Microfiber vegan leather stands out for its affordability and wide range of style options. Many choose this material for its animal welfare benefits and consistent texture. Industry reports note that users often appreciate its easy cleaning and uniform appearance. However, drawbacks include peeling, disposal challenges, and a shorter lifespan when compared to genuine leather. Factors like durability, sustainability, tactile feel, cost, and ethical impact play a crucial role in the decision to use this material.

Key Takeaways

- Microfiber vegan leather is durable and resists wear, making it ideal for products that need to last.

- This material offers a consistent texture and finish, appealing to designers for its polished look.

- Cleaning microfiber vegan leather is easy; spills can be wiped away quickly, saving time and effort.

- Choosing microfiber vegan leather supports animal welfare, as it is made without animal hides.

- Consider the environmental impact and longevity concerns when deciding if microfiber vegan leather is right for you.

Microfiber Vegan Leather Benefits

Durability and Strength

Manufacturers design microfiber vegan leather to withstand daily wear and tear. This durable material resists abrasion and hydrolysis, making it suitable for products that require long-lasting performance. Many users notice that this synthetic option maintains its structure even after repeated use. High-quality production methods contribute to its impressive strength. People often select it for items that need to endure frequent handling or movement.

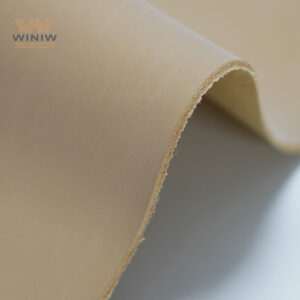

Uniform Texture and Finish

Microfiber vegan leather offers a consistent appearance across every piece. Unlike natural leather, which can show scars or irregularities, this material provides a smooth and even surface. Designers appreciate the uniform texture because it allows for predictable results in finished products. High-quality manufacturing ensures that each batch matches the desired color and grain. This consistency appeals to brands seeking a polished and professional look.

Easy Cleaning and Maintenance

Many consumers choose microfiber vegan leather because it is easy to clean. The surface does not absorb liquids quickly, so spills can be wiped away with a damp cloth. This material is also stain resistant, which helps maintain its appearance over time. People find that regular dusting or gentle washing keeps it looking fresh. The easy to clean nature of this fabric reduces the need for harsh chemicals or specialized cleaners. For busy households or commercial spaces, this feature saves time and effort.

Tip: For best results, use a soft cloth and mild soap when cleaning microfiber vegan leather. Avoid abrasive tools to preserve the finish.

Sustainable and Animal-Free

Microfiber vegan leather appeals to those who value sustainability and animal welfare. Production does not involve animal hides, so it provides an ethical alternative to traditional leather. Many manufacturers use advanced processes to reduce water and energy consumption during fabrication. Some brands incorporate recycled materials into their products, further lowering the environmental impact. This animal-free approach aligns with the values of eco-conscious consumers.

Versatile Uses

Microfiber vegan leather finds applications in many industries due to its adaptability. Market research highlights its popularity in the following sectors:

| Industry/Product Category |

|---|

| Automotive |

| Muebles |

| Footwear |

| Apparel |

| Accessories |

Designers use this material for car interiors, sofas, shoes, jackets, and bags. Its stain resistant and easy to clean properties make it ideal for both fashion and functional items. The high-quality finish and broad color range allow for creative freedom in product development. Companies rely on its versatility to meet diverse consumer needs.

Microfiber Vegan Leather Cons

Environmental Impact

Environmental impact remains a significant concern for manufacturers and consumers considering microfiber vegan leather. Studies highlight several issues associated with both production and disposal:

- Water depletion occurs during the creation of synthetic fibers, placing stress on local water resources.

- Microplastic pollution results from the shedding of synthetic fibers, which can harm marine and freshwater ecosystems.

- The textile industry generates substantial resource consumption and waste, contributing to broader environmental challenges.

These factors prompt many to weigh the pros and cons of choosing microfiber vegan leather over other materials. While the animal-free aspect appeals to some, the environmental impact of synthetic production and disposal cannot be ignored.

Limited Breathability

Microfiber vegan leather often lacks the breathability found in genuine leather. The synthetic structure restricts airflow, which can lead to discomfort in warm climates or during extended use. Shoes, jackets, and furniture made from this material may feel warmer and less ventilated. Designers sometimes address this issue by adding perforations or mesh panels, but the core material remains less breathable than natural alternatives.

Note: Limited breathability may affect comfort, especially in products worn close to the skin or used in hot environments.

Cost Factors

Price differences between microfiber vegan leather and other materials arise from several attributes. Durability, water resistance, aesthetic appeal, and eco-friendliness contribute to its value in the marketplace. Furniture and interior design sectors favor this material for its stylish appearance and low-maintenance qualities. Designers appreciate the versatility, which allows for unique creations that meet modern tastes. Consumers benefit from the stain resistant surface and ease of cleaning, but these advantages often result in higher costs compared to basic synthetic options.

Longevity Concerns

Although microfiber vegan leather offers durability, it does not always match the lifespan of genuine leather. Over time, users may notice peeling, cracking, or fading, especially with frequent use or exposure to harsh conditions. The material resists stains and abrasion, but repeated flexing and environmental stress can shorten its useful life. Some products require replacement sooner than those made from natural leather, which may influence purchasing decisions for those seeking long-term value.

Heat Sensitivity

Manufacturers advise several precautions to prevent heat damage to microfiber vegan leather products:

- Avoid high heat, which can cause warping and irreversible damage.

- Never use solvents such as gasoline, as they can dissolve the material.

- Avoid traditional industrial washers to prevent creasing and abrasion.

- If machine washing is necessary, use a gentle wet cleaning machine with very low rotation speeds and wrap the item in a towel for spin drying.

- Never iron polyurethane leather.

- Wipe down items with a damp cloth before storage and keep them away from direct heat and sunlight.

Heat sensitivity limits the cleaning and maintenance options for this material. Users must follow care instructions closely to preserve the appearance and function of their products.

Microfiber Vegan Leather Pros and Cons Compared

Microfiber vs. Genuine Leather

Manufacturers and designers often compare microfiber leather vs genuine leather to evaluate performance and sustainability. The table below highlights key differences:

| Feature | Genuine Leather | Piel de microfibra |

|---|---|---|

| Material Source | Animal hide | Microfibra + PU |

| Texture | Natural, unique | Very leather-like |

| Durabilidad | Good | Excellent |

| Water Resistance | Moderate | Alta |

| Eco-Friendliness | Depends on tanning | Higher (no animal use) |

| Price | Alta | Moderate |

Microfiber vegan leather demonstrates excellent durability. It resists cracking and stretching, even with daily use. Genuine leather can thin and crack at stress points, especially over time. Microfiber vegan leather also offers superior moisture resistance. It withstands sweat and water without damage, while genuine leather may stain or warp when wet. The animal-free production process makes microfiber vegan leather a more sustainable choice for those seeking high-quality accessories without ethical concerns.

Microfiber vs. Other Vegan Leathers

Microfiber vegan leather stands out among other vegan leather options. Polyurethane (PU) and polyvinyl chloride (PVC) leathers often lack the high-quality texture and durability found in microfiber. Microfiber vegan leather provides a very leather-like feel and appearance, which appeals to brands that prioritize a premium look. Many users appreciate its easy to clean surface and stain resistant properties, which outperform basic synthetic alternatives. Other vegan leathers may peel or fade more quickly, while microfiber maintains its finish longer.

Tip: Microfiber vegan leather works well for products that require a high-quality, consistent appearance and long-lasting performance.

Pros and Cons of Microfiber Leather

When evaluating the pros and cons of microfiber leather, several factors emerge:

Pros:

- High-quality texture and finish

- Excellent durability and water resistance

- Easy to clean and stain resistant

- Animal-free and more sustainable than genuine leather

- Moderate price compared to natural leather

Cons:

- Limited breathability compared to genuine leather

- Environmental concerns related to synthetic fiber production

- May peel or crack over time with heavy use

Consumers and designers should weigh these pros and cons before choosing microfiber vegan leather for their projects. The material offers a balance of high-quality appearance, ethical production, and practical benefits.

Who Should Choose Microfiber Vegan Leather

Best Use Cases

Microfiber vegan leather suits a wide range of applications. The automotive and furniture industries benefit most from this material. Manufacturers in these sectors prioritize sustainability, cost-effectiveness, and performance. They value the flexibility in design that microfiber offers. Car interiors and sofas require materials that resist abrasion and maintain a consistent appearance. Microfiber vegan leather meets these demands. Designers select it for products that need to look polished and withstand frequent use.

Fashion brands also favor microfiber vegan leather for accessories, footwear, and outerwear. The material provides a uniform texture and finish, which appeals to consumers seeking stylish and ethical options. Retailers highlight its easy to clean surface, making it ideal for busy households and commercial spaces. Students, professionals, and families appreciate products that require minimal maintenance. The stain resistance and durability make microfiber vegan leather a practical choice for everyday items.

Tip: Microfiber vegan leather works well for those who want animal-free products without sacrificing style or performance.

Who Might Avoid It

Some consumers may find microfiber vegan leather less suitable for their needs. Individuals who prioritize breathability in clothing or footwear might prefer natural materials. Genuine leather allows more airflow, which increases comfort in warm climates. People seeking heirloom-quality goods may avoid microfiber vegan leather due to longevity concerns. Over time, the material can peel or crack, especially with heavy use.

Eco-conscious buyers sometimes hesitate because of the environmental impact associated with synthetic fiber production and disposal. Those who require products that withstand extreme heat or industrial cleaning processes may encounter limitations. Artisans and collectors who value the unique character of natural leather often choose traditional options.

| Group | Reason to Avoid Microfiber Vegan Leather |

|---|---|

| Outdoor enthusiasts | Limited breathability |

| Collectors | Preference for natural patina |

| Eco-focused shoppers | Concerns about microplastic pollution |

| Industrial users | Heat sensitivity and cleaning restrictions |

Microfiber vegan leather offers durability, easy maintenance, and ethical appeal. Users benefit from its consistent texture and versatile applications. However, environmental concerns, limited breathability, and longevity issues remain important drawbacks.

- Best suited for those who value animal-free products and easy care.

- Less ideal for buyers seeking maximum breathability or heirloom quality.

Consider priorities such as durability, sustainability, and cost before selecting microfiber vegan leather for any project.

PREGUNTAS FRECUENTES

What makes microfiber vegan leather different from PU or PVC leather?

Microfiber vegan leather uses ultra-fine synthetic fibers for a more realistic leather feel and greater durability. PU and PVC leathers often feel less natural and may peel or crack sooner. Microfiber offers a higher-quality alternative for brands seeking premium finishes.

Can microfiber vegan leather be recycled?

Most microfiber vegan leather products cannot be recycled through standard municipal programs. Specialized facilities may accept them, but options remain limited. Consumers should check local recycling guidelines or contact manufacturers for disposal recommendations.

How should users clean microfiber vegan leather?

Manufacturers recommend wiping the surface with a soft cloth and mild soap. Avoid harsh chemicals or abrasive tools. For best results, spot clean spills quickly. This approach helps maintain the material’s finish and extends its lifespan.

Does microfiber vegan leather contain animal products?

Microfiber vegan leather contains no animal-derived ingredients. Manufacturers use synthetic fibers and polyurethane to create the material. This makes it suitable for vegans and those seeking cruelty-free alternatives.