Introduction: Navigating the Global Market for custom leather motorcycle seats

In the dynamic world of motorcycle customization, sourcing high-quality custom leather motorcycle seats presents a unique challenge for international B2B buyers. With an increasing demand for personalized designs that enhance both comfort and aesthetics, stakeholders must navigate a complex landscape of suppliers, materials, and pricing structures. This guide aims to demystify the global market for custom leather motorcycle seats by providing actionable insights into various types, applications, and the nuances of supplier vetting.

We will explore the intricacies of materials, from durable vinyl to luxurious exotic hides, and discuss the implications of craftsmanship on product longevity and rider satisfaction. Additionally, buyers will gain a comprehensive understanding of cost considerations, ensuring that they can make informed decisions that align with their budget and quality expectations.

Designed specifically for B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including markets like Nigeria and Germany—this guide empowers organizations to confidently approach the procurement process. By equipping you with the knowledge to assess supplier capabilities and product specifications, we aim to facilitate successful partnerships and enhance your offerings in the custom motorcycle seat sector. Prepare to transform your purchasing strategy as we delve into the essential factors that define excellence in this niche market.

Table Of Contents

- Top 8 Custom Leather Motorcycle Seats Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather motorcycle seats

- Understanding custom leather motorcycle seats Types and Variations

- Key Industrial Applications of custom leather motorcycle seats

- 3 Common User Pain Points for ‘custom leather motorcycle seats’ & Their Solutions

- Strategic Material Selection Guide for custom leather motorcycle seats

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather motorcycle seats

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather motorcycle seats’

- Comprehensive Cost and Pricing Analysis for custom leather motorcycle seats Sourcing

- Alternatives Analysis: Comparing custom leather motorcycle seats With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather motorcycle seats

- Navigating Market Dynamics and Sourcing Trends in the custom leather motorcycle seats Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather motorcycle seats

- Strategic Sourcing Conclusion and Outlook for custom leather motorcycle seats

- Important Disclaimer & Terms of Use

Understanding custom leather motorcycle seats Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Solo Seats | Designed for one rider, often with a sleek profile | Custom builds, chopper and cafe racer markets | Pros: Lightweight, customizable design. Cons: Limited passenger comfort. |

| Two-Up Seats | Accommodates both rider and passenger, wider seating | Touring motorcycles, family-oriented models | Pros: Enhanced comfort for two riders. Cons: Bulkier, can be heavier. |

| Custom Touring Seats | Extra padding and ergonomic design for long rides | Long-distance touring, motorcycle rentals | Pros: Superior comfort, often includes back support. Cons: Higher cost due to materials. |

| Hand Tooled Leather Seats | Unique artistic designs and textures, handcrafted | High-end custom builds, luxury motorcycle markets | Pros: Distinctive appearance, premium craftsmanship. Cons: Longer lead times for production. |

| Matching Saddlebag Sets | Complements seats with matching leather saddlebags | Full custom setups for brands like Harley and Indian | Pros: Cohesive aesthetic, functional storage. Cons: Requires additional investment. |

What are the Characteristics of Solo Seats in Custom Leather Motorcycle Seats?

Solo seats are designed specifically for one rider, featuring a streamlined profile that enhances the aesthetic appeal of custom motorcycles, particularly choppers and cafe racers. They are lightweight and can be customized in various leather types and colors, making them a popular choice for businesses focused on unique builds. When purchasing, B2B buyers should consider the target market’s style preferences and the overall balance of the motorcycle’s design.

How Do Two-Up Seats Differ from Other Custom Leather Motorcycle Seats?

Two-up seats accommodate both the rider and a passenger, offering a wider seating area and additional padding for comfort. These seats are particularly suited for touring motorcycles and models designed for family use. B2B buyers should evaluate the need for comfort in their customer base, as well as the potential trade-off of added weight and bulkiness compared to solo seats.

What Makes Custom Touring Seats Ideal for Long-Distance Rides?

Custom touring seats are engineered for long-distance comfort, featuring enhanced padding and ergonomic shapes that support the rider’s back. These seats are essential for businesses catering to long-distance riders or motorcycle rental services. When sourcing these seats, consider factors such as durability, ease of installation, and the potential for customization to meet specific rider needs.

Illustrative image related to custom leather motorcycle seats

Why Choose Hand Tooled Leather Seats for a Unique Offering?

Hand tooled leather seats stand out due to their unique designs and textures, crafted by skilled artisans. These seats appeal to high-end markets and customers seeking a distinctive aesthetic for their motorcycles. B2B buyers should be prepared for longer lead times and potentially higher costs, but the investment often pays off through increased customer satisfaction and brand loyalty.

How Do Matching Saddlebag Sets Enhance Custom Leather Motorcycle Seats?

Matching saddlebag sets offer a cohesive look when paired with custom leather seats, enhancing both the functionality and aesthetic of motorcycles. They are particularly popular among brands like Harley Davidson and Indian, as they cater to consumers looking for a complete custom setup. Buyers should assess the additional investment required for these sets but can benefit from upselling opportunities in full-package deals.

Key Industrial Applications of custom leather motorcycle seats

| Industry/Sector | Specific Application of custom leather motorcycle seats | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Motorcycle Manufacturing | Custom seating solutions for production lines | Enhances product differentiation and customer satisfaction | Quality of materials, design compatibility, lead times |

| Motorcycle Customization Shops | Personalized seat designs for diverse motorcycle models | Increases customer loyalty and repeat business | Customization options, craftsmanship, pricing |

| Tourism and Rental Services | High-quality seats for rental motorcycles | Improves rider comfort and experience | Durability, maintenance requirements, warranty terms |

| Motorsports and Racing Teams | Specialized seats for performance motorcycles | Enhances rider ergonomics and safety | Compliance with safety regulations, weight considerations |

| Luxury Vehicle Accessories | Premium leather seats for high-end motorcycle models | Elevates brand image and attracts affluent customers | Aesthetic appeal, branding options, exclusivity |

How Are Custom Leather Motorcycle Seats Used in the Motorcycle Manufacturing Industry?

In the motorcycle manufacturing sector, custom leather motorcycle seats are integral to product differentiation. Manufacturers can offer bespoke seating solutions that cater to various styles and rider preferences, from touring bikes to choppers. This customization not only enhances the aesthetic appeal but also elevates rider comfort, which is crucial for customer satisfaction. Buyers in this sector need to consider the quality of materials and design compatibility with existing motorcycle models, ensuring that the seats can withstand rigorous use.

Illustrative image related to custom leather motorcycle seats

What Role Do Custom Leather Motorcycle Seats Play in Customization Shops?

Customization shops leverage custom leather motorcycle seats to create unique offerings tailored to individual customer preferences. By providing options for personalized designs, these shops can enhance customer loyalty and drive repeat business. The ability to match seats with specific motorcycle models or even create one-of-a-kind designs is a significant selling point. Buyers should focus on the availability of customization options, craftsmanship quality, and competitive pricing to ensure they meet customer expectations effectively.

How Do Custom Leather Motorcycle Seats Enhance Tourism and Rental Services?

In the tourism and rental services industry, high-quality custom leather motorcycle seats play a vital role in enhancing the rider experience. Comfort is paramount for tourists who may spend extended periods on the road, and well-designed seats can significantly improve their overall satisfaction. This, in turn, leads to positive reviews and repeat customers. Rental companies should prioritize durability and ease of maintenance when sourcing these seats, as well as warranty terms to mitigate risks associated with wear and tear.

Why Are Custom Leather Motorcycle Seats Important for Motorsports and Racing Teams?

Motorsports and racing teams utilize custom leather motorcycle seats to improve rider ergonomics and safety. These specialized seats are designed to provide optimal support during high-speed maneuvers, which is essential for performance and safety. Compliance with safety regulations is a critical consideration for buyers in this sector, alongside weight considerations to enhance speed and agility on the track. The right seat can make a significant difference in a rider’s performance and overall experience in competitive environments.

How Do Custom Leather Motorcycle Seats Appeal to Luxury Vehicle Accessory Markets?

Luxury vehicle accessory markets benefit from offering premium leather seats for high-end motorcycle models. These seats not only elevate the motorcycle’s aesthetic appeal but also enhance the brand image, attracting affluent customers seeking exclusivity. Buyers in this market should focus on the aesthetic appeal, branding options, and overall exclusivity of the leather used, ensuring that the seats align with the luxury experience they aim to provide.

3 Common User Pain Points for ‘custom leather motorcycle seats’ & Their Solutions

Scenario 1: Inconsistent Quality and Craftsmanship in Custom Leather Seats

The Problem: B2B buyers often face significant challenges when sourcing custom leather motorcycle seats due to inconsistent quality and craftsmanship. Many suppliers may offer attractive pricing but fail to deliver on durability and aesthetic appeal. This inconsistency can lead to dissatisfaction among end customers, resulting in potential loss of business and reputational damage. Buyers from regions like Africa or South America may also find it difficult to assess quality remotely, increasing the risk of receiving subpar products.

The Solution: To mitigate these risks, B2B buyers should prioritize suppliers with a proven track record of quality craftsmanship. This can be achieved by requesting samples of previous work or visiting manufacturing facilities if feasible. Buyers should also seek suppliers who provide detailed information about their materials, production processes, and quality assurance measures. Engaging in direct communication to understand the supplier’s capabilities and obtaining references from previous clients can further ensure reliability. Additionally, implementing a rigorous inspection process upon receiving products can help maintain quality standards before products reach the market.

Scenario 2: Difficulty in Customization and Design Alignment

The Problem: One of the prevalent pain points for buyers is the struggle to achieve the desired level of customization and design alignment with their brand identity. Many motorcycle enthusiasts seek unique designs that reflect their style or business branding, but not all suppliers offer flexible options for customization. This limitation can result in unsatisfactory products that do not resonate with the target audience, ultimately affecting sales and brand perception.

The Solution: Buyers should partner with manufacturers who specialize in bespoke services, allowing for extensive customization options. When sourcing custom leather motorcycle seats, it’s crucial to communicate specific design requirements, including color schemes, stitching patterns, and material preferences. Buyers can leverage digital tools or mock-ups to visualize the final product, ensuring alignment with their vision. Additionally, establishing a collaborative relationship with the manufacturer can facilitate iterative design processes, allowing for adjustments based on feedback. This proactive approach not only enhances satisfaction but also strengthens the partnership with the supplier.

Scenario 3: Long Lead Times and Delayed Deliveries

The Problem: Timeliness is critical in the motorcycle industry, and many B2B buyers struggle with long lead times and delivery delays when ordering custom leather motorcycle seats. Delays can disrupt inventory management and sales plans, leading to missed market opportunities, especially in fast-paced markets in Europe and the Middle East. This issue is often exacerbated by global supply chain challenges, making it essential for buyers to find reliable partners who can meet their timelines.

The Solution: To address this issue, buyers should engage with suppliers that offer transparent lead time estimates and a clear production schedule. It’s beneficial to inquire about the manufacturer’s supply chain logistics and any potential bottlenecks that could affect delivery. Establishing a buffer in inventory planning can also help mitigate the impact of unexpected delays. Additionally, buyers may consider forming partnerships with multiple suppliers to diversify sourcing options and reduce dependency on a single source. This strategy not only ensures a steady supply of products but also fosters competitive pricing and innovation within the custom leather motorcycle seat market.

Strategic Material Selection Guide for custom leather motorcycle seats

When selecting materials for custom leather motorcycle seats, it is essential to consider various factors that influence performance, durability, and cost. Below, we analyze four common materials—full-grain leather, top-grain leather, synthetic leather (PU), and vinyl—highlighting their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What Are the Key Properties of Full-Grain Leather for Motorcycle Seats?

Full-grain leather is the highest quality leather available, made from the top layer of the hide, retaining the natural grain. This material is known for its exceptional durability and breathability, making it suitable for various weather conditions. Full-grain leather can withstand high temperatures and pressures, ensuring that it maintains its shape and comfort over time.

Illustrative image related to custom leather motorcycle seats

Pros and Cons:

The primary advantage of full-grain leather is its longevity and ability to develop a unique patina over time, enhancing its aesthetic appeal. However, it comes at a higher cost and requires more complex manufacturing processes, which may not be suitable for all buyers. Additionally, it requires regular maintenance to preserve its appearance.

Impact on Application:

Full-grain leather is compatible with various motorcycle styles, from cruisers to sport bikes, providing a luxurious feel. However, it may not be the best choice for extreme environments without proper treatment.

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East may prefer this material due to its premium quality. Compliance with EU regulations regarding leather sourcing and treatment is crucial, as is adherence to standards such as DIN.

How Does Top-Grain Leather Compare in Performance and Cost?

Top-grain leather is a step down from full-grain leather, as it has been sanded and treated to remove imperfections. This process makes it more uniform in appearance and easier to maintain while still offering good durability and breathability.

Pros and Cons:

Top-grain leather is generally more affordable than full-grain leather, making it a popular choice for manufacturers. However, it may not develop the same depth of character over time and is less resistant to scratches and wear.

Illustrative image related to custom leather motorcycle seats

Impact on Application:

This material is suitable for a wide range of motorcycles and can be used effectively in custom designs. Its lower cost makes it attractive for bulk orders, especially for B2B buyers looking to optimize their budgets.

Considerations for International Buyers:

Buyers in Africa and South America may find top-grain leather appealing due to its balance of quality and cost. Understanding local regulations regarding leather imports and environmental standards is essential.

What Are the Benefits and Limitations of Synthetic Leather (PU)?

Synthetic leather, particularly polyurethane (PU), is a popular alternative to natural leather. It is designed to mimic the look and feel of leather while offering enhanced water resistance and ease of cleaning.

Pros and Cons:

The key advantage of synthetic leather is its cost-effectiveness and low maintenance requirements. However, it may not offer the same durability or breathability as genuine leather and can wear out more quickly under heavy use.

Impact on Application:

Synthetic leather is suitable for budget-conscious buyers and can be used in various motorcycle seat designs. It is particularly advantageous in humid or wet climates, making it a viable option for buyers in tropical regions.

Considerations for International Buyers:

Buyers from regions like Nigeria may prefer synthetic materials due to their affordability and ease of maintenance. It’s important to ensure that the synthetic leather meets local quality standards and regulations.

Why Choose Vinyl for Custom Motorcycle Seats?

Vinyl is another synthetic option that is widely used in the motorcycle industry. It is known for its durability, resistance to fading, and ease of cleaning.

Pros and Cons:

Vinyl is an economical choice, making it attractive for large-scale production. However, it lacks the luxurious feel of leather and may not be as breathable, leading to discomfort during long rides.

Impact on Application:

Vinyl is suitable for entry-level motorcycle seats and can be customized in various colors and textures. It is particularly effective for riders who prioritize ease of maintenance over aesthetics.

Considerations for International Buyers:

For buyers in Europe, vinyl must comply with specific safety and quality standards, such as REACH. Understanding local preferences for material quality is essential for successful market penetration.

Summary Table of Material Selection for Custom Leather Motorcycle Seats

| Material | Typical Use Case for custom leather motorcycle seats | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Full-Grain Leather | Premium custom seats for high-end motorcycles | Exceptional durability and aesthetics | High cost and maintenance required | High |

| Top-Grain Leather | Versatile seats for various motorcycle styles | Good balance of quality and cost | Less durable than full-grain | Medium |

| Synthetic Leather (PU) | Budget-friendly options for casual riders | Cost-effective and easy to clean | Less durable and breathable | Low |

| Vinyl | Entry-level seats for mass production | Economical and low maintenance | Lacks luxury feel and comfort | Low |

This strategic material selection guide provides B2B buyers with critical insights into the various materials available for custom leather motorcycle seats, helping them make informed decisions based on their specific needs and market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather motorcycle seats

What Are the Key Stages in the Manufacturing Process of Custom Leather Motorcycle Seats?

The manufacturing process of custom leather motorcycle seats typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is essential for ensuring that the final product meets the high standards expected by B2B buyers.

Material Preparation: How Is Leather Selected and Processed?

The journey begins with material selection. High-quality leather is sourced from reputable suppliers, often featuring various grades and types, including top-grain and full-grain leathers. These options provide durability and aesthetic appeal. Once selected, the leather undergoes conditioning to enhance its pliability and longevity. This might involve treatments to resist water and stains, ensuring the product remains functional and visually appealing over time.

In addition to leather, other materials such as foam for cushioning and backing materials are also prepared. The foam is cut to specific dimensions and densities to provide optimal comfort for riders.

Illustrative image related to custom leather motorcycle seats

What Techniques Are Used in Forming Custom Motorcycle Seats?

Forming is a crucial step where the prepared materials are shaped into the desired seat form. This often involves several techniques, including:

-

Pattern Making: Custom patterns are created to match the specific dimensions of different motorcycle models. These patterns ensure that each seat fits perfectly.

-

Molding: In some cases, the foam may be molded to create contoured shapes that enhance comfort. This is often done using heat to allow the foam to adapt to specific forms.

-

Stitching and Assembly: The leather and foam are stitched together using industrial sewing machines. Various stitch patterns can be employed to enhance both durability and aesthetics. This stage also includes attaching any additional features, such as backrests or decorative elements.

How Is Finishing Done to Ensure Quality and Aesthetics?

Finishing is the final stage in manufacturing, where the seat undergoes several processes to enhance its appearance and durability. This includes:

- Edge Finishing: Edges may be trimmed, painted, or sealed to prevent fraying and to provide a polished look.

- Application of Treatments: Leather finishes, such as dyes or protective coatings, are applied to enhance color and protect against wear.

- Final Inspection: A thorough inspection is performed to check for any defects or inconsistencies in workmanship.

What Quality Assurance Measures Are Essential for Custom Leather Motorcycle Seats?

Quality assurance (QA) is crucial in the production of custom leather motorcycle seats, ensuring that products meet both customer expectations and regulatory standards.

Which International Standards Should B2B Buyers Look For?

B2B buyers should be aware of international standards that govern manufacturing quality, such as:

- ISO 9001: This standard outlines the criteria for a quality management system, emphasizing consistent quality and continuous improvement.

- CE Marking: Particularly relevant in Europe, this indicates compliance with health, safety, and environmental protection standards.

- API Standards: While more common in industrial applications, some manufacturers may align with these standards, particularly if their products are intended for high-performance motorcycles.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) involves several checkpoints throughout the manufacturing process to ensure that products meet the required specifications:

-

Incoming Quality Control (IQC): At this stage, materials are inspected upon arrival. Leather hides are checked for defects, while foam and other materials are assessed for quality.

-

In-Process Quality Control (IPQC): During the manufacturing stages, QC personnel monitor production processes, ensuring that each step adheres to predefined standards. This might include checking stitching patterns, foam density, and overall assembly integrity.

-

Final Quality Control (FQC): Before shipment, finished products undergo a final inspection. This includes checking for visual defects, functionality, and compliance with customer specifications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers adhere to high-quality standards, B2B buyers can employ several strategies:

-

Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes and quality assurance practices firsthand. This can reveal the supplier’s commitment to maintaining standards.

-

Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s QC processes, including any certifications they hold and results from internal audits.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the manufacturer’s quality practices. These services often include detailed reports and recommendations for improvement.

What Nuances Should International Buyers Consider Regarding Quality Control?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider several nuances in quality control:

-

Cultural Differences: Different regions may have varying standards of quality and workmanship. Understanding these differences can help buyers set realistic expectations and build better relationships with suppliers.

-

Regulatory Compliance: Ensure that suppliers are aware of and comply with local regulations regarding materials and manufacturing practices. This is particularly important for markets with strict environmental and safety regulations.

-

Supply Chain Transparency: A transparent supply chain can significantly enhance trust. Buyers should seek suppliers who are willing to share information about their sourcing, production processes, and any third-party certifications.

By focusing on these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing custom leather motorcycle seats, ensuring they partner with reputable manufacturers capable of delivering high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather motorcycle seats’

The following practical sourcing guide is designed to assist B2B buyers in procuring custom leather motorcycle seats. This checklist outlines essential steps that ensure a successful sourcing process, enabling buyers to make informed decisions while minimizing risks.

Step 1: Identify Your Target Market and Use Cases

Understanding the specific needs of your market is crucial. Determine whether you are targeting motorcycle manufacturers, retailers, or individual customizers. Consider what styles (e.g., touring, sport, cruiser) are most popular in your region, as this will inform your design and material choices.

Illustrative image related to custom leather motorcycle seats

- Research local preferences: Different regions may have unique requirements based on climate, culture, and motorcycle types.

- Gather insights from local dealers: Engaging with dealers can provide valuable information about customer preferences and trends.

Step 2: Define Your Technical Specifications

Establish clear technical specifications for the seats you wish to procure. This includes dimensions, materials, weight capacity, and design features.

- Material selection: Decide between various leather types (e.g., full-grain, top-grain) and consider alternatives like vinyl for cost-effectiveness.

- Design features: Specify any customizations, such as stitching patterns, embossing, or added comfort features like memory foam.

Step 3: Research and Evaluate Potential Suppliers

Conduct thorough research on potential suppliers to ensure they meet your quality and service standards.

- Check supplier credentials: Verify certifications, industry experience, and customer reviews.

- Request product samples: Ask for samples to assess the quality of materials and craftsmanship firsthand.

Step 4: Request Quotes and Compare Pricing

Solicit quotes from multiple suppliers to get a clear picture of the market price for the custom leather motorcycle seats.

- Consider total cost: Look beyond the unit price to include shipping, customs duties, and any potential tariffs.

- Negotiate terms: Don’t hesitate to negotiate pricing, especially for bulk orders, and inquire about discounts for long-term partnerships.

Step 5: Assess Manufacturing Capabilities

Understanding the supplier’s manufacturing capabilities is vital to ensure they can meet your order requirements.

- Production capacity: Confirm if the supplier can handle your order volume within your desired timeline.

- Quality control processes: Inquire about their quality assurance practices to ensure consistent product quality.

Step 6: Review Shipping and Logistics Options

Evaluate the logistics involved in importing custom leather motorcycle seats from your chosen supplier.

Illustrative image related to custom leather motorcycle seats

- Shipping methods: Discuss available shipping options and their associated costs and delivery times.

- Customs clearance: Ensure the supplier has experience with international shipping and can provide necessary documentation for smooth customs clearance.

Step 7: Finalize the Contract and Payment Terms

Once you have selected a supplier, finalize the contract, ensuring all terms are clear and agreed upon.

- Payment terms: Define payment schedules, deposit requirements, and acceptable payment methods.

- Warranty and returns policy: Ensure the contract includes warranty details and a clear returns policy in case the product does not meet specifications.

By following this checklist, B2B buyers can streamline the procurement process for custom leather motorcycle seats, ensuring they partner with reputable suppliers who meet their specific needs and quality standards.

Comprehensive Cost and Pricing Analysis for custom leather motorcycle seats Sourcing

What Are the Key Cost Components for Custom Leather Motorcycle Seats?

When sourcing custom leather motorcycle seats, understanding the cost structure is vital for B2B buyers. The primary cost components include:

-

Materials: The choice of leather—be it standard cowhide, exotic leathers, or synthetic alternatives—significantly influences pricing. Premium materials typically increase costs but offer better durability and aesthetics. Suppliers often provide a range of material options, which can affect the final price substantially.

-

Labor: Skilled craftsmanship is essential in producing high-quality custom seats. Labor costs can vary based on the complexity of the design, the level of customization, and the region where the manufacturing takes place. Handcrafted items generally incur higher labor costs compared to mass-produced options.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, rent, and equipment maintenance. A manufacturer’s location can affect these costs, with facilities in areas with higher living costs charging more.

-

Tooling: Custom tooling for unique designs or specific motorcycle models can add to the initial setup costs. This is particularly relevant for specialized shapes or features that require bespoke molds or tools.

-

Quality Control (QC): Ensuring that each seat meets quality standards incurs additional costs. This includes inspection, testing materials, and ensuring compliance with industry certifications, which can be particularly important for international buyers seeking reliable products.

-

Logistics: Shipping costs can vary widely based on destination, weight, and dimensions of the packaged seats. Incoterms play a crucial role in determining who bears these costs, impacting the overall price structure.

-

Margin: Suppliers typically add a margin to cover operational costs and profit. This margin can fluctuate based on competition, market demand, and the perceived value of the product.

How Do Price Influencers Affect Custom Leather Motorcycle Seat Costs?

Several factors influence the final pricing of custom leather motorcycle seats:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases can lead to discounts. Buyers should negotiate for better rates based on their order size.

-

Specifications and Customization: Highly customized seats with intricate designs or special features will generally command higher prices. Understanding the specifications that add value can help buyers make informed decisions.

-

Material Quality and Certifications: Higher quality materials and specific certifications (e.g., eco-friendly, fire-resistant) can increase costs. Buyers should weigh the benefits against the additional costs.

-

Supplier Factors: Reliability, reputation, and the supplier’s manufacturing capabilities can influence pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: Understanding shipping terms is crucial, as they dictate responsibility for shipping costs and risks. This can significantly impact the total cost of ownership.

What Are the Best Practices for Negotiating Prices on Custom Leather Motorcycle Seats?

B2B buyers should adopt strategic approaches when negotiating prices:

-

Research and Benchmarking: Gather data on market prices and competitor offerings to have a solid basis for negotiations.

-

Build Relationships: Establishing a strong relationship with suppliers can lead to better pricing, especially for repeat orders.

-

Consider Total Cost of Ownership: Look beyond the sticker price. Evaluate durability, maintenance costs, and potential resale value when assessing overall value.

-

Be Flexible: Be open to alternative materials or designs that may reduce costs without compromising quality.

-

Understand Regional Pricing Nuances: Buyers from regions such as Africa, South America, the Middle East, and Europe may encounter different pricing structures due to local market conditions, tariffs, and regulations. Tailor negotiations to these factors.

Disclaimer on Indicative Prices

Prices for custom leather motorcycle seats can vary widely based on specifications, supplier, and market conditions. It is advisable for buyers to obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing custom leather motorcycle seats With Other Solutions

Introduction to Alternatives for Custom Leather Motorcycle Seats

When considering motorcycle seat options, B2B buyers have a range of alternatives to custom leather motorcycle seats. Each option varies in terms of performance, cost, and ease of implementation. Understanding these alternatives helps businesses make informed purchasing decisions that align with their specific needs, whether for retailing or integration into motorcycle manufacturing.

Illustrative image related to custom leather motorcycle seats

Comparison Table

| Comparison Aspect | Custom Leather Motorcycle Seats | Alternative 1: Vinyl Seats | Alternative 2: Gel Seats |

|---|---|---|---|

| Performance | High comfort and durability | Moderate comfort, less durable | High comfort, good shock absorption |

| Cost | Higher investment (variable) | Lower cost (generally more affordable) | Mid-range cost (varies by brand) |

| Ease of Implementation | Requires skilled craftsmanship | Easier to install, less skill needed | Moderately easy, may need adjustments |

| Maintenance | Requires periodic conditioning | Low maintenance, easy to clean | Moderate maintenance, check for leaks |

| Best Use Case | Luxury/custom builds | Budget-conscious projects | Touring motorcycles seeking comfort |

Detailed Breakdown of Alternatives

Vinyl Seats: What Are Their Advantages and Disadvantages?

Vinyl motorcycle seats are a popular alternative due to their affordability and ease of maintenance. They offer moderate comfort but may not provide the same level of durability as leather. Vinyl is often easier to clean and resistant to water, making it suitable for everyday riders. However, the lack of breathability can lead to discomfort during long rides, especially in hot climates. For businesses focusing on budget-conscious customers or those new to motorcycling, vinyl seats can be an attractive option.

Gel Seats: Are They Worth the Investment?

Gel motorcycle seats are designed for optimal comfort, particularly during long-distance rides. The gel material provides excellent shock absorption, reducing fatigue for riders. While they typically fall within a mid-range price point, they can be heavier and may require more adjustments for proper fitment. Maintenance is moderate, as users need to check for leaks in the gel material over time. This option is best suited for touring motorcycles or for businesses that prioritize comfort and rider experience.

Conclusion: How to Choose the Right Motorcycle Seat Solution

For B2B buyers, selecting the right motorcycle seat solution requires careful consideration of the specific needs and preferences of their target market. Custom leather seats offer a premium product that stands out in luxury markets, whereas vinyl seats serve as an economical alternative for budget-conscious customers. Gel seats provide exceptional comfort for long rides, appealing to touring enthusiasts. By evaluating the performance, cost, ease of implementation, and maintenance of each option, businesses can make strategic decisions that align with their product offerings and customer expectations.

Essential Technical Properties and Trade Terminology for custom leather motorcycle seats

What Are the Key Technical Properties of Custom Leather Motorcycle Seats?

Custom leather motorcycle seats are crafted with various technical specifications that impact their durability, comfort, and aesthetic appeal. Understanding these properties is crucial for B2B buyers to ensure they select the best products for their clients. Here are some critical specifications to consider:

Illustrative image related to custom leather motorcycle seats

-

Material Grade

The quality of leather used in motorcycle seats can vary significantly. Common grades include full-grain, top-grain, and bonded leather. Full-grain leather is the highest quality, offering superior durability and natural aesthetics. In contrast, bonded leather is less expensive but may not withstand the rigors of motorcycle use. Selecting the right material grade is essential to meet customer expectations for longevity and appearance. -

Comfort Foam Density

The foam used in motorcycle seats affects rider comfort during long rides. Higher density foams provide better support and resist sagging over time. For B2B buyers, understanding foam density options can help ensure that the seats meet comfort standards for various riding styles, from casual cruising to long-distance touring. -

Stitching and Thread Type

The stitching technique and thread type are vital for both aesthetic appeal and structural integrity. Heavy-duty nylon or polyester threads are commonly used for their strength and resistance to wear. A well-stitched seat not only looks professional but also prevents seam failures, which is crucial for maintaining product quality and customer satisfaction. -

Water Resistance

Water-resistant treatments can enhance the durability of leather motorcycle seats, especially for riders in regions with varying weather conditions. Buyers should inquire about the water resistance capabilities of the leather and any additional coatings that can protect against moisture damage. This property is particularly important for ensuring that seats maintain their appearance and functionality over time. -

Customization Options

Customization capabilities, such as embroidery, color options, and design patterns, are significant for B2B buyers aiming to offer unique products to their customers. Understanding the extent of customization available can help businesses differentiate themselves in the market and cater to specific client preferences.

What Are Common Trade Terms in the Custom Leather Motorcycle Seat Industry?

Familiarity with industry-specific terminology is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are sold under another company’s brand name. In the context of motorcycle seats, OEM parts ensure compatibility with specific motorcycle models. Understanding OEM specifications can help buyers ensure that the seats they purchase will fit properly and function as intended. -

MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell in a single order. Knowing the MOQ is vital for B2B buyers as it affects inventory management and cash flow. Buyers should negotiate MOQs that align with their sales forecasts to avoid excess inventory or stockouts. -

RFQ (Request for Quotation)

An RFQ is a document that buyers use to solicit price quotes from suppliers. It typically includes detailed specifications and quantities. Using RFQs can streamline the procurement process, allowing buyers to compare offers and select the best supplier based on quality and cost. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, covering aspects such as shipping, insurance, and risk management. Familiarity with these terms helps B2B buyers understand their obligations and negotiate better shipping agreements, particularly when sourcing products from overseas suppliers. -

Lead Time

Lead time refers to the time it takes from placing an order until the product is delivered. Understanding lead times is essential for inventory planning and meeting customer demand. B2B buyers should always clarify lead times with suppliers to ensure timely delivery and prevent disruptions in their supply chain.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, ensuring they select the right custom leather motorcycle seats that meet their customers’ needs while optimizing their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the custom leather motorcycle seats Sector

What are the Key Trends Shaping the Custom Leather Motorcycle Seats Market?

The custom leather motorcycle seats market is experiencing significant growth driven by a combination of lifestyle changes, technological advancements, and evolving consumer preferences. With the rise of motorcycle tourism and the increasing popularity of bespoke motorcycle modifications, buyers are seeking unique, high-quality leather seats that reflect their personal style. Emerging technologies, such as 3D scanning and printing, are facilitating more precise and customizable designs, allowing manufacturers to meet specific customer needs. Additionally, the accessibility of online platforms has broadened the market, enabling international buyers from regions like Africa, South America, the Middle East, and Europe to connect with suppliers directly.

In terms of market dynamics, the demand for premium leather materials is on the rise, which is influencing sourcing strategies. International buyers are increasingly looking for suppliers who can offer a range of high-quality leather options, including exotic hides and sustainable materials. This trend emphasizes the need for manufacturers to establish robust supply chains that can accommodate diverse sourcing needs while maintaining quality. Furthermore, the growing emphasis on comfort and ergonomics is prompting innovations in seat design, with features like memory foam and adjustable backrests becoming standard.

How is Sustainability Influencing Sourcing in the Custom Leather Motorcycle Seats Industry?

Sustainability has become a crucial consideration for B2B buyers in the custom leather motorcycle seats sector. The environmental impact of leather production, including deforestation and chemical pollution, is prompting buyers to seek suppliers who prioritize ethical sourcing and sustainable practices. This shift is reflected in the growing demand for ‘green’ certifications and materials, such as vegetable-tanned leather and recycled components, which appeal to environmentally conscious consumers.

Moreover, buyers are increasingly interested in transparency within the supply chain, valuing suppliers who can demonstrate ethical practices and responsible sourcing. This trend not only enhances brand reputation but also fosters customer loyalty among environmentally aware consumers. Suppliers who adopt sustainable practices, such as waste reduction in the manufacturing process and the use of renewable energy, are likely to gain a competitive edge in the market. As sustainability continues to shape consumer preferences, B2B buyers must align their sourcing strategies with these values to remain relevant and responsive to market demands.

What is the Historical Context of Custom Leather Motorcycle Seats?

The evolution of custom leather motorcycle seats can be traced back to the early days of motorcycling, where comfort and aesthetics were secondary to functionality. As motorcycle culture grew, particularly in the mid-20th century, enthusiasts began to recognize the importance of personalized modifications, leading to the rise of custom leather seats. Initially, these modifications were made from available materials, but over time, the demand for high-quality leather and craftsmanship surged.

By the late 20th century, custom leather seats became a hallmark of motorcycle personalization, driven by the emergence of motorcycle clubs and a burgeoning aftermarket industry. Today, the market is characterized by a blend of traditional craftsmanship and modern technology, offering B2B buyers a diverse range of options that cater to both performance and style. This historical context underscores the importance of quality and customization in the current market, guiding buyers toward suppliers who can deliver both exceptional products and a unique purchasing experience.

Conclusion

In summary, international B2B buyers in the custom leather motorcycle seats sector must navigate a landscape shaped by evolving consumer preferences, sustainability demands, and historical craftsmanship. By understanding these dynamics and trends, buyers can make informed sourcing decisions that align with market demands while fostering strong supplier relationships.

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather motorcycle seats

-

How do I choose the right supplier for custom leather motorcycle seats?

Choosing the right supplier involves evaluating their experience, reputation, and capabilities. Look for suppliers with a robust portfolio showcasing previous custom work, especially in the specific style of seats you require, such as choppers or baggers. Check customer testimonials and industry reviews to gauge reliability. Additionally, consider suppliers who offer comprehensive services, including design consultations and a variety of material options. Engaging in direct communication can also help assess their responsiveness and willingness to meet your specific needs. -

What customization options are available for leather motorcycle seats?

Customization options can vary significantly by supplier. Common choices include different types of leather (e.g., full-grain, top-grain), stitching patterns, and colors. Some suppliers offer personalized designs through hand tooling or laser engraving. Consider your brand identity and the motorcycle model when selecting custom features. It’s essential to discuss your specific requirements with the supplier to ensure they can accommodate your vision while maintaining comfort and functionality. -

What are the minimum order quantities (MOQ) for custom leather motorcycle seats?

Minimum order quantities can differ by supplier, with some offering flexibility for smaller businesses while others may require bulk orders. Typically, MOQs may range from 5 to 50 units, depending on the complexity of the design and materials used. For international buyers, it’s crucial to confirm MOQs upfront to avoid unexpected costs. Discussing your potential order volume during initial communications can help negotiate favorable terms. -

What payment terms should I expect when ordering custom motorcycle seats?

Payment terms can vary widely among suppliers. Common practices include a deposit upfront (usually 30-50%) with the balance due upon completion or prior to shipping. Some suppliers might offer financing options for larger orders. It’s essential to clarify these terms during negotiations and ensure they align with your cash flow capabilities. Additionally, inquire about accepted payment methods, especially if you are dealing with international transactions. -

How long does the production and shipping process take for custom motorcycle seats?

The production time for custom motorcycle seats generally ranges from 2 to 8 weeks, depending on the complexity of the design and the supplier’s workload. Shipping time will add to this, varying based on your location and the shipping method chosen. Always ask suppliers for estimated lead times and confirm whether they provide tracking information once the order is shipped. Planning ahead and placing orders well in advance can help mitigate delays in your supply chain. -

What quality assurance measures should I look for in a supplier?

Quality assurance is crucial when sourcing custom leather motorcycle seats. Look for suppliers who implement rigorous quality control processes, including material inspections and final product evaluations. Certifications or industry standards can also indicate a commitment to quality. Request information on their return policy and warranty to ensure you have recourse should the products not meet specified standards. Engaging suppliers who are transparent about their QA processes can provide added confidence in your investment. -

How do I handle international shipping and customs for leather motorcycle seats?

When ordering internationally, it’s vital to understand the shipping and customs process. Confirm whether the supplier handles shipping logistics or if you need to arrange it yourself. Be aware of potential customs duties and taxes that may apply upon import, which can vary by country. It’s advisable to work with a shipping partner experienced in handling motorcycle parts to ensure compliance with all regulations. Having clear communication with your supplier about shipping options and timelines can help streamline the process. -

What are the key trends in custom leather motorcycle seat design?

Current trends in custom leather motorcycle seat design include the use of sustainable materials, ergonomic shapes for increased comfort, and integration of technology, such as heated seats. Customization is also becoming more popular, with riders seeking unique designs that reflect their personal style. Additionally, the demand for matching accessories, like saddlebags and tank panels, is on the rise. Staying informed about these trends can help B2B buyers align their product offerings with market preferences and enhance their competitive edge.

Top 8 Custom Leather Motorcycle Seats Manufacturers & Suppliers List

1. Sinister Seats – Custom Motorcycle Seats

Domain: sinisterseats.com

Registered: 2009 (16 years)

Introduction: Sinister Seats offers high quality custom motorcycle seats tailored to various styles including baggers, choppers, cafe racers, and bobbers. They specialize in fabrication and design, including pattern making, fiberglassing, sheet metal work, and leather work. The company can repair, recover, or build custom motorcycle seats from scratch. They provide options for hand tooled leather seats and can …

2. Rich Phillips Cycles – Handcrafted Biker Saddles

Domain: richphillipscycles.com

Registered: 2018 (7 years)

Introduction: Biker Saddles by Rich Phillips Cycles: Handcrafted leather biker saddles, tool rolls, and saddle bags. Custom leather seats made to fit individual style. Featured products include: Honda eu2200i/eu2000i generator mount (no rotopax) – $395.00, Honda eu2200i/eu2000i generator mount with rotopax – $495.00, Honda eu3000is 2″ hitch receiver generator mount – $395.00, Rich Phillips Leather Indian Head P…

3. Leatherworks Inc. – Custom Leather Motorcycle Seats & Saddlebags

Domain: leatherworksinc.com

Registered: 1999 (26 years)

Introduction: Custom Leather Motorcycle Seat and Saddlebag Sets from Leatherworks Inc. American Made with over 100,000 saddlebags made since 1976. Options for full customization available. Matching seats and saddlebags can be made for Corbin™, Le Pera™, and Mustang™ seats. Leather color options include Black, Brown, White, Tan, and more. Additional products include tank panels, fender bibs, mud flaps, and lever…

4. Ends Cuoio – Motorcycle Seats

Domain: endscuoio.com

Registered: 2016 (9 years)

Introduction: Seats for motorcycles crafted from genuine Italian vegetable-tanned leather, designed for brands including Harley Davidson®, Indian Motorcycle®, Triumph®, Moto Guzzi®, BMW®, and Royal Enfield®. Products include multiple variants with prices ranging from US$ 220 to US$ 546. Specific models mentioned are Zuni, Zuni Chaps, Zuni Diamante, Dyna Low Outlet, Little Single Trapuntata, Middle Police, Middl…

5. C&C Motorcycle Seats – Handmade Harley Davidson Pan America Seats

Domain: ccseats.com

Registered: 2005 (20 years)

Introduction: C&C Motorcycle Seats offers high-quality, handmade motorcycle seats for various models including Harley Davidson, Indian, Honda, and Yamaha. Key products include:

– Harley Davidson Pan America Seats (2023-2024+)

– New Bagger Seats (2008-2024+)

– Bagger Solo Seats (2008-2024+)

– Bagger 2-Up Seats (2020-2024)

– Freewheeler & RG3 (2023)

– Highway King Softail Seats

– Softail models including L…

6. Mustang Seats – Custom Motorcycle Seats

Domain: mustangseats.com

Registered: 1996 (29 years)

Introduction: Custom Motorcycle Seats with over 1,500 combinations available. Options include: 19 different vinyl colors and styles, 5 stitch patterns (single diamond, double diamond, tuck ‘n’ roll, etc.), and 16 vibrant thread colors. Customization allows for a personalized touch to match individual style and comfort preferences.

7. Bob Pena – Custom Motorcycle Seats

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Custom motorcycle seats made by Bob Pena, who has over 30 years of experience in the craft. Based in Georgetown, Texas since 1994, Bob is known for his top-quality craftsmanship and has been recognized in magazines like Biker Living and Chromed Out. He is an old school biker who rides a 1960 Panhead and won the Rat Class in Luckenbach Texas in 2010. Business has been slow, and he has a GoFundMe fo…

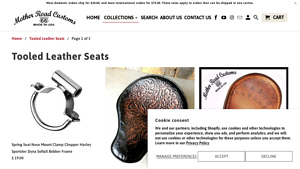

8. Mother Road Customs – Tooled Leather Motorcycle Seats

Domain: motherroadcustoms.com

Registered: 2010 (15 years)

Introduction: Tooled Leather Seats from Mother Road Customs include various styles and sizes suitable for different motorcycle models. Key details include: 1. Shipping Costs: Domestic orders – $20.00; International orders – $75.00. 2. Seat Types: Spring Solo Seats, including options like Antique Black and Copper Oak Leaf Leather, Brown Distressed Hand Tooled Leather, Antique Brown Distressed Indian Engraving, a…

Strategic Sourcing Conclusion and Outlook for custom leather motorcycle seats

How Can Strategic Sourcing Enhance Your Custom Leather Motorcycle Seat Offerings?

In the competitive landscape of custom leather motorcycle seats, strategic sourcing emerges as a vital component for success. By carefully selecting suppliers who specialize in high-quality materials and craftsmanship, businesses can ensure that their offerings not only meet but exceed customer expectations. Engaging with manufacturers that provide customizable options, such as hand-tooled designs and a variety of leather types, allows businesses to cater to diverse market demands across regions like Africa, South America, the Middle East, and Europe.

Furthermore, understanding the regional preferences for motorcycle aesthetics and comfort can help in tailoring products that resonate with local buyers. This localized approach, combined with a focus on quality and unique designs, positions businesses to stand out in a crowded marketplace.

As we look to the future, it is essential for international B2B buyers to embrace innovation in product development and supplier relationships. By leveraging strategic sourcing practices, you can not only enhance your product offerings but also build a reputation for excellence in custom leather motorcycle seats. Connect with reliable suppliers today to secure your competitive edge and meet the evolving needs of motorcycle enthusiasts globally.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to custom leather motorcycle seats

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.