Introduction: Navigating the Global Market for basketball fabric material

The global market for basketball fabric material presents unique challenges for international B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe. Sourcing high-quality, durable basketball fabrics that meet specific performance and aesthetic requirements can be daunting. With a plethora of options available, buyers must navigate varying supplier standards, material types, and pricing structures to make informed decisions that align with their business needs.

This comprehensive guide delves into the diverse landscape of basketball fabric materials, examining the different types available—from vinyl and mesh to specialty textiles that enhance performance and style. It also highlights the various applications of these materials, whether for sports apparel, interior design, or promotional items. Additionally, the guide provides essential insights into supplier vetting processes, cost considerations, and best practices for negotiating terms that ensure value and quality.

By empowering buyers with actionable information, this resource enables them to confidently approach their sourcing strategies. Whether you’re a manufacturer in Saudi Arabia seeking innovative fabric solutions or a retailer in Vietnam looking to expand your product line, this guide serves as a vital tool in navigating the complexities of the basketball fabric market. Equip yourself with the knowledge to make strategic purchasing decisions that drive your business forward.

Table Of Contents

- Top 6 Basketball Fabric Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for basketball fabric material

- Understanding basketball fabric material Types and Variations

- Key Industrial Applications of basketball fabric material

- 3 Common User Pain Points for ‘basketball fabric material’ & Their Solutions

- Strategic Material Selection Guide for basketball fabric material

- In-depth Look: Manufacturing Processes and Quality Assurance for basketball fabric material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘basketball fabric material’

- Comprehensive Cost and Pricing Analysis for basketball fabric material Sourcing

- Alternatives Analysis: Comparing basketball fabric material With Other Solutions

- Essential Technical Properties and Trade Terminology for basketball fabric material

- Navigating Market Dynamics and Sourcing Trends in the basketball fabric material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of basketball fabric material

- Strategic Sourcing Conclusion and Outlook for basketball fabric material

- Important Disclaimer & Terms of Use

Understanding basketball fabric material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Polyester Mesh | Breathable, lightweight, and moisture-wicking | Athletic jerseys, training wear | Pros: Comfortable, durable. Cons: Less abrasion-resistant compared to other materials. |

| Vinyl Fabric | Textured surface mimicking basketball leather | Upholstery, interior decor | Pros: Durable, easy to clean. Cons: May not be as breathable as fabrics like mesh. |

| Cotton Blends | Soft, breathable, and often blended with synthetic fibers | Casual wear, promotional items | Pros: Comfortable, versatile. Cons: Less moisture-wicking capability. |

| Nylon Fabric | High tensile strength, abrasion-resistant, and lightweight | Performance gear, outdoor wear | Pros: Highly durable, retains shape. Cons: Can be less comfortable in hot climates. |

| Canvas | Heavyweight, durable, and often treated for weather resistance | Sports bags, outdoor gear | Pros: Extremely durable, good for heavy use. Cons: Can be stiff and less flexible. |

What Are the Key Characteristics of Polyester Mesh Fabric in Basketball?

Polyester mesh fabric is a popular choice for basketball apparel due to its breathable and lightweight properties. This material effectively wicks moisture away from the body, keeping athletes comfortable during intense gameplay. Its durability ensures that it can withstand the wear and tear of regular use, making it ideal for athletic jerseys and training wear. B2B buyers should consider the fabric’s weight and breathability, as these factors significantly impact player comfort and performance.

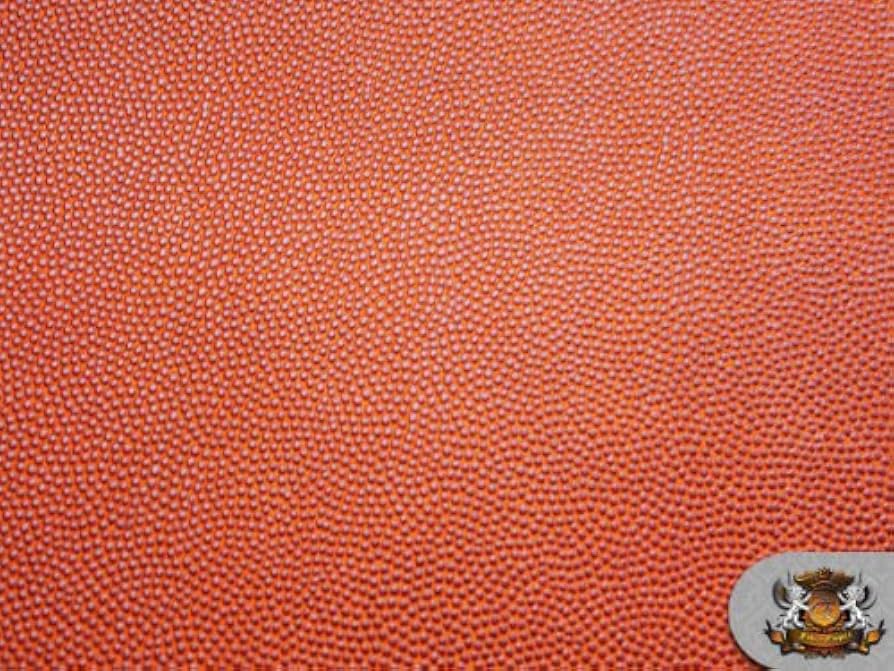

How Does Vinyl Fabric Compare for Basketball Applications?

Vinyl fabric is known for its textured surface that closely resembles basketball leather, making it an attractive option for upholstery and interior decor. Its durability and ease of maintenance are significant advantages, particularly for high-traffic areas where spills and stains are common. B2B buyers in the interior design sector or those looking to create themed environments will find vinyl fabric’s aesthetic appeal and practical benefits compelling. However, they should be aware that vinyl may lack breathability compared to mesh options.

What Advantages Do Cotton Blends Offer for Basketball Gear?

Cotton blends combine the softness of cotton with the durability of synthetic fibers, making them suitable for casual wear and promotional items. This fabric offers comfort and versatility, which can appeal to a wide range of customers. However, B2B buyers should note that while cotton blends are comfortable, they may not provide the same moisture-wicking capabilities as polyester or nylon. This can be a crucial factor when considering the performance needs of athletes.

Why Choose Nylon Fabric for High-Performance Basketball Gear?

Nylon fabric is celebrated for its high tensile strength and abrasion resistance, making it an excellent choice for performance gear and outdoor wear. Its lightweight nature and ability to retain shape under stress are significant benefits for athletes. However, B2B buyers should consider the potential discomfort in hot climates, as nylon can be less breathable than other fabrics. Evaluating the intended use and environmental conditions is essential for making informed purchasing decisions.

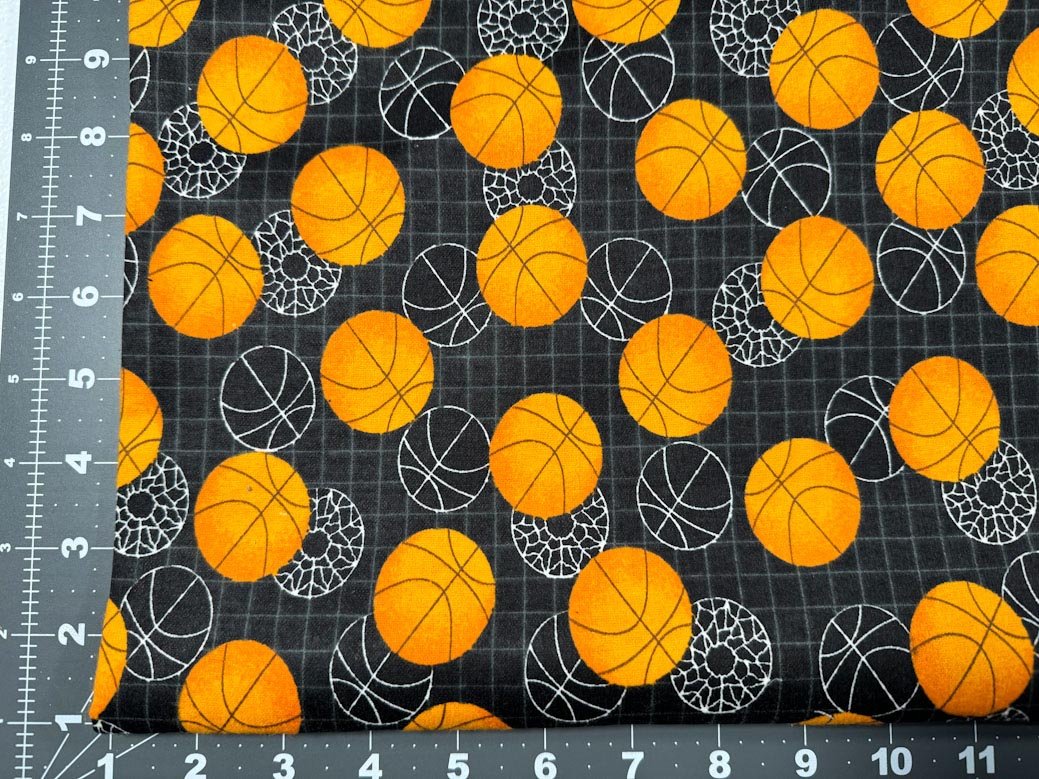

Illustrative image related to basketball fabric material

What Are the Benefits and Drawbacks of Using Canvas for Basketball Accessories?

Canvas is a heavyweight fabric known for its exceptional durability, making it suitable for sports bags and outdoor gear. Its resistance to wear and tear makes it ideal for items that require frequent handling. However, B2B buyers should be aware that canvas can be stiff and less flexible, which might not be suitable for all applications. Understanding the specific needs of the target audience will help buyers make the best choice regarding canvas products.

Key Industrial Applications of basketball fabric material

| Industry/Sector | Specific Application of basketball fabric material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Sports Apparel | Manufacturing of athletic wear and uniforms | Provides durability and moisture-wicking properties | Sourcing high-quality, breathable fabric with UV resistance |

| Interior Design | Upholstery for sports-themed interiors | Enhances aesthetic appeal while ensuring comfort | Availability of a variety of colors and textures |

| Event Management | Production of promotional items like banners and décor | Creates a vibrant and engaging atmosphere | Custom printing options and bulk purchasing discounts |

| Educational Institutions | Development of school sports kits | Promotes school spirit and team identity | Compliance with safety standards and durability requirements |

| Home Decor | Creation of basketball-themed home textiles | Appeals to sports enthusiasts and adds character | Variety in design and fabric weight for different uses |

How is Basketball Fabric Material Used in Sports Apparel Manufacturing?

Basketball fabric material is extensively used in the production of athletic wear and uniforms due to its durability and moisture-wicking properties. This fabric helps athletes remain dry and comfortable during intense games, which is essential for performance. For international buyers, especially from Africa and South America, sourcing high-quality fabrics that withstand varying climates and are resistant to UV rays is crucial. Buyers should ensure that the fabric meets local regulations regarding material safety and performance standards.

In What Ways Does Basketball Fabric Enhance Interior Design?

In the interior design sector, basketball fabric is utilized for upholstery in sports-themed environments, such as sports bars and recreational facilities. This application not only enhances the aesthetic appeal of the space but also ensures that the furniture is comfortable and durable. For buyers in the Middle East and Europe, sourcing a variety of colors and textures is essential to match diverse design preferences. Additionally, the fabric should be easy to clean and maintain, given the high traffic in these spaces.

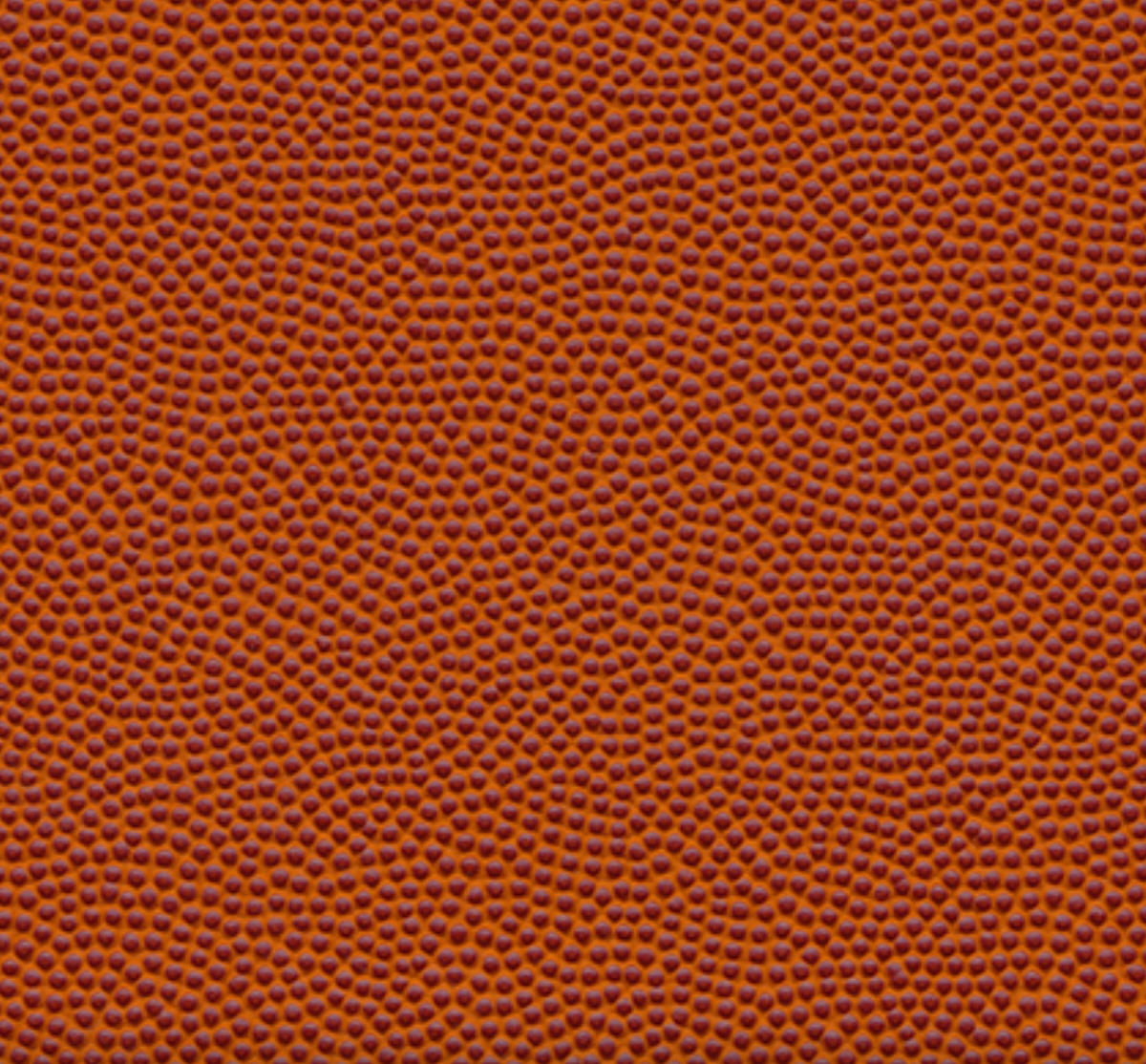

Illustrative image related to basketball fabric material

How is Basketball Fabric Utilized in Event Management?

Event management companies often use basketball fabric for creating promotional items like banners, backdrops, and décor for sporting events. This vibrant fabric can significantly contribute to an engaging atmosphere, attracting attendees and enhancing brand visibility. For international buyers, especially in regions like Saudi Arabia and Vietnam, custom printing options and bulk purchasing discounts are vital considerations. Ensuring that the fabric can withstand outdoor conditions and is easily transportable is also important for successful event execution.

What Role Does Basketball Fabric Play in Educational Institutions?

In educational settings, basketball fabric is commonly used to develop school sports kits, fostering school spirit and team identity. This application is particularly significant in regions where sports play a crucial role in community engagement. Buyers from Europe and South America need to ensure compliance with safety standards and durability requirements, as these kits must withstand rigorous use. Additionally, fabric that allows for customization can enhance team branding and unity.

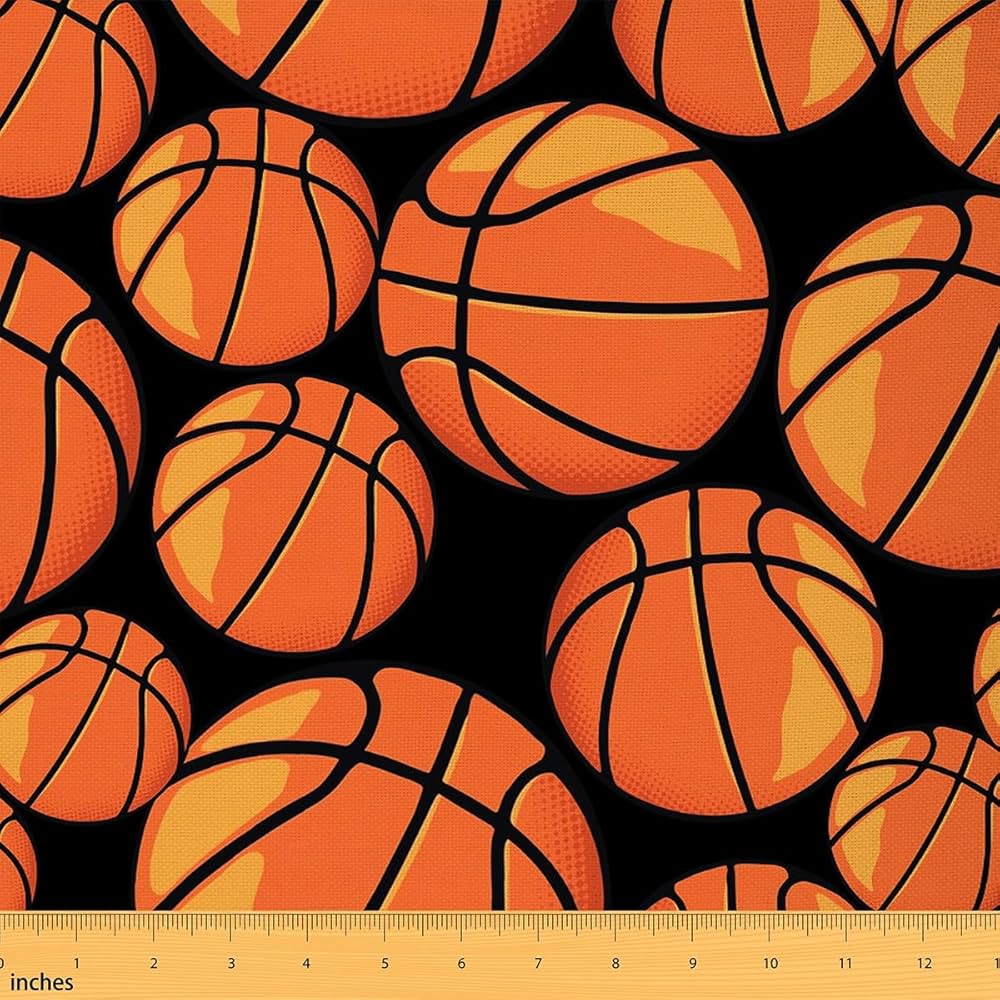

How Does Basketball Fabric Contribute to Home Decor?

Basketball fabric is increasingly popular in home décor, particularly for creating textiles that appeal to sports enthusiasts, such as curtains, cushions, and bedding. This application allows homeowners to express their passion for basketball while adding character to their living spaces. For international buyers, sourcing a variety of designs and fabric weights is essential to cater to different preferences and uses. Buyers should also consider the fabric’s ease of cleaning and maintenance, particularly in homes with children or pets.

3 Common User Pain Points for ‘basketball fabric material’ & Their Solutions

Scenario 1: Sourcing Quality Basketball Fabric for Diverse Markets

The Problem: B2B buyers often struggle to source high-quality basketball fabric that meets both aesthetic and functional requirements. In regions like Africa and South America, where market demands may vary significantly, buyers find it challenging to navigate through a plethora of options while ensuring that the material can withstand diverse climatic conditions. For instance, a fabric that works well in the humid climates of Brazil might not be suitable for the arid environments of Saudi Arabia, leading to potential dissatisfaction and increased returns.

The Solution: To address this issue, buyers should engage in thorough market research to understand the specific requirements of their target regions. Collaborating with local experts can provide insights into the durability and performance needs of basketball fabrics under varying conditions. When sourcing, prioritize manufacturers that offer samples and detailed specifications, including UV resistance, breathability, and moisture-wicking properties. This ensures that the selected fabric not only meets aesthetic criteria but also performs well in its intended environment. Additionally, establishing relationships with suppliers who can provide custom solutions tailored to specific regional needs can further enhance buyer confidence.

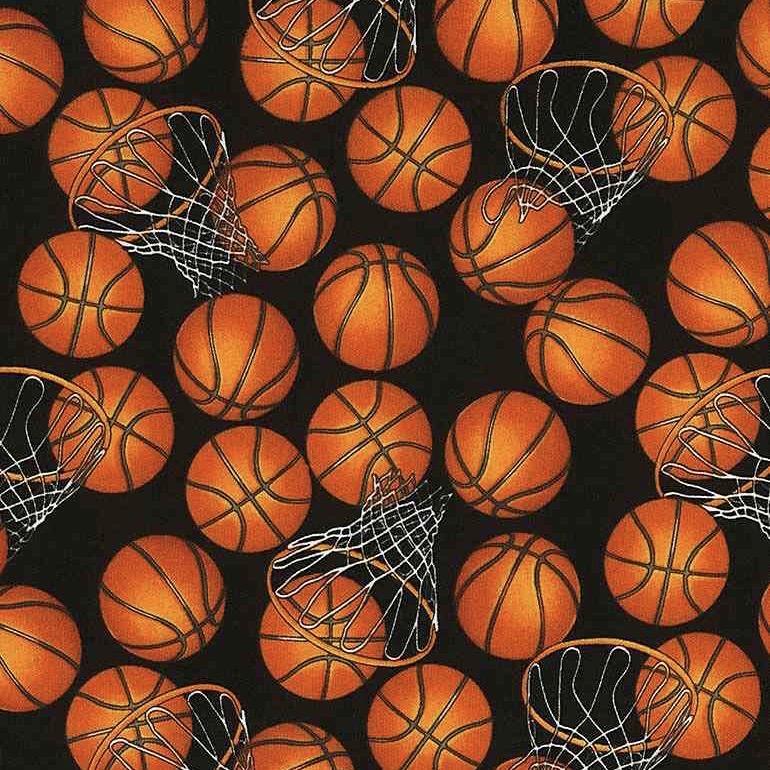

Illustrative image related to basketball fabric material

Scenario 2: Balancing Cost and Quality in Basketball Fabric Purchases

The Problem: Many B2B buyers face the dilemma of balancing cost and quality when purchasing basketball fabric. With tight budgets, especially in emerging markets, the temptation to opt for lower-priced materials can lead to subpar products that fail to meet customer expectations. This often results in negative feedback, returns, and ultimately damage to brand reputation.

The Solution: To effectively manage this balance, buyers should implement a value-based purchasing strategy. This involves evaluating suppliers not just on price but on quality certifications, customer reviews, and the longevity of the material. Consider investing in a pilot program where a small batch of fabric is tested in real-world conditions before committing to larger orders. This approach allows buyers to gauge quality and durability firsthand, reducing the risk associated with bulk purchases. Furthermore, negotiating long-term contracts with suppliers can lead to cost savings without compromising quality, as suppliers may offer discounts for consistent orders.

Scenario 3: Customization Challenges for Unique Designs

The Problem: B2B buyers often encounter difficulties when seeking customized basketball fabrics that align with specific branding or design requirements. In competitive markets, the ability to offer unique designs can be a significant differentiator, yet many fabric manufacturers may lack the capacity or willingness to produce bespoke materials. This can leave buyers frustrated, especially when deadlines are tight and custom designs are essential for promotional events or launches.

The Solution: To overcome customization challenges, buyers should prioritize working with manufacturers that specialize in custom fabric production. Establish clear communication about design expectations, including patterns, colors, and performance characteristics. Utilizing digital design tools to create prototypes can help streamline the design process and ensure that the final product aligns with the buyer’s vision. Additionally, leveraging on-demand production technologies can minimize lead times and reduce the burden of excess inventory. Building a strong partnership with a flexible supplier can also facilitate quicker adjustments and iterations in the design, ensuring that the final product is both unique and market-ready.

Strategic Material Selection Guide for basketball fabric material

What Are the Key Properties of Common Basketball Fabric Materials?

When selecting basketball fabric materials for production, it is essential to understand the unique properties and performance characteristics of each type. Common materials include polyester, nylon, vinyl, and cotton blends. Each material offers distinct advantages and disadvantages, impacting their suitability for various applications in the basketball industry.

Illustrative image related to basketball fabric material

How Does Polyester Perform as a Basketball Fabric Material?

Polyester is a popular choice for basketball fabric due to its excellent durability and resistance to shrinking and stretching. It typically has a high tensile strength, allowing it to withstand the rigors of athletic use. Polyester fabrics can also be treated to enhance moisture-wicking properties, making them ideal for performance wear.

Pros: Polyester is lightweight and dries quickly, which is beneficial for athletes. It is also relatively cost-effective, making it suitable for mass production.

Cons: While polyester is durable, it may not provide the same level of breathability as natural fibers, potentially leading to discomfort in hot climates.

Impact on Application: Polyester is compatible with various dyeing processes, enabling vibrant colors and patterns, which can appeal to younger audiences.

Considerations for International Buyers: Buyers from regions with high humidity, such as parts of Africa and South America, may prefer moisture-wicking polyester blends. Compliance with international textile standards like ASTM D5034 (breaking strength) is crucial.

Illustrative image related to basketball fabric material

What Are the Advantages of Nylon in Basketball Fabrics?

Nylon is another synthetic option known for its exceptional strength and elasticity. It offers a soft feel and is resistant to abrasion, making it suitable for high-contact sports like basketball.

Pros: Nylon’s elasticity allows for a snug fit, which is essential for athletic wear. It also has good resistance to mildew and UV light, making it suitable for outdoor applications.

Cons: Nylon can be more expensive than polyester and may require more complex manufacturing processes. It can also be prone to static electricity, which might be a concern in certain environments.

Impact on Application: Nylon’s durability makes it suitable for both uniforms and accessories like bags and nets.

Illustrative image related to basketball fabric material

Considerations for International Buyers: Buyers in regions with high UV exposure, such as the Middle East, should consider nylon for its protective qualities. Ensuring compliance with local textile regulations is essential.

How Does Vinyl Compare as a Basketball Fabric Material?

Vinyl, particularly in the form of faux leather, is often used in basketball applications for its aesthetic appeal and durability. It mimics the texture of real leather, providing a high-end look.

Pros: Vinyl is easy to clean and maintain, making it ideal for environments where hygiene is a priority. It is also water-resistant, which is beneficial for outdoor use.

Cons: Vinyl can be less breathable than other materials, which might affect comfort during extended wear. Additionally, it can be more expensive due to its manufacturing process.

Impact on Application: Vinyl is commonly used for upholstery in sports facilities and for custom branding on uniforms.

Illustrative image related to basketball fabric material

Considerations for International Buyers: Buyers should be aware of the environmental regulations regarding PVC in their countries, especially in Europe, where stricter standards may apply.

What Role Do Cotton Blends Play in Basketball Fabric Selection?

Cotton blends are often used in basketball apparel for their comfort and breathability. Blending cotton with synthetic fibers can enhance durability while retaining the soft feel of cotton.

Pros: Cotton blends are comfortable and absorbent, making them suitable for casual wear and practice gear.

Illustrative image related to basketball fabric material

Cons: They may not be as durable as pure synthetic options and can shrink or lose shape over time.

Impact on Application: Cotton blends are ideal for training uniforms and casual wear, appealing to a broader audience.

Considerations for International Buyers: Buyers should ensure that cotton blends meet local standards for shrinkage and colorfastness, particularly in regions with varying climate conditions.

Summary Table of Basketball Fabric Materials

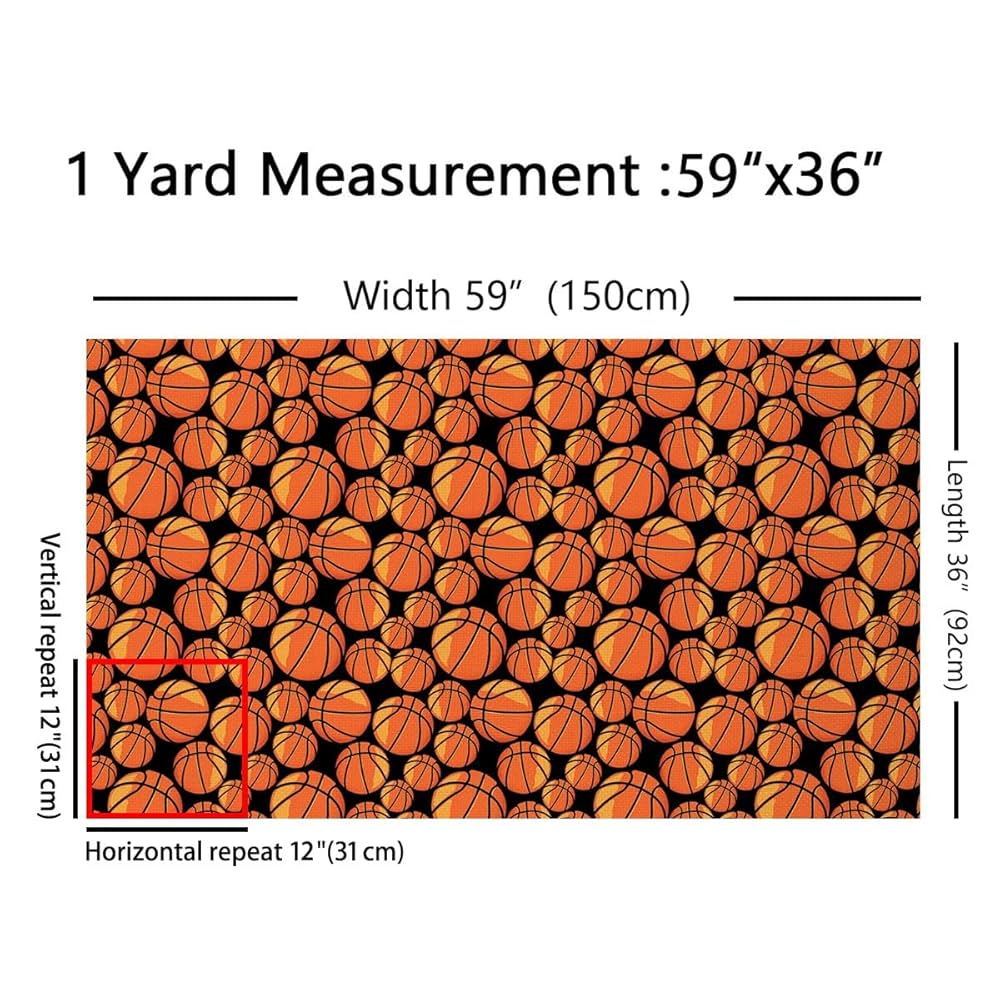

| Material | Typical Use Case for basketball fabric material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Athletic uniforms and performance wear | Lightweight and moisture-wicking | Less breathable than natural fibers | Low |

| Nylon | Athletic wear and accessories | High strength and elasticity | More expensive and static-prone | Medium |

| Vinyl | Upholstery and custom branding | Easy to clean and water-resistant | Less breathable and higher cost | High |

| Cotton Blends | Training uniforms and casual wear | Comfortable and breathable | Less durable and potential for shrinkage | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for basketball fabric material

What Are the Main Stages in the Manufacturing Process of Basketball Fabric Material?

The manufacturing process of basketball fabric material involves several critical stages designed to ensure high-quality output. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first stage involves sourcing high-quality raw materials, typically synthetic fibers such as polyester or nylon, which are chosen for their durability and performance characteristics. The fibers are treated to enhance their properties, such as moisture-wicking and UV resistance. This stage may also include dyeing the fibers to achieve specific colors and patterns, essential for branding and aesthetic appeal.

-

Forming: In this stage, the prepared materials are processed into fabric. Techniques like weaving or knitting are employed to create a dense, textured surface that mimics the feel of a traditional basketball. Advanced technology, such as warp-knitting, may be utilized to produce fabrics with enhanced elasticity and strength.

-

Assembly: Following the formation of the fabric, the next step is cutting and sewing the material into specific shapes and sizes, especially if the fabric is to be used for products like basketballs or sportswear. Automated cutting machines and sewing robots may be used to ensure precision and efficiency, reducing waste and labor costs.

-

Finishing: The final stage involves applying various treatments to the fabric to enhance its performance and durability. This can include waterproofing, anti-microbial treatments, and surface coatings to improve texture and grip. Quality checks are conducted throughout this stage to ensure that the finished product meets industry standards.

How Do Quality Assurance Practices Ensure Basketball Fabric Material Meets International Standards?

Quality assurance (QA) is a critical component in the manufacturing of basketball fabric material, ensuring that products not only meet but exceed international standards.

-

International Standards Compliance: Many manufacturers adhere to ISO 9001, a globally recognized quality management standard that outlines the criteria for a quality management system. Compliance ensures consistency in product quality, customer satisfaction, and continuous improvement. Additionally, industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for products requiring specific performance criteria can also be relevant.

-

Quality Control Checkpoints: Several checkpoints exist throughout the manufacturing process, including:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards before production begins.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify and rectify any issues immediately, minimizing defects.

– Final Quality Control (FQC): The finished products undergo thorough testing for durability, color fastness, and performance attributes before being dispatched. -

Testing Methods for Quality Assurance: Common testing methods include tensile strength tests, abrasion resistance tests, and colorfastness tests. These tests help manufacturers evaluate the fabric’s performance under various conditions, ensuring it can withstand the rigors of use in sports environments.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential for ensuring product reliability and compliance with local regulations.

Illustrative image related to basketball fabric material

-

Conducting Supplier Audits: Regular audits of suppliers can provide insight into their manufacturing processes and quality assurance practices. Buyers should request documentation of the supplier’s quality management systems, including ISO certifications and quality control procedures.

-

Reviewing Quality Reports: Suppliers should provide detailed quality reports that outline testing methods, results, and corrective actions taken for any deviations. These reports can help buyers assess the supplier’s commitment to quality.

-

Engaging Third-Party Inspectors: Employing third-party inspection services can offer an unbiased evaluation of the manufacturing process and product quality. Inspectors can assess compliance with international standards and verify the results of quality tests.

What Are the Specific Quality Control Nuances for International B2B Buyers?

International B2B buyers must be aware of specific nuances regarding quality control when sourcing basketball fabric materials.

-

Regulatory Compliance: Different countries may have varying regulations regarding textile imports. Buyers should ensure that their suppliers meet the regulatory requirements of their target markets, which can include safety, environmental, and labeling standards.

-

Cultural Considerations: Understanding cultural differences in business practices is crucial. For example, in some regions, the emphasis may be on personal relationships and trust, while in others, strict adherence to documentation and formal agreements is prioritized. Buyers should adapt their approach accordingly to foster effective partnerships.

-

Supply Chain Transparency: Transparency in the supply chain is becoming increasingly important. Buyers should seek suppliers who are willing to share information about their sourcing, manufacturing processes, and quality control practices. This transparency can enhance trust and facilitate smoother transactions.

-

Sustainability Practices: As global awareness of environmental issues grows, buyers are increasingly looking for suppliers who implement sustainable practices in their manufacturing processes. This can include the use of eco-friendly materials and energy-efficient production methods.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing basketball fabric materials, ensuring they select suppliers who meet their quality and performance expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘basketball fabric material’

This practical sourcing guide aims to assist B2B buyers in procuring high-quality basketball fabric material. As the demand for basketball-related products grows, understanding how to efficiently source the right fabric can significantly impact your business’s success. Follow this step-by-step checklist to ensure a smooth and effective procurement process.

Illustrative image related to basketball fabric material

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Determine the type of fabric needed (e.g., vinyl, cotton blends), desired durability, texture, and visual appeal. Consider the end use of the fabric—whether for uniforms, accessories, or interior décor—since this will dictate specific requirements such as moisture-wicking properties or UV resistance.

Step 2: Research Market Trends and Innovations

Stay informed about the latest trends in basketball fabrics. New materials and technologies may enhance performance and design, such as moisture-management fabrics or eco-friendly options. Engaging with industry reports, attending trade shows, or connecting with suppliers can provide insights into innovative products that may give your offerings a competitive edge.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is essential. Request company profiles, case studies, and references from buyers within your industry. Look for suppliers who have a proven track record in delivering basketball fabrics and can provide samples of their work to assess quality firsthand.

- Verify Supplier Certifications: Check for certifications that indicate compliance with international quality standards (e.g., ISO certifications) and environmental regulations. This adds a layer of credibility to your supplier choice.

Step 4: Request Samples for Quality Assessment

Always request fabric samples before finalizing any orders. This allows you to evaluate the fabric’s texture, durability, and color accuracy. It’s crucial to assess how the fabric performs under conditions similar to its intended use, such as exposure to wear and tear, laundering, and environmental factors.

Step 5: Negotiate Pricing and Terms

Once you have selected potential suppliers, initiate negotiations on pricing, minimum order quantities, and lead times. Ensure you understand the total cost of acquisition, including shipping and any potential tariffs, especially when sourcing internationally. Aim for a balance between cost-effectiveness and quality to ensure long-term value.

Illustrative image related to basketball fabric material

Step 6: Establish Clear Communication Channels

Effective communication is vital throughout the sourcing process. Set up a clear line of communication with your supplier to discuss requirements, timelines, and any potential issues that may arise. Regular updates can help manage expectations and foster a collaborative relationship, which is beneficial for future orders.

Step 7: Finalize Contracts and Monitor Performance

Once all terms are agreed upon, finalize contracts that clearly outline expectations, deliverables, and timelines. After procurement, monitor the supplier’s performance against the agreed terms to ensure compliance and quality standards are met. This will help build a reliable supply chain and enable you to make informed decisions for future sourcing needs.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing basketball fabric material, ensuring that they secure high-quality products that meet their business needs.

Comprehensive Cost and Pricing Analysis for basketball fabric material Sourcing

What Are the Key Cost Components for Sourcing Basketball Fabric Material?

When sourcing basketball fabric material, understanding the cost structure is essential for B2B buyers. The primary components include:

-

Materials: The cost of the fabric itself is influenced by the type (e.g., vinyl, polyester, or custom blends) and quality. Higher-quality fabrics that mimic authentic textures, such as those imitating basketball leather, typically command a premium.

-

Labor: Labor costs encompass the wages of workers involved in manufacturing the fabric. This can vary significantly based on the region; for instance, labor costs in Southeast Asia may be lower compared to Europe or North America.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, equipment depreciation, and administrative expenses. Efficient manufacturing processes can help reduce overhead, thereby lowering the overall cost of the fabric.

-

Tooling: Initial tooling costs can be significant, especially for custom designs or unique fabric specifications. These costs are typically amortized over larger production runs, making them less impactful per unit for bulk orders.

-

Quality Control (QC): Ensuring that the fabric meets specified quality standards incurs costs for testing and inspections. This is particularly crucial for B2B buyers who require certifications for safety and quality compliance.

-

Logistics: Transportation costs play a vital role in the total cost. Factors such as distance from the supplier, shipping methods, and customs duties can significantly influence the final price.

-

Margin: Suppliers will add a profit margin to cover their expenses and ensure sustainability. This margin can vary based on market demand and competitive pressures.

How Do Price Influencers Affect Basketball Fabric Material Sourcing?

Several factors can influence the pricing of basketball fabric material:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer discounts for larger orders. Understanding the MOQ is crucial for cost-efficiency; purchasing below this threshold can lead to higher per-unit costs.

-

Specifications and Customization: Custom designs or specific fabric characteristics (like weight, durability, or color) can increase costs. Buyers should clearly define their specifications to avoid unexpected price hikes.

-

Materials and Quality Certifications: Fabrics that meet certain certifications (e.g., eco-friendly or safety standards) may be priced higher. Buyers should assess the importance of these certifications against their budget.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a strong track record may charge more, but they often provide better quality assurance and service.

-

Incoterms: Understanding shipping terms (like FOB, CIF, or DDP) is essential, as they dictate who bears the cost and risk during transportation. This can significantly affect the total landed cost of the fabric.

What Buyer Tips Can Enhance Cost-Efficiency in Basketball Fabric Procurement?

To optimize sourcing strategies for basketball fabric, buyers should consider the following tips:

-

Negotiation: Effective negotiation can lead to better pricing. Establishing long-term relationships with suppliers often yields favorable terms and discounts.

-

Total Cost of Ownership (TCO): Buyers should evaluate not just the purchase price but also the TCO, which includes logistics, storage, and any potential waste or defects. A slightly higher upfront cost may lead to savings in other areas.

-

Understanding Pricing Nuances for International Markets: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of local market conditions and currency fluctuations that may impact pricing. Being informed about regional trends can provide leverage in negotiations.

-

Market Research: Conducting thorough market research helps buyers understand prevailing prices and trends. This knowledge can empower buyers to make informed decisions and identify the best sourcing options.

-

Supplier Diversity: Engaging with multiple suppliers can create competition, which may lead to better pricing and terms. Diversifying sources also mitigates risk in case of supply chain disruptions.

Disclaimer on Pricing

Prices for basketball fabric materials can vary widely based on the factors discussed above. It is advisable for buyers to conduct due diligence and obtain multiple quotes to ensure competitive pricing. Always factor in the potential for fluctuations in material costs and shipping fees when budgeting for procurement.

Alternatives Analysis: Comparing basketball fabric material With Other Solutions

Understanding Alternatives for Basketball Fabric Material

When selecting materials for basketball applications, it’s essential to consider alternatives that can offer similar or enhanced functionality. This comparison will focus on basketball fabric material against two viable alternatives: synthetic leather and mesh fabric. Each option has unique characteristics that can cater to different requirements and preferences in the sports and design industries.

Comparison Table

| Comparison Aspect | Basketball Fabric Material | Synthetic Leather | Mesh Fabric |

|---|---|---|---|

| Performance | Durable, excellent grip, breathable | Strong, water-resistant, easy to clean | Highly breathable, lightweight |

| Cost | Moderate, varies by design and quality | Generally higher due to material cost | Lower cost, budget-friendly |

| Ease of Implementation | Requires specific sewing techniques | Easy to cut and sew, versatile | Simple to work with, requires minimal tools |

| Maintenance | Moderate, machine washable | Low, wipe clean with a damp cloth | Low, quick drying, machine washable |

| Best Use Case | Sports uniforms, decorative applications | Upholstery, high-end athletic gear | Sportswear, casual wear, active wear |

Analyzing Synthetic Leather as an Alternative

Synthetic leather is a popular choice in sports and fashion due to its durability and aesthetic appeal. It mimics the look and feel of genuine leather while offering superior resistance to water and stains. This material is often used in high-end athletic gear and interiors, making it an attractive option for buyers aiming for a luxurious finish. However, synthetic leather can be more expensive than traditional basketball fabric, which may deter budget-conscious buyers. Additionally, while it offers high durability, it may not provide the same level of breathability, potentially leading to discomfort during intense physical activities.

Illustrative image related to basketball fabric material

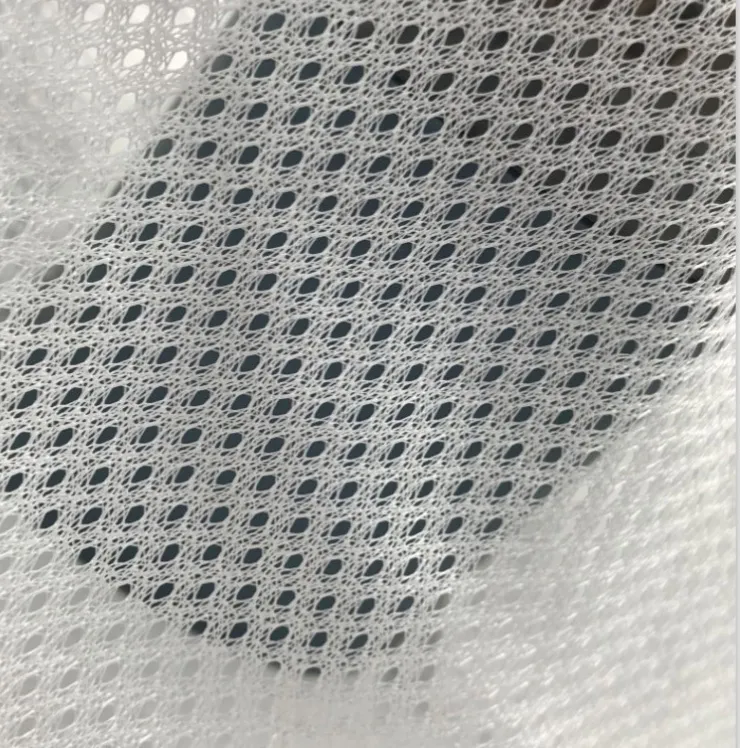

Exploring Mesh Fabric Benefits

Mesh fabric stands out for its lightweight and highly breathable qualities, making it ideal for activewear and sports uniforms. This material allows for excellent air circulation, helping to regulate body temperature during physical exertion. Moreover, mesh fabric is typically more affordable, making it an attractive choice for manufacturers looking to keep costs down. However, mesh may lack the durability and visual appeal of basketball fabric and synthetic leather, making it less suitable for high-end applications or items that require a polished look. Its structure also means it might not provide the same level of grip, which is essential in certain basketball contexts.

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers, selecting the right material hinges on understanding the specific requirements of their projects. Basketball fabric material is ideal for applications needing durability and an authentic aesthetic, especially in sports environments. In contrast, synthetic leather offers a luxurious touch with superior water resistance, suitable for high-end applications. Alternatively, mesh fabric is best for budget-friendly, breathable options in activewear. By assessing performance needs, cost constraints, and desired aesthetics, buyers can make informed decisions that align with their project goals and target markets.

Essential Technical Properties and Trade Terminology for basketball fabric material

What Are the Key Technical Properties of Basketball Fabric Material?

When considering basketball fabric materials for manufacturing or sourcing, several technical properties are critical to ensure quality, durability, and performance. Understanding these specifications can aid in making informed purchasing decisions.

1. Material Composition

Basketball fabrics are typically made from synthetic fibers such as polyester, nylon, or a blend of both. Polyester is favored for its durability and resistance to wear, while nylon offers superior elasticity and strength. The choice of material significantly impacts the fabric’s performance, including moisture-wicking capabilities and abrasion resistance, which are essential for sports applications.

Illustrative image related to basketball fabric material

2. Weight and Thickness

The weight of the fabric is often measured in grams per square meter (GSM). A higher GSM generally indicates a denser, more durable fabric, which can withstand the rigors of play. Thickness, measured in millimeters, also contributes to the overall durability and feel of the fabric. For basketball applications, a balance between lightweight and robust materials is crucial to enhance player comfort and performance.

3. Coating and Finish

Many basketball fabrics undergo specialized coatings, such as polyurethane (PU) or polyvinyl chloride (PVC), which enhance water resistance and durability. The finish can affect the texture and grip of the fabric, impacting the handling of the basketball. A well-coated fabric can also contribute to the aesthetic appeal, making it suitable for various applications beyond sports, such as interior design.

4. Stretch and Recovery

The elasticity of basketball fabric is vital, particularly for performance apparel. Fabrics with good stretch and recovery properties allow for a full range of motion while maintaining their shape. This is especially important for uniforms and footwear, where comfort and fit can influence athletic performance.

Illustrative image related to basketball fabric material

5. Colorfastness and UV Resistance

Basketball fabrics should exhibit colorfastness to ensure that colors remain vibrant after repeated washing and exposure to sunlight. UV resistance is also an important property, especially for outdoor applications, as it prevents fading and degradation of the material over time.

Which Trade Terms Are Commonly Used in the Basketball Fabric Industry?

Understanding the trade terminology is essential for effective communication and negotiation in the basketball fabric market. Here are some commonly used terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are used in another company’s end product. In the context of basketball fabric, this could involve manufacturers who create custom fabrics for sports brands. Understanding OEM relationships can help buyers ensure they are sourcing from reputable manufacturers.

Illustrative image related to basketball fabric material

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it impacts inventory management and budgeting. Knowing the MOQ can help businesses plan their purchases effectively, especially when considering new fabric lines.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. In the basketball fabric industry, submitting an RFQ can provide buyers with competitive pricing and options. It’s a vital step in the procurement process, helping to ensure cost-effective sourcing.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, which define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk management, and delivery obligations, which are crucial for international sourcing of basketball fabrics.

5. Lead Time

Lead time refers to the amount of time taken from placing an order to the delivery of the product. In the context of basketball fabric sourcing, understanding lead time is critical for inventory planning and ensuring timely product availability for seasonal needs.

Illustrative image related to basketball fabric material

By familiarizing yourself with these technical properties and trade terms, you can navigate the basketball fabric market more effectively, ensuring that your business makes informed decisions that align with your operational goals.

Navigating Market Dynamics and Sourcing Trends in the basketball fabric material Sector

What Are the Key Trends Driving the Basketball Fabric Material Market?

The basketball fabric material sector is witnessing dynamic growth driven by several global factors. Increased participation in sports, particularly basketball, across regions like Africa, South America, and the Middle East has resulted in heightened demand for quality sports materials. The rise of e-commerce and digital sourcing platforms has also transformed how international B2B buyers engage with suppliers, providing broader access to diverse fabric options and designs. Emerging technologies, such as 3D printing and advanced textile engineering, are enabling manufacturers to create more innovative and customized fabric solutions that meet specific market needs.

Additionally, trends like athleisure—a fusion of athletic and leisurewear—are influencing fabric choices. Buyers are increasingly looking for materials that not only perform well during sports but also offer aesthetic appeal for everyday wear. This trend is particularly prominent in regions like Europe and the Middle East, where fashion and functionality intersect. Furthermore, the integration of smart textiles—fabrics embedded with technology to enhance performance—is becoming an area of interest, setting the stage for future innovations in basketball fabric materials.

How Are Sustainability and Ethical Sourcing Shaping the Basketball Fabric Material Sector?

Sustainability is increasingly at the forefront of the basketball fabric material sector, driven by growing consumer awareness and regulatory pressures. International B2B buyers are now prioritizing suppliers who can demonstrate a commitment to ethical sourcing and environmental responsibility. This includes the use of recycled materials, low-impact dyes, and manufacturing processes that minimize waste and energy consumption.

Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® Standard 100 have become critical for buyers looking to ensure that their materials meet rigorous environmental and social criteria. These certifications not only enhance the marketability of products but also align with the values of increasingly eco-conscious consumers. Moreover, brands that embrace sustainability often experience improved loyalty and trust from their customers, making ethical sourcing a strategic advantage in competitive markets.

Illustrative image related to basketball fabric material

What is the Historical Context of Basketball Fabric Materials in B2B?

The evolution of basketball fabric materials is deeply intertwined with the growth of the sport itself. Initially, basketball uniforms and gear were made from basic cotton fabrics, which were not ideal for performance. As the sport gained popularity, manufacturers began to innovate with synthetic fibers that offered better durability, moisture-wicking properties, and comfort.

By the late 20th century, advancements in textile technology led to the introduction of specialized materials like polyester and nylon, which revolutionized the design and functionality of basketball gear. Today, the sector continues to evolve with the integration of smart textiles and sustainable practices, reflecting broader trends in sports and fashion. This historical context is essential for B2B buyers as it informs sourcing decisions and highlights the importance of quality and innovation in basketball fabric materials.

Frequently Asked Questions (FAQs) for B2B Buyers of basketball fabric material

-

How can I identify quality basketball fabric material for my business?

To identify quality basketball fabric material, consider the fabric’s texture, durability, and design. Look for samples that accurately represent the feel of authentic basketball leather, such as textured vinyl or high-quality polyester blends. Additionally, verify the supplier’s certifications and reputation in the market. Request product specifications and test reports to ensure compliance with international standards, especially if sourcing from different regions like Africa or South America. -

What types of basketball fabric materials are available for bulk purchase?

Basketball fabric materials typically include vinyl, polyester blends, and cotton options. Vinyl fabrics, such as those mimicking authentic basketball leather, are popular for their durability and aesthetic appeal. Polyester blends offer moisture-wicking properties, making them suitable for activewear. Depending on your market needs, you can source these fabrics in various patterns and colors, ensuring they meet your design specifications and target audience preferences. -

What should I consider when vetting suppliers for basketball fabric?

When vetting suppliers, assess their production capacity, quality control processes, and past client reviews. Check for certifications related to sustainable practices and compliance with international trade regulations. It’s also beneficial to request samples and conduct site visits if possible. Establish clear communication regarding lead times, minimum order quantities (MOQ), and payment terms to ensure a smooth transaction. -

What are the typical minimum order quantities (MOQ) for basketball fabric?

Minimum order quantities for basketball fabric can vary significantly based on the supplier and the type of fabric. Generally, MOQs range from 50 to 500 yards or meters. Some suppliers may offer lower MOQs for standard designs, while custom fabrics often require higher quantities. Discuss your specific needs with suppliers to negotiate favorable terms that align with your business model. -

What payment terms should I expect when sourcing basketball fabric internationally?

Payment terms for international orders can vary widely. Common practices include upfront payments (often 30-50% of the total order) with the balance due prior to shipping. Some suppliers may offer net terms (e.g., net 30 or 60 days) for established customers. Ensure clarity on payment methods (bank transfer, letters of credit, etc.) and any applicable fees to avoid unexpected costs during the transaction. -

How do I ensure quality assurance (QA) for my basketball fabric orders?

To ensure quality assurance, request detailed product specifications and sample approvals before placing a bulk order. Establish clear quality control standards and communicate these with your supplier. It may also be prudent to conduct third-party inspections, especially for large shipments, to verify that the fabric meets your quality criteria. Document all agreements regarding quality expectations to prevent disputes later. -

What logistics considerations should I keep in mind when importing basketball fabric?

When importing basketball fabric, consider shipping methods (air vs. sea), delivery times, and associated costs. Ensure compliance with customs regulations in your destination country, including tariffs and import duties. Work with experienced freight forwarders who understand the nuances of international shipping. Proper documentation is crucial; ensure all paperwork, including invoices and certificates of origin, is accurate and complete to facilitate smooth customs clearance. -

How can I customize basketball fabric designs for my brand?

Customizing basketball fabric designs typically involves collaborating with suppliers that offer digital printing services or custom weaving. Provide clear design specifications, including colors, patterns, and fabric types. Discuss production timelines and MOQs for custom orders. Many suppliers can accommodate low-volume custom requests, especially if you are willing to pay a premium for the service. Always request samples of the custom fabric to ensure it meets your expectations before finalizing the order.

Top 6 Basketball Fabric Material Manufacturers & Suppliers List

1. Spoonflower – Basketball-Themed Fabric and Home Decor

Domain: spoonflower.com

Registered: 2005 (20 years)

Introduction: Basketball-themed fabric, wallpaper, and home decor available at Spoonflower. Products include fabric by the yard or meter, wallpaper options (peel and stick, pre-pasted, non-pasted, grasscloth, metallic, vinyl), and home decor items such as bedding (duvet covers, sheet sets, pillow shams), dining items (napkins, placemats, tablecloths), and living decor (throw pillows, blankets, curtains). The de…

2. Missouri Quilt Company – Basketball Fabric

Domain: missouriquiltco.com

Registered: 2009 (16 years)

Introduction: This company, Missouri Quilt Company – Basketball Fabric, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. American™ Sports – Basketball Vinyl Fabric

Domain: designerwallcoverings.com

Registered: 2003 (22 years)

Introduction: American™ Sports Basketball Vinyl Fabric – Fake PigSkin, 54″ vinyl, textured surface mimicking authentic basketball leather, fine pebbling, rich brown tones, designed for sporty, stylish interiors, appeals to high-end interior designers.

4. Hobby Lobby – Basketballs Cotton Calico Fabric

Domain: hobbylobby.com

Registered: 1995 (30 years)

Introduction: {‘name’: ‘Basketballs Cotton Calico Fabric’, ‘sku’: ‘496166’, ‘original_price’: ‘$6.99 YDS’, ‘description’: ‘Sew together something spirited and sporty with Basketballs Cotton Calico Fabric! This fabric features orange basketballs of various sizes overlapping each other and filling up every inch of material. Use it to make pillows, quilts, totes, memo board covers, fashion accessories, and persona…

5. Expert O Wears – Choosing the Right Fabric for Basketball Uniforms

Domain: expertowears.com

Registered: 2021 (4 years)

Introduction: How To Choose The Right Fabric For Basketball Uniforms: 1. Importance of fabric choice for performance and comfort. 2. Traditional fabrics (wool, cotton) vs. modern fabrics (polyester, nylon). 3. Polyester: lightweight, breathable, quick-drying, moisture-wicking, durable, vibrant colors, ideal for large-scale production, eco-friendly options available. 4. Nylon: strong, abrasion-resistant, flexibl…

6. Travel Laundry Company – YD Basketball Fabric

Domain: travellaundrycompany.com

Registered: 2012 (13 years)

Introduction: {“product_name”: “YD- Basketball Fabric by the Yard”, “price”: “$7.99”, “material”: “100% quality cotton”, “width”: “44 inches”, “minimum_order”: “1 yard minimum per each fabric design (full yards only)”, “shipping”: “Free Shipping with $35 minimum Purchase”, “description”: “100% cotton responsibly sourced from around the globe. Quality fabrics ranging from solid Kona Cottons and stylish Batiks to…

Strategic Sourcing Conclusion and Outlook for basketball fabric material

In the rapidly evolving market for basketball fabric materials, strategic sourcing emerges as a pivotal element for B2B buyers aiming to enhance their product offerings. Key takeaways emphasize the importance of understanding regional preferences, quality standards, and the latest design trends in basketball fabric, which range from luxurious vinyl options to custom printed textiles. By leveraging these insights, businesses can not only meet the demands of various markets but also differentiate themselves in a competitive landscape.

Moreover, international buyers from Africa, South America, the Middle East, and Europe should prioritize partnerships with reliable suppliers who can provide high-quality materials that resonate with local tastes and preferences. Establishing strong relationships with manufacturers and designers can lead to innovative solutions and unique product lines that cater to diverse customer bases.

Illustrative image related to basketball fabric material

Looking ahead, the potential for growth in the basketball fabric market remains robust. As consumer interest in sports-themed décor and apparel continues to rise, now is the time for B2B buyers to explore new sourcing opportunities. Embrace strategic sourcing to capitalize on these trends and elevate your business to new heights. Engage with suppliers today to secure your position in this dynamic market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to basketball fabric material

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.