Introduction: Navigating the Global Market for alcantara headliner fabric

In the competitive landscape of automotive and interior design, sourcing high-quality Alcantara headliner fabric presents a unique challenge for B2B buyers. This versatile material, known for its luxurious feel and durability, is essential for enhancing both aesthetics and functionality in various applications, from luxury vehicles to high-end furniture. However, navigating the global market for Alcantara can be daunting, especially when considering factors such as material specifications, supplier reliability, and cost-effectiveness.

This comprehensive guide aims to empower international B2B buyers—particularly those from Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Germany—by providing essential insights into Alcantara headliner fabric. Within these pages, you will discover detailed analyses of different types of Alcantara, their specific applications, and expert advice on vetting suppliers to ensure quality and reliability. Additionally, we will explore pricing strategies and offer tips on negotiating favorable terms, enabling you to make informed purchasing decisions that align with your business needs.

By leveraging the information and strategies outlined in this guide, you can confidently navigate the complexities of the Alcantara market, ensuring that you select the best materials for your projects while optimizing your procurement processes.

Table Of Contents

- Top 4 Alcantara Headliner Fabric Manufacturers & Suppliers List

- Introduction: Navigating the Global Market for alcantara headliner fabric

- Understanding alcantara headliner fabric Types and Variations

- Key Industrial Applications of alcantara headliner fabric

- 3 Common User Pain Points for ‘alcantara headliner fabric’ & Their Solutions

- Strategic Material Selection Guide for alcantara headliner fabric

- In-depth Look: Manufacturing Processes and Quality Assurance for alcantara headliner fabric

- Practical Sourcing Guide: A Step-by-Step Checklist for ‘alcantara headliner fabric’

- Comprehensive Cost and Pricing Analysis for alcantara headliner fabric Sourcing

- Alternatives Analysis: Comparing alcantara headliner fabric With Other Solutions

- Essential Technical Properties and Trade Terminology for alcantara headliner fabric

- Navigating Market Dynamics and Sourcing Trends in the alcantara headliner fabric Sector

- Frequently Asked Questions (FAQs) for B2B Buyers of alcantara headliner fabric

- Strategic Sourcing Conclusion and Outlook for alcantara headliner fabric

- Important Disclaimer & Terms of Use

Understanding alcantara headliner fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

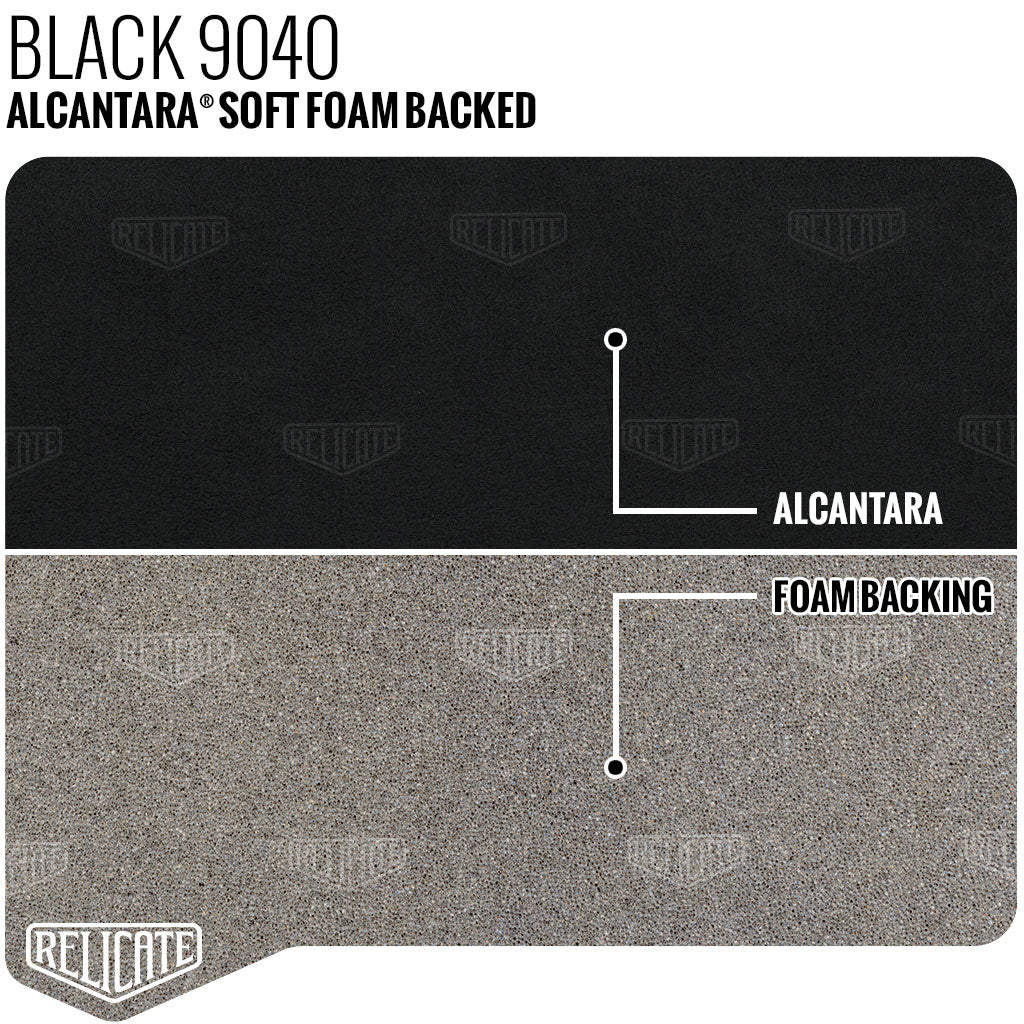

| Alcantara Soft Foam Backed | 2mm foam backing, soft texture, high durability | Automotive headliners, interior panels | Pros: Easy to clean, reduces glare; Cons: Higher cost |

| Alcantara Unbacked | Lightweight, no foam, more flexible | Custom upholstery, fashion accessories | Pros: Versatile, lightweight; Cons: Less durability |

| Alcantara Auto Panel | Pre-cut panels, various colors, ready for installation | Automotive interiors, custom builds | Pros: Convenience, consistent quality; Cons: Limited customization options |

| Alcantara Performance | Enhanced wear resistance, ideal for high-use areas | Racing seats, luxury vehicles | Pros: High durability, superior grip; Cons: Premium pricing |

| Alcantara Eco-Friendly | Made from recycled materials, sustainable production | Green automotive designs, eco-friendly interiors | Pros: Sustainable choice, growing market appeal; Cons: Limited availability |

What Are the Key Features of Alcantara Soft Foam Backed Fabric?

Alcantara Soft Foam Backed fabric is characterized by its 2mm foam backing, which provides a plush feel and enhances its durability. This type is predominantly used in automotive applications, particularly for headliners and interior panels. B2B buyers should consider its ease of maintenance and glare reduction properties, making it suitable for high-end vehicles. However, it comes at a higher price point, which may impact budget-sensitive projects.

How Does Alcantara Unbacked Fabric Compare?

Alcantara Unbacked fabric is notable for its lightweight and flexible nature. It is often used in custom upholstery projects and fashion accessories. This type offers versatility and is easier to manipulate during installations. However, it lacks the durability provided by foam backing, making it less ideal for high-wear areas. B2B buyers should weigh the benefits of adaptability against the potential need for more frequent replacements.

Why Choose Alcantara Auto Panels for Automotive Interiors?

Alcantara Auto Panels are pre-cut and available in a variety of colors, making them an attractive option for automotive interiors. These panels are designed for quick installation, saving time and labor costs. While they offer consistent quality, buyers may find limited customization options compared to other fabric types. This can be a consideration for businesses aiming for a unique aesthetic in their projects.

What Advantages Does Alcantara Performance Fabric Offer?

Alcantara Performance fabric is engineered for enhanced wear resistance, making it ideal for high-use areas such as racing seats and luxury vehicles. Its superior grip and durability cater to performance-oriented applications, appealing to a niche market. However, the premium pricing may deter budget-conscious buyers. This fabric is best suited for businesses focused on high-performance automotive solutions.

How Does Alcantara Eco-Friendly Fabric Fit into Sustainable Design?

Alcantara Eco-Friendly fabric is produced using recycled materials, aligning with the growing demand for sustainable options in various industries. Its appeal lies in its environmentally conscious production methods, making it suitable for green automotive designs and eco-friendly interiors. While this type is gaining traction, its limited availability might pose challenges for B2B buyers looking to implement sustainable practices across larger projects.

Key Industrial Applications of alcantara headliner fabric

| Industry/Sector | Specific Application of alcantara headliner fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Interior headliners and dashboards | Enhances luxury appeal, reduces glare, and improves acoustics | Ensure foam backing for adhesion; consider color matching; check for wear resistance. |

| Aviation | Cabin interiors and overhead storage compartments | Lightweight, durable, and easy to clean, enhancing passenger experience | Compliance with aviation safety standards; sourcing from certified suppliers. |

| Luxury Yachts | Ceiling and wall coverings | Provides a premium aesthetic while being resistant to moisture | Look for marine-grade Alcantara; consider UV resistance for longevity. |

| Furniture Design | Upholstery for high-end furniture | Offers a luxurious feel and easy maintenance, appealing to upscale markets | Assess fabric durability and ease of cleaning; color and texture consistency is vital. |

| Consumer Electronics | Covers for high-end audio equipment | Enhances product design and protects against scratches | Ensure compatibility with electronic components; focus on acoustic properties for sound devices. |

How is Alcantara Headliner Fabric Used in the Automotive Industry?

In the automotive sector, Alcantara headliner fabric is primarily utilized for interior headliners and dashboards, providing a luxurious finish that enhances the overall aesthetic of vehicles. Its unique properties, such as glare reduction and sound absorption, contribute to a more comfortable driving experience. For B2B buyers, especially in regions like Europe and the Middle East, sourcing foam-backed Alcantara is crucial for ensuring proper adhesion during installation. Buyers should also consider color matching to existing interiors and the fabric’s resistance to wear and tear, which is essential for maintaining a premium appearance over time.

What Role Does Alcantara Play in Aviation Cabin Interiors?

In aviation, Alcantara headliner fabric is employed in cabin interiors and overhead storage compartments, where its lightweight and durable nature significantly enhances passenger comfort. The fabric is easy to clean and maintains its appearance, essential for high-traffic areas in aircraft. International buyers must ensure that their sourcing meets aviation safety standards and consider materials that comply with fire resistance regulations. Additionally, establishing relationships with certified suppliers can streamline the procurement process and ensure consistent quality.

How is Alcantara Fabric Applied in Luxury Yachts?

For luxury yachts, Alcantara is used for ceiling and wall coverings, providing an upscale aesthetic that aligns with high-end design expectations. Its moisture resistance and durability make it a practical choice for marine environments, where exposure to humidity is a concern. Buyers from regions like South America and the Middle East should focus on sourcing marine-grade Alcantara, which offers enhanced UV resistance to prevent fading. Ensuring the fabric’s compatibility with marine applications will enhance the longevity and visual appeal of yacht interiors.

Why is Alcantara Important in Furniture Design?

In furniture design, Alcantara headliner fabric is favored for upholstery in high-end furniture pieces due to its luxurious texture and ease of maintenance. It appeals to upscale markets where aesthetic and tactile qualities are paramount. B2B buyers should assess the fabric’s durability and cleaning ease, as these factors influence customer satisfaction and product longevity. Additionally, consistency in color and texture is vital for maintaining brand integrity, making reliable sourcing channels essential for businesses in this sector.

How is Alcantara Used in Consumer Electronics?

Alcantara headliner fabric finds application in the covers of high-end audio equipment, where it enhances both design and functionality. The fabric not only adds a touch of elegance but also protects devices from scratches while potentially improving acoustic properties. For B2B buyers, particularly in Europe and the Middle East, sourcing Alcantara that is compatible with electronic components is critical. Buyers should also focus on the fabric’s sound-dampening qualities, which can significantly impact the overall user experience in audio products.

3 Common User Pain Points for ‘alcantara headliner fabric’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Alcantara Headliner Fabric

The Problem:

B2B buyers often struggle to find reliable suppliers for high-quality Alcantara headliner fabric. This challenge can be exacerbated by the prevalence of counterfeit materials and varying fabric standards across suppliers. Buyers in regions such as Africa and South America may find it particularly difficult to access genuine Alcantara, leading to concerns about product durability, aesthetic appeal, and overall value. Furthermore, discrepancies in color and texture can result in mismatched interiors, which can be detrimental for businesses focused on high-end automotive or interior design projects.

The Solution:

To address sourcing challenges, buyers should prioritize establishing relationships with official Alcantara distributors. It’s essential to request certification and documentation that confirms the authenticity of the fabric. Additionally, leveraging online platforms that connect buyers with verified suppliers can streamline the sourcing process. For example, utilizing resources like Relicate, a recognized Alcantara distributor, ensures the procurement of genuine materials. Buyers should also consider ordering samples before making large purchases to assess color accuracy and fabric texture firsthand, which can help avoid costly errors in the long run.

Scenario 2: Challenges with Installation and Adhesion of Alcantara Headliner Fabric

The Problem:

Another common pain point is the difficulty in installing Alcantara headliner fabric correctly. Many B2B buyers, particularly those in the automotive sector, face issues with adhesion, resulting in peeling or sagging after installation. This is often due to improper adhesive selection or inadequate preparation of the headliner surface. Such problems can lead to increased labor costs and dissatisfaction among clients, which may ultimately harm a company’s reputation in a competitive market.

The Solution:

To ensure a successful installation, it is crucial to choose the right adhesive specifically designed for automotive applications. For instance, 3M Super Trim Adhesive is highly recommended for bonding Alcantara to headliner surfaces. Prior to installation, buyers should thoroughly clean and prepare the surface of the headliner to ensure optimal adhesion. Additionally, using foam-backed Alcantara can significantly enhance the bonding process, as the foam provides a better surface for adhesives to grip. Implementing best practices in installation, such as applying consistent pressure and allowing adequate curing time, will help ensure a durable and professional finish.

Scenario 3: Maintaining the Quality and Appearance of Alcantara Headliner Fabric

The Problem:

Alcantara headliner fabric is known for its luxurious appearance, but maintaining its quality over time can be a concern for B2B buyers. Factors such as dust accumulation, stains, and UV exposure can lead to deterioration, affecting the aesthetic and functional properties of the fabric. Buyers in regions with high humidity or intense sunlight may notice faster wear and tear, leading to costly replacements and repairs.

The Solution:

To extend the lifespan of Alcantara headliner fabric, it is essential to implement a regular maintenance routine. Buyers should educate their clients on proper cleaning methods, emphasizing the use of a soft brush or a vacuum cleaner with a soft attachment to remove dust without damaging the fabric. For stains, a mild detergent diluted in water can be used, along with a soft cloth for blotting, rather than scrubbing, to avoid damaging the fibers. Additionally, applying a UV protectant spray can help shield the fabric from sun damage, particularly in regions with high exposure. By providing clients with comprehensive care instructions, B2B buyers can ensure that their installations maintain their luxurious appearance and durability for years to come.

Strategic Material Selection Guide for alcantara headliner fabric

What Are the Key Properties of Alcantara Headliner Fabrics?

Alcantara headliner fabrics are primarily composed of a blend of polyester and polyurethane, which contributes to their unique properties. The foam-backed variant, for instance, typically has a thickness of around 3 mm, providing added cushioning and sound dampening. This material is designed to withstand wear and tear, with a Martindale abrasion resistance rating exceeding 30,000 cycles, making it suitable for automotive applications where durability is essential. Additionally, it offers good resistance to light and rubbing, ensuring that it maintains its aesthetic appeal over time.

What Are the Advantages and Disadvantages of Different Alcantara Materials?

-

Alcantara Soft Foam-Backed

– Key Properties: Composed of 68% polyester and 32% polyurethane, this material is designed for headliners and wrapping panels. It has a unit weight of over 270 gm² and a breaking load of at least 225 N lengthwise.

– Pros: The foam backing provides excellent adhesion to substrates, enhances comfort, and reduces noise. It is also easy to clean and maintain, making it ideal for automotive interiors.

– Cons: The cost is relatively high compared to other synthetic materials. Additionally, the manufacturing process can be complex due to the need for foam backing.

– Impact on Application: Suitable for high-end vehicles, it offers a luxurious feel and aesthetic, but may not be the best choice for budget-sensitive applications. -

Alcantara Unbacked

– Key Properties: This variant is lighter and thinner, making it less durable than its foam-backed counterpart. It typically has a weight of around 150 gm².

– Pros: Lower cost and easier to handle during installation. It can be used in applications where weight savings are critical.

– Cons: Lacks the cushioning and sound-dampening properties of foam-backed options, making it less suitable for headliners.

– Impact on Application: Best used in areas where aesthetics are prioritized over comfort and durability, such as decorative panels. -

Alcantara with Different Textures

– Key Properties: Available in various textures, these materials can provide a different tactile experience while maintaining similar chemical compositions.

– Pros: Offers versatility in design and can cater to specific aesthetic requirements of luxury vehicles.

– Cons: Variability in texture can lead to inconsistent performance in terms of durability and maintenance.

– Impact on Application: Ideal for custom automotive interiors, but buyers must ensure that the texture aligns with performance requirements. -

Alcantara for Specialty Applications

– Key Properties: Some Alcantara materials are treated for specific applications, such as flame retardancy or enhanced UV resistance.

– Pros: Tailored for niche markets, these materials can meet stringent safety standards.

– Cons: Often come at a premium price point and may have longer lead times for production.

– Impact on Application: Essential for vehicles that require compliance with specific safety regulations, particularly in regions with strict automotive standards.

What Should International B2B Buyers Consider When Sourcing Alcantara Fabrics?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should consider several factors when sourcing Alcantara fabrics. Compliance with local and international standards, such as ASTM, DIN, and JIS, is crucial. Buyers should also be aware of local preferences for colors and textures, as these can vary significantly by region. Additionally, understanding the logistics of shipping and potential tariffs can impact overall costs and delivery times.

Illustrative image related to alcantara headliner fabric

| Material | Typical Use Case for alcantara headliner fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Alcantara Soft Foam-Backed | Automotive headliners and wrapping panels | Excellent durability and comfort | Higher cost and complex manufacturing | High |

| Alcantara Unbacked | Decorative panels and lightweight applications | Lower cost and easy handling | Less durable and lacks cushioning | Medium |

| Alcantara with Different Textures | Custom automotive interiors | Versatile design options | Inconsistent performance across textures | Medium |

| Alcantara for Specialty Applications | Vehicles requiring flame retardancy or UV resistance | Meets stringent safety standards | Premium pricing and longer lead times | High |

In-depth Look: Manufacturing Processes and Quality Assurance for alcantara headliner fabric

What Are the Main Stages in the Manufacturing Process of Alcantara Headliner Fabric?

The production of Alcantara headliner fabric involves several critical stages, each designed to ensure the final product meets high performance and aesthetic standards.

Material Preparation

The first step in the manufacturing process is the selection and preparation of raw materials. Alcantara is primarily composed of a blend of polyester and polyurethane, typically around 68% and 32%, respectively. This unique composition contributes to its softness, durability, and ease of maintenance. The raw materials undergo rigorous quality checks to ensure they meet the required specifications before proceeding to the next stage.

Forming

In the forming stage, the prepared materials are processed into sheets or panels of Alcantara fabric. This may involve techniques such as extrusion or spinning, where the fibers are aligned and bonded under controlled conditions to create a consistent texture and thickness. For headliner applications, foam backing is often added to enhance insulation and sound absorption properties, ensuring that the fabric is suitable for automotive interiors.

Assembly

Once the Alcantara fabric is formed, it is cut and shaped according to specific design requirements. This stage often includes the application of additional features such as adhesives or coatings that enhance the fabric’s performance characteristics, such as water resistance or UV protection. The assembly process is critical, as it determines how well the fabric will perform in its intended application.

Finishing

The final stage in manufacturing Alcantara headliner fabric is finishing, where the fabric undergoes treatments to enhance its appearance and durability. This may involve dyeing, embossing, or applying protective coatings. The finishing process is essential for achieving the desired aesthetic qualities, such as color uniformity and texture, as well as ensuring that the fabric meets industry standards for wear resistance and longevity.

How Is Quality Assurance Implemented in Alcantara Fabric Manufacturing?

Quality assurance is a vital component in the production of Alcantara headliner fabric, ensuring that the final product meets international and industry-specific standards.

What International Standards Are Relevant for Alcantara Fabric Quality Assurance?

Manufacturers typically adhere to international quality management standards such as ISO 9001, which outlines criteria for a quality management system. Compliance with this standard indicates that the manufacturer has established processes in place to ensure consistent quality in production.

In addition to ISO standards, Alcantara fabrics may also be subject to specific certifications such as CE marking, which signifies compliance with European health, safety, and environmental protection standards. These certifications are particularly important for B2B buyers in Europe and other regions with strict regulatory requirements.

Illustrative image related to alcantara headliner fabric

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control checkpoints are established at various stages of the manufacturing process to ensure that any defects are identified and addressed promptly. Key checkpoints include:

-

Incoming Quality Control (IQC): At this stage, raw materials are inspected for conformity to specifications before they enter production. This step prevents defects from being introduced into the manufacturing process.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, in-process inspections are conducted to monitor production quality. This may involve testing the fabric’s thickness, strength, and other physical properties.

-

Final Quality Control (FQC): Before the Alcantara fabric is shipped, a final inspection is performed to ensure that it meets all specifications, including visual checks for color consistency and texture.

What Common Testing Methods Are Used for Alcantara Fabric?

Testing methods play a crucial role in verifying the quality of Alcantara headliner fabric. Common tests include:

-

Martindale Abrasion Test: Measures wear resistance by simulating rubbing against a surface, ensuring the fabric can withstand typical usage.

-

Xenotest for Color Fastness: Assesses how well the fabric retains its color when exposed to light, which is vital for automotive interiors subject to sunlight.

-

Breaking Load Tests: Evaluate the tensile strength of the fabric, ensuring it can withstand stresses during installation and use.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential to ensure they are sourcing high-quality Alcantara fabric.

What Steps Can B2B Buyers Take to Ensure Supplier Compliance?

-

Conduct Supplier Audits: Regular audits of suppliers can help verify compliance with international quality standards. This can include reviewing their quality management systems and inspecting their manufacturing facilities.

-

Request Quality Control Reports: Buyers should request documentation related to quality control processes, including test results and compliance certifications. This information can provide insights into the supplier’s commitment to quality.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can add an additional layer of assurance. These independent inspectors can conduct quality checks and provide unbiased reports on the fabric’s quality.

What Nuances Should International B2B Buyers Be Aware of When Sourcing Alcantara Fabric?

International buyers must be cognizant of various nuances when sourcing Alcantara headliner fabric.

Are There Specific Compliance Considerations for Different Regions?

Different regions may have specific regulations regarding materials used in automotive interiors. For instance, European markets are known for stringent environmental regulations, which may require suppliers to provide detailed information about the materials used in their products. Buyers should ensure that their suppliers are compliant with local regulations to avoid potential legal issues.

How Do Cultural Differences Impact Sourcing and Quality Expectations?

Cultural differences can also impact quality expectations and sourcing practices. For instance, buyers from regions with a strong focus on sustainability may prioritize suppliers who demonstrate eco-friendly manufacturing processes. Understanding these cultural nuances can help B2B buyers make informed decisions and establish stronger relationships with their suppliers.

By understanding the manufacturing processes and quality assurance practices associated with Alcantara headliner fabric, B2B buyers can make more informed sourcing decisions, ensuring they receive high-quality products that meet their specific needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alcantara headliner fabric’

Introduction

Sourcing Alcantara headliner fabric can be a complex process, especially for international B2B buyers looking for quality, durability, and specific performance characteristics. This guide provides a practical checklist to help you navigate the procurement process effectively, ensuring you make informed decisions that align with your business needs.

1. Define Your Technical Specifications

Establishing clear technical specifications is crucial when sourcing Alcantara headliner fabric. Consider factors such as thickness, backing type (foam-backed vs. unbacked), and color options. These specifications will guide your selection process and ensure that the material meets the specific demands of your application, such as automotive interiors or luxury furnishings.

2. Research Reliable Suppliers

Conduct thorough research to identify reliable suppliers of Alcantara headliner fabric. Look for distributors known for their product quality and customer service, especially those with a proven track record in your target regions like Africa, South America, the Middle East, and Europe. Utilize industry-specific directories and trade shows to find reputable vendors and gather insights from other buyers about their experiences.

3. Evaluate Supplier Certifications

Before making a commitment, verify the certifications of potential suppliers. Certifications such as ISO quality standards or environmental compliance indicate that the supplier adheres to industry best practices. This step is vital to ensure the authenticity of the Alcantara fabric and to mitigate risks associated with counterfeit products that may not meet performance expectations.

4. Request Samples for Quality Assessment

Always request fabric samples before placing a bulk order. This allows you to assess the quality, texture, and color fidelity of the Alcantara headliner fabric. Pay attention to the fabric’s performance characteristics, such as wear resistance and ease of cleaning, as these factors will significantly impact the longevity and appearance of your finished products.

5. Check Lead Times and Shipping Options

Understanding lead times and shipping logistics is essential for planning your production schedules. Confirm how quickly suppliers can fulfill orders and whether they can accommodate your timeline. Additionally, inquire about their shipping options, especially for international deliveries, to avoid unexpected delays that could affect your project deadlines.

6. Negotiate Pricing and Terms

Once you have identified potential suppliers, engage in negotiations to secure favorable pricing and terms. Consider factors such as minimum order quantities, payment terms, and potential discounts for bulk purchases. Having clear terms can help establish a mutually beneficial relationship and contribute to long-term partnerships.

7. Finalize the Order with Clear Documentation

Before finalizing your order, ensure all details are clearly documented in a purchase agreement. This should include specifications, pricing, lead times, and payment terms. Clear documentation will help prevent misunderstandings and ensure that both parties are aligned on expectations, facilitating a smoother transaction process.

By following this checklist, B2B buyers can effectively navigate the sourcing process for Alcantara headliner fabric, ensuring they secure quality materials that meet their business needs.

Comprehensive Cost and Pricing Analysis for alcantara headliner fabric Sourcing

What Are the Key Cost Components in Sourcing Alcantara Headliner Fabric?

When sourcing Alcantara headliner fabric, understanding the cost structure is essential for B2B buyers. The main cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materials: The cost of Alcantara fabric can vary significantly based on the type, with foam-backed options typically priced higher due to additional processing. For example, prices for Alcantara fabric can range from $145 to $158 per yard, depending on the supplier and specifications.

Labor and Manufacturing Overhead: Labor costs may differ based on the region of production. Countries with lower labor costs may offer competitive pricing, but this could impact quality. Manufacturing overhead, including facility costs, utilities, and equipment maintenance, also contributes to the final price.

Tooling and QC: Customization requests can lead to higher tooling costs. Quality control processes ensure that the fabric meets industry standards, which may also affect pricing. Suppliers often invest in rigorous QC to maintain a reputation for high-quality materials.

Logistics and Margins: Logistics costs involve shipping and handling, which can be affected by distance and chosen shipping methods. International buyers should consider Incoterms that define responsibility for shipping costs and risks. Margins can vary from supplier to supplier, influenced by brand reputation and product quality.

How Do Price Influencers Affect Alcantara Fabric Costs?

Several factors influence the pricing of Alcantara headliner fabric, particularly for international buyers from Africa, South America, the Middle East, and Europe.

Volume and Minimum Order Quantities (MOQs): Larger orders typically result in lower per-unit costs due to economies of scale. Suppliers may offer discounts for bulk purchases, making it advantageous for businesses to assess their needs carefully before placing orders.

Illustrative image related to alcantara headliner fabric

Specifications and Customization: Tailoring specifications such as color, texture, and backing type can increase costs. Buyers should clearly outline their requirements to avoid unnecessary expenses related to rework or additional processing.

Material Quality and Certifications: High-quality Alcantara fabric often comes with certifications that validate its performance, such as wear resistance and colorfastness. Buyers should weigh the benefits of sourcing certified materials against potential cost savings from unverified alternatives.

Supplier Factors: The reputation and reliability of suppliers can significantly influence pricing. Established suppliers may charge a premium for their products due to perceived quality and service guarantees. Conversely, emerging suppliers may offer lower prices to gain market traction.

What Are the Best Practices for Negotiating Alcantara Fabric Prices?

For B2B buyers, effective negotiation can lead to significant savings. Here are some practical tips:

Understand Total Cost of Ownership (TCO): Beyond the initial purchase price, consider additional costs such as shipping, customs duties, and potential waste from defective materials. A comprehensive view of TCO will provide a clearer picture of the overall investment.

Leverage Relationships: Building long-term relationships with suppliers can result in better pricing and terms. Regular communication and feedback can foster trust and encourage suppliers to prioritize your orders.

Be Prepared to Walk Away: Establish a budget and be willing to explore alternative suppliers if negotiations do not meet your financial requirements. This position can enhance your leverage during discussions.

Explore Payment Terms: Flexible payment terms can ease cash flow and provide more favorable pricing. For instance, offering upfront payments may incentivize suppliers to offer discounts.

What Should International Buyers Consider When Sourcing Alcantara Fabric?

International buyers should be aware of pricing nuances that can arise from cross-border transactions. Currency fluctuations can affect pricing, so consider securing prices in a stable currency. Additionally, familiarize yourself with local regulations regarding imports, as tariffs and taxes can impact overall costs.

In conclusion, while the initial price of Alcantara headliner fabric can be a crucial deciding factor, a thorough understanding of the cost structure, price influencers, and negotiation strategies will empower B2B buyers to make informed decisions that align with their business objectives. Always remember that indicative prices can fluctuate, so it’s advisable to verify current rates directly with suppliers.

Alternatives Analysis: Comparing alcantara headliner fabric With Other Solutions

When evaluating options for automotive headliners, Alcantara headliner fabric stands out for its unique blend of aesthetics, functionality, and durability. However, there are alternative materials and methods that can also be considered, each with its own set of advantages and limitations. This analysis will compare Alcantara headliner fabric with two viable alternatives: synthetic suede and traditional leather.

| Comparison Aspect | Alcantara Headliner Fabric | Synthetic Suede | Traditional Leather |

|---|---|---|---|

| Performance | High durability, stain resistant, lightweight, reduces glare | Good durability, stain resistant, lightweight | Very durable, high-end look, good insulation |

| Cost | Moderate to high ($145-$158 per yard) | Low to moderate ($50-$100 per yard) | High ($200+ per yard) |

| Ease of Implementation | Requires specialized adhesive; foam-backed options preferred | Easy to install with standard adhesive | Requires professional installation and handling |

| Maintenance | Easy to clean with mild detergents; resistant to wear | Easy to clean; may require special cleaners | Requires regular conditioning; prone to scratching |

| Best Use Case | Luxury vehicles, custom interiors, high-performance applications | Budget-friendly projects, custom interiors | Premium vehicles, high-end applications |

What Are the Advantages and Disadvantages of Synthetic Suede Compared to Alcantara?

Synthetic suede is a popular alternative to Alcantara, often used for its affordability and similar aesthetic appeal. It offers good durability and is stain resistant, making it suitable for various applications. The cost of synthetic suede is typically lower, making it an attractive option for budget-conscious projects. However, it may not provide the same level of performance and luxury feel that Alcantara is known for. Additionally, while installation is straightforward, the longevity and resistance to wear may not match Alcantara’s standards.

How Does Traditional Leather Compare to Alcantara in Automotive Applications?

Traditional leather is regarded as a premium choice for automotive interiors due to its luxurious appearance and durability. It provides excellent insulation and is highly resistant to wear and tear. However, the cost of leather is significantly higher than Alcantara, often exceeding $200 per yard. Installation can also be more complex, requiring professional handling to ensure a perfect fit. Maintenance is another factor; leather requires regular conditioning to maintain its appearance and prevent damage. While leather can create a high-end look, it may not be the best choice for applications where lightweight materials and easy cleaning are priorities.

Conclusion: Which Headliner Solution is Right for Your Needs?

Choosing the right headliner material depends on several factors, including budget, desired aesthetics, and specific application requirements. For luxury and performance-oriented projects, Alcantara headliner fabric remains a top choice due to its blend of durability, aesthetics, and ease of maintenance. However, for those prioritizing cost or seeking a more straightforward installation process, synthetic suede could serve as a viable alternative. Conversely, if a premium look and feel are paramount, traditional leather may be the preferred option, albeit at a higher investment. B2B buyers should weigh these aspects carefully to align their choice with their project’s objectives and client expectations.

Essential Technical Properties and Trade Terminology for alcantara headliner fabric

What Are the Key Technical Properties of Alcantara Headliner Fabric?

Understanding the essential technical properties of Alcantara headliner fabric is crucial for B2B buyers, especially when making informed procurement decisions. Here are some critical specifications to consider:

Illustrative image related to alcantara headliner fabric

-

Material Composition

Alcantara is a synthetic suede made predominantly of 68% polyester and 32% polyurethane. This unique blend not only provides the luxurious feel associated with suede but also enhances durability and ease of maintenance. For B2B buyers, knowing the material composition helps in assessing the fabric’s performance and compatibility with various applications. -

Thickness

Alcantara headliner fabric typically has a thickness of 3.0 mm or more. This measurement is significant because it affects the fabric’s draping ability and overall performance when applied to headliners and wrapping panels. A thicker fabric often translates to better insulation and sound absorption properties, which are important for automotive applications. -

Wear Resistance

The wear resistance of Alcantara is quantified using the Martindale test, with a minimum rating of 30,000 cycles. This property indicates how well the fabric can withstand abrasion and maintain its appearance over time. For businesses, investing in high-wear-resistant materials ensures longevity and reduces the need for frequent replacements, thus minimizing costs. -

Breaking Load

The breaking load measures the tensile strength of the fabric, with specifications generally exceeding 225 N lengthwise and 175 N transversally. This property is vital for applications where the fabric will experience tension or stress. A higher breaking load means greater reliability in automotive interiors, ensuring that the fabric remains intact under various conditions. -

Colorfastness

Colorfastness is tested through exposure to light and rubbing. Alcantara typically shows a minimum rating of 3 on the grey scale for lightfastness and 4 for dry rubbing. This property is essential for maintaining aesthetic appeal in vehicles, especially in regions with strong sunlight. Colorfast materials help preserve the appearance of the interior, enhancing customer satisfaction. -

Cohesion

Measured under specific standards, cohesion rates of 10 N or more indicate the fabric’s ability to adhere properly to substrates during application. This is particularly important for headliners, where strong adhesion ensures durability and prevents peeling over time.

What Are Common Trade Terms Related to Alcantara Headliner Fabric?

Navigating the world of B2B procurement involves familiarizing oneself with specific terminology. Here are some common terms relevant to Alcantara headliner fabric:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components for other manufacturers. In the context of Alcantara, it often denotes the original fabric supplied for vehicle interiors. Understanding OEM relationships can help buyers ensure they are sourcing authentic materials that meet industry standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ for Alcantara headliner fabric is essential for B2B buyers to plan their inventory and budget effectively. This term helps in negotiating terms with suppliers and managing supply chain logistics. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotes from suppliers for specific products. For Alcantara fabrics, submitting an RFQ allows buyers to compare prices, quality, and delivery options across different suppliers, ensuring they make the most cost-effective decision. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce. They clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers dealing with Alcantara suppliers from different countries, as they dictate shipping costs, risks, and delivery responsibilities. -

Lead Time

Lead time refers to the amount of time from placing an order to the delivery of the product. Understanding lead times for Alcantara fabric can help businesses better manage production schedules and customer expectations.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing Alcantara headliner fabric, ensuring they meet both quality and operational requirements.

Navigating Market Dynamics and Sourcing Trends in the alcantara headliner fabric Sector

What Are the Current Market Dynamics and Key Trends for Alcantara Headliner Fabric?

The alcantara headliner fabric market is experiencing significant growth driven by several global factors. The automotive industry remains the largest consumer of alcantara fabric, primarily due to its luxurious feel and durability. In regions like Europe, particularly Germany, as well as in the Middle East and Africa, there is a growing demand for high-end automotive interiors that prioritize aesthetics and functionality. The trend towards electric vehicles is also influencing this sector, as manufacturers look for lightweight, sustainable materials that enhance vehicle performance while providing a premium feel.

Emerging B2B technologies are reshaping sourcing practices in this market. E-commerce platforms and digital procurement tools are facilitating faster and more efficient transactions. Buyers can now access a wider range of suppliers globally, enhancing competition and driving down costs. Additionally, advancements in supply chain management software are enabling companies to better track inventory and streamline logistics, making it easier to source alcantara fabric in various colors and finishes.

For international B2B buyers, understanding regional market dynamics is crucial. In South America, for instance, there is a burgeoning automotive sector that is increasingly adopting alcantara for its interiors. Meanwhile, buyers in Saudi Arabia are focusing on luxury and customization, seeking unique fabric options that reflect local tastes. Companies must stay abreast of these trends to adapt their sourcing strategies effectively and leverage the best opportunities in this evolving market.

How Does Sustainability and Ethical Sourcing Impact Alcantara Headliner Fabric Procurement?

Sustainability is becoming a central theme in the alcantara headliner fabric sector. As environmental concerns rise, buyers are increasingly prioritizing materials that are produced with minimal ecological impact. Alcantara, being a synthetic suede composed of 68% polyester and 32% polyurethane, is noted for its durability and ease of maintenance, which contributes to longer product lifecycles. However, it is essential for B2B buyers to ensure that their sourcing aligns with sustainable practices.

Ethical sourcing is another important consideration. Buyers should seek suppliers who are committed to responsible manufacturing processes, including waste reduction and fair labor practices. Certifications such as OEKO-TEX® and Global Recycled Standard can help buyers identify fabrics that meet environmental and social standards. By prioritizing suppliers that adhere to these certifications, companies can enhance their brand reputation and appeal to increasingly eco-conscious consumers.

Furthermore, the demand for “green” materials is reshaping the market landscape. Suppliers that invest in eco-friendly production methods, such as using recycled materials or sustainable dyes, are likely to gain a competitive edge. For B2B buyers in regions like Europe, where regulatory pressures around sustainability are stronger, aligning procurement strategies with these trends is not just beneficial; it is imperative.

Illustrative image related to alcantara headliner fabric

What Is the Historical Context of Alcantara Headliner Fabric in the B2B Market?

The history of alcantara fabric dates back to the late 1970s when it was developed in Italy as a high-performance alternative to leather. Initially used in luxury automotive applications, its unique properties—such as softness, durability, and ease of maintenance—quickly made it a preferred choice for premium car interiors. Over the decades, alcantara has evolved beyond the automotive sector and is now utilized in various applications, including fashion and interior design.

This historical significance has solidified alcantara’s position as a luxury material in the B2B market. As manufacturers and designers continue to seek high-quality, aesthetically pleasing materials, alcantara remains at the forefront, particularly in regions that value craftsmanship and premium finishes. Understanding this evolution helps B2B buyers appreciate the fabric’s value proposition and its ongoing relevance in contemporary design trends.

Frequently Asked Questions (FAQs) for B2B Buyers of alcantara headliner fabric

-

How do I ensure the quality of alcantara headliner fabric before purchasing?

To ensure the quality of alcantara headliner fabric, request samples from suppliers before placing a bulk order. Evaluate the samples based on texture, thickness, and durability. Look for specifications such as wear resistance (Martindale cycles) and colorfastness to light and rubbing. Additionally, verify that the fabric meets international quality standards. Establishing a good relationship with your supplier can also provide insights into their production processes and quality control measures. -

What is the best type of alcantara for automotive headliners?

The best type of alcantara for automotive headliners is foam-backed alcantara, as it provides the necessary adhesion and durability for overhead applications. This type typically features a 2mm foam layer, enhancing insulation and soundproofing while reducing glare. Look for alcantara that has a high Martindale test rating (30,000+ cycles) for wear resistance, ensuring longevity in high-use environments. Additionally, consider the color options that align with your brand or customer preferences. -

What are the typical minimum order quantities (MOQs) for alcantara headliner fabric?

Minimum order quantities (MOQs) for alcantara headliner fabric can vary significantly between suppliers. Generally, MOQs range from 10 to 50 yards, depending on the supplier’s production capacity and stock availability. When negotiating with suppliers, inquire about their flexibility with MOQs, especially if you are a new buyer or testing the market. Establishing a good rapport may also lead to favorable terms. -

What payment terms should I expect when sourcing alcantara fabric internationally?

Payment terms for international sourcing of alcantara fabric typically include options such as advance payment, letters of credit, or net payment terms (e.g., Net 30 or Net 60 days). It’s crucial to discuss and agree on payment terms upfront to avoid misunderstandings. Additionally, consider using secure payment methods that offer buyer protection, especially when dealing with new suppliers. Familiarize yourself with any currency exchange implications that may affect the total cost. -

How can I verify the credibility of an alcantara fabric supplier?

To verify the credibility of an alcantara fabric supplier, conduct thorough research on their business history and customer reviews. Request references from previous clients and inquire about their experiences. Check if the supplier holds relevant certifications and adheres to international quality standards. Additionally, consider visiting their manufacturing facilities if possible, or request third-party audits to ensure compliance with ethical and quality practices. -

What shipping options are available for alcantara headliner fabric?

Shipping options for alcantara headliner fabric usually include air freight, sea freight, and express courier services. The choice of shipping method will depend on your budget, urgency, and destination. Air freight is faster but more expensive, while sea freight is cost-effective for larger orders but takes longer. Ensure to discuss shipping costs and delivery timelines with your supplier, and consider using a freight forwarder to manage logistics and customs clearance. -

Can alcantara headliner fabric be customized for my specific needs?

Yes, many suppliers offer customization options for alcantara headliner fabric, including color matching, texture variations, and backing types. When seeking customization, clearly communicate your requirements, including specifications such as thickness and width. Be aware that custom orders may come with higher MOQs and longer lead times. It’s beneficial to establish a close working relationship with your supplier to ensure that your custom needs are met efficiently. -

What quality assurance measures should I implement when sourcing alcantara fabric?

Implementing quality assurance measures when sourcing alcantara fabric involves setting clear specifications and standards with your supplier. Conduct pre-shipment inspections to verify the fabric meets your requirements. Utilize third-party inspection services if necessary. Additionally, establish a return policy for defective materials and ensure that your supplier provides documentation for compliance with quality standards. Regular communication throughout the sourcing process can help address any quality concerns promptly.

Top 4 Alcantara Headliner Fabric Manufacturers & Suppliers List

1. DLT Corporation – Alcantara Soft

Domain: dltcorporation.com

Registered: 2009 (16 years)

Introduction: Alcantara Soft is a foam-backed, Italian synthetic suede composed of 68% Polyester and 32% Polyurethane. It is easy to clean, offers more grip and durability, reduces glare on the windshield, and remains cool to the touch. Available colors include Pearl White, Silver Grey, Orion Grey, Sand Grey, Mouse Grey, Basalt, Slate Grey, Dark Grey, Charcoal Black, Deep Black, Raw Amber, Dark Brown, Brombeer,…

2. BMW E90 – Fabric vs. Alcantara Headliners

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The discussion revolves around the choice between fabric and Alcantara headliners for a BMW E90. The user, AndrewwwwM, is considering redoing their grey fabric headliner in black and is questioning whether Alcantara looks significantly better than fabric and if the price difference is justified. Another user mentions they spent $120 on materials to redo their headliner and pillars themselves. Ther…

3. Alcantara – Auto Panel Collection

Domain: autointeriorspecialists.com

Registered: 2019 (6 years)

Introduction: [{‘name’: ‘Alcantara Auto Panel Deep Black 9040’, ‘price’: 145}, {‘name’: ‘Alcantara Auto Panel Charcoal Black 9002’, ‘price’: 145}, {‘name’: ‘Alcantara Auto Panel Dark Grey 9052’, ‘price’: 145}, {‘name’: ‘Alcantara Auto Panel Slate Grey 2957’, ‘price’: 145}, {‘name’: ‘Alcantara Auto Panel Red 4996’, ‘price’: 145}, {‘name’: ‘Alcantara Auto Panel 9002 Soft’, ‘price’: 157}, {‘name’: ‘Alcantara Auto …

4. BMW – Anthracite Alcantara Headliner

Domain: g05.bimmerpost.com

Registered: 2006 (19 years)

Introduction: Anthracite Alcantara Headliner vs Regular Headliner for BMW X5; MY21-22 option price: $650 (partial coverage, roof only); MY20 option price: $850 (full coverage); provides a luxurious feel and better sound absorption; available only in anthracite black for MY21-22; previous models offered in anthracite, ivory, or night blue; some users report dissatisfaction with the mismatch on the sunroof cover;…

Strategic Sourcing Conclusion and Outlook for alcantara headliner fabric

In navigating the strategic sourcing of Alcantara headliner fabric, international B2B buyers are presented with a unique opportunity to leverage its superior characteristics, such as durability, easy maintenance, and aesthetic appeal. The value of Alcantara lies not only in its premium quality but also in its versatility across various applications, from automotive interiors to luxury furnishings. By prioritizing reliable suppliers and understanding the specific product specifications—such as foam backing and color matching—buyers can ensure they select the most suitable materials for their projects.

Illustrative image related to alcantara headliner fabric

As the demand for high-quality materials continues to rise in regions such as Africa, South America, the Middle East, and Europe, establishing strong partnerships with trusted suppliers will be crucial. Engaging with manufacturers that offer rapid shipping and comprehensive customer support can enhance the sourcing experience and lead to successful project outcomes.

Looking ahead, it is essential for B2B buyers to stay informed about market trends and innovations in Alcantara offerings. By doing so, they can position themselves advantageously in a competitive landscape. Take the next step in your sourcing journey—explore quality Alcantara suppliers today to elevate your product offerings and meet the evolving needs of your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.