Catalog

Material Insight: What Is Imitation Leather

Understanding Imitation Leather: The Modern Performance Material

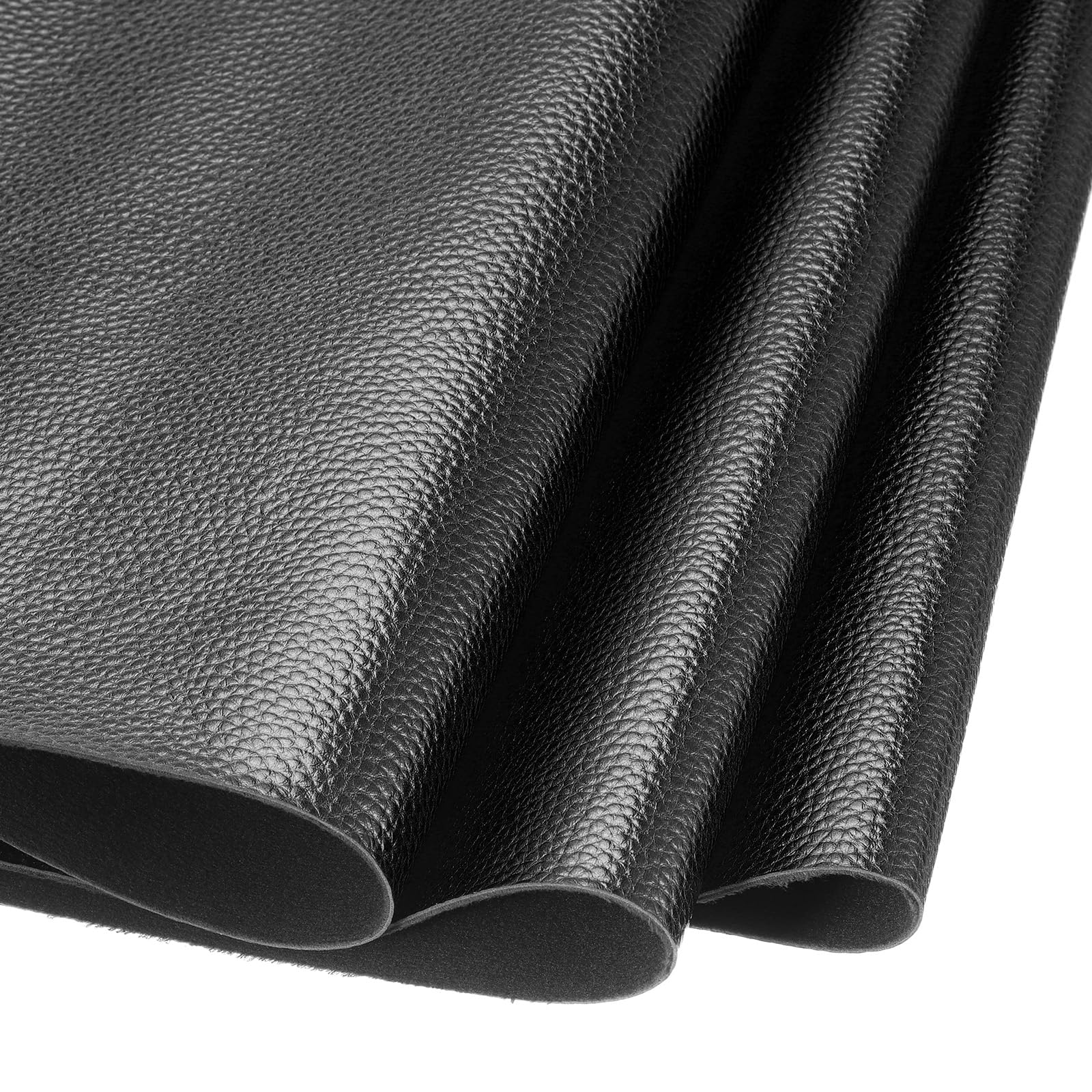

Imitation leather, also known as synthetic or faux leather, is a technologically advanced engineered material designed to replicate the aesthetic, texture, and performance characteristics of genuine leather without utilizing animal hides. Constructed primarily from polyurethane (PU) or polyvinyl chloride (PVC) bases, often reinforced with non-woven or knit fabric backings, it offers a consistent, customizable, and ethically sourced alternative. Modern iterations prioritize sustainability through water-based production processes, recycled content integration (e.g., post-consumer polyester), and compliance with stringent environmental regulations like REACH and OEKO-TEX®. Unlike traditional leather, it eliminates variability in grain, scars, and thickness, ensuring uniformity critical for high-volume manufacturing.

Why Synthetic Leather Is the Optimal Choice for Commercial Applications

For B2B manufacturers and designers seeking reliability, cost-efficiency, and ethical alignment, synthetic leather outperforms both genuine leather and inferior alternatives:

– Consistent Quality & Scalability: Eliminates natural hide defects, enabling seamless production runs and reducing waste by up to 30% compared to leather cutting.

– Enhanced Durability: Engineered for superior abrasion resistance, colorfastness, and dimensional stability—critical for high-use sectors like automotive seating, contract furniture, and luggage.

– Sustainability Credentials: Requires 90% less water than leather tanning, avoids toxic chromium, and leverages recycled materials (e.g., WINIW’s Eco Series uses 40%+ recycled content).

– Cost Predictability: Stable pricing unaffected by livestock market volatility, with lower total cost of ownership due to reduced waste and maintenance.

– Design Flexibility: Customizable in color, texture, thickness (0.6mm–2.0mm), and performance (e.g., fire retardancy, antimicrobial properties) to meet exact specifications.

WINIW: Your Trusted Partner in Advanced Synthetic Leather Solutions

With over 20 years of specialized expertise, WINIW has pioneered innovations in eco-conscious synthetic leather for global B2B markets. We serve leading brands in automotive, furniture, fashion accessories, and electronics—delivering materials that balance uncompromising performance with planetary responsibility. Our vertically integrated manufacturing, backed by a 12,000m² R&D facility and ISO 14001 certification, ensures rigorous quality control from raw material sourcing to finished roll goods. WINIW’s commitment extends beyond product: we provide technical co-engineering support, rapid prototyping, and transparent lifecycle assessments to help partners achieve both commercial and ESG goals. When you choose WINIW, you gain a partner dedicated to advancing the future of sustainable material science—one innovation at a time.

Technical Performance & Standards

WINIW Imitation Leather: B2B Product Technical Guide

WINIW’s imitation leather is an advanced synthetic leather engineered for industrial and commercial applications across footwear, fashion, furniture, automotive interiors, and accessories. Designed with performance, sustainability, and cost-efficiency in mind, WINIW’s solution offers a compelling alternative to genuine leather—without compromising on quality or environmental responsibility.

Engineered using proprietary microfiber and polyurethane (PU) technologies, WINIW’s imitation leather delivers consistent physical properties, high yield efficiency, and reduced waste during production. It is ideal for B2B manufacturers seeking reliable, scalable, and eco-conscious materials.

Key Technical Advantages

-

Cost-effective Production

WINIW’s imitation leather reduces raw material and processing costs compared to genuine leather. It eliminates variability in hide quality, minimizes cutting waste due to uniform grain and thickness, and requires no complex preservation or tanning infrastructure. -

Superior Durability

Our synthetic leather exhibits excellent abrasion resistance, tear strength, and hydrolysis resistance. It maintains structural integrity under repeated stress and exposure to environmental factors, ensuring longer product life cycles. -

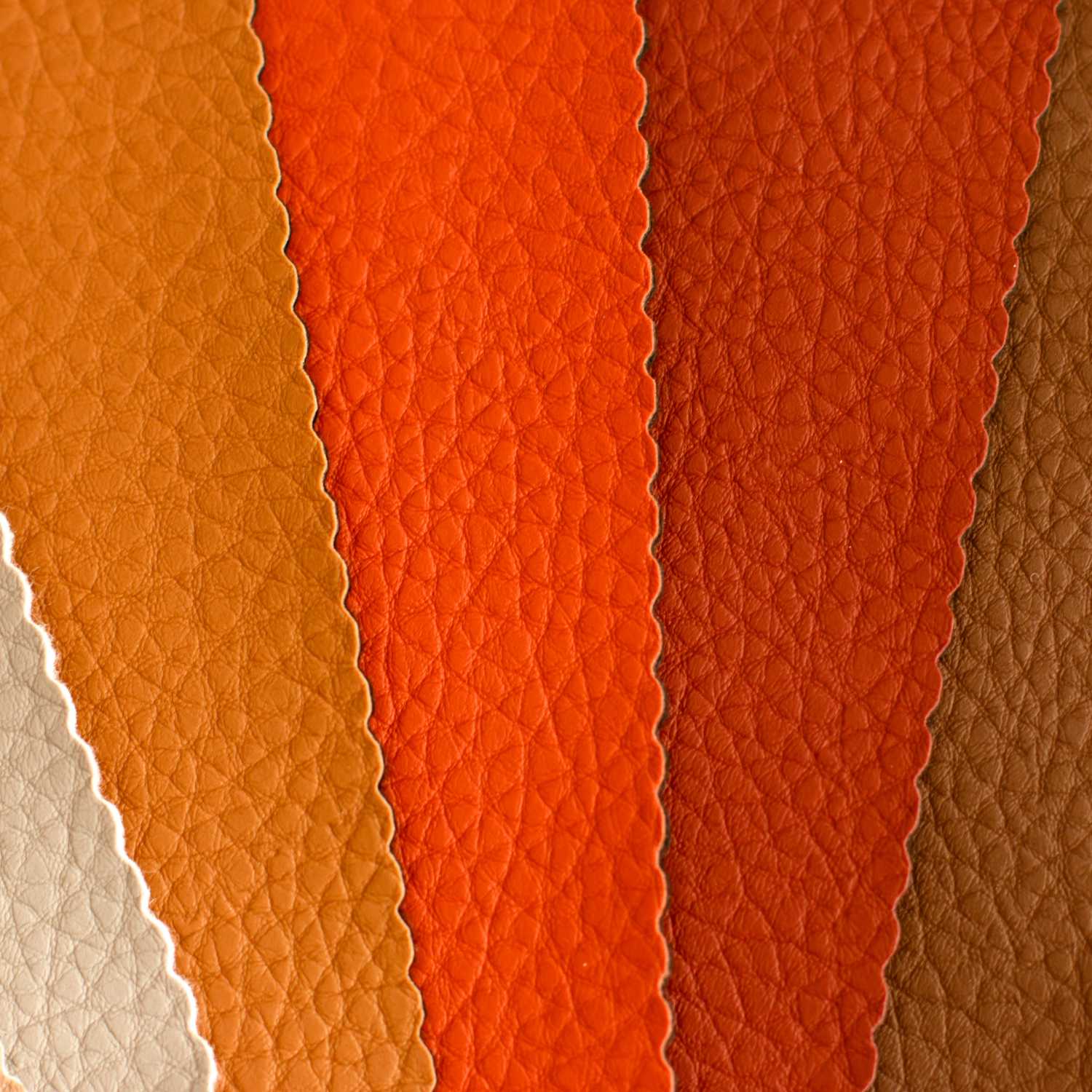

Customizable Colors & Finishes

WINIW offers full color and texture customization to meet brand-specific requirements. From matte and glossy finishes to embossed patterns (e.g., grain, nubuck), our production process supports rapid prototyping and batch consistency. -

REACH Compliance

All WINIW imitation leather products are fully compliant with EU REACH regulations (EC 1907/2006), ensuring the absence of SVHCs (Substances of Very High Concern) and restricted chemicals. This supports safer manufacturing and end-product safety for global markets. -

ISO9001-Certified Quality Management

WINIW operates under ISO9001-certified quality systems, guaranteeing strict process controls, traceability, and continuous improvement in product consistency and customer satisfaction.

Technical Specifications

| Property | Specification | Test Standard |

|---|---|---|

| Material Composition | Microfiber PU / High-performance PU | – |

| Thickness Range | 0.6 mm – 2.0 mm (customizable) | ISO 2417:2019 |

| Tensile Strength | ≥ 25 N/cm² (warp & weft) | ISO 17679:2015 |

| Elongation at Break | ≤ 40% | ISO 17679:2015 |

| Seam Strength | ≥ 120 N | ISO 13935-1:2014 |

| Color Fastness to Rubbing | ≥ Grade 4 (dry), ≥ Grade 3 (wet) | ISO 105-X12:2016 |

| Light Fastness | ≥ Grade 4 (after 40 hrs UV exposure) | ISO 105-B02:2014 |

| Martindale Abrasion | ≥ 30,000 cycles (no break) | ISO 12947-2:2016 |

| Hydrolysis Resistance | Pass (14 days at 70°C, 65% RH) | ISO 1419:2018 (modified) |

| REACH SVHC Status | None detected (as per latest candidate list) | EC 1907/2006 |

| ISO9001 Certification | Certified (Quality Management System) | ISO 9001:2015 |

WINIW’s imitation leather is engineered for B2B partners who demand performance, compliance, and production flexibility. With a focus on sustainable innovation and operational efficiency, WINIW supports global supply chains in delivering high-quality, responsible products to market.

Why Choose Synthetic over Real Leather

B2B Product Guide: Understanding Synthetic Leather vs. Genuine Leather

As a leading innovator in sustainable materials, WINIW provides this objective comparison to support informed procurement decisions. Understanding the fundamental differences between synthetic leather (often historically termed “imitation leather”) and genuine leather is critical for product design, cost management, and sustainability strategy.

Defining the Materials

– Synthetic Leather (WINIW’s Specialty): Engineered materials designed to replicate the aesthetic and functional properties of leather. WINIW utilizes advanced polyurethane (PU) or polyvinyl chloride (PVC) bases, combined with non-woven or knit fabric substrates. Our formulations prioritize resource efficiency, recyclability, and performance consistency for industrial applications.

– Genuine Leather: A natural product derived from the tanned hides or skins of animals (primarily bovine). It undergoes chemical treatment (tanning) to prevent decomposition, resulting in a material with unique grain patterns and inherent variability.

Core Comparison: Synthetic Leather vs. Genuine Leather

| Metric | Synthetic Leather (WINIW) | Genuine Leather |

|---|---|---|

| Cost | Lower initial cost per square meter. Highly consistent pricing due to controlled manufacturing. Reduced waste in cutting optimizes total project cost. | Higher initial cost. Significant price volatility based on hide grade, origin, and market fluctuations. Substantial waste (up to 30%) due to natural defects and irregular shapes increases effective cost. |

| Durability | Engineered for specific performance: High resistance to abrasion, tearing, UV fading, and moisture. Consistent thickness and properties across batches ensure predictable product lifespan. Resists cracking in variable climates. | Natural durability varies significantly by hide quality and tanning method. Prone to drying, cracking, and staining without meticulous maintenance. Susceptible to water damage and UV degradation over time. Grain inconsistency can lead to weak spots. |

| Eco-Friendliness | WINIW prioritizes closed-loop processes: Lower water consumption (>90% less than wet-blue tanning), reduced energy use, and elimination of hazardous chemicals (e.g., chrome VI). Bio-based PU options and recyclable formulations minimize landfill burden. Traceable, consistent supply chain. | High environmental footprint: Intensive water use (15,000+ liters per hide), toxic tanning chemicals (e.g., chromium salts), methane emissions from livestock, and significant land/water resource demands. Recycling is complex; disposal often leads to landfill. Ethical concerns regarding animal sourcing persist. |

Key Business Implications for B2B Buyers

– Supply Chain Reliability: Synthetic leather offers consistent quality and on-time delivery, mitigating risks from hide shortages or tannery compliance issues.

– Design Flexibility: WINIW’s materials provide uniform color, texture, and thickness across large volumes, enabling precise manufacturing and reduced rework.

– Sustainability Compliance: Our synthetics align with global ESG goals and circular economy frameworks, supporting brand reputation and regulatory adherence (e.g., EU Green Deal, REACH).

– Total Cost of Ownership: While genuine leather carries prestige, synthetic alternatives often deliver superior long-term value through durability, lower maintenance, and minimized waste in production.

WINIW’s engineered leathers are not mere substitutes—they represent a strategic evolution for forward-thinking brands demanding performance, ethical integrity, and environmental responsibility without compromise. Contact our technical team to specify materials aligned with your product lifecycle requirements.

WINIW Factory Capabilities

WINIW is a leading manufacturer of high-performance synthetic leather, specializing in innovative, eco-friendly materials for global B2B clients. Our vertically integrated production capabilities and commitment to quality have positioned us as a trusted supplier across diverse industries, including automotive, fashion, furniture, and technical textiles.

Our manufacturing strength is anchored in a state-of-the-art facility spanning over 100,000 square meters. This expansive campus enables large-scale production with optimized efficiency, ensuring reliable lead times and consistent supply even for high-volume orders.

Key strengths of the WINIW factory include:

- Advanced production lines equipped with automated systems for precision coating, embossing, and finishing

- A dedicated R&D team of over 100 engineers and material scientists driving continuous innovation

- Proprietary technologies in water-based, solvent-free, and recycled material formulations

- Strict quality control protocols compliant with international standards (REACH, RoHS, OEKO-TEX®)

- On-site testing laboratory for physical, chemical, and durability performance validation

- Full traceability and batch control systems to ensure product consistency and compliance

WINIW maintains long-standing export relationships with premium brands and distributors across Europe and the USA. Our products meet the rigorous environmental and safety requirements of these markets, supported by third-party certifications and sustainable manufacturing practices.

By combining scale, innovation, and quality, WINIW delivers synthetic leather solutions that meet the highest global standards—helping partners achieve performance, sustainability, and commercial success.

Contact Us for Samples

WINIW Microfiber Leather: Professional B2B Product Guide

WINIW Microfiber Leather represents the forefront of high-performance, sustainable synthetic alternatives for demanding industrial and design applications. Engineered for durability, consistency, and environmental responsibility, our materials serve global leaders in automotive, furniture, footwear, and luxury goods manufacturing. This guide outlines core specifications and advantages for procurement and design teams seeking reliable, eco-conscious material solutions.

What is Imitation Leather?

Imitation leather (synthetic leather, faux leather, or microfiber leather) is an engineered material designed to replicate the aesthetic, texture, and performance of genuine leather without utilizing animal hides. Modern iterations, like WINIW’s advanced microfiber leather, utilize ultra-fine polyester or polyamide fibers bonded with polyurethane (PU) resins to create a non-woven substrate. This structure delivers superior uniformity, enhanced physical properties, and a significantly reduced environmental footprint compared to traditional leather or lower-grade PVC/PU synthetics.

Why WINIW Microfiber Leather for B2B Applications?

- Unmatched Durability & Performance: Engineered for >100,000 double rubs (Martindale), exceptional tear strength (>40 N), and consistent color fastness (ISO 105-B02: Grade 4-5), ensuring longevity in high-use products.

- Eco-Certified Production: OEKO-TEX® STANDARD 100 Class I (skin-safe), ISO 14001 certified manufacturing, and >30% bio-based content options. Zero use of DMF, APEOs, or heavy metals.

- Design Versatility: Available in 0.6mm–1.2mm thicknesses, 1,370mm–1,520mm widths, and 1,000+ curated color/finish options (suede, glossy, embossed, matte). Custom formulations for UV resistance, flame retardancy (MVSS-302, BS 5852), and hydrolysis resistance.

- Supply Chain Reliability: ISO 9001 quality management, 99.5% on-time delivery rate, and global inventory hubs (EU, NA, APAC) enabling just-in-time logistics.

Technical Performance Comparison

| Property | WINIW Microfiber Leather | Standard PVC Leather | Genuine Leather |

|---|---|---|---|

| Tensile Strength (MPa) | ≥ 35 | 15–25 | 20–30 |

| Abrasion Resistance | >100,000 cycles | 10,000–20,000 cycles | Varies (wear) |

| Hydrolysis Resistance | Excellent (5+ years) | Poor | Moderate |

| VOC Emissions | <10 µg/m³ (Chamber test) | High | Moderate |

| Recyclability | Technically recyclable | Non-recyclable | Limited |

| CO2 Footprint (kg/kg) | 3.2 | 8.7 | 15.4 |

Data based on ISO 1767, ISO 5470-1, and LCA studies (2023). All WINIW products meet REACH/EPA TSCA compliance.

Target Industries & Applications

- Automotive: Seat covers, door panels, steering wheels (MVSS-302 compliant)

- Furniture: Upholstery for contract, residential, and hospitality (BS 5852 ignition source 5)

- Footwear & Accessories: Sneakers, handbags, watch straps (flex resistance >150k cycles)

- Electronics: Premium device covers, speaker grilles (dimensional stability ±0.5%)

Next Steps for Procurement & Design Integration

Elevate your product specifications with WINIW’s sustainable microfiber solutions. Our technical team provides:

– Free physical samples for performance validation

– Custom color matching (Pantone®/RAL) and texture development

– Full lifecycle assessment (LCA) reports for ESG reporting

Learn more about how imitation leather technology can transform your material strategy.

→ Request technical datasheets, compliance certificates, or free samples for evaluation:

Contact WINIW Marketing: MKT88@MicrofiberLeather.com

WINIW: Engineered Responsibility. Performance Redefined.

💰 Leather Cost Savings Calculator

See how much you save by switching to WINIW Microfiber Leather.