Introduction: Navigating the Global Market for brown fake leather fabric

In the dynamic world of B2B sourcing, one of the pressing challenges faced by international buyers is finding high-quality brown fake leather fabric that meets both aesthetic and functional requirements. As markets in regions such as Africa, South America, the Middle East, and Europe expand, the demand for versatile, sustainable materials like faux leather continues to rise. This comprehensive guide aims to assist B2B buyers in navigating the complexities of sourcing brown fake leather fabric, offering insights into various types, applications, and supplier vetting processes.

Throughout this guide, you will discover the diverse applications of brown faux leather, from upholstery and fashion to automotive and craft projects. Each section is designed to empower you with the knowledge needed to make informed purchasing decisions, ensuring you select the right fabric for your specific needs. We delve into factors such as cost considerations, quality assessments, and supplier reliability, addressing the unique challenges faced by buyers in countries like Nigeria and Saudi Arabia.

By leveraging the insights provided here, you will be equipped to streamline your procurement processes, enhance product offerings, and ultimately drive your business success in the competitive landscape of faux leather sourcing. The aim is to demystify the market, allowing you to make strategic decisions that align with your business goals and customer expectations.

Table Of Contents

- Top 7 Brown Fake Leather Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for brown fake leather fabric

- Understanding brown fake leather fabric Types and Variations

- Key Industrial Applications of brown fake leather fabric

- 3 Common User Pain Points for ‘brown fake leather fabric’ & Their Solutions

- Strategic Material Selection Guide for brown fake leather fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for brown fake leather fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘brown fake leather fabric’

- Comprehensive Cost and Pricing Analysis for brown fake leather fabric Sourcing

- Alternatives Analysis: Comparing brown fake leather fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for brown fake leather fabric

- Navigating Market Dynamics and Sourcing Trends in the brown fake leather fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of brown fake leather fabric

- Strategic Sourcing Conclusion and Outlook for brown fake leather fabric

- Important Disclaimer & Terms of Use

Understanding brown fake leather fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Vegan Leather | Made from synthetic materials, eco-friendly, soft texture | Apparel, handbags, upholstery | Pros: Environmentally friendly, versatile; Cons: May not be as durable as genuine leather. |

| Vinyl Faux Leather | Waterproof, easy to clean, available in various finishes | Furniture upholstery, automotive interiors | Pros: Highly durable, low maintenance; Cons: Can feel less luxurious than genuine leather. |

| Leatherette | Smooth, leather-like finish, often more affordable | Home décor, fashion accessories | Pros: Cost-effective, wide variety of colors; Cons: Less breathable than natural leather. |

| Synthetic Suede | Soft, textured feel, mimics the look of suede | Upholstery, fashion items | Pros: Soft touch, good for casual applications; Cons: Can be prone to staining. |

| Marine Vinyl | UV resistant, water-resistant, heavy-duty | Marine applications, outdoor furniture | Pros: Excellent durability in harsh conditions; Cons: Limited color options compared to other types. |

What are the Characteristics of Vegan Leather for B2B Buyers?

Vegan leather is a synthetic alternative to traditional leather, appealing to environmentally-conscious brands. It is typically made from polyurethane or other synthetic materials, providing a soft, luxurious feel. B2B buyers should consider its applications in apparel, handbags, and upholstery, as it offers versatility without the ethical concerns associated with animal products. When sourcing vegan leather, look for suppliers that emphasize sustainability and production methods.

How Does Vinyl Faux Leather Stand Out in the Market?

Vinyl faux leather is known for its waterproof properties and ease of maintenance, making it a popular choice for furniture upholstery and automotive interiors. This material is available in various finishes, allowing for customization to meet specific aesthetic demands. Buyers should evaluate durability ratings, such as double rubs, to ensure the material meets their project’s longevity requirements. Additionally, vinyl’s resistance to stains and spills makes it an appealing option for high-traffic applications.

Illustrative image related to brown fake leather fabric

What Makes Leatherette a Cost-Effective Option?

Leatherette is a synthetic fabric designed to imitate leather, often at a fraction of the cost. It is widely used in home décor and fashion accessories due to its smooth finish and variety of color options. B2B buyers should consider the trade-offs between affordability and quality, as leatherette may lack the breathability and durability of natural leather. However, its ease of cleaning and maintenance can be advantageous for businesses focused on practicality.

Why Choose Synthetic Suede for Specific Applications?

Synthetic suede mimics the soft texture of natural suede, making it suitable for casual upholstery and fashion items. It is lightweight and offers a comfortable feel, appealing to consumers looking for a plush touch. However, B2B buyers should be aware that synthetic suede can be more prone to staining compared to other faux leather types. When purchasing, consider the intended use and environment to ensure it aligns with the fabric’s characteristics.

How Does Marine Vinyl Address Specific Industry Needs?

Marine vinyl is designed for durability in outdoor and marine environments, featuring UV and water-resistant properties. This makes it ideal for use in boats, outdoor furniture, and other applications exposed to harsh conditions. B2B buyers should prioritize suppliers that offer high-quality marine vinyl with adequate warranties, as this will ensure longevity and performance. While the color options may be limited, the material’s robustness is a significant advantage for businesses in the marine sector.

Key Industrial Applications of brown fake leather fabric

| Industry/Sector | Specific Application of brown fake leather fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Upholstery for sofas and chairs | Enhances aesthetic appeal while being cost-effective | Ensure durability and ease of cleaning for end-users. |

| Automotive | Seat covers and interior trim | Provides a luxurious look with lower maintenance costs | Consider resistance to wear and tear, and colorfastness. |

| Fashion Retail | Handbags and apparel | Offers trendy designs at a lower price point | Look for eco-friendly options and compliance with regulations. |

| Home Décor | Wall coverings and decorative accents | Adds a stylish touch while being easy to maintain | Check for fire-retardant properties and color variety. |

| Craft and DIY Projects | Custom craft items and accessories | Allows for creativity without the cost of genuine leather | Source in bulk for cost savings and assess flexibility in design. |

How is brown fake leather fabric used in furniture manufacturing?

In the furniture manufacturing sector, brown fake leather fabric is extensively used for upholstery on sofas and chairs. This synthetic material provides a high-end appearance similar to genuine leather but at a fraction of the cost. It is particularly appealing to businesses looking to offer stylish yet affordable options for their customers. For international B2B buyers, particularly from regions like Africa and South America, sourcing durable and easy-to-clean fabrics is crucial, as these qualities enhance the longevity of the furniture and minimize maintenance costs.

Illustrative image related to brown fake leather fabric

What are the applications of brown fake leather fabric in the automotive industry?

The automotive industry utilizes brown fake leather fabric primarily for seat covers and interior trim. This fabric not only enhances the aesthetic appeal of vehicles but also offers practical benefits, such as resistance to stains and easy maintenance. For B2B buyers in the Middle East, where luxury vehicles are in demand, sourcing high-quality faux leather that mimics the feel of genuine leather can significantly improve the overall customer experience. Key considerations include durability against wear and tear, as well as colorfastness to ensure the fabric retains its appearance over time.

How does brown fake leather fabric serve the fashion retail sector?

In fashion retail, brown fake leather fabric is utilized for creating handbags, shoes, and apparel. This versatile material allows designers to produce trendy items at competitive prices, appealing to a broad consumer base. For B2B buyers from Europe, sourcing eco-friendly options is increasingly important, aligning with consumer preferences for sustainable products. Compliance with local regulations regarding synthetic materials is also a critical factor to consider when selecting suppliers.

What are the uses of brown fake leather fabric in home décor?

Brown fake leather fabric is a popular choice in home décor for applications like wall coverings and decorative accents. Its stylish appearance and ease of maintenance make it a preferred material for interior designers and homeowners alike. For international buyers, especially in regions with diverse climate conditions, sourcing materials that are fire-retardant and available in various colors is essential to meet safety standards and aesthetic preferences. This ensures the final products not only look good but are also safe for use in homes.

Illustrative image related to brown fake leather fabric

How can brown fake leather fabric be utilized in craft and DIY projects?

In the craft and DIY sector, brown fake leather fabric is used for a wide range of custom items and accessories. This material allows crafters to explore their creativity without the high costs associated with genuine leather. For B2B buyers, sourcing in bulk can lead to significant cost savings, especially for small businesses or startups. Flexibility in design options and the ability to easily manipulate the fabric for various projects are essential considerations when selecting suppliers, ensuring that the material meets the diverse needs of the crafting community.

3 Common User Pain Points for ‘brown fake leather fabric’ & Their Solutions

Scenario 1: Sourcing Quality Brown Fake Leather Fabric

The Problem: Many B2B buyers face challenges in sourcing high-quality brown fake leather fabric that meets their specific requirements for durability and aesthetics. This can be particularly frustrating when suppliers do not provide clear information about the fabric’s properties, such as its weight, finish, and intended use. Buyers often receive samples that do not accurately represent the final product, leading to discrepancies in customer expectations and a potential waste of resources.

The Solution: To address this issue, buyers should prioritize suppliers that provide comprehensive product descriptions and samples that reflect the actual fabric. Look for suppliers who offer detailed specifications, including the fabric’s weight (measured in grams per square meter), tensile strength, and abrasion resistance ratings. For example, a fabric with a high double rub count (over 50,000) is ideal for upholstery applications. Additionally, establishing a good relationship with suppliers can facilitate better communication, allowing buyers to request custom samples that match their exact specifications. When placing bulk orders, consider negotiating terms for consistent quality assurance checks to mitigate risks of receiving inferior products.

Scenario 2: Managing Color Consistency Across Batches

The Problem: Color inconsistency is a common pain point for B2B buyers of brown fake leather fabric, particularly when ordering in large quantities or across multiple shipments. Variations in dye lots can lead to mismatched shades, which can be problematic for businesses involved in upholstery, fashion, or other applications where uniformity is crucial. This inconsistency can result in increased production costs, delays, and dissatisfied clients.

The Solution: To minimize issues related to color consistency, buyers should work closely with suppliers who can guarantee color matching across different batches. Before finalizing a large order, request a color sample that represents the desired shade and stipulate that all future shipments must match this sample. Additionally, implementing a color standard, such as Pantone or RAL, can help maintain uniformity across products. It’s also wise to document the color specifications in the purchase agreement, which can serve as a reference point should discrepancies arise. Periodic quality checks on received materials can help catch any inconsistencies early in the production process.

Scenario 3: Ensuring Compliance with Industry Regulations

The Problem: Buyers often struggle with ensuring that the brown fake leather fabric they purchase complies with various industry regulations, such as flammability standards or environmental certifications. This can be particularly challenging for businesses operating in regions with stringent regulations, as non-compliance can lead to legal repercussions and damage to brand reputation.

The Solution: To navigate this challenge, B2B buyers should conduct thorough due diligence on potential suppliers to verify that their products meet the necessary compliance standards. Request documentation such as Certificates of Compliance or test reports that confirm adherence to relevant safety standards, such as ASTM or ISO certifications. Additionally, buyers should inquire about the materials used in the manufacturing process to ensure they align with eco-friendly practices, especially if sustainability is part of their business model. Engaging in ongoing supplier audits and maintaining an updated database of compliant suppliers can provide an additional layer of assurance and streamline the procurement process.

Strategic Material Selection Guide for brown fake leather fabric

What Are the Key Materials Used in Brown Fake Leather Fabric?

When selecting brown fake leather fabric for various applications, it is essential to understand the different materials available, their properties, and how they fit into specific use cases. Below, we analyze several common materials used in the production of brown fake leather fabric from a B2B perspective.

Illustrative image related to brown fake leather fabric

What Are the Key Properties of PVC (Polyvinyl Chloride) Faux Leather?

PVC is one of the most prevalent materials used in faux leather production. It is known for its durability and resistance to moisture, making it suitable for various applications such as upholstery, automotive interiors, and fashion accessories.

Pros: PVC faux leather is cost-effective and easy to clean, which is a significant advantage for manufacturers and end-users alike. It can withstand a wide range of temperatures and is resistant to wear and tear, making it ideal for high-traffic areas.

Cons: However, PVC can be less breathable compared to other materials, which may affect comfort in clothing applications. Additionally, environmental concerns regarding PVC production and disposal may pose compliance challenges for international buyers.

Illustrative image related to brown fake leather fabric

Impact on Application: PVC’s compatibility with various media, including inks and adhesives, makes it a versatile choice for printing and crafting.

How Does PU (Polyurethane) Compare to Other Faux Leather Materials?

Polyurethane is another popular synthetic leather material, often chosen for its soft texture and breathability. It is frequently used in high-end applications such as luxury furniture, handbags, and footwear.

Pros: PU faux leather is more environmentally friendly than PVC and offers a more authentic leather-like feel. It is also resistant to cracking and fading, enhancing its longevity.

Cons: The primary downside is that PU can be more expensive than PVC, which may deter budget-conscious buyers. Additionally, while it is durable, it may not be as resistant to heavy wear as some other materials.

Impact on Application: PU’s excellent compatibility with dyes makes it suitable for vibrant color applications, which is appealing for fashion and design industries.

What Are the Advantages of Using Recycled Materials in Faux Leather Production?

Recycled materials, such as recycled polyester or other repurposed plastics, are increasingly being used in faux leather production. This trend aligns with sustainability goals and consumer preferences for eco-friendly products.

Pros: The use of recycled materials can significantly reduce environmental impact and appeal to socially conscious consumers. Additionally, these materials can provide comparable durability and performance to traditional faux leathers.

Cons: However, sourcing high-quality recycled materials can be challenging, and the manufacturing process may be more complex and costly.

Impact on Application: Recycled faux leather is particularly suitable for brands looking to enhance their sustainability credentials, making it an attractive option for various applications, including fashion and automotive.

What Should International B2B Buyers Consider When Sourcing Brown Fake Leather Fabric?

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, compliance with local regulations and standards is crucial. Familiarity with standards such as ASTM (American Society for Testing and Materials), DIN (Deutsches Institut für Normung), and JIS (Japanese Industrial Standards) can facilitate smoother transactions and ensure product quality.

Buyers should also consider regional preferences for materials. For instance, Middle Eastern markets may favor PU for its luxurious feel, while African markets may prioritize cost-effectiveness and durability. Understanding these nuances can help buyers make informed decisions.

Illustrative image related to brown fake leather fabric

Summary Table of Material Selection for Brown Fake Leather Fabric

| Material | Typical Use Case for brown fake leather fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Upholstery, automotive interiors | Cost-effective and durable | Less breathable than other materials | Low |

| PU | Luxury furniture, handbags, footwear | Soft texture and environmentally friendly | Higher cost compared to PVC | Medium |

| Recycled Materials | Fashion, eco-friendly products | Reduces environmental impact | Sourcing quality can be challenging | Medium to High |

By understanding these materials and their implications, B2B buyers can make strategic decisions that align with their business objectives and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for brown fake leather fabric

What Are the Key Stages in the Manufacturing Process of Brown Fake Leather Fabric?

The manufacturing process of brown fake leather fabric encompasses several critical stages that transform raw materials into a finished product suitable for various applications, including upholstery, apparel, and accessories. Understanding these stages is essential for B2B buyers looking to source high-quality materials.

1. Material Preparation: What Raw Materials Are Used?

The primary component of brown fake leather is synthetic materials, typically polyvinyl chloride (PVC) or polyurethane (PU). These materials are chosen for their durability, flexibility, and resemblance to genuine leather. The manufacturing process begins with the selection and preparation of these raw materials. This involves:

- Compounding: Raw polymers are mixed with additives such as plasticizers, stabilizers, and pigments to achieve desired properties, including color and texture.

- Sheeting: The compounded material is then extruded or calendered into sheets of various thicknesses, which will form the base of the fake leather.

2. Forming: How Is the Fabric Created?

Once the material is prepared, it moves to the forming stage, where it takes on its characteristic look and feel. This stage includes:

- Coating: The synthetic base is coated with a layer of PVC or PU to enhance its leather-like appearance and functionality. This coating can be textured to mimic the grain of real leather.

- Embossing: To further enhance the aesthetic appeal, the coated material may undergo an embossing process, where patterns are pressed into the surface, creating a tactile and visual effect that closely resembles natural leather.

3. Assembly: What Techniques Are Used for Production?

During the assembly phase, the fabric is cut and sewn into various products. This involves:

- Cutting: The fabric is cut according to specific patterns and dimensions required for different applications, whether for furniture, fashion, or automotive use.

- Sewing: Skilled workers or automated machines stitch the cut pieces together, ensuring strength and durability in the seams. This process often requires specialized machinery to handle the thickness and density of the fake leather.

4. Finishing: How Is Quality Enhanced?

The final stage of manufacturing involves finishing processes that enhance the fabric’s properties. This may include:

Illustrative image related to brown fake leather fabric

- Surface Treatment: Additional treatments can be applied to improve water resistance, stain resistance, or UV protection. These treatments ensure the fabric maintains its appearance and functionality over time.

- Quality Inspection: Before packaging, the finished product undergoes a thorough inspection to ensure it meets quality standards.

What Quality Assurance Measures Are Essential for Brown Fake Leather Fabric?

Quality assurance (QA) is a critical aspect of the manufacturing process for brown fake leather fabric, ensuring that the end product meets international standards and customer expectations. Here are some essential QA measures:

1. What International Standards Should Buyers Be Aware Of?

B2B buyers should familiarize themselves with relevant international quality standards, including:

- ISO 9001: This standard focuses on quality management systems and is applicable to any organization. It ensures that manufacturers have processes in place to consistently deliver products that meet customer and regulatory requirements.

- CE Marking: For products sold within the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

2. What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integral throughout the manufacturing process. These include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specifications before production begins.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing stages help identify any defects early, allowing for immediate corrective actions.

- Final Quality Control (FQC): The finished product is thoroughly inspected against predefined criteria, including appearance, texture, and durability, before it is approved for shipment.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure they are sourcing from reliable suppliers, B2B buyers can implement several verification strategies:

1. Conducting Audits: What Should Be Included?

Buyers should consider conducting regular audits of their suppliers. These audits should assess:

- Manufacturing Processes: Evaluate the efficiency and effectiveness of the manufacturing processes.

- Quality Management Systems: Review the supplier’s adherence to quality standards and their QA processes.

- Compliance with Regulations: Ensure that the supplier complies with local and international regulations, especially concerning environmental and safety standards.

2. Reviewing Quality Reports: What Information Is Valuable?

Suppliers should provide quality assurance reports that detail:

- Test Results: Document the outcomes of various tests, such as tensile strength, water resistance, and colorfastness.

- Non-Conformance Reports: Any deviations from quality standards should be reported along with corrective actions taken.

3. Engaging Third-Party Inspectors: Why Is It Important?

Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality assurance practices. These services typically offer:

- Independent Verification: Confirming that the products meet specified standards and requirements.

- Detailed Reporting: Providing comprehensive reports that help buyers make informed decisions.

What Are the Specific QC Considerations for International Buyers?

For B2B buyers from regions like Africa, South America, the Middle East, and Europe, there are additional QC nuances to consider:

Illustrative image related to brown fake leather fabric

- Cultural and Regulatory Differences: Buyers should be aware of local regulations that may affect product compliance and safety standards. Understanding these differences can prevent costly errors in sourcing.

- Supply Chain Transparency: Buyers should ensure that their suppliers have a transparent supply chain, which can help mitigate risks associated with sourcing materials from multiple regions.

- Logistics and Shipping: Quality can be affected during shipping; thus, working with suppliers who have robust logistics practices is essential.

By understanding the manufacturing processes and quality assurance measures associated with brown fake leather fabric, B2B buyers can make informed decisions that align with their business needs and standards. This comprehensive approach not only ensures product quality but also fosters strong supplier relationships in the competitive global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘brown fake leather fabric’

Introduction

Navigating the procurement process for brown fake leather fabric can be complex, especially for international B2B buyers. This guide offers a practical checklist to streamline your sourcing efforts, ensuring you find high-quality materials that meet your specific needs. By following these steps, you can minimize risks and enhance your purchasing decisions.

Step 1: Define Your Technical Specifications

Before you start sourcing, it’s essential to have a clear understanding of your technical requirements. Determine the thickness, texture, and finish of the faux leather you need based on its intended use—whether for upholstery, apparel, or accessories. Knowing these specifications helps you communicate effectively with suppliers and ensures that the material will perform as expected in your applications.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers. Look for companies that specialize in faux leather and have a strong presence in the regions you are targeting, such as Africa, South America, or Europe. Utilize online platforms, trade shows, and industry directories to compile a list of potential suppliers, paying attention to their customer reviews and product quality.

Step 3: Evaluate Supplier Certifications

Verify that your potential suppliers hold relevant certifications and adhere to industry standards. Certifications like ISO 9001 for quality management and OEKO-TEX for safety can be indicators of a supplier’s commitment to quality. Additionally, check if they comply with local regulations regarding materials, especially if you are importing into regions with stringent guidelines.

Step 4: Request Samples

Always request samples of the brown fake leather fabric before placing a bulk order. This allows you to assess the texture, durability, and color accuracy firsthand. Ensure that the samples reflect the specifications you defined earlier and request multiple variations to compare. This step is crucial for confirming that the supplier can meet your quality expectations.

Step 5: Understand Pricing and Payment Terms

Clarify the pricing structure and payment terms with potential suppliers. Look for options that offer bulk discounts, as this can significantly reduce your costs. Additionally, inquire about payment methods—some suppliers may require upfront payments, while others might offer credit terms. Understanding these financial aspects upfront can help you manage your budget effectively.

Step 6: Assess Shipping and Delivery Options

Evaluate the shipping options provided by your suppliers, considering both cost and delivery time. Check if they offer international shipping and what their policies are regarding customs and duties. Knowing the lead times is essential for planning your production schedules and ensuring timely delivery of materials.

Step 7: Establish a Clear Communication Channel

Maintain open and clear communication with your chosen supplier throughout the sourcing process. Establish a point of contact for any queries or concerns that may arise. A reliable communication channel fosters a better working relationship and ensures that any issues can be addressed promptly, minimizing delays in your procurement process.

Illustrative image related to brown fake leather fabric

By following these steps, you can effectively source brown fake leather fabric that meets your business needs while mitigating risks associated with international procurement.

Comprehensive Cost and Pricing Analysis for brown fake leather fabric Sourcing

What Are the Key Cost Components in Sourcing Brown Fake Leather Fabric?

When sourcing brown fake leather fabric, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The primary ingredient in faux leather is synthetic polymers, such as polyurethane or polyvinyl chloride (PVC). The price of these materials fluctuates based on global oil prices and availability, which can impact overall costs.

-

Labor: Labor costs vary significantly by region. Countries with lower labor costs may offer competitive pricing, but this can also affect the quality of the finished product. It’s essential to evaluate the labor quality against cost.

-

Manufacturing Overhead: This includes utilities, rent, and equipment maintenance. Factories with modern machinery may have higher overhead costs but can produce higher-quality products more efficiently.

-

Tooling: Custom tooling for specific designs can increase initial costs but is essential for producing unique patterns or textures. Consider whether the tooling cost can be amortized over a large order.

-

Quality Control (QC): Implementing rigorous QC processes can add to costs but is vital for ensuring that the fabric meets the required specifications and standards.

-

Logistics: Shipping and handling costs can vary greatly based on the distance, mode of transport, and the Incoterms agreed upon. Buyers should factor in these costs to determine the total landed cost of the fabric.

-

Margin: Suppliers typically include a profit margin that can range from 10% to 30%, depending on the market and competition. Understanding this margin can help buyers negotiate better deals.

How Do Price Influencers Affect Sourcing Decisions for Brown Fake Leather Fabric?

Several factors influence the pricing of brown fake leather fabric, particularly for international buyers. Key price influencers include:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often offer better pricing for bulk orders. Understanding MOQs can help buyers negotiate lower per-unit costs.

-

Specifications and Customization: Custom specifications, such as specific finishes or performance characteristics (e.g., fire retardancy), can lead to increased costs. Buyers should weigh the necessity of customization against budget constraints.

-

Materials Quality and Certifications: Fabrics with higher quality or eco-friendly certifications often come at a premium. Buyers should assess whether the added cost aligns with their target market’s expectations.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can significantly impact pricing. Engaging with reputable suppliers can ensure quality, but may come at a higher price.

-

Incoterms: The choice of Incoterms affects shipping costs and responsibilities. Familiarizing oneself with terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help buyers understand their total costs and responsibilities.

What Buyer Tips Can Help Ensure Cost-Efficiency When Sourcing Brown Fake Leather Fabric?

To maximize cost-efficiency and ensure a successful sourcing experience, international buyers should consider the following tips:

Illustrative image related to brown fake leather fabric

-

Negotiate Pricing: Don’t hesitate to negotiate with suppliers. Understanding the cost components allows buyers to identify areas where they can push for better pricing.

-

Evaluate Total Cost of Ownership (TCO): Consider not only the purchase price but also costs related to shipping, customs duties, and potential returns. A lower initial price may lead to higher TCO if quality is compromised.

-

Understand Pricing Nuances for International Markets: Different regions may have varying price expectations and market conditions. Buyers from Africa, South America, the Middle East, and Europe should conduct market research to understand local trends and pricing structures.

-

Request Samples: Before placing a large order, request samples to evaluate quality. This step can help prevent costly mistakes that arise from purchasing subpar materials.

-

Stay Informed About Market Trends: Keeping abreast of changes in material costs, labor rates, and global economic conditions can provide buyers with insights that influence their sourcing strategies.

Disclaimer on Indicative Prices

Pricing for brown fake leather fabric can vary significantly based on the aforementioned factors. Prices mentioned in this analysis are indicative and should be verified with suppliers to ensure accuracy and relevance to your specific sourcing needs.

Alternatives Analysis: Comparing brown fake leather fabric With Other Solutions

When considering materials for upholstery, fashion, or various design projects, it’s essential to evaluate different options based on performance, cost, maintenance, and specific use cases. Brown fake leather fabric, known for its versatility and aesthetic appeal, competes with several alternatives that also serve similar purposes. Below, we compare brown fake leather fabric against two viable alternatives: natural leather and canvas.

| Comparison Aspect | Brown Fake Leather Fabric | Natural Leather | Canvas |

|---|---|---|---|

| Performance | Durable, water-resistant, soft to touch | Highly durable, breathable, develops a patina | Less durable, can be water-resistant with treatment |

| Cost | Generally lower cost ($5 – $15 per yard) | Higher cost ($50 – $200 per square foot) | Affordable ($5 – $20 per yard) |

| Ease of Implementation | Easy to cut and sew, requires no special tools | Requires specialized tools and skills | Simple to work with, widely available |

| Maintenance | Low maintenance, easy to clean | Requires conditioning and care | Moderate maintenance, can be machine washed |

| Best Use Case | Upholstery, bags, clothing, crafts | High-end furniture, luxury goods | Casual bags, tents, outdoor gear |

What Are the Pros and Cons of Natural Leather Compared to Brown Fake Leather Fabric?

Natural leather is renowned for its durability and unique aesthetic that matures beautifully over time. It is breathable and tends to provide better comfort in warm conditions. However, the high cost and the need for special care can be drawbacks. In B2B applications, natural leather is best suited for luxury items and high-end upholstery, where the investment aligns with the target market’s expectations.

How Does Canvas Compare to Brown Fake Leather Fabric?

Canvas is a robust fabric often used in a variety of applications, including bags, tents, and outdoor gear. It is generally more affordable than both brown fake leather and natural leather, making it an excellent choice for budget-conscious projects. However, canvas may not have the same level of durability or aesthetic appeal as fake leather, and while it can be treated for water resistance, it does not possess the same elegance or tactile quality. Canvas is ideal for casual items and outdoor applications, where functionality outweighs the need for luxury.

Conclusion: How Can B2B Buyers Select the Right Material for Their Needs?

When selecting the appropriate material for a project, B2B buyers should consider their specific requirements, including budget constraints, desired aesthetic, and the intended use of the final product. Brown fake leather fabric is an excellent choice for those seeking a cost-effective, stylish, and low-maintenance option. Conversely, natural leather is preferable for high-end applications where quality and longevity are paramount. Canvas offers a practical alternative for budget-friendly solutions in casual contexts. By evaluating these factors, buyers can make informed decisions that best suit their operational needs and target market.

Essential Technical Properties and Trade Terminology for brown fake leather fabric

What Are the Key Technical Properties of Brown Fake Leather Fabric?

When sourcing brown fake leather fabric, understanding its technical specifications is crucial for making informed purchasing decisions. Here are some essential properties to consider:

-

Material Composition

– Definition: Brown fake leather typically comprises synthetic materials such as PVC (Polyvinyl Chloride) or PU (Polyurethane).

– Importance: Knowing the material helps in assessing durability, maintenance, and environmental impact. For instance, PU is generally more breathable and flexible than PVC, making it suitable for applications requiring comfort. -

Width

– Definition: The width of faux leather fabric usually ranges from 54 to 60 inches.

– Importance: Understanding the width is essential for calculating fabric requirements for various projects, such as upholstery or fashion items. A wider fabric can reduce waste and minimize seams in larger applications. -

Weight and Durability Rating

– Definition: Weight is often measured in grams per square meter (GSM), while durability can be assessed through the “double rub” test, indicating how many rubs a fabric can withstand before showing wear.

– Importance: Fabrics with higher GSM and durability ratings are ideal for high-traffic areas, ensuring longevity and reducing the need for frequent replacements. For example, a fabric rated for 55,000 double rubs is suitable for upholstery in commercial settings. -

Flammability Certification

– Definition: Some faux leathers come with flammability ratings, indicating whether they meet safety standards for various applications.

– Importance: This property is particularly critical for products used in public spaces or for children’s items, where safety regulations may apply. Fabrics that are inherently fire-retardant provide an extra layer of security. -

Water and Stain Resistance

– Definition: Many brown faux leather fabrics are treated to be water and stain-resistant.

– Importance: This feature simplifies maintenance and extends the life of the fabric, making it ideal for both upholstery and fashion items that may encounter spills or humidity. -

Color Fastness

– Definition: This property indicates how well the color of the fabric holds up under various conditions, such as washing and exposure to light.

– Importance: For B2B buyers, color fastness is crucial for maintaining the aesthetic quality of products over time, especially in regions with high UV exposure.

What Are Common Trade Terms Related to Brown Fake Leather Fabric?

Familiarizing yourself with industry jargon can streamline communication and negotiations. Here are key terms to know:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or products that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers identify potential partners for custom designs or specialized fabric needs. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is essential for budgeting and inventory management, particularly for small businesses or start-ups looking to minimize upfront costs. -

RFQ (Request for Quotation)

– Definition: A formal request sent to suppliers to obtain price estimates for specific products.

– Importance: An RFQ helps buyers compare prices and terms, ensuring they get the best deal possible. -

Incoterms (International Commercial Terms)

– Definition: A set of international rules that define the responsibilities of buyers and sellers in international trade.

– Importance: Familiarity with Incoterms is critical for navigating shipping logistics and understanding cost responsibilities, especially when dealing with international suppliers. -

Lead Time

– Definition: The time it takes from placing an order to receiving the product.

– Importance: Knowing the lead time is vital for project planning and inventory management, allowing businesses to align their production schedules with supply availability. -

Sample Approval

– Definition: The process of reviewing a fabric sample before finalizing a bulk order.

– Importance: Sample approval is crucial for ensuring that the fabric meets quality and design specifications before committing to a larger purchase, reducing the risk of costly errors.

By understanding these essential properties and terms, B2B buyers can make more informed decisions when sourcing brown fake leather fabric, ensuring alignment with their specific business needs and market demands.

Illustrative image related to brown fake leather fabric

Navigating Market Dynamics and Sourcing Trends in the brown fake leather fabric Sector

What Are the Current Market Dynamics and Key Trends in the Brown Fake Leather Fabric Sector?

The brown fake leather fabric market is witnessing significant growth driven by several global factors. The increasing demand for sustainable and cruelty-free alternatives to genuine leather is one of the primary market drivers, particularly in regions such as Africa, South America, the Middle East, and Europe. As consumers and businesses alike become more environmentally conscious, the appeal of faux leather, often made from recycled materials, is on the rise. Additionally, the versatility of faux leather in applications ranging from upholstery to fashion and automotive industries enhances its marketability.

Emerging technologies, such as digital printing and advanced textile manufacturing techniques, are reshaping sourcing trends. These innovations allow for customization and on-demand production, which is particularly advantageous for B2B buyers looking to minimize inventory costs. Furthermore, the rise of e-commerce platforms has made it easier for international buyers to access a broader range of suppliers and materials, facilitating competitive pricing and quicker turnaround times. The integration of supply chain technologies, including blockchain for traceability, is also becoming more common, ensuring transparency and fostering trust between manufacturers and buyers.

How Is Sustainability and Ethical Sourcing Impacting the Brown Fake Leather Fabric Market?

Sustainability and ethical sourcing are becoming increasingly crucial in the brown fake leather fabric sector. The environmental impact of traditional leather production—characterized by high water usage, chemical tanning processes, and significant greenhouse gas emissions—has prompted a shift towards more sustainable materials. Faux leather, particularly those made from recycled plastics or organic sources, offers a lower environmental footprint.

For B2B buyers, engaging with suppliers that prioritize ethical practices is essential. Certifications such as Global Recycle Standard (GRS) and OEKO-TEX® can help identify suppliers committed to sustainable practices. Additionally, many manufacturers are beginning to adopt eco-friendly production methods, which not only reduce environmental impact but also appeal to a growing consumer base that values sustainability. By prioritizing suppliers with green certifications, buyers can enhance their brand reputation and meet the increasing demand for sustainable products in the market.

What Is the Historical Context of Brown Fake Leather Fabric in the B2B Market?

The evolution of brown fake leather fabric can be traced back to the mid-20th century when synthetic materials began to gain popularity due to their affordability and versatility. Initially used as a substitute for leather in various applications, faux leather has developed into a highly sophisticated material, now available in numerous textures and finishes. The introduction of PVC and polyurethane revolutionized the market, allowing for products that closely mimic the look and feel of genuine leather.

Over the years, advancements in manufacturing technologies and increased awareness of animal welfare and environmental sustainability have further propelled the demand for faux leather. Today, it is not merely a substitute but a preferred choice for many industries, reflecting changing consumer values and preferences. As the market continues to evolve, the focus on quality, sustainability, and ethical sourcing will remain critical for B2B buyers navigating this dynamic landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of brown fake leather fabric

-

How do I select the right supplier for brown fake leather fabric?

Selecting the right supplier involves thorough research and vetting. Look for suppliers with a solid reputation and positive reviews in the industry. Verify their certifications and compliance with international quality standards. Request samples to assess the material quality and durability. Additionally, consider their responsiveness and customer service. Engaging in initial conversations can provide insights into their reliability and willingness to accommodate your specific needs. -

What are the common uses for brown fake leather fabric in B2B applications?

Brown fake leather fabric is versatile and widely used in various applications, including upholstery for furniture, automotive interiors, handbags, shoes, and apparel. Its durability and aesthetic appeal make it suitable for both high-end and everyday products. Additionally, it is often used in craft projects and home décor, providing businesses with the opportunity to create unique offerings that meet customer demands. -

What minimum order quantities (MOQs) should I expect when sourcing brown fake leather fabric?

Minimum order quantities can vary significantly among suppliers, typically ranging from 10 to 100 yards or more, depending on the manufacturer and the specific fabric type. It is advisable to inquire directly with suppliers about their MOQs and any potential flexibility for smaller orders. Many suppliers may offer bulk discounts for larger purchases, which can help in managing costs while meeting your production needs. -

What payment terms are commonly offered by suppliers of brown fake leather fabric?

Payment terms can vary based on the supplier and the relationship established. Common arrangements include upfront payment, a deposit followed by the balance upon shipment, or net terms (e.g., net 30 or net 60 days). Discussing payment options early in negotiations is crucial to ensure that terms align with your cash flow management strategy and to build trust with the supplier. -

How can I ensure the quality of brown fake leather fabric before purchase?

To ensure quality, always request samples from potential suppliers before placing large orders. This allows you to evaluate the texture, durability, and color accuracy of the fabric. Additionally, inquire about the supplier’s quality assurance processes, such as testing for water resistance, fire retardancy, and wear resistance. Establishing a quality control agreement can also help in maintaining standards throughout production. -

What are the logistics considerations when importing brown fake leather fabric?

Logistics play a crucial role in international trade. Consider shipping options, lead times, and customs clearance processes for your destination country. Choose a reliable freight forwarder experienced in handling textile imports to navigate potential challenges. Be mindful of import duties and taxes, and ensure all documentation is accurate to avoid delays. Effective communication with your supplier regarding shipping schedules is essential for timely delivery. -

Are there customization options available for brown fake leather fabric?

Many suppliers offer customization options, including color variations, textures, and finishes. If you have specific design requirements, it’s essential to communicate these to your supplier early in the process. Be prepared to provide detailed specifications and examples to ensure your vision is accurately translated into the final product. Discuss any additional costs associated with customization, as these may vary based on the complexity of the request. -

What are the best practices for maintaining brown fake leather products?

To prolong the lifespan of products made from brown fake leather, regular maintenance is essential. Clean the surface with a damp cloth and mild soap to remove dirt and stains, avoiding harsh chemicals that can damage the material. For optimal care, avoid prolonged exposure to direct sunlight and excessive moisture. Implementing these maintenance practices can help preserve the appearance and durability of your products, ensuring customer satisfaction.

Top 7 Brown Fake Leather Fabric Manufacturers & Suppliers List

1. All About Fabrics – Faux Leather Fabric in Spanish Brown

Domain: allaboutfabrics.com

Registered: 2002 (23 years)

Introduction: {“name”: “Faux Leather Fabric in Spanish Brown”, “width”: “57.5 inches”, “content”: “100% Synthetic Leather”, “description”: “Faux-leather is also known as vegan leather, pleather and leatherette. Our faux-leathers are very versatile, low maintenance and exceptionally easy to clean. Faux-leathers are water and stain resistant, soft to the touch and have a uniform appearance. This faux-leather fabr…

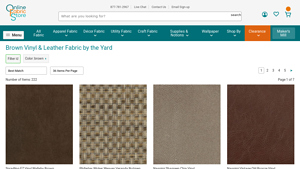

2. Online Fabric Store – 6-Day Delivery

Domain: onlinefabricstore.com

Registered: 2000 (25 years)

Introduction: This company, Online Fabric Store – 6-Day Delivery, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Hobby Lobby – Brown Saddle Faux Leather Fabric

Domain: hobbylobby.com

Registered: 1995 (30 years)

Introduction: {‘name’: ‘Brown Saddle Faux Leather Fabric’, ‘SKU’: ‘1533801’, ‘original_price’: ‘$17.99 YDS’, ‘description’: ‘Brown Saddle Faux Leather Fabric boasts a warm, medium brown color with a sleek design and a leather-like texture.’, ‘available_increments’: ‘1-yard increments’, ‘average_bolt_size’: ‘approximately 9 yards’, ‘width’: ’55 inches’, ‘vertical_repeat’: ‘29.13 inches’, ‘horizontal_repeat’: ‘8….

4. Naugahyde – Brown Faux Leather Upholstery Vinyl

Domain: decorativefabricsdirect.com

Registered: 2004 (21 years)

Introduction: Brown Faux Leather Upholstery Vinyl fabric available from various brands including Naugahyde and Boltaflex. Prices range from $8.95 to $33.95 per yard. Multiple colors and patterns available. Free shipping on orders over $199 with coupon code SHIPFREE. In stock yardage varies by product, with some items having more yardage available upon request.

5. Ellbee Fabrics – BROWN Faux Leather Upholstery Fabric

Domain: ellbeefabrics.com

Registered: 2016 (9 years)

Introduction: {“name”: “BROWN Faux Leather Upholstery Fabric”, “price_range”: “£1.00 – £9.95”, “description”: “A quality Faux Leather with a smooth slightly grained finish, ideal for various furnishing projects including furniture and caravans. Inherently fire retardant.”, “fabric_width”: “54”/1.38m”, “pattern_repeat”: {“vertical”: “n/a”, “horizontal”: “n/a”}, “length_options”: [“By the Metre”, “Half Metre”, “S…

6. Sewport – Faux Leather Solutions

Domain: sewport.com

Registered: 2015 (10 years)

Introduction: Faux leather, also known as synthetic leather, is a petroleum-based alternative to genuine leather. It is soft to the touch, water-resistant, and highly resistant to stains, making it easy to clean. While less durable than real leather, it is resistant to abrasions and cuts, ideal for upholstery in homes with children or pets. Faux leather can be produced in various colors, including unconventiona…

7. Inweave Fabric – Faux Leather Vinyl Horse Brown Upholstery

Domain: inweavefabric.com

Registered: 2007 (18 years)

Introduction: {‘product_name’: ‘Discount Fabric FAUX LEATHER VINYL Horse Brown Upholstery & Automotive’, ‘regular_price’: ‘$1.00’, ‘sale_price’: ‘$1.00’, ‘sizes_available’: [‘3″ x 5″ Sample’, ‘5 Yards (continuous)’, ’10 Yards (continuous)’], ‘sku’: ‘10503-ZZ5’, ‘fabric_model’: ‘VYL-103’, ‘description’: ’54” Faux Leather Vinyl–mid-weight & breathable. Has embossed look, light felt backing. Shipped on a roll.’, …

Strategic Sourcing Conclusion and Outlook for brown fake leather fabric

In conclusion, the strategic sourcing of brown fake leather fabric offers significant opportunities for international B2B buyers. This versatile material, known for its durability and low maintenance, is increasingly popular across various sectors, including upholstery, fashion, and automotive applications. By prioritizing suppliers who provide high-quality, sustainable options, businesses can not only enhance their product offerings but also align with growing consumer preferences for eco-friendly materials.

Moreover, as markets in Africa, South America, the Middle East, and Europe continue to expand, the demand for competitively priced faux leather is projected to rise. Buyers should leverage bulk purchasing options and price match guarantees to maximize savings while ensuring quality. Establishing strong relationships with trusted suppliers can facilitate smoother transactions and better negotiation outcomes.

Looking ahead, it is vital for B2B buyers to stay informed about emerging trends and innovations in faux leather production. By doing so, they can position themselves at the forefront of the market. Engage with suppliers today to explore how brown fake leather fabric can be a game-changer for your business and meet the evolving needs of your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to brown fake leather fabric