Introduction: Navigating the Global Market for ultrasuede material

In the ever-evolving landscape of material sourcing, international B2B buyers face the challenge of finding high-quality, sustainable options like ultrasuede material that meet both aesthetic and functional demands. Whether you’re seeking versatile upholstery for commercial spaces or innovative solutions for automotive applications, understanding the nuances of ultrasuede is crucial. This guide delves into the diverse types and applications of ultrasuede, offering valuable insights into supplier vetting processes, cost considerations, and the material’s unique benefits.

As a luxurious yet eco-friendly alternative to traditional suede, ultrasuede has gained traction across various industries, particularly in Africa, South America, the Middle East, and Europe, including key markets like Nigeria and Germany. By exploring its durability, stain resistance, and easy maintenance, this comprehensive resource empowers B2B buyers to make informed purchasing decisions.

The guide not only highlights the advantages of ultrasuede but also provides actionable strategies for effective sourcing, ensuring that your procurement process is seamless and efficient. Whether you are updating an office’s interior design or outfitting a hospitality venue, understanding the global market for ultrasuede material will enhance your ability to deliver quality while meeting sustainability goals. Dive into this guide to navigate the complexities of sourcing ultrasuede and elevate your product offerings in a competitive marketplace.

Table Of Contents

- Top 3 Ultrasuede Material Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for ultrasuede material

- Understanding ultrasuede material Types and Variations

- Key Industrial Applications of ultrasuede material

- 3 Common User Pain Points for ‘ultrasuede material’ & Their Solutions

- Strategic Material Selection Guide for ultrasuede material

- In-depth Look: Manufacturing Processes and Quality Assurance for ultrasuede material

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘ultrasuede material’

- Comprehensive Cost and Pricing Analysis for ultrasuede material Sourcing

- Alternatives Analysis: Comparing ultrasuede material With Other Solutions

- Essential Technical Properties and Trade Terminology for ultrasuede material

- Navigating Market Dynamics and Sourcing Trends in the ultrasuede material Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of ultrasuede material

- Strategic Sourcing Conclusion and Outlook for ultrasuede material

- Important Disclaimer & Terms of Use

Understanding ultrasuede material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ultrasuede® | Made from ultra-fine fibers; soft and durable; eco-friendly production. | High-end upholstery, automotive interiors, fashion. | Pros: Luxurious feel, stain-resistant, machine-washable. Cons: Higher cost compared to microsuede. |

| Ultrasuede® nu | Enhanced texture and colorfastness; sustainable materials. | Commercial interiors, hospitality, luxury goods. | Pros: Eco-conscious choice, vibrant colors. Cons: Limited availability in some regions. |

| Performance Ultrasuede | Extra durability and stain resistance; ideal for heavy use. | Hospitality, healthcare, automotive. | Pros: Long-lasting, easy maintenance. Cons: Slightly heavier than standard ultrasuede. |

| Microfiber Ultrasuede | Budget-friendly alternative; softer, yet less durable. | Residential upholstery, fashion accessories. | Pros: Cost-effective, wide range of colors. Cons: Less durable than Ultrasuede; may require more frequent replacement. |

| Automotive Ultrasuede | Specifically designed for vehicle interiors; UV resistant. | Automotive upholstery, custom car interiors. | Pros: Customizable, enhances vehicle aesthetics. Cons: May not be suitable for non-automotive applications. |

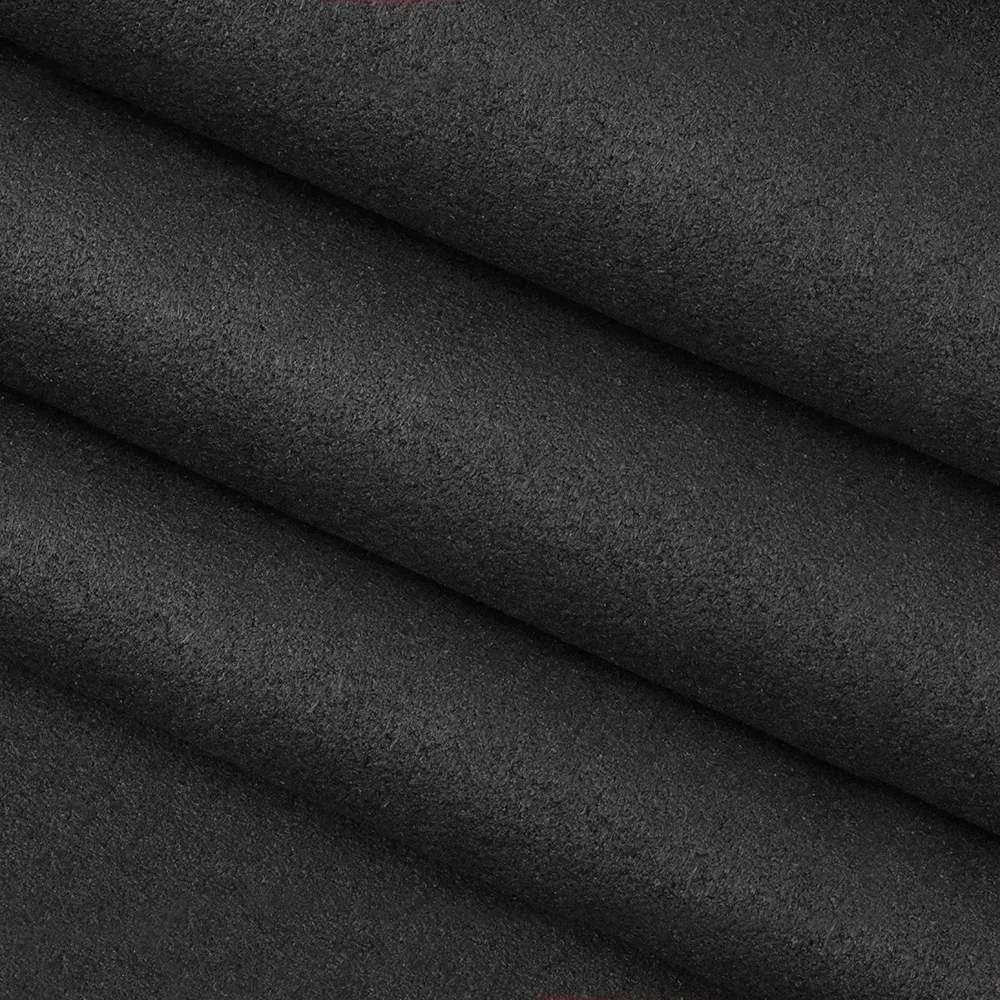

What Are the Key Characteristics of Ultrasuede®?

Ultrasuede® is a premium synthetic fabric made from ultra-fine fibers, providing a luxurious feel akin to natural suede. Its eco-friendly production processes, which incorporate recycled materials, make it an attractive option for businesses focused on sustainability. This material is commonly used in high-end upholstery, automotive interiors, and fashion items, appealing to B2B buyers looking for quality and durability. When purchasing, companies should consider its higher price point compared to alternatives like microsuede, but the investment often pays off in longevity and aesthetic appeal.

How Does Ultrasuede® nu Differ from Other Variations?

Ultrasuede® nu offers an enhanced texture and superior colorfastness compared to standard Ultrasuede®. This variation is particularly suitable for commercial settings, including hospitality and luxury goods, where a vibrant and durable appearance is essential. Its sustainable production aligns with the growing demand for eco-conscious materials. B2B buyers should assess availability and sourcing options, as this specialized fabric may be less accessible in certain markets.

What Advantages Does Performance Ultrasuede Offer?

Performance Ultrasuede is designed for high-traffic environments, providing extra durability and superior stain resistance. This makes it an ideal choice for industries such as hospitality and healthcare, where upholstery must withstand heavy use while maintaining a clean appearance. Buyers should consider the slightly heavier weight of this material, which may influence application suitability, but its long-lasting nature and ease of maintenance typically outweigh this concern.

Why Choose Microfiber Ultrasuede for Budget-Conscious Projects?

Microfiber Ultrasuede serves as a budget-friendly alternative to traditional Ultrasuede, offering a soft texture and a wide range of colors. It is often used in residential upholstery and fashion accessories, making it appealing to businesses with tighter budgets. However, B2B buyers should be aware that while it is cost-effective, it may not offer the same level of durability as Ultrasuede, potentially leading to more frequent replacements.

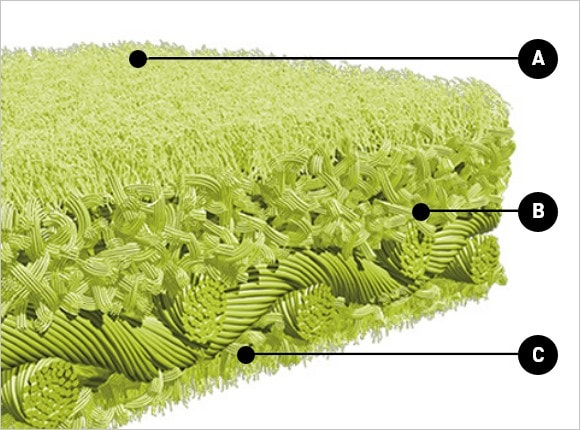

Illustrative image related to ultrasuede material

What Makes Automotive Ultrasuede Unique for Vehicle Interiors?

Automotive Ultrasuede is specifically engineered for vehicle interiors, featuring UV resistance and customizable options to enhance aesthetics. This variation is perfect for businesses in the automotive industry looking to provide high-quality upholstery solutions. When sourcing Automotive Ultrasuede, companies should evaluate its compatibility with non-automotive applications, as its specialized properties may limit its use elsewhere.

Key Industrial Applications of ultrasuede material

| Industry/Sector | Specific Application of ultrasuede material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Upholstery for car interiors | Enhances vehicle aesthetics while providing durability and comfort | Ensure compliance with automotive standards and regulations |

| Hospitality | Upholstery for furniture in hotels and restaurants | Offers a luxurious look while being easy to clean and maintain | Focus on stain resistance and fade-proof qualities |

| Fashion & Apparel | High-end clothing and accessories | Provides a vegan alternative to leather without compromising style | Source from suppliers with sustainable practices |

| Interior Design | Wall coverings and decorative elements | Adds elegance and warmth to spaces while being easy to maintain | Look for colorfast options and a variety of textures available |

| Pet Products | Durable pet furniture and accessories | Combines style with functionality, resistant to stains and wear | Prioritize hypoallergenic properties and ease of cleaning |

How is Ultrasuede Material Used in the Automotive Sector?

In the automotive industry, ultrasuede is increasingly utilized for upholstery in car interiors, including seats and trim. Its luxurious feel enhances the overall aesthetic of the vehicle while ensuring durability and comfort for passengers. For international buyers, particularly in regions like Africa and Europe, it’s crucial to source ultrasuede that meets automotive safety standards and is resistant to wear and tear from daily use. Buyers should also consider the material’s resistance to fading, as exposure to sunlight can diminish the fabric’s appearance over time.

What are the Benefits of Ultrasuede in the Hospitality Industry?

In the hospitality sector, ultrasuede is favored for its application in furniture upholstery within hotels and restaurants. This material not only provides a high-end look but is also easy to clean, making it ideal for high-traffic areas. For B2B buyers in regions like South America and the Middle East, sourcing ultrasuede that offers stain resistance and durability is essential for maintaining the aesthetic appeal of hospitality spaces. Additionally, the fabric’s colorfastness ensures that it retains its vibrant hues despite frequent cleaning and exposure to sunlight.

How is Ultrasuede Revolutionizing Fashion and Apparel?

Ultrasuede is making waves in the fashion industry as a premium material for high-end clothing and accessories. It serves as a sustainable, vegan alternative to traditional leather, appealing to eco-conscious consumers without sacrificing style. International buyers, particularly in Europe, should focus on sourcing ultrasuede from suppliers committed to sustainable practices, ensuring that the fabric is produced ethically. The versatility in color and texture also allows designers to create unique, fashionable pieces that cater to diverse markets.

Illustrative image related to ultrasuede material

What Role Does Ultrasuede Play in Interior Design?

In interior design, ultrasuede is commonly used for wall coverings and decorative elements, adding warmth and elegance to various spaces. Its ease of maintenance and durability make it a preferred choice for residential and commercial applications alike. For B2B buyers from Africa and the Middle East, it is important to seek out suppliers that offer a wide range of colors and textures, as well as options that are colorfast and resistant to staining. This ensures that the design remains visually appealing and functional over time.

How is Ultrasuede Beneficial for Pet Products?

Ultrasuede is gaining popularity in the pet product industry for use in durable pet furniture and accessories. Its resistance to stains and wear makes it a practical choice for pet owners who want stylish yet functional products. When sourcing ultrasuede for pet applications, international buyers should prioritize hypoallergenic properties and ease of cleaning, as these factors contribute to the overall health and comfort of pets. This makes ultrasuede an ideal material for creating products that stand the test of time while maintaining aesthetic appeal.

3 Common User Pain Points for ‘ultrasuede material’ & Their Solutions

Scenario 1: Sourcing Ultrasuede Material with Quality Assurance

The Problem: B2B buyers often face challenges in ensuring the quality of ultrasuede materials sourced from various suppliers. Inconsistent fabric quality can lead to product returns, customer dissatisfaction, and increased costs. Buyers may also struggle with identifying reputable suppliers, especially when sourcing from different regions such as Africa or South America, where standards may vary significantly. These factors can complicate inventory management and lead to delays in project timelines.

The Solution: To mitigate these risks, buyers should establish a robust supplier evaluation process. This includes requesting samples from multiple suppliers to assess the material’s texture, durability, and colorfastness. Additionally, consider utilizing suppliers who are certified by recognized organizations or have a proven track record in the industry. It’s also beneficial to engage in direct communication with suppliers to understand their production processes and quality control measures. Establishing long-term relationships with trusted suppliers can ensure consistent quality and reliability, reducing the likelihood of unexpected issues. Furthermore, leveraging technology such as supplier management software can streamline the sourcing process, helping buyers keep track of supplier performance and material quality over time.

Scenario 2: Addressing Environmental Concerns with Ultrasuede

The Problem: As sustainability becomes a crucial factor in purchasing decisions, many B2B buyers are under pressure to ensure that the materials they procure align with eco-friendly practices. Ultrasuede, while being a sustainable alternative to leather, can still pose challenges if the sourcing and production processes are not transparent. Buyers may find it difficult to ascertain whether the ultrasuede they are considering meets their sustainability criteria, especially in regions where environmental regulations may not be as stringent.

Illustrative image related to ultrasuede material

The Solution: To address these concerns, buyers should prioritize sourcing ultrasuede from manufacturers that provide clear documentation on their sustainability practices. Look for certifications such as Global Organic Textile Standard (GOTS) or OEKO-TEX, which can provide assurance of eco-friendly production methods. Additionally, engaging in discussions with suppliers about their sourcing of raw materials—specifically, the use of recycled or organic fibers—can provide insights into the environmental impact of the product. Buyers can also consider partnering with suppliers who are committed to corporate social responsibility and transparency in their operations, thereby ensuring that their procurement processes contribute positively to sustainability goals.

Scenario 3: Managing Maintenance and Longevity of Ultrasuede Upholstery

The Problem: One of the frequent challenges faced by B2B buyers using ultrasuede for upholstery is maintaining its appearance and longevity, particularly in high-traffic areas such as hospitality environments. Without proper care, ultrasuede can accumulate dirt and stains, leading to a diminished aesthetic and increased maintenance costs. Buyers may struggle with how to educate their teams on the appropriate cleaning methods and maintenance routines necessary to preserve the fabric’s quality over time.

The Solution: To effectively manage the maintenance of ultrasuede, buyers should implement a comprehensive care guide tailored to their specific applications. This guide should include detailed cleaning instructions, emphasizing the importance of immediate spill response—such as using a lint brush for surface dirt and a damp cloth for stains—to prevent permanent damage. Offering training sessions for staff on the correct cleaning techniques can also empower them to maintain the upholstery effectively. Additionally, consider investing in protective treatments that enhance the stain resistance of ultrasuede, thus extending its life and appearance. Regularly scheduled deep cleanings by professional services can further ensure that the upholstery remains in prime condition, ultimately leading to a better return on investment for the buyer.

Strategic Material Selection Guide for ultrasuede material

What are the Key Properties of Ultrasuede Material?

Ultrasuede is a synthetic fabric made from ultra-fine polyester fibers, offering a luxurious texture similar to genuine suede. This high-performance, non-woven fabric is recognized for its durability, stain resistance, and ease of maintenance. It is lightweight, breathable, and retains a comfortable temperature, making it suitable for various applications, including upholstery, automotive interiors, and fashion. Its colorfast properties ensure that it maintains its vibrant hues even when exposed to sunlight, making it an ideal choice for both residential and commercial settings.

Illustrative image related to ultrasuede material

What are the Advantages and Disadvantages of Ultrasuede?

Pros:

– Durability: Ultrasuede is known for its long-lasting performance, resisting wear and tear, which is crucial for high-traffic areas in commercial environments.

– Stain Resistance: The fabric’s inherent stain resistance simplifies maintenance, making it easier to clean and restore its appearance.

– Eco-Friendly Options: Many Ultrasuede products are made from recycled materials, aligning with sustainability goals that are increasingly important to B2B buyers.

Cons:

– Cost: While Ultrasuede is more affordable than genuine leather, it can still be considered a higher-cost option compared to standard synthetic fabrics.

– Manufacturing Complexity: The production process of Ultrasuede can be more complex than simpler fabrics, potentially leading to longer lead times for large orders.

How Does Ultrasuede Impact Application in Various Industries?

Ultrasuede’s versatility allows it to be used across multiple sectors. In the furniture industry, its durability and aesthetic appeal make it a preferred choice for upholstery in both residential and commercial spaces. In automotive applications, its lightweight nature and resistance to fading make it suitable for car interiors, enhancing both comfort and style. Fashion designers also favor Ultrasuede for its luxurious feel and wide range of colors, allowing for creative applications in clothing and accessories.

What Should International B2B Buyers Consider When Selecting Ultrasuede?

When sourcing Ultrasuede, international buyers must consider compliance with local regulations and standards. For example, in Europe, adherence to DIN standards is crucial, while ASTM standards are often referenced in the United States. Buyers from regions like Africa and South America should be aware of local preferences for sustainable materials, as eco-consciousness is a growing trend. Furthermore, understanding the supply chain logistics, including shipping costs and lead times, is essential for effective procurement.

Illustrative image related to ultrasuede material

Summary Table of Ultrasuede Material Selection

| Material | Typical Use Case for ultrasuede material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Ultrasuede | Upholstery for furniture and automotive | Durable and stain-resistant | Higher cost compared to standard synthetics | Medium |

| Ultrasuede | Fashion items like bags and clothing | Luxurious feel with a wide color range | Complex manufacturing process | High |

| Ultrasuede | Commercial settings (hotels, offices) | Colorfast and easy to maintain | May require special cleaning methods | Medium |

| Ultrasuede | Automotive interiors | Lightweight and breathable | Not as cost-effective as some alternatives | Medium |

This strategic material selection guide provides B2B buyers with essential insights into Ultrasuede, ensuring informed decisions that align with their operational needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for ultrasuede material

What Are the Main Stages in the Manufacturing Process of Ultrasuede Material?

The manufacturing process of Ultrasuede involves several critical stages that contribute to its unique properties and high-quality finish. Understanding these stages is essential for B2B buyers looking to source this material effectively.

Material Preparation

The process begins with the selection and preparation of raw materials. Ultrasuede is predominantly made from ultra-fine polyester fibers, which are engineered to mimic the texture and appearance of genuine suede. These fibers are sourced from sustainable materials, aligning with eco-friendly production practices. During this stage, the fibers undergo a rigorous quality check to ensure that only the best materials proceed to the next phase.

Illustrative image related to ultrasuede material

Forming Techniques

Once the materials are prepared, they enter the forming stage. Ultrasuede is produced using a non-woven technique that involves bonding the polyester fibers through a unique process of heat and pressure. This method not only enhances the fabric’s durability but also ensures that it retains its softness and luxurious feel. The non-woven structure is critical as it contributes to the fabric’s stain resistance and easy cleanability, two vital attributes for upholstery applications.

Assembly and Finishing

Following the forming stage, Ultrasuede undergoes assembly and finishing processes. This includes dyeing the fabric to achieve a wide range of colors and patterns. The dyeing process is conducted using advanced technology to ensure colorfastness, which is essential for maintaining the fabric’s aesthetic appeal over time. After dyeing, the fabric is treated with additional coatings to enhance its water and stain resistance. Finally, it is inspected for any defects and rolled for distribution.

How Is Quality Assurance Implemented in Ultrasuede Manufacturing?

Quality assurance is a critical aspect of Ultrasuede production, ensuring that the final product meets international standards and customer expectations. B2B buyers should be aware of the specific quality control measures in place.

Illustrative image related to ultrasuede material

What International Standards Are Relevant for Ultrasuede Quality Control?

Ultrasuede manufacturers typically adhere to several international quality standards, including ISO 9001, which focuses on quality management systems. Compliance with ISO 9001 indicates that a company has established a framework for consistently providing products that meet customer and regulatory requirements. Additionally, industry-specific certifications such as CE marking for European markets and API standards for automotive applications may also be applicable, depending on the intended use of the fabric.

What Are the Key Quality Control Checkpoints?

Quality control in Ultrasuede manufacturing involves multiple checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This phase involves inspecting raw materials upon arrival to ensure they meet predefined specifications. Any non-conforming materials are rejected or reprocessed.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are performed to monitor the quality of the product at various stages, including during fiber bonding and dyeing. This ensures that any issues are identified and rectified immediately.

-

Final Quality Control (FQC): Once production is complete, the finished Ultrasuede is subjected to final inspections. This includes testing for colorfastness, durability, and overall appearance. Only products that pass these checks are approved for shipment.

What Common Testing Methods Are Used for Ultrasuede Quality Assurance?

To ensure the quality of Ultrasuede, several testing methods are employed:

-

Abrasion Resistance Testing: This assesses the fabric’s durability and how well it withstands wear over time.

-

Colorfastness Testing: This evaluates how well the fabric retains its color when exposed to light, washing, or rubbing.

-

Water Repellency Testing: This determines the fabric’s ability to resist water penetration, which is critical for upholstery and automotive applications.

-

Flame Resistance Testing: For certain applications, especially in commercial settings, testing for flame resistance is essential to meet safety regulations.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control processes of Ultrasuede suppliers:

-

Conduct Audits: Regular audits of suppliers can provide insight into their quality management practices and compliance with international standards. Audits can be conducted by the buyer or through third-party organizations.

-

Request Quality Assurance Reports: Suppliers should be able to provide documentation of their quality assurance processes, including results from IQC, IPQC, and FQC.

-

Third-Party Inspection Services: Engaging third-party inspection services can offer an unbiased review of the supplier’s manufacturing processes and quality control measures.

-

Certifications Verification: Buyers should check for relevant certifications and ensure they are current. This may include ISO certifications and any industry-specific credentials.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential:

-

Regulatory Compliance: Different regions may have varying regulations regarding textile products. Buyers should be aware of local standards and ensure that their suppliers comply with them.

-

Cultural Considerations: Quality perceptions can vary by region. B2B buyers should communicate clearly about their quality expectations and ensure that suppliers understand these nuances.

-

Supply Chain Transparency: Buyers should seek suppliers who provide transparency in their supply chains. This includes insight into sourcing practices and labor conditions, which can impact overall product quality.

In conclusion, understanding the manufacturing processes and quality assurance measures for Ultrasuede is crucial for B2B buyers. By focusing on the stages of production and the relevant quality control standards, buyers can make informed decisions that align with their needs and expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ultrasuede material’

To assist B2B buyers in sourcing ultrasuede material effectively, this guide outlines crucial steps to streamline the procurement process. Ultrasuede, known for its durability, aesthetic appeal, and eco-friendliness, is an excellent choice for various applications, from furniture upholstery to automotive interiors. By following this checklist, buyers can ensure they select the best products and suppliers for their needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications required for your project. This includes determining the type of ultrasuede (e.g., thickness, texture, colorfastness) that aligns with your intended application. Knowing your specifications will help you communicate effectively with suppliers and ensure the materials meet your quality standards.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in ultrasuede. Look for manufacturers with a solid reputation in the industry, particularly those with a history of serving businesses similar to yours. Make use of online directories, trade shows, and industry networks to compile a list of reputable suppliers.

Step 3: Evaluate Supplier Certifications

Verify that potential suppliers hold relevant certifications that demonstrate their commitment to quality and sustainability. Certifications such as ISO 9001 for quality management systems or eco-labels indicating sustainable production practices can provide assurance of the material’s quality and ethical sourcing. This step is vital to mitigate risks associated with substandard materials.

Step 4: Request Samples for Quality Assessment

Always request samples of ultrasuede before making a bulk order. This allows you to assess the texture, color, and durability firsthand. Evaluate the samples against your specifications and perform any necessary tests, such as stain resistance or colorfastness, to ensure they meet your project requirements.

Step 5: Analyze Pricing and Payment Terms

Once you have narrowed down your supplier options, analyze their pricing structures and payment terms. Compare quotes from different suppliers to ensure you receive competitive pricing while considering the quality offered. Additionally, clarify payment terms, including deposits, payment methods, and any discounts for bulk orders, to optimize your budget.

Step 6: Negotiate Delivery Timelines

Discuss delivery timelines with your selected suppliers to ensure they align with your project schedule. Establish clear expectations regarding lead times and shipping methods. Timely delivery is critical in B2B transactions, as delays can affect your production timelines and overall project success.

Step 7: Establish a Communication Plan

Maintain an open line of communication with your suppliers throughout the sourcing process. Establish a communication plan that outlines how often you will check in and the preferred methods of communication. This proactive approach can help address any issues promptly and foster a strong working relationship.

By following this checklist, B2B buyers can streamline their sourcing process for ultrasuede material, ensuring they select high-quality products that meet their specific needs while building strong relationships with reliable suppliers.

Comprehensive Cost and Pricing Analysis for ultrasuede material Sourcing

What Are the Key Cost Components in Ultrasuede Material Sourcing?

When sourcing ultrasuede material, understanding the cost structure is essential for effective budgeting and procurement. The primary cost components include:

-

Materials: The base cost of ultrasuede is influenced by the quality of raw materials used. Ultrasuede is produced from ultra-fine fibers, and sourcing high-quality, sustainable materials can affect pricing. Generally, premium grades of ultrasuede will command higher prices due to their durability and aesthetic appeal.

-

Labor: Labor costs encompass the wages of workers involved in the manufacturing process. This can vary significantly based on the region where the ultrasuede is produced. In countries with higher labor costs, such as Germany, overall production costs may be elevated compared to regions like South America or parts of Africa.

-

Manufacturing Overhead: This includes costs associated with the factory’s operational expenses, such as utilities, equipment maintenance, and administrative costs. Efficient production processes can help mitigate these overhead costs, leading to more competitive pricing.

-

Tooling: If custom designs or specifications are required, tooling costs can arise. This includes the expense of creating molds or specific machinery to produce unique patterns or colors in ultrasuede.

-

Quality Control (QC): Ensuring that the final product meets quality standards requires investment in QC processes. This can include testing for durability, colorfastness, and other performance metrics, which contributes to the overall cost.

-

Logistics: Shipping and transportation costs must also be considered, particularly for international buyers. Factors such as shipping distance, freight methods, and local tariffs can add to the final cost of sourced ultrasuede.

-

Margin: Suppliers will typically mark up the cost of production to ensure profitability. Understanding the margins within the industry can help buyers negotiate better deals.

How Do Price Influencers Affect Ultrasuede Material Costs?

Several factors can significantly influence the pricing of ultrasuede materials:

-

Volume and Minimum Order Quantity (MOQ): Purchasing larger quantities often results in lower per-unit prices. Suppliers may offer discounts for bulk orders, making it more cost-effective for larger projects.

-

Specifications and Customization: Custom orders may incur additional costs for tooling and setup. Standard products will generally be less expensive than customized options.

-

Material Quality and Certifications: Higher quality materials with certifications (e.g., eco-friendly or hypoallergenic) can increase costs. Buyers should assess the value of these certifications against their project requirements.

-

Supplier Factors: The reputation and reliability of the supplier can also impact pricing. Established suppliers with a track record may charge more but offer better quality assurance.

-

Incoterms: The terms of sale can influence the overall cost. For instance, choosing a DDP (Delivered Duty Paid) arrangement might seem pricier upfront but can simplify the logistics and customs process for international buyers.

What Negotiation Tips Can Enhance Cost-Efficiency for Buyers?

To maximize cost-efficiency when sourcing ultrasuede, buyers should consider the following strategies:

-

Research and Benchmarking: Understand market prices and compare quotes from multiple suppliers. This knowledge can provide leverage during negotiations.

-

Leverage Relationships: Build strong relationships with suppliers. Long-term partnerships can lead to better pricing, priority service, and favorable payment terms.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider the longevity, maintenance, and potential replacement costs of the ultrasuede, as a higher upfront cost may lead to savings over time.

-

Understand Pricing Nuances: Be aware of local economic conditions, currency fluctuations, and trade regulations that may affect pricing, particularly for buyers in Africa, South America, the Middle East, and Europe.

Disclaimer on Pricing

It is important to note that pricing for ultrasuede materials can vary widely based on the factors discussed. The information provided is indicative and subject to change based on market conditions, supplier negotiations, and specific buyer requirements. Always seek updated quotes and detailed breakdowns from suppliers to ensure accurate budgeting.

Illustrative image related to ultrasuede material

Alternatives Analysis: Comparing ultrasuede material With Other Solutions

When considering materials for upholstery and fashion applications, it’s essential for B2B buyers to evaluate various options that can meet their specific needs. Ultrasuede, a high-performance synthetic fabric, offers unique advantages, but there are also other viable alternatives worth exploring. This analysis will compare Ultrasuede against two popular alternatives: microsuede and genuine leather, assessing their respective performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Ultrasuede Material | Microsuede | Genuine Leather |

|---|---|---|---|

| Performance | Highly durable, stain-resistant, and soft | Good durability, less expensive | Excellent durability and luxury feel |

| Cost | Higher cost per yard | Lower cost, budget-friendly | Higher initial investment |

| Ease of Implementation | Easy to work with, versatile colors | Easy to sew and manipulate | Requires more specialized handling |

| Maintenance | Machine-washable, easy to clean | Generally easy, but may stain easily | Requires regular conditioning and care |

| Best Use Case | High-end furniture, automotive, fashion | Residential furniture, pet areas | Luxury furniture, high-end fashion |

What Are the Key Pros and Cons of Microsuede as an Alternative to Ultrasuede?

Microsuede is a popular alternative that mimics the appearance and feel of real suede at a lower price point. It is made from tightly woven polyester fibers, providing a soft texture that is appealing for residential furniture and pet-friendly environments. The cost-effectiveness of microsuede makes it an attractive option for budget-conscious buyers. However, it may not offer the same level of durability and stain resistance as Ultrasuede, making it less suitable for high-traffic or luxury applications.

What Makes Genuine Leather a Compelling Option Compared to Ultrasuede?

Genuine leather is often regarded as the gold standard in upholstery due to its unparalleled durability and luxurious aesthetic. It ages beautifully and can withstand significant wear and tear, making it ideal for high-end furniture and fashion items. However, genuine leather comes with a higher price tag and requires more maintenance, including regular conditioning to prevent drying and cracking. While it provides a sophisticated look, the environmental impact and ethical considerations related to animal sourcing may deter some buyers.

How Can B2B Buyers Choose the Right Upholstery Solution for Their Needs?

When selecting the right upholstery material, B2B buyers should consider their specific application, budget constraints, and desired aesthetic. Ultrasuede is an excellent choice for those looking for a blend of luxury and durability, particularly in high-end settings. Microsuede serves as a budget-friendly option for residential applications, especially in homes with pets. On the other hand, genuine leather appeals to luxury markets but requires careful consideration of maintenance and ethical sourcing. By evaluating these factors, buyers can make informed decisions that align with their business objectives and customer expectations.

Essential Technical Properties and Trade Terminology for ultrasuede material

What Are the Key Technical Properties of Ultrasuede Material?

Ultrasuede is a high-performance, non-woven fabric made from ultra-fine fibers, making it a popular choice in various industries, including automotive, fashion, and interior design. Understanding its critical technical properties can help B2B buyers make informed decisions.

1. Material Composition

Ultrasuede is typically composed of polyester fibers, which are engineered to replicate the softness and durability of genuine suede. The unique manufacturing process results in a lightweight yet robust fabric that is resistant to wear and tear. For buyers, this means reduced costs associated with replacement and maintenance, especially in commercial applications.

2. Durability and Performance

One of the standout features of Ultrasuede is its exceptional durability. It is resistant to stains, fading, and soiling, making it ideal for high-traffic areas. In B2B scenarios, this property translates to lower lifecycle costs, as the fabric requires less frequent cleaning and replacement, providing long-term value for upholstery projects.

3. Colorfastness

Ultrasuede maintains its vibrant colors over time, even when exposed to sunlight. This colorfastness is crucial for applications in environments such as hotels, restaurants, and automotive interiors, where aesthetics play a significant role. Buyers can confidently select Ultrasuede for projects requiring a consistent and appealing visual appeal throughout its lifespan.

Illustrative image related to ultrasuede material

4. Ease of Maintenance

The fabric’s inherent stain resistance allows for easy cleaning with minimal effort. Most spills can be dealt with by simply blotting with a paper towel, and many Ultrasuede products are machine-washable. For B2B buyers, this ease of maintenance can lead to significant labor savings and customer satisfaction, particularly in hospitality and automotive sectors.

5. Sustainability

Ultrasuede is manufactured using eco-friendly processes and often incorporates recycled materials. This aligns with the growing demand for sustainable products in the B2B market, allowing companies to enhance their brand reputation while meeting environmental standards.

6. Temperature Regulation

Ultrasuede fabric stays cool to the touch, making it a comfortable choice for upholstery, especially in warmer climates. This property is particularly beneficial for automotive applications, where temperature control can enhance user comfort.

What Are Common Trade Terms Related to Ultrasuede Material?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms related to Ultrasuede:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. In the context of Ultrasuede, businesses might engage with OEMs to create custom upholstery solutions for their products, ensuring quality and brand consistency.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. For Ultrasuede, understanding the MOQ is vital for buyers looking to manage inventory costs effectively, especially when placing bulk orders for upholstery projects.

3. RFQ (Request for Quotation)

An RFQ is a formal process where a buyer requests pricing information from suppliers. This is crucial for B2B buyers of Ultrasuede to compare costs and make budget-conscious decisions based on supplier capabilities.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. Familiarity with these terms helps B2B buyers understand shipping costs, risk, and delivery obligations when sourcing Ultrasuede from overseas suppliers.

5. Lead Time

Lead time refers to the period between placing an order and receiving it. For Ultrasuede, knowing the lead time is essential for project planning and ensuring timely delivery for upholstery needs, particularly in industries with tight deadlines.

By grasping these technical properties and trade terminologies, international B2B buyers can navigate the Ultrasuede market more effectively, ensuring they make informed purchasing decisions that align with their business needs.

Illustrative image related to ultrasuede material

Navigating Market Dynamics and Sourcing Trends in the ultrasuede material Sector

What Are the Current Market Dynamics and Key Trends in the Ultrasuede Material Sector?

The ultrasuede material sector is witnessing significant growth driven by various global factors. The rising demand for sustainable and cruelty-free alternatives to leather is a key driver, particularly in markets across Africa, South America, the Middle East, and Europe. As consumers and businesses become increasingly aware of environmental issues, the preference for ultrasuede—made from synthetic materials yet offering a luxurious feel—has surged. Additionally, advancements in manufacturing technologies are enhancing the material’s durability and versatility, making it suitable for diverse applications, from high-end fashion to automotive interiors.

Emerging B2B tech trends, such as digital sourcing platforms and data analytics, are transforming how buyers in these regions procure ultrasuede materials. International buyers are leveraging e-commerce solutions to access a wider range of suppliers, facilitating competitive pricing and improved supply chain efficiencies. Furthermore, the rise of customization services, allowing businesses to order specific colors and patterns, aligns with the growing trend of personalized products in the market.

How Is Sustainability and Ethical Sourcing Impacting the Ultrasuede Material Sector?

Sustainability has become a cornerstone of the ultrasuede material sector, reflecting a broader shift towards environmentally responsible practices. The production of ultrasuede is increasingly being associated with reduced environmental impact due to the use of recycled materials and sustainable manufacturing processes. This focus on sustainability not only meets the demands of environmentally conscious consumers but also positions brands favorably in the global marketplace.

Ethical sourcing is paramount for international B2B buyers, especially in regions where regulatory frameworks are evolving. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® ensure that ultrasuede materials are produced without harmful chemicals and under fair labor conditions. Buyers are encouraged to prioritize suppliers who demonstrate commitment to ethical practices, as these certifications can enhance brand reputation and consumer trust.

Incorporating sustainability into purchasing decisions not only aligns with global trends but also opens up opportunities for collaboration with brands dedicated to environmental stewardship. As buyers from Africa, South America, the Middle East, and Europe increasingly seek out sustainable options, the demand for responsibly sourced ultrasuede is expected to grow.

What Is the Evolution of Ultrasuede and Its Significance for B2B Buyers?

Ultrasuede was developed in the 1970s by Toray Industries, marking a significant innovation in synthetic fabrics. Initially designed as a high-performance alternative to natural suede, it quickly gained popularity for its softness, durability, and ease of maintenance. The fabric’s unique composition allows it to mimic the luxurious feel of leather while offering advantages such as stain resistance and machine washability.

For B2B buyers, understanding the evolution of ultrasuede is crucial for recognizing its value in modern applications. Its transformation from a niche product to a mainstream choice across various industries highlights its adaptability and appeal. As the market continues to evolve, staying informed about the historical context and advancements in ultrasuede technology will enable buyers to make strategic sourcing decisions that align with current trends and consumer preferences.

Illustrative image related to ultrasuede material

Frequently Asked Questions (FAQs) for B2B Buyers of ultrasuede material

-

How do I choose the right supplier for ultrasuede material?

Choosing the right supplier for ultrasuede involves assessing their reputation, quality standards, and production capabilities. Look for suppliers with certifications that indicate adherence to international quality standards, such as ISO. Additionally, request samples to evaluate the material’s texture, durability, and colorfastness. It’s also beneficial to inquire about their experience in your specific industry and their ability to meet your volume needs, including their logistics capabilities for international shipping. -

What are the key benefits of using ultrasuede for upholstery?

Ultrasuede offers several advantages for upholstery, including its luxurious feel, durability, and ease of maintenance. It is stain-resistant and machine-washable, making it suitable for both residential and commercial applications. The fabric also maintains its color well, even in sunlit environments, reducing the need for frequent replacements. Furthermore, its eco-friendly production methods appeal to environmentally-conscious buyers, making it a versatile choice for various upholstery projects. -

What is the minimum order quantity (MOQ) for ultrasuede fabric?

Minimum order quantities for ultrasuede can vary significantly between suppliers. Typically, MOQs range from 10 to 50 yards, depending on the supplier’s production capabilities and your specific requirements. It’s advisable to discuss your project needs with potential suppliers to negotiate MOQs that align with your purchasing strategy. Larger orders may also qualify for volume discounts, so consider your long-term needs when placing orders. -

Can I customize the color and texture of ultrasuede fabric?

Yes, many suppliers offer customization options for ultrasuede, including color matching and texture variations. When discussing customization, provide specific color references or samples to ensure the final product meets your expectations. Keep in mind that custom orders may have longer lead times and higher costs, so it’s essential to plan accordingly. Additionally, inquire about the minimum quantities required for custom orders. -

What payment terms should I expect when sourcing ultrasuede material internationally?

Payment terms for international orders can vary, but common practices include upfront payments, letters of credit, or payment upon delivery. It’s crucial to clarify terms before finalizing any agreements. Many suppliers may require a deposit to begin processing your order, especially for custom fabrics. Always ensure that the payment method is secure and that you understand any associated fees, such as currency conversion or international transfer costs. -

What quality assurance measures should I look for in ultrasuede suppliers?

When sourcing ultrasuede, inquire about the supplier’s quality assurance processes. Look for suppliers who conduct regular fabric testing for durability, colorfastness, and stain resistance. Certifications from recognized organizations can also indicate adherence to quality standards. Establishing a clear communication channel for reporting and resolving quality issues is essential, as this will help ensure that the fabric meets your specifications consistently. -

How does logistics impact the sourcing of ultrasuede fabric?

Logistics play a crucial role in the sourcing of ultrasuede, especially for international buyers. Consider the supplier’s ability to manage shipping times, customs clearance, and delivery to your location. Discuss shipping options, including air versus sea freight, to find the most cost-effective and timely solution. It’s also advisable to work with suppliers who have experience in handling international shipments to minimize delays and ensure compliance with import regulations. -

What are the typical applications of ultrasuede in various industries?

Ultrasuede is versatile and used across multiple industries, including automotive, furniture, fashion, and interior design. In automotive applications, it is popular for seat covers due to its durability and ease of cleaning. The hospitality industry often uses it for upholstery in hotels and restaurants, providing a luxurious yet practical solution. Additionally, fashion designers utilize ultrasuede for garments and accessories, capitalizing on its aesthetic appeal and comfort. Understanding these applications can help you target specific markets effectively.

Top 3 Ultrasuede Material Manufacturers & Suppliers List

1. Kovi Fabrics – Ultrasuede Fabric

Domain: kovifabrics.com

Registered: 2010 (15 years)

Introduction: Ultrasuede Fabric by the Yard – Premium Quality Suede Leather Alternative. Soft, luxurious, vegan fabric that mimics the feel and durability of suede leather. Colorfast and fade-resistant, ideal for upholstery on sofas, chairs, and automotive applications. Made using sustainable methods with natural and recycled materials. Manufactured by Toray Industries in Japan. Not the same as microsuede; Ultr…

2. Vogue Fabrics – Ultrasuede® Upholstery & Apparel Fabric

Domain: voguefabricsstore.com

Registered: 2001 (24 years)

Introduction: Ultrasuede® Upholstery and Apparel Fabric

3. Sailrite – Ultrasuede® HP Stone 55 Fabric

Domain: sailrite.com

Registered: 1996 (29 years)

Introduction: {‘name’: ‘Ultrasuede® HP Stone 55″ Fabric’, ‘sku’: ‘120636’, ‘price_per_yard’: ‘$99.95’, ‘available_quantity’: 17, ‘discount_code’: ‘FAB10’, ‘discount_expiration’: ‘9/30/25, at 8 a.m. ET’, ‘return_policy’: ‘Not Returnable’, ‘sample_price’: ‘$4.00’, ‘sample_size’: ‘6″ x 6″‘, ‘description’: ‘Ultrasuede HP Fabric is an ultra-microfiber developed to maintain its soft, suede hand and luxurious aestheti…

Strategic Sourcing Conclusion and Outlook for ultrasuede material

In summary, strategic sourcing of Ultrasuede material offers B2B buyers a unique opportunity to leverage its high-performance characteristics, sustainability, and versatility across various applications. This premium fabric not only mimics the luxurious feel of genuine suede but also provides significant benefits such as durability, ease of cleaning, and a wide range of color options, making it an ideal choice for diverse industries, from hospitality to automotive.

For international buyers, particularly in emerging markets such as Africa and South America, as well as established sectors in Europe and the Middle East, investing in Ultrasuede can enhance product offerings while aligning with growing consumer demand for sustainable and ethically produced materials. The strategic sourcing of this innovative fabric can lead to improved supply chain efficiencies and reduced operational costs, ultimately driving profitability.

Looking ahead, B2B buyers are encouraged to engage with reputable suppliers and explore volume purchasing options to maximize cost-effectiveness. By prioritizing Ultrasuede in your sourcing strategy, you not only elevate your product line but also position your business as a leader in sustainable practices. Act now to secure partnerships that will pave the way for future growth and innovation in your market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to ultrasuede material

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.