Introduction: Navigating the Global Market for make leather

In today’s competitive landscape, sourcing high-quality make leather can pose significant challenges for international B2B buyers. With varying standards and practices across different regions, understanding the nuances of leather production is crucial for securing reliable suppliers and achieving product excellence. This guide serves as a comprehensive resource, exploring the diverse types of leather available, their various applications, and critical insights into supplier vetting and cost considerations.

By delving into the intricacies of leather sourcing—from the initial selection of materials to the final product specifications—this guide empowers buyers, particularly those from Africa, South America, the Middle East, and Europe, such as Vietnam and Germany. Our objective is to equip you with actionable insights that facilitate informed purchasing decisions. Whether you are seeking leather for fashion, upholstery, or bespoke crafts, understanding the global market’s dynamics will help you navigate challenges and seize opportunities effectively.

As you explore the sections ahead, expect to gain clarity on the essential aspects of leather procurement, enabling you to foster successful partnerships and enhance your supply chain management. Let this guide be your trusted companion in the quest for quality make leather, ensuring that your investments yield both aesthetic appeal and long-lasting durability.

Table Of Contents

- Top 6 Make Leather Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for make leather

- Understanding make leather Types and Variations

- Key Industrial Applications of make leather

- 3 Common User Pain Points for ‘make leather’ & Their Solutions

- Strategic Material Selection Guide for make leather

- In-depth Look: Manufacturing Processes and Quality Assurance for make leather

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘make leather’

- Comprehensive Cost and Pricing Analysis for make leather Sourcing

- Alternatives Analysis: Comparing make leather With Other Solutions

- Essential Technical Properties and Trade Terminology for make leather

- Navigating Market Dynamics and Sourcing Trends in the make leather Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of make leather

- Strategic Sourcing Conclusion and Outlook for make leather

- Important Disclaimer & Terms of Use

Understanding make leather Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vegetable-Tanned | Made using natural tannins; retains rigidity; eco-friendly. | Leather goods, tooling, crafts | Pros: Eco-friendly, versatile, can be dyed. Cons: Takes longer to tan, may be stiffer. |

| Chrome-Tanned | Soft, supple, and more resistant to water; quick tanning process. | Garments, upholstery, accessories | Pros: Fast production, softer feel. Cons: May contain chemicals, less eco-friendly. |

| Top-Grain Leather | Highest quality, retains natural grain; durable and flexible. | High-end products, fashion items | Pros: Luxurious appearance, long-lasting. Cons: Higher cost, sensitive to scratches. |

| Suede | Napped finish, soft texture; less durable than full-grain. | Footwear, garments, accessories | Pros: Soft and luxurious feel, great for fashion. Cons: Less durable, harder to clean. |

| Exotic Leathers | Unique patterns from animals like snakes or alligators; premium pricing. | Luxury goods, high-fashion items | Pros: Distinctive and exclusive appearance. Cons: High cost, ethical sourcing concerns. |

What Are the Characteristics of Vegetable-Tanned Leather?

Vegetable-tanned leather is processed using natural tannins derived from plant sources. This method results in a leather that is firm and retains its shape, making it ideal for tooling and crafting detailed designs. It is commonly used in the production of belts, wallets, and other leather goods. When purchasing, B2B buyers should consider the time frame for tanning, as it can take longer than other methods. Additionally, the ability to dye and customize this leather adds to its appeal, especially for businesses focusing on bespoke products.

How Does Chrome-Tanned Leather Differ from Other Types?

Chrome-tanned leather is known for its softness and flexibility, thanks to a quicker tanning process using chromium salts. This type of leather is commonly used in garments and upholstery due to its water resistance and ease of care. B2B buyers should be aware of the environmental implications of chrome tanning, as it involves chemicals that can be harmful. However, the rapid production time and the luxurious feel of chrome-tanned leather make it an attractive option for businesses looking to meet high demand quickly.

Why Choose Top-Grain Leather for Premium Products?

Top-grain leather is the second-highest quality leather, made from the top layer of the hide while still retaining the natural grain. This type of leather is durable and flexible, making it suitable for high-end products like handbags and luxury accessories. B2B buyers should consider the aesthetic value and longevity of top-grain leather, which justifies its higher price point. However, it is essential to note that it can be sensitive to scratches, requiring careful handling during production and distribution.

What Are the Advantages and Disadvantages of Suede?

Suede is characterized by its soft, napped finish, which provides a luxurious feel. It is often used in fashion items like shoes, jackets, and bags. While suede offers a unique aesthetic and comfort, it is less durable than full-grain leather and can be challenging to clean. B2B buyers should weigh the fashion appeal against the practicality of suede, especially for products that will see heavy use. Understanding the maintenance requirements and potential for wear is crucial for making informed purchasing decisions.

What Makes Exotic Leathers a Unique Choice?

Exotic leathers, such as those sourced from snakes, alligators, and other unique animals, provide distinct patterns and textures that appeal to luxury markets. These leathers are often used in high-end fashion and accessories, making them a premium choice for discerning buyers. However, ethical sourcing and high costs are significant considerations for B2B buyers. It is essential to ensure compliance with regulations regarding exotic leathers and to communicate the value of exclusivity to potential customers.

Key Industrial Applications of make leather

| Industry/Sector | Specific Application of make leather | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion and Apparel | High-end clothing and accessories | Enhances brand image and customer loyalty | Quality of leather, sourcing sustainability, lead times |

| Automotive | Upholstery for vehicles | Improves durability and luxury appeal | Material specifications, compliance with regulations |

| Furniture and Upholstery | Custom leather furniture | Adds value through aesthetics and comfort | Design requirements, leather grades, sourcing ethics |

| Sporting Goods | Leather equipment and gear | Increases performance and durability | Weight and thickness of leather, customization options |

| Leather Goods Manufacturing | Handcrafted leather goods | Supports artisanal craftsmanship and uniqueness | Availability of tools and materials, training support |

How is ‘make leather’ Used in the Fashion and Apparel Industry?

In the fashion and apparel sector, ‘make leather’ is primarily utilized for creating high-end clothing, bags, and accessories. The durability and aesthetic appeal of leather enhance brand image, attracting discerning customers who value quality. International buyers must consider sourcing practices, including the origin of leather, to ensure sustainability and ethical production, which are increasingly important in markets across Africa, South America, Europe, and the Middle East.

Illustrative image related to make leather

What Role Does Leather Play in Automotive Upholstery?

In the automotive industry, ‘make leather’ is essential for vehicle upholstery, including seats, dashboards, and door panels. Leather provides a luxurious feel while significantly enhancing the durability of interiors. For B2B buyers, critical sourcing considerations include compliance with automotive safety standards, availability of specific grades of leather, and the ability to meet production timelines, especially for manufacturers in regions like Europe and South America where quality standards are stringent.

How is Leather Integrated into Furniture and Upholstery?

Custom leather furniture is a significant application of ‘make leather,’ where it is used for sofas, chairs, and other furnishings. The material adds considerable value through its visual appeal and comfort. Buyers must focus on the leather grade and its compatibility with design requirements. Additionally, sourcing from suppliers who prioritize ethical practices can enhance the brand’s reputation in markets across the Middle East and Europe.

What are the Benefits of Leather in Sporting Goods?

In the sporting goods sector, ‘make leather’ is widely used for equipment such as gloves, balls, and protective gear. The material’s durability and performance characteristics make it ideal for high-impact sports. Buyers should consider the weight and thickness of leather suitable for specific applications, as well as customization options to meet branding needs. This is particularly relevant for manufacturers in Africa and South America, where local sports markets are expanding.

Illustrative image related to make leather

Why is Leather Important for Leather Goods Manufacturing?

Leather is fundamental in the production of handcrafted leather goods, including wallets, belts, and bags. This application supports artisanal craftsmanship and offers unique products that appeal to niche markets. For international B2B buyers, sourcing considerations include the availability of high-quality tools and materials, as well as training support for artisans. This is especially relevant in regions like Europe, where there is a strong tradition of leather craftsmanship.

3 Common User Pain Points for ‘make leather’ & Their Solutions

Scenario 1: Sourcing Quality Leather Materials for Production

The Problem: B2B buyers often face difficulties in sourcing high-quality leather that meets their production standards. In regions like Africa and South America, where local suppliers may offer inconsistent quality, buyers risk ending up with subpar materials that can affect the durability and aesthetics of their finished products. This inconsistency not only leads to production delays but also impacts brand reputation, as low-quality leather can result in customer dissatisfaction and returns.

The Solution: To overcome this challenge, it is essential for buyers to establish strong relationships with reputable suppliers who can provide consistent quality. Conduct thorough market research to identify suppliers that specialize in high-grade leather suitable for your specific applications, such as veg-tanned or chrome-tanned leather. Request samples to evaluate the texture, thickness, and finish. Additionally, consider attending leather trade shows or industry events where you can meet suppliers in person and discuss your needs directly. Creating a checklist of quality indicators—such as certification of ethical sourcing and processing—can also help ensure that you make informed purchasing decisions.

Scenario 2: Understanding Leather Grades and Specifications

The Problem: Many buyers are often unclear about the various grades of leather and the specifications that best suit their products. For instance, the difference between top-grain, full-grain, and split leather can be confusing, leading to incorrect purchases that do not align with their manufacturing requirements. This lack of understanding can lead to wasted resources and increased costs as buyers try to rectify their mistakes.

The Solution: To navigate this complexity, it is crucial to invest time in learning about the different leather grades and their specific applications. Create a detailed guide that outlines the properties of each leather type, including durability, maintenance, and best uses. Collaborating with leather experts or consultants can provide valuable insights into selecting the right leather for your needs. Additionally, request detailed product specifications from suppliers, including information on tanning processes and finishes, to ensure that you are making educated choices. This proactive approach will minimize errors and enhance the quality of your end products.

Illustrative image related to make leather

Scenario 3: Managing Leather Waste and Sustainability Concerns

The Problem: As sustainability becomes increasingly important in the global market, B2B buyers are challenged with managing leather waste and addressing environmental concerns associated with leather production. In regions where leather is a primary industry, the environmental impact of tanning processes and waste disposal can pose significant challenges for buyers who want to maintain a green supply chain.

The Solution: To tackle these concerns, buyers should prioritize working with suppliers who adhere to sustainable practices in leather production. Look for certifications that indicate environmentally friendly tanning processes, such as vegetable tanning, which is less harmful than traditional chemical tanning methods. Implementing a waste management strategy that includes recycling scrap leather into smaller products or accessories can also help minimize waste. Additionally, consider investing in biodegradable leather alternatives or upcycled leather products to further align with sustainability goals. By actively engaging in sustainable sourcing, buyers can contribute to environmental stewardship while enhancing their brand’s reputation in the marketplace.

Strategic Material Selection Guide for make leather

What Are the Key Properties of Common Materials Used in Leather Production?

When selecting materials for leather production, understanding the properties of various leather types is crucial for ensuring product performance, durability, and suitability for specific applications. Below, we analyze four common materials used in leather production: vegetable-tanned leather, chrome-tanned leather, suede, and exotic leathers.

How Does Vegetable-Tanned Leather Perform in Leather Applications?

Vegetable-tanned leather is renowned for its eco-friendly tanning process, utilizing natural tannins from plant sources. Key properties include excellent durability and the ability to be dyed and stamped, making it suitable for a wide range of applications, from bags to belts.

Illustrative image related to make leather

Pros: It is highly durable and ages beautifully, developing a rich patina over time. Its natural composition allows for easy tooling and dyeing, making it a favorite among artisans.

Cons: The tanning process can be time-consuming and may result in higher costs compared to chrome-tanned options. Additionally, it can be less resistant to water and stains if not treated properly.

Impact on Application: Vegetable-tanned leather is ideal for products requiring a natural finish and aesthetic appeal, such as high-end bags and wallets. However, it may not be suitable for applications exposed to harsh environments without additional protective treatments.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East may prefer this leather due to its sustainability. Compliance with environmental regulations (e.g., REACH in Europe) is essential.

What Are the Advantages of Chrome-Tanned Leather?

Chrome-tanned leather is processed using chromium salts, resulting in a more supple and water-resistant material. Its key properties include high flexibility and resistance to wear.

Pros: It is quicker to produce and generally more affordable than vegetable-tanned leather. Its water resistance makes it suitable for a variety of applications, including upholstery and fashion items.

Cons: The environmental impact of the tanning process raises concerns, particularly in regions with strict environmental regulations. Additionally, it may not have the same aesthetic appeal as vegetable-tanned leather.

Illustrative image related to make leather

Impact on Application: Chrome-tanned leather is often used in products that require durability and flexibility, such as shoes and automotive upholstery. However, it may not be suitable for high-end artisan products that emphasize natural aesthetics.

Considerations for International Buyers: Compliance with international standards like ASTM and DIN is critical, especially for buyers in Europe and the Middle East, where environmental regulations are stringent.

How Does Suede Compare to Other Leather Types?

Suede, made from the inner layer of animal hides, is characterized by its soft texture and unique appearance. It is less durable than full-grain leather but offers a distinct aesthetic.

Illustrative image related to make leather

Pros: Suede is lightweight and provides a luxurious feel, making it popular in fashion and accessories. Its unique texture allows for creative designs.

Cons: It is more susceptible to stains and damage from water, requiring careful maintenance. Additionally, it may not be suitable for heavy-duty applications.

Impact on Application: Suede is ideal for fashion items like shoes and jackets, where aesthetics are prioritized over durability. However, it may not perform well in outdoor or rugged environments.

Illustrative image related to make leather

Considerations for International Buyers: Buyers should be aware of the care requirements and potential limitations of suede, particularly in humid climates. Compliance with quality standards is also essential.

What Unique Benefits Do Exotic Leathers Offer?

Exotic leathers, such as those from snakes, alligators, or ostriches, are sought after for their unique patterns and high-end appeal. Their key properties include distinct aesthetics and rarity.

Pros: Exotic leathers offer unparalleled luxury and exclusivity, making them desirable for high-end fashion and accessories.

Illustrative image related to make leather

Cons: They are often expensive and may have ethical sourcing concerns. Additionally, they can require specialized care and handling.

Impact on Application: Exotic leathers are typically used in luxury items, such as handbags and belts. Their unique appearance can significantly enhance the perceived value of a product.

Considerations for International Buyers: Buyers must ensure compliance with CITES regulations regarding the trade of exotic leathers. This is particularly important in Europe and North America, where regulations are stringent.

Illustrative image related to make leather

Summary Table of Common Leather Materials

| Material | Typical Use Case for make leather | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Vegetable-Tanned Leather | High-end bags, wallets, belts | Eco-friendly and durable | Higher cost and time-consuming | High |

| Chrome-Tanned Leather | Shoes, upholstery, fashion items | Quick production and water resistance | Environmental concerns | Medium |

| Suede | Fashion items, shoes, jackets | Luxurious feel and aesthetic appeal | Susceptible to stains and damage | Medium |

| Exotic Leathers | Luxury handbags, belts | Unique patterns and exclusivity | High cost and ethical sourcing issues | High |

This comprehensive analysis provides B2B buyers with actionable insights into material selection for leather production, ensuring informed decisions that align with product requirements and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for make leather

What Are the Main Stages in Leather Manufacturing?

The leather manufacturing process can be broken down into four primary stages: material preparation, forming, assembly, and finishing. Each stage plays a vital role in ensuring the quality and durability of the final leather product.

How is Material Prepared in Leather Manufacturing?

Material preparation begins with the selection of hides, which are the raw materials for leather production. The hides are sourced from various animals, predominantly cattle, but can also include goats, sheep, and exotic animals. Once procured, the hides undergo a series of treatments including curing and tanning.

Curing involves preserving the hides to prevent decomposition. This is typically done using salt or drying methods. After curing, hides are tanned to convert them into leather, a process that removes moisture and adds durability. There are several tanning methods including vegetable tanning, chrome tanning, and synthetic tanning, each affecting the leather’s characteristics and applications.

What Techniques Are Used in the Forming Stage?

In the forming stage, the tanned leather is shaped into desired forms. This may involve cutting the leather into specific patterns and sizes, which can be done using manual tools or automated cutting machines. Advanced technologies like laser cutting can ensure precision and reduce waste.

After cutting, the leather may undergo processes such as embossing or tooling, where designs are stamped onto the surface. This not only enhances aesthetics but can also add value to the product.

What Does the Assembly Process Entail?

The assembly phase involves stitching or bonding the cut leather pieces together to create the final product. This can range from handbags and wallets to upholstery and footwear. High-quality stitching is crucial as it affects both the durability and appearance of the final product. Techniques such as double-stitching or using reinforced seams are common to enhance strength.

Additionally, adhesive bonding may be employed in cases where stitching isn’t feasible. Quality control at this stage is critical, as any flaws in assembly can compromise the entire product.

How is Finishing Performed on Leather Products?

Finishing is the final stage in leather manufacturing, where the leather is treated to enhance its appearance and durability. This can include dyeing, applying protective coatings, and conditioning the leather.

Illustrative image related to make leather

Dyeing not only adds color but can also enhance the leather’s texture and feel. Protective coatings help resist stains, moisture, and wear, extending the product’s life. The finishing stage is essential for ensuring that the leather meets market expectations for quality and aesthetics.

What Quality Assurance Standards Are Relevant for Leather Manufacturing?

Quality assurance in leather manufacturing is critical for maintaining product consistency and meeting international standards. The most recognized standard is ISO 9001, which outlines criteria for a quality management system (QMS). Manufacturers seeking to export their products to international markets often pursue ISO certification to demonstrate their commitment to quality.

In addition to ISO standards, industry-specific certifications such as CE marking for products sold in Europe and compliance with local regulations in Africa and South America may also be necessary. Understanding these standards is essential for B2B buyers to ensure they are sourcing from compliant suppliers.

What Are the Key Quality Control Checkpoints in Leather Manufacturing?

Quality control (QC) in leather manufacturing involves several checkpoints to ensure that products meet specified standards. These checkpoints typically include:

Illustrative image related to make leather

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials (hides) upon arrival at the facility to verify their quality against predetermined standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor the quality of materials and workmanship at various stages, such as cutting, stitching, and finishing.

-

Final Quality Control (FQC): Before shipping, the finished products undergo a comprehensive inspection to ensure they meet design specifications and quality standards. This includes checking for defects, color consistency, and overall craftsmanship.

What Common Testing Methods Are Used for Leather Products?

Various testing methods are employed to verify the quality of leather products. Common tests include:

- Physical Properties Testing: Assessing tensile strength, tear resistance, and flexibility to ensure the leather can withstand regular use.

- Chemical Testing: Evaluating the presence of harmful substances, particularly in products intended for consumer use, to comply with safety regulations.

- Aging Tests: Simulating long-term use to determine how well the leather maintains its properties over time.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can verify supplier quality control practices through several methods:

-

Audits: Conducting on-site audits of potential suppliers to assess their manufacturing processes and quality control measures. This provides firsthand insight into the supplier’s operations.

-

Quality Reports: Requesting detailed quality reports that outline the results of IQC, IPQC, and FQC processes. These documents should detail any non-conformities and corrective actions taken.

-

Third-Party Inspections: Engaging independent inspection services to evaluate the supplier’s quality control practices and product quality before shipment. This adds an additional layer of assurance.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control is essential, especially when sourcing from diverse regions such as Africa, South America, the Middle East, and Europe. Factors such as local regulations, cultural differences in manufacturing practices, and varying standards of quality can influence purchasing decisions.

Buyers should invest time in understanding the specific requirements for importing leather goods into their respective markets, including any necessary certifications and compliance with local laws. Establishing clear communication with suppliers regarding quality expectations and standards is vital for ensuring a successful partnership.

By comprehensively understanding the manufacturing processes and quality assurance measures in leather production, B2B buyers can make informed decisions and establish strong supplier relationships that meet their quality and compliance needs.

Illustrative image related to make leather

Practical Sourcing Guide: A Step-by-Step Checklist for ‘make leather’

Introduction

This practical sourcing guide aims to assist B2B buyers in effectively procuring leather products for various applications. Understanding the complexities involved in leather sourcing—from material specifications to supplier vetting—will empower you to make informed decisions that enhance product quality and business success.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to clearly outline your technical requirements. This includes determining the type of leather (e.g., top-grain, full-grain, or veg-tanned) and its intended use, such as upholstery, garments, or accessories.

– Consider factors like thickness, finish, and durability to ensure that the leather meets your product standards.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers. Utilize industry directories, trade shows, and online platforms to compile a list of potential candidates.

– Look for suppliers with experience in your specific industry and geographical region to ensure they understand your market needs and challenges.

Step 3: Evaluate Supplier Certifications

Verify that your selected suppliers hold relevant certifications that demonstrate their compliance with industry standards and regulations. Certifications such as ISO 9001 for quality management or environmental certifications like ISO 14001 are crucial indicators of a supplier’s reliability.

– These certifications ensure that the supplier adheres to ethical practices and quality control measures, which are critical for long-term partnerships.

Illustrative image related to make leather

Step 4: Request Samples for Quality Assessment

Before making a bulk order, always request samples of the leather. This step allows you to assess the quality, feel, and durability of the material firsthand.

– Evaluate the samples based on your technical specifications and ensure they meet your quality standards. Pay attention to aspects such as texture, color consistency, and absence of defects.

Step 5: Understand Pricing Structures

Engage with suppliers to understand their pricing models, including any additional costs for customization or bulk orders.

– Request a detailed quotation that outlines unit prices, shipping costs, and any applicable taxes or tariffs. This transparency will help you gauge the overall affordability and value of the leather offered.

Step 6: Negotiate Terms and Conditions

Once you’ve shortlisted your suppliers, initiate discussions on terms and conditions. This includes payment terms, delivery timelines, and return policies.

– Ensure that you establish clear communication about expectations to avoid potential disputes later in the procurement process.

Step 7: Plan for Long-Term Relationships

Finally, consider the potential for building long-term relationships with your suppliers. Establishing a rapport can lead to better pricing, priority service, and collaboration on product development.

– Regularly evaluate supplier performance and maintain open lines of communication to foster a mutually beneficial partnership.

By following this checklist, B2B buyers can streamline their leather procurement process, ensuring they source high-quality materials that meet their specific needs and foster successful business relationships.

Comprehensive Cost and Pricing Analysis for make leather Sourcing

What Are the Key Cost Components in Leather Sourcing?

When sourcing leather, international B2B buyers must consider various cost components that contribute to the overall price of leather products. These include:

-

Materials: The primary cost driver in leather sourcing is the raw material itself, which can vary significantly based on quality and type. For example, top-grain leather typically commands a higher price due to its durability and aesthetic appeal compared to lower-grade options. The sourcing region also impacts material costs; for instance, hides from Europe may be more expensive due to stricter regulations and higher farming standards.

-

Labor: Labor costs can fluctuate based on geographic location and the skill level required for leather processing. Countries with lower labor costs may offer more competitive pricing, but this can sometimes compromise quality. It’s crucial for buyers to evaluate the skill level of the workforce, especially for intricate leatherwork that requires specialized craftsmanship.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, including utilities, rent, and equipment maintenance. Manufacturers in regions with high operational costs may pass these expenses onto buyers, making it essential to assess the production environment when negotiating prices.

-

Tooling: The cost of tools and equipment used in leather manufacturing can be significant, especially for custom designs. Buyers should inquire about the tooling costs and whether these are included in the quoted price or charged separately.

-

Quality Control (QC): Implementing quality control measures is vital to ensure that the leather meets the required standards. QC costs can vary depending on the complexity of the products being manufactured and the extent of inspection required before shipment.

-

Logistics: Transportation costs are another significant factor. They can fluctuate based on the shipping method, distance, and current fuel prices. International buyers should also consider customs duties and tariffs, which can add to the overall cost of leather sourcing.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. Understanding the standard margins in the leather industry can help buyers negotiate better deals.

How Do Price Influencers Impact Leather Sourcing Costs?

Several factors influence the pricing of leather products, which buyers should consider during negotiations:

-

Volume/MOQ: Purchasing larger quantities often leads to volume discounts. Buyers should assess their needs carefully and consider bulk purchasing to reduce per-unit costs.

-

Specifications and Customization: Custom leather products generally incur higher costs due to the additional labor and materials involved. Buyers should clearly define their requirements to avoid unexpected price increases.

-

Materials and Quality Certifications: The choice of leather type significantly affects pricing. Additionally, certifications such as eco-friendliness or compliance with international standards can impact costs. Buyers must evaluate the value of these certifications against their requirements.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge a premium for their reliability and quality assurance, while lesser-known suppliers might offer lower prices but at a risk to quality.

-

Incoterms: The terms of shipment (Incoterms) dictate who is responsible for shipping costs, insurance, and tariffs. Understanding these terms can help buyers negotiate better overall pricing by clarifying financial responsibilities.

What Are the Best Buyer Tips for Cost-Efficiency in Leather Sourcing?

International buyers should consider the following strategies to enhance cost-efficiency in leather sourcing:

-

Negotiation: Always negotiate terms and pricing. Understanding the supplier’s cost structure can provide leverage during discussions. Establishing long-term relationships may also yield better pricing over time.

-

Total Cost of Ownership (TCO): Look beyond the initial purchase price and consider TCO, which includes shipping, handling, and potential future costs related to product quality and durability. This holistic view can help in making more informed purchasing decisions.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and their impact on pricing. Additionally, consider the implications of local regulations and tariffs on total costs.

-

Disclaimer for Indicative Prices: Prices can vary widely based on the aforementioned factors and market conditions. Buyers should always seek updated quotes and be prepared for fluctuations in the leather market.

By carefully evaluating these cost components, price influencers, and employing strategic negotiation tactics, B2B buyers can optimize their leather sourcing processes and achieve better pricing outcomes.

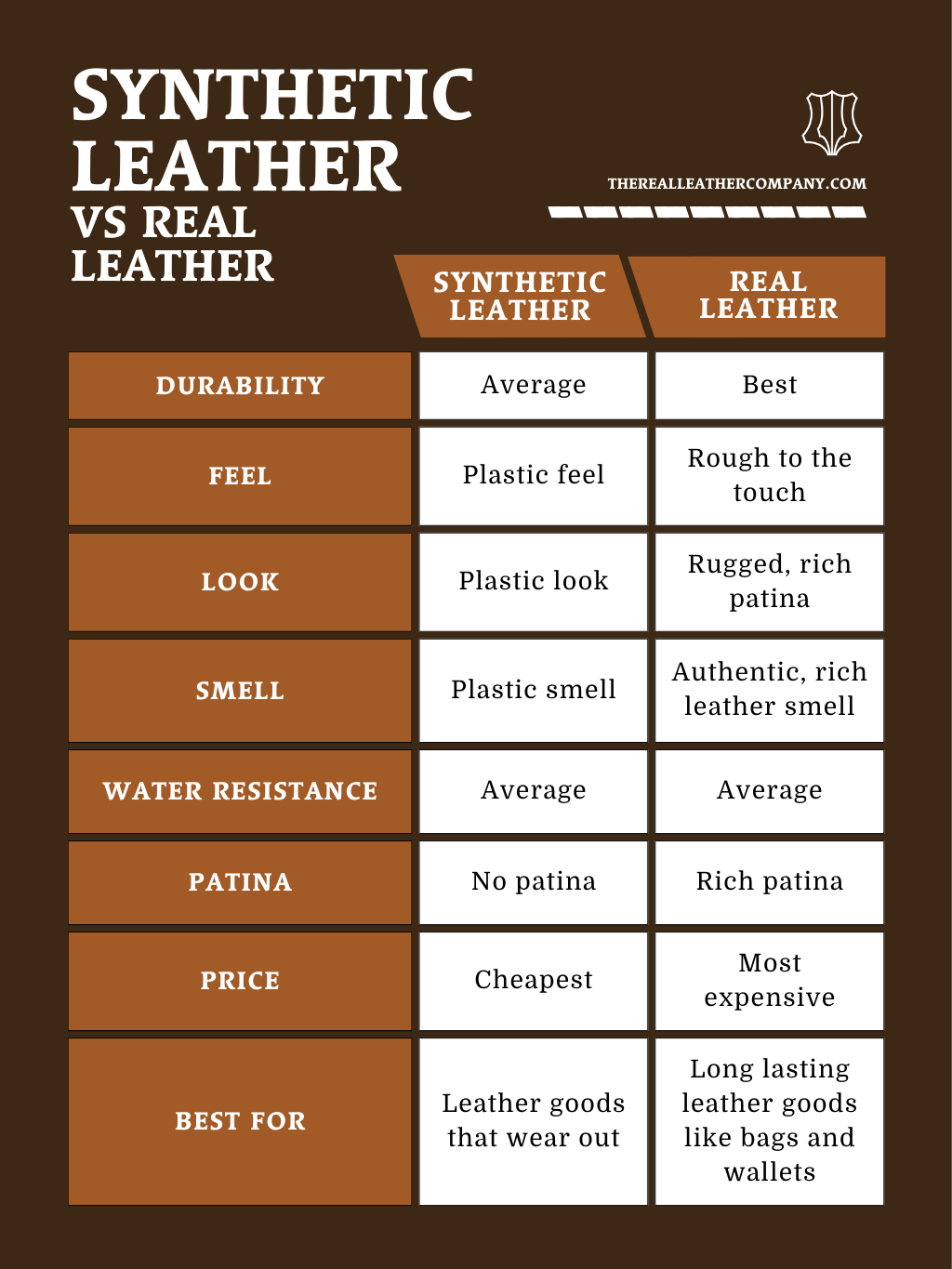

Alternatives Analysis: Comparing make leather With Other Solutions

Understanding Alternatives to ‘Make Leather’

In the pursuit of innovative and sustainable materials for various applications, businesses often explore alternatives to traditional leather. These alternatives can provide similar performance characteristics or offer unique benefits that cater to specific market demands. This analysis compares ‘make leather’ with two notable alternatives: synthetic leather and eco-friendly natural materials.

| Comparison Aspect | ‘Make Leather’ | Synthetic Leather | Eco-Friendly Natural Materials |

|---|---|---|---|

| Performance | High durability and flexibility; age gracefully with proper care | Durable but may wear out faster than genuine leather; can lack breathability | Varies widely; some offer excellent durability, while others may be less resilient |

| Cost | Generally higher due to sourcing and processing of animal hides | Often lower cost due to mass production; pricing can vary by brand | Can be cost-effective or premium depending on the source and processing |

| Ease of Implementation | Requires specific tools and skills for crafting | Readily available; easy to cut and sew | May require specialized knowledge for processing; availability can be inconsistent |

| Maintenance | Needs regular conditioning and care to prevent drying or cracking | Low maintenance; easy to clean, but can degrade over time | Varies; some may require special care, while others are low maintenance |

| Best Use Case | High-end fashion, bespoke items, luxury goods | Mass-produced items, fashion, and automotive industries | Sustainable fashion, eco-conscious brands, and niche markets |

What Are the Pros and Cons of Synthetic Leather?

Synthetic leather, often made from polyurethane (PU) or polyvinyl chloride (PVC), offers a cost-effective alternative to traditional leather. Its production typically involves less environmental impact than animal leather, and it can be manufactured in various textures and colors. The advantages include its ease of cleaning and resistance to moisture, making it suitable for casual fashion and upholstery. However, synthetic leather may not provide the same breathability or durability as genuine leather, and concerns over its long-term environmental impact persist.

How Do Eco-Friendly Natural Materials Compare?

Eco-friendly natural materials, such as cork, hemp, or plant-based leathers made from mushrooms or pineapples, present an innovative solution for sustainable fashion. These materials often boast lower environmental footprints and can be biodegradable. They are gaining popularity among brands focused on eco-conscious production. However, the performance characteristics can vary significantly; some may not match the durability or aesthetic appeal of traditional leather. Additionally, sourcing and processing these materials can be more complex, potentially leading to higher costs and longer lead times.

Making the Right Choice: What Should B2B Buyers Consider?

When choosing between ‘make leather’ and its alternatives, B2B buyers should evaluate their specific needs, including the target market, product application, and environmental considerations. For high-end products where durability and luxury are paramount, ‘make leather’ remains a superior choice. Conversely, if cost-effectiveness and ease of production are critical, synthetic leather may serve well. For brands committed to sustainability, exploring eco-friendly natural materials can align with their ethos while attracting a growing consumer segment focused on environmental impact. Understanding these nuances will empower buyers to select the most suitable material for their business objectives.

Essential Technical Properties and Trade Terminology for make leather

What Are the Key Technical Properties of Leather for B2B Buyers?

Understanding the technical properties of leather is essential for B2B buyers looking to source high-quality materials. Here are some critical specifications:

Illustrative image related to make leather

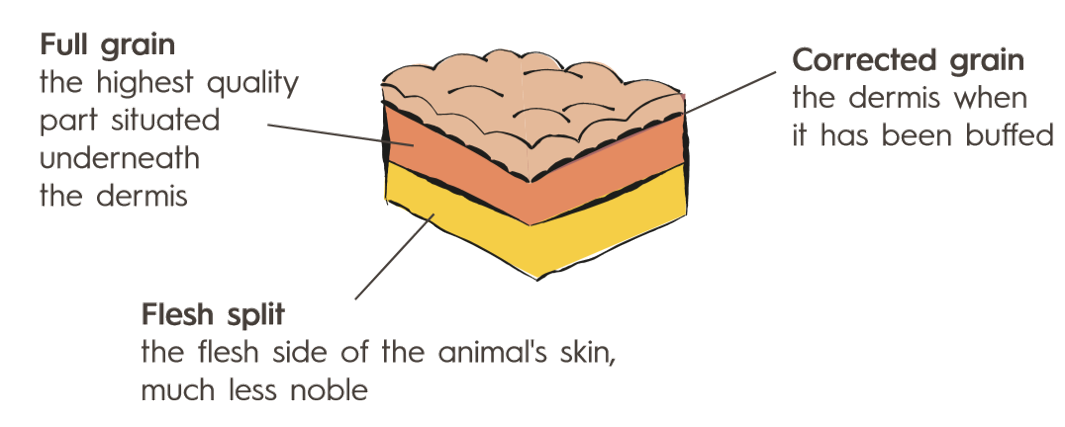

1. Material Grade

Material grade refers to the quality classification of leather based on its finish and imperfections. Common grades include full-grain, top-grain, and corrected grain. Full-grain leather is the highest quality, retaining the natural texture and imperfections, which adds character. For buyers, selecting the right grade is crucial as it directly influences product durability, aesthetic appeal, and resale value.

2. Tolerance

Tolerance in leather refers to the acceptable variation in thickness and dimensions of the leather hides. It is typically measured in ounces (oz), with thicker hides being more durable but also heavier. For B2B buyers, understanding tolerance is vital for ensuring that the leather meets specific manufacturing requirements and maintains consistency in product quality.

3. Weight

Weight denotes the thickness of leather, with typical ranges from 2 oz (thin) to 12 oz (very thick). This specification affects the leather’s use; for example, lighter weights are ideal for garments, while heavier weights are suited for belts or saddles. Buyers need to match the weight of leather to the intended application to ensure functionality and performance.

4. Finish Type

Leather finish types, such as chrome-tanned and vegetable-tanned, define the leather’s final treatment and appearance. Chrome-tanned leather is softer and more pliable, while vegetable-tanned leather offers a more rigid structure. For B2B buyers, understanding the finish type is essential for ensuring that the leather meets specific aesthetic and functional requirements.

Illustrative image related to make leather

5. Grain Type

Grain type refers to the surface texture of the leather, which can be smooth, pebbled, or suede. Different grain types cater to various applications, such as upholstery, accessories, or clothing. Knowing the grain type helps buyers select the appropriate leather for their products, enhancing quality and customer satisfaction.

6. Durability Rating

Durability rating assesses how well leather withstands wear and tear over time. Factors such as tensile strength, abrasion resistance, and exposure to environmental conditions contribute to this rating. For B2B buyers, understanding durability is critical in making informed decisions about long-term investment in leather products.

What Are Common Trade Terms in the Leather Industry?

Familiarizing yourself with industry jargon can streamline communication and negotiations in the leather trade. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or products that are used in another company’s end product. In leather, this could involve manufacturers creating leather goods for brands. For B2B buyers, understanding OEM relationships can help in establishing partnerships and managing supply chains effectively.

Illustrative image related to make leather

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial in the leather industry, where raw materials often come in large quantities. Buyers need to be aware of MOQs to plan their purchases and manage inventory efficiently.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific goods or services. In leather procurement, an RFQ can help buyers compare prices and terms from multiple suppliers, ensuring the best deal and quality.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping contracts. They clarify who is responsible for shipping costs, insurance, and risk during transit. For B2B buyers, understanding Incoterms is essential for smooth international transactions and avoiding disputes.

Illustrative image related to make leather

5. Lead Time

Lead time is the amount of time between placing an order and receiving it. In the leather industry, lead times can vary significantly based on the type of leather and manufacturing processes involved. B2B buyers must consider lead times for effective inventory management and meeting customer demand.

By grasping these technical properties and trade terms, B2B buyers can navigate the leather market more effectively, ensuring that their sourcing decisions align with their business objectives and customer expectations.

Navigating Market Dynamics and Sourcing Trends in the make leather Sector

What Are the Current Market Dynamics and Key Trends in the Make Leather Sector?

The global leather market is experiencing significant transformations driven by evolving consumer preferences, technological advancements, and environmental considerations. As international B2B buyers from regions like Africa, South America, the Middle East, and Europe engage with the leather sector, they must navigate several key trends. One notable driver is the increasing demand for high-quality, durable leather products, particularly top-grain and full-grain leather, which are favored for their longevity and aesthetic appeal. This trend is particularly pronounced in markets such as Germany and Vietnam, where craftsmanship and product quality are paramount.

Emerging technologies are reshaping sourcing practices within the make leather sector. Digital platforms that facilitate direct sourcing from manufacturers are becoming increasingly popular, enabling buyers to connect with suppliers across the globe efficiently. Additionally, innovations in leather processing, such as waterless tanning methods and digital printing, are gaining traction, allowing manufacturers to reduce costs and improve production efficiency. Buyers should also be aware of the growing trend towards customization, as consumers seek unique leather products tailored to their preferences.

Market dynamics are influenced by fluctuating raw material costs and global supply chain disruptions. Buyers must stay informed about these factors to make strategic sourcing decisions. By leveraging data analytics and market insights, B2B buyers can better anticipate shifts in demand and adjust their procurement strategies accordingly.

How Is Sustainability and Ethical Sourcing Shaping the Make Leather Sector?

Sustainability is no longer a niche consideration; it is a fundamental requirement for B2B buyers in the make leather sector. The environmental impact of leather production, including water consumption and chemical usage, has led to increased scrutiny from consumers and regulators alike. This awareness has prompted a shift towards more sustainable practices, with many buyers now prioritizing suppliers that adhere to eco-friendly production methods.

Ethical sourcing is essential in establishing a responsible supply chain. Buyers should seek out suppliers who are transparent about their sourcing practices and labor conditions. Certifications such as the Global Organic Textile Standard (GOTS) and Leather Working Group (LWG) offer assurances that products are sourced sustainably and ethically. By prioritizing suppliers with these certifications, businesses can enhance their brand reputation while contributing to a more sustainable industry.

The adoption of alternative materials, such as bio-based and recycled leathers, is also gaining momentum. These innovative materials not only reduce the reliance on traditional leather but also appeal to environmentally conscious consumers. B2B buyers should consider integrating these materials into their product offerings to meet the growing demand for sustainable solutions.

What Is the Historical Context of the Make Leather Sector for B2B Buyers?

The history of leather production dates back thousands of years, with evidence of leatherworking found in ancient civilizations across the globe. Early leather artisans utilized rudimentary methods for tanning hides, often relying on natural substances such as tree bark and animal fats. As societies evolved, so too did the techniques and technologies involved in leather processing.

In modern times, the leather industry has undergone significant changes, particularly with the introduction of chemical tanning methods in the 19th century, which revolutionized production efficiency and expanded the variety of available leather products. Today, the industry is at a crossroads, balancing traditional craftsmanship with modern sustainability challenges. For B2B buyers, understanding this evolution is crucial for making informed sourcing decisions that align with both market trends and ethical considerations.

By recognizing the historical context and current dynamics of the make leather sector, international buyers can better navigate the complexities of sourcing while ensuring they meet the demands of a rapidly changing market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of make leather

-

How do I ensure the quality of leather products from suppliers?

To ensure the quality of leather products, conduct thorough supplier vetting. Request samples to assess the material’s texture, durability, and finish. Look for certifications that indicate adherence to industry standards, such as ISO or environmental compliance. Engage in direct communication to understand the supplier’s production process and quality control measures. Additionally, consider third-party inspections for larger orders to confirm that the products meet your specifications before shipment. -

What is the best type of leather for making durable products?

The best type of leather for durability largely depends on the intended use. Full-grain leather is known for its strength and ability to develop a rich patina over time, making it ideal for high-quality goods like bags and belts. Top-grain leather is also durable but has a more refined finish, suitable for a variety of applications. For outdoor gear, consider using vegetable-tanned leather, which is resistant to wear and aging. Always discuss your specific requirements with suppliers to identify the best option. -

What customization options should I consider when sourcing leather?

When sourcing leather, consider various customization options such as color, texture, thickness, and treatment. Many suppliers offer dyeing services, embossing, or tooling to add unique features to your products. Discuss your design needs upfront, as some customizations may require minimum order quantities (MOQs) or longer lead times. Additionally, inquire about the supplier’s capabilities in terms of sourcing specialty leathers or sustainable options, which can enhance your product offering. -

What are the typical minimum order quantities (MOQs) for leather products?

Minimum order quantities (MOQs) for leather products can vary significantly by supplier and product type. Generally, MOQs range from as low as 50 to several hundred units, depending on factors like customization and production methods. For specialty or high-quality leathers, MOQs may be higher. Always clarify MOQs with your supplier before committing to an order to avoid potential issues with supply and demand. -

What payment terms are standard in B2B leather transactions?

Standard payment terms in B2B leather transactions typically range from 30 to 90 days after invoice, depending on the supplier’s policies and your business relationship. Some suppliers may require a deposit upfront, especially for custom orders or larger quantities. Always negotiate payment terms that align with your cash flow needs and ensure they are clearly outlined in your purchase agreement to avoid misunderstandings. -

How do I manage logistics when importing leather products internationally?

Managing logistics for international leather imports involves several key steps. First, work with a reputable freight forwarder familiar with customs regulations in both the exporting and importing countries. Ensure all documentation, such as commercial invoices and certificates of origin, is accurate and complete. Consider shipping methods (air or sea) based on cost and urgency, and be aware of potential tariffs or duties applicable to leather products in your country. Regular communication with your supplier and logistics partner can help mitigate delays. -

What quality assurance (QA) practices should I implement for leather products?

Implementing effective quality assurance (QA) practices for leather products starts with setting clear specifications for the materials and finished goods. Conduct regular inspections at various production stages, including raw material quality checks and final product assessments. Utilize third-party QA services for unbiased evaluations, especially for large orders. Additionally, establish a feedback loop with your suppliers to address any quality issues promptly and ensure continuous improvement. -

How can I identify reliable leather suppliers for international trade?

To identify reliable leather suppliers for international trade, start by researching industry directories and attending trade shows to connect with potential partners. Look for suppliers with positive reviews and strong reputations in the market. Verify their certifications and compliance with international standards. Request references from other B2B buyers who have worked with them. Finally, consider conducting factory visits or virtual audits to assess their production capabilities and working conditions directly.

Top 6 Make Leather Manufacturers & Suppliers List

1. Love Your Leather – Leather Production Process

Domain: loveyourleather.ca

Registered: 2011 (14 years)

Introduction: The process of making leather involves 23 steps, taking an average of 10 working days to turn hides into leather. Key steps include: 1. Curing hides to prevent deterioration, 2. Soaking to rehydrate and clean, 3. Painting to remove wool, 4. Liming to remove hair, 5. Fleshing to remove tissue, 6. De-Liming to neutralize alkali, 7. Bating to relax the pelt, 8. Pickling to prepare for tanning, 9. De-…

2. Makers Leather Supply – 3/32 Plastic Piping Core

Domain: makersleathersupply.com

Registered: 2012 (13 years)

Introduction: [{‘name’: ‘3/32 Plastic Piping Core by the Yard’, ‘regular_price’: ‘$1.00’, ‘sale_price’: ‘$1.00’}, {‘name’: ‘Cross Body 1.5 inch Buckle’, ‘regular_price’: ‘$8.95’, ‘sale_price’: ‘$8.95’}, {‘name’: ‘Dye Bottle Caps-5 Pack’, ‘regular_price’: ‘$4.95’, ‘sale_price’: ‘$4.95’}, {‘name’: ‘El Matador 1.75″ Belt Liners’, ‘regular_price’: ‘$14.95’, ‘sale_price’: ‘$14.95’}, {‘name’: ‘GUNSLINGER DEAL! 5-Pack…

3. Tandy Leather – Sneaker Starter Pack

Domain: tandyleather.com

Registered: 1996 (29 years)

Introduction: This company, Tandy Leather – Sneaker Starter Pack, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. WikiHow – Leather Tanning Process

Domain: wikihow.com

Registered: 2004 (21 years)

Introduction: Leather is a material made from the skin of an animal using tanning or similar processes. The process of making leather involves several steps: 1. Remove the hide and trim off any fat or flesh. 2. Apply salt to the skin side, fold the hide, and wait 24 hours. 3. Soak the hide in cool water for at least 1 day. 4. Remove the hair from the skin and hang it to dry. 5. Place the hide in a lime bath and…

5. Steel Horse Leather – Handmade Leather Bags

Domain: steelhorseleather.com

Registered: 2019 (6 years)

Introduction: Leather Bags, Leather Duffle Bags, Leather Backpacks, Leather Messenger Bags, Leather Tote Bags, Leather Work Bags, Leather Briefcases, Leather Laptop Bags, Leather Satchels, Leather Crossbody Bags, Leather Accessories, Leather Gifts, Handmade Leather Bags, Vintage Leather Bags, Men’s and Women’s Leather Bags, Various Sizes and Styles including Large, Mini, and Vintage options.

6. Reddit – Leather Making Guide

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Leather Making Guide, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for make leather

In the ever-evolving landscape of leather production, strategic sourcing has emerged as a critical element for B2B buyers aiming to optimize their supply chains. By understanding the diverse grades and types of leather—from the robust top-grain to the versatile veg-tan—buyers can make informed decisions that enhance product quality and appeal. Collaborating with reliable suppliers who emphasize sustainability and ethical practices not only ensures a consistent supply of high-quality materials but also aligns with the growing demand for eco-conscious products.

As markets in Africa, South America, the Middle East, and Europe continue to expand, the importance of establishing strong partnerships with suppliers cannot be overstated. Leveraging local expertise while maintaining global standards will be key to staying competitive.

Looking ahead, international buyers are encouraged to embrace innovative sourcing strategies that prioritize flexibility and responsiveness to market trends. This proactive approach will not only enhance product offerings but also foster resilience in an increasingly dynamic marketplace. By investing in strategic sourcing today, businesses can secure a sustainable and prosperous future in the leather industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.