubuck is its affordability and softness, making it suitable for garments and accessories. However, it is less durable and more prone to wear and tear, which may limit its application in high-contact items.

Illustrative image related to nubuck leathe

Impact on Application:

Sheepskin nubuck is often used in fashion items like jackets and gloves, where comfort is prioritized over durability. Its vulnerability to moisture and staining requires careful handling and maintenance.

Considerations for International Buyers:

In regions like South America, where cost sensitivity is higher, sheepskin nubuck presents an attractive option. Buyers should be aware of local regulations regarding animal welfare and leather sourcing.

Summary Table of Nubuck Leather Materials

| Materiaal | Typical Use Case for nubuck leathe | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cowhide Nubuck | Footwear, high-end upholstery | High durability and aesthetic appeal | Requires careful maintenance | Hoog |

| Calfskin Nubuck | Luxury handbags, high-fashion apparel | Superior softness and luxurious feel | Less durable than cowhide | Hoog |

| Sheepskin Nubuck | Fashion jackets, gloves | Affordable and lightweight | Less durable, prone to wear | Medium |

This strategic material selection guide provides B2B buyers with essential insights into nubuck leather materials, helping them make informed decisions based on application needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for nubuck leathe

What Are the Main Stages in the Manufacturing Process of Nubuck Leather?

The manufacturing of nubuck leather involves several critical stages, each designed to enhance the quality and aesthetic appeal of the final product.

-

Material Preparation: The journey begins with the selection of high-quality hides, predominantly from cattle, calves, or sheep. These hides undergo a rigorous selection process, ensuring that only those with minimal imperfections are chosen. Post-selection, the hides are soaked in water to remove salt and other preservatives, followed by liming, which helps to loosen the hair and prepare the skin for tanning.

-

Tanning: The tanning process is crucial as it transforms raw hides into durable leather. Nubuck is typically tanned using either chrome or vegetable tanning methods. Chrome tanning is faster and produces a more consistent finish, while vegetable tanning is more environmentally friendly, yielding a more natural look. This stage ensures that the leather maintains its flexibility and strength.

-

Sanding and Buffing: After tanning, the grain side of the hide is lightly sanded or buffed to achieve the characteristic soft, velvety texture of nubuck. This step also enhances the natural grain and markings, which add to the leather’s unique appeal.

-

Dyeing and Finishing: Following sanding, the leather is dyed to achieve the desired color. Finishing treatments may include applying protective coatings to enhance durability and resistance to stains and water. This is an essential step, as nubuck leather is prone to damage if not properly treated.

-

Cutting and Assembly: Once the leather has been dyed and finished, it is cut into specific shapes and sizes for various applications, such as footwear, bags, or upholstery. This is followed by assembly, where different parts are stitched or glued together, ensuring structural integrity.

What Quality Control Measures Should Be in Place for Nubuck Leather?

Quality assurance is vital in the production of nubuck leather to ensure that the final product meets international standards and customer expectations. Here are the key quality control measures typically implemented:

-

International Standards Compliance: Manufacturers should adhere to recognized international standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with these standards helps ensure consistent quality and reliability in production.

-

Industry-Specific Certifications: Depending on the application, additional certifications may be required. For example, CE marking may be necessary for products sold in the European market, ensuring compliance with health, safety, and environmental protection standards.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified requirements. Hides are checked for quality and consistency before processing begins.

– In-Process Quality Control (IPQC): During production, various checkpoints are established to monitor the tanning, sanding, and finishing stages. This ensures any deviations from quality standards are addressed promptly.

– Final Quality Control (FQC): After the manufacturing process is complete, a thorough inspection of the finished products is conducted. This includes checking for defects, color consistency, and overall craftsmanship.

What Testing Methods Are Commonly Used in Nubuck Leather Production?

To validate the quality of nubuck leather, several testing methods are employed:

-

Physical Testing: This includes tensile strength tests, abrasion resistance tests, and tear strength tests to ensure the leather can withstand everyday use without compromising its integrity.

-

Water Resistance Testing: Since nubuck leather is prone to water damage, tests are conducted to assess its resistance to moisture. This may involve applying water to the leather and measuring absorption rates.

-

Colorfastness Testing: This test evaluates how well the color holds up under various conditions, such as exposure to light or friction. It ensures that the dye used in the leather does not fade or transfer.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those operating in international markets such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is crucial. Here are several strategies:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes and quality control practices. This can help buyers assess compliance with international standards and identify potential areas of concern.

-

Requesting Quality Reports: Buyers should request detailed quality reports that outline testing results, compliance with standards, and any certifications held by the supplier. This documentation can serve as a benchmark for quality assurance.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures. These inspections can cover various stages of production, ensuring that standards are met consistently.

-

Understanding Certification Nuances: Different regions may have specific certification requirements. Buyers should familiarize themselves with these nuances to ensure that their suppliers meet local regulations, particularly in regions like Europe, where compliance can significantly impact market access.

What Are the Key Considerations for International B2B Buyers?

When sourcing nubuck leather from international suppliers, buyers should consider several factors:

-

Cultural and Regulatory Differences: Understanding the cultural context and regulatory environment of the supplier’s country can facilitate smoother transactions and compliance with local laws.

-

Logistics and Supply Chain: Assessing the supplier’s logistics capabilities is essential, particularly for international shipping. Timely delivery and the condition of the leather upon arrival should be prioritized.

-

Sustainability Practices: Increasingly, buyers are seeking suppliers who adopt sustainable practices in their manufacturing processes. This includes using environmentally friendly tanning methods and ensuring ethical sourcing of raw materials.

By paying close attention to these manufacturing processes and quality assurance measures, B2B buyers can confidently source nubuck leather that meets their quality expectations and market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘nubuck leathe’

To assist B2B buyers in effectively sourcing nubuck leather, this guide provides a structured checklist that outlines essential steps for a successful procurement process. Nubuck leather is prized for its luxurious feel and durability, making it a popular choice for high-end products. This checklist will ensure that buyers make informed decisions, maximizing both quality and value.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your specific requirements for nubuck leather. Consider factors such as the intended use (e.g., footwear, upholstery), desired thickness, color, and finish. This clarity will help you communicate effectively with suppliers and ensure that the materials meet your project needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in nubuck leather. Look for companies with a strong reputation, ideally those that have been in the industry for several years. Utilize industry directories, trade shows, and online platforms to compile a list of potential vendors.

- Tip: Prioritize suppliers with a history of international shipping, especially if you are sourcing from regions like Africa or South America.

Step 3: Evaluate Supplier Certifications

It’s essential to verify that potential suppliers hold relevant certifications, such as ISO or environmental compliance certifications. These certifications indicate that the supplier adheres to industry standards for quality and sustainability.

- Why It Matters: Certifications can mitigate risks related to quality control and ethical sourcing, ensuring that the leather is produced responsibly.

Step 4: Request Samples

Always request samples of nubuck leather before placing a bulk order. This allows you to assess the texture, color, and overall quality firsthand. Examine the samples for consistency and ensure they align with your specifications.

- Consideration: Pay attention to any natural imperfections, as nubuck should maintain a certain character derived from the hide.

Step 5: Understand Pricing Structures

Engage with suppliers to understand their pricing models. Inquire about minimum order quantities, bulk discounts, and payment terms. Transparent pricing structures will help you budget accurately and avoid unexpected costs.

- Negotiation Tip: Be prepared to discuss your requirements and potential long-term partnerships, which may provide leverage for better pricing.

Step 6: Check References and Reviews

Request references from previous clients or look for online reviews to gauge the supplier’s reliability. Understanding the experiences of other buyers can provide insight into the supplier’s customer service, delivery timelines, and product quality.

- Action: Focus on reviews from businesses in similar industries or regions to ensure relevance.

Step 7: Finalize Logistics and Delivery Terms

Once you have selected a supplier, finalize the logistics surrounding your order. Discuss delivery timelines, shipping methods, and any customs considerations if you are importing. Clear communication about these terms will prevent delays and ensure a smooth procurement process.

- Final Check: Ensure that the supplier can provide tracking information and support throughout the shipping process.

By following these steps, B2B buyers can confidently navigate the complexities of sourcing nubuck leather, ensuring they receive high-quality materials tailored to their specific needs.

Comprehensive Cost and Pricing Analysis for nubuck leathe Sourcing

What Are the Key Cost Components in Nubuck Leather Sourcing?

Nubuck leather sourcing involves several cost components that collectively determine the pricing structure. The primary components include:

-

Materials: The quality of the hides significantly influences costs. Nubuck is typically made from high-grade cowhide, calfskin, or sheepskin, which can vary in price based on quality and availability. Higher-quality materials may lead to a more luxurious end product but also increase the initial investment.

-

Labor: Skilled artisans are required to process nubuck leather, particularly during the sanding and buffing stages. Labor costs can vary significantly depending on the region and expertise of the workforce.

-

Manufacturing Overhead: This encompasses the costs of maintaining facilities, equipment depreciation, utilities, and other operational expenses. Efficient production methods can help mitigate overhead costs.

-

Tooling: The initial investment in tooling for cutting and shaping leather can be substantial. Custom tooling for specific designs may further increase these costs.

-

Quality Control (QC): Ensuring that the nubuck meets specific quality standards requires rigorous QC processes, which contribute to overall costs. This is especially critical for high-end applications where imperfections are unacceptable.

-

Logistics: Shipping and handling costs vary based on the distance, weight, and mode of transport. International buyers should factor in customs duties and tariffs, which can significantly affect total costs.

-

Margin: Suppliers typically apply a markup to cover their expenses and profit. Understanding the expected margin in your sourcing region can help in negotiating better pricing.

How Do Price Influencers Affect Nubuck Leather Costs?

Several factors can influence the pricing of nubuck leather:

-

Volume/MOQ: Suppliers often have minimum order quantities (MOQs), and larger orders can lead to volume discounts. Understanding a supplier’s MOQ can help in planning purchases strategically to optimize costs.

-

Specifications and Customization: Custom specifications, such as specific colors, finishes, or treatments, may increase costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Materials and Quality Certifications: The presence of quality certifications (such as ISO or eco-labels) can influence pricing. Buyers seeking certified nubuck may pay a premium for assurance of quality and sustainability.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can significantly affect pricing. Established suppliers with a track record of reliability may charge more but offer better service.

-

Incoterms: The shipping terms agreed upon between buyer and seller can impact overall costs. Understanding Incoterms is vital for budgeting and calculating total landed costs.

What Buyer Tips Can Help in Sourcing Nubuck Leather Cost-Effectively?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can help in sourcing nubuck leather more efficiently:

-

Negotiation: Engage suppliers in negotiations to explore better pricing options or favorable payment terms. Building a relationship can lead to more flexibility in pricing.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also maintenance, logistics, and potential wastage. A lower upfront cost may not always equate to long-term savings.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, local economic conditions, and trade regulations that may impact pricing. Leveraging local partnerships can sometimes provide insights into better sourcing options.

-

Research and Due Diligence: Conduct thorough research on potential suppliers, including visiting manufacturing facilities if possible. This can provide insights into their operations and help gauge product quality.

Disclaimer on Indicative Prices

Pricing for nubuck leather can vary widely based on the aforementioned factors. It is essential to obtain quotes from multiple suppliers to ensure competitive pricing and to account for fluctuating market conditions. Always consider obtaining a sample before committing to a large order to ensure the quality meets your expectations.

Illustrative image related to nubuck leathe

Alternatives Analysis: Comparing nubuck leathe With Other Solutions

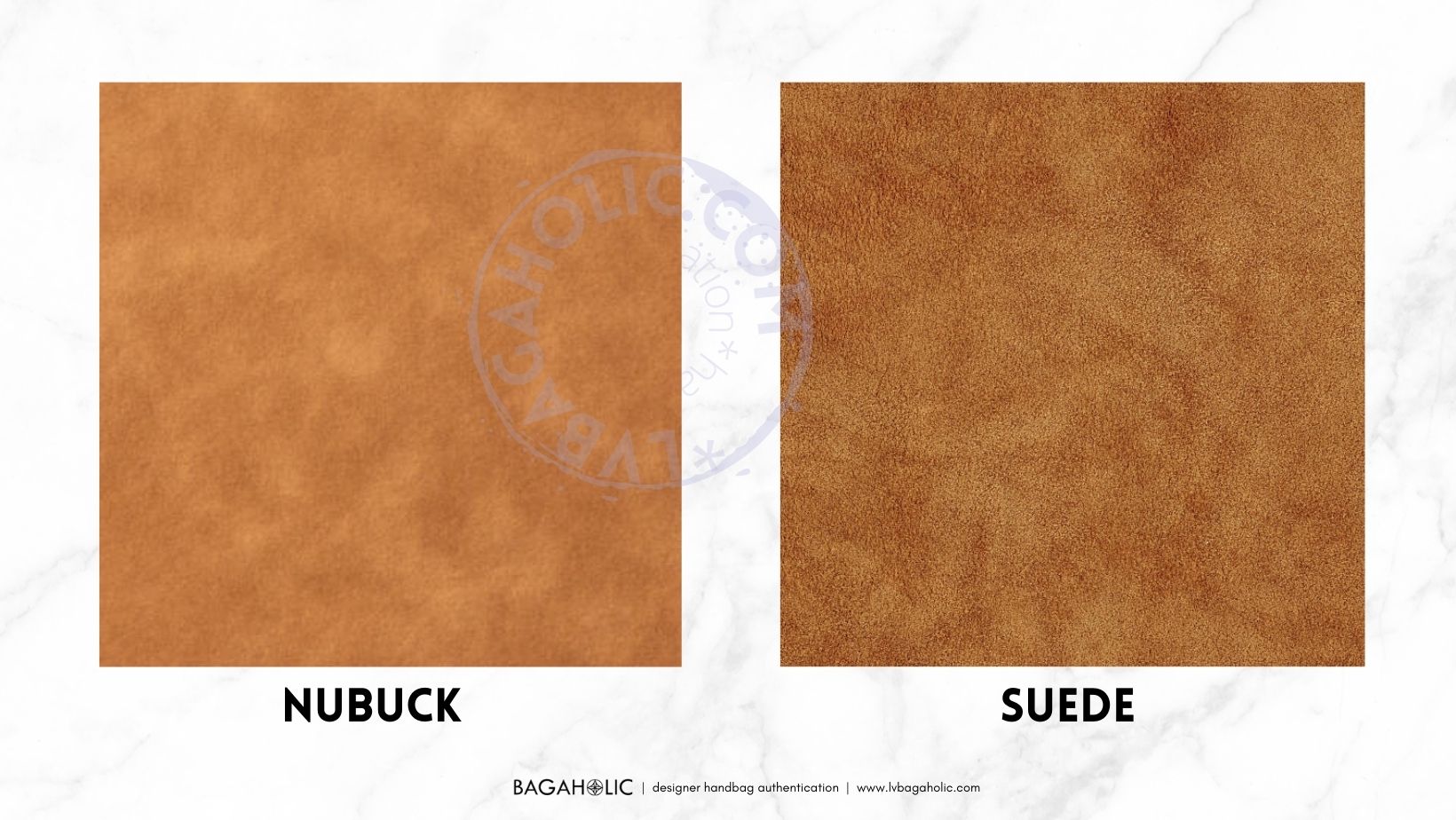

Understanding Alternatives to Nubuck Leather

When considering materials for leather goods, nubuck leather is often a top choice due to its luxurious feel and durability. However, various alternatives can also meet the needs of different applications. This section will explore how nubuck leather compares to suede leather and synthetic leather, offering insights into their respective advantages and drawbacks for B2B buyers.

Comparison Table

| Comparison Aspect | Nubuckleer | Suede Leather | Synthetic Leather |

|---|---|---|---|

| Performance | Durable, luxurious, but prone to stains | Softer, less durable, prone to staining | Highly durable, resistant to water and stains |

| Cost | Generally higher | More affordable | Varies, often lower than nubuck |

| Ease of Implementation | Requires careful handling and specialized tools | Easier to work with | Simple to handle and manipulate |

| Maintenance | Needs regular brushing and protection | Requires frequent cleaning | Low maintenance, easy to clean |

| Best Use Case | High-end fashion, upholstery, footwear | Fashion items, garments, accessories | Everyday items, budget-friendly products |

Detailed Breakdown of Alternatives

1. Suede Leather

Suede leather, while similar in appearance to nubuck, is made from the inner flesh side of the hide. Its soft, fuzzy texture appeals to many designers, particularly in fashion. Pros include a lower cost and a softer feel, making it suitable for garments and accessories that don’t experience heavy wear. However, its durability is notably less than that of nubuck, and it can easily become stained or damaged. Therefore, suede is best for items that are not subject to rigorous use.

2. Synthetic Leather

Synthetic leather, often made from polyurethane or PVC, presents a versatile alternative to both nubuck and suede. Its performance is superior in terms of water resistance and durability, making it an excellent choice for everyday items like bags and shoes. Additionally, synthetic leather is typically more affordable and easier to clean than natural leathers. However, it may lack the luxurious feel and aesthetic appeal of nubuck, which could be a drawback for high-end applications. Synthetic options are ideal for budget-conscious projects or those requiring easy maintenance.

Conclusion: Choosing the Right Leather Solution for Your Needs

Selecting the right leather solution hinges on the specific requirements of your project. Nubuck leather stands out for its luxury and durability, making it perfect for high-end items, while suede offers a softer, more economical alternative better suited for fashion items. On the other hand, synthetic leather shines in durability and maintenance ease, making it a practical choice for everyday products. B2B buyers should assess their project’s demands, including budget constraints, intended use, and maintenance capabilities, to make an informed decision that aligns with their brand identity and customer expectations.

Illustrative image related to nubuck leathe

Essential Technical Properties and Trade Terminology for nubuck leathe

What Are the Key Technical Properties of Nubuck Leather?

When engaging with nubuck leather as a B2B buyer, understanding its critical specifications is essential for making informed purchasing decisions. Here are some of the most important properties to consider:

1. Material Grade

Nubuck leather is typically classified based on its quality, which directly influences its durability and appearance. Common grades include full-grain, top-grain, and corrected-grain. Full-grain nubuck is the highest quality, retaining the hide’s natural characteristics, making it ideal for luxury goods. Understanding material grades helps buyers select the right quality for their specific applications, ensuring product longevity and customer satisfaction.

2. Thickness

The thickness of nubuck leather is often measured in millimeters (mm) and can vary between 0.8 mm to 2.0 mm. Thicker leather is generally more durable and better suited for products that undergo heavy use, such as footwear and upholstery. For B2B buyers, this specification is crucial as it affects both the product’s performance and cost.

3. Tanning Method

Nubuck can be tanned using either chrome or vegetable methods. Chrome-tanned nubuck is more common and offers enhanced flexibility and water resistance, while vegetable-tanned nubuck is more environmentally friendly and develops a unique patina over time. Understanding the tanning method helps buyers assess the leather’s properties, such as its environmental impact and maintenance needs.

Illustrative image related to nubuck leathe

4. Color Fastness

Color fastness refers to how well the dye adheres to the leather and resists fading or bleeding. This property is particularly important for fashion items and upholstery, where visual appeal is paramount. Buyers should inquire about color fastness ratings to ensure that the nubuck leather meets their aesthetic and quality standards.

5. Water Resistance

While nubuck is generally more water-resistant than suede, it is not inherently waterproof. Many manufacturers apply protective coatings to enhance water resistance. For B2B buyers, understanding the water resistance of nubuck leather is vital, especially for products exposed to moisture or humidity, such as footwear and outdoor gear.

What Are Common Trade Terms Related to Nubuck Leather?

Familiarity with trade terminology can streamline the procurement process and enhance communication between buyers and suppliers. Here are several essential terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components or products that are used in another company’s final product. In the context of nubuck leather, an OEM might source hides to manufacture leather goods. Understanding OEM relationships can help buyers secure high-quality materials tailored to their specifications.

Illustrative image related to nubuck leathe

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For nubuck leather, MOQs can vary significantly based on the supplier and type of leather. Knowing the MOQ is essential for B2B buyers to manage inventory costs and supply chain logistics effectively.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request price quotes from suppliers for specific products. For nubuck leather, submitting an RFQ allows buyers to compare prices and terms, ensuring they receive the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, including shipping, insurance, and tariffs. Understanding these terms is crucial for B2B buyers involved in the importation of nubuck leather, as they dictate who bears the risk at various stages of the shipping process.

Illustrative image related to nubuck leathe

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. For nubuck leather, lead times can vary based on production schedules and shipping logistics. Buyers should factor in lead times when planning their projects to avoid delays.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions in sourcing nubuck leather, ensuring they select the right materials for their specific needs while optimizing their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the nubuck leathe Sector

Market Overview & Key Trends in Nubuck Leather Sourcing

The global nubuck leather market is experiencing notable growth, driven by rising consumer preferences for high-quality, durable materials in fashion and upholstery. Key trends influencing this sector include an increasing demand for luxury items, as well as the growth of the e-commerce platform, which is facilitating easier access for international B2B buyers. Notably, markets in Africa, South America, the Middle East, and Europe are witnessing a surge in demand for nubuck leather, particularly in the footwear and high-end upholstery segments.

Emerging technologies such as AI-driven inventory management systems and blockchain for supply chain transparency are reshaping sourcing strategies. These technologies enhance operational efficiency and provide buyers with real-time data, enabling informed purchasing decisions. Additionally, the trend toward customization and bespoke products is leading manufacturers to adapt their offerings, allowing for tailored solutions that meet specific buyer requirements.

Furthermore, the shift towards sustainable practices is becoming increasingly important, with buyers prioritizing suppliers who demonstrate a commitment to ethical sourcing and environmentally friendly production methods. As international trade regulations evolve, understanding the dynamic landscape of tariffs and trade agreements is crucial for B2B buyers to navigate sourcing effectively.

How is Sustainability and Ethical Sourcing Impacting the Nubuck Leather Market?

Sustainability and ethical sourcing are pivotal considerations for B2B buyers in the nubuck leather market. The environmental impact of leather production has come under scrutiny, with increasing awareness around water usage, chemical runoff, and waste management. As a result, many buyers are seeking suppliers who prioritize eco-friendly tanning processes and sustainable practices.

The importance of ethical supply chains cannot be overstated. Buyers are now more inclined to partner with manufacturers who adhere to fair labor practices and provide transparency regarding their sourcing methods. Certifications such as the Global Organic Textile Standard (GOTS) and Leather Working Group (LWG) are becoming essential indicators of a supplier’s commitment to sustainability. These certifications not only enhance brand reputation but also appeal to a growing consumer base that values ethical consumption.

Incorporating ‘green’ materials into product offerings, such as vegetable-tanned nubuck leather, is also gaining traction. This shift not only aligns with environmental goals but can also open new market opportunities as consumers increasingly demand responsibly sourced products.

Brief Evolution of Nubuck Leather in the B2B Context

The history of nubuck leather can be traced back to its roots in the traditional tanning practices of the 19th century. Originally developed as a more affordable alternative to suede, nubuck quickly gained popularity for its luxurious texture and durability. The use of high-quality hides, typically from cow or calf, has positioned nubuck as a premium product in the leather industry.

Illustrative image related to nubuck leathe

In the B2B context, the evolution of nubuck leather reflects broader trends in consumer behavior, where quality and sustainability have become central to purchasing decisions. As manufacturers adapt to these demands, the nubuck leather market continues to evolve, offering innovative solutions that cater to the needs of discerning international buyers. Today, nubuck leather is not only a symbol of luxury but also a testament to the industry’s commitment to sustainable practices and ethical sourcing.

Frequently Asked Questions (FAQs) for B2B Buyers of nubuck leathe

-

How do I choose the right supplier for nubuck leather?

When selecting a supplier for nubuck leather, prioritize those with a strong reputation for quality and reliability. Check for certifications, such as ISO, and inquire about their sourcing practices to ensure they use high-quality hides. Request samples to assess the texture and durability of the leather. Additionally, consider their production capacity and lead times to meet your demands, especially if you operate in regions with specific delivery timelines. -

What are the typical minimum order quantities (MOQs) for nubuck leather?

MOQs for nubuck leather can vary significantly between suppliers. Typically, they range from 50 to 200 square meters, depending on the type and quality of the leather. Some manufacturers may offer lower MOQs for custom orders, while others may have higher requirements for bulk purchases. Always clarify these terms upfront to avoid any misunderstandings and ensure they align with your purchasing needs. -

How do I ensure the quality of nubuck leather before placing a large order?

To ensure quality, request physical samples of the nubuck leather you intend to purchase. Conduct a thorough inspection for texture, color consistency, and the presence of any defects. Additionally, ask for information on the tanning process and any treatments applied to the leather. Establish a quality assurance agreement with the supplier, outlining specific criteria that the leather must meet before shipment. -

What customization options are available for nubuck leather products?

Most suppliers offer a range of customization options, including color, thickness, and finish for nubuck leather. You can also request specific textures or treatments to enhance durability or water resistance. When discussing customization, provide clear specifications and confirm the supplier’s capability to meet your requirements, including any potential impacts on pricing and lead times. -

What payment terms should I expect when sourcing nubuck leather internationally?

Payment terms can vary, but common practices include a deposit of 30-50% upfront, with the balance due upon delivery or before shipping. Some suppliers may offer letters of credit or other financing options for larger orders. Always negotiate terms that work for your cash flow needs and ensure they are clearly documented in the contract to avoid any disputes later. -

How can I mitigate shipping risks when importing nubuck leather?

To mitigate shipping risks, work with reputable freight forwarders who specialize in handling leather products. Ensure that all shipments are insured to cover potential loss or damage during transit. Additionally, consider using incoterms that define responsibilities between you and the supplier, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), to clarify who bears the risk at each stage of the shipping process. -

What are the best practices for storing nubuck leather?

Proper storage of nubuck leather is essential to maintain its quality. Store it in a cool, dry place away from direct sunlight, which can cause fading and drying. Use breathable cotton bags for protection, avoiding plastic that can trap moisture. Ensure the leather is clean and dry before storage, and periodically check for any signs of mold or damage, particularly in humid climates. -

What are the main applications for nubuck leather in various industries?

Nubuck leather is widely used in industries such as footwear, high-end upholstery, and fashion accessories. Its luxurious appearance and durability make it ideal for high-quality shoes, handbags, and furniture. Additionally, it is used in automotive interiors and sporting goods due to its resistance to wear and its breathable nature. Understanding these applications can help you identify potential markets for your products and tailor your offerings accordingly.

Top 4 Nubuck Leathe Manufacturers & Suppliers List

1. Leather Hide Store – Nubuck Leather

Domain: leatherhidestore.com

Registered: 2010 (15 years)

Introduction: Nubuck is a top grain leather that has been lightly sanded and brushed to create a supple, velvety-like surface. The sanding process removes the top layer of the hide exposing a layer of tiny soft fibers or nap. Nubuck is compared to suede, but is a stronger upholstery grade leather. Traditional Nubuck is susceptible to staining, but the Italia Nubuck Collection offers a waterproof and highly stai…

2. Maverick Leather Company – Nubuck Leather Products

Domain: maverickleathercompany.com

Registered: 2009 (16 years)

Introduction: Nubuck leather products available in various weights and colors. Key products include: 1. SB Foot – Voyager – Mahogany 5/6oz, Price: $63.99 – $84.99 2. SB Foot- Mississippi – Dark Brown 4/5oz, Price: $63.99 – $84.99 3. SB Foot – Nubuck – Pale Yellow 4-6oz, Price: $63.99 – $84.99 4. SB Foot – Nubuck – Natural 5/6oz, Price: $73.99 – $84.99 5. SB Foot – Tramper – Hazelnut 5/6oz, Price: $73.99 – $84.9…

3. Carl Friedrik – Nubuck Leather Care

Domain: carlfriedrik.com

Registered: 2016 (9 years)

Introduction: Nubuck leather is durable, made from the outer layer of animal hide, and has a velvety surface known as the ‘nap’. It is breathable but prone to oil and grease stains. Care involves using a nubuck brush to clean and re-fluff the surface, applying waterproofing spray 2-3 times a year, and using nubuck conditioner sprays for nourishment. Cleaning requires a nubuck-specific brush, eraser, and cleaner…

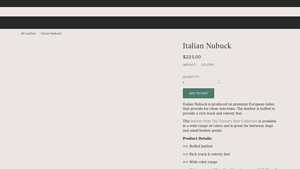

4. The Tannery Row – Italian Nubuck

Domain: thetanneryrow.com

Registered: 2011 (14 years)

Introduction: {“name”: “Italian Nubuck”, “price”: “$225.00”, “description”: “Italian Nubuck is produced on premium European hides that provide for clean selections. The leather is buffed to provide a rich track and velvety feel. This leather from The Tannery Row Collection is available in a wide range of colors and is great for footwear, bags and small leather goods.”, “product_details”: {“type”: “Buffed leathe…

Strategic Sourcing Conclusion and Outlook for nubuck leathe

Nubuck leather stands as a premier choice for businesses seeking quality, durability, and aesthetic appeal in their products. By understanding the distinct characteristics and applications of nubuck, international buyers can make informed decisions that enhance their offerings in various markets. The luxurious texture and resilience of nubuck make it ideal for high-end footwear, upholstery, and leather goods, catering to consumers who prioritize both style and longevity.

Strategic sourcing of nubuck leather not only ensures access to superior materials but also fosters partnerships with reputable suppliers who can provide consistent quality and innovative solutions. As markets in Africa, South America, the Middle East, and Europe continue to evolve, leveraging the unique attributes of nubuck can differentiate your products and meet growing consumer demands for premium leather goods.

Looking ahead, businesses should capitalize on emerging trends and consumer preferences by integrating nubuck leather into their product lines. Now is the time to explore collaborations with trusted suppliers to secure the finest nubuck leather and position your brand at the forefront of the leather industry. Embrace the potential of nubuck leather to elevate your offerings and drive success in a competitive marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to nubuck leathe

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.