Introduction: Navigating the Global Market for custom leather crafting

In the competitive landscape of custom leather crafting, international B2B buyers often face the challenge of sourcing high-quality products that meet specific design needs. Whether you’re looking for bespoke leather goods for retail or specialized applications like motorcycle accessories, understanding the nuances of the custom leather market is essential. This guide offers a comprehensive overview of the various types of custom leather products, including their applications, supplier vetting processes, and cost considerations. By leveraging this information, businesses can make informed purchasing decisions that align with their operational goals and customer expectations.

The custom leather crafting industry is rich with opportunities, but navigating it requires insight into supplier capabilities and market trends. From traditional craftsmanship to modern innovations, the potential for customization is vast, catering to diverse industries across Africa, South America, the Middle East, and Europe, including key markets like Germany and Saudi Arabia. This guide not only highlights the essential factors to consider when selecting suppliers but also provides practical tips for negotiating and managing supplier relationships. By empowering B2B buyers with knowledge and actionable strategies, this resource aims to facilitate successful sourcing and enhance product offerings in an increasingly globalized market.

Table Of Contents

- Top 7 Custom Leather Crafting Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather crafting

- Understanding custom leather crafting Types and Variations

- Key Industrial Applications of custom leather crafting

- 3 Common User Pain Points for ‘custom leather crafting’ & Their Solutions

- Strategic Material Selection Guide for custom leather crafting

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather crafting

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather crafting’

- Comprehensive Cost and Pricing Analysis for custom leather crafting Sourcing

- Alternatives Analysis: Comparing custom leather crafting With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather crafting

- Navigating Market Dynamics and Sourcing Trends in the custom leather crafting Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather crafting

- Strategic Sourcing Conclusion and Outlook for custom leather crafting

- Important Disclaimer & Terms of Use

Understanding custom leather crafting Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Custom Motorcycle Gear | Tailored to fit specific models, often with unique designs | Motorcycle retailers, custom shops | Pros: High customization; brand differentiation. Cons: Longer lead times for production. |

| Personalized Accessories | Items like wallets, belts, and bags, often featuring logos or designs | Corporate gifts, promotional items | Pros: Enhances brand visibility; unique offerings. Cons: Higher initial costs for small quantities. |

| Functional Tool Pouches | Designed for specific tools or equipment, often modular | Construction, trades, and DIY markets | Pros: Increased organization; tailored functionality. Cons: Limited aesthetic appeal compared to fashion items. |

| Artistic Leather Goods | Focus on artistic designs, often incorporating mixed materials | Art galleries, craft fairs, specialty shops | Pros: Unique products; supports local artisans. Cons: Niche market; potentially higher price points. |

| Specialty Fashion Items | Includes custom clothing and accessories, emphasizing style | Fashion boutiques, online retailers | Pros: High demand for unique fashion; potential for high margins. Cons: Seasonal trends may affect sales. |

What are the Key Characteristics of Custom Motorcycle Gear?

Custom motorcycle gear is specifically designed to fit various motorcycle models, offering unique features such as personalized artwork, tailored sizing, and specialized materials. This type of crafting is particularly suitable for retailers and custom shops looking to offer exclusive products that cater to motorcycle enthusiasts. B2B buyers should consider the lead time for production and the ability to accommodate specific requests, as these factors can influence customer satisfaction and inventory management.

How Do Personalized Accessories Enhance Brand Visibility?

Personalized accessories, such as wallets, belts, and bags, often feature logos or custom designs that make them ideal for corporate gifts or promotional items. These products allow businesses to enhance their brand visibility while providing customers with functional items. When purchasing, B2B buyers should weigh the benefits of customization against the higher initial costs, especially for smaller quantities, as this can impact the overall marketing budget.

What Makes Functional Tool Pouches a Practical Choice?

Functional tool pouches are designed to hold specific tools or equipment, often featuring modular designs for versatility. They are particularly beneficial for tradespeople and DIY enthusiasts who value organization and accessibility. B2B buyers should consider the practical applications of these pouches, as well as their durability and material quality, to ensure they meet the needs of their target audience.

Why are Artistic Leather Goods Unique Offerings?

Artistic leather goods focus on creativity and craftsmanship, often incorporating mixed materials and unique designs. These items are commonly sold in art galleries, craft fairs, and specialty shops, appealing to consumers looking for one-of-a-kind products. B2B buyers should recognize the niche market for these goods and evaluate the potential for higher price points, while also considering the support for local artisans and craftsmanship.

How Do Specialty Fashion Items Cater to Market Trends?

Specialty fashion items, including custom clothing and accessories, emphasize unique style and personalization. They are highly sought after by fashion boutiques and online retailers, especially those catering to trends. B2B buyers should be mindful of seasonal trends that can influence demand, as well as the potential for high margins on unique fashion items, which can significantly impact profitability.

Key Industrial Applications of custom leather crafting

| Industry/Sector | Specific Application of custom leather crafting | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Custom leather interiors for vehicles | Enhances brand image and customer satisfaction | Quality of leather, customization options, lead times |

| Fashion & Accessories | Personalized leather handbags and wallets | Unique products that cater to niche markets | Design flexibility, material sourcing, production capacity |

| Equestrian | Custom saddles and riding gear | Improved performance and comfort for riders | Durability of materials, ergonomic design, safety standards |

| Hospitality | Leather furnishings for hotels and restaurants | Elevates ambiance and customer experience | Aesthetic appeal, customization options, maintenance needs |

| Military & Tactical | Custom tactical gear and holsters | Enhanced functionality and durability for demanding use | Compliance with specifications, material strength, lead times |

How is Custom Leather Crafting Used in the Automotive Sector?

In the automotive industry, custom leather crafting is widely utilized to create bespoke interiors that enhance the aesthetic and functional appeal of vehicles. Businesses often seek tailored leather seats, steering wheel covers, and interior trims that reflect their brand identity. This customization not only elevates the vehicle’s luxury appeal but also improves customer satisfaction by providing unique options. For international buyers, particularly in regions like Europe and the Middle East, it is crucial to ensure that the leather meets local quality and sustainability standards, while also considering the lead time for production and delivery.

What Role Does Custom Leather Crafting Play in Fashion & Accessories?

In the fashion sector, custom leather crafting allows brands to offer unique handbags, wallets, and accessories that resonate with specific consumer preferences. By providing personalized options, businesses can cater to niche markets and enhance customer loyalty. Buyers must focus on sourcing high-quality leather that aligns with current fashion trends and sustainability practices. For international B2B buyers, understanding regional style preferences and compliance with trade regulations is essential for successful transactions.

How is Custom Leather Crafting Essential for Equestrian Gear?

The equestrian industry benefits significantly from custom leather crafting through the production of high-quality saddles, bridles, and riding gear. These products require a perfect balance of durability and comfort to ensure optimal performance for both horse and rider. Buyers in this sector should prioritize sourcing leather that meets specific safety and durability standards while also allowing for customization to fit individual rider preferences. International buyers, especially from regions with strong equestrian traditions, must consider local equestrian regulations and preferences when sourcing.

In What Ways Does Custom Leather Crafting Enhance Hospitality?

In the hospitality sector, custom leather crafting is utilized to create luxurious furnishings that enhance the ambiance of hotels and restaurants. Items such as leather chairs, menus, and decorative accents can significantly elevate the customer experience. Businesses benefit from sourcing unique leather products that reflect their brand’s identity and values. International buyers should consider the aesthetic appeal, customization options, and maintenance requirements of leather products to ensure they meet the expectations of their clientele, especially in competitive markets in Europe and the Middle East.

How Does Custom Leather Crafting Support Military & Tactical Applications?

Custom leather crafting plays a vital role in the military and tactical sectors by providing tailored gear such as holsters, belts, and protective equipment. These products are designed to meet rigorous durability and functionality standards, essential for demanding environments. Businesses must source materials that comply with military specifications while also considering the customization needs of their end-users. For international buyers, understanding the specific requirements of different military contracts and ensuring compliance with local regulations is critical for successful procurement.

3 Common User Pain Points for ‘custom leather crafting’ & Their Solutions

Scenario 1: Quality Assurance in Custom Leather Crafting

The Problem: B2B buyers often face challenges with the inconsistent quality of custom leather products. This inconsistency can stem from variations in leather sourcing, manufacturing processes, or craftsmanship. For businesses in sectors like fashion, automotive, or specialty goods, receiving products that do not meet the specified quality standards can lead to customer dissatisfaction, increased returns, and damage to brand reputation. The stakes are particularly high for international buyers who may have limited options for recourse.

Illustrative image related to custom leather crafting

The Solution: To mitigate quality concerns, B2B buyers should establish clear communication and expectations with suppliers from the outset. This includes detailed specifications regarding leather types, finish, and durability requirements. Requesting samples before placing large orders can also help ensure that the products meet quality standards. Additionally, buyers should consider suppliers who are transparent about their sourcing and production processes, as this can provide reassurance about the quality of materials used. Building a strong relationship with a reputable supplier that offers consistent quality checks and is willing to adapt to specific needs can be invaluable.

Scenario 2: Delays in Custom Orders

The Problem: Timeliness is critical in the B2B landscape, yet many buyers encounter delays in the delivery of custom leather items. These delays can result from unexpected production bottlenecks, supply chain disruptions, or poor communication between the buyer and supplier. Such setbacks can affect inventory management and sales strategies, particularly for businesses that rely on just-in-time delivery models or have seasonal demands.

The Solution: To address potential delays, buyers should implement a proactive approach to order management. This includes setting realistic timelines for production and delivery based on the supplier’s capabilities. Establishing a clear timeline with milestones and regular check-ins can help track the progress of the order and address any issues that arise promptly. Additionally, diversifying the supplier base by working with multiple manufacturers can provide a buffer against delays, allowing businesses to maintain inventory levels and meet customer demand without interruption.

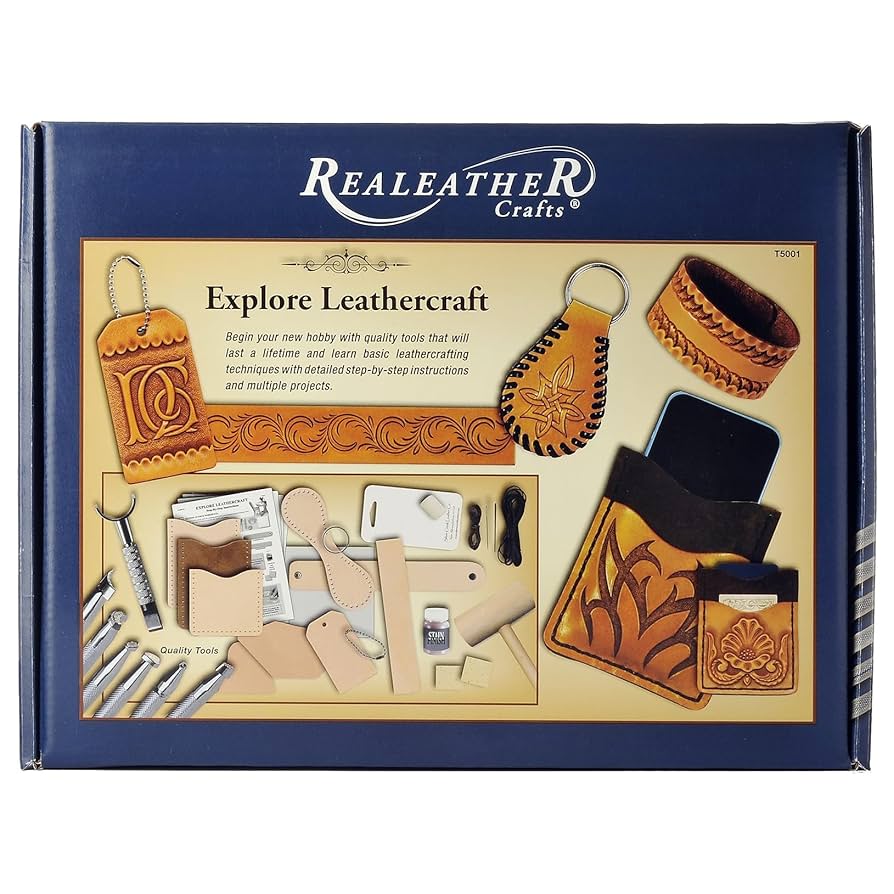

Scenario 3: Complexity in Customization Options

The Problem: The beauty of custom leather crafting lies in its ability to create unique products tailored to specific needs. However, the complexity of customization options can overwhelm buyers, making it difficult to make informed decisions. With a plethora of choices regarding materials, designs, and finishes, B2B buyers may struggle to align their vision with what is feasible within their budget and timelines.

Illustrative image related to custom leather crafting

The Solution: To navigate the complexities of customization, buyers should engage in thorough market research and seek input from experienced professionals in the leather crafting industry. Creating a clear and detailed design brief that outlines the desired features, budget constraints, and intended use can streamline the customization process. Collaborating closely with the supplier during the design phase allows for creative input and expert advice on what is practical and achievable. Additionally, asking for past examples of similar projects can help buyers visualize their options and make more informed choices. Emphasizing open communication throughout the process can ensure that the final product aligns with expectations while staying within budget and timeline constraints.

Strategic Material Selection Guide for custom leather crafting

What Are the Key Properties of Common Materials Used in Custom Leather Crafting?

When selecting materials for custom leather crafting, understanding the properties and applications of various leather types is crucial for B2B buyers. The choice of material can significantly influence product performance, durability, and overall customer satisfaction.

1. Full-Grain Leather

Full-grain leather is the highest quality leather available, made from the top layer of the hide, which retains the natural grain. Its key properties include excellent breathability and moisture resistance, making it suitable for a variety of applications, from high-end handbags to motorcycle gear.

Illustrative image related to custom leather crafting

Pros: Full-grain leather is exceptionally durable, developing a rich patina over time, which enhances its aesthetic appeal. It is also resistant to wear and tear, making it ideal for products that require longevity.

Cons: The primary drawback is its cost, as full-grain leather is more expensive than other types. Additionally, it can be more challenging to work with due to its thickness, which may require specialized tools.

Impact on Application: Full-grain leather is compatible with various media, including dyes and finishes, allowing for customization. It is particularly favored in markets focused on luxury goods, making it appealing to B2B buyers in Europe and affluent regions.

Illustrative image related to custom leather crafting

Considerations for International Buyers: Buyers should be aware of compliance with international quality standards such as ASTM and DIN, especially in regions like Germany where quality assurance is paramount.

2. Top-Grain Leather

Top-grain leather is similar to full-grain but has been sanded and treated to remove imperfections. This process gives it a more uniform appearance while maintaining some durability.

Pros: It is more affordable than full-grain leather and easier to work with, making it suitable for a wide range of products, including wallets and belts. Its smooth surface allows for effective dyeing and stamping.

Cons: While durable, it is not as robust as full-grain leather and may show signs of wear more quickly. Additionally, the sanding process can reduce its natural breathability.

Impact on Application: Top-grain leather is versatile and works well for both casual and formal products. Its compatibility with various finishes makes it a popular choice for many manufacturers.

Considerations for International Buyers: Buyers should consider the sourcing of top-grain leather, ensuring it meets local regulations regarding animal welfare and environmental impact, particularly in regions with strict compliance laws.

3. Suede Leather

Suede is made from the underside of the hide, giving it a soft texture and unique aesthetic. It is often used for accessories and clothing.

Pros: Suede offers a luxurious feel and is lightweight, making it ideal for fashion applications. It is also more affordable than full-grain and top-grain leathers.

Cons: Its primary disadvantage is susceptibility to stains and water damage, which can limit its use in certain applications. Additionally, it may require more maintenance to keep it looking good.

Impact on Application: Suede is particularly popular in the fashion industry for items like shoes and jackets. Its unique texture adds value to products aimed at style-conscious consumers.

Considerations for International Buyers: Buyers should be cautious about the environmental impact of suede production. Compliance with local regulations regarding chemical treatments used in processing is essential, especially in markets like the Middle East.

4. Bonded Leather

Bonded leather is made from leather scraps that are bonded together with adhesives, often resulting in a more affordable product.

Pros: This material is cost-effective and can mimic the appearance of genuine leather, making it attractive for budget-conscious buyers.

Illustrative image related to custom leather crafting

Cons: It lacks the durability and quality of genuine leather, making it unsuitable for high-end applications. Over time, bonded leather can peel and wear out more quickly.

Impact on Application: Bonded leather is often used in lower-cost items such as notebooks and furniture, appealing to a different market segment.

Considerations for International Buyers: Buyers should be aware of the varying quality standards for bonded leather and ensure that products meet local regulations regarding material composition and safety.

Illustrative image related to custom leather crafting

Summary Table of Material Selection for Custom Leather Crafting

| Material | Typical Use Case for custom leather crafting | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | High-end handbags, motorcycle gear | Exceptional durability and patina | Higher cost and manufacturing complexity | High |

| Top-Grain Leather | Wallets, belts | More affordable and easier to work with | Less durable than full-grain | Medium |

| Suede Leather | Fashion accessories, clothing | Luxurious feel and lightweight | Susceptible to stains and damage | Medium |

| Bonded Leather | Notebooks, furniture | Cost-effective and visually appealing | Lacks durability and quality | Low |

This strategic material selection guide provides valuable insights for B2B buyers in the custom leather crafting industry, helping them make informed decisions based on material properties, applications, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather crafting

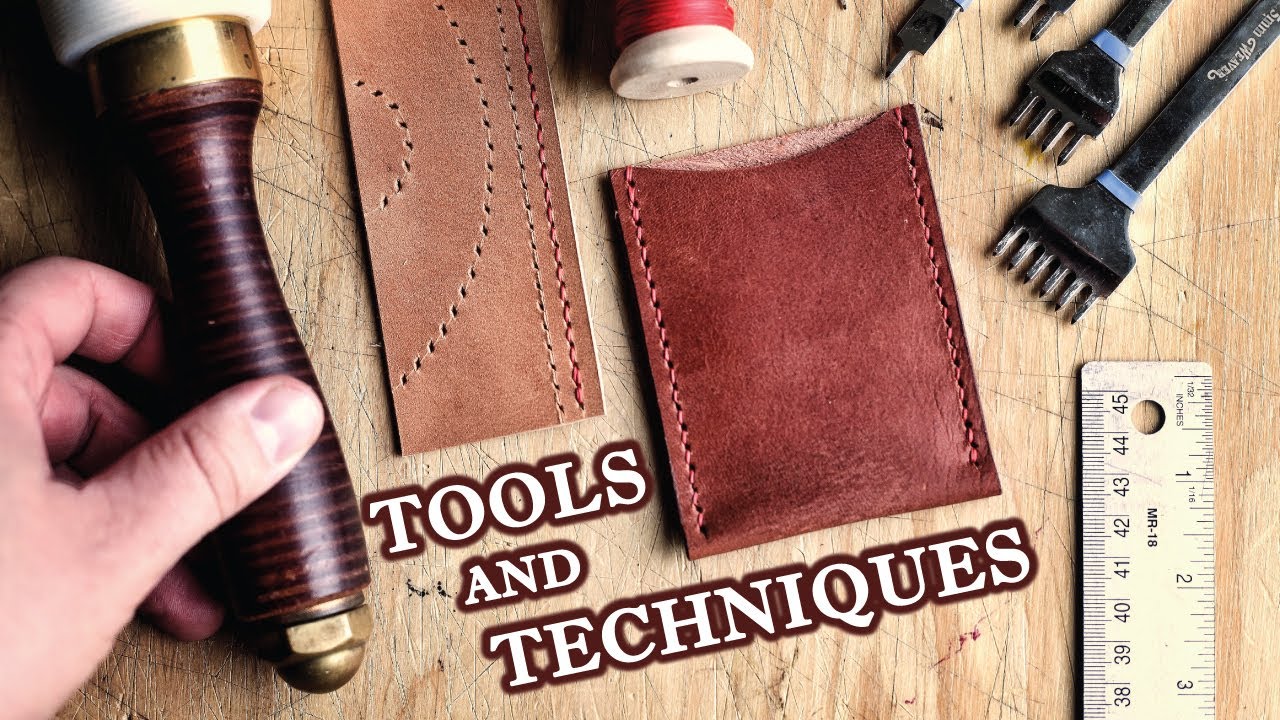

What Are the Key Stages in the Manufacturing Process of Custom Leather Crafting?

The manufacturing process for custom leather crafting can be broadly divided into four main stages: material preparation, forming, assembly, and finishing. Each stage is crucial to ensure that the final product meets the high standards expected by B2B buyers.

-

Material Preparation

The first step involves selecting high-quality leather, which is essential for durability and aesthetic appeal. Leather is typically sourced from various suppliers, depending on the desired characteristics such as texture, thickness, and color. After sourcing, the leather undergoes a conditioning process to enhance its flexibility and prevent cracking. This preparation may also involve cutting the leather into specific shapes and sizes, tailored to the product design. -

Forming

During the forming stage, artisans use various techniques such as molding, stamping, and carving to shape the leather. This is where the unique designs requested by clients come to life. Techniques may include embossing logos or intricate patterns, which require precise tools and skilled craftsmanship. Each piece is crafted with attention to detail, ensuring that it aligns with the client’s specifications. -

Assembly

The assembly stage is where individual components come together. This may involve stitching, riveting, or gluing parts of the leather product. Depending on the complexity of the design, multiple artisans may work on different sections concurrently to optimize efficiency. Quality stitching is vital, as it not only contributes to the product’s durability but also affects its visual appeal. -

Finishing

Finishing touches can include dyeing, polishing, and applying protective coatings to enhance the leather’s appearance and longevity. This stage is crucial for achieving the desired look and feel, and it often includes quality checks to ensure that the product meets the expected standards. Finishing techniques can vary widely, from natural wax finishes to high-gloss coatings, depending on customer preferences.

How Does Quality Assurance Play a Role in Custom Leather Crafting?

Quality assurance (QA) is critical in the custom leather crafting process to ensure that products are consistent, reliable, and meet international standards. B2B buyers should be particularly aware of various QA measures that suppliers implement.

-

What International Standards Should B2B Buyers Be Aware Of?

Many manufacturers adhere to international standards such as ISO 9001, which focuses on quality management systems. This standard helps organizations ensure they meet customer and regulatory requirements consistently. Additionally, industry-specific standards like CE marking for products sold in the European Economic Area and API specifications for oil and gas applications can also apply to certain leather products. -

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to catch defects early. Key stages include:

– Incoming Quality Control (IQC): Inspection of raw materials as they arrive at the facility.

– In-Process Quality Control (IPQC): Regular checks during the manufacturing process to ensure that each stage meets quality specifications.

– Final Quality Control (FQC): A thorough inspection of the finished product before it is packaged and shipped. This includes checking for defects, ensuring proper assembly, and verifying that the product meets design specifications. -

What Testing Methods Are Commonly Used in Quality Assurance?

Common testing methods may include tensile strength tests to assess durability, colorfastness tests to ensure dyes do not bleed, and water-resistance tests for specific applications. These tests provide assurance that the products will perform as expected in real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those operating internationally, verifying a supplier’s quality control processes is essential to mitigate risks associated with subpar products.

-

What Audits and Reports Can Buyers Request?

Buyers should request documentation of quality audits conducted by the supplier. This could include internal audits and any external certifications achieved. Regular reports detailing quality metrics and improvements can also provide insights into the supplier’s commitment to quality. -

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging a third-party inspection service can provide an unbiased assessment of a supplier’s quality control processes. These services can conduct inspections at various stages of the manufacturing process, offering buyers confidence that products meet agreed-upon standards before shipment. -

What Are the Nuances of Quality Control for International Buyers?

International buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, may encounter varying quality expectations and regulations. It is crucial to communicate specific quality requirements clearly and ensure that suppliers are equipped to meet these standards. Understanding local regulations and how they apply to leather products can also help in selecting the right supplier.

Conclusion: The Importance of Manufacturing and Quality Assurance in Custom Leather Crafting

In summary, the manufacturing processes and quality assurance measures in custom leather crafting are vital to ensuring that products meet the high standards expected by B2B buyers. By understanding the stages of production and the importance of quality control, buyers can make informed decisions when selecting suppliers. Leveraging international standards and conducting thorough audits will further enhance the reliability of their partnerships in the custom leather industry.

Illustrative image related to custom leather crafting

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather crafting’

This guide serves as a practical checklist for B2B buyers looking to procure custom leather crafting services. By following these steps, you can ensure a streamlined sourcing process that meets your specific needs and quality standards.

Step 1: Define Your Project Requirements

Clearly outline the specifications for your custom leather products, including dimensions, materials, and design elements. This initial step is crucial to communicate your vision effectively to suppliers. Consider creating detailed sketches or prototypes to convey your ideas.

- Material Selection: Specify the type of leather (e.g., full-grain, top-grain) and any additional materials required.

- Design Elements: Include any necessary design features, such as embossing, stitching patterns, or color choices.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in custom leather crafting. Look for companies with a solid reputation in the industry and a portfolio that aligns with your project needs.

- Online Reviews and Testimonials: Check platforms like Google, Trustpilot, or industry-specific forums for feedback.

- Social Media Presence: Evaluate their engagement and customer interactions on platforms like Instagram or Facebook, which can reflect their craftsmanship and customer service.

Step 3: Evaluate Supplier Capabilities

Assess the capabilities of shortlisted suppliers to ensure they can meet your project requirements. This includes evaluating their production capacity, lead times, and flexibility to accommodate custom requests.

Illustrative image related to custom leather crafting

- Sample Requests: Ask for samples of previous work to gauge the quality and craftsmanship.

- Customization Options: Inquire about their ability to customize products beyond standard offerings.

Step 4: Verify Certifications and Compliance

Ensure that potential suppliers adhere to industry standards and certifications. This is especially important for buyers in regions with specific regulations regarding materials and production practices.

- Sustainability Practices: Look for certifications related to sustainable sourcing and ethical production, which are increasingly important in global markets.

- Quality Assurance: Confirm that suppliers follow quality control measures to maintain high standards in their products.

Step 5: Request Quotes and Compare Pricing

Once you have narrowed down your options, request detailed quotes from each supplier. Ensure that these quotes include all costs associated with the project, such as materials, labor, and shipping.

- Transparent Pricing: Look for suppliers who provide a breakdown of costs to avoid hidden fees.

- Negotiation Opportunities: Be prepared to negotiate terms and pricing to align with your budget.

Step 6: Establish Clear Communication Channels

Effective communication is key to a successful partnership. Establish clear channels for discussing project details, timelines, and any potential issues that may arise.

- Regular Updates: Set expectations for regular progress updates to stay informed about the project’s status.

- Point of Contact: Designate a primary contact person on both sides to streamline communication.

Step 7: Finalize Contracts and Terms

Before starting production, ensure that all terms are clearly documented in a contract. This should include delivery timelines, payment terms, and any warranties or guarantees.

Illustrative image related to custom leather crafting

- Legal Review: Consider having a legal professional review the contract to protect your interests.

- Exit Clauses: Include terms for cancellation or changes to the order, should circumstances require it.

By following this checklist, B2B buyers can navigate the complexities of sourcing custom leather crafting services more effectively, leading to successful partnerships and high-quality products.

Comprehensive Cost and Pricing Analysis for custom leather crafting Sourcing

What Are the Key Cost Components in Custom Leather Crafting?

When engaging in custom leather crafting, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of leather significantly impacts the overall cost. High-quality hides, such as full-grain or top-grain leather, come at a premium. Additionally, sourcing exotic materials like ostrich or snake leather will further increase costs. Leather treatments and finishes also add to the material expense.

-

Labor: Handcrafting leather products requires skilled artisans. Labor costs can vary greatly depending on the region, with labor-intensive processes like tooling or custom stitching demanding higher wages. In regions with a lower cost of living, labor may be more affordable, but this could also affect the craftsmanship quality.

-

Manufacturing Overhead: This includes costs related to the facility, utilities, and equipment maintenance. Custom leather crafting often requires specialized tools and machinery, which can drive up overhead costs.

-

Tooling: Custom molds, dies, and stitching machines are essential for unique designs. The initial investment in these tools can be substantial, but they can lead to economies of scale in larger orders.

-

Quality Control (QC): Ensuring that each product meets quality standards is vital. This may involve additional labor for inspections and testing, which can add to the overall cost.

-

Logistics: Shipping costs can be significant, especially for international orders. Factors such as the size and weight of leather goods, as well as shipping methods (air vs. sea), will influence logistics costs.

-

Margin: Suppliers typically mark up their prices to cover costs and ensure profitability. Understanding the expected margins in the custom leather market can help buyers gauge price fairness.

How Do Price Influencers Impact Custom Leather Crafting Costs?

Several factors influence pricing in the custom leather crafting sector:

-

Volume/MOQ: Minimum Order Quantities (MOQs) play a significant role in pricing. Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their needs while ensuring they receive favorable pricing.

-

Specifications and Customization: The more complex and customized the leather product, the higher the price. Custom designs, special stitching, or unique finishes can increase both material and labor costs.

-

Material Quality and Certifications: Products made from certified sustainable leather or with eco-friendly processes can command higher prices. Buyers should consider the value of certifications when evaluating costs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Well-established suppliers may charge more due to their experience and the quality assurance they provide.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions. These terms dictate who bears responsibility for shipping costs, insurance, and tariffs, which can significantly affect the total cost.

What Are the Best Buyer Tips for Cost-Efficiency in Custom Leather Crafting?

To maximize value in custom leather sourcing, consider the following strategies:

-

Negotiate Terms: Don’t hesitate to negotiate prices, especially on larger orders. Suppliers may be willing to offer discounts for bulk purchases or long-term contracts.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider ongoing costs such as maintenance and durability. Investing in higher-quality leather may lead to lower TCO over time due to reduced replacement needs.

-

Understand Pricing Nuances for International Orders: International buyers should be aware of additional costs such as customs duties, taxes, and potential shipping delays. Factor these into your budget to avoid surprises.

-

Seek Local Suppliers: For buyers in Africa, South America, the Middle East, and Europe, sourcing from local suppliers may reduce shipping costs and lead times, while also supporting regional economies.

Conclusion

Navigating the cost landscape of custom leather crafting requires a deep understanding of the various components influencing pricing. By considering these factors and employing strategic negotiation techniques, B2B buyers can enhance their sourcing decisions and ensure they receive quality products at competitive prices. Always remember that prices may vary significantly, and it’s essential to engage in thorough discussions with suppliers to clarify costs.

Alternatives Analysis: Comparing custom leather crafting With Other Solutions

When exploring solutions for leather goods, it’s essential to consider various approaches that can meet specific business needs. Custom leather crafting stands out for its unique designs and adaptability, but alternatives exist that may also fulfill requirements based on performance, cost, and other factors. This analysis compares custom leather crafting with two viable alternatives: mass-produced leather goods and synthetic leather manufacturing.

| Comparison Aspect | Custom Leather Crafting | Mass-Produced Leather Goods | Synthetic Leather Manufacturing |

|---|---|---|---|

| Performance | High durability, unique craftsmanship | Standard quality, often less durable | Varies widely based on quality |

| Cost | Higher initial investment, long-term value | Lower upfront costs, potential hidden costs | Generally lower costs, but quality can vary |

| Ease of Implementation | Requires skilled artisans and time | Quick to source, simple logistics | Streamlined production, easy to source |

| Maintenance | Requires care to maintain appearance | Varies, often less care needed | Easy to clean, durable against wear |

| Best Use Case | High-end products, bespoke projects | High-volume retail, budget-conscious consumers | Eco-friendly products, fashion-forward designs |

What Are the Advantages and Disadvantages of Mass-Produced Leather Goods?

Mass-produced leather goods are designed for quick availability and affordability. These products typically utilize standardized designs and materials, making them readily accessible for businesses that need large quantities. However, the trade-off often comes in the form of reduced durability and uniqueness, which may not meet the expectations of customers seeking quality craftsmanship. For businesses focused on cost-cutting and fast turnover, mass-produced options can be an attractive solution.

Illustrative image related to custom leather crafting

How Does Synthetic Leather Manufacturing Compare to Custom Leather Crafting?

Synthetic leather manufacturing offers a modern alternative that emphasizes cost-effectiveness and versatility. These materials can mimic the look and feel of genuine leather while often being easier to maintain. Synthetic options are also increasingly eco-friendly, appealing to businesses focused on sustainability. However, the performance can be inconsistent, and high-quality synthetic leather may still lack the distinctive character and longevity that custom leather crafting provides. For brands targeting a younger, fashion-conscious demographic, synthetic leather can be a viable choice.

How Can B2B Buyers Choose the Right Leather Solution?

Selecting the right leather solution hinges on understanding the specific needs of your business and clientele. Buyers should assess the intended use of the products, budget constraints, and desired quality levels. Custom leather crafting is ideal for those looking for bespoke, high-quality items that stand out in the market. In contrast, mass-produced goods may suit businesses aiming for volume sales at competitive prices. Synthetic leather serves well for eco-conscious brands or those targeting a fashion-forward audience. By carefully weighing these factors, B2B buyers can make informed decisions that align with their strategic goals and customer expectations.

Essential Technical Properties and Trade Terminology for custom leather crafting

What Are the Key Technical Properties of Custom Leather Crafting?

When sourcing custom leather products, understanding the essential technical properties can significantly impact the quality and suitability of the final product for your business needs. Here are several critical specifications to consider:

Material Grade

Material grade refers to the quality and type of leather used in crafting. Common grades include full-grain, top-grain, genuine leather, and bonded leather. Full-grain leather, for instance, is the highest quality, retaining the natural grain and durability, making it ideal for high-end products. B2B buyers must assess the material grade to ensure that the leather meets the expected performance and aesthetic standards.

Illustrative image related to custom leather crafting

Thickness

Thickness is a crucial specification, typically measured in ounces or millimeters. Thicker leather (e.g., 8-10 oz) is generally more durable and suited for items like bags or motorcycle gear, while thinner leather (e.g., 2-4 oz) is often used for wallets and lighter accessories. Understanding the appropriate thickness for your products ensures they can withstand wear and maintain structural integrity.

Tolerance

Tolerance defines the acceptable range of variation in measurements during the leather crafting process. Tight tolerances are essential for components that require precise fitting, such as custom motorcycle saddlebags. A lack of adherence to specified tolerances can result in products that do not fit or function as intended, leading to increased costs and customer dissatisfaction.

Finish Type

The finish of leather can affect its appearance, texture, and durability. Common finishes include aniline, semi-aniline, and pigmented. Aniline leather retains a natural look and feel but may be less resistant to stains, while pigmented leather is more durable and easier to clean. Selecting the right finish based on the intended use and target market can enhance product appeal and longevity.

Stitching Techniques

Stitching not only adds to the aesthetic but also affects the durability of leather products. Techniques such as saddle stitching and machine stitching have distinct advantages. Saddle stitching is often preferred for its strength and ability to withstand stress, while machine stitching can provide uniformity and faster production times. Understanding these techniques helps buyers make informed decisions based on product application.

Illustrative image related to custom leather crafting

What Are Common Trade Terms Used in Custom Leather Crafting?

Navigating the custom leather crafting industry also involves familiarity with specific trade jargon that can impact negotiations and operations. Here are several key terms:

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products that are branded by another company. In the leather industry, an OEM might create custom leather goods according to a buyer’s specifications, which can be crucial for businesses looking to develop unique product lines without investing in manufacturing infrastructure.

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers, as it can affect budgeting and inventory management. Suppliers often set MOQs to ensure production efficiency, so negotiating this term can be critical for startups or smaller businesses.

Illustrative image related to custom leather crafting

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products or services. This document helps ensure clarity and allows for comparison between different suppliers. For custom leather crafting, an RFQ should detail specifications, material preferences, and desired quantities to facilitate accurate quotes.

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. These terms clarify who is responsible for shipping, insurance, and tariffs, which is particularly important for B2B transactions involving custom leather goods across different countries, including those in Africa, South America, the Middle East, and Europe.

Lead Time

Lead time refers to the time taken from placing an order to delivery. In custom leather crafting, lead times can vary significantly based on product complexity and supplier capacity. Understanding lead times is crucial for B2B buyers to effectively manage inventory and meet customer demands.

By grasping these technical properties and trade terms, B2B buyers can enhance their purchasing strategies, ensuring they select the right products and suppliers for their custom leather crafting needs.

Illustrative image related to custom leather crafting

Navigating Market Dynamics and Sourcing Trends in the custom leather crafting Sector

What Are the Current Market Dynamics and Key Trends in Custom Leather Crafting?

The custom leather crafting sector is experiencing notable growth, driven by increasing demand for personalized and high-quality products across various industries, including fashion, automotive, and home décor. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are particularly keen on unique offerings that cater to local tastes and preferences. The rise of e-commerce platforms has also facilitated easier access to suppliers, enabling buyers to explore a wider range of custom products and negotiate better terms.

Emerging technologies such as 3D printing and digital design software are transforming the production processes in custom leather crafting, allowing for more intricate designs and faster turnaround times. Additionally, the integration of Artificial Intelligence (AI) in supply chain management helps businesses forecast demand more accurately, reducing excess inventory and enhancing operational efficiency. As a result, companies that leverage these technological advancements are better positioned to meet the evolving needs of B2B buyers.

Another key trend is the growing emphasis on niche markets. Custom leather products tailored for specific sectors—such as motorcycle accessories, luxury handbags, and cosplay gear—are gaining traction. This trend not only attracts dedicated customer bases but also encourages artisans to innovate and diversify their offerings, thus enhancing their competitive edge.

How Does Sustainability and Ethical Sourcing Impact B2B Relationships in Custom Leather Crafting?

Sustainability and ethical sourcing have become critical considerations for B2B buyers in the custom leather crafting sector. The environmental impact of leather production is significant, with concerns ranging from deforestation to water pollution. Buyers are increasingly seeking suppliers who adhere to sustainable practices, such as sourcing leather from tanneries that utilize eco-friendly processes and materials.

The importance of ethical supply chains cannot be overstated. Suppliers who prioritize humane treatment of livestock and fair labor practices enhance their appeal to conscientious buyers. Certifications such as the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) provide assurance regarding the sustainability and ethicality of products, making them attractive options for B2B partnerships.

Illustrative image related to custom leather crafting

Furthermore, the demand for alternative materials, such as vegan leather and plant-based options, is on the rise. This shift not only aligns with consumer preferences for sustainability but also opens new avenues for innovation in product development. B2B buyers are encouraged to engage with suppliers who are at the forefront of these trends, ensuring that their sourcing strategies align with global sustainability goals.

What Is the Historical Context of Custom Leather Crafting Relevant to B2B Buyers?

The history of custom leather crafting dates back thousands of years, with ancient civilizations using leather for clothing, armor, and tools. Over time, the craft evolved, incorporating artistic techniques and specialized tools that enhanced the quality and variety of leather goods. In the 20th century, the rise of mass production posed challenges for artisans, but a resurgence of interest in handmade and bespoke products has revitalized the sector.

Today, the custom leather crafting market is characterized by a blend of traditional craftsmanship and modern technology. B2B buyers are increasingly drawn to suppliers who honor this legacy while embracing innovation, allowing them to offer unique, high-quality products that stand out in a competitive marketplace. Understanding this historical context can help buyers appreciate the value of craftsmanship and the stories behind the products they source, fostering deeper connections with their suppliers.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather crafting

-

How can I ensure the quality of custom leather products before placing a large order?

To ensure quality, request samples of the leather products you intend to order. Many suppliers offer prototype services, allowing you to assess materials, craftsmanship, and overall design. Additionally, verify the supplier’s reputation through reviews, certifications, and past client testimonials. Consider visiting their production facility if feasible, as this will give you insight into their manufacturing processes and quality control measures. Establishing a clear communication line for discussing specifications and expectations is also crucial. -

What should I consider when selecting a supplier for custom leather crafting?

When selecting a supplier, evaluate their experience in the industry, product range, and customization capabilities. Look for suppliers who specialize in the type of leather products you need, whether it’s fashion, automotive, or industrial applications. Assess their production capacity to ensure they can meet your volume requirements, and inquire about lead times. Additionally, consider their customer service responsiveness, flexibility in design changes, and willingness to provide references from previous clients. -

What are typical minimum order quantities (MOQs) for custom leather items?

Minimum order quantities (MOQs) vary by supplier and product type. Generally, MOQs can range from 50 to 100 units for standard items, while highly customized products may have higher MOQs due to the complexity of the manufacturing process. When negotiating with suppliers, discuss your specific needs and see if they can accommodate smaller orders, especially for initial trials. Building a long-term relationship may also provide leverage to negotiate lower MOQs in future orders. -

What customization options are usually available for custom leather products?

Customization options can include various factors such as leather type, color, texture, size, and design elements like stitching patterns, embossing, or laser engraving. Some suppliers may offer unique features like personalized logos or specific hardware choices. When discussing customization, provide detailed specifications and examples of desired features to ensure the supplier can meet your expectations. It’s beneficial to have a clear vision of your product requirements and explore the supplier’s portfolio for inspiration. -

What payment terms should I expect when working with international suppliers?

Payment terms can vary significantly among suppliers. Common arrangements include upfront deposits (typically 30-50%) with the balance due upon completion or shipment of the order. Some suppliers may accept letters of credit or other forms of secured payment to mitigate risk. When engaging with a new supplier, clarify payment terms early in negotiations and consider using escrow services for larger transactions to protect your investment. Always ensure you are aware of any additional fees associated with international transactions, including currency conversion and bank charges. -

How do I handle logistics and shipping when sourcing custom leather goods internationally?

Logistics can be complex when sourcing internationally. Start by discussing shipping options with your supplier, including air and sea freight, to determine the most cost-effective and timely method. Understand the customs regulations in both the exporting and importing countries to avoid delays. It’s advisable to work with a freight forwarder who can assist with documentation, tariffs, and compliance. Additionally, factor in shipping costs and delivery timelines into your overall budget and planning. -

What quality assurance (QA) measures should I require from my custom leather supplier?

Request that your supplier provides a detailed quality assurance plan that outlines their inspection processes throughout production. This should include checks on material quality, craftsmanship, and adherence to design specifications. Ask for documentation of their QA procedures, including any certifications they hold. You may also want to negotiate periodic updates or inspections during production to ensure that the final products meet your standards before shipment. -

What are the common challenges faced in international trade of custom leather products?

Challenges in international trade can include language barriers, differing regulations, and variations in quality standards. Additionally, logistical issues such as shipping delays, customs clearance, and unexpected tariffs can arise. To mitigate these risks, establish clear communication with your supplier and consider engaging a local agent who understands the nuances of the market. It’s also beneficial to conduct thorough research on the legal requirements for importing leather goods into your country to avoid compliance issues.

Top 7 Custom Leather Crafting Manufacturers & Suppliers List

1. CLC – Tool Carriers and Gear

Domain: goclc.com

Registered: 2007 (18 years)

Introduction: New Products, Tool Carriers, CLC Tech Gear™, Molded Base Bags, Nail and Tool Bags, Softside Tool Carriers, Tool Pouches, Work Gear, Aprons and Combos, Belts and Suspenders, Canvas, CLC Signature, CLC Signature Elite, Climate Gear®, Hi-Viz® Gear, Strap-It™ Tie-Downs, Tool Holders, Tool Lanyards, Knee Protection, Work Gloves, Automotive Gloves, Chemical/Disposables Gloves, Flexgrip 363 Gloves, High …

2. Forged Glory – Custom Leather Heat Shields

Domain: forgedglory.com

Registered: 2019 (6 years)

Introduction: Forged Glory Custom Leather Craft LLC offers a variety of handmade leather products tailored for motorcycles. Key products include:

1. **Heat Shields** – Custom Art, double pouch, compatible with Indian Chief, Chieftain, Springfield, Vintage, and Roadmaster models. Available in regular and 2-tone leather options, priced at $300.00. A variant with metal studs and suede backing is available for $39…

3. Reddit – Custom Leather Pen Case

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Custom leather work for a pen case with specific dimensions: 3″L x 2″W x 0.75″H. The project requires reducing the size of an existing design with a fold-down closure that tucks under a band. The user is seeking a leathercraftsman willing to consider this custom project.

4. Weaver Leather Supply – Leathercrafting Supplies

Domain: weaverleathersupply.com

Registered: 2013 (12 years)

Introduction: Weaver Leather Supply offers a wide range of leathercrafting and leatherworking supplies, including various types of leather (ChahinLeather®, Hermann Oak® Veg Tan, Chrome Tanned, Water Buffalo Leather), leather cuts (double shoulders, single shoulders, panels, whole hides), textures (top grain, pebbled, smooth), and leathercraft tools (cutting tools, hand stitching tools, tooling tools). They also…

5. Cargill Custom Leather – Custom Saddles & Accessories

Domain: jcargillleather.com

Registered: 2019 (6 years)

Introduction: Cargill Custom Leather offers a variety of products including custom saddles, leggings, belts, and leather repair services. Their product range includes accessories such as belt buckles, hats, authentic and fashion jewelry, BEX® sunglasses, and men’s and women’s apparel. They also provide a selection of boots and shoes, specifically Fenoglio boots and ropers. The knives and sheaths category featur…

6. Leathersmith Designs – Custom Leather Products

Domain: leathersmithdesigns.com

Registered: 2000 (25 years)

Introduction: Custom Leather Products & Leather Craft Supplies, including:

– Belt Pouches (Personalized, Money Belts, Design Belts, Plain Belts, Studded Belts)

– Cellular Cases (Rugged, Soft Leather Smartphone iPhone Cases)

– Change Purses & Wallets

– Dog Collars (Personalized, Plain, Studded)

– Dog Leashes (Personalized, Plain, Braided, Specialty, Studded)

– Guitar Straps (Classic Series, Inlay Series, W…

7. Tandy Leather – Utility Leather Sale

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: SHOP SELECT UTILITY LEATHER UP TO 50% OFF!

Strategic Sourcing Conclusion and Outlook for custom leather crafting

In the evolving landscape of custom leather crafting, strategic sourcing is paramount for international B2B buyers looking to capitalize on the unique offerings of this industry. By leveraging partnerships with skilled artisans and manufacturers, businesses can ensure high-quality, customizable products that meet specific market demands. Engaging with suppliers who prioritize craftsmanship and innovation can provide a competitive edge, particularly as trends shift towards personalized and sustainable leather goods.

Illustrative image related to custom leather crafting

For buyers in regions such as Africa, South America, the Middle East, and Europe, the potential for growth is substantial. Custom leather products—from motorcycle accessories to bespoke fashion items—are increasingly sought after, allowing companies to cater to diverse consumer preferences. As you explore your sourcing options, consider the importance of communication and collaboration with suppliers to develop tailored solutions that resonate with your target market.

Looking ahead, the custom leather crafting sector is poised for growth, driven by consumer demand for unique, high-quality items. Take proactive steps now to establish partnerships that will not only meet current needs but also adapt to future trends. Embrace the opportunity to differentiate your offerings and drive your business forward in this dynamic marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.