Introduction: Navigating the Global Market for dream factory leather

In an increasingly competitive global marketplace, sourcing high-quality Dream Factory leather tools can be a daunting task for international B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, including Vietnam and Germany. With a myriad of options available, understanding the nuances of quality, functionality, and pricing becomes essential to making informed purchasing decisions. This guide serves as a comprehensive resource, delving into the various types of Dream Factory leather products, their applications in different industries, and strategies for vetting suppliers.

By equipping you with insights into the cost structures and market trends, this guide empowers buyers to navigate the complexities of sourcing. It highlights key considerations, such as product durability, usability, and the innovative design features that set Dream Factory tools apart in the leatherworking landscape. Whether you are an established manufacturer or a burgeoning artisan, understanding these elements will enhance your procurement strategy, ensuring you invest in tools that elevate your craftsmanship and meet your business objectives.

Explore the extensive range of Dream Factory leather tools and machines, and discover how to leverage this knowledge for strategic sourcing, ultimately driving growth and success in your business ventures.

Table Of Contents

- Top 2 Dream Factory Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for dream factory leather

- Understanding dream factory leather Types and Variations

- Key Industrial Applications of dream factory leather

- 3 Common User Pain Points for ‘dream factory leather’ & Their Solutions

- Strategic Material Selection Guide for dream factory leather

- In-depth Look: Manufacturing Processes and Quality Assurance for dream factory leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘dream factory leather’

- Comprehensive Cost and Pricing Analysis for dream factory leather Sourcing

- Alternatives Analysis: Comparing dream factory leather With Other Solutions

- Essential Technical Properties and Trade Terminology for dream factory leather

- Navigating Market Dynamics and Sourcing Trends in the dream factory leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of dream factory leather

- Strategic Sourcing Conclusion and Outlook for dream factory leather

- Important Disclaimer & Terms of Use

Understanding dream factory leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vegetable Tanned Leather | Naturally tanned, eco-friendly, develops a rich patina | High-end fashion, luxury goods | Pros: Sustainable, durable, ages beautifully. Cons: Longer tanning process, may be more expensive. |

| Chrome Tanned Leather | Fast tanning process, soft and supple feel | Mass production of bags, wallets, upholstery | Pros: Quick production, vibrant colors. Cons: Less eco-friendly, can lack character over time. |

| Suede | Soft, napped finish, lightweight | Footwear, garments, accessories | Pros: Versatile, adds texture. Cons: Less durable, can stain easily. |

| Exotic Leather (e.g., Alligator, Ostrich) | Unique textures and patterns, premium quality | Luxury handbags, high-end fashion items | Pros: Highly sought after, exclusive look. Cons: Costly, ethical sourcing concerns. |

| Full Grain Leather | Retains natural grain, very durable | High-quality leather goods, furniture | Pros: Long-lasting, develops a unique character. Cons: Can be expensive, requires maintenance. |

What are the Characteristics of Vegetable Tanned Leather and Its B2B Suitability?

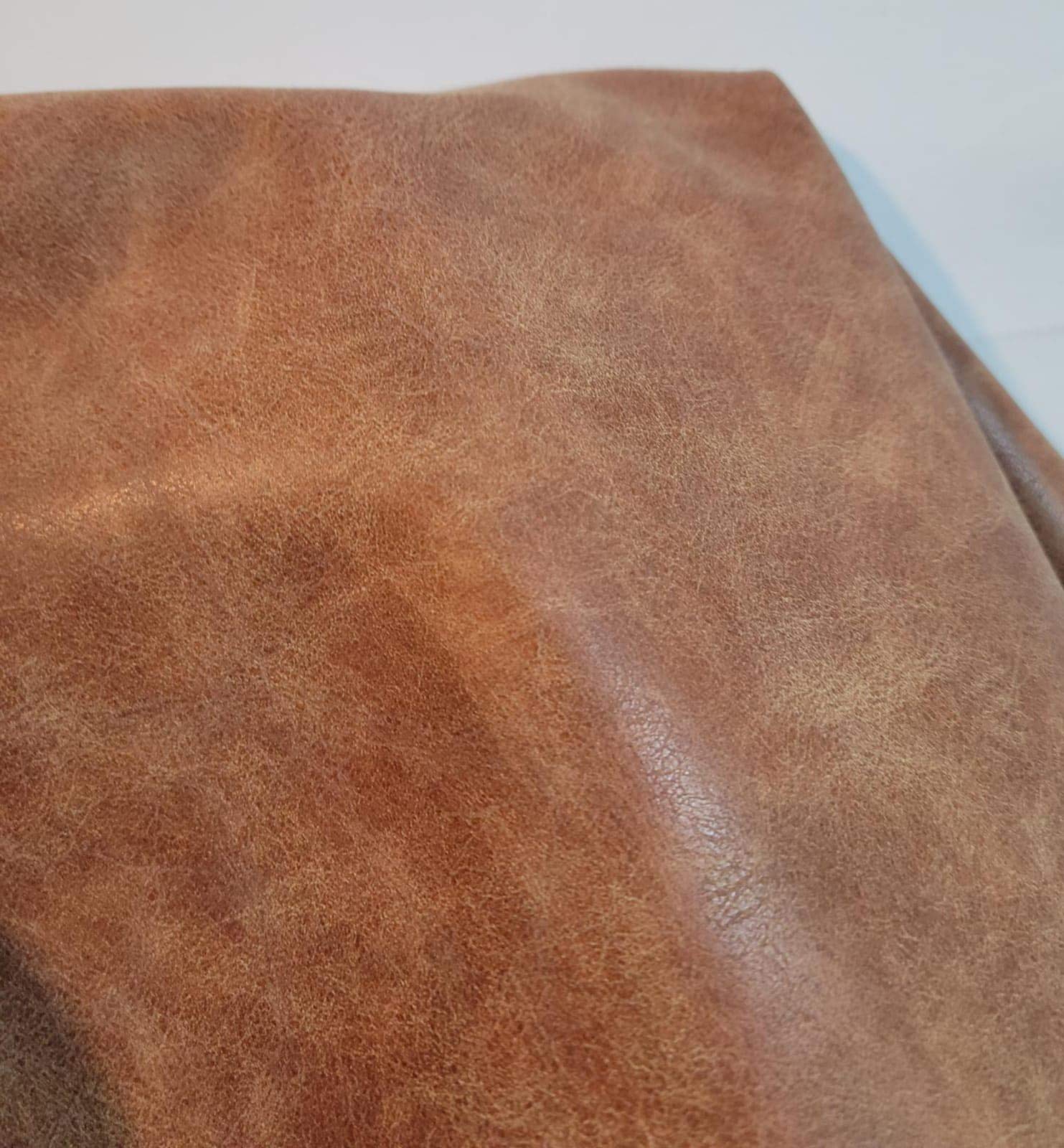

Vegetable tanned leather is renowned for its eco-friendly tanning process that utilizes natural materials. This type of leather develops a rich patina over time, making it highly desirable for high-end fashion and luxury goods. B2B buyers should consider its sustainability, as many consumers are increasingly seeking environmentally responsible products. However, the longer tanning process can lead to higher costs, making it essential for businesses to evaluate pricing strategies carefully.

How Does Chrome Tanned Leather Compare for Mass Production?

Chrome tanned leather is favored for its quick production time and soft, supple feel. This type of leather is widely used in mass production for items such as bags, wallets, and upholstery. B2B buyers can benefit from its vibrant colors and consistent quality, which is crucial for high-volume manufacturing. However, the environmental impact of chrome tanning may be a concern, requiring buyers to weigh the benefits of speed against sustainability.

Illustrative image related to dream factory leather

What Makes Suede a Versatile Choice for Various Applications?

Suede is characterized by its soft, napped finish, making it lightweight and versatile. This type of leather is commonly used in footwear, garments, and accessories. For B2B buyers, suede offers an opportunity to add texture and style to products. However, its durability is generally less than that of other leathers, and it can be prone to staining, which should be considered when targeting specific markets.

Why Choose Exotic Leather for Luxury Items?

Exotic leather, such as alligator or ostrich, is prized for its unique textures and patterns, making it a premium choice for luxury handbags and high-end fashion items. B2B buyers should recognize the exclusivity and high demand for these materials, which can significantly elevate a brand’s status. However, the cost and ethical sourcing concerns associated with exotic leathers require careful consideration and transparency in marketing strategies.

What are the Advantages of Full Grain Leather for High-Quality Products?

Full grain leather is celebrated for retaining its natural grain and exceptional durability, making it ideal for high-quality leather goods and furniture. B2B buyers should appreciate the long-lasting nature of this material, which can develop a unique character over time, appealing to consumers seeking authenticity. While full grain leather can be more expensive and requires proper maintenance, its quality often justifies the investment, especially in premium markets.

Key Industrial Applications of dream factory leather

| Industry/Sector | Specific Application of dream factory leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | Production of high-end leather garments | Enhances brand image through quality craftsmanship | Ensure compliance with local regulations and sourcing of ethical materials |

| Footwear | Manufacturing of premium leather shoes | Offers durability and style, appealing to luxury markets | Consider local weather conditions affecting leather care and longevity |

| Automotive | Interior leather fittings for vehicles | Improves aesthetic appeal and comfort for consumers | Assess compatibility with automotive standards and regulations in target markets |

| Furniture and Upholstery | Crafting luxury leather furniture | Adds value through high-quality materials and design | Evaluate local demand for custom designs and eco-friendly options |

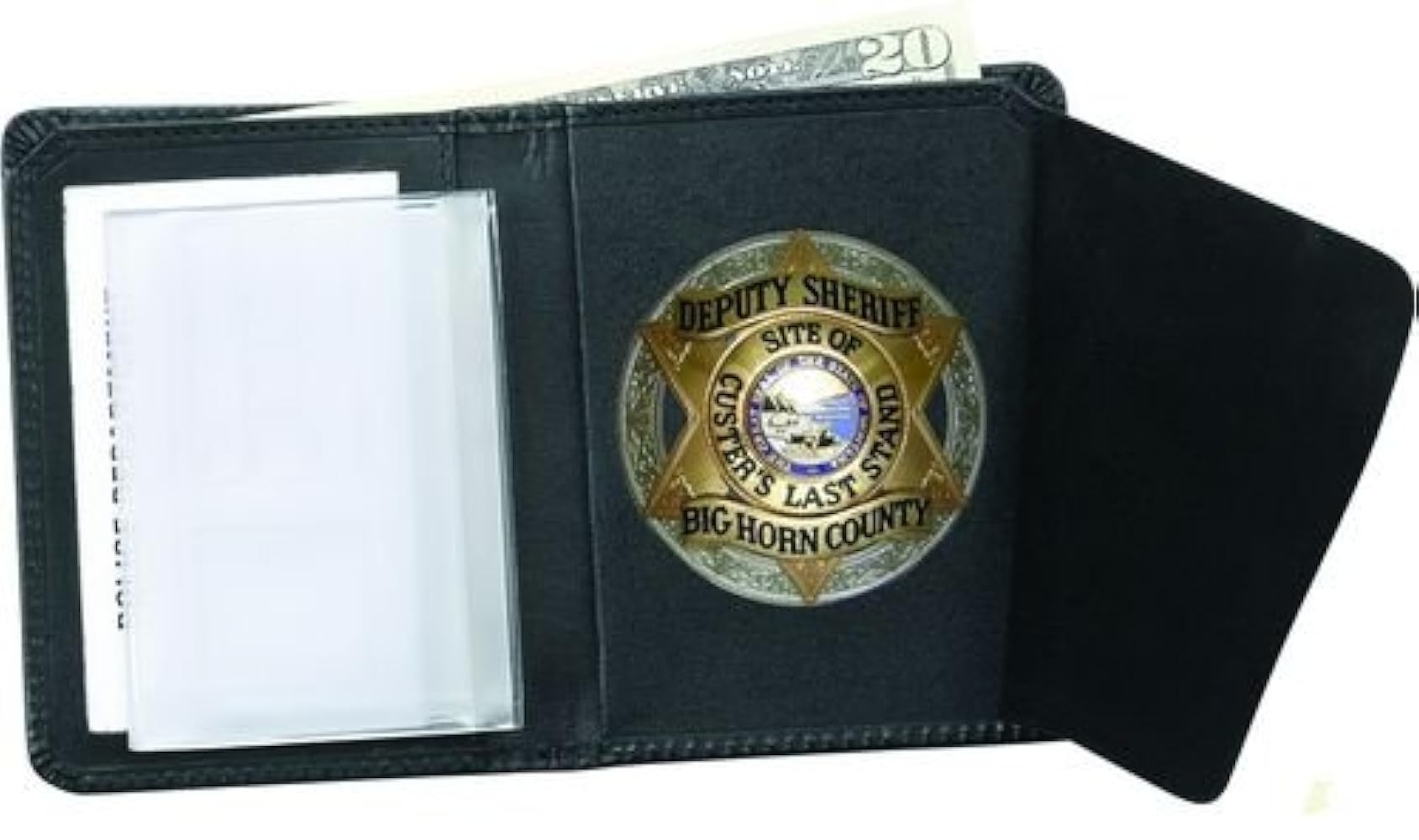

| Crafting and DIY | Tools for leather crafting | Simplifies production processes and enhances creativity | Look for local distributors for tools and training programs to support artisans |

How is Dream Factory Leather Used in the Fashion and Apparel Industry?

Dream Factory leather is highly sought after in the fashion industry for creating high-end leather garments. Its superior quality and craftsmanship allow brands to differentiate themselves in a competitive market. This leather not only meets aesthetic demands but also provides durability, making it ideal for luxury fashion. International buyers should ensure that the leather complies with local regulations and that the sourcing process adheres to ethical standards to maintain brand integrity.

What are the Applications of Dream Factory Leather in Footwear Production?

In the footwear sector, Dream Factory leather is utilized to manufacture premium leather shoes that combine style and durability. The leather’s ability to withstand wear while providing comfort makes it a preferred choice among high-end brands. Buyers from diverse regions, particularly those facing varying climatic conditions, should consider the leather’s care requirements and ensure that it meets local consumer preferences for both style and functionality.

How is Dream Factory Leather Applied in the Automotive Industry?

Dream Factory leather plays a crucial role in enhancing the interior aesthetics of vehicles. It is used for upholstery, seat covers, and trim, providing a luxurious feel that appeals to consumers. The challenge for international buyers lies in ensuring that the leather meets automotive standards and regulations specific to their markets. Additionally, understanding the local consumer preferences for colors and textures can significantly impact sales.

What Role Does Dream Factory Leather Play in Furniture and Upholstery?

In the furniture industry, Dream Factory leather is favored for crafting luxurious leather furniture pieces. Its unique qualities add significant value, enabling manufacturers to cater to high-end markets. Buyers should evaluate local demand for bespoke designs and consider sourcing eco-friendly options, as sustainability is increasingly becoming a key factor in consumer purchasing decisions.

How is Dream Factory Leather Beneficial for Crafting and DIY Projects?

For crafting and DIY enthusiasts, Dream Factory leather provides high-quality materials and tools that simplify the leather crafting process. The availability of innovative tools enhances creativity and allows artisans to produce intricate designs with ease. B2B buyers should seek local distributors who can offer not just the materials but also training programs to support skill development among artisans, fostering a vibrant crafting community.

Illustrative image related to dream factory leather

3 Common User Pain Points for ‘dream factory leather’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Leather Tools

The Problem: B2B buyers often struggle to find reliable suppliers of high-quality leather tools that meet their production needs. Many suppliers offer subpar products that compromise the quality of the leatherwork. This can lead to delays, increased costs, and ultimately unsatisfactory end products. Buyers may also face challenges in verifying the authenticity and quality of the tools, particularly when sourcing from international markets.

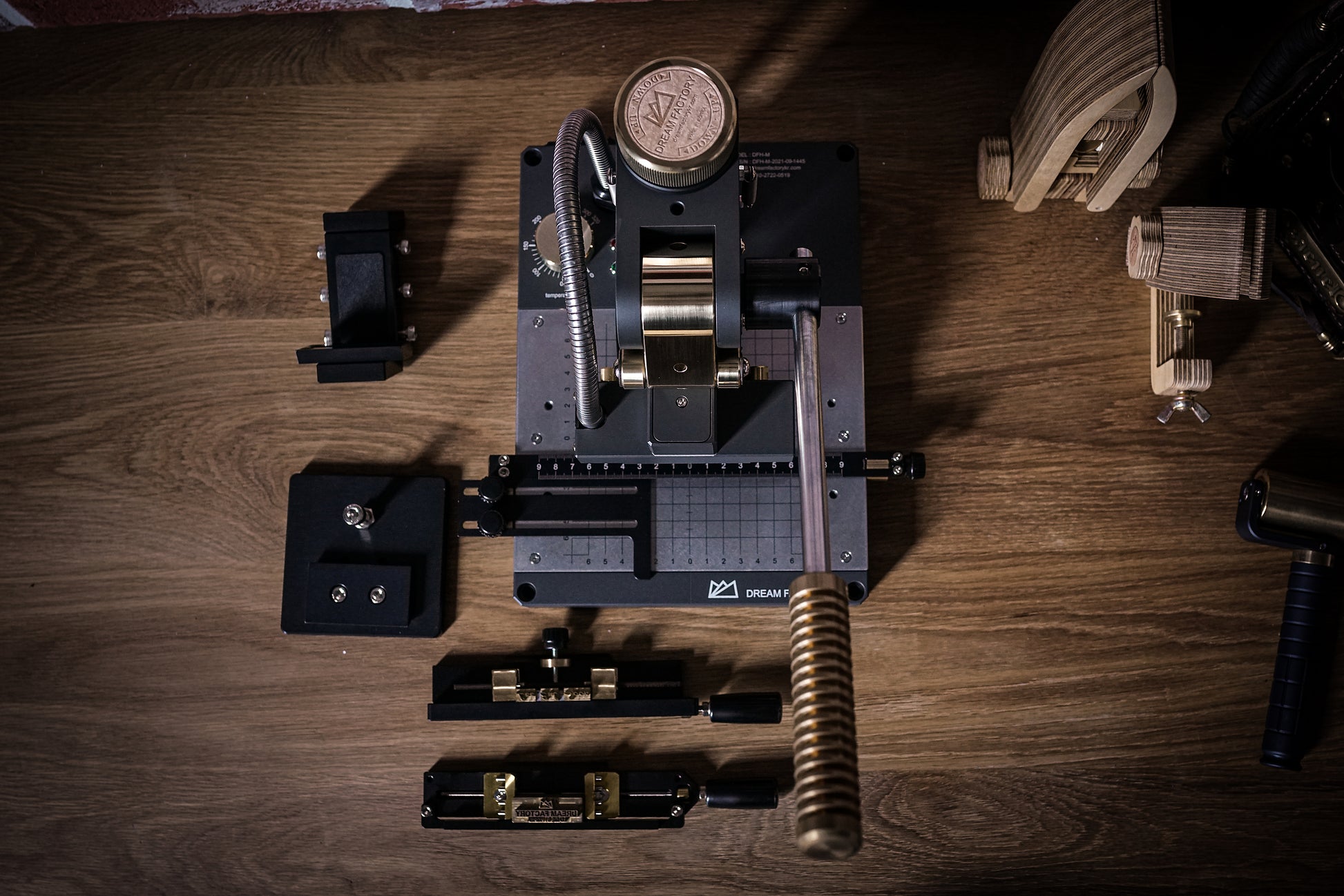

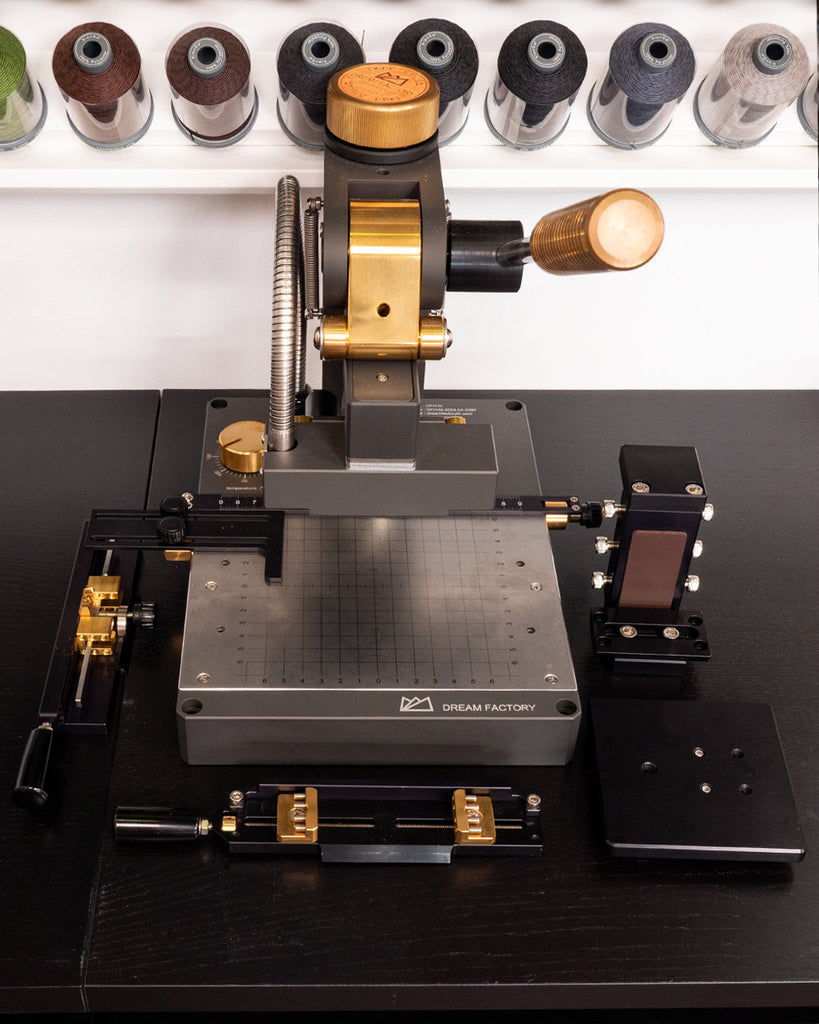

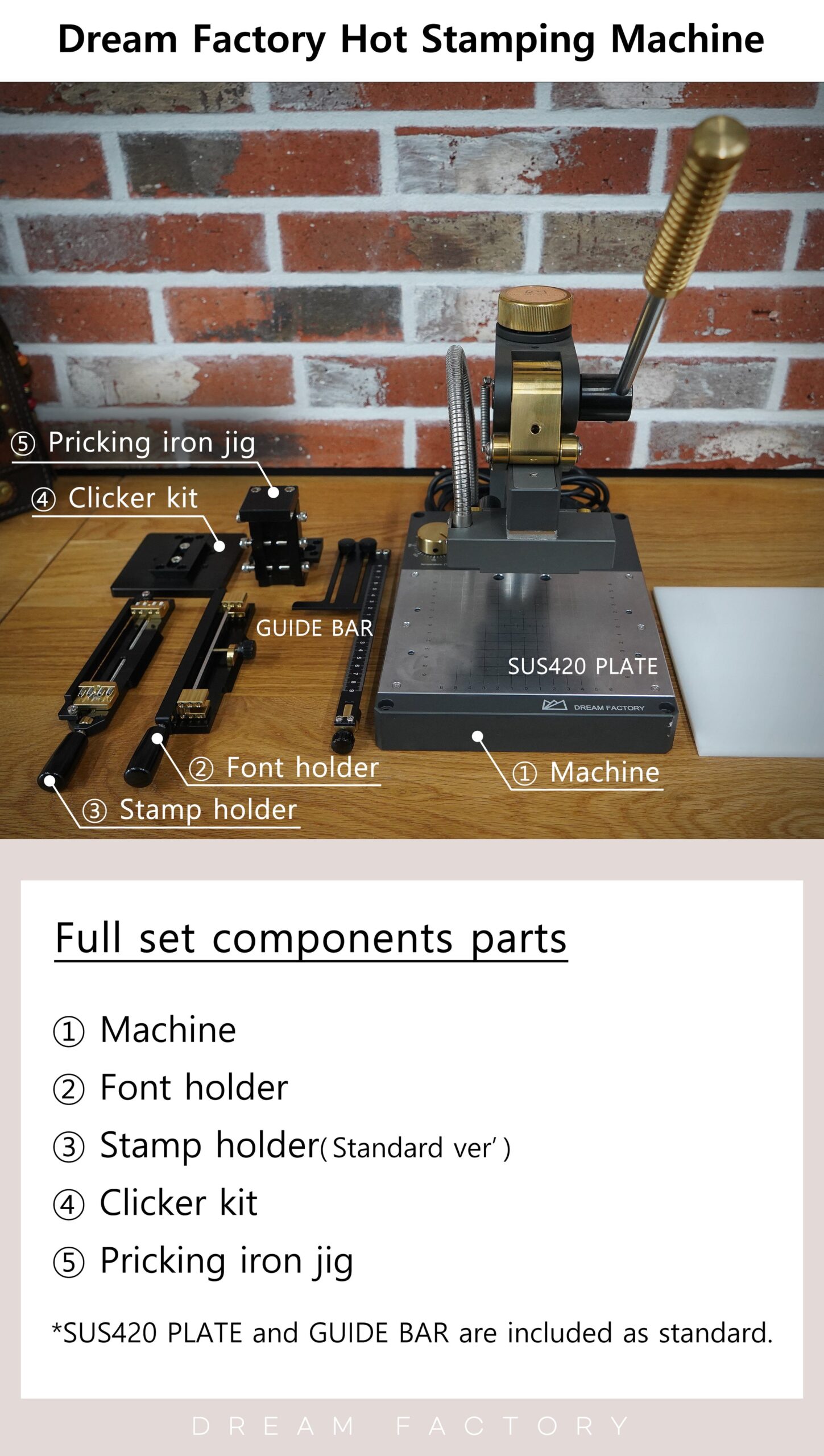

The Solution: To address this issue, buyers should conduct thorough research and establish relationships with reputable suppliers like Dream Factory Leather. Start by evaluating the supplier’s history, customer reviews, and product offerings. When sourcing, prioritize tools that are specifically designed for durability and precision, such as the adjustable folding stitching pony or the hot stamping machine from Dream Factory. Request product samples to assess quality firsthand before making bulk purchases. Additionally, consider leveraging trade shows or industry events to connect with manufacturers and gain insights into new innovations in leatherworking tools. Building a solid partnership with a trusted supplier can greatly enhance the quality of your leatherwork and reduce the risk of sourcing inferior products.

Scenario 2: Challenges with Tool Usability and Adaptability

The Problem: Many B2B buyers encounter issues when it comes to the usability and adaptability of leatherworking tools. As businesses grow and evolve, their production processes may change, requiring tools that can adapt to new techniques or materials. Buyers often find that some tools are not user-friendly or do not cater to various skill levels, which can hinder productivity and lead to employee frustration.

The Solution: To overcome usability challenges, buyers should look for tools that are designed with versatility and ease of use in mind. Dream Factory offers a range of products, such as the 5-in-1 leather craft multi-tool, which can simplify various tasks and accommodate different skill levels. Buyers should invest time in training their staff on the proper use of these tools to ensure everyone is comfortable and efficient. Furthermore, consider tools that offer adjustable features or multiple functions to cater to diverse projects. Engaging with the supplier for training resources or manuals can also enhance the overall usability of the tools, ensuring that all employees can maximize productivity and creativity.

Illustrative image related to dream factory leather

Scenario 3: Navigating Import Regulations and Shipping Costs

The Problem: International B2B buyers often face significant hurdles regarding import regulations and shipping costs when sourcing leather tools from abroad. These challenges can lead to unexpected delays, increased expenses, and difficulties in ensuring that products meet local compliance standards. For buyers in regions like Africa or South America, where logistics can be more complex, navigating these issues becomes even more critical.

The Solution: To mitigate these challenges, buyers should familiarize themselves with the import regulations specific to their country and the countries they are sourcing from. Collaborating with experienced logistics partners who specialize in international shipping can help streamline the process and reduce costs. When ordering from Dream Factory, inquire about bulk shipping options or distribution centers that may be closer to your location, as this can significantly reduce freight costs. Additionally, ensure that all necessary documentation is in order to avoid customs delays. By being proactive in understanding import regulations and leveraging the expertise of logistics professionals, buyers can enhance their sourcing efficiency and minimize unexpected hurdles in the supply chain.

Strategic Material Selection Guide for dream factory leather

What Are the Key Materials Used in Dream Factory Leather Products?

When selecting materials for Dream Factory leather products, it’s essential to consider properties that affect performance and durability. Here, we analyze four common materials used in the production of leather tools and machines, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

Illustrative image related to dream factory leather

How Does Cowhide Perform in Leather Crafting?

Cowhide is one of the most prevalent materials used in leather crafting due to its robust nature. It boasts high tensile strength, making it suitable for a variety of applications, including bags, wallets, and belts. Cowhide can withstand moderate temperature and pressure, providing a reliable performance in everyday use.

Pros: Its durability and resistance to wear make it ideal for high-traffic items. Additionally, cowhide is relatively affordable, making it accessible for both small and large-scale manufacturers.

Cons: However, cowhide can be heavy, which may not be suitable for all products. It also requires significant processing, which can increase manufacturing complexity.

Illustrative image related to dream factory leather

Impact on Application: Cowhide is compatible with various media, including dyes and finishes, allowing for diverse aesthetic options.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is critical. Buyers from regions like Europe may prefer sustainably sourced cowhide, aligning with environmental regulations.

What Role Does Vegetable-Tanned Leather Play?

Vegetable-tanned leather is renowned for its eco-friendly properties, as it is tanned using natural tannins from plants. This material is highly breathable and develops a unique patina over time, making it aesthetically appealing for high-end products.

Pros: Its natural characteristics make it safe for a variety of applications, especially in items that come into contact with skin. Additionally, it is relatively easy to work with, allowing for intricate designs.

Illustrative image related to dream factory leather

Cons: On the downside, vegetable-tanned leather can be less water-resistant than chrome-tanned alternatives, making it less suitable for wet environments. It is also generally more expensive due to the labor-intensive tanning process.

Impact on Application: This leather is ideal for artisanal products where quality and craftsmanship are prioritized.

Considerations for International Buyers: Buyers in Africa and South America may find the higher cost a barrier, but the increasing demand for sustainable products can justify the investment.

How Does Synthetic Leather Compare?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers a cost-effective alternative to traditional leather. It is designed to mimic the appearance and feel of natural leather while providing additional benefits.

Illustrative image related to dream factory leather

Pros: Synthetic leather is lightweight, water-resistant, and easy to clean, making it suitable for various applications, including upholstery and fashion accessories.

Cons: However, it lacks the breathability and durability of genuine leather, which can lead to wear over time. Additionally, the environmental impact of synthetic materials can be a concern for eco-conscious buyers.

Impact on Application: Its versatility allows for use in a wide range of products, but it may not appeal to traditional leather artisans.

Considerations for International Buyers: Buyers in Europe may be more inclined to select synthetic options that meet EU regulations for environmental safety and sustainability.

What Advantages Does Suede Offer?

Suede, a type of leather with a soft, napped finish, is often used in fashion and luxury items. It provides a unique texture and aesthetic appeal that is highly sought after.

Pros: Suede is lightweight and offers a luxurious feel, making it perfect for high-end products. It also has good thermal insulation properties.

Cons: However, suede is less durable and more susceptible to staining and damage from water, which can limit its applications.

Illustrative image related to dream factory leather

Impact on Application: Suede is particularly effective in fashion accessories but requires careful handling and maintenance.

Considerations for International Buyers: Buyers from regions with humid climates, such as parts of Africa and the Middle East, should consider the material’s limitations regarding moisture exposure.

Summary Table of Material Selection for Dream Factory Leather

| Material | Typical Use Case for dream factory leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cowhide | Bags, wallets, belts | High durability and strength | Heavy and complex to process | Medium |

| Vegetable-Tanned Leather | High-end artisanal products | Eco-friendly and develops patina | Less water-resistant | High |

| Synthetic Leather | Upholstery, fashion accessories | Lightweight and easy to clean | Less durable than genuine leather | Low |

| Suede | Luxury fashion items | Soft texture and aesthetic appeal | Susceptible to stains and moisture | Medium |

This guide provides international B2B buyers with a comprehensive understanding of material options, helping them make informed decisions based on performance, cost, and application suitability.

In-depth Look: Manufacturing Processes and Quality Assurance for dream factory leather

What Are the Main Stages in the Manufacturing Process of Dream Factory Leather?

The manufacturing process for Dream Factory leather involves several critical stages that ensure the creation of high-quality leather products. Understanding these stages can provide B2B buyers with insights into the craftsmanship and quality they can expect.

Material Preparation: How Are Leather Materials Selected and Processed?

The journey begins with the careful selection of raw materials. Dream Factory prioritizes high-quality hides, often sourced from reputable tanneries that adhere to ethical and sustainable practices. The hides undergo thorough inspection to ensure they meet the required standards for quality and durability.

Once selected, the hides are processed through various methods, including vegetable tanning and chrome tanning. These processes not only enhance the leather’s aesthetic qualities but also ensure its longevity and resistance to wear. The preparation phase also includes cutting the hides into manageable sizes for further processing, ensuring minimal waste.

Forming: What Techniques Are Used to Shape Leather Products?

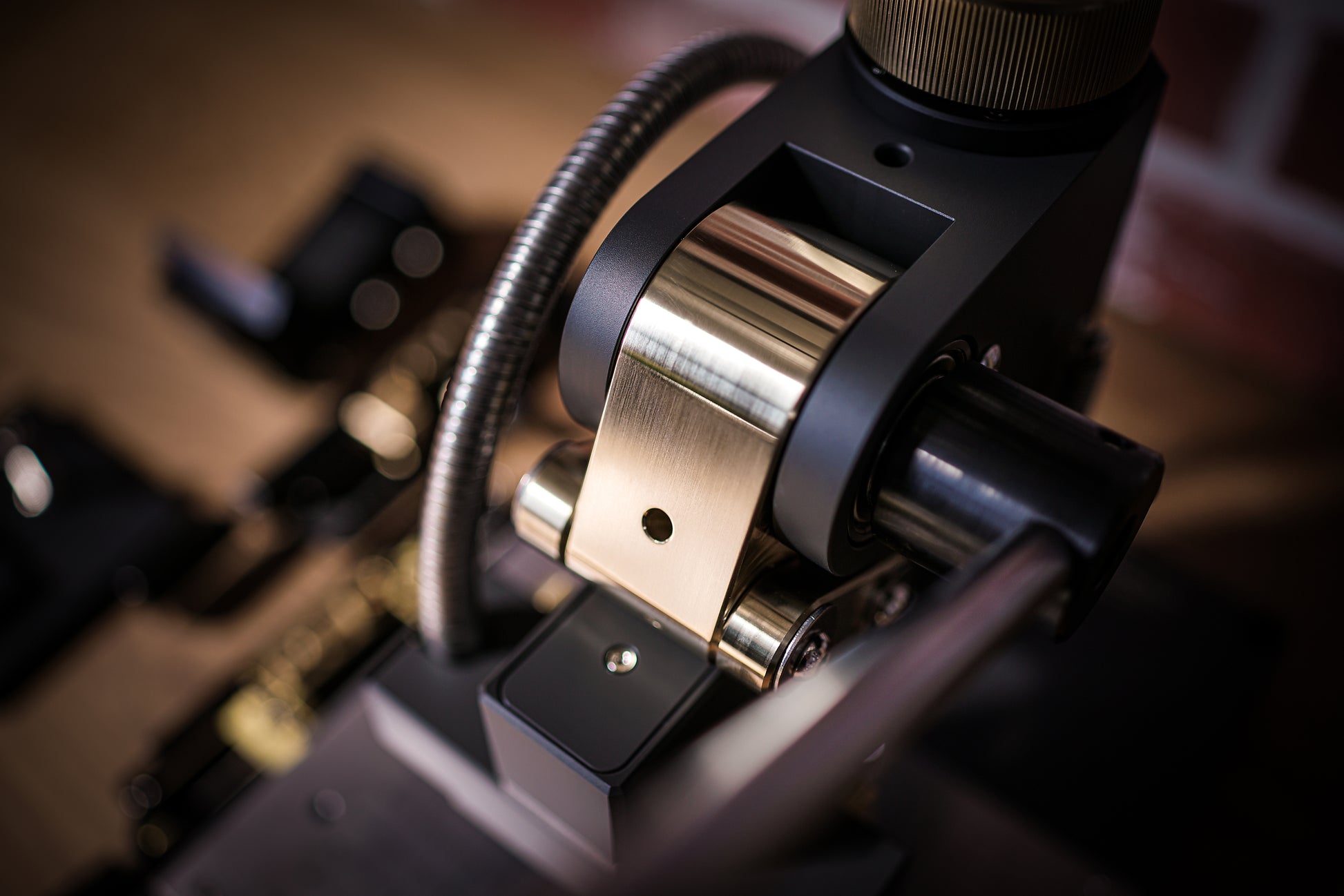

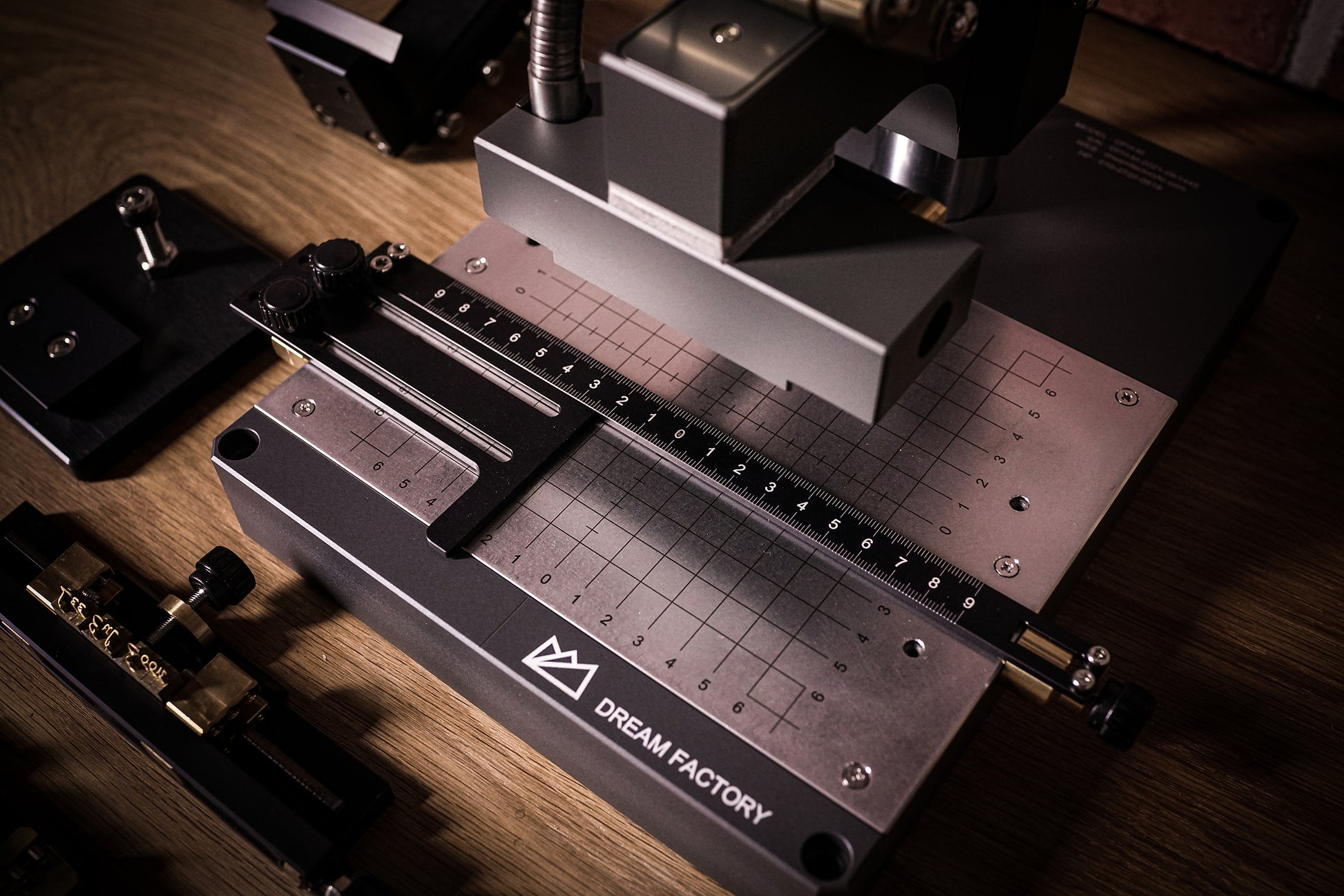

After the materials are prepared, the next stage involves forming. This includes techniques such as cutting, stamping, and molding. Dream Factory utilizes advanced machinery, including clicker presses and stamping machines, to achieve precise cuts and designs.

Artisans skilled in leatherwork also play a vital role in this phase. They employ traditional handcrafting techniques alongside modern technology to ensure that every piece retains a unique character while meeting design specifications. This blend of craftsmanship and technology enhances the overall quality of the final product.

Assembly: How Is Leather Assembled into Final Products?

Once the leather pieces are formed, they move to the assembly stage. This involves stitching, gluing, and securing various components together. Dream Factory emphasizes the use of high-strength threads and adhesives to ensure durability.

Illustrative image related to dream factory leather

Quality control checkpoints are integrated into this stage, where artisans inspect seams and joints to confirm they meet stringent quality standards. The assembly process is crucial for the overall integrity of the product, as weak points can lead to premature wear and tear.

Finishing: What Are the Final Steps in Leather Production?

The finishing stage is where Dream Factory leather truly shines. This phase includes sanding, dyeing, and applying protective coatings to enhance the leather’s appearance and functionality. The finishing techniques used are designed to provide a smooth surface while maintaining the leather’s natural texture.

Additionally, embossing and hot stamping techniques are employed to add unique designs or branding elements. These finishing touches not only elevate the product’s aesthetic appeal but also contribute to its marketability.

What Quality Assurance Measures Are Implemented in Dream Factory Leather Production?

Quality assurance is paramount in the manufacturing of Dream Factory leather, ensuring that every product meets international and industry-specific standards. B2B buyers can benefit from understanding these measures to ensure they are sourcing high-quality leather products.

Which International Standards Are Applicable to Dream Factory Leather?

Dream Factory adheres to several international quality standards, including ISO 9001, which focuses on quality management systems. Compliance with these standards demonstrates a commitment to consistent quality, customer satisfaction, and continuous improvement.

Illustrative image related to dream factory leather

In addition to ISO standards, Dream Factory products may also meet industry-specific certifications such as CE marking for products sold in Europe, ensuring compliance with health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are strategically placed throughout the manufacturing process to ensure that each stage meets predefined criteria. The main checkpoints include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to confirm they meet quality specifications.

- In-Process Quality Control (IPQC): During the forming and assembly stages, products are regularly inspected to identify any defects early in the process.

- Final Quality Control (FQC): Before products are packaged and shipped, a final inspection is conducted to ensure they meet all quality standards and specifications.

These checkpoints help identify issues early, reducing waste and ensuring that only products that meet quality standards reach the market.

Illustrative image related to dream factory leather

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, verifying a supplier’s quality control measures is essential to ensure reliability and trustworthiness. Here are some actionable steps buyers can take:

What Methods Can Be Used to Verify Supplier Quality Control?

-

Supplier Audits: Conducting on-site audits allows buyers to observe the manufacturing process firsthand and assess the quality control measures in place. This can help identify any potential issues and verify compliance with international standards.

-

Quality Reports: Requesting quality assurance reports can provide insights into the supplier’s quality control practices. These reports should detail inspection results, defect rates, and corrective actions taken in case of non-compliance.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures. These services can conduct random inspections and provide detailed reports on product quality and compliance.

-

Certification Verification: Buyers should verify any certifications claimed by the supplier, such as ISO 9001 or CE marking. This can often be done through official certification bodies or industry associations.

What Are the Unique Quality Control Nuances for International B2B Buyers?

International B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, must navigate specific quality control nuances. Understanding these can aid in making informed purchasing decisions.

How Does Regional Variation Impact Quality Standards?

Quality standards can vary significantly across regions. For instance, European markets may have stricter regulations regarding environmental impact and product safety compared to other regions. Buyers should familiarize themselves with these standards to ensure compliance.

Additionally, cultural differences may influence quality expectations. Buyers should communicate their quality requirements clearly and ensure that suppliers understand and are capable of meeting these expectations.

Illustrative image related to dream factory leather

What Role Does Supply Chain Transparency Play in Quality Assurance?

Supply chain transparency is critical for ensuring quality in international trade. Buyers should seek suppliers who are willing to provide detailed information about their sourcing, manufacturing processes, and quality control measures. This transparency can help build trust and ensure that the products meet the required standards.

In conclusion, the manufacturing processes and quality assurance measures employed by Dream Factory leather are designed to meet the high standards expected by B2B buyers. By understanding these processes, buyers can make informed decisions and ensure they receive products that meet their needs for quality, durability, and performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dream factory leather’

To assist international B2B buyers in procuring high-quality leather tools and products from Dream Factory Leather, this step-by-step checklist provides essential actions to ensure a successful sourcing process. By following these guidelines, buyers can make informed decisions that meet their specific needs.

Illustrative image related to dream factory leather

Step 1: Define Your Technical Specifications

Establish clear technical specifications for the leather tools you intend to procure. This includes the type of tools required, such as stitching ponies, stamping machines, or pricking irons, along with size, material preferences, and any specific features necessary for your production processes. Having precise specifications helps streamline communication with suppliers and ensures you receive products that meet your operational requirements.

Step 2: Research and Identify Reputable Suppliers

Conduct thorough research to identify reputable suppliers of Dream Factory Leather products. Look for suppliers with positive reviews and a strong presence in the leather goods industry, especially those who cater to your geographical market, such as Africa, South America, the Middle East, or Europe. Utilize industry directories, trade shows, and online platforms to compile a list of potential suppliers.

Step 3: Evaluate Potential Suppliers

Before finalizing any agreements, it’s crucial to evaluate potential suppliers comprehensively. Request company profiles, product catalogs, and references from businesses in similar sectors. Pay attention to their experience with international shipping and any certifications they hold, as these factors can greatly influence product quality and reliability.

Step 4: Verify Quality Assurance Processes

Ensure that the suppliers have robust quality assurance processes in place. Inquire about their production methods, material sourcing, and testing protocols for their leather tools. Confirm that their products meet international standards to minimize the risk of receiving defective items that could impact your production line.

Step 5: Request Samples for Assessment

Before placing a large order, request samples of the tools you’re interested in. This step allows you to assess the quality, craftsmanship, and functionality of the products firsthand. Evaluate how well the samples meet your specifications and consider how they align with your production needs and expectations.

Illustrative image related to dream factory leather

Step 6: Negotiate Terms and Pricing

Once you’ve identified a suitable supplier and assessed product quality, engage in negotiations regarding pricing, payment terms, and delivery schedules. Be clear about your budget and any volume discounts you might need. Effective negotiation can lead to better pricing and more favorable terms, ultimately impacting your overall costs.

Step 7: Establish Clear Communication Channels

Finally, establish clear communication channels with your selected supplier. Ensure that you have direct lines of communication for discussing orders, addressing any issues, and receiving updates on delivery timelines. Effective communication fosters a strong partnership and can help resolve any potential challenges that may arise during the sourcing process.

By following this checklist, B2B buyers can effectively navigate the procurement process for Dream Factory Leather tools, ensuring they secure high-quality products that meet their business needs.

Comprehensive Cost and Pricing Analysis for dream factory leather Sourcing

What Are the Key Cost Components in Dream Factory Leather Sourcing?

When analyzing the cost structure of sourcing Dream Factory leather tools, several critical components must be considered. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The primary cost driver is the quality of the leather and other materials used in production. Dream Factory emphasizes high-quality components, such as birch plywood and brass accents, which can lead to higher material costs but ultimately enhance the product’s durability and performance.

-

Labor: Skilled artisans are essential for the production of premium leather tools. Labor costs will vary based on location and the level of expertise required. Countries with lower labor costs may provide a competitive advantage; however, the quality of craftsmanship is paramount.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, rent, and maintenance of equipment. Efficient manufacturing processes can help minimize these overhead costs while maintaining quality.

-

Tooling: The initial investment in specialized tooling and machinery is significant. For example, Dream Factory’s hot stamping machines and adjustable stitching ponies require precision engineering, which adds to the upfront costs but ensures better long-term performance.

-

Quality Control (QC): Rigorous QC processes are crucial to ensure that products meet the high standards expected by customers. This may involve additional labor and testing costs but is necessary to maintain brand reputation.

-

Logistics: Shipping and handling costs can vary greatly depending on the destination. International buyers must consider freight charges, customs duties, and potential delays, which can significantly impact the total cost of procurement.

-

Margin: Finally, the profit margin will depend on the brand’s positioning in the market. Dream Factory aims to provide value through high-quality products, which justifies a higher margin compared to lower-end competitors.

How Do Price Influencers Affect B2B Buyers of Dream Factory Leather?

Several factors influence the pricing of Dream Factory leather tools, which international B2B buyers should consider:

Illustrative image related to dream factory leather

-

Volume/MOQ: Purchasing in bulk can lead to significant discounts. Buyers should negotiate minimum order quantities (MOQs) to lower per-unit costs.

-

Specifications and Customization: Customized tools tailored to specific needs may incur additional costs. Buyers should assess whether the added value justifies the higher price.

-

Materials and Quality Certifications: The use of premium materials and certifications (like ISO or CE) can increase costs but also enhance product credibility. Buyers should weigh the benefits of certification against the price increase.

-

Supplier Factors: The reputation and reliability of the supplier can influence price. Established brands may charge a premium due to their proven track record, while new entrants may offer lower prices to gain market share.

-

Incoterms: Understanding shipping terms is crucial. Different Incoterms can shift the responsibility for costs and risks, affecting the final price. Buyers should clarify these terms to avoid unexpected expenses.

What Buyer Tips Can Help Achieve Cost-Efficiency in Dream Factory Leather Sourcing?

-

Negotiation Strategies: Engage suppliers in discussions about pricing and terms. Building a strong relationship can lead to better deals and flexible payment options.

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the upfront price. Consider maintenance, durability, and potential resale value when assessing the overall investment.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be mindful of currency fluctuations, trade tariffs, and local regulations that may affect pricing.

-

Research Market Trends: Stay informed about industry trends and competitor pricing. This knowledge can empower buyers during negotiations and help them make informed purchasing decisions.

-

Leverage Reviews and Feedback: Utilize feedback from other buyers to assess product value and performance. This can help in making more informed decisions and identifying potential pitfalls.

In conclusion, navigating the cost and pricing landscape for Dream Factory leather tools requires a thorough understanding of various cost components and price influencers. By leveraging strategic negotiation and understanding the total cost of ownership, international B2B buyers can optimize their sourcing decisions for maximum efficiency and value.

Alternatives Analysis: Comparing dream factory leather With Other Solutions

Understanding Alternatives in Leatherworking Tools

When evaluating tools and equipment for leatherworking, it’s crucial for international B2B buyers to consider various alternatives that can meet specific needs and preferences. Dream Factory Leather tools are recognized for their quality and innovation, but understanding how they stack up against other options can lead to more informed purchasing decisions. Below, we compare Dream Factory Leather tools with two notable alternatives: Tandy Leather Tools and Craftool.

Comparison Table

| Comparison Aspect | Dream Factory Leather | Tandy Leather Tools | Craftool |

|---|---|---|---|

| Performance | High precision, durable | Reliable but varied quality | Consistent quality, user-friendly |

| Cost | Moderate to high price range | Affordable options available | Mid-range pricing |

| Ease of Implementation | User-friendly designs | Some tools require assembly | Straightforward setup |

| Maintenance | Low maintenance | Moderate, depends on usage | Low maintenance |

| Best Use Case | Professional artisans, high-end craft | Beginners, hobbyists | General leatherworking needs |

Detailed Breakdown of Alternatives

Tandy Leather Tools

Tandy Leather is a well-established name in the leatherworking industry, known for providing a wide range of tools and supplies. The primary advantage of Tandy tools is their affordability, making them accessible for beginners and hobbyists. However, the quality can vary significantly across different products, which may affect the final outcome of projects. While Tandy offers some high-quality items, buyers should be cautious and research specific tools before purchasing to ensure they meet professional standards.

Craftool

Craftool is another reputable brand that provides a solid selection of leatherworking tools. Their products are designed with usability in mind, catering to both beginners and experienced artisans. Craftool’s tools are often praised for their consistency in quality, which helps users achieve reliable results. The price point is generally mid-range, making them a viable option for those seeking balance between cost and quality. However, Craftool may not have the same level of innovation or advanced features found in Dream Factory tools, which could limit some artisans looking for specialized equipment.

Conclusion: How to Choose the Right Leatherworking Tools

Selecting the right leatherworking tools requires careful consideration of your specific needs, budget, and the level of expertise. Dream Factory Leather tools excel in precision and innovation, making them ideal for professional artisans who value quality and performance. In contrast, Tandy Leather and Craftool offer more budget-friendly options that can be great for beginners or general use. Ultimately, B2B buyers should evaluate the intended application of the tools, their performance requirements, and the overall investment they are willing to make. By comparing these alternatives, businesses can make informed decisions that align with their operational goals and craftsmanship standards.

Illustrative image related to dream factory leather

Essential Technical Properties and Trade Terminology for dream factory leather

What Are the Key Technical Properties of Dream Factory Leather Tools?

Understanding the essential technical properties of Dream Factory leather tools is crucial for B2B buyers aiming to enhance their production quality and efficiency. Here are some critical specifications:

-

Material Grade

Dream Factory tools are crafted from high-grade materials, such as birch plywood and brass. The material grade affects durability and performance, making it vital for buyers to ensure they are investing in tools that can withstand rigorous use. High-quality materials lead to lower replacement rates and improved productivity. -

Precision Tolerance

Precision tolerance refers to the allowable deviation in dimensions during manufacturing. Dream Factory tools are designed with high precision tolerances, which ensures consistent results in leather crafting. For B2B buyers, this means fewer errors in production and higher quality finished products, crucial in competitive markets. -

Weight and Portability

Many Dream Factory tools, such as the adjustable folding stitching pony, are designed to be lightweight and portable. This is particularly important for artisans and businesses that require mobility, allowing them to transport tools easily without compromising on performance. Portability can enhance flexibility in production locations, catering to diverse client needs. -

Adjustability Features

Tools like the stitching pony come with adjustable features, allowing users to customize settings for different projects. This adaptability is essential for businesses that handle a variety of leather products, enabling them to switch between tasks with minimal downtime. It also enhances user experience, making the crafting process more enjoyable. -

Durability Ratings

Durability ratings indicate how well tools can endure wear and tear over time. Dream Factory tools are engineered for longevity, providing excellent value for investment. B2B buyers must consider durability to minimize maintenance costs and ensure continuous operations without interruptions. -

Safety Standards Compliance

Compliance with safety standards is crucial for all industrial tools. Dream Factory tools are built to meet international safety guidelines, ensuring that users are protected while operating them. For businesses, adhering to safety standards reduces liability risks and fosters a safe working environment.

What Common Trade Terms Should B2B Buyers Understand When Purchasing Dream Factory Leather Tools?

Familiarity with industry jargon is essential for B2B buyers to facilitate smoother transactions and negotiations. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify trusted suppliers and ensure they are purchasing high-quality tools that meet specific needs. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to manage inventory costs effectively and to negotiate better pricing based on larger orders, which can lead to significant savings. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit bids from suppliers for specific products or services. Crafting a clear RFQ can help buyers receive accurate pricing and terms, allowing for informed decision-making in the procurement process. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk transfer, and delivery obligations, ensuring smoother logistics and compliance. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times is essential for inventory planning and production scheduling, helping businesses to avoid delays in their supply chain. -

Warranty and Service Agreement

A warranty is a guarantee provided by the manufacturer regarding the condition of the product. Service agreements can outline the terms for maintenance and support. Buyers should review these documents carefully to ensure they are protected against defects and have access to necessary support.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing Dream Factory leather tools, ultimately enhancing their production capabilities and market competitiveness.

Navigating Market Dynamics and Sourcing Trends in the dream factory leather Sector

What Are the Key Market Dynamics and Trends in the Dream Factory Leather Sector?

The global leather market, particularly the dream factory leather sector, is experiencing significant growth, driven by rising consumer demand for high-quality leather products across various industries. Key trends include the increasing utilization of advanced technology in leather crafting, such as automated cutting and embossing machines, which streamline production processes. Moreover, the rise of e-commerce platforms is facilitating direct trade between manufacturers and international buyers, particularly from regions like Africa, South America, the Middle East, and Europe. For instance, countries like Vietnam and Germany are becoming pivotal players due to their strategic positions in the supply chain, providing access to both raw materials and skilled craftsmanship.

Illustrative image related to dream factory leather

Emerging sourcing trends indicate a shift towards more personalized and customizable leather goods, allowing businesses to cater to niche markets. Additionally, digitalization is reshaping traditional sourcing methods, enabling B2B buyers to leverage online marketplaces for better pricing and inventory management. As manufacturers adopt more sustainable practices, buyers are increasingly seeking suppliers who can provide transparent information regarding their sourcing processes and materials used.

How Is Sustainability and Ethical Sourcing Impacting the Dream Factory Leather Industry?

Sustainability is becoming a critical consideration for B2B buyers in the dream factory leather sector. The environmental impact of leather production, particularly concerning water usage, chemical waste, and carbon emissions, has prompted a shift towards more sustainable practices. Buyers are now prioritizing suppliers who implement eco-friendly methods, such as vegetable tanning and the use of recycled materials, which significantly reduce the ecological footprint of leather products.

Ethical sourcing is also gaining traction, with businesses increasingly aware of the importance of maintaining ethical supply chains that respect labor rights and promote fair trade. Certifications like the Global Organic Textile Standard (GOTS) and the Leather Working Group (LWG) are becoming essential for suppliers aiming to establish credibility in the marketplace. These certifications not only enhance brand reputation but also attract environmentally conscious consumers, thereby creating a competitive advantage.

How Has the Dream Factory Leather Sector Evolved Over Time?

The dream factory leather sector has undergone a transformative journey since its inception, particularly with the establishment of brands like Dream Factory in South Korea. Founded by Mister Lee Ho-Myung, the brand began as a response to the needs of leather craft enthusiasts and students. The introduction of innovative tools, such as the adjustable folding stitching pony, marked a significant leap in enhancing the crafting experience. Over the years, the focus has shifted towards integrating technology with traditional craftsmanship, ensuring that products are not only functional but also of superior quality.

As the sector continues to evolve, the emphasis on innovation, sustainability, and ethical practices is likely to shape its future, presenting new opportunities for international B2B buyers. By staying attuned to these developments, businesses can navigate the complexities of the market and make informed sourcing decisions that align with their strategic goals.

Illustrative image related to dream factory leather

Frequently Asked Questions (FAQs) for B2B Buyers of dream factory leather

-

How do I determine the quality of Dream Factory leather tools?

To evaluate the quality of Dream Factory leather tools, consider the materials used, such as birch plywood and brass accents, which are known for their durability and performance. Look for user reviews and testimonials from other B2B buyers, as they can provide insights into the tools’ functionality and ease of use. Additionally, check if the supplier offers product demonstrations or samples, allowing you to assess the tools firsthand before making a bulk purchase. -

What are the best Dream Factory tools for professional leatherworking?

For professional leatherworking, the adjustable folding stitching pony and the hot stamping machine are among the top choices. The stitching pony is portable and offers adjustable angles for comfort and precision, while the stamping machine provides versatility for embossing and personalizing leather goods. Investing in these high-quality tools can enhance your productivity and craftsmanship, making them ideal for both artisans and larger manufacturing operations. -

What customization options are available for Dream Factory leather tools?

Many suppliers of Dream Factory leather tools offer customization options, such as personalized embossing or tailored tool kits to meet specific business needs. When inquiring about customization, communicate your requirements clearly, including design specifications and quantities. Be sure to verify lead times and any additional costs associated with customization to ensure it aligns with your project timelines and budget. -

What is the minimum order quantity (MOQ) for Dream Factory leather tools?

The minimum order quantity (MOQ) for Dream Factory leather tools can vary depending on the supplier and the specific products being ordered. Typically, MOQs may range from a few units to several dozen, especially for specialized tools. It’s advisable to contact your chosen supplier directly to confirm their MOQ policies and explore options for smaller initial orders or samples, which can be beneficial for assessing quality before committing to larger purchases. -

What payment terms should I expect when sourcing Dream Factory leather tools?

Payment terms for sourcing Dream Factory leather tools often depend on the supplier’s policies and your business relationship. Common options include upfront payment, partial payments, or net payment terms (e.g., net 30 or net 60 days). Discuss payment options early in the negotiation process to establish clear expectations and consider using secure payment methods to protect your transaction. -

How can I ensure quality assurance when purchasing Dream Factory leather tools?

To ensure quality assurance, request certifications or quality control documentation from your supplier that verifies the tools meet industry standards. Implement a systematic inspection process upon receipt of goods, checking for defects and functionality. Establishing a good relationship with your supplier can also facilitate better communication regarding quality issues and potential replacements or refunds if necessary. -

What logistics considerations should I keep in mind when importing Dream Factory leather tools?

When importing Dream Factory leather tools, consider shipping methods, customs regulations, and potential tariffs that may apply to your order. Evaluate your logistics options, including air versus sea freight, based on cost and delivery time. Partnering with a reliable freight forwarder can simplify the import process and ensure compliance with international shipping regulations, particularly when dealing with multiple countries. -

How can I vet suppliers of Dream Factory leather tools effectively?

To vet suppliers effectively, conduct thorough research, including reviewing their company history, product range, and customer testimonials. Request references from previous clients and check their reputation on industry forums or trade platforms. Additionally, consider visiting the supplier’s facility if feasible, or engaging in virtual meetings to assess their capabilities and commitment to quality. This diligence will help ensure you partner with a reputable supplier that aligns with your business goals.

Top 2 Dream Factory Leather Manufacturers & Suppliers List

1. Dream Factory – Clicker Press

Domain: dreamfactorytools.com

Registered: 2019 (6 years)

Introduction: {“products”:[{“name”:”Clicker press, Hand clicker”,”regular_price”:”$2,399.00 USD”,”sale_price”:”$1,999.00 USD”},{“name”:”Stamping Machine”,”regular_price”:”From $50.00 USD”,”sale_price”:”From $50.00 USD”},{“name”:”Font Holder”,”regular_price”:”$100.00 USD”,”sale_price”:”$100.00 USD”},{“name”:”Stamp Holder (Standard jaw ver’)”,”regular_price”:”$100.00 USD”,”sale_price”:”$100.00 USD”},{“name”:”Stam…

2. RM Leather Supply – Premium Leather Goods

Domain: rmleathersupply.com

Registered: 2014 (11 years)

Introduction: This company, RM Leather Supply – Premium Leather Goods, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for dream factory leather

Why Is Strategic Sourcing Crucial for Dream Factory Leather Buyers?

In the dynamic world of leathercraft, Dream Factory Leather stands out for its commitment to quality and innovation. By sourcing high-quality tools like adjustable stitching ponies and embossing machines, international B2B buyers can significantly enhance their product offerings. The precision and usability of Dream Factory tools not only simplify the crafting process but also elevate the overall quality of leather products, making them more competitive in the global market.

How Can Strategic Partnerships Enhance Your Leather Business?

Establishing strategic partnerships with suppliers like Dream Factory can lead to long-term benefits, including improved supply chain efficiency and access to cutting-edge technology. This approach allows buyers from Africa, South America, the Middle East, and Europe to stay ahead of trends and meet customer demands for premium leather goods.

What’s Next for B2B Buyers in the Leather Industry?

As the leather market continues to evolve, embracing strategic sourcing will be essential. Buyers are encouraged to explore the diverse range of Dream Factory products to discover how these tools can inspire creativity and drive business success. By investing in quality and innovation, you position your brand for sustainable growth and profitability in the competitive landscape of leathercraft. Start your journey with Dream Factory Leather today and transform your creative visions into reality.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to dream factory leather

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.