Introduction: Navigating the Global Market for leather manufacturing

In the ever-evolving landscape of leather manufacturing, international B2B buyers face the critical challenge of sourcing high-quality materials that meet both aesthetic and functional demands. As the global leather market continues to grow, projected to reach USD 414.3 billion by 2028, understanding the nuances of leather production—from sourcing raw hides to selecting the right finishing techniques—becomes essential. This comprehensive guide delves into the complexities of the leather manufacturing process, outlining various types of leather, their applications across multiple industries, and the best practices for supplier vetting.

By equipping buyers with insights into cost structures, quality control measures, and sustainable practices, this guide empowers businesses in Africa, South America, the Middle East, and Europe—particularly in regions such as Saudi Arabia and Germany—to make informed purchasing decisions. Whether you’re seeking leather for fashion, automotive, or furniture applications, our expert analysis and actionable recommendations will help you navigate supplier relationships and optimize your procurement strategies. Embrace the opportunities that lie within the leather manufacturing sector and position your business for success in this dynamic global market.

Table Of Contents

- Top 6 Leather Manufacturing Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for leather manufacturing

- Understanding leather manufacturing Types and Variations

- Key Industrial Applications of leather manufacturing

- 3 Common User Pain Points for ‘leather manufacturing’ & Their Solutions

- Strategic Material Selection Guide for leather manufacturing

- In-depth Look: Manufacturing Processes and Quality Assurance for leather manufacturing

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather manufacturing’

- Comprehensive Cost and Pricing Analysis for leather manufacturing Sourcing

- Alternatives Analysis: Comparing leather manufacturing With Other Solutions

- Essential Technical Properties and Trade Terminology for leather manufacturing

- Navigating Market Dynamics and Sourcing Trends in the leather manufacturing Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of leather manufacturing

- Strategic Sourcing Conclusion and Outlook for leather manufacturing

- Important Disclaimer & Terms of Use

Understanding leather manufacturing Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vegetable Tanning | Uses natural tannins from plant sources; longer process; eco-friendly. | Footwear, belts, bags, and upholstery. | Pros: Eco-friendly, unique patina; Cons: Longer production time, less color variety. |

| Chrome Tanning | Utilizes chromium salts; faster and more efficient; produces softer leather. | Fashion apparel, handbags, automotive interiors. | Pros: Quick processing, versatile colors; Cons: Environmental concerns, potential health risks. |

| Synthetic Tanning | Employs synthetic agents; quick and cost-effective; consistent quality. | Mass-produced items, fashion accessories. | Pros: Cost-effective, uniform quality; Cons: Perceived lower quality, less eco-friendly. |

| Suede and Nubuck | Created from the underside of the hide; soft texture; requires special care. | Footwear, jackets, and furniture. | Pros: Luxurious feel, unique appearance; Cons: Less durable, requires more maintenance. |

| Exotic Leather | Sourced from non-traditional animals (e.g., snakes, crocodiles); unique patterns. | High-end fashion, luxury goods, specialty items. | Pros: Distinctive and high-value; Cons: High cost, ethical and regulatory concerns. |

What are the Characteristics of Vegetable Tanned Leather?

Vegetable tanning is a traditional method that relies on natural tannins extracted from plant materials such as tree bark. This process is lengthy, often taking several weeks, which results in a robust leather that develops a unique patina over time. It is particularly suitable for products that require durability and a natural aesthetic, such as footwear, belts, and bags. When purchasing, B2B buyers should consider the longer lead times and the potential for color variability, which may affect large-scale production schedules.

How Does Chrome Tanned Leather Stand Out?

Chrome tanning is the most prevalent method in the industry due to its efficiency and ability to produce soft, supple leather in a shorter timeframe. This process employs chromium salts, allowing for a wide array of colors and finishes, making it ideal for fashion apparel and automotive interiors. However, buyers should weigh the benefits of quick production against the environmental concerns associated with chromium use. Ensuring suppliers adhere to safety and environmental regulations is crucial for responsible sourcing.

What Makes Synthetic Tanning an Attractive Option?

Synthetic tanning utilizes chemical agents to expedite the leather production process, resulting in a uniform and cost-effective product. This method is particularly attractive for manufacturers focused on mass production, such as fashion accessories and budget-friendly items. B2B buyers should consider the trade-offs between cost and perceived quality, as synthetic leathers may not carry the same prestige as traditional methods. Additionally, the environmental impact of synthetic agents should be evaluated.

Illustrative image related to leather manufacturing

Why Choose Suede and Nubuck for Luxury Items?

Suede and nubuck are types of leather that showcase the soft, velvety underside of the hide, offering a luxurious feel and unique appearance. These materials are commonly used in high-end footwear, jackets, and furniture. While they provide an upscale aesthetic, buyers must be aware of their lower durability and higher maintenance requirements. Consideration for care instructions and potential wear should be factored into purchasing decisions, particularly for items intended for heavy use.

What are the Considerations for Sourcing Exotic Leather?

Exotic leathers, derived from animals such as snakes and crocodiles, are sought after for their distinctive patterns and high value, often used in luxury fashion and specialty goods. While they provide an exclusive appeal, B2B buyers must navigate ethical sourcing concerns and regulatory compliance. The high cost associated with these materials can be a barrier, and buyers should ensure their suppliers are transparent about sourcing practices and sustainability efforts.

Key Industrial Applications of leather manufacturing

| Industry/Sector | Specific Application of leather manufacturing | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | High-end leather clothing and accessories | Enhances brand prestige and marketability | Quality of leather, sustainability practices, and certifications |

| Automotive | Interior upholstery for vehicles | Improves aesthetics and durability of interiors | Compliance with automotive standards, sourcing from certified tanneries |

| Furniture | Leather upholstery for seating and decor | Adds luxury and comfort, increasing consumer appeal | Material durability, color options, and maintenance requirements |

| Footwear | Leather shoes and boots | Provides style and comfort, essential for brand loyalty | Sourcing from ethical suppliers, quality assurance, and design compatibility |

| Sports Equipment | Leather goods for sportswear and gear | Enhances performance and longevity of products | Specific performance standards, sourcing from reliable manufacturers |

How is Leather Manufacturing Used in the Fashion and Apparel Sector?

In the fashion and apparel industry, leather is integral for creating high-end clothing and accessories, such as jackets, bags, and belts. Leather’s durability and aesthetic appeal enhance brand prestige, allowing businesses to charge premium prices. Buyers need to consider the quality of leather, ethical sourcing practices, and industry certifications to meet consumer demand for sustainable fashion, particularly in markets like Europe and North America.

What is the Role of Leather Manufacturing in Automotive Interiors?

Leather manufacturing plays a crucial role in the automotive sector, where it is used for upholstery in vehicle interiors. High-quality leather enhances the aesthetic appeal and provides durability, contributing to a luxurious customer experience. International buyers must ensure that their suppliers comply with automotive safety standards and environmental regulations, particularly when sourcing from regions with differing regulations.

How Does Leather Enhance Furniture Design?

In furniture manufacturing, leather upholstery is a popular choice for sofas, chairs, and decorative items. It adds a touch of luxury and comfort, appealing to consumers seeking quality and style. Buyers should focus on the leather’s durability, available color options, and maintenance requirements, as these factors can significantly impact customer satisfaction and product longevity.

Illustrative image related to leather manufacturing

Why is Leather Important for Footwear Production?

The footwear industry heavily relies on leather for crafting shoes and boots, providing both style and comfort. Leather’s natural properties allow for breathability and a custom fit, which are essential for consumer loyalty. B2B buyers should prioritize sourcing from ethical suppliers, ensuring quality assurance, and compatibility with existing designs to meet market demands effectively.

How is Leather Used in Sports Equipment?

Leather is commonly used in the production of sports equipment and apparel, such as gloves, balls, and protective gear. It enhances performance and longevity, making it a preferred material among athletes. Buyers in this sector need to focus on specific performance standards and ensure that they source from reliable manufacturers who can provide consistent quality and timely delivery, particularly in competitive markets.

3 Common User Pain Points for ‘leather manufacturing’ & Their Solutions

Scenario 1: Navigating Quality Control Challenges in Leather Production

The Problem:

B2B buyers often face significant quality control challenges when sourcing leather products. Variability in leather quality can stem from differences in animal hides, inconsistencies in manufacturing processes, or inadequate supplier standards. For instance, a buyer may receive a batch of leather that has varying colors, textures, or durability, making it difficult to meet their own customers’ expectations. This can lead to increased returns, damaged relationships, and ultimately, a loss of revenue.

The Solution:

To tackle quality control issues effectively, B2B buyers should establish a robust supplier evaluation process. Begin by developing a comprehensive checklist that includes specific quality metrics such as thickness, grain consistency, and color uniformity. Engage with suppliers who provide transparency in their processes and are willing to share their quality assurance protocols. Additionally, consider implementing regular quality audits and on-site inspections to ensure adherence to agreed-upon standards. Collaborating with third-party quality assurance firms can also add an extra layer of reliability, helping to validate the quality of leather before it reaches your production line.

Scenario 2: Managing Environmental Compliance in Leather Manufacturing

The Problem:

Environmental concerns are increasingly at the forefront of consumer preferences, and B2B buyers face pressure to source leather products that comply with sustainability standards. The tanning process, particularly when using traditional methods, can be hazardous, releasing harmful chemicals into the environment. Buyers may struggle to find suppliers who prioritize eco-friendly practices and can substantiate their claims with certifications, leading to potential reputational risks and regulatory challenges.

Illustrative image related to leather manufacturing

The Solution:

Buyers should prioritize partnerships with suppliers committed to sustainable practices. Look for manufacturers that utilize vegetable tanning methods or innovative synthetic alternatives that reduce environmental impact. Request documentation of certifications such as ISO 14001 or the Leather Working Group (LWG) audit results to ensure compliance with environmental standards. Establishing long-term relationships with suppliers focused on sustainability not only mitigates risks but can also enhance your brand’s reputation in the market. Further, consider incorporating lifecycle assessments to evaluate the environmental impact of the leather products you intend to purchase, ensuring that they align with your company’s sustainability goals.

Scenario 3: Addressing Supply Chain Disruptions in Leather Sourcing

The Problem:

Supply chain disruptions can severely impact the leather manufacturing industry, especially for B2B buyers who rely on timely deliveries to meet production schedules. Factors such as political instability, trade restrictions, and even natural disasters can lead to delays or increased costs in sourcing leather. This unpredictability can hinder a buyer’s ability to fulfill orders, resulting in lost contracts and diminished customer trust.

The Solution:

To mitigate supply chain risks, buyers should diversify their supplier base across different geographic regions. This strategy reduces dependency on a single source and enhances flexibility when disruptions occur. Establishing strategic partnerships with multiple suppliers also allows for quicker adjustments in response to changes in demand or unforeseen delays. Additionally, implementing a robust supply chain management system can improve visibility into order statuses and potential disruptions. Buyers should also consider maintaining a safety stock of essential leather materials to buffer against unexpected shortages, ensuring that production can continue smoothly even during challenging times.

By proactively addressing these common pain points, B2B buyers can enhance their procurement strategies and foster stronger relationships with suppliers, ultimately leading to greater success in the leather manufacturing market.

Strategic Material Selection Guide for leather manufacturing

What Are the Key Materials Used in Leather Manufacturing?

In the leather manufacturing industry, the selection of materials significantly influences product quality, performance, and cost. Below, we analyze four common materials used in leather manufacturing, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

Illustrative image related to leather manufacturing

1. Animal Hides (Cow, Goat, Sheep)

Key Properties

Animal hides are the primary raw material for leather production, known for their durability and flexibility. They can withstand various environmental conditions, making them suitable for diverse applications, from fashion to automotive interiors.

Pros & Cons

The primary advantage of using animal hides is their natural strength and aesthetic appeal. However, they can be expensive, particularly high-quality grades. The manufacturing complexity increases with the need for proper tanning and finishing processes to enhance durability and appearance.

Impact on Application

Animal hides are compatible with a wide range of media, including dyes and finishes, allowing for customization. However, their susceptibility to moisture can impact longevity if not treated correctly.

Illustrative image related to leather manufacturing

Considerations for International Buyers

Buyers must be aware of compliance with animal welfare standards and environmental regulations, which can vary significantly across regions like Europe and the Middle East. Certifications such as ISO 14001 for environmental management may be required.

2. Synthetic Leather (PU, PVC)

Key Properties

Synthetic leather, made from polyurethane (PU) or polyvinyl chloride (PVC), offers a high degree of water resistance and can mimic the appearance of genuine leather effectively. Its temperature resistance is generally superior to that of natural leather.

Pros & Cons

The main advantage of synthetic leather is its cost-effectiveness and ease of manufacturing, making it suitable for mass production. However, it may lack the breathability and tactile qualities of natural leather, leading to potential discomfort in certain applications.

Impact on Application

Synthetic leather is often used in products requiring high moisture resistance, such as automotive interiors and outdoor furniture. However, its compatibility with certain dyes and finishes may be limited compared to natural leather.

Considerations for International Buyers

Buyers should consider compliance with material safety standards, such as REACH in Europe, which restricts harmful substances. Additionally, preferences for eco-friendly materials are growing, particularly in markets like Germany.

3. Recycled Leather

Key Properties

Recycled leather is made from leftover scraps and offcuts, offering a sustainable alternative to traditional leather. It retains some of the durability of genuine leather while providing a unique texture and finish.

Pros & Cons

The key advantage of recycled leather is its environmental benefits, reducing waste and resource consumption. However, it may not have the same strength and longevity as full-grain leather, which can limit its application in high-stress environments.

Impact on Application

Recycled leather is suitable for fashion accessories, bags, and upholstery, where aesthetic appeal is paramount. Its variable quality may affect its use in high-performance applications.

Considerations for International Buyers

International buyers should be aware of certifications related to sustainability, such as Global Recycled Standard (GRS), which can enhance marketability in eco-conscious regions like Europe and South America.

Illustrative image related to leather manufacturing

4. Exotic Hides (Crocodile, Ostrich)

Key Properties

Exotic hides are known for their unique textures and patterns, offering luxury and exclusivity. These materials are generally more durable and resistant to wear compared to standard hides.

Pros & Cons

The primary advantage of exotic hides is their high-end appeal and market value, making them desirable in luxury products. However, they come with a high price tag and strict regulations regarding sourcing and trade.

Impact on Application

Exotic hides are often used in premium fashion items, accessories, and high-end automotive interiors. Their unique characteristics can significantly enhance the product’s perceived value.

Considerations for International Buyers

Buyers must navigate complex regulations around the sourcing of exotic hides, including CITES compliance for endangered species. Understanding local market preferences and ethical sourcing is crucial, especially in Europe.

Summary Table

| Material | Typical Use Case for leather manufacturing | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Animal Hides | Fashion, automotive interiors | Natural strength and aesthetic appeal | High cost and complex manufacturing | High |

| Synthetic Leather | Mass-produced fashion, automotive | Cost-effective and versatile | Lacks breathability and tactile quality | Medium |

| Recycled Leather | Fashion accessories, upholstery | Eco-friendly and sustainable | Variable quality and durability | Medium |

| Exotic Hides | Luxury fashion, high-end automotive | Unique textures and high market value | High cost and strict sourcing regulations | High |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, ensuring informed decisions that align with market demands and compliance standards.

Illustrative image related to leather manufacturing

In-depth Look: Manufacturing Processes and Quality Assurance for leather manufacturing

What Are the Main Stages of the Leather Manufacturing Process?

The leather manufacturing process is intricate, involving multiple stages that transform raw hides into finished leather products. Understanding these stages is crucial for B2B buyers looking for quality assurance in their supply chain.

1. Material Preparation

The first stage focuses on preparing the hides or skins, which includes several key steps:

-

Soaking: Hides are soaked in water to eliminate impurities like dirt and blood. This process also helps soften the hides for easier handling in subsequent steps.

-

Liming and Deliming: Lime or alkaline substances are used to remove hair and fats, followed by a deliming process that neutralizes the alkaline solution. This is essential for making the hides ready for tanning.

-

Bating and Pickling: Enzymatic treatment softens the hides further, while pickling with salt and acid preserves them for tanning. Proper execution of these steps sets the foundation for high-quality leather.

2. Tanning

Tanning is pivotal in making the leather durable and resistant to decay. Various methods can be employed:

-

Vegetable Tanning: A traditional method using tannins from plants. This process is eco-friendly but time-consuming, often taking weeks to months.

-

Chrome Tanning: The most common method today, utilizing chromium salts for a quicker and more versatile tanning process. It results in softer leather with vibrant colors.

-

Synthetic Tanning: An emerging technique that employs synthetic agents, providing rapid results and greater control over leather properties.

Each tanning method has implications for the final product’s quality, appearance, and environmental footprint.

3. Finishing

The finishing stage enhances leather’s aesthetics and durability. It includes:

-

Dyeing: Various methods such as immersion, spraying, or hand painting are used to add color. The choice of dye and method significantly affects the leather’s appearance.

-

Buffing and Coating: Buffing smooths the surface, while protective coatings, like wax or oil, increase resistance to stains and water.

-

Polishing and Embossing: These techniques can add shine and texture, providing additional value and uniqueness to the leather products.

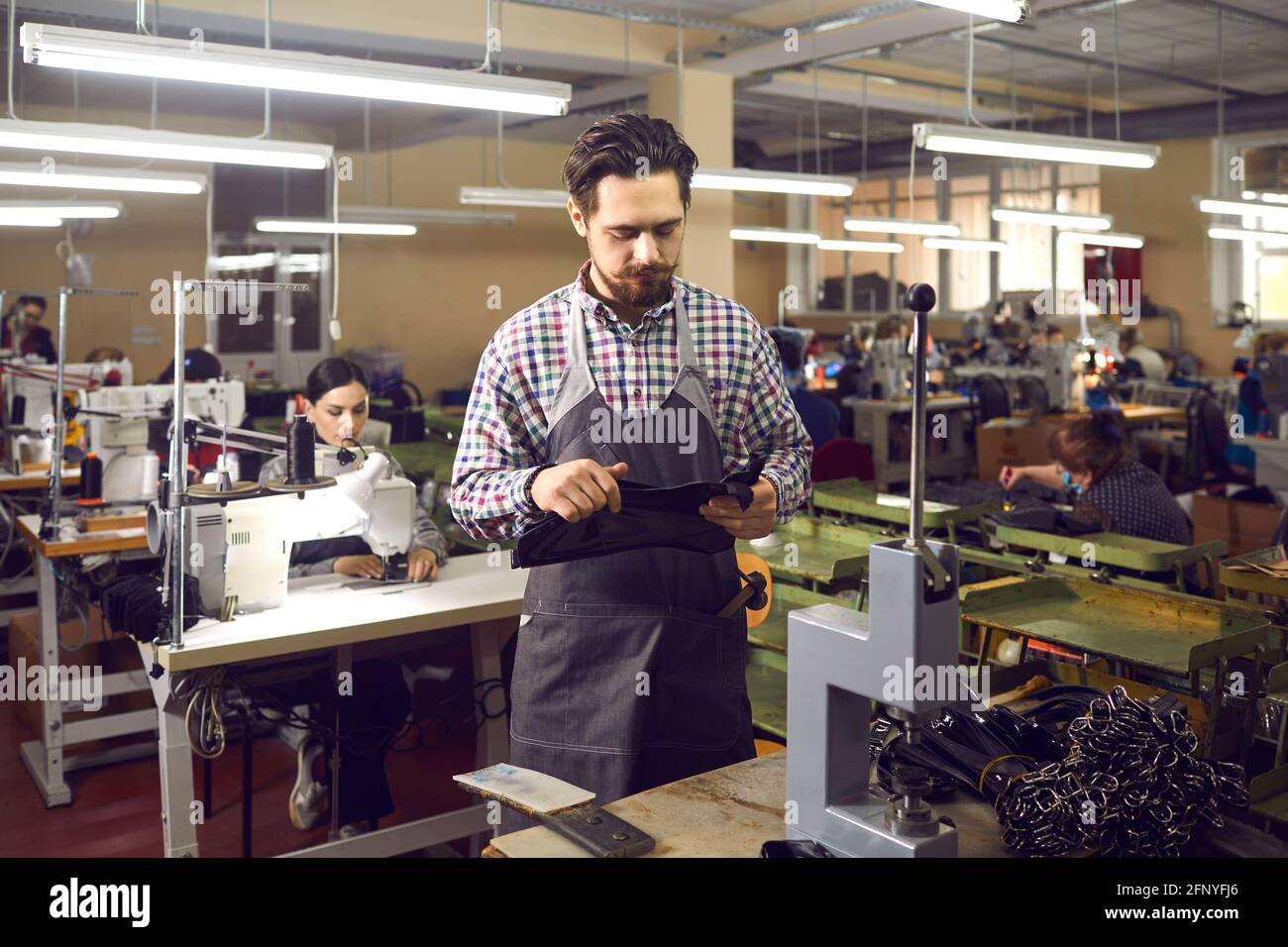

4. Cutting and Assembly

The final stage involves cutting the leather into specific shapes and sewing them to create the finished products. Techniques include:

Illustrative image related to leather manufacturing

-

Pattern Cutting: Leather pieces are cut using patterns for precision.

-

Sewing: High-quality stitching techniques are employed to ensure durability and aesthetic appeal. This stage is critical for products like footwear, bags, and garments.

How Is Quality Assurance Integrated into Leather Manufacturing?

Quality assurance in leather manufacturing is essential for maintaining product standards and meeting international requirements. Here are key aspects of the QC process:

Relevant International Standards for Leather Quality Assurance

B2B buyers should be familiar with several international standards that govern leather manufacturing quality:

-

ISO 9001: This standard focuses on quality management systems and ensures that manufacturers maintain consistent quality throughout the production process.

-

CE Marking: Particularly relevant in Europe, this certification indicates that products meet health, safety, and environmental protection standards.

-

API Standards: For leather used in specific applications, such as automotive interiors, adherence to American Petroleum Institute standards may be required.

These standards help ensure that leather products are safe, reliable, and of high quality.

What Are the Key Quality Control Checkpoints in Leather Manufacturing?

Quality control checkpoints are integrated throughout the leather manufacturing process to catch defects early:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing stages helps identify issues before they affect the final product.

-

Final Quality Control (FQC): A thorough inspection is conducted after finishing to confirm that the leather meets all quality standards before shipment.

What Common Testing Methods Are Used in Leather Quality Control?

To ensure the quality of leather products, several testing methods are employed:

-

Physical Testing: Assessing durability, tensile strength, and flexibility through standardized tests.

-

Chemical Testing: Checking for the presence of harmful substances, such as heavy metals or toxic dyes, to ensure compliance with safety standards.

-

Aesthetic Testing: Evaluating color consistency, texture, and overall appearance to ensure that the finished product meets customer expectations.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is crucial. Here are some effective strategies:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes and quality assurance measures.

-

Requesting Quality Reports: Suppliers should be able to provide documentation detailing their quality control processes, testing results, and certifications.

-

Third-Party Inspections: Engaging independent third-party inspectors can provide an unbiased evaluation of the supplier’s quality practices and adherence to international standards.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges:

Illustrative image related to leather manufacturing

-

Cultural Differences: Understanding local manufacturing practices and quality expectations can help mitigate risks.

-

Regulatory Compliance: Different regions have varying requirements for leather products. Buyers must ensure that suppliers comply with local regulations, particularly regarding environmental standards.

-

Supply Chain Transparency: Establishing a transparent supply chain can help buyers track the quality of materials and processes, ensuring adherence to agreed-upon standards.

By understanding the manufacturing processes and quality assurance techniques involved in leather production, B2B buyers can make informed decisions, ensuring they partner with suppliers that meet their quality expectations and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘leather manufacturing’

Introduction

Navigating the leather manufacturing landscape can be complex, especially for international B2B buyers. This guide provides a practical checklist to streamline your sourcing process, ensuring you find reliable suppliers who meet your quality, ethical, and sustainability standards. By following these steps, you can enhance your procurement strategy and secure high-quality leather products for your business needs.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements. This includes the type of leather, intended applications (e.g., footwear, upholstery), and specific qualities (e.g., thickness, finish). Establishing these specifications upfront helps suppliers provide accurate quotes and ensures the final product meets your expectations.

- Consider the end-use: Different products may require varying leather characteristics, such as durability or flexibility.

- Document your requirements: Create a detailed specification sheet to share with potential suppliers for clarity.

Step 2: Research and Shortlist Potential Suppliers

Conduct thorough research to identify potential leather manufacturers that align with your specifications. Utilize online platforms, industry trade shows, and trade associations to compile a list of candidates. Focus on suppliers with a proven track record in your desired market.

- Look for industry experience: Suppliers with years of experience in leather manufacturing are more likely to understand the nuances of quality and compliance.

- Check geographical proximity: Consider suppliers in regions with established leather production to reduce shipping times and costs.

Step 3: Verify Supplier Certifications

It is essential to ensure that your chosen suppliers adhere to industry standards and regulations. Request certifications related to quality management (like ISO 9001), environmental management (ISO 14001), and ethical sourcing practices.

Illustrative image related to leather manufacturing

- Review compliance documents: Ensure that suppliers meet local and international regulations regarding leather production and environmental impact.

- Confirm sustainability practices: Look for certifications such as the Leather Working Group (LWG) for sustainable practices in leather production.

Step 4: Request Samples for Quality Assessment

Before making a bulk order, request samples of the leather products you intend to purchase. This step allows you to evaluate the quality, texture, and overall finish of the leather.

- Inspect for consistency: Ensure that the samples match your specifications and are free from defects.

- Test durability: If possible, conduct tests to assess the leather’s performance under various conditions relevant to its intended use.

Step 5: Evaluate Pricing and Payment Terms

Pricing is a critical factor in supplier selection, but it should not be the sole determinant. Compare quotes while considering the quality of materials and services offered. Discuss payment terms to ensure they align with your financial capabilities and risk management strategies.

- Consider total cost of ownership: Factor in shipping, duties, and potential tariffs to understand the full financial impact.

- Negotiate flexible terms: Seek terms that allow for better cash flow management, such as installment payments based on delivery milestones.

Step 6: Conduct a Factory Audit

If feasible, conduct an on-site factory audit to assess the supplier’s operational capabilities and working conditions. This firsthand experience can provide invaluable insights into the supplier’s commitment to quality and ethical practices.

- Review production processes: Ensure they follow environmentally friendly practices and maintain high-quality standards.

- Evaluate workforce conditions: Assess the working environment to ensure compliance with labor laws and ethical sourcing standards.

Step 7: Establish Clear Communication Channels

Effective communication is vital to a successful partnership. Establish clear lines of communication with your supplier to ensure transparency throughout the procurement process.

Illustrative image related to leather manufacturing

- Define points of contact: Identify key individuals in both your organization and the supplier’s team to facilitate smooth interactions.

- Set regular updates: Schedule periodic check-ins to discuss order status, quality concerns, and any necessary adjustments.

By following this step-by-step checklist, B2B buyers can enhance their sourcing strategy and establish fruitful partnerships in the leather manufacturing sector.

Comprehensive Cost and Pricing Analysis for leather manufacturing Sourcing

What Are the Key Cost Components in Leather Manufacturing?

Understanding the cost structure of leather manufacturing is critical for international B2B buyers. The primary components include:

-

Materials: Raw hides and skins are the most significant cost driver. Prices can vary based on the type of leather (e.g., full-grain, top-grain, split) and the quality of the hide. Buyers should consider sourcing from regions known for specific types of leather, as this can influence both cost and quality.

-

Labor: Labor costs in leather manufacturing can differ significantly between countries. Regions with lower wage standards may offer more competitive pricing but could pose risks regarding quality and compliance with labor regulations.

-

Manufacturing Overhead: This includes expenses related to factory operation, utilities, and equipment maintenance. Efficient production processes can help mitigate these costs, making it essential for buyers to partner with manufacturers that utilize advanced technologies and lean manufacturing principles.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs or specialized products. Buyers should inquire about tooling fees and amortization over production runs to understand the total cost impact.

-

Quality Control (QC): Implementing robust QC processes ensures product consistency and compliance with international standards. Buyers should factor in the cost of QC as a critical component of overall pricing.

-

Logistics: Shipping and handling costs can vary based on the supplier’s location, the chosen shipping method, and the delivery timeline. Understanding Incoterms is essential for clarifying responsibilities and potential costs.

-

Margin: Suppliers typically build a profit margin into their pricing, which can fluctuate based on market demand, competition, and buyer negotiation leverage.

How Do Price Influencers Affect Leather Manufacturing Costs?

Several factors can significantly influence pricing in the leather manufacturing sector:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should assess their needs carefully to negotiate favorable pricing based on volume.

-

Specifications and Customization: Customized products generally incur higher costs due to additional tooling and production complexities. Buyers should clearly define their specifications to avoid unexpected charges.

-

Materials: The choice of leather type directly impacts pricing. For instance, exotic leathers like alligator or ostrich are significantly more expensive than cowhide. Buyers should consider the end-use of the product when selecting materials to balance cost and quality.

-

Quality and Certifications: Products with certifications (e.g., eco-friendly, ethical sourcing) may come at a premium. Buyers should weigh the benefits of certified products against their budget constraints.

-

Supplier Factors: Supplier reputation, reliability, and production capabilities can all influence pricing. Building long-term relationships with reputable suppliers can lead to better pricing and terms.

-

Incoterms: Understanding the implications of Incoterms (e.g., FOB, CIF) is crucial for managing logistics costs and responsibilities. Buyers should negotiate terms that align with their supply chain capabilities.

What Tips Can Help Buyers Optimize Leather Manufacturing Costs?

B2B buyers can employ several strategies to optimize costs and ensure a favorable purchasing experience:

-

Negotiation Strategies: Effective negotiation can lead to better pricing and terms. Buyers should prepare by understanding the market and competitors’ pricing structures.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership (TCO), which encompasses not only the purchase price but also logistics, maintenance, and potential returns. This holistic view can lead to better decision-making.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of potential tariffs, import duties, and currency fluctuations that can impact overall costs. Engaging with local experts or consultants can provide valuable insights.

-

Supplier Diversity: Diversifying suppliers can mitigate risks and provide leverage during negotiations. Consider sourcing from multiple regions to balance cost, quality, and supply chain stability.

Disclaimer

Prices mentioned in this analysis are indicative and can vary based on market fluctuations, supplier negotiations, and specific buyer requirements. Always conduct thorough due diligence and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing leather manufacturing With Other Solutions

Exploring Alternative Solutions to Leather Manufacturing

In the quest for durable and aesthetically pleasing materials, leather manufacturing has long been a staple in various industries, including fashion, automotive, and furniture. However, as global demands shift towards sustainability and ethical practices, exploring alternatives has become essential for B2B buyers. This analysis examines leather manufacturing in comparison to synthetic leather and biodegradable materials, providing insights into their respective advantages and disadvantages.

Illustrative image related to leather manufacturing

| Comparison Aspect | Leather Manufacturing | Synthetic Leather (e.g., PU, PVC) | Biodegradable Materials (e.g., Piñatex, Mylo) |

|---|---|---|---|

| Performance | Highly durable, natural feel | Varies; generally durable but may lack breathability | Good durability; feel can be less premium |

| Cost | Higher production costs | Generally lower production costs | Moderate costs; varies by material source |

| Ease of Implementation | Complex; requires specialized skills | Easier; can be produced at scale | Varies; may require new processing techniques |

| Maintenance | Requires regular care | Low maintenance; easy to clean | Similar to leather; care may vary by material |

| Best Use Case | High-end fashion, automotive | Mass-produced goods, fashion, furniture | Sustainable fashion, eco-conscious products |

Understanding Synthetic Leather as an Alternative

Synthetic leather, commonly made from materials such as polyurethane (PU) and polyvinyl chloride (PVC), offers a compelling alternative to traditional leather. It is often less expensive to produce and can be manufactured in various colors and textures, making it appealing for mass-market applications. However, the environmental impact of synthetic leather is a concern due to its reliance on petroleum-based products, and it may lack the breathability and aging characteristics of genuine leather.

Exploring Biodegradable Materials as a Sustainable Option

Biodegradable materials, including Piñatex (made from pineapple leaves) and Mylo (derived from mycelium), represent a growing trend towards sustainability in the fashion industry. These materials are designed to break down naturally, reducing environmental impact. While they offer a unique aesthetic and appeal to eco-conscious consumers, their durability and feel may not match that of traditional leather. Additionally, production processes can be less established, leading to variability in quality.

Making the Right Choice for Your Business Needs

When choosing between leather manufacturing and its alternatives, B2B buyers should consider several factors, including the target market, product application, and sustainability goals. Leather remains a strong choice for high-end products requiring durability and a premium feel. In contrast, synthetic leather may be more suitable for mass-market items, while biodegradable options appeal to brands prioritizing environmental responsibility. Ultimately, aligning the choice with brand values and customer expectations will guide businesses in making the most effective decision.

Essential Technical Properties and Trade Terminology for leather manufacturing

What Are the Key Technical Properties in Leather Manufacturing?

In the leather manufacturing industry, understanding critical technical properties is essential for maintaining product quality and meeting market demands. Here are some of the key specifications that B2B buyers should consider:

1. Material Grade

Material grade refers to the classification of leather based on its quality, which can vary from full-grain to corrected grain. Full-grain leather, for instance, retains the natural grain and imperfections, making it more durable and desirable for high-end products. In contrast, corrected grain leather undergoes processing to hide flaws, often resulting in a less expensive option. Knowing the material grade helps buyers assess product suitability for their target market.

2. Tolerance

Tolerance in leather manufacturing defines the permissible limits of variation in dimensions and characteristics of the leather. This can include thickness, width, and overall quality attributes. Strict adherence to tolerances ensures uniformity across production batches, allowing manufacturers to maintain high standards while minimizing waste. For B2B buyers, understanding tolerances is vital when evaluating supplier capabilities and ensuring product consistency.

Illustrative image related to leather manufacturing

3. Durability

Durability measures a leather product’s resistance to wear and tear over time. Factors influencing durability include the tanning method used, the type of hide, and any finishing treatments applied. High durability is critical for products like footwear and automotive interiors, where long-lasting performance is expected. Buyers should prioritize suppliers that can provide durable leather to meet customer expectations and reduce returns.

4. Breathability

Breathability refers to the ability of leather to allow air and moisture to pass through, which is particularly important in apparel and footwear. Leather with good breathability helps prevent discomfort and odor, enhancing user experience. For buyers in regions with warm climates, this property can be a significant selling point, influencing purchasing decisions.

5. Water Resistance

Water resistance indicates how well leather can withstand exposure to moisture without degrading. While not all leather products require high water resistance, items such as outdoor gear and fashion accessories may benefit from it. Buyers should consider the intended use of the leather products when assessing water resistance levels.

What Are Common Trade Terms in Leather Manufacturing?

In addition to understanding technical properties, familiarity with industry terminology is crucial for effective communication and negotiation in the leather manufacturing sector. Here are some common trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces goods for another company to sell under its brand. In the leather industry, an OEM may manufacture leather goods for fashion brands, allowing those brands to focus on marketing and distribution. B2B buyers should evaluate potential OEMs based on their manufacturing capabilities and quality standards.

Illustrative image related to leather manufacturing

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In leather manufacturing, MOQs can vary significantly based on the type of leather and customization options. Understanding MOQ is essential for buyers to plan inventory levels and manage cash flow effectively.

3. RFQ (Request for Quotation)

An RFQ is a formal request sent by buyers to suppliers, asking for pricing and terms for specific products. This document typically includes details about the leather specifications and quantities required. B2B buyers should prepare detailed RFQs to ensure they receive accurate and competitive quotes.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions, including shipping, risk transfer, and cost allocation. Familiarity with these terms helps buyers understand their obligations regarding transportation and delivery, reducing the likelihood of disputes.

5. Lead Time

Lead time refers to the time it takes from placing an order to delivery. In leather manufacturing, lead times can vary based on production schedules and material availability. Buyers should account for lead time when planning product launches or seasonal inventory to ensure timely delivery.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, foster better supplier relationships, and enhance their overall procurement strategies in the leather manufacturing industry.

Navigating Market Dynamics and Sourcing Trends in the leather manufacturing Sector

What Are the Current Trends Driving the Leather Manufacturing Market?

The global leather goods market, valued at over USD 414 billion, is witnessing a robust growth trajectory, projected to expand at a CAGR of 5.5% through 2028. This growth is driven by several factors, including rising disposable incomes, increasing consumer demand for luxury and durable products, and the proliferation of e-commerce platforms facilitating easier access to leather goods. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must recognize these trends to leverage market opportunities effectively.

Emerging technologies are reshaping the leather manufacturing landscape. Automation in production processes is enhancing efficiency and quality, allowing manufacturers to meet the growing demand for customized leather products. Digital tools for supply chain management are also gaining traction, enabling real-time tracking and transparency in sourcing, which is critical for international trade. Additionally, there is a notable shift toward direct-to-consumer models, prompting manufacturers to rethink their distribution strategies.

Illustrative image related to leather manufacturing

Another vital trend is the increasing importance of branding and storytelling in leather goods. B2B buyers should consider partnering with manufacturers that emphasize unique narratives around their products, as consumers are increasingly drawn to brands that reflect their values and heritage. Understanding these market dynamics will empower international buyers to make informed sourcing decisions that align with their business strategies.

How Is Sustainability Shaping Ethical Sourcing in Leather Manufacturing?

The leather manufacturing sector faces significant scrutiny regarding its environmental impact, particularly concerning water usage, chemical waste, and animal welfare. As a result, sustainability has become a key focus for B2B buyers seeking to establish ethical supply chains. Ethical sourcing is not just a regulatory requirement; it is a business imperative that resonates with increasingly eco-conscious consumers.

Sustainable practices in leather manufacturing include the adoption of vegetable tanning methods, which utilize natural plant materials, and the use of by-products from the meat industry to minimize waste. Additionally, buyers should look for manufacturers that hold certifications such as the Leather Working Group (LWG) certification, which assesses environmental practices in tanneries. Such certifications serve as indicators of a supplier’s commitment to sustainability and can enhance a brand’s reputation in the marketplace.

Moreover, the demand for alternative leather materials, such as those made from recycled or plant-based sources, is on the rise. International B2B buyers should consider integrating these innovative materials into their product offerings to cater to the growing market segment that prioritizes sustainability. By embracing ethical sourcing practices, businesses can not only mitigate risks associated with environmental concerns but also align themselves with consumer expectations for responsible production.

What Is the Historical Context of Leather Manufacturing for Today’s B2B Buyers?

Leather manufacturing has a rich history that dates back thousands of years, evolving from primitive methods of hide processing to a sophisticated industry today. Initially, leather was primarily used for functional purposes, such as clothing and shelter. However, as civilizations advanced, the craft of leatherworking transformed into an art form, leading to the production of intricate designs for fashion and accessories.

Illustrative image related to leather manufacturing

The industrial revolution marked a significant turning point, introducing mechanization and mass production techniques that changed the scale and efficiency of leather manufacturing. In recent decades, technological advancements and globalization have further shaped the industry, allowing for faster production times and expanded market reach.

For contemporary B2B buyers, understanding this historical context is essential. It provides insights into the evolution of consumer preferences and manufacturing practices, which can inform sourcing strategies. Acknowledging the journey of leather manufacturing helps buyers appreciate the craftsmanship involved and the importance of maintaining quality and ethical standards in today’s competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of leather manufacturing

-

How do I solve challenges related to sourcing high-quality leather suppliers?

To address sourcing challenges, begin by conducting thorough market research to identify reputable suppliers with a proven track record. Utilize online platforms, industry trade shows, and networking within leather manufacturing associations. Request samples to assess the quality of their leather, and inquire about their production processes, sustainability practices, and compliance with international standards. Establish clear communication about your quality requirements and expectations to ensure alignment. -

What are the best practices for vetting leather manufacturers?

Vetting leather manufacturers involves assessing their credentials, production capabilities, and ethical practices. Request certifications, such as ISO or environmental management certifications, to ensure compliance with industry standards. Conduct factory visits if possible, or utilize third-party inspection services. Check references and reviews from other B2B buyers to gauge reliability. Additionally, evaluate their transparency regarding sourcing materials and labor practices to ensure ethical manufacturing. -

What customization options should I consider when sourcing leather products?

Customization options can significantly enhance your product offerings. Inquire about the manufacturer’s ability to provide tailored solutions, such as specific leather types, colors, and finishes. Discuss the possibility of bespoke designs, embossing, or branding options. Understand the minimum order quantities (MOQs) for custom orders, as these can vary significantly. Collaborating closely with your supplier during the design phase can lead to better outcomes that align with your brand vision. -

What are the typical minimum order quantities (MOQs) for leather products?

Minimum order quantities can vary widely among leather manufacturers and depend on factors like product type, customization, and production capacity. Generally, MOQs can range from as low as 50 pieces for standard items to several hundred for custom designs. Discuss your requirements upfront with potential suppliers to understand their policies. Some manufacturers may offer flexibility for first-time buyers or larger orders, so negotiating based on your needs can be beneficial. -

What payment terms should I expect when working with international leather suppliers?

Payment terms can vary based on the supplier’s policies and your negotiation. Common practices include a deposit (typically 30-50%) upfront, with the balance due upon delivery or before shipment. Consider using secure payment methods such as letters of credit, which can provide protection against fraud. Always clarify terms such as currency, payment schedule, and penalties for late payments to avoid misunderstandings. -

How can I ensure quality assurance (QA) in leather products?

To ensure quality assurance, establish clear specifications and standards for the leather products you are sourcing. Collaborate with your supplier to create a quality control checklist that includes aspects like leather thickness, finish quality, and color consistency. Request regular updates and samples throughout the production process. Conduct final inspections before shipment to verify that the products meet your standards. Utilizing third-party QA services can also provide an unbiased assessment. -

What logistics considerations should I keep in mind when importing leather products?

When importing leather products, consider factors such as shipping methods, customs regulations, and import duties. Choose a reliable logistics partner experienced in handling leather goods to ensure smooth transit. Familiarize yourself with the import regulations of your country, including any specific documentation required for leather products. Additionally, factor in lead times for production and shipping to avoid delays in your supply chain. -

How do I stay updated on trends in the leather manufacturing industry?

Staying informed about industry trends involves engaging with professional associations, subscribing to industry publications, and attending trade shows and conferences. Online platforms like LinkedIn and specialized forums can provide valuable insights from industry experts. Additionally, following influential companies and thought leaders on social media can help you stay abreast of innovations, sustainability practices, and market demands. Regularly reviewing market reports and analyses can also provide strategic insights for your sourcing decisions.

Top 6 Leather Manufacturing Manufacturers & Suppliers List

1. Steel Horse Leather – Durable Animal Hides

Domain: steelhorseleather.com

Registered: 2019 (6 years)

Introduction: This company, Steel Horse Leather – Durable Animal Hides, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Spinneybeck – Full Grain Leathers

Domain: spinneybeck.com

Registered: 1996 (29 years)

Introduction: Spinneybeck produces full grain leathers at a tannery in Arzignano, Italy. The leather manufacturing process consists of six phases: raw material preparation, tanning, retanning, drying, finishing, and final inspection. The raw material is sourced from Europe, particularly Italy, Southern Germany, and Denmark, ensuring high-quality hides due to moderate climates and stringent beef industry standar…

3. Nera Tanning – Leather Making Process

Domain: neratanning.com

Registered: 2020 (5 years)

Introduction: The leather making process consists of five key steps: 1. Preservation – allows transport and storage of raw materials. 2. Preparatory operations (beamhouse) – cleaning hides, opening collagen structure, fleshing, processing with base chemicals, and splitting. 3. Tanning – transforming collagen into leather using various agents like Zeology, chrome, GDA, synthetic products, or vegetable extracts. …

4. Love Your Leather – Crafting Quality Leather

Domain: loveyourleather.ca

Registered: 2011 (14 years)

Introduction: Leather production involves 23 detailed steps, starting from curing hides to the final measurement of the leather. The process includes soaking, liming, fleshing, tanning with various materials (minerals, oils, vegetables), dyeing, fatliquoring, and finishing to ensure quality and durability. The entire process takes an average of 10 working days, performed by skilled artisans known as tanners. Le…

5. Tandy Leather – Quality Leather Supplies

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Quality Leather Supplies, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. First MFG Co. – Custom Jackets

Domain: firstmfg.com

Registered: 2000 (25 years)

Introduction: First MFG Co. offers a wide range of motorcycle leather apparel and gear, including custom jackets and vests for both men and women. Key products include:

1. **Custom Jackets**:

– Custom Men’s Jacket

– Custom Women’s Jacket

– Custom Men’s Cafe Style Jacket

– Custom Men’s Club Style Jacket

– Custom Men’s Bomber Jacket

– Custom Women’s Club Style Vest

– Custom Men’s Moto Mesh V…

Strategic Sourcing Conclusion and Outlook for leather manufacturing

What Are the Key Insights for Strategic Sourcing in Leather Manufacturing?

In conclusion, effective strategic sourcing in the leather manufacturing sector is vital for maximizing profitability and enhancing supply chain resilience. As the global demand for leather products continues to rise, driven by a projected CAGR of 5.5% through 2028, international B2B buyers must prioritize partnerships with manufacturers who embrace sustainable practices and innovative technologies. This includes understanding the complexities of the leather production process—from tanning to finishing—and ensuring that suppliers adhere to environmental regulations while maintaining high-quality standards.

How Can Buyers Prepare for Future Trends in Leather Manufacturing?

Looking ahead, buyers should focus on sourcing from suppliers who are committed to ethical practices and who leverage advancements in eco-friendly materials. By fostering relationships with manufacturers that prioritize sustainability, buyers can not only meet consumer demands but also align with global trends that favor responsible sourcing.

What Should International B2B Buyers Do Next?

As a call to action, we encourage B2B buyers from Africa, South America, the Middle East, and Europe—particularly in regions like Saudi Arabia and Germany—to actively seek partnerships that enhance their competitive edge in the leather market. Engage with suppliers who can provide transparency in their processes and demonstrate a commitment to quality and sustainability. By doing so, you will not only ensure a robust supply chain but also contribute positively to the future of the leather industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.