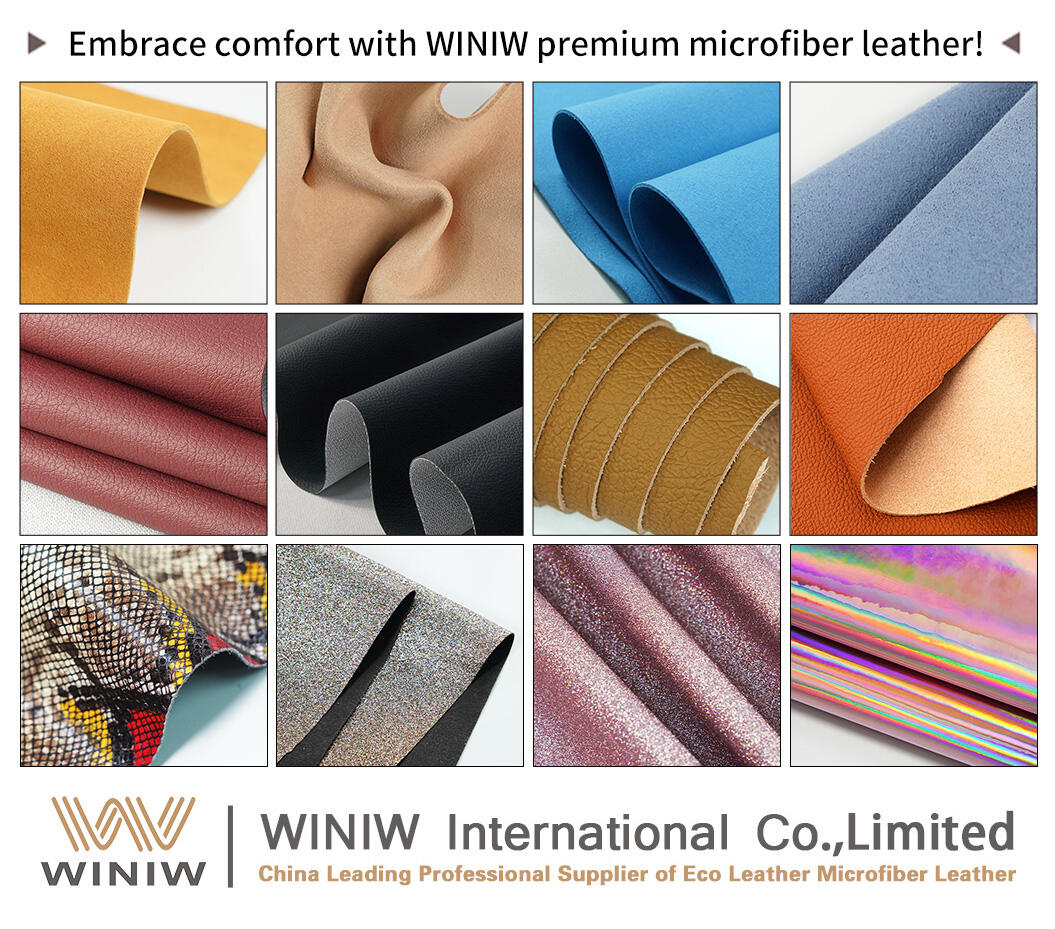

Dok je prirodna koža ostala simbolom luksuznosti, mikrovlakna pu koža pojavila se kao transformacijski materijal u industrijama od aerokosmičke do medicinskih uređaja. U nastavku istražujemo njegove ključne prednosti kroz tehnički prizor, podržane inovacijama i vodećim stručnim znanjem WINIW-a.

nepremačiva trajeća za primjene pod visokim optuženjem

Tehnička uvid: Mikrovlaknovita PU koža kombinira gusti poliuretanski oblog s fleksibilnim mikrovlaknovitim podložjem, stvarajući materijal koji otporn je na oštrice, probode i UV degradaciju.

izvrsna prilagodljivost za branđiranje i funkcionalnost

Tehnički uvid: Mikrovlakna pu koža sintetička baza omogućuje preciznu kontrolu nad teksturom, bojom i završetkom. Može imitirati žiljavu cijelog kožnog prekrivača ili usvojiti jedinstvene uzorke, čime postaje idealna za proizvode s brendom.

Potencirana disljivost za tržišta usredotočena na udobnost

Tehnički uvid: Na različite od neporoze vinile, otvorena mrežasta sloja mikrovlakna mikrofibre PU promiču zrakoplov, smanjujući nagomilavanje patuljke tijekom dugačkog korištenja. Njegove svojstva odbacivanja vlage poboljšavaju se WINIW-ovim vlasničkim obradama.

Ravnoteža između cijene i performansi za skalabilna rješenja

Tehnički uvid: Mikrovlakna pu koža nudi trajnost kože uz 60% nižu cijenu materijala, s minimalnim održavanjem. Njena lagana priroda smanjuje troškove slanja za globalne brendove.

budućnost mikrovlaknene PU leđe leži u stručnosti

Mikrovlakna PU koža nije samo sintetička alternativa—ono je materijal inženiran za potrebe savremenih industrija. U WINIW-u kombiniramo tehničku preciznost s održivostjo, osiguravajući da naši klijenti dobiju konkurentnu prednost. Bilo da projektirate zaštitnu opremu za astronave ili luksuzne torbe, naše mikrovlakne PU rješenja pružaju neusporedivu učinkovitost.

EN

EN