Introduction: Navigating the Global Market for custom leather gloves

In an increasingly competitive global market, sourcing high-quality custom leather gloves presents both a challenge and an opportunity for B2B buyers. Whether you are seeking durable work gloves for industrial applications or luxurious leather gloves for fashion retail, navigating the diverse offerings can be daunting. This guide is designed to empower international buyers, particularly those in Africa, South America, the Middle East, and Europe, by providing actionable insights into the types of custom leather gloves available, their applications, and the critical factors to consider when vetting suppliers.

From understanding the nuances of leather quality to evaluating manufacturing processes, this comprehensive resource will equip you with the knowledge needed to make informed purchasing decisions. We will delve into various styles and functionalities, explore pricing structures, and highlight the importance of ethical sourcing practices. Additionally, the guide will address common pitfalls to avoid, ensuring you select suppliers who align with your business values and quality standards.

By leveraging this information, B2B buyers can confidently navigate the complexities of the custom leather glove market, ultimately leading to successful partnerships and enhanced product offerings. As you embark on this journey, let this guide serve as your essential companion in making strategic and impactful purchasing decisions.

Table Of Contents

- Top 6 Custom Leather Gloves Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for custom leather gloves

- Understanding custom leather gloves Types and Variations

- Key Industrial Applications of custom leather gloves

- 3 Common User Pain Points for ‘custom leather gloves’ & Their Solutions

- Strategic Material Selection Guide for custom leather gloves

- In-depth Look: Manufacturing Processes and Quality Assurance for custom leather gloves

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather gloves’

- Comprehensive Cost and Pricing Analysis for custom leather gloves Sourcing

- Alternatives Analysis: Comparing custom leather gloves With Other Solutions

- Essential Technical Properties and Trade Terminology for custom leather gloves

- Navigating Market Dynamics and Sourcing Trends in the custom leather gloves Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of custom leather gloves

- Strategic Sourcing Conclusion and Outlook for custom leather gloves

- Important Disclaimer & Terms of Use

Understanding custom leather gloves Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Work Gloves | Durable, reinforced stitching, often made from goat or cow leather | Construction, agriculture, manufacturing | Pros: High durability, protection from abrasions. Cons: May lack flexibility compared to other types. |

| Driving Gloves | Lightweight, often fingerless or with perforations for breathability | Automotive, motorsports, luxury retail | Pros: Enhanced grip, stylish appearance. Cons: Limited protection against impacts. |

| Fashion Gloves | Made from premium leathers, often with unique designs and embellishments | Fashion retail, luxury gifting | Pros: High aesthetic value, customization options. Cons: Less functional for heavy-duty tasks. |

| Fingerless Gloves | Open fingers for dexterity, often made from soft leather | Crafts, electronics, outdoor activities | Pros: Greater dexterity, comfort. Cons: Less protection for the fingers. |

| Custom Monogrammed Gloves | Personalized with initials or designs, often hand-sewn | Corporate gifts, branding, events | Pros: Unique branding opportunity, high perceived value. Cons: Longer production times, often higher cost. |

What Are the Key Characteristics of Work Gloves for B2B Buyers?

Work gloves are designed for durability and functionality, making them essential for industries such as construction and agriculture. Typically made from tough materials like goat or cow leather, these gloves feature reinforced stitching and padding in high-wear areas. B2B buyers should consider factors such as abrasion resistance and fit, as these elements directly impact safety and comfort during prolonged use. Customization options may include sizes and additional protective features, catering to specific industry needs.

Illustrative image related to custom leather gloves

How Do Driving Gloves Enhance Performance and Style?

Driving gloves are crafted to provide a blend of comfort and grip, making them ideal for automotive applications. Lightweight materials, often featuring perforations, allow for breathability while maintaining a stylish appearance. B2B buyers in the automotive and luxury sectors should focus on the glove’s fit and grip quality, as these factors enhance driving performance. Customization options are available, allowing businesses to align the gloves with their branding or vehicle aesthetics.

What Makes Fashion Gloves a Valuable Investment for Retail?

Fashion gloves are made from high-quality leathers and are often characterized by unique designs and embellishments. They serve a dual purpose, offering both style and a degree of warmth. For B2B buyers in the fashion retail sector, investing in customizable fashion gloves can enhance product offerings and appeal to luxury consumers. However, these gloves may not provide the same level of protection as work gloves, so understanding the target market’s needs is crucial.

Why Are Fingerless Gloves Suitable for Specific Tasks?

Fingerless gloves are designed to provide dexterity and comfort, making them popular in crafts and electronic work. The open-finger design allows for greater tactile sensitivity, which can be essential for tasks requiring precision. B2B buyers should consider the trade-off between protection and dexterity when selecting fingerless gloves, as they may not offer full hand coverage. Custom options can enhance the appeal for specific industries, such as outdoor activities or specialized crafts.

How Can Custom Monogrammed Gloves Serve as a Unique Branding Tool?

Custom monogrammed gloves offer a personalized touch that can enhance brand identity and customer loyalty. These gloves are often hand-sewn and made from high-quality leather, making them ideal for corporate gifts or promotional items. B2B buyers should be aware of the longer production times and higher costs associated with customization, but the unique branding opportunity can justify the investment. Such gloves can be a memorable addition to events or client gifts, reinforcing brand values and commitment to quality.

Key Industrial Applications of custom leather gloves

| Industry/Sector | Specific Application of custom leather gloves | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Driving gloves for automotive professionals | Enhanced grip and comfort, reducing fatigue | Sourcing durable, breathable materials; customization options for fit and style. |

| Construction | Protective gloves for manual labor | Improved hand protection and dexterity | Compliance with safety standards; availability of various sizes and styles. |

| Agriculture | Gloves for handling livestock and machinery | Protection against cuts, abrasions, and chemicals | Sourcing resistant materials; ensuring comfort for extended wear. |

| Manufacturing | Gloves for assembly line workers | Enhanced grip and reduced risk of injury | Custom sizing and fit for diverse workforce; durability for high-volume use. |

| Hospitality & Events | Stylish gloves for service staff | Improved professionalism and brand image | Options for personalization and branding; availability in various colors and styles. |

How Are Custom Leather Gloves Used in the Automotive Industry?

In the automotive sector, custom leather gloves are essential for professionals who require enhanced grip and comfort while driving. These gloves not only provide a stylish accessory for car enthusiasts but also serve a functional purpose by reducing hand fatigue during long drives. Buyers in this industry should consider sourcing gloves made from high-quality materials that allow for breathability and flexibility, ensuring comfort without compromising on style.

Illustrative image related to custom leather gloves

What Role Do Custom Leather Gloves Play in Construction?

For the construction industry, custom leather gloves are vital for protecting workers’ hands during manual labor. These gloves help prevent injuries from sharp objects, abrasions, and harsh chemicals commonly encountered on job sites. B2B buyers should prioritize sourcing gloves that meet safety standards while offering various sizes and styles to accommodate the diverse workforce. Customization options can enhance fit and functionality, ensuring maximum protection and comfort.

How Are Custom Leather Gloves Beneficial in Agriculture?

In agriculture, custom leather gloves are indispensable for workers handling livestock and machinery. They provide essential protection against cuts, abrasions, and exposure to chemicals. Buyers in this sector should focus on sourcing gloves made from durable, resistant materials that can withstand the rigors of farm work. Comfort is also crucial, as agricultural tasks often require extended wear, making it important to find gloves that fit well and allow for dexterity.

Why Are Custom Leather Gloves Important in Manufacturing?

In manufacturing, custom leather gloves are used by assembly line workers to enhance grip and reduce the risk of injury. These gloves are designed to provide durability and protection without sacrificing dexterity, which is essential for handling small parts and tools. B2B buyers should consider sourcing gloves tailored to the specific needs of their workforce, including custom sizing options and materials that can withstand high-volume use.

How Do Custom Leather Gloves Enhance Professionalism in Hospitality?

In the hospitality and events sector, custom leather gloves serve as a stylish accessory for service staff, enhancing professionalism and brand image. These gloves can be personalized and branded, making them a valuable asset for businesses aiming to create a cohesive look. Buyers should look for options that offer a variety of colors and styles to match their brand identity while ensuring comfort and functionality for staff during service.

3 Common User Pain Points for ‘custom leather gloves’ & Their Solutions

Scenario 1: Sizing and Fit Issues with Custom Leather Gloves

The Problem: One of the most significant challenges B2B buyers face when procuring custom leather gloves is ensuring proper sizing and fit for their workforce. In many industries, gloves must be tailored to accommodate various hand sizes, and a poor fit can lead to reduced dexterity, discomfort, and even safety hazards. Buyers may struggle to communicate the specific sizing needs of their teams, leading to a mismatch between the product received and the intended use, which can ultimately result in wasted resources and time.

The Solution: To effectively address sizing challenges, buyers should implement a structured sizing process. This can involve creating a comprehensive sizing guide that includes visual aids, like hand tracing templates, allowing employees to accurately measure their hands. Suppliers should be encouraged to offer flexible sizing options, such as custom measurements or a range of sizes that can cater to diverse hand shapes. Additionally, consider requesting samples to test fit and comfort before placing a bulk order. This proactive approach not only ensures a better fit but also fosters a stronger relationship with the supplier, as they can provide tailored solutions based on the buyer’s specific requirements.

Scenario 2: Material Quality Concerns for Custom Leather Gloves

The Problem: B2B buyers often encounter uncertainty regarding the quality of leather used in custom gloves, especially when sourcing from international suppliers. Variability in leather quality can lead to products that do not meet durability or performance standards, resulting in customer dissatisfaction and increased replacement costs. Buyers may feel overwhelmed by the myriad of leather types available and unsure of which would be best suited for their particular application, whether for industrial use, fashion, or driving.

The Solution: To mitigate concerns about material quality, buyers should conduct thorough research on potential suppliers, focusing on those who provide transparent information about their sourcing and production processes. Request detailed specifications on the types of leather used, including grades and treatment processes. Engaging in direct communication with suppliers can also clarify any uncertainties; ask for samples to assess the texture, durability, and overall feel of the leather. Establishing a long-term partnership with a reputable supplier who specializes in high-quality leather products can help ensure consistency and reliability in future orders.

Scenario 3: Customization Challenges in Production and Delivery

The Problem: Another common pain point for B2B buyers is navigating the complexities of customization in both design and delivery timelines. Buyers may have specific branding or functional requirements that necessitate unique designs, such as embossed logos or specialized stitching. However, delays in customization processes can disrupt supply chains and lead to missed deadlines, impacting business operations. Additionally, varying lead times across suppliers can create confusion and complicate inventory management.

Illustrative image related to custom leather gloves

The Solution: To streamline the customization process, buyers should establish clear communication with suppliers about their specific needs right from the outset. Providing detailed specifications, including design mockups and examples of desired features, can minimize misunderstandings. It’s also advisable to set realistic timelines for production and delivery, factoring in potential delays. Prioritizing suppliers with proven track records of meeting deadlines and offering reliable customer service can significantly enhance the procurement experience. Utilizing project management tools to track orders and maintain open lines of communication with suppliers will further ensure that customization and delivery processes run smoothly, allowing buyers to maintain operational efficiency.

Strategic Material Selection Guide for custom leather gloves

What Are the Key Properties of Common Materials Used in Custom Leather Gloves?

When selecting materials for custom leather gloves, understanding the properties of various types of leather is crucial for ensuring performance and durability. Here, we analyze four common materials used in the manufacturing of custom leather gloves: cowhide, goatskin, deerskin, and peccary leather.

Cowhide Leather: A Versatile Option

Cowhide is one of the most commonly used leathers in glove manufacturing due to its durability and availability. It offers excellent abrasion resistance and can withstand a range of temperatures, making it suitable for various applications, from industrial work to casual wear.

Illustrative image related to custom leather gloves

Pros: Cowhide is relatively affordable and readily available, making it an economical choice for bulk orders. It is also robust, providing good protection against wear and tear.

Cons: While durable, cowhide can be stiff and less flexible compared to softer leathers, which may impact comfort during extended wear. Additionally, it may not perform as well in wet conditions unless treated.

Impact on Application: Cowhide gloves are suitable for heavy-duty tasks, including construction and automotive work, where durability is paramount.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM for safety gloves. Cowhide is widely accepted in markets across Africa, South America, and Europe.

Goatskin Leather: Softness Meets Strength

Goatskin leather is known for its softness and flexibility, making it an excellent choice for gloves that require dexterity, such as driving or precision work. It also offers good abrasion resistance and breathability.

Pros: The softness of goatskin provides a comfortable fit, enhancing the user experience. It is also lighter than cowhide, making it ideal for applications requiring fine motor skills.

Cons: Goatskin can be more expensive than cowhide and may not be as durable in extreme conditions. It is also more susceptible to water damage unless properly treated.

Impact on Application: Goatskin gloves are often used in high-precision tasks, such as electronics assembly or artisan crafts, where tactile sensitivity is essential.

Illustrative image related to custom leather gloves

Considerations for International Buyers: Buyers should check for compliance with international leather standards and ensure that the goatskin used is sourced ethically, as this is increasingly important in European markets.

Deerskin Leather: Luxury and Comfort

Deerskin is prized for its luxurious feel and natural softness. It provides excellent comfort and conforms well to the hand, making it a popular choice for high-end gloves.

Pros: Deerskin offers superior comfort and a unique aesthetic appeal, making it ideal for fashion-oriented applications. It is also naturally water-resistant to some degree.

Cons: The high cost of deerskin can be a barrier for bulk purchases. Additionally, it may not be as durable as cowhide in heavy-duty applications.

Impact on Application: Deerskin gloves are often used in luxury markets, including fashion and high-end driving gloves, where aesthetics and comfort are prioritized.

Illustrative image related to custom leather gloves

Considerations for International Buyers: Buyers should be aware of the sourcing regulations for deerskin, particularly in Europe, where sustainability is a key concern.

Peccary Leather: The Pinnacle of Luxury

Peccary leather is considered one of the finest leathers available, known for its unique texture and durability. It is often used in luxury gloves due to its softness and resistance to wear.

Pros: Peccary leather is extremely durable and offers a unique tactile experience, making it highly desirable in luxury markets.

Cons: It is one of the most expensive leathers, which may limit its use in mass production. Additionally, its sourcing is subject to strict regulations due to conservation efforts.

Impact on Application: Peccary gloves are typically used in high-end fashion and luxury driving gloves, where quality and exclusivity are paramount.

Considerations for International Buyers: Buyers must ensure compliance with international wildlife protection regulations when sourcing peccary leather, particularly in Europe and North America.

Summary of Material Properties for Custom Leather Gloves

| Material | Typical Use Case for custom leather gloves | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cowhide | Heavy-duty work gloves | Durable and cost-effective | Less flexible | Medium |

| Goatskin | Precision and driving gloves | Soft and flexible | More expensive | Medium to High |

| Deerskin | Luxury and fashion gloves | Superior comfort and aesthetics | High cost | High |

| Peccary | High-end luxury gloves | Unique texture and durability | Very high cost | High |

This guide provides a comprehensive overview of the materials available for custom leather gloves, helping international B2B buyers make informed decisions based on their specific needs and market preferences.

Illustrative image related to custom leather gloves

In-depth Look: Manufacturing Processes and Quality Assurance for custom leather gloves

What Are the Main Stages of Manufacturing Custom Leather Gloves?

The manufacturing process of custom leather gloves involves several key stages, each critical to ensuring the final product meets quality standards and customer expectations.

Material Preparation: How Is Leather Selected and Processed?

The first step in the manufacturing process is selecting high-quality leather. Common choices include goat, peccary, and deerskin, each offering unique characteristics such as softness, durability, and breathability. After selection, the leather undergoes several treatments including tanning, which preserves the material and enhances its properties. Depending on the end-use, it may also be dyed or finished to achieve specific aesthetics and functionality, such as water resistance or added grip.

Forming: What Techniques Are Used to Shape Gloves?

Once the leather is prepared, the next stage involves cutting the material into glove patterns. This is typically done using precision cutting tools or die-cutting machines to ensure accuracy. Skilled artisans may also use templates derived from hand measurements to create custom fits. The forming stage may include various techniques such as heat molding or stretching to ensure the glove conforms perfectly to the hand shape, enhancing comfort and dexterity.

Assembly: How Are Gloves Constructed?

Assembly is a crucial phase where individual glove components are stitched together. Hand-sewing is a common technique used to ensure durability and maintain the glove’s aesthetic appeal. For high-end products, artisans often employ specialized stitching methods, such as the “whip stitch” or “blind stitch,” which contribute to the glove’s overall strength and elegance. Automated sewing machines may also be utilized for mass production, but quality craftsmanship remains paramount in custom orders.

Finishing: What Quality Enhancements Are Applied?

The finishing stage involves several processes aimed at enhancing the glove’s look and feel. This may include edge finishing, polishing, and the application of protective coatings. Additionally, quality checks are conducted at this stage to ensure that the gloves meet all design specifications. Customization options such as engraving or embossing can be added, allowing for personal touches that appeal to B2B buyers looking for unique branding opportunities.

Illustrative image related to custom leather gloves

How Is Quality Assurance Implemented in Custom Leather Gloves Manufacturing?

Quality assurance (QA) is essential in the production of custom leather gloves, ensuring that every product meets international standards and customer expectations.

What International Standards Are Relevant for Quality Assurance?

One of the most recognized international standards for quality management is ISO 9001. This standard outlines the requirements for a quality management system (QMS) that organizations must fulfill to demonstrate their ability to consistently provide products that meet customer and regulatory requirements. In the context of leather gloves, adherence to ISO 9001 means that manufacturers must have robust processes in place for quality control, customer feedback, and continual improvement.

Additional certifications may include CE marking for products sold within the European Economic Area, indicating compliance with health, safety, and environmental protection standards. For specialized gloves, such as those used in industrial applications, compliance with API standards may also be relevant.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints throughout the manufacturing process help ensure that any defects are identified and rectified promptly. Common QC checkpoints include:

Illustrative image related to custom leather gloves

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials, such as leather, for quality and compliance with specifications before they enter the production line.

-

In-Process Quality Control (IPQC): During production, random samples of gloves are checked for stitching quality, fit, and overall craftsmanship to ensure that standards are maintained throughout the assembly process.

-

Final Quality Control (FQC): Once the gloves are completed, a thorough inspection is conducted. This includes checking for defects, verifying measurements, and assessing overall finish and presentation.

What Common Testing Methods Are Employed?

Testing methods for custom leather gloves often include tensile strength tests, abrasion resistance tests, and waterproofing assessments, depending on the intended use of the gloves. These tests help verify that the gloves can withstand the rigors of their intended environments, whether for industrial work, driving, or fashion.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to ensure that their suppliers adhere to stringent quality control measures.

What Audits and Reports Should Be Requested?

Buyers can request documentation of quality audits, including internal and external audit reports, to assess the supplier’s compliance with international standards. Regular audits conducted by third-party organizations can provide an unbiased evaluation of the supplier’s quality management systems.

How Can Third-Party Inspections Provide Assurance?

Engaging third-party inspection services can further enhance buyer confidence. These firms can conduct on-site inspections during various production stages, providing real-time feedback and quality verification. This is particularly important for international buyers who may not have the capacity to visit manufacturing sites personally.

Illustrative image related to custom leather gloves

What Are the QC and Certification Nuances for International Buyers?

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, it’s essential to understand the nuances of quality control and certification. Different markets may have varying requirements for compliance, and navigating these can be complex.

-

Regional Standards: Buyers should familiarize themselves with local regulations and standards that may affect importation and sale. This includes understanding tariffs, customs regulations, and potential import restrictions on leather goods.

-

Cultural Considerations: Preferences for styles, sizes, and finishes may vary by region. Customization options should cater to these preferences to enhance market acceptance.

By understanding the manufacturing processes and quality assurance measures for custom leather gloves, B2B buyers can make informed decisions that align with their business needs and customer expectations. Engaging with reputable suppliers who prioritize quality and compliance will ultimately lead to successful partnerships and satisfied customers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘custom leather gloves’

Introduction

This practical sourcing guide provides B2B buyers with a comprehensive checklist for procuring custom leather gloves. By following these steps, you can ensure that you select high-quality products that meet your specific needs while fostering a reliable partnership with manufacturers. Whether you’re sourcing for a retail business or corporate gifting, this checklist will streamline your procurement process.

Step 1: Define Your Technical Specifications

Before you begin sourcing, it’s essential to outline your technical requirements. Determine the type of leather, glove style, and any specific features you need, such as insulation or touchscreen compatibility. This will not only guide your supplier search but also help in comparing products effectively.

Illustrative image related to custom leather gloves

- Leather Type: Consider whether you want goat, cow, or specialty leathers like peccary or deerskin for durability and luxury.

- Design Features: Identify if you require custom monograms, colors, or sizes to cater to your target audience.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers with a proven track record in producing custom leather gloves. Look for companies that specialize in your required glove type and have experience in international shipping, especially if you’re sourcing from regions like Europe or Asia.

- Online Reviews: Check customer testimonials and ratings on platforms like Trustpilot or industry-specific forums.

- Supplier Portfolios: Review their previous work to gauge the quality and craftsmanship of their products.

Step 3: Evaluate Supplier Certifications

It’s crucial to verify the certifications of potential suppliers to ensure they adhere to industry standards. Certifications can indicate compliance with quality control and ethical manufacturing practices, which are particularly important in the leather industry.

- Quality Certifications: Look for ISO or similar certifications that reflect their commitment to quality.

- Sustainability Practices: Ensure that the supplier uses sustainable leather sourcing and production methods to meet modern consumer expectations.

Step 4: Request Samples

Once you have shortlisted suppliers, request samples of their custom leather gloves. This will provide insight into the quality, fit, and craftsmanship of their products, allowing you to make an informed decision.

- Test for Durability: Evaluate the sample gloves for comfort, flexibility, and wear resistance.

- Customization Options: Check how well the supplier can accommodate your specific design requests through the samples.

Step 5: Clarify Pricing and Payment Terms

Understanding the pricing structure and payment terms is crucial for budgeting and financial planning. Clarify whether the quoted prices include shipping, customization, and any additional fees.

- Bulk Discounts: Inquire about pricing for larger orders, as many suppliers offer discounts for bulk purchases.

- Payment Methods: Ensure that the payment methods are secure and suitable for international transactions, especially when dealing with suppliers from different continents.

Step 6: Establish Communication Protocols

Effective communication is key to a successful partnership. Set clear expectations regarding response times, updates on order status, and any potential issues that may arise during the production process.

- Preferred Communication Channels: Determine whether to use email, phone, or instant messaging apps for quick communication.

- Regular Updates: Agree on how often you expect updates on production timelines and shipping.

Step 7: Finalize the Contract

Before placing a large order, ensure you have a detailed contract in place that outlines all agreed-upon terms, including specifications, pricing, delivery schedules, and return policies. This protects both parties and establishes a clear framework for your business relationship.

- Legal Review: Consider having a legal expert review the contract to ensure all terms are fair and enforceable.

- Dispute Resolution: Include clauses that specify how disputes will be handled should they arise during the partnership.

By following this checklist, you can navigate the complexities of sourcing custom leather gloves effectively and establish a fruitful business relationship with your suppliers.

Comprehensive Cost and Pricing Analysis for custom leather gloves Sourcing

What Are the Key Cost Components in Custom Leather Gloves Manufacturing?

When sourcing custom leather gloves, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of leather significantly impacts costs. Premium leathers like peccary or deerskin are more expensive than standard cowhide. Additional elements such as linings, stitching, and embellishments (e.g., monograms) also add to material costs.

-

Labor: Skilled craftsmanship is essential for producing high-quality leather gloves. Labor costs vary by region, with countries known for craftsmanship, like Italy and the UK, typically commanding higher wages. Hand-sewn gloves often require more labor, increasing overall costs.

-

Manufacturing Overhead: This encompasses utilities, rent, and operational costs associated with running a manufacturing facility. High-quality manufacturers may invest more in overhead to maintain standards.

-

Tooling: For custom designs, specific tools and molds are necessary. The initial setup cost can be significant, especially for unique designs requiring specialized machinery.

-

Quality Control (QC): Implementing stringent QC processes ensures the gloves meet quality standards. This may involve additional inspections and testing, contributing to higher costs.

-

Logistics: Shipping and handling costs can vary widely based on destination and shipping method. Buyers must account for these costs when considering the total price.

-

Margin: Suppliers typically add a profit margin on top of their costs, which can vary based on competition, demand, and perceived value of their product.

What Influences Pricing in Custom Leather Gloves?

Several factors influence the pricing of custom leather gloves:

-

Volume/MOQ: Minimum order quantities (MOQ) often dictate pricing. Larger orders can lead to reduced per-unit costs due to economies of scale.

-

Specifications/Customization: Custom designs or specific requirements (like touchscreen capability or waterproofing) can increase costs. The more complex the customization, the higher the price.

-

Material Quality and Certifications: Premium materials and certifications (like ethical sourcing or sustainability) can command higher prices. Buyers should assess the long-term value of investing in high-quality, certified gloves.

-

Supplier Factors: Supplier reputation, reliability, and geographical location can affect pricing. Suppliers in regions with high labor costs may charge more than those in lower-cost areas.

-

Incoterms: The shipping terms agreed upon can influence total costs. Understanding Incoterms helps buyers manage risks and additional fees associated with shipping.

What Are Some Negotiation Tips for B2B Buyers in the Custom Leather Gloves Market?

Effective negotiation can significantly impact the final price:

-

Research and Compare: Conduct thorough research on different suppliers and their offerings. Comparing quotes can give you leverage during negotiations.

-

Discuss Volume Discounts: If you plan to place large orders, discuss volume discounts upfront. Suppliers may be willing to reduce prices for bulk purchases.

-

Be Clear on Specifications: Clearly define your requirements to avoid misunderstandings that could lead to additional costs later on.

-

Consider Total Cost of Ownership: Evaluate the long-term value of the gloves, including durability and maintenance costs, rather than just the initial purchase price.

-

Understand Pricing Nuances for International Transactions: For buyers in Africa, South America, the Middle East, and Europe, consider currency fluctuations, import duties, and taxes that could affect the overall cost.

What Should Buyers Be Aware of Regarding Indicative Prices?

While indicative prices can serve as a starting point for negotiations, they can vary based on the aforementioned factors. Always seek detailed quotes that outline all costs, including potential hidden fees, to ensure a comprehensive understanding of the pricing structure. This diligence will help you make informed decisions and secure the best value for your investment in custom leather gloves.

Illustrative image related to custom leather gloves

Alternatives Analysis: Comparing custom leather gloves With Other Solutions

When considering the procurement of protective gear or accessories, it’s essential to evaluate various options available in the market. Custom leather gloves offer a tailored solution for those seeking quality and functionality. However, there are alternative products that may meet similar needs, each with its own advantages and disadvantages. Below, we explore two viable alternatives: synthetic gloves and cotton work gloves.

| Comparison Aspect | Custom Leather Gloves | Synthetic Gloves | Cotton Work Gloves |

|---|---|---|---|

| Performance | High durability and grip; excellent for manual tasks | Good flexibility and grip; may not provide the same level of protection | Moderate protection; best for light-duty tasks |

| Cost | Premium pricing due to craftsmanship | Generally lower cost; varies with brand and quality | Low-cost option; budget-friendly |

| Ease of Implementation | Requires custom fitting; longer lead time | Readily available; easy to purchase in bulk | Readily available; no custom fitting required |

| Maintenance | Requires special care; can be long-lasting with proper maintenance | Low maintenance; disposable after wear | Machine washable; easy to care for |

| Best Use Case | Ideal for high-end industries or specialized tasks requiring precision | Suitable for general use in varied industries | Best for light-duty tasks in construction or gardening |

What Are the Benefits and Drawbacks of Synthetic Gloves?

Synthetic gloves, often made from materials like nitrile or PVC, provide a cost-effective alternative to leather. They are flexible, offer good grip, and are typically resistant to chemicals, making them ideal for various industries, including food service and healthcare. However, they may lack the durability of leather and can wear out more quickly under heavy use. Additionally, they might not provide the same level of tactile feedback, which can be crucial for precision tasks.

How Do Cotton Work Gloves Compare?

Cotton work gloves are a staple in many industries due to their affordability and comfort. They are breathable and can be used for light-duty tasks, such as gardening or assembly work. While they are easy to maintain and can be washed multiple times, they do not offer the same level of protection against abrasion or cuts as leather or synthetic options. Thus, they may not be suitable for tasks that require heavy lifting or exposure to sharp objects.

How Should B2B Buyers Decide on the Right Solution?

When evaluating the best option for their needs, B2B buyers should consider several factors, including the specific tasks at hand, the working environment, and budget constraints. Custom leather gloves are an excellent investment for high-end applications where durability and precision are paramount. Conversely, synthetic gloves may be better suited for businesses that prioritize cost and flexibility, while cotton gloves can serve as a practical choice for light-duty tasks. By aligning the choice of gloves with operational needs and budget, businesses can ensure they are equipped with the right tools for efficiency and safety.

Essential Technical Properties and Trade Terminology for custom leather gloves

What Are the Key Technical Properties of Custom Leather Gloves?

When sourcing custom leather gloves, understanding specific technical properties is crucial for ensuring quality and suitability for intended use. Here are some critical specifications to consider:

Illustrative image related to custom leather gloves

1. Material Grade

The material grade indicates the quality of leather used in glove production. Common types include full-grain, top-grain, and split leather. Full-grain leather, made from the top layer of hide, is the most durable and breathable, making it ideal for high-performance gloves. Buyers should prioritize high-grade materials to ensure longevity and comfort.

2. Stitching Type

The stitching type affects both the durability and aesthetic of the gloves. Hand-sewn gloves often provide superior strength and a personalized touch compared to machine-sewn options. Different stitching techniques, like lockstitch or chain stitch, can influence the flexibility and fit of the gloves, making this an essential factor for custom orders.

3. Sizing Tolerance

Sizing tolerance refers to the permissible variation in glove dimensions. Accurate sizing is vital for comfort and usability, especially in sectors like automotive or industrial applications. Manufacturers should provide detailed sizing guides and templates to help buyers achieve the perfect fit, reducing the risk of returns and enhancing user satisfaction.

4. Lining Material

The lining material impacts both insulation and comfort. Common options include cotton, fleece, or leather. For colder climates, gloves with thermal linings are preferred, while breathable linings are essential for warmer environments. Understanding the intended use will guide buyers in selecting the appropriate lining for their needs.

5. Customization Options

Customization options can include color, size, and additional features like monogramming or reinforced palms. The ability to tailor these aspects allows businesses to align their products with branding or specific functional requirements. This flexibility is particularly valuable in competitive markets.

Illustrative image related to custom leather gloves

6. Compliance Standards

Buyers should inquire about compliance with industry standards, such as EN388 for cut resistance or EN511 for cold protection. Compliance not only ensures safety but can also enhance a brand’s credibility and marketability. Understanding these standards is essential for businesses operating in regulated industries.

What Are Common Trade Terms Related to Custom Leather Gloves?

Familiarity with industry jargon can streamline communication and negotiations with suppliers. Here are some essential terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce goods under another brand’s label. In the context of custom leather gloves, an OEM may manufacture gloves designed by a third party, allowing businesses to leverage established expertise while maintaining brand identity.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of products a supplier is willing to sell. Understanding MOQ is essential for budget planning and inventory management, as it can affect the overall cost of acquiring custom gloves. Buyers should negotiate MOQs based on their needs and sales projections.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. For custom leather gloves, an RFQ can detail specifications, quantities, and desired delivery timelines. A well-prepared RFQ can lead to more accurate quotes and better supplier relationships.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping. Terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) specify who bears costs and risks at various stages of transport. Understanding Incoterms helps buyers mitigate risks and manage shipping logistics effectively.

5. Lead Time

Lead time refers to the duration from placing an order to receiving the finished product. In custom manufacturing, lead times can vary based on design complexity and materials availability. Buyers should communicate their deadlines clearly to suppliers to ensure timely delivery.

6. Custom Duties

Custom duties are tariffs imposed on imported goods. Understanding these fees is vital for international buyers to accurately calculate total costs when importing custom leather gloves. This knowledge can influence sourcing decisions and pricing strategies.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their procurement processes and product offerings in the custom leather glove market.

Navigating Market Dynamics and Sourcing Trends in the custom leather gloves Sector

What Are the Current Market Dynamics and Key Trends in the Custom Leather Gloves Sector?

The custom leather gloves market is experiencing significant growth driven by various global factors. Increasing demand for personalized products, coupled with a rising interest in luxury accessories, has led to a surge in custom leather glove offerings. This trend is particularly pronounced in regions like Europe, where craftsmanship and quality are highly valued, and in emerging markets in Africa and South America, where consumers are becoming increasingly discerning about product quality and customization options.

Illustrative image related to custom leather gloves

Technological advancements are shaping the sourcing landscape as well. B2B buyers are leveraging digital platforms for custom orders, allowing them to configure gloves according to their specific requirements. For instance, online configurators enable businesses to select styles, materials, and sizes, streamlining the ordering process. Additionally, the integration of augmented reality (AR) tools is enhancing the customer experience by allowing buyers to visualize products before making a purchase.

Sustainability is another critical trend influencing market dynamics. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to ethical sourcing and environmentally friendly practices. This shift is prompting manufacturers to adopt sustainable production methods and source materials responsibly, aligning with the growing consumer demand for eco-conscious products. As a result, international B2B buyers should be aware of these trends to make informed decisions that resonate with their target audiences.

How Is Sustainability and Ethical Sourcing Transforming the Custom Leather Gloves Sector?

Sustainability and ethical sourcing have become paramount in the custom leather gloves market, significantly impacting buyer decisions. The leather industry is often scrutinized for its environmental footprint, including water usage and chemical treatment processes. Thus, buyers are increasingly seeking suppliers who prioritize sustainable practices, such as using vegetable-tanned leather, which is less harmful to the environment compared to traditional tanning methods.

Moreover, ethical supply chains are gaining importance. B2B buyers are more likely to partner with manufacturers that ensure fair labor practices and humane treatment of animals. Certifications like the Leather Working Group (LWG) and Global Organic Textile Standard (GOTS) are becoming essential benchmarks for buyers who want to validate the sustainability claims of their suppliers. Brands that can provide transparency regarding their sourcing and production processes will likely gain a competitive edge in the market.

Incorporating sustainable materials and practices not only meets the demands of eco-conscious consumers but also enhances brand reputation. B2B buyers should actively seek partners who align with these values, as this can lead to long-term relationships and customer loyalty.

Illustrative image related to custom leather gloves

What Is the Brief History and Evolution of Custom Leather Gloves in the B2B Market?

The custom leather gloves market has evolved significantly over the centuries, reflecting changes in fashion, technology, and consumer preferences. Historically, leather gloves were essential for protection and warmth, evolving into luxury items favored by the elite in Europe during the 18th and 19th centuries. The craftsmanship involved in glove-making became a mark of status, with artisans honing their skills to create bespoke products that catered to individual tastes.

As industrialization progressed, mass production techniques began to emerge, making leather gloves more accessible to the general public. However, the recent resurgence of interest in personalized and high-quality goods has reignited the custom leather glove sector. Modern consumers, especially in B2B markets, now seek unique products that reflect their identity and values, leading to a renewed focus on craftsmanship and customization.

Today, this market is characterized by a blend of traditional craftsmanship and modern technology, allowing buyers to engage with suppliers in innovative ways. As the sector continues to evolve, understanding its historical context can provide valuable insights for B2B buyers aiming to navigate current market trends effectively.

Illustrative image related to custom leather gloves

Frequently Asked Questions (FAQs) for B2B Buyers of custom leather gloves

-

How do I ensure the quality of custom leather gloves when sourcing?

To ensure the quality of custom leather gloves, request samples from potential suppliers to evaluate craftsmanship and material quality firsthand. Look for certifications that confirm adherence to international quality standards, such as ISO 9001. Additionally, consider visiting the manufacturing facility if feasible, or utilize third-party inspection services that can assess quality before shipment. Establishing clear communication regarding your quality expectations and specifications will also help in aligning with the supplier’s capabilities. -

What is the best material for custom leather gloves in different climates?

The best material for custom leather gloves depends on the climate of the end user. For warmer climates, lightweight leathers such as goat or lambskin are preferable as they provide breathability and comfort. In contrast, for colder regions, thicker leathers like deerskin or cowhide, often lined with insulation, offer better warmth and protection. Understanding your target market’s climate will help you select the most suitable leather type for your custom gloves. -

What customization options should I consider for my order of leather gloves?

When customizing leather gloves, consider options such as leather type, color, size, and stitching patterns. Additional customizations can include monogramming, linings, and special features like touchscreen compatibility or reinforced palms for added durability. Discussing these options with your supplier will help you create a unique product that meets your clients’ specific needs and preferences, enhancing their appeal in the market. -

What is the minimum order quantity (MOQ) for custom leather gloves?

Minimum order quantities (MOQs) for custom leather gloves vary by supplier and can range from a few dozen to several hundred pairs. It’s essential to discuss MOQs during initial negotiations, as some suppliers may offer flexibility based on your specific requirements or long-term partnership potential. Be sure to balance your order size with your budget and anticipated demand to optimize inventory management. -

What payment terms are typically used in international B2B transactions for custom products?

Payment terms in international B2B transactions often include options such as advance payment, letter of credit, or payment against documents. It’s common for suppliers to request a deposit (typically 30-50%) upon order confirmation, with the balance due before shipping. Ensure that you clarify payment terms upfront to avoid misunderstandings and to protect both parties during the transaction. -

How can I effectively vet suppliers for custom leather gloves?

To effectively vet suppliers, begin by conducting thorough research on their reputation and experience in the industry. Check for customer reviews, testimonials, and case studies to gauge their reliability. Request references from previous clients and consider their production capabilities, quality control processes, and compliance with international regulations. Visiting the factory or utilizing third-party audits can further ensure that the supplier meets your standards. -

What logistics considerations should I be aware of when importing custom leather gloves?

When importing custom leather gloves, consider shipping methods, costs, and delivery times. Ensure compliance with import regulations, including tariffs and customs documentation, to avoid delays. Choosing a reliable freight forwarder can streamline the logistics process, while tracking shipments will help you stay informed about delivery status. Additionally, factor in lead times for production and shipping when planning your inventory. -

How do I handle quality assurance (QA) for custom leather gloves?

Implementing a robust quality assurance (QA) process is crucial when sourcing custom leather gloves. Start by setting clear quality specifications and standards with your supplier. Consider arranging for pre-shipment inspections to verify that products meet your requirements. Establish a return policy for defective items and maintain open communication with the supplier to address any quality issues promptly. Regular audits of the supplier’s quality control practices can also enhance long-term product consistency.

Top 6 Custom Leather Gloves Manufacturers & Suppliers List

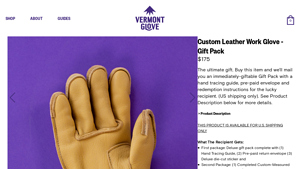

1. Vermont Glove – Custom Leather Work Glove Gift Pack

Domain: vermontglove.com

Registered: 2018 (7 years)

Introduction: {“product_name”: “Custom Leather Work Glove – Gift Pack”, “price”: “$175”, “shipping”: “U.S. shipping only”, “gift_pack_contents”: [{“item”: “Hand Tracing Guide”}, {“item”: “Pre-paid return envelope”}, {“item”: “Deluxe die-cut sticker”}, {“item”: “Completed Custom-Measured & Monogrammed pair of Vermonter gloves”}, {“item”: “Custom canvas glove bag”}, {“item”: “Leather Conditioner”}, {“item”: “Carp…

2. Magnoli Clothiers – Custom Gloves

Domain: magnoliclothiers.com

Registered: 2006 (19 years)

Introduction: Custom gloves designed for a perfect fit and personalized style. Available in various materials and colors. Ideal for both professional and casual use. Options for customization include size, color, and additional features. Durable and comfortable for extended wear.

3. Opinari – Custom Handcrafted Driving Gloves

Domain: opinari-drivers.com

Registered: 2017 (8 years)

Introduction: Custom Made Driving Gloves Service, handcrafted in Italy. Free delivery for orders over €150, free Express shipping outside Europe.

4. Dents Gloves – Luxury Leather Accessories

Domain: us.dentsgloves.com

Registered: 2008 (17 years)

Introduction: Dents Gloves offers luxury leather gloves, belts, and accessories. Key product categories include men’s and women’s gloves by style (driving, touchscreen, winter, fingerless, water resistant, shooting) and by color (black, brown, blue, green, red, grey, yellow). Accessories include leather wallets, card holders, belts, scarves, hats, and leather bags. The gloves are designed in Britain, with a Her…

5. Sullivan Glove – Work Collection

Domain: sullivanglove.com

Registered: 1999 (26 years)

Introduction: Collection: Work

– 100% Made in the USA

– Free Shipping in USA on all orders over $50

– Products include:

– Buffalo Roper: $85.00 (Sold out)

– Deerskin Roper: $85.00 (Sold out)

– Deerskin Gardener: $85.00 (Sold out)

– Elk Roper: $85.00 (Sold out)

– Goat Roper: $75.00 (Sold out)

– Buffalo Roper: Lined: $95.00 (Sold out)

– Elk Roper: Lined: $95.00 (Sold out)

– Goat Roper: Lined: $85….

6. Ortho Custom Gloves – Custom & Orthopaedic Gloves

Domain: orthocustomgloves.com

Registered: 2010 (15 years)

Introduction: Ortho Custom Gloves specializes in custom gloves, work gloves, and orthopaedic gloves. They offer a nationally acclaimed alteration service for work gloves, particularly for individuals with hand injuries. Their products include winter gloves, driving gloves, and custom modifications. Customers can choose from various leather colors and lining options for their gloves. The company has been in oper…

Strategic Sourcing Conclusion and Outlook for custom leather gloves

In the evolving landscape of custom leather gloves, strategic sourcing emerges as a critical factor for international B2B buyers aiming to enhance their product offerings. The insights gathered from various manufacturers highlight the importance of selecting suppliers who prioritize quality craftsmanship, sustainable practices, and personalization options. Buyers should focus on building relationships with reputable artisans who can provide bespoke solutions tailored to their unique requirements, whether for fashion, utility, or both.

The demand for high-quality, custom leather gloves is on the rise across global markets, particularly in regions like Africa, South America, the Middle East, and Europe. By leveraging strategic sourcing, businesses can secure not only premium products but also gain a competitive edge through differentiated offerings. The opportunity to customize gloves allows companies to meet diverse consumer preferences, fostering brand loyalty and enhancing customer satisfaction.

Looking ahead, businesses are encouraged to explore innovative sourcing strategies that incorporate technology and craftsmanship. Engaging with suppliers who offer customization tools and sustainable materials will not only fulfill market demands but also align with global trends towards responsible consumption. Act now to elevate your product line with exceptional custom leather gloves that resonate with today’s discerning consumers.

Illustrative image related to custom leather gloves

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.